warning JAGUAR XJ6 1994 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 241 of 521

12.3 BRAKE FLUID LEVEL CHECK

WARNING: AVOID SKIN / EYE CONTACT OR INGESTION OF BRAKE FLUID. IF SKIN OR EYES ARE ACCIDENTALLY

SPLASHED WITH BRAKE FLUID, RINSE THE AFFECTED AREA IMMEDIATELY WITH PLENTY OF WATER

AND SEEK MEDICAL AlTENTlON IMMEDIATELY.

Checking the fluid level

CAUTION: Fluid must not be allowed to contact the vehicle paintwork. Remove any spilt fluid from the paintwork

by rinsing away with running water. Methylated spirit (denatured alcohol) must not be used to clean the contaminated area.

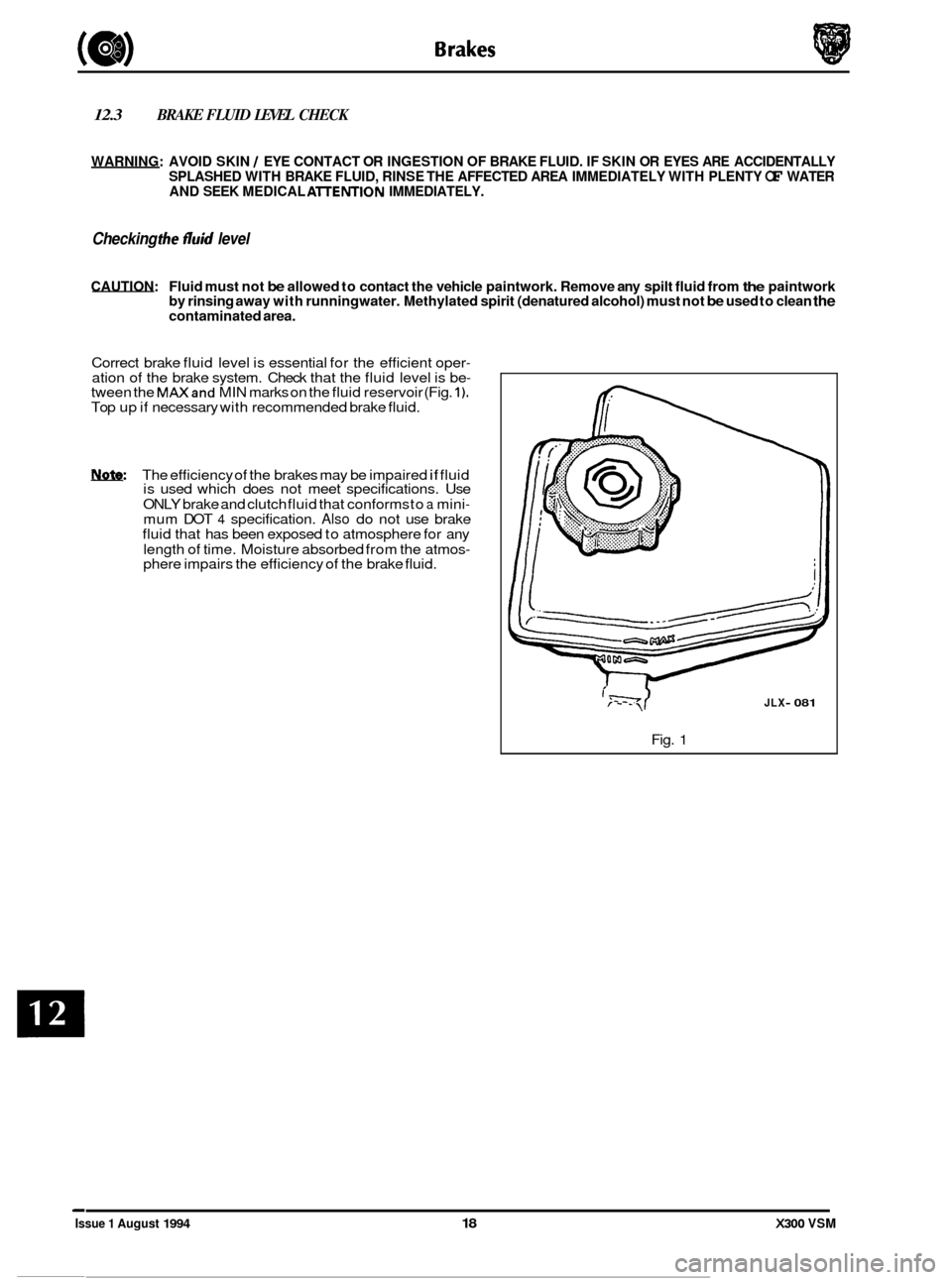

Correct brake fluid level is essential for the efficient oper- ation of the brake system. Check that the fluid level is be- tween the MAXand MIN marks on the fluid reservoir (Fig. 1). Top up if necessary with recommended brake fluid.

BMQ: The efficiency of the brakes may be impaired if fluid

is used which does not meet specifications. Use

ONLY brake and clutch fluid that conforms to

a mini- mum DOT 4 specification. Also do not use brake

fluid that has been exposed to atmosphere for any

length of time. Moisture absorbed from the atmos

- phere impairs the efficiency of the brake fluid.

JLX- 081

Fig. 1

Issue 1 August 1994 18 X300 VSM

Page 242 of 521

Brakes

12.4 BRAKE SYSTEM BLEEDING

WAR-: GREAT CARE MUST BE EXERCISED WHEN SERVICING OR REPAIRING THE SYSTEM. AVOID SKIN/ EYE

CONTACT OR INGESTION OF BRAKE FLUID. IF SKIN OR EYES ARE ACCIDENTALLY SPLASHED WITH

BRAKE FLUID,

RINSETHE AFFECTED AREA IMMEDIATELY WITH PLENTY OF WATER AND SEEK MEDICAL

ATTENTION. IF BRAKE FLUID IS INGESTED, SEEK MEDICAL ATTENTION IMMEDIATELY.

CAUm: Fluid must not be allowed to contact the vehicle paintwork. Remove any spilt fluid from the paintwork

by rinsing away with running water. Methylated spirit (denatured alcohol) must not be used to clean the

contaminated area.

CAUTION: Never use methylated spirit (denatured alcohol) for component cleaning purposes. Use only a proprietary

brake cleaning fluid.

WARNING : THROUGHOUT THE FOLLOWING MAINTENANCE / SERVICE OPERATIONS, ABSOLUTE CLEANLINESS

MUST BE OBSERVED TO PREVENT FOREIGN MATTER CONTAMINATING THE BRAKE SYSTEM.

12.4.1 System Bleeding - General Instructions

Use a brake bleeder bottle with a clear bleeder tube. Also recommended is a filler unit with a fill pressure of 1.0 bar. If a filler unit is not used, ensure that their is sufficient brake fluid in the reservoir throughout the bleeding procedure.

m: Always bleed the caliper furthest away from the actuation unit first. On right hand drive vehicles, bleed in the

following order: front

left (FL),front right (FR), rear left (RL) and rear right (RR). On left hand drive vehicles bleed in the following order: FR, FL, RR and RL.

12.4.2

. Ensure that the vehicle is standing level. Switch the igni-

tion off.

Check that the fluid level in the reservoir is between the min and max marks.

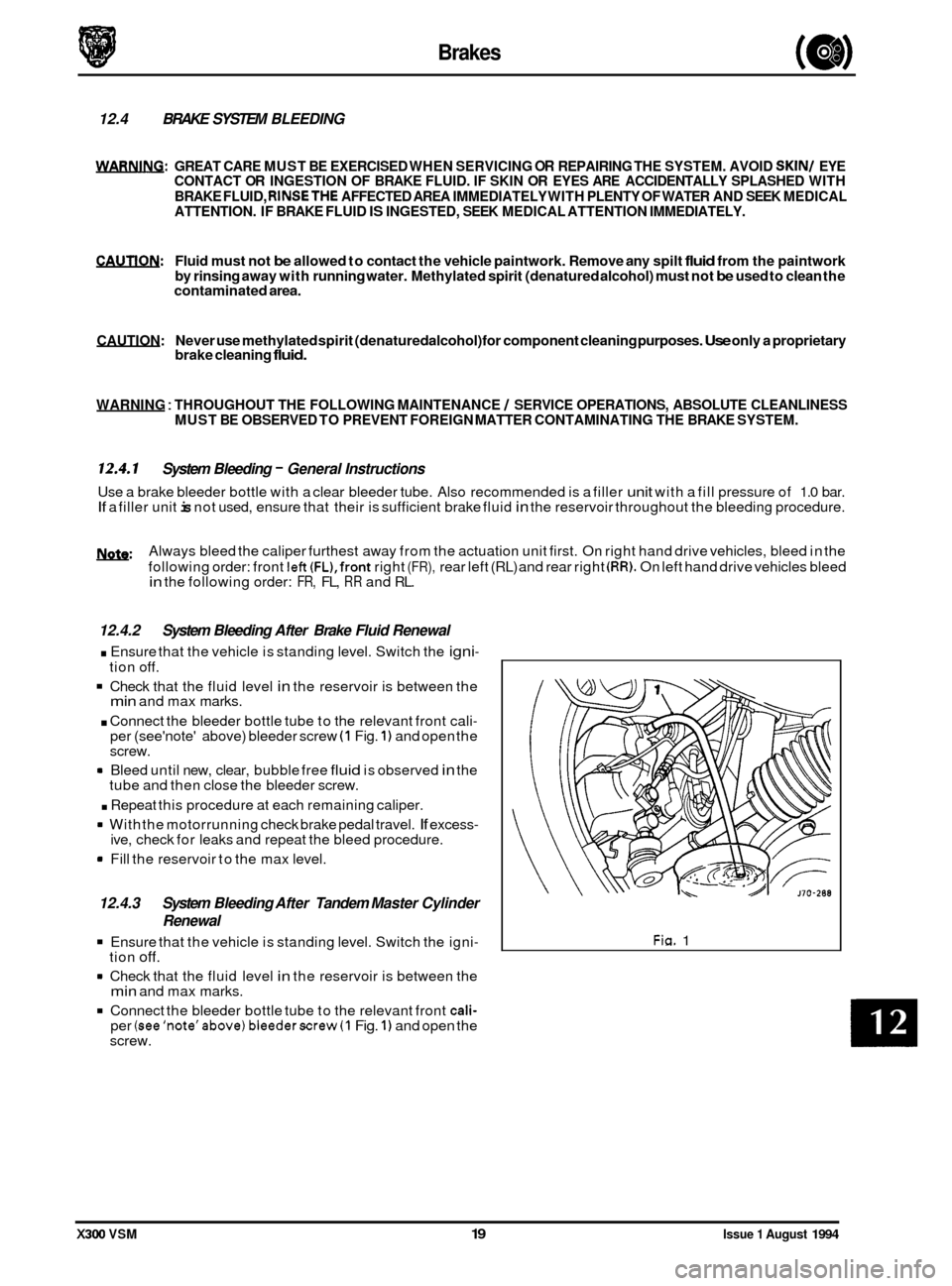

. Connect the bleeder bottle tube to the relevant front cali- per (see'note' above) bleeder screw (1 Fig. 1) and open the

screw.

rn Bleed until new, clear, bubble free fluid is observed in the

tube and then close the bleeder screw.

. Repeat this procedure at each remaining caliper.

With the motorrunning check brake pedal travel.

If excess- ive, check for leaks and repeat the bleed procedure.

Fill the reservoir to the max level.

System Bleeding After Brake Fluid Renewal

12.4.3 System Bleeding After Tandem Master Cylinder

Renewal

Ensure that the vehicle is standing level. Switch the igni- tion off.

rn Check that the fluid level in the reservoir is between the min and max marks.

Connect the bleeder bottle tube to the relevant front cali- per (see'note'above) bleederscrew(1 Fig. 1) and open the

screw.

Ficr. 1

X300 VSM 19 Issue 1 August 1994

Page 244 of 521

Brakes

a 12.5 GENERAL FI77lNG lNSTRUCTlONS

12.5.1 Brake Fluid

WARNING: BRAKE FLUID IS CORROSIVE. EXTREME CARE MUST BE TAKEN WHEN HANDLING. AVOID SKIN OR EYE

CONTACT. AVOID INGESTION. IF SKIN OR EYES ARE ACCIDENTALLY SPLASHED WITH BRAKE FLUID,

RINSE THE AFFECTED AREA IMMEDIATELY WITH PLENTY OF WATER AND SEEK MEDICAL ATTENTION.

IF BRAKE FLUID

IS INGESTED, SEEK MEDICAL ATTENTION IMMEDIATELY.

CAUTION:

Fluid must not be allowed to contact the vehicle paintwork. Remove any spilt fluid from the paintwork

by rinsing away with running water. Methylated spirit (denatured alcohol) must not be used to clean the

contaminated area.

Cleaning Solvents

CAUTION: Never use methylated spirit (denatured alcohol) for cleaning purposes. Use only a proprietary brake

cleaning fluid.

m: THROUGHOUT THE FOLLOWING MAINTENANCE / SERVICE OPERATIONS, ABSOLUTE CLEANLINESS

MUST BE OBSERVED TO PREVENT GRIT OR OTHER FOREIGN MATTER CONTAMINATING THE BRAKE

TION. TO CLEAN BRAKE SYSTEM COMPONENTS, WASH

IN A PROPRIETARY BRAKE CLEANING FLUID.

REMOVE ALL TRACES OF CLEANING FLUID BEFORE REASSEMBLY. ALL BRAKE SYSTEM RUBBER COh PONENTS MUST BE DIPPED IN CLEAN BRAKE FLUID AND ASSEMBLED USING THE FINGERS ONLY.

SYSTEM.

IFTHE SYSTEM IS TO

BE FLUSHED, USE CLEAN BRAKE FLUID TO MINIMUM DOT 4 SPECIFICA-

12.5.2 Hoses

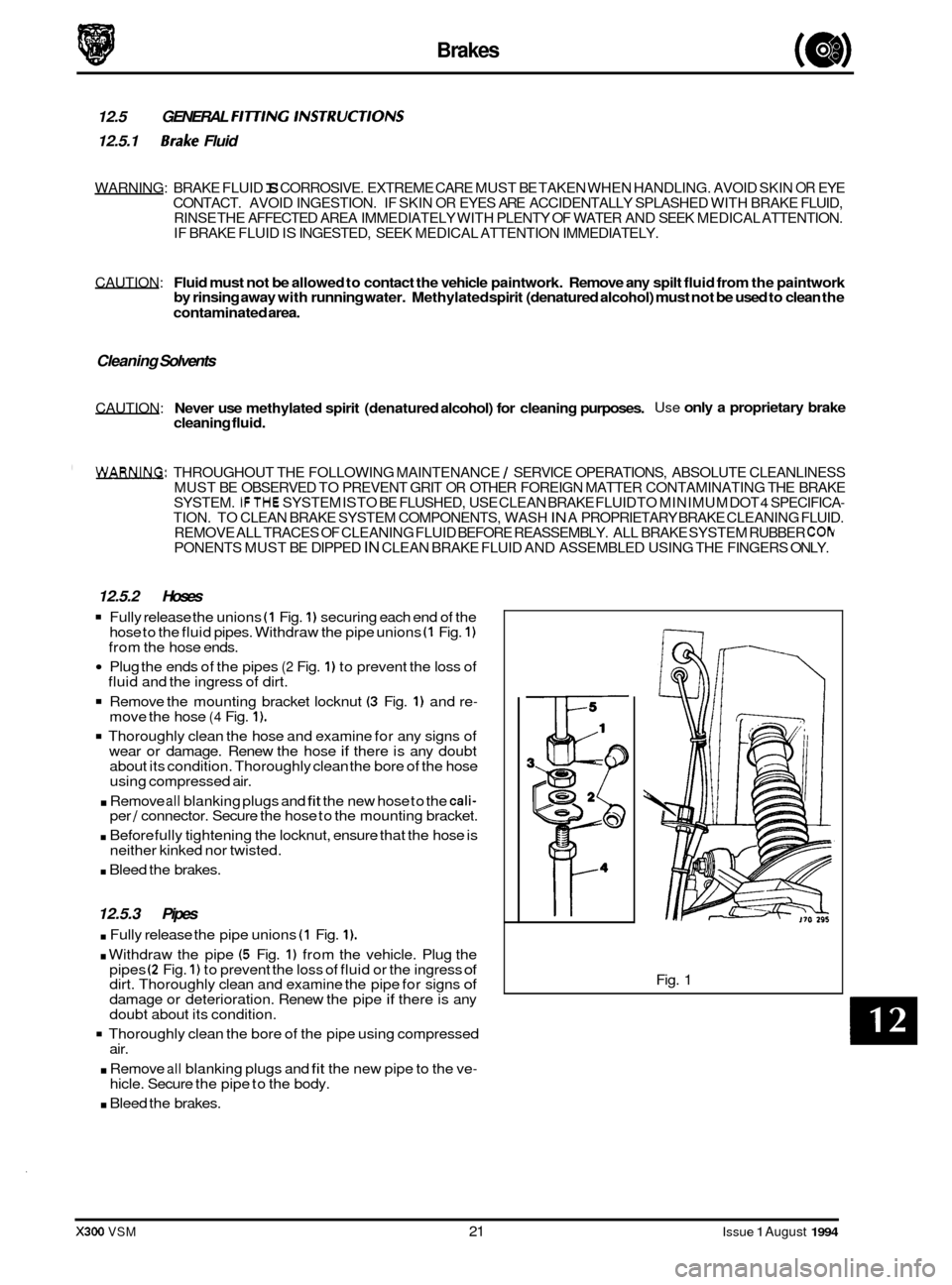

Fully release the unions (1 Fig. 1) securing each end of the

hose to the fluid pipes. Withdraw the pipe unions (1 Fig. 1) from the hose ends.

Plug the ends of the pipes (2 Fig. 1) to prevent the loss of

fluid and the ingress of dirt.

Remove the mounting bracket locknut (3 Fig. 1) and re- move the hose (4 Fig. 1).

Thoroughly clean the hose and examine for any signs of

wear or damage. Renew the hose if there is any doubt

about its condition. Thoroughly clean the bore of the hose

using compressed air.

. Remove all blanking plugs and fit the new hose to the cali- per / connector. Secure the hose to the mounting bracket.

. Before fully tightening the locknut, ensure that the hose is

neither kinked nor twisted.

. Bleed the brakes.

12.5.3 Pipes

. Fully release the pipe unions (1 Fig. 1).

. Withdraw the pipe (5 Fig. 1) from the vehicle. Plug the

pipes (2 Fig. 1) to prevent the loss of fluid or the ingress of dirt. Thoroughly clean and examine the pipe for signs of damage or deterioration. Renew the pipe if there is any

doubt about its condition.

Thoroughly clean the bore of the pipe using compressed

air.

. Remove all blanking plugs and fit the new pipe to the ve- hicle. Secure the pipe to the body.

. Bleed the brakes.

17

Fig. 1

X300 VSM 21 Issue 1 August 1994

Page 254 of 521

Body Components & Trim -

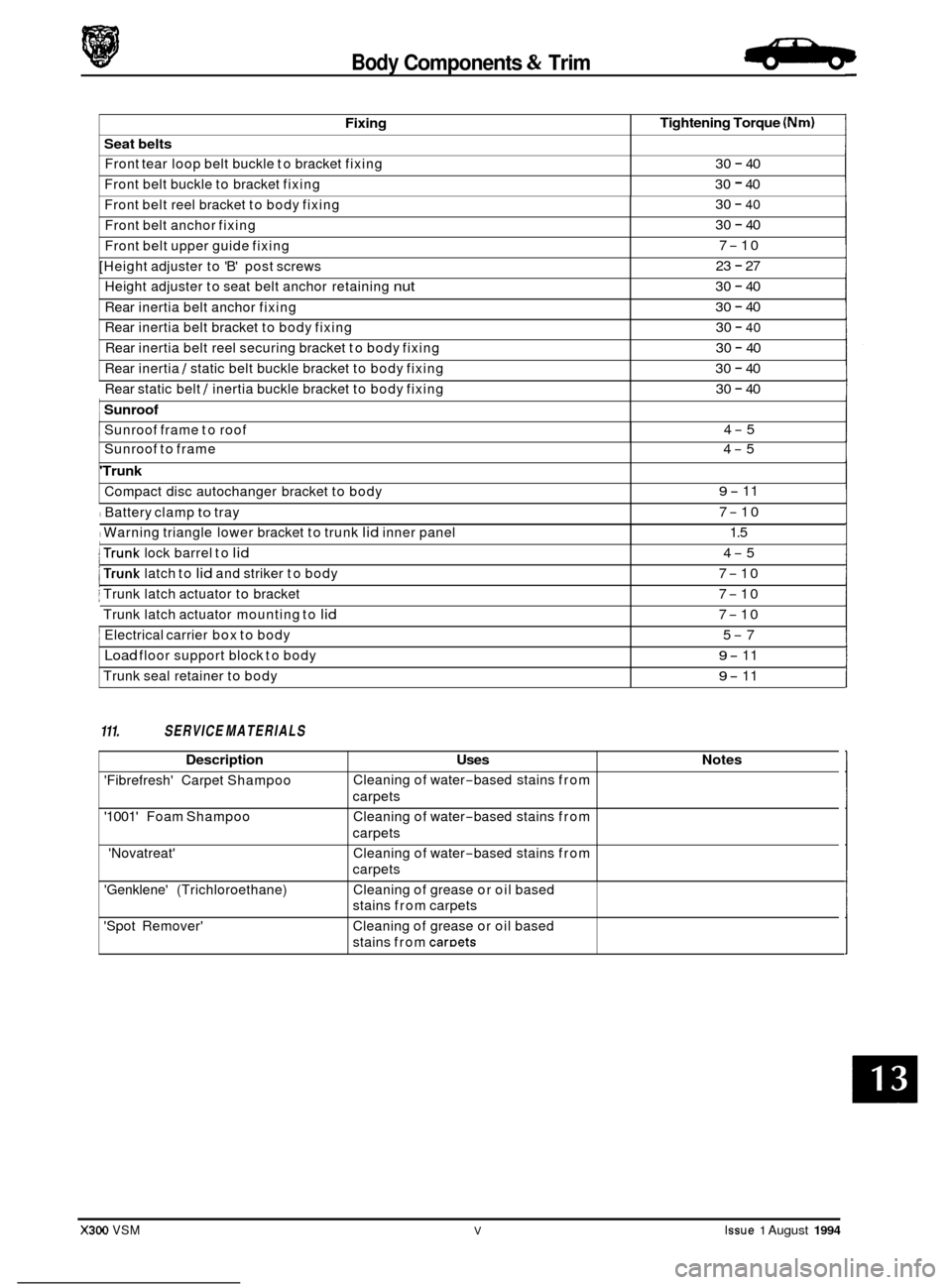

Fixing

Seat belts

Front tear loop belt buckle to bracket fixing

Front belt buckle to bracket fixing

Tightening Torque (Nm)

30 - 40

30

- 40

Front belt reel bracket to body fixing

Front belt anchor fixing 30 - 40

30 - 40

7

-10

23

- 27

30

- 40

30 - 40

30

- 40

30 - 40

30

- 40

Front belt upper guide fixing

[Height adjuster to 'B' post screws

Height adjuster to seat belt anchor retaining

nut

Rear inertia belt anchor fixing

Rear inertia belt bracket to body fixing

Rear inertia belt reel securing bracket to body fixing

Rear inertia

/ static belt buckle bracket to body fixing ~

Rear

static belt / inertia buckle bracket to body fixing

: Sunroof ~

Sunroof frame

to roof

30 - 40

4

-5

111. SERVICE MATERIALS

Sunroof to frame 4-5

'Trunk

Compact disc autochanger bracket to body

I Battery clamp to tray

I Warning triangle lower bracket to trunk lid inner panel

9- 11

7

-10

1.5

X300 VSM V Issue 1 August 1994

I trunk lock barrel to lid

j Trunk latch actuator to bracket

Trunk latch actuator mounting to

lid

j Electrical carrier box to body

Load floor support block to body

Trunk seal retainer to body

trunk latch to lid and striker to body

4-5

7

-10

7

-10

7

-10

5

-7

9- 11

9- 11

Description Uses

'Fibrefresh' Carpet Shampoo

'1001' Foam Shampoo

'Novatreat' Cleaning

of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Notes

'Genklene' (Trichloroethane)

'Spot Remover' Cleaning

of grease or oil based

stains from carpets

Cleaning of grease or oil based

stains from

caroets

Page 288 of 521

Body Components & Trim -

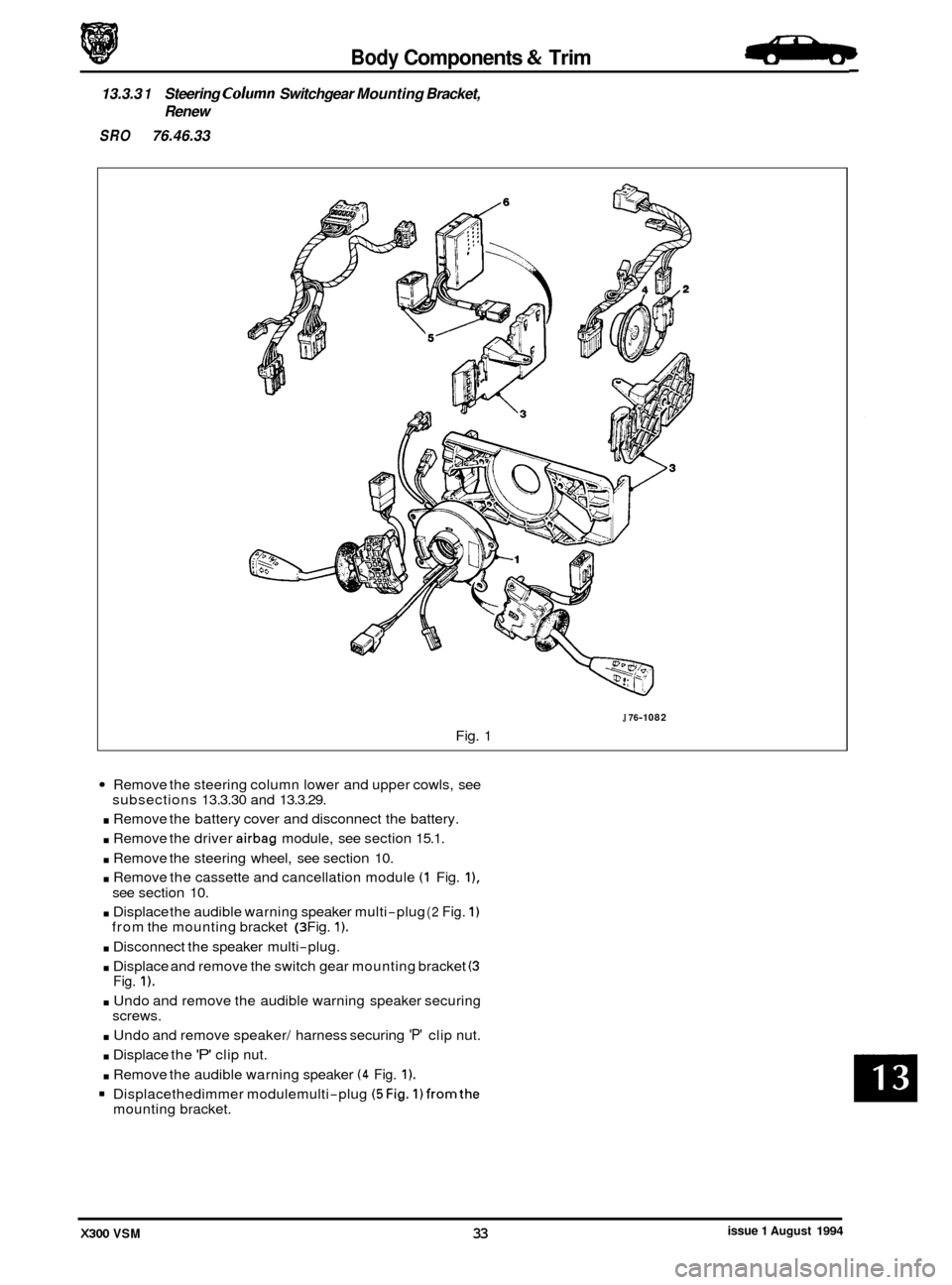

13.3.3 1 Steering Column Switchgear Mounting Bracket,

Renew

SRO 76.46.33

J 76-1 082

Fig. 1

Remove the steering column lower and upper cowls, see

. Remove the battery cover and disconnect the battery.

. Remove the driver airbag module, see section 15.1.

. Remove the steering wheel, see section 10.

. Remove the cassette and cancellation module (1 Fig. I),

. Displace the audible warning speaker multi-plug (2 Fig. 1)

. Disconnect the speaker multi-plug.

. Displace and remove the switch gear mounting bracket (3

. Undo and remove the audible warning speaker securing

. Undo and remove speaker/ harness securing 'P' clip nut.

. Displace the 'P' clip nut.

. Remove the audible warning speaker (4 Fig. 1).

Displacethedimmer modulemulti-plug (5Fig. 1)fromthe

subsections 13.3.30 and 13.3.29.

see section 10.

from the mounting bracket

(3 Fig. 1).

Fig. 1).

screws.

mounting bracket.

issue 1 August 1994 X300 VSM 33

Page 289 of 521

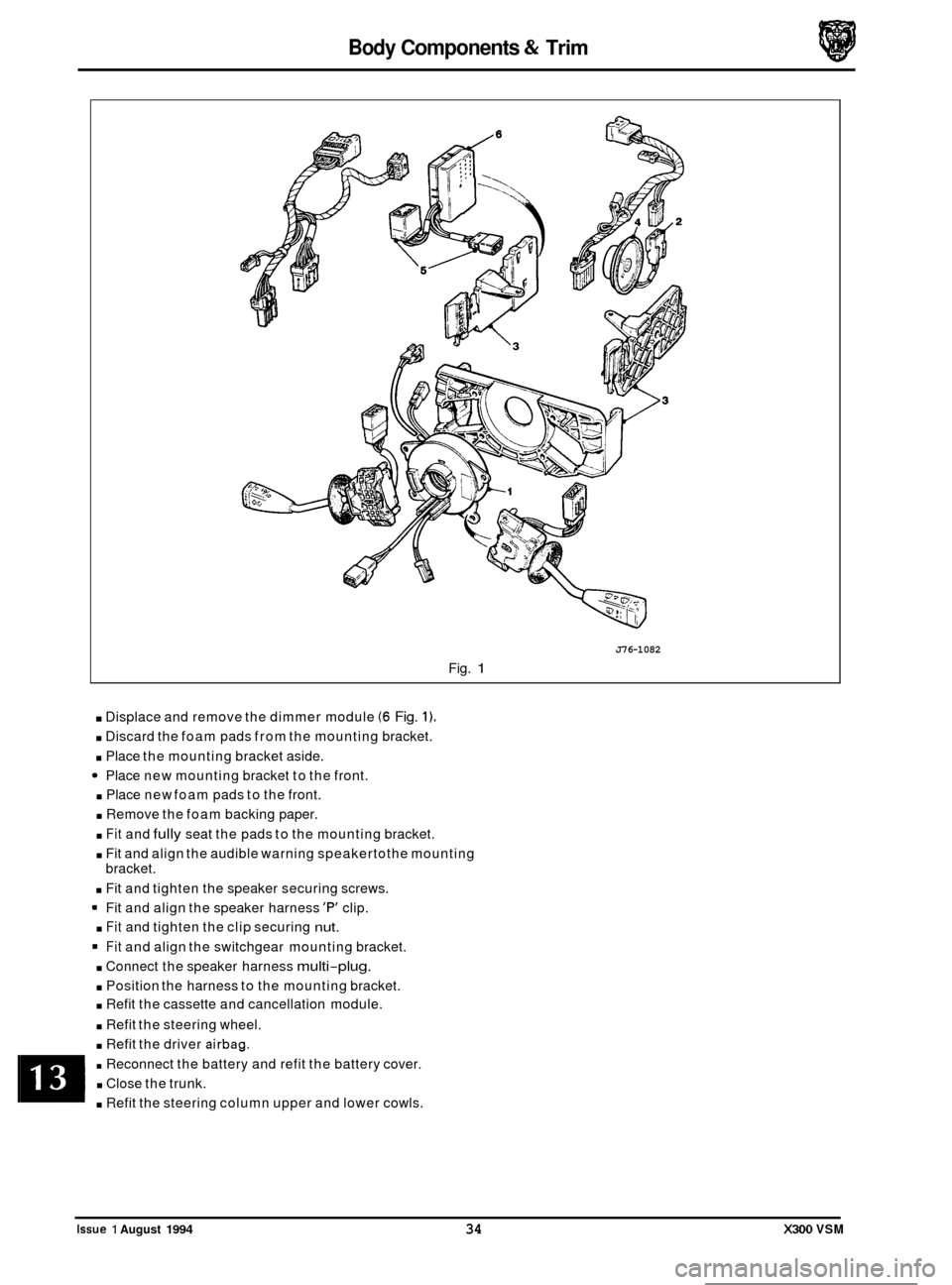

Body Components & Trim

J76-1082

Fig. 1

. Displace and remove the dimmer module (6 Fig. 1).

. Discard the foam pads from the mounting bracket.

. Place the mounting bracket aside.

Place new mounting bracket to the front.

. Place new foam pads to the front.

. Remove the foam backing paper.

. Fit and fully seat the pads to the mounting bracket.

. Fit and align the audible warning speakertothe mounting

bracket.

. Fit and tighten the speaker securing screws.

Fit and align the speaker harness

'F" clip.

. Fit and tighten the clip securing nut.

Fit and align the switchgear mounting bracket.

. Connect the speaker harness multi-plug.

. Position the harness to the mounting bracket.

. Refit the cassette and cancellation module.

. Refit the steering wheel.

. Refit the driver airbag.

. Reconnect the battery and refit the battery cover.

. Close the trunk.

. Refit the steering column upper and lower cowls.

0

0

0

0

Issue 1 August 1994 34 X300 VSM

Page 290 of 521

Body Components & Trim -

13.3.32 'A' Post lower Trim Pad, Renew

SRO 76.13.30

. Locally displace the draught welting from the front door

= Undo and remove the 'A' post lower trim pad quarter turn

. Displace and remove the 'A' post lower trim pad by pulling

. Fit and seat the new 'A' post lower trim pad, engaging the

. Fit and secure the 'A' post lower trim pad quarter turn fas-

Reposition and fully seat the draught welting to the front

aperture

flange.

fastener. rearwards to disengage clips and place aside.

clips on the front door flange.

tener. door aperture flange.

13.3.33 Rear Quarter Upper Trim Pad, Renew

. Remove the rear seat belt upper anchorage RH or LH.

. Remove the trim pad securing screw.

. Slacken but do not remove thecombined grab handle and

. Unclip the rear quarter trim pad and remove.

. To refit, carry out reversal of the above procedure, noting

that seat belt fixings must be tightened to the specified

torque.

coat hook securing screws.

13.3.34 'B' Post Upper Trim Pad, Renew

. Position front seat and squab fully forward.

. Remove seat belt lower anchorage and feed the belt

through the lower trim aperture.

. Remove seat belt upper anchorage.

. Remove trim finisher upper seat belt aperture and door

. Release upper trim pad from its fixings by exerting down-

. To refit, carry out reversal of the above procedure.

aperture edge

trim.

ward pressure.

WARNING: ENSURE THAT THE SEAT BELT IS CORRECTLY

ASSEMBLED AND FlXlNGS TORQUE TIGH-

0 TENED.

13.3.35 'B' Post lower Trim Pad, Renew

. Position front seat and squab fully forward.

Remove seat belt lower anchorage and feed the belt

. Release trim pad quarter turn fasteners and remove trim

Remove fasteners from trim pad as required.

= To refit, carry out reversal of the above procedure.

through the lower

trim aperture.

pad.

WARNING: ENSURE THAT THE SEAT BELT IS CORRECTLY

ASSEMBLED AND FlXlNGS TORQUE TIGH- TENED.

X300 VSM 35 Issue 1 August 1994

Page 293 of 521

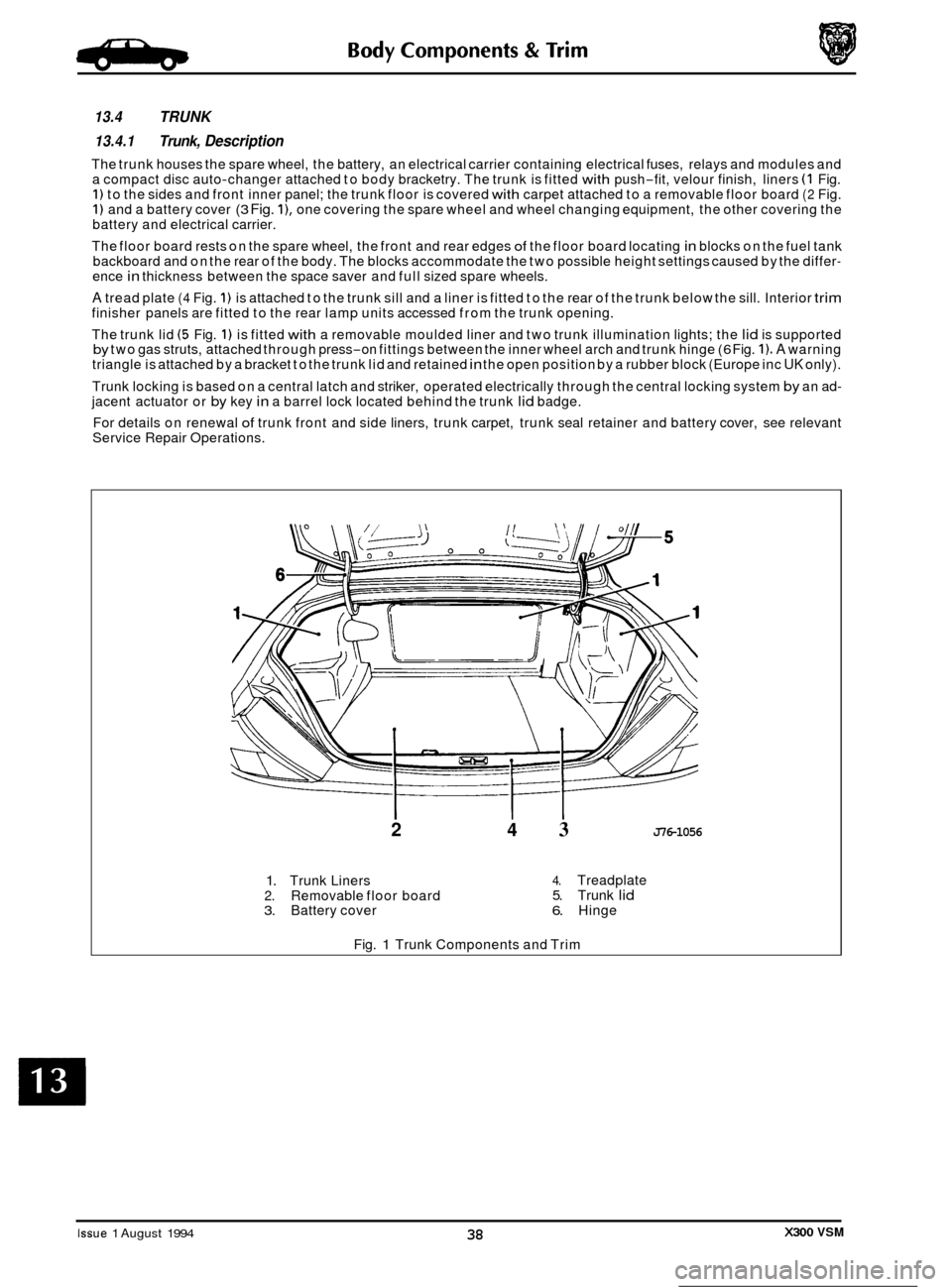

13.4 TRUNK

13.4.1 Trunk, Description

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and

a compact disc auto-changer attached to body bracketry. The trunk is fitted with push-fit, velour finish, liners (1 Fig. 1) to the sides and front inner panel; the trunk floor is covered with carpet attached to a removable floor board (2 Fig. 1) and a battery cover (3 Fig. I), one covering the spare wheel and wheel changing equipment, the other covering the

battery and electrical carrier.

The floor board rests on the spare wheel, the front and rear edges

of the floor board locating in blocks on the fuel tank

backboard and on the rear of the body. The blocks accommodate the two possible height settings caused by the differ- ence in thickness between the space saver and full sized spare wheels.

A tread plate (4 Fig. 1) is attached to the trunk sill and a liner is fitted to the rear of the trunk below the sill. Interior trim finisher panels are fitted to the rear lamp units accessed from the trunk opening.

The trunk lid

(5 Fig. 1) is fitted with a removable moulded liner and two trunk illumination lights; the lid is supported by two gas struts, attached through press-on fittings between the inner wheel arch and trunk hinge (6 Fig. 1). A warning

triangle is attached by a bracket to the trunk lid and retained in the open position by a rubber block (Europe inc UK only).

Trunk locking is based on a central latch and striker, operated electrically through the central locking system

by an ad- jacent actuator or by key in a barrel lock located behind the trunk lid badge.

For details on renewal

of trunk front and side liners, trunk carpet, trunk seal retainer and battery cover, see relevant

Service Repair Operations.

2 4 3 J76-1056

1. Trunk Liners 2. Removable floor board 3. Battery cover

4. Treadplate 5. Trunk lid 6. Hinge

Fig.

1 Trunk Components and Trim

Issue 1 August 1994 X300 VSM 38

Page 306 of 521

Body Components & Trim

13.8.10 Tear loop Seat Belts, Description

The tear loop seat belt (Fig.1) is used to control the rate of forward travel of the occupant towards the deployed airbag

(the airbag is covered in Section 15, Electrical). The tear loop assembly is designed to release additional webbing when

the stitching, which retains the webbing loops, breaks under

a predetermined load. The wires (1 Fig. 1) within the as- sembly have the following functions:

0 To protect the stitching from 'normal' loads such as heavy braking or cornering.

o To control the rate of deployment.

0 To support the extended head following deployment.

When the passenger unit has been activated, the buckle will extend from the shroud and reveal

a warning label (2 Fig. 1); the extent of deployment will depend upon the severity of the load.

-: IF THE LABEL IS VISIBLE AT ALL (3 FIG. 3). THE COMPLETE ASSEMBLY MUST BE RENEWED, AS MUST

ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT.

2

Fia. 1 Tear LOOO Seat Belt

X300 VSM 51 Issue 1 August 1994 ~~

Page 333 of 521

Climate Control Systems

14.13 SYSTEM CHECKING WITH MANIFOLD GAUGE Sm

14.13.1 Evacuating the Manifold Gauge Set

Attach the centre (service) hose to a vacuum pump and start the pump. Open fully both high anddow valves and allow

the vacuum to remove air and moisture from the manifold set for at least five minutes.

Turn the vacuum pump off and isolate it from the centre service hose but do not open the hose to atmosphere.

CAUTION: It is imperative that the vacuum pump is not subjected to a positive pressure of any degree. Therefore

the pump must be frtted with an isolation valve at the centre (service hose) connection and this valve

must be closed before the pump is switched off. This operation replaces the 'purge' procedure used on

previous systems. Observe the manufacturefs recommendation with regard to vacuum pump oil

changes.

14.13.2 Connecting the Manifold Gauge Set

CAUTION: Only use hoses with connectors which are dedicated to HFC 134A charge ports.

Attachment of the hose quick release connectors to the high and low side system ports is straightfotward, provided

that the high and low valves are closed and the system is NOT operational.

Assessment of system operating efficiency and fault classification may be achieved by using the facilities on your

Re- covery / Recharging / Recycling station, follow the manufacturers instructions implicitly and observe all safety con- siderations.

WARNING: UNDER NO CIRCUMSTANCES SHOULD THE CONNECTIONS BE MADE WITH THE SYSTEM IN

OPERATION OR THE VALVES OPEN. SHOULD THE VALVES BE OPEN AND A VACUUM PUMP OR

REFRIGERANT CONTAINER ATTACHED, AN EXPLOSION COULD OCCUR AS A RESULT OF HIGH

PRESSURE REFRIGERANT BEING FORCED BACK INTO THE VACUUM PUMP

OR CONTAINER.

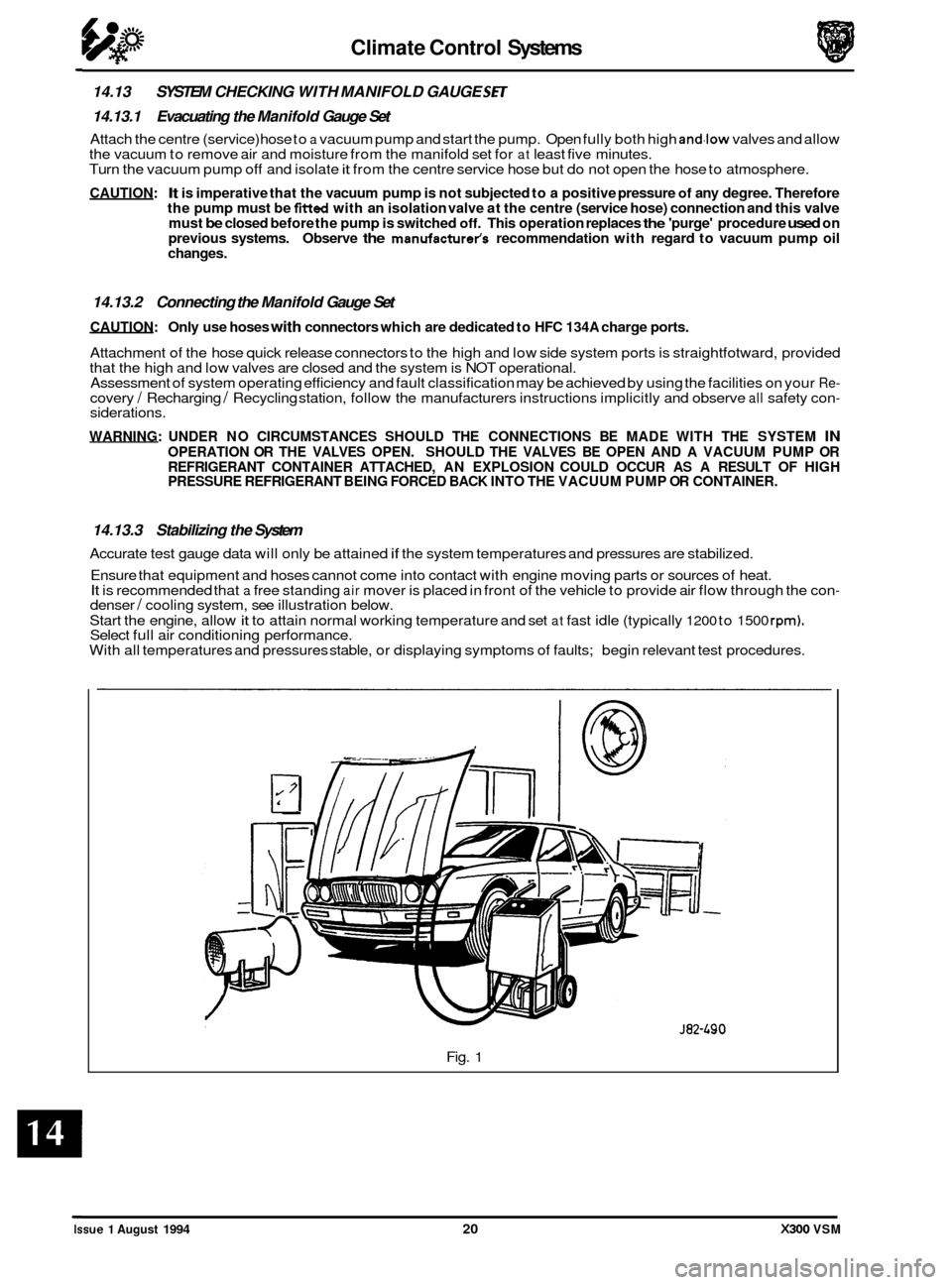

14.13.3 Stabilizing the System

Accurate test gauge data will only be attained if the system temperatures and pressures are stabilized.

Ensure that equipment and hoses cannot come into contact with engine moving parts or sources of heat.

It is recommended that a free standing air mover is placed in front of the vehicle to provide air flow through the con- denser / cooling system, see illustration below.

Start the engine, allow

it to attain normal working temperature and set at fast idle (typically 1200 to 1500 rpm). Select full air conditioning performance.

With all temperatures and pressures stable, or displaying symptoms of faults; begin relevant test procedures.

Fig.

1

Issue 1 August 1994 20 X300 VSM