steering JAGUAR XJ6 1994 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 206 of 521

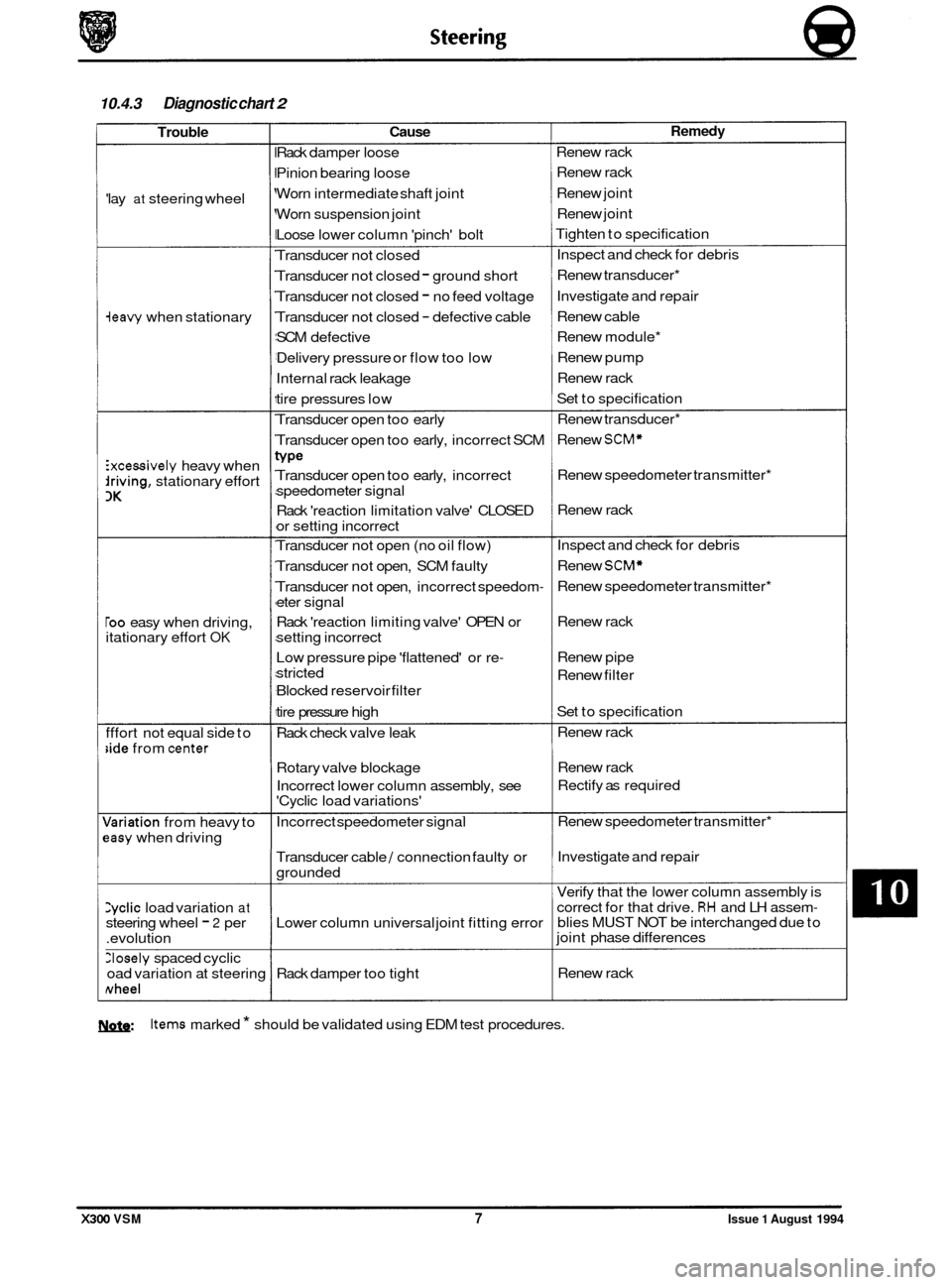

10.4.3 Diagnostic chart 2

0 Trouble

'lay at steering wheel

ieavy when stationary

Excessively heavy when

hiving, stationary effort

3K

Too easy when driving,

itationary effort OK

fffort not equal side to

;ide from center

dariation from heavy to

?asy when driving

:yclic load variation at steering wheel - 2 per

.evolution

:losely spaced cyclic

oad variation at steering

Nheel

Cause

Rack damper loose

Pinion bearing loose

Worn intermediate shaft joint

Worn suspension joint

Loose lower column 'pinch' bolt

Transducer not closed

Transducer not closed

- ground short

Transducer not closed

- no feed voltage

Transducer not closed

- defective cable

SCM defective

Delivery pressure or flow too low

Internal rack leakage

tire pressures low

Transducer open too early

Transducer open too early, incorrect SCM

h/Pe

Transducer open too early, incorrect

speedometer signal

Rack 'reaction limitation valve' CLOSED

or setting incorrect

Transducer not open (no oil flow)

Transducer not open, SCM faulty

Transducer not open, incorrect speedom

-

eter signal

Rack 'reaction limiting valve' OPEN or

setting incorrect

Low pressure pipe 'flattened' or re

-

stricted

Blocked reservoir filter

tire pressure high

Rack check valve leak

Rotary valve blockage Incorrect lower column assembly, see

'Cyclic load variations'

Incorrect speedometer signal

Transducer cable

/ connection faulty or

grounded

Lower column universal joint fitting error

Rack damper too tight

Remedy

Renew rack

Renew rack

Renew joint

Renew joint

Tighten to specification

Inspect and check for debris

Renew transducer*

Investigate and repair

Renew cable

Renew module*

Renew pump

Renew rack

Set to specification

Renew transducer*

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Inspect and check for debris

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Renew pipe

Renew filter

Set to specification

Renew rack

Renew rack

Rectify as required

Renew speedometer transmitter*

Investigate and repair

Verify that the lower column assembly is

correct for that drive.

RH and LH assem- blies MUST NOT be interchanged due to

joint phase differences

Renew rack

W: Items marked * should be validated using EDM test procedures.

X300 VSM 7 Issue 1 August 1994

Page 207 of 521

@ Steering

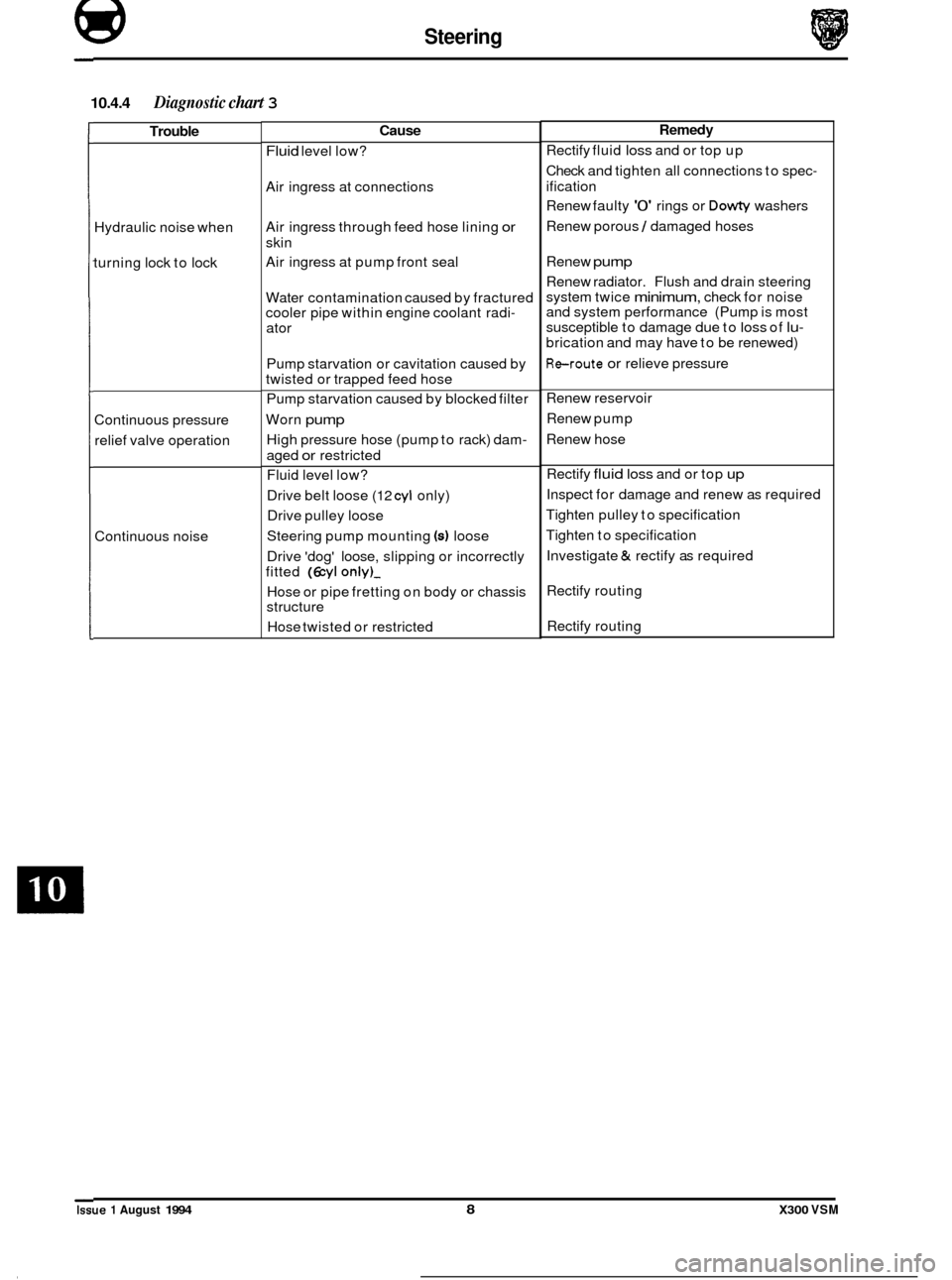

10.4.4 Diagnostic chart 3

Trouble

Hydraulic noise when

turning lock to lock

Continuous pressure

relief valve operation

Continuous noise

Cause

Fluid level low?

Air ingress at connections

Air ingress through feed hose lining

or

skin

Air ingress at pump front seal

Water contamination caused by fractured

cooler pipe within engine coolant radi

-

ator

Pump starvation or cavitation caused by

twisted or trapped feed hose

Pump starvation caused by blocked filter

Worn

pump

High pressure hose (pump to rack) dam-

aged or restricted

Fluid level low?

Drive belt loose

(12 cyl only)

Drive pulley loose

Steering pump mounting

(4 loose

Drive 'dog' loose, slipping or incorrectly

fitted

(6 cyl only)-

Hose or pipe fretting on body or chassis

structure

Hose twisted or restricted

Remedy

Rectify fluid loss and or top up

Check and tighten all connections to spec

-

ification

Renew faulty

'0' rings or Dowty washers

Renew porous

1 damaged hoses

Renew

pump

Renew radiator. Flush and drain steering

system twice

minimum, check for noise

and system performance (Pump is most

susceptible to damage due to

loss of lu-

brication and may have to be renewed)

Reroute or relieve pressure

Renew reservoir

Renew pump

Renew hose

Rectify

fluid loss and or top up

Inspect for damage and renew as required

Tighten pulley to specification

Tighten to specification

Investigate

& rectify as required

Rectify routing

Rectify routing

Issue 1 August 1994 8 X300 VSM

Page 208 of 521

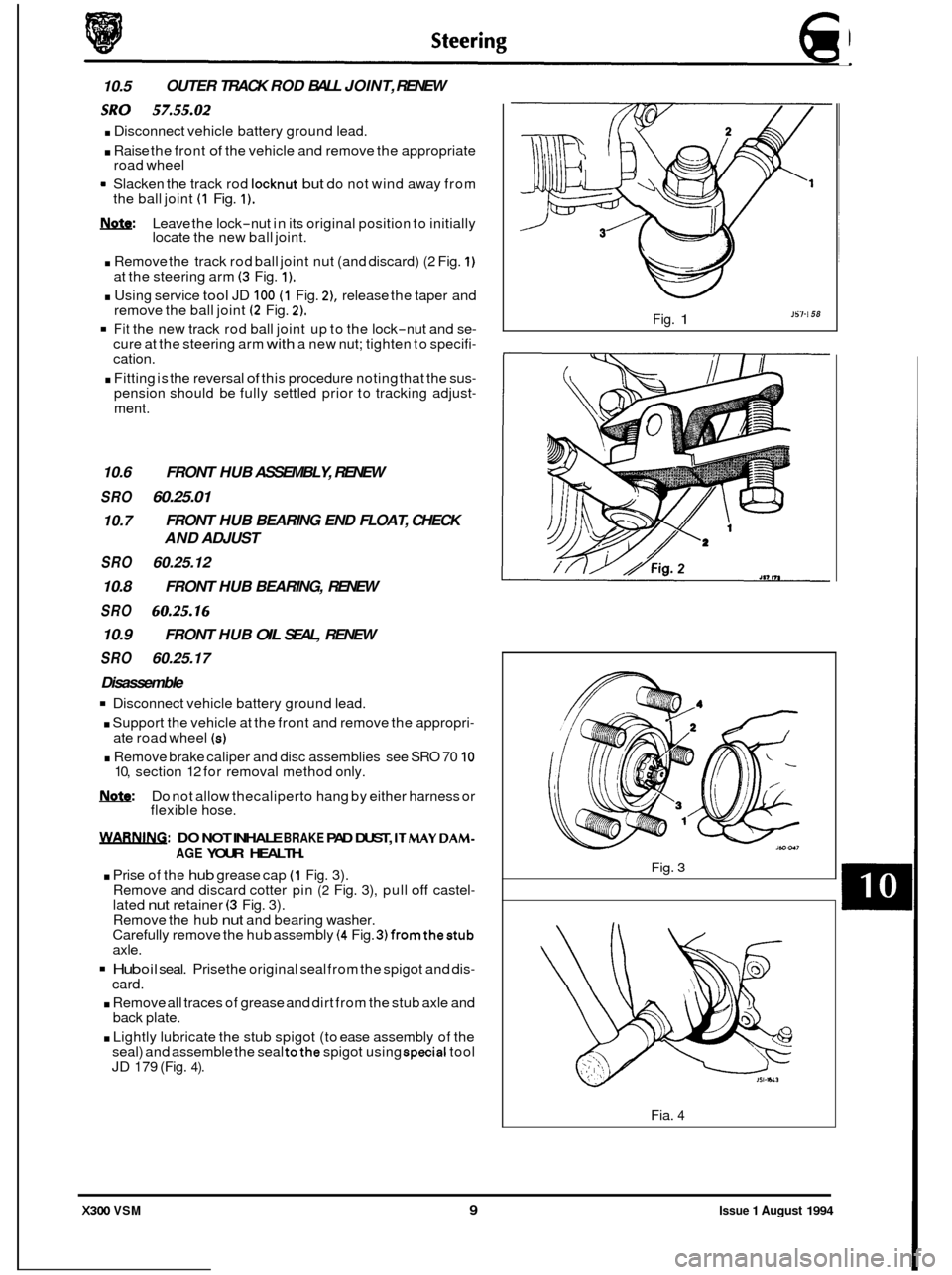

10.5 OUTER

TRACK ROD BALL JOINT, RENEW

sRo . Disconnect 57.55.02 vehicle battery ground lead.

. Raise the front of the vehicle and remove the appropriate

road wheel

Slacken the track rod

locknut but do not wind away from

the ball joint (1 Fig. 1).

m: Leave the lock-nut in its original position to initially

locate the new ball joint.

. Remove the track rod ball joint nut (and discard) (2 Fig. 1)

at the steering arm (3 Fig. 1).

. Using service tool JD 100 (1 Fig. 2), release the taper and

remove the ball joint (2 Fig. 2).

Fit the new track rod ball joint up to the lock-nut and se- cure at the steering arm with a new nut; tighten to specifi- cation.

. Fitting is the reversal of this procedure noting that the sus- pension should be fully settled prior to tracking adjust-

ment.

0 10.6 FRONT HUB ASSEMBLY, RENEW

SRO 60.25.01

10.7

SRO 60.25.12

10.8 FRONT HUB BEARING, RENEW

SRO 60.25.16

10.9

SRO 60.25.17

Disassemble

Disconnect vehicle battery ground lead.

. Support the vehicle at the front and remove the appropri-

. Remove brake caliper and disc assemblies see SRO 70 10

IWQ: Do not allow thecaliperto hang by either harness or

flexible hose.

FRONT HUB BEARING END FLOAT, CHECK

AND ADJUST

FRONT HUB

OIL SEAL, RENEW

ate road wheel (s)

10, section 12 for removal method only.

WARNIM: DO NOT INHALE BRAKE PAD DUST, ITMAY DAM-

0

AGE YOUR HEALTH.

. Prise of the hub grease cap (1 Fig. 3).

Remove and discard cotter pin (2 Fig. 3), pull off castel- lated nut retainer (3 Fig. 3).

Remove the hub nut and bearing washer.

Carefully remove the hub assembly (4 Fig. 3)fromthestub axle.

Hub oil seal. Prise the original seal from the spigot and dis-

card.

. Remove all traces of grease and dirt from the stub axle and

back plate.

. Lightly lubricate the stub spigot (to ease assembly of the

seal) and assemble the seal tothe spigot using special tool JD 179 (Fig. 4).

JS7-i 58 Fig. 1

Fig. 3

Fia.

4

X300 VSM 9 Issue 1 August 1994

Page 209 of 521

@ Steering

. Pack the annular gaps of the oil seal lips with grease.

. Bearing. Wash the hub assembly thoroughly and 'drift' the affected bearing cup(s) from the hub.

!&!$Q:

rn Hub. At this point the hub may be renewed if required.

Assembly

. Bearing. Assemble the inner bearing track to the hub using service tool 18G 134 and adaptor JD 550 - 5 / 1.

Ensure that the hub inner seal diameter is free of debris or damage and is lightly lubricated prior to assembly.

Only replace complete bearings, never cup or race in isolation.

Assemble the outer bearing cup to the hub using service tool

18G 134 and adaptor JD 550 - 5 / 2. Pack each race with approximately 4 ml of grease and position the inner race onto the stub axle.

Apply a smear of grease to hub inner surfaces and bearing cups. Assemble the hub to the stub axle followed by

outer race, bearing washer and hub nut.

It is not necessary to fill the hub cavity with grease, merely protect from corrosion with a coat of IubricanL'Seat'the bear-

ings by slightly tightening the hub nut whilst rotating the hub. Do not apply load without rotation. m:

. End float. Set a Dial Test Indicator (DTI) as shown in Fig. 1 and adjust the hub nut to achieve the correct end float.

As the adjustment is made, continually load the hub axial-

ly in both directions.

. Without disturbing the end float setting, fit the castellated

nut retainer so that it aligns with both hub nut and stub

axle drilling.

. Secure nut retainer using a new cotter pin.

9 Assembly and fitting is the reversal of this procedure not- ing that; all fixings MUST be tightened to specification

and operation of the braking system verified.

Fig. 1

Issue 1 August 1994 10 X300 VSM

Page 211 of 521

1. SERVICE TOOLS & EQUIPMENT

Illustration

Not illustrated

Jaguar Number

JDID

JD 60

JDIOO

JD115

JD133

JD135

JD143

JD143-1

50143-2

JD143-3

Description

Hub Remover Rear Suspension

Nishbone Upper Bush Remover

1 Replacer

Remover Steering Arm and Swivel

Hub Ball Pins

Spring Compressor Front Suspension

Camber Tie Down Link (Front)

RemoverIRenewer Front Damper

Lower Bush

Remover

1 Renewer Suspension

Bushes (Main

Tool)

Adaptor Ring Front Sub Frame Rear

Bushes

Anvil adapter

Adaptor Remover

1 Renewer

Suspension Bushes

Issue 1 August 1994 ii X300 VSM

Page 214 of 521

Suspension Systems

11.1 INTRODUCTION

This section describes the front and rear suspension systems, and also covers diagnostic procedures.

Fig. 1 Front Suspension Layout

11.2 FRONT SUSPENSION, DESCRIPTION

Theupperrearwishbone(1 Fig.l)andthe upperfrontwishbone(2 Fig.1)arepivotedon the upperfulcrum bolt (3Fig.l), passing through the front cross beam assembly. They are also fitted via an upper ball joint assembly (4 Fig.1) to a verti- cal linkaccommodating the stub axle (5 Fig.l), whereas the vertical linkisfittedvia a lower ball joint assembly (6 Fig.1) to the lower wishbone assembly.

The lower wishbone assembly comprises

a lower rear wishbone (7 Fig.l), lower front wishbone (8 Fig.l), damper (9 Fig.1) (incorporating damper bush 10 Fig.1) and spring pan (1 1 Fig.1) supporting the road spring (12 Fig.1). The lower

wishbone assembly is pivoted on the bushed lower fulcrum shaft (13 Fig.1) which also passes through thecross beam

assembly.

Both independent front suspension assemblies are linked by a stabilizer bar (14 Fig.1) which is secured to the cross

member using a fixing arrangement of mounting rubbers (15 Fig.1, clamps (16 Fig.l), nuts bolts, washers (17 Fig.1) and two link arm assemblies (18 Fig.1). Each link arm assembly is fitted to one end of the stabilizer bar and to one end

of the lower front wishbone using a fixing arrangement of bolts washers and self locking nuts.

All suspension loads, except the damper, are fed into a pressed steel crossbeam which is isolated from the body by

rubber bushes. This mounting method allows the necessary amount of compliance.

The degree

of caster is adjustable via shims positioned on either side of the upper ball joint assembly but camber is facton/ set and is not adjustable. The vertical link and the steering arm form a single forging. Cast iron hubs rotate

on twin tapered roller bearings.

X300 VSM 1 Issue 1 August 1994

Page 216 of 521

may include:

0

0

Loose or worn wheel bearings.

Loose or worn suspensions or steering components.

0 Worn or damaged drive shaft slip yoke joint.

0 Front disc rotor runout.

o Loose engine or transmission supports.

0 Driveline alignment.

0 Engine driven accessories.

Suspension Systems

11.4 DIAGNOSIS AND TESTING

' 11.4.1 Tire Wear

Tires should be inspected as abnormal or excessive wear may becaused by incorrect wheel alignment, wheelbire im- balance, or incorrect tire pressure.

1 1.4.2 vibration and Roughness

Vibration, roughness, and shimmy conditions may be caused by excessive tire or wheel runout, worn or cupped tires,

or wheel and tire unbalance.

Most of these conditions are due to irregularities in the road surface, hence driving the vehicle on different types of

road surface will often indicate the cause of the condition.

Do not automatically suspect the tires when attempting to diagnose a vibration concern as other sources of vibration

Before investigating any other vibration concerns,

a roaG &est and a customer inter\,.dw (if possible) should be carried

out. This can provide much of the information needed to find the source of vibration.

Drive the vehicle on a road that is preferably smooth and free of undulation and

if vibration is apparent note, the speed at which thevibration occurs, whattype of vibration occurs in each speed range (mechanical or audible), howthevibra- tion is affected by changes in vehicle speed , engine speed and engine torque, and the type of vibration sensitivity

(torque sensitive, vehicle speed sensitive, or speed sensitive).

Some of the condition terms used when describing sources of vibration are explained as follows:

0 Torque Sensitive

This condition can be improved or worsened by accelerating, decelerating, coasting, maintaining

a steady

vehicle speed and application of engine torque.

0 Vehicle Speed Sensitive

This means that the vibration always occurs at the same vehicle speed and is not affected by engine torque,

engine rpm, or transmission gear selection.

B

0 Engine Speed Sensitive

This means that the vibration occurs

at varying vehicle speeds when a different transmission gear is selected.

It can sometimes be isolated by increasing or decreasing engine speed with the transmission in 'NEUTRAL', or

by stall testing with the engine in gear. If the condition is enginesensitive, the condition is not related to tires.

If the road tests indicates that the vibration is related to the tires or wheels,use a 'lire Wear Diagnosis Chart' to

investigate the cause of concern. Should the road test indicate that there is tire whine, but noshake or vibration,

the noise originates from the contact between the tire and the road surface.

X300 VSM 3 Issue 1 August 1994

Page 217 of 521

Suspension Systems

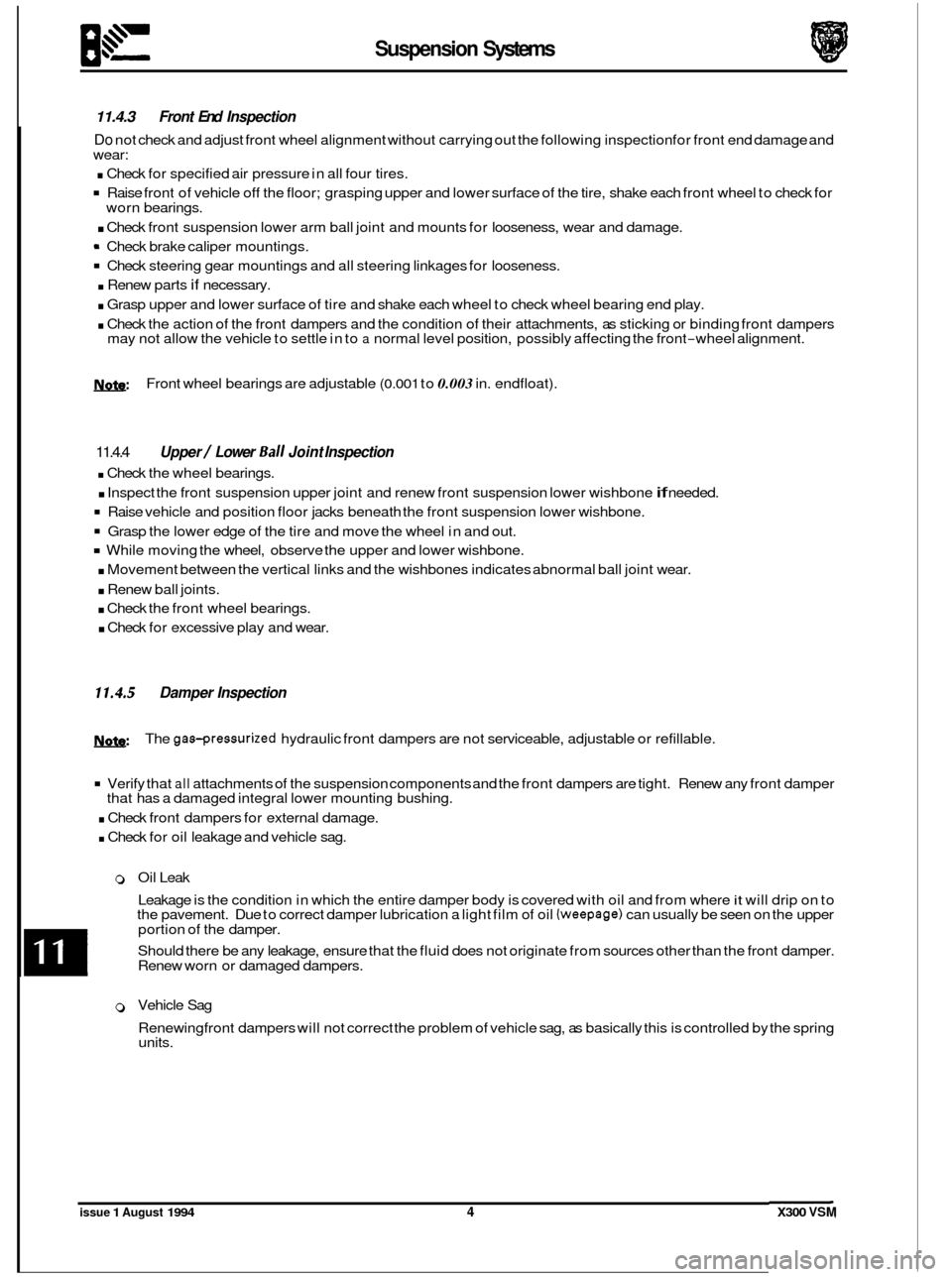

11.4.3 Front End Inspection

Do not check and adjust front wheel alignment without carrying out the following inspection for front end damage and

wear:

. Check for specified air pressure in all four tires.

Raise front of vehicle off the floor; grasping upper and lower surface of the tire, shake each front wheel to check for

. Check front suspension lower arm ball joint and mounts for looseness, wear and damage.

Check steering gear mountings and all steering linkages for looseness.

. Renew parts if necessary.

. Grasp upper and lower surface of tire and shake each wheel to check wheel bearing end play.

. Check the action of the front dampers and the condition of their attachments, as sticking or binding front dampers

worn

bearings.

Check brake caliper mountings.

may not allow the vehicle to settle in to a normal level position, possibly affecting the front-wheel alignment.

m: Front wheel bearings are adjustable (0.001 to 0.003 in. endfloat).

11.4.4

. Check the wheel bearings.

. Inspect the front suspension upper joint and renew front suspension lower wishbone if needed.

Raise vehicle and position floor jacks beneath the front suspension lower wishbone.

Grasp the lower edge of the tire and move the wheel in and out.

While moving the wheel, observe the upper and lower wishbone.

. Movement between the vertical links and the wishbones indicates abnormal ball joint wear.

. Renew ball joints.

. Check the front wheel bearings.

. Check for excessive play and wear.

Upper / Lower Ball Joint Inspection

11.4.5 Damper Inspection

m: The gas-pressurized hydraulic front dampers are not serviceable, adjustable or refillable.

Verify that all attachments of the suspension components and the front dampers are tight. Renew any front damper

. Check front dampers for external damage.

. Check for oil leakage and vehicle sag.

that

has a damaged integral lower mounting bushing.

0 Oil Leak

Leakage is the condition in which the entire damper body is covered with oil and from where

it will drip on to

the pavement. Due to correct damper lubrication a light film of oil (weepage) can usually be seen on the upper

portion of the damper.

Should there be any leakage, ensure that the fluid does not originate from sources other than the front damper.

Renew worn or damaged dampers.

0 Vehicle Sag

Renewing front dampers will not correct the problem of vehicle sag, as basically this is controlled by the spring

units.

issue 1 August 1994 4 X300 VSM

Page 219 of 521

Suspension Systems

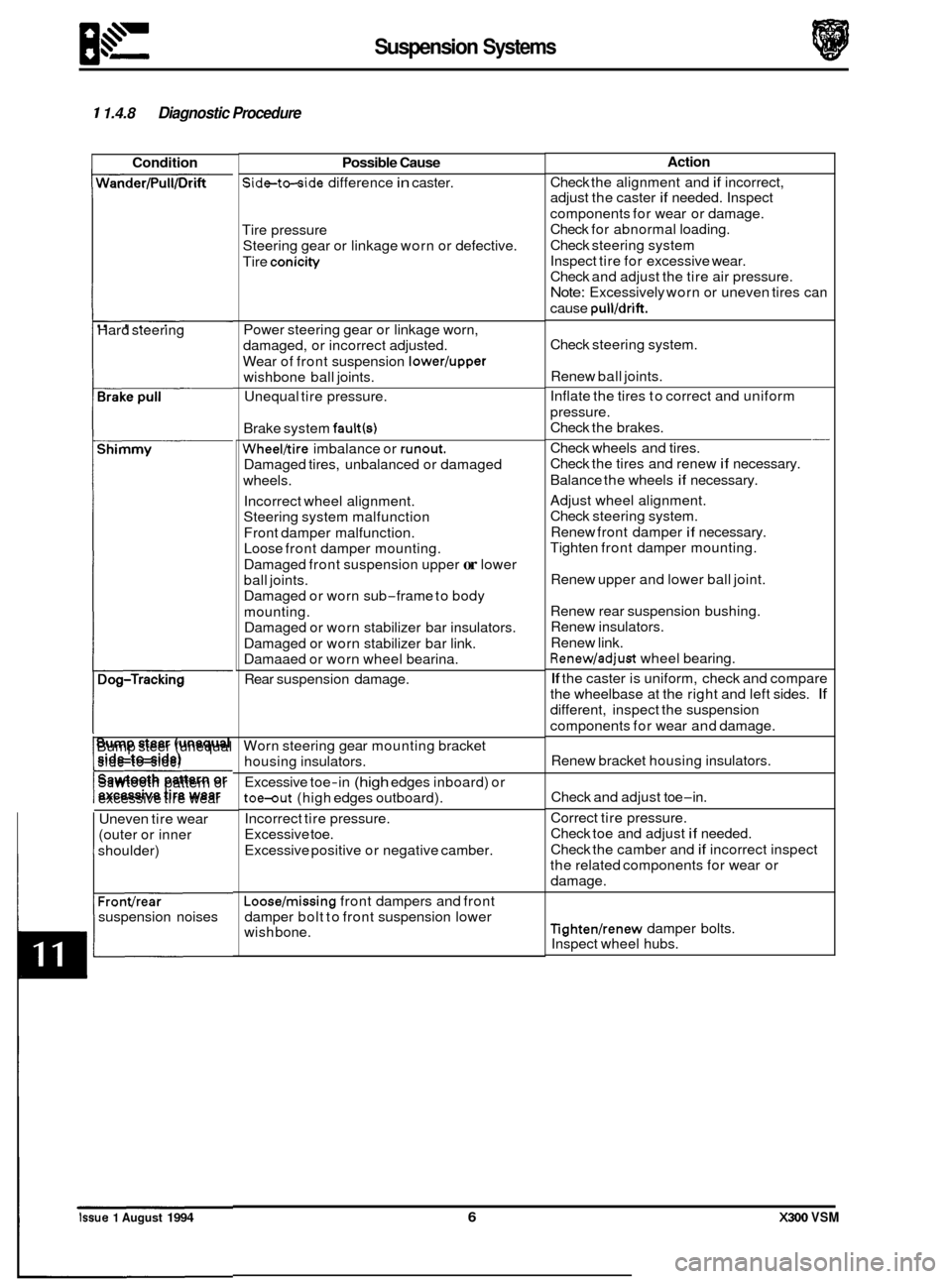

1 1.4.8 Diagnostic Procedure

Condition

Hard steering

Shimmy

I----

Bump steer (unequal

side-to-side)

Sawtooth pattern or

t excessive tire wear

Uneven tire wear

(outer or inner

shoulder)

Fronvrear

suspension noises

Possible Cause

Side-to-side difference in caster.

Tire pressure Steering gear or linkage worn or defective.

Tire

conicity

Power steering gear or linkage worn,

damaged, or incorrect adjusted.

Wear of front suspension

lower/upper

wishbone ball joints.

Unequal tire pressure.

Brake system

fault(s)

Wheel/tire imbalance or runout.

Damaged tires, unbalanced or damaged

wheels.

Incorrect wheel alignment.

Steering system malfunction

Front damper malfunction.

Loose front damper mounting.

Damaged front suspension upper

or lower

ball joints.

Damaged or worn sub

-frame to body

mounting. Damaged or worn stabilizer bar insulators.

Damaged or worn stabilizer bar link.

Damaaed or worn wheel bearina.

Rear suspension damage.

Worn steering gear mounting bracket

housing insulators.

Excessive toe

-in (high edges inboard) or

toe-out (high edges outboard).

Incorrect tire pressure.

Excessive toe.

Excessive positive or negative camber.

Loose/missing front dampers and front

damper bolt to front suspension lower

wish bone.

Action

Check the alignment and if incorrect,

adjust the caster

if needed. Inspect

components for wear or damage.

Check for abnormal loading.

Check steering system

Inspect tire for excessive wear.

Check and adjust the tire air pressure.

Note: Excessively worn or uneven tires can

cause

pull/drift.

Check steering system.

Renew ball joints.

Inflate the tires to correct and uniform

pressure.

Check the brakes.

Check wheels and tires.

Check the tires and renew

if necessary.

Balance the wheels

if necessary.

Adjust wheel alignment.

Check steering system.

Renew front damper

if necessary.

Tighten front damper mounting.

-

Renew upper and lower ball joint.

Renew rear suspension bushing.

Renew insulators.

Renew link.

Renew/adjust wheel bearing.

If the caster is uniform, check and compare

the wheelbase at the right and left sides.

If

different, inspect the suspension

components for wear and damage.

Renew bracket housing insulators.

Check and adjust toe

-in.

Correct tire pressure.

Check toe and adjust

if needed.

Check the camber and

if incorrect inspect

the related components for wear or

damage.

Tighten/renew damper bolts.

Inspect wheel hubs.

0

0

0

lssue 1 August 1994 6 X300 VSM

Page 220 of 521

Suspension Systems I.\" b-

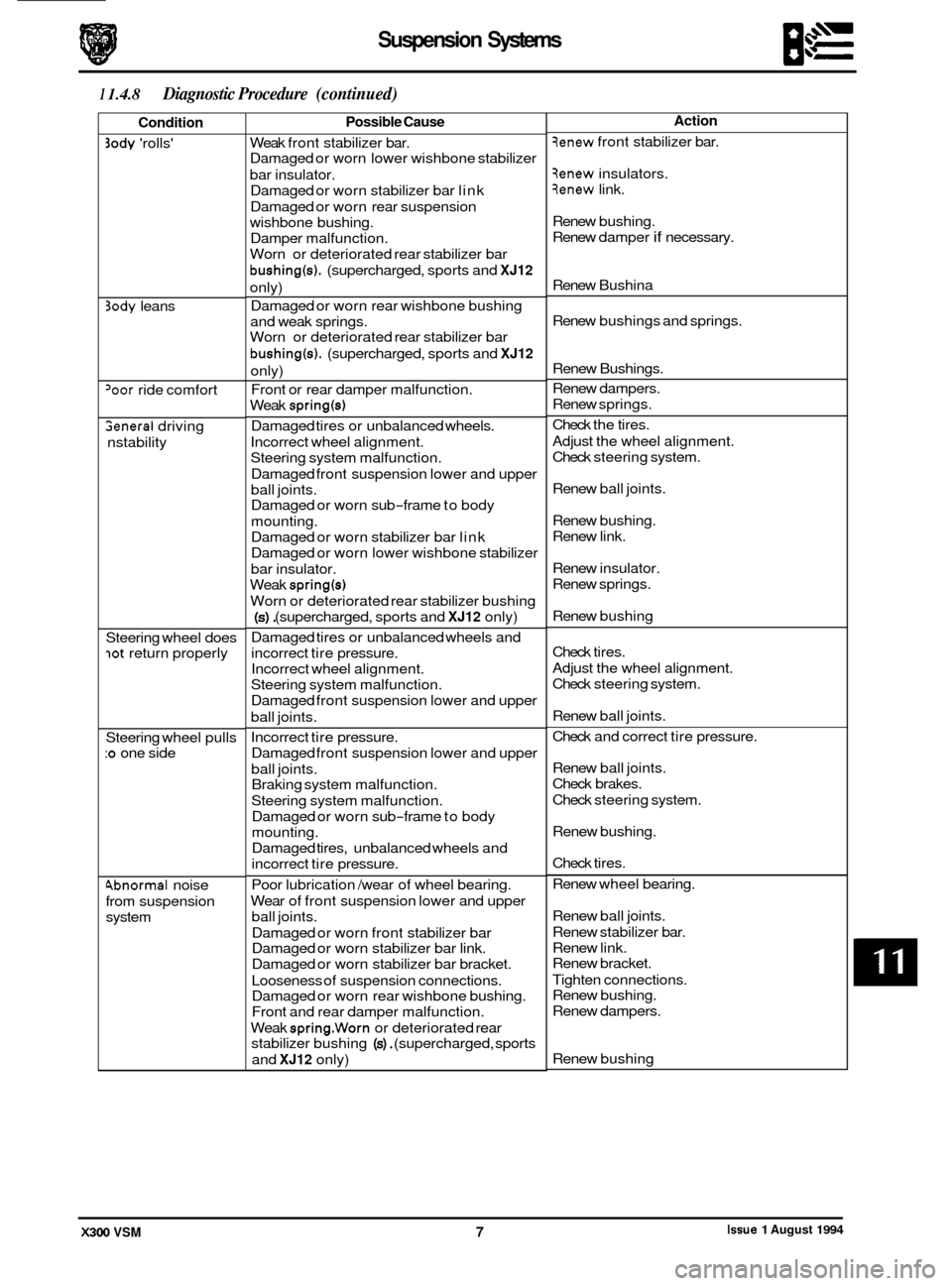

1 1.4.8 Diagnostic Procedure (continued)

Condition

30dy 'rolls'

3ody leans

'oor ride comfort

Seneral driving

nstability

Steering wheel does

lot return properly

Steering wheel pulls

:o one side

4bnormal noise

from suspension

system

Possible Cause

Weak front stabilizer bar.

Damaged or worn lower wishbone stabilizer

bar insulator. Damaged or worn stabilizer bar link

Damaged or worn rear suspension

wishbone bushing.

Damper malfunction.

Worn or deteriorated rear stabilizer bar

bushing(s). (supercharged, sports and XJ12

only)

Damaged or worn rear wishbone bushing

and weak springs.

Worn or deteriorated rear stabilizer bar

bushing(s). (supercharged, sports and XJ12

only)

Front or rear damper malfunction.

Weak

spring(s1

Damaged tires or unbalanced wheels.

Incorrect wheel alignment.

Steering system malfunction.

Damaged front suspension lower and upper

ball joints.

Damaged or worn sub

-frame to body

mounting.

Damaged or worn stabilizer bar link

Damaged or worn lower wishbone stabilizer

bar insulator.

Weak

spring(s)

Worn or deteriorated rear stabilizer bushing

(s). (supercharged, sports and XJ12 only)

Damaged tires or unbalanced wheels and

incorrect tire pressure.

Incorrect wheel alignment.

Steering system malfunction.

Damaged front suspension lower and upper

ball joints.

Incorrect tire pressure.

Damaged front suspension lower and upper

ball joints. Braking system malfunction.

Steering system malfunction.

Damaged or worn sub

-frame to body

mounting.

Damaged tires, unbalanced wheels and

incorrect tire pressure.

Poor lubrication /wear of wheel bearing.

Wear of front suspension lower and upper

ball joints.

Damaged or worn front stabilizer bar

Damaged or worn stabilizer bar link.

Damaged or worn stabilizer bar bracket.

Looseness of suspension connections.

Damaged or worn rear wishbone bushing.

Front and rear damper malfunction.

Weak

spring.Worn or deteriorated rear

stabilizer bushing

(s). (supercharged, sports

and

XJ12 only)

Action

3enew front stabilizer bar.

3enew insulators.

3enew link.

Renew bushing.

Renew damper

if necessary.

Renew Bushina

Renew bushings and springs.

Renew Bushings.

Renew dampers.

Renew springs.

Check the tires.

Adjust the wheel alignment.

Check steering system.

Renew ball joints.

Renew bushing.

Renew link.

Renew insulator.

Renew springs.

Renew bushing

Check tires.

Adjust the wheel alignment.

Check steering system.

Renew ball joints.

Check and correct tire pressure.

Renew ball joints.

Check brakes.

Check steering system.

Renew bushing.

Check tires.

Renew wheel bearing.

Renew ball joints.

Renew stabilizer bar.

Renew link.

Renew bracket.

Tighten connections.

Renew bushing.

Renew dampers.

Renew bushing

Issue 1 August 1994 X300 VSM 7