steering JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 399 of 521

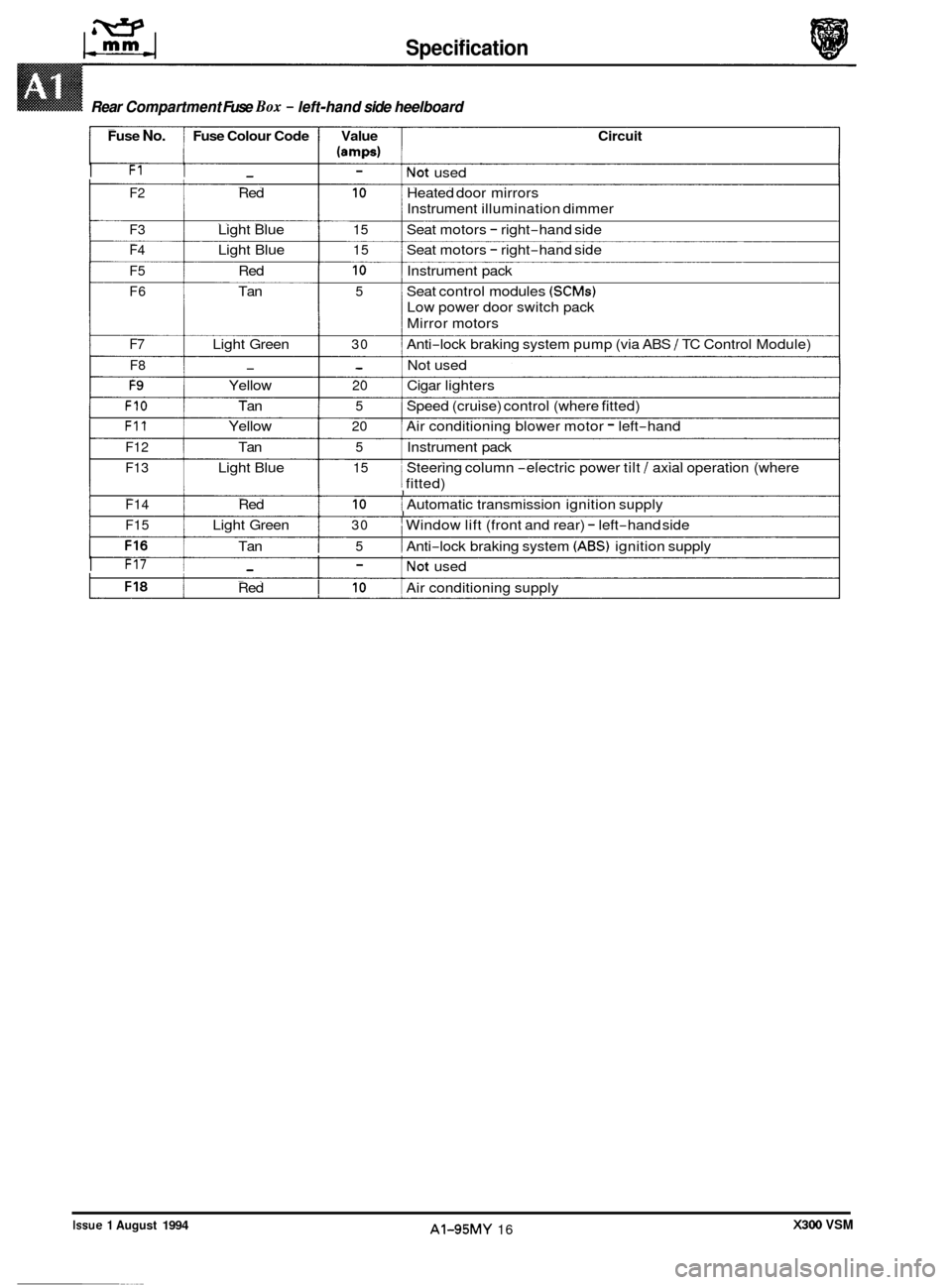

Specification

Rear Compartment Fuse Box - left-hand side heelboard

Fuse No. Fuse Colour Code Value Circuit

(amps)

I F1 I - I - lNot used

F2 Red 10 Heated door mirrors

F3 Light Blue 15 Seat motors - right-hand side

F4 Light Blue 15 Seat motors - right-hand side

F5 Red 10 Instrument pack

F6 Tan 5 Seat control modules (SCMs)

Low power door switch pack

Mirror motors

Instrument

illumination dimmer

F7 Light Green 30 Anti-lock braking system pump (via ABS / TC Control Module)

F8 - - Not used

F9 Yellow 20 Cigar lighters

FIO Tan 5 Speed (cruise) control (where fitted)

F11 Yellow 20 Air conditioning blower motor - left-hand

F12 Tan 5 Instrument pack

F13 Light Blue 15 Steering column -electric power tilt / axial operation (where

j fitted) 1 I I F14 Red 10 i Automatic transmission ignition supply I I I F15 Light Green 30 I Window lift (front and rear) - left-hand side

Tan

I 5 1 Anti-lock braking system (ABS) ignition supply

I F17 1 - I - lNot used

Red

I 10 I Air conditioning supply

Rear Compartment Fuse Box - left-hand side heelboard ~~

X300 VSM Issue 1 August 1994 AI-95MY 16

0

0

0

Page 400 of 521

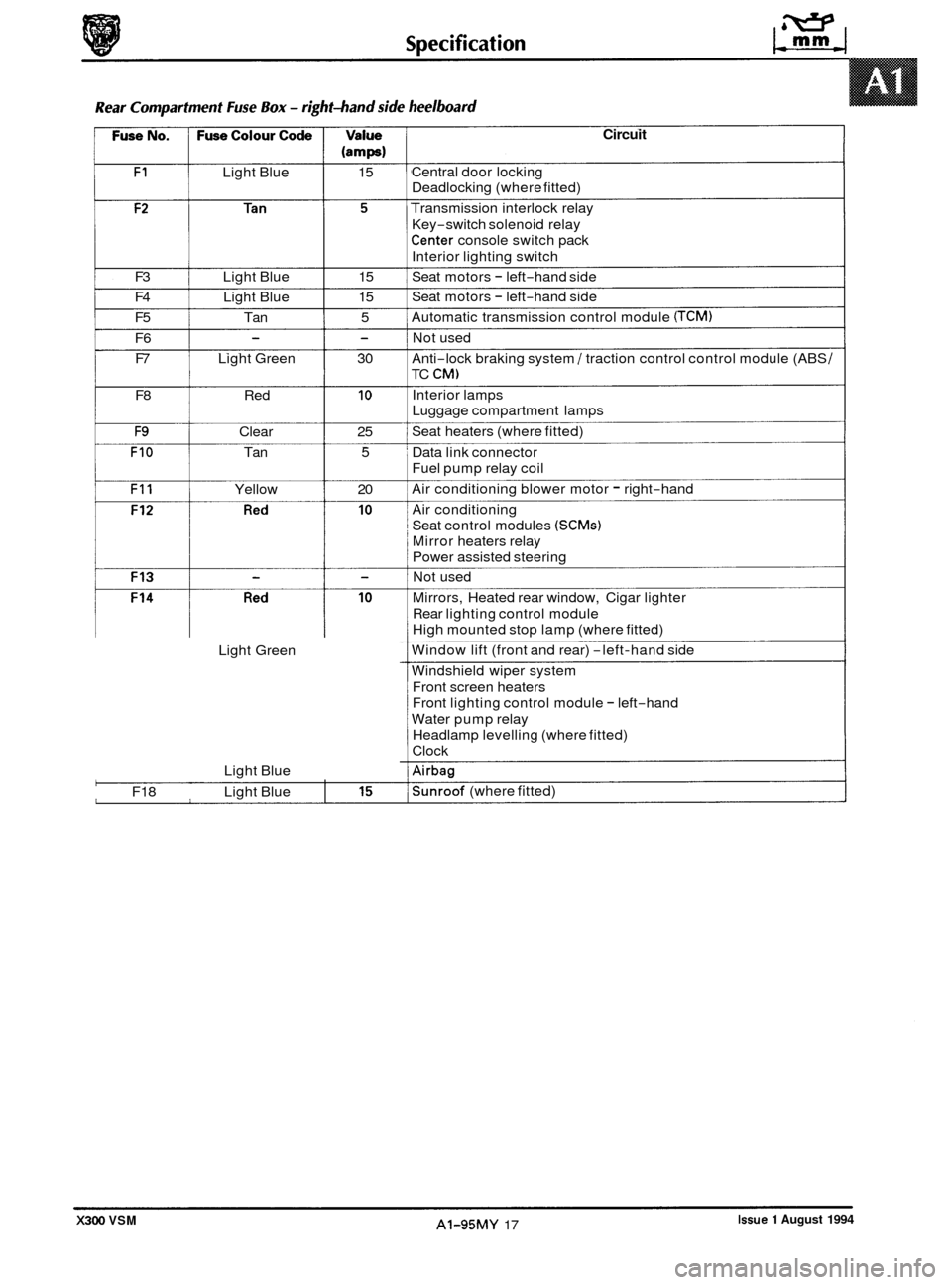

(amps)

F1 Light Blue 15

F3 Light Blue 15

F4 Light Blue 15

F5 Tan 5

F6 F7 Light Green 30

- -

F8 Red 10

F9 Clear 25

FIO Tan 5

F11 Yellow 20 0

Light Green

Light Blue

F18 Light Blue

0'

I

Circuit

Central door locking

Deadlocking (where fitted)

Transmission interlock relay

Key

-switch solenoid relay

Center console switch pack

Interior lighting switch

Seat motors

- left-hand side

Seat motors

- left-hand side

Automatic transmission control module

(TCM)

Not used

Anti

-lock braking system / traction control control module (ABS /

TC CM)

Interior lamps

Luggage compartment lamps

Seat heaters (where fitted)

Data link connector

Fuel pump relay coil

Air conditioning blower motor

- right-hand

Air conditioning

Seat control modules

(SCMs)

Mirror heaters relay

Power assisted steering

Not used

Mirrors, Heated rear window, Cigar lighter

Rear lighting control module

High mounted stop lamp (where fitted)

Window lift (front and rear)

-left-hand side

Windshield wiper system Front screen heaters

Front lighting control module

- left-hand

Water pump relay

Headlamp levelling (where fitted)

Clock

Airbag

Sunroof (where fitted)

Issue 1 August 1994 AI-95MY 17 X300 VSM

Page 407 of 521

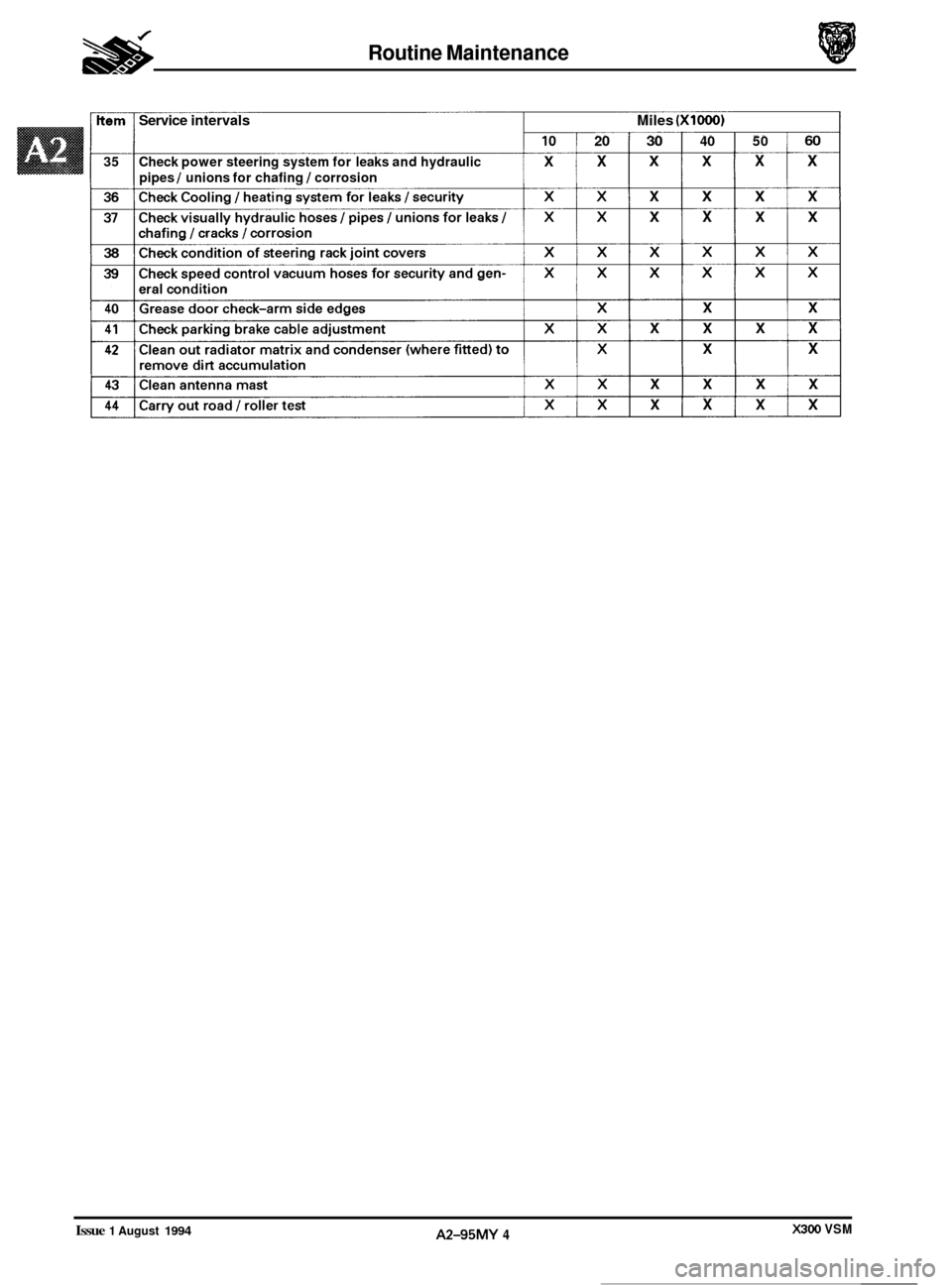

* Routine Maintenance

Item Service intervals Miles (XlOOO)

10 20

35 Check power steering system for leaks and hydraulic X X

pipes 1 unions for chafing I corrosion

30 40 50 60

X X X X

X X X X

X X X X

X X

X X X

X

X X

X X X X

X

X X X

.

X300 VSM Issue 1 August 1994 A2-95MY 4

Page 409 of 521

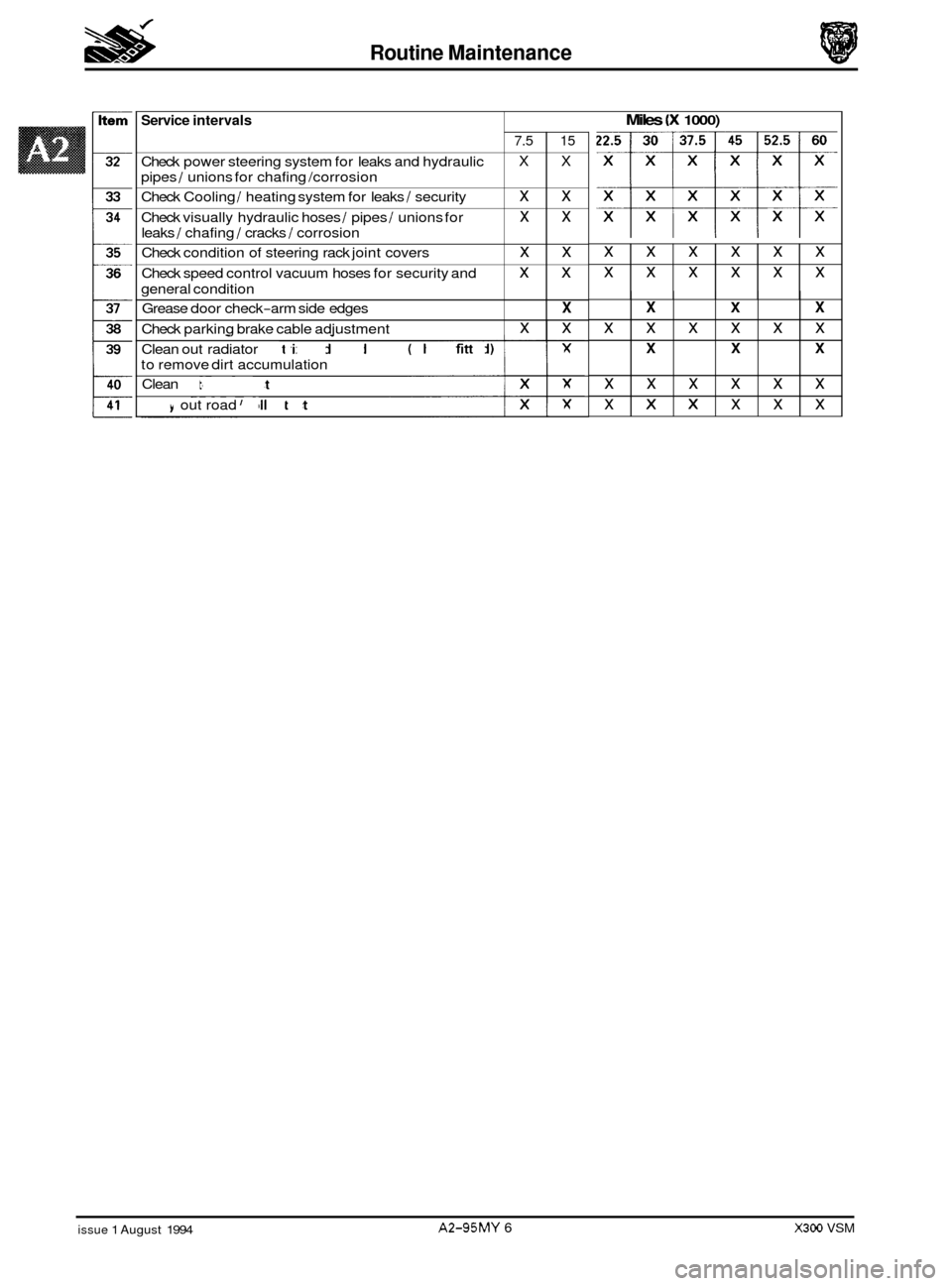

Routine Maintenance

Service intervals

Check power steering system for leaks and hydraulic

pipes

/ unions for chafing /corrosion

Check Cooling

/ heating system for leaks / security

Check visually hydraulic hoses

/ pipes / unions for

leaks

/ chafing / cracks / corrosion

Check condition of steering rack joint covers

Check speed control vacuum hoses for security and

general condition

Grease door check

-arm side edges

Check parking brake cable adjustment

Miles (X 1000)

7.5 15

X X

xx

xx

xx

xx

X

xx

xxxxxx

xxxxxx

x

X X X

xxxxxx

X X X

xxxxxx

XIX x x x

-

Clean out radiator matrix and condenser (where fitted)

to remove dirt accumulation

Clean antenna mast

xx

Carry out road / roller test Ix

i

0

0

0

X

x

issue 1 August 1994 A2-95MY 6 X300 VSM

Page 415 of 521

General Fitting Instructions

Pressordrifttheseal in tothefull depthofthe housing ifthe housing is shouldered,orflush withthefaceofthe housing

where no shoulder is provided.

Note: Careless fitting of oil seals, which can result in damage to the seal and sealing surfaces, accounts for most

cases of failure of seals. Care in fitting is essential

if good results are to be obtained.

A3.2.7 joints And joint Faces

Remove all traces of old jointing materials prior to reassembly. Inspect joint faces for scratches or burrs and remove

with a fine file or oilstone; do not allow swarf or dirt to enter tapped holes or enclosed parts. Blow out any pipes, chan- nels or crevices with compressed air, refitting or renewing any 0-rings or seals which have been displaced by the com- pressed air.

Always use the specified gaskets. Use jointing compound only when recommended, otherwise fit joints dry. When

jointing compound is used, apply in

a thin film to metal surfaces; take great care to prevent it from entering oilways, pipes or blind tapped holes.

A3.2.8

Before removing a hose from the brake or power steering systems, thoroughly clean the end fittings and the area sur- rounding them. Obtain blanking caps beforedetaching hosefittings,sothat portscan becovered to excludedirt. Clean

the hose externally and blow through with compressed air. Examine the hose carefully for cracks, separation of plies,

security of end fittings and external damage. Reject any hose found to be faulty. When refitting the hose, ensure that

no unnecessary bends are introduced and that the hose is not twisted before or during tightening of union nuts.

Do not store hydraulic fluid in an unsealed container because it will absorb water. Fluid in this condition would be dan- gerous to use due to a lowering of its boiling point. Do not allow hydraulic fluid to be contaminated with mineral oil,

or use a container which has previously contained mineral oil.

Do not re-use fluid bled from the system. Always use clean brake fluid, or a recommended alternative, to clean the

hydraulic components. Fit a blanking cap to the hydraulic union and

a plug to its mating socket, after removal from

the vehicle, to prevent ingress of dirt. Absolute cleanliness must be observed with hydraulic components at all times.

After any work has been performed on hydraulicsystems, inspect carefully for leaks underneath the car while a second

operator applies maximum pressure to the brakes (with the engine running) and operates the steering.

Hydraulic Flexible Pipes And Hoses

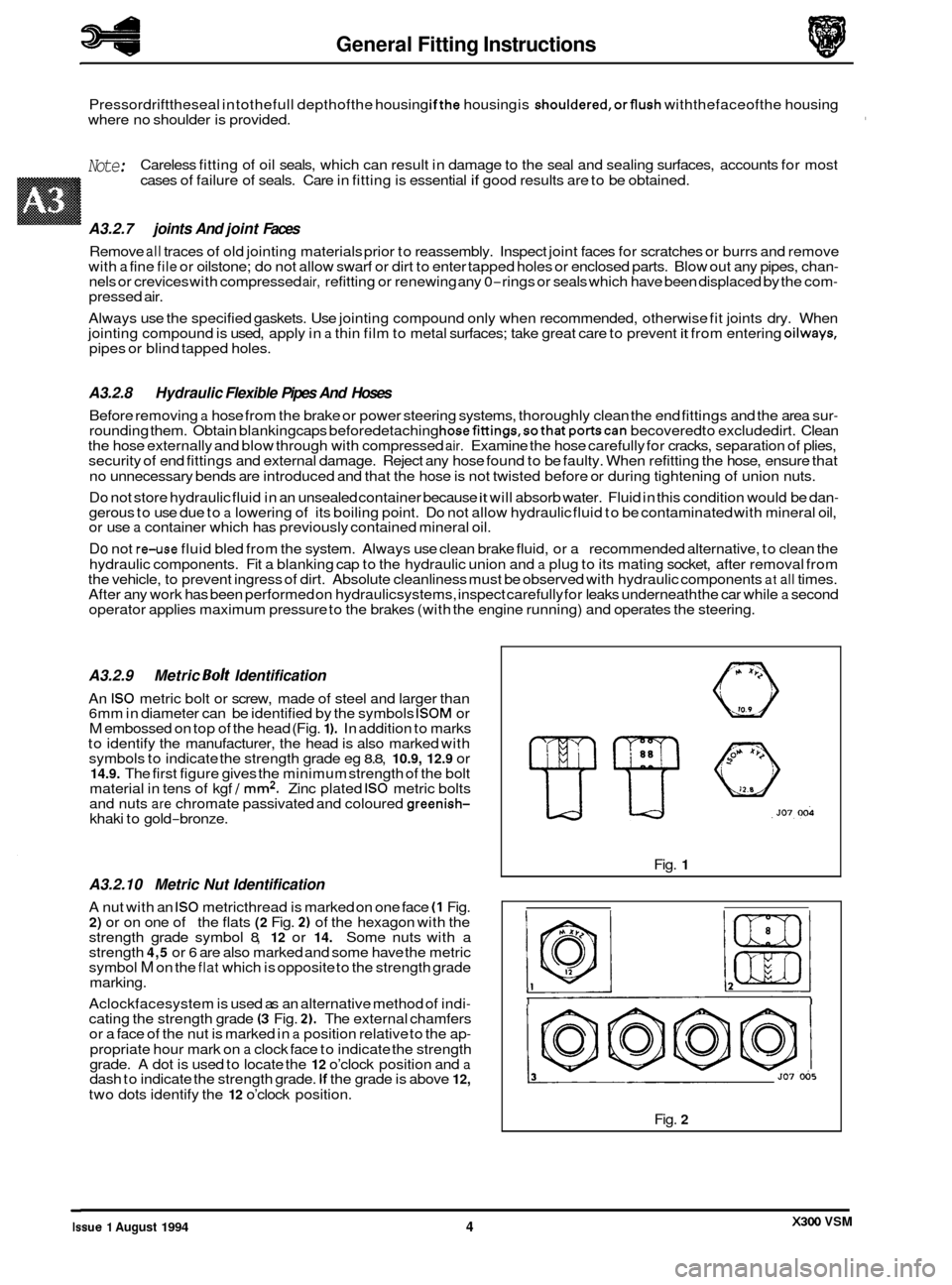

A3.2.9 Metric

Bolt Identification

An IS0 metric bolt or screw, made of steel and larger than

6mm in diameter can be identified by the symbols ISOM or M embossed on top of the head (Fig. 1 ). In addition to marks

to identify the manufacturer, the head is also marked with

symbols to indicate the strength grade eg

8.8, 10.9, 12.9 or 14.9. The first figure gives the minimum strength of the bolt

material in tens of kgf / mm2. Zinc plated IS0 metric bolts

and nuts are chromate passivated and coloured greenish- khaki to gold-bronze.

A3.2.10 Metric Nut Identification

A nut with an IS0 metricthread is marked on one face (1 Fig. 2) or on one of the flats (2 Fig. 2) of the hexagon with the

strength grade symbol 8, 12 or 14. Some nuts with a

strength 4,5 or 6 are also marked and some have the metric

symbol M on the flat which is opposite to the strength grade

marking.

Aclockfacesystem is used as an alternative method of indi

- cating the strength grade (3 Fig. 2). The external chamfers

or a face of the nut is marked in a position relative to the ap-

propriate hour mark on a clock face to indicate the strength

grade. A dot is used to locate the 12 o’clock position and a dash to indicate the strength grade. If the grade is above 12,

two dots identify the 12 o’clock position. Fig.

1

I I

Fig. 2

X300 VSM Issue 1 August 1994 4

Page 428 of 521

0

0

0

Body Systems Body Repair

A4.1 BODY REPAIR

Introduction

This section contains information, specifications and procedures for body repair and rectification of the Jaguar sedan

range (with standard wheelbase).

All repairs, whether structural or cosmetic, must ensure the continuance of the Paint Surface and Corrosion warranty,

where applicable.

Following repair or rectification, the vehicle must be returned to the original manufactured condition with regard to

occupant safety, dimensional accuracy, finish and corrosion protection.

Similarly, repaired vehicles must be fully checked, and where appropriate reset, with regard to steering, suspension,

restraint and

braking systems.

A4.1.1 Health and Safety

(Please Read The

Fol/owing Notes Carethlly)

Where legislation governing working conditions and practises is applicable, you should observe it. Do not forget that

you have a duty, to yourself and those around you, to act in a responsible manner in the workplace.

In the United Kingdom the Health and Safety

at Work Act (1974) places a duty on employers and employees to ensure,

whenever possible, safe working conditions and practices. Wherever a potential hazard is notified to, or identified by

the operator, he must employ the correct safety procedures and equipment.

Should

a personal injury occur as a result of any workshop activity, seek medical help as soon as possible and do not

attempt self-treatment other than by the application of first aid.

With the constant introduction of new materials in the manufacture of vehicles,

it is important that potential risks are

identified and precautions made known.

WARNING: READ AND UNDERSTAND WORKING PRACTICES CLIMATE CONTROL SYSTEMS, SECTION 14, WITH SPECIAL REFERENCE TO

ERY

/ RECYCLE / RECHARGE EQUIPMENT.

WEAR SUITABLE EYE AND SKIN PROTECTION.

OBSERVE ALL APPLICABLE SAFETY REQUIREMENTS.

DO

NOT VENT REFRIGERANT DIRECTLY TO ATMOSPHERE, ALWAYS USE JAGUAR APPROVED RECOV

-

Issue 1 August 1994 1 X300 VSM

Page 442 of 521

Body Systems & Body Repair

A4.2.4 PANELS - ASSOCIATED, RENEW

SRO 77.10.02

w: Where other components must be removed to gain access, please referto the relevant manual section for guid- ance. This is critically important with regard to steering, braking, suspension, electrical and safety systems.

. Expose the resistance spot welds, for those spot welds which are not obviously visible, use a rotary wire brush fitted to an air drill or a hand held wire brush (A Fig. 1).

WARM: DO NOT BURN UNDERSEAL OFF. USE A 'HOT KNIFE' OR SUITABLE SOLVENT.

. Cut out the spot welds using a Zipcutter or Roto-Bor (B Fig. 1).

Jhh: On some panels, before removing the bulk of panel with the pneumatic saw, brazed areas and MIG welded

seams should be removed.

= Separate the spot welded joints and remove the panel remnants.

At

this point

it may be necessary to cut out the bulk of the panel using a pneumatic saw (C Fig. 1).

A

C

Fia. 1

B

II I

II I

15 Issue 1 August 1994 X300 VSM

Page 459 of 521

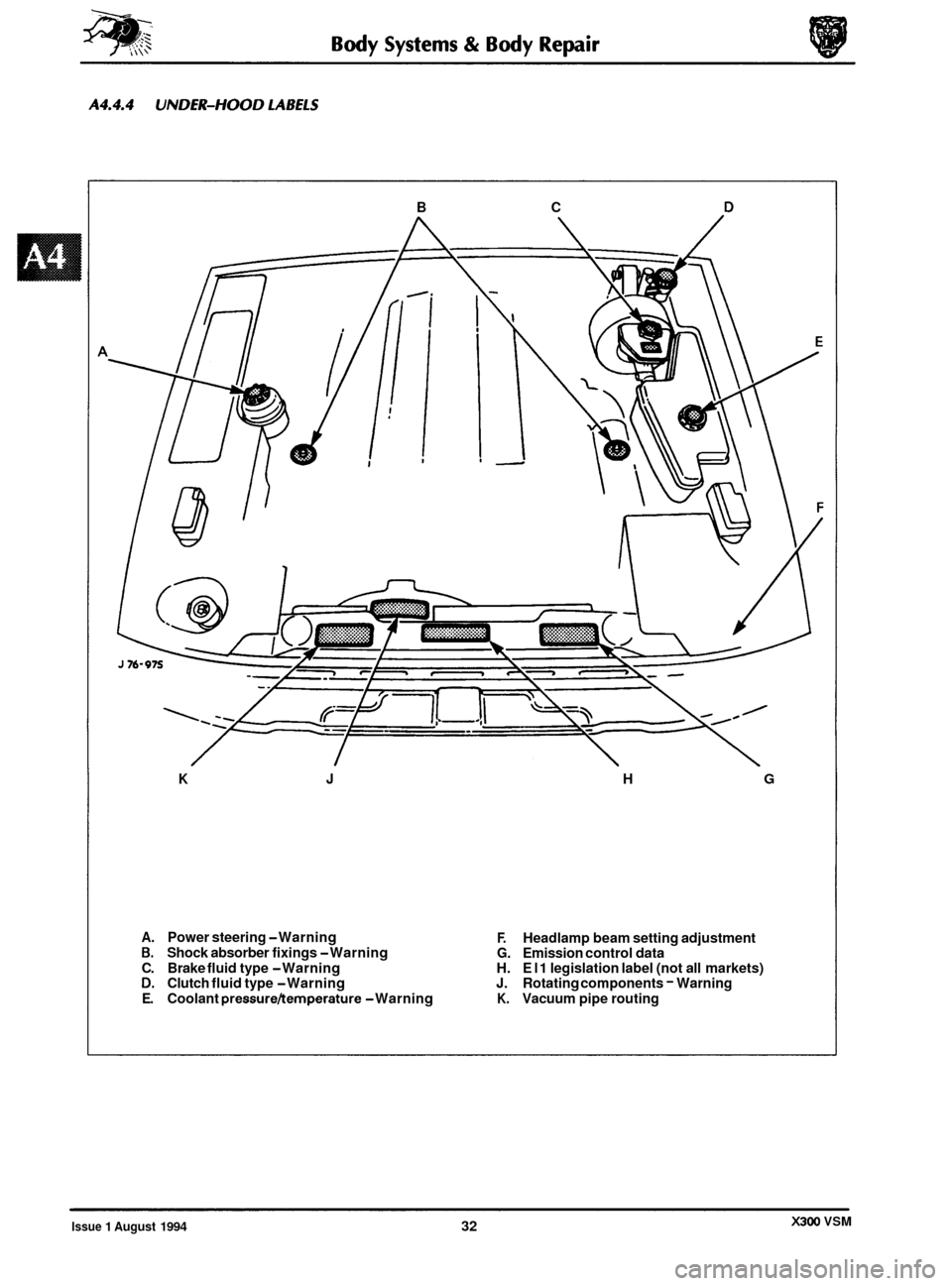

B C D

K J H G

A. Power steering -Warning F. Headlamp beam setting adjustment B. Shock absorber fixings -Warning G. Emission control data

C. Brake fluid type -Warning H. El 1 legislation label (not all markets) D. Clutch fluid type -Warning J. Rotating components - Warning

E. Coolant pressureltemperature -Warning K. Vacuum pipe routing

0

0

X300 VSM Issue 1 August 1994 32

Page 480 of 521

I 03 I Door lock actuators (4 off) 1 part of door assemblv I I

Issue 1 August 1994 X300 VSM 3 I

1 04 I Door lock switches (2 off) I part of door latch assembly I I

1 05 IHoodswitch 1 located above siren I I

1 06 IHorn 1 located on front RH side of en(

1 07 I Inclination sensor I behind luggage compartment LH liner I I

I 08 I Intrusion sensor (LH) I located above LH door behind roof lining I

I 09 I intrusion sensor (RH) 1 located above LH door behind roof lining I

I

1 1 part of door latch assembly I 10 I Key barrel switches (2 off)

1 11 I Key fob transmitter 1 part of key fob I I

I 12 I Key transponder 1 part of key I I

I 13 I Reader exciter coil 1 part of ignition switch I I

I 14 I Reader exciter module 1 part of steering column assembly I I

1 15 I Relays (deadlock) I I I

1 18 I Security active indicator part of central locking switch I I

I 19 I Securitv and lockina control module (SLCM) located in luaaaae compartment behind LH liner I I

1 20 ISounder , located on front RH side of engine bay I I

1 25 IValet switch 1 in centre console compartment I I

A5.2 COMPONENT DESCR/PT/O NS I

stem - RESTRICTED ISSUE

Key to Component Locations

Item No. Description Access details

01 Central locking switch part of clock module

02

1 I

Door ajar switches (4 off)

I I

part of rear screen

I 21 I Trunk release actuator located in trunk latch mechanism

22 I Trunk release relay

23

24 I Trunk lid release switch (external)

I Trunk lid release switch (internal) part of

fascia switchpack ,

A5.2.1 Central locking switch

A5.2.2 Door ajar switches

Located in each front door lock mechanism to indicate door not closed correctly.

-

The central locking switch is located on the driver'sfascia switchpack and allows locking / unlocking and all close from

inside the vehicle when all doors are closed.

A5.2.3

Located within each front door panel assembly to provide automatic lock / unlock operation.

Door lock actuator and switch

A5.2.4 Door lock switch

Located in each front door lock mechanism to indicate door lock/ unlock state.

A5.2.5 Hood switch

Located underhood adjacent to the horn to give indication of hood not closed correctly.

A5.2.6 Horns

Located adjacent to each headlight unit and utilized as part of the full alarm application.

Page 481 of 521

84

- Security System - RESTRICTED /SSU€

A5.2.7 Inclination sensor

Located adjacent to the SLCM underthe luggage compartment LH side linerto give indication of unauthorized jacking / lifting of the vehicle.

A5.2.8 Intrusion sensors

Located above each front door to give indication of unauthorized entry into the vehicle passenger compartment.

A5.2.9 Reader exciter coil

Forms an integral part of the ignition switch to prove correct key insertion by communicating key transponder signal

to control module.

A5.2.10 Reader exciter module

Located on the steering column to receive signals from the reader/ exciter coil and disarm the engine immobilization

system on correct demand.

A5.2.11 Security active indicator

An LED built into the central locking switch to indicate when security system is armed.

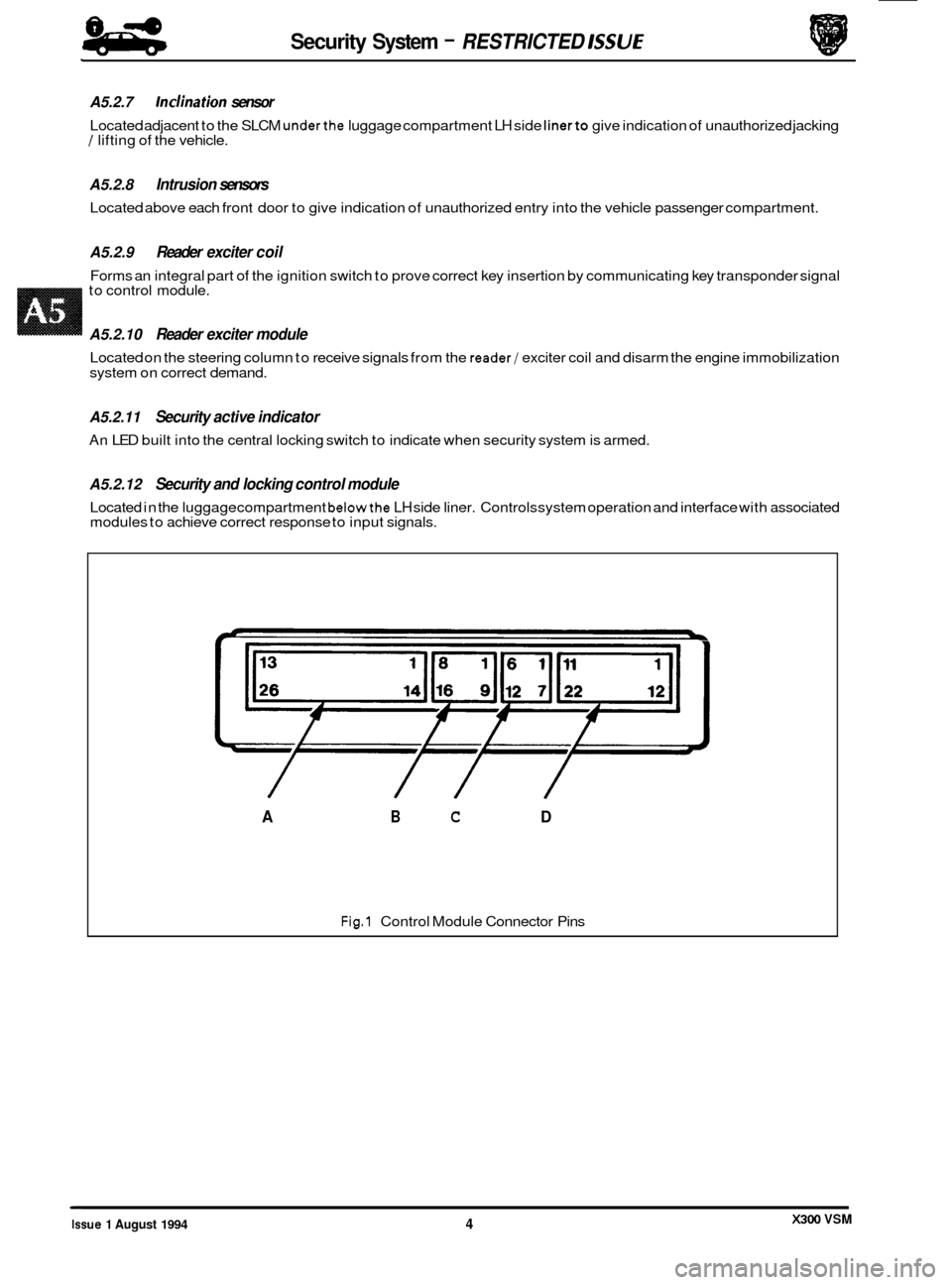

A5.2.12 Security and locking control module

Located in the luggage compartment belowthe LH side liner. Controls system operation and interface with associated

modules to achieve correct response to input signals.

L

Fig.1 Control Module Connector Pins

/ // /

A B C D

X300 VSM Issue 1 August 1994 4