wheel JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 227 of 521

Pressure conscious reduction valves (PCRVs) are fitted between the outlet of the valve block and the rear brake circuit

to optimize. The valves are fitted to prevent over braking due to the increased size of the rear brake calipers which are

required for traction control. Up to a threshold of 15 bar, brake pressure to the front and rear brakes is equal. Above

15 bar the PCRVs reduce pressure to the rear brakes to provide a closer balance between front and rear brakes and

optimize road adhesion.

Wheel speed sensors are fitted to all wheels to transmit wheel speed information to the control module. The module

uses this information to modulate brake pressure during anti

-lock braking or traction control.

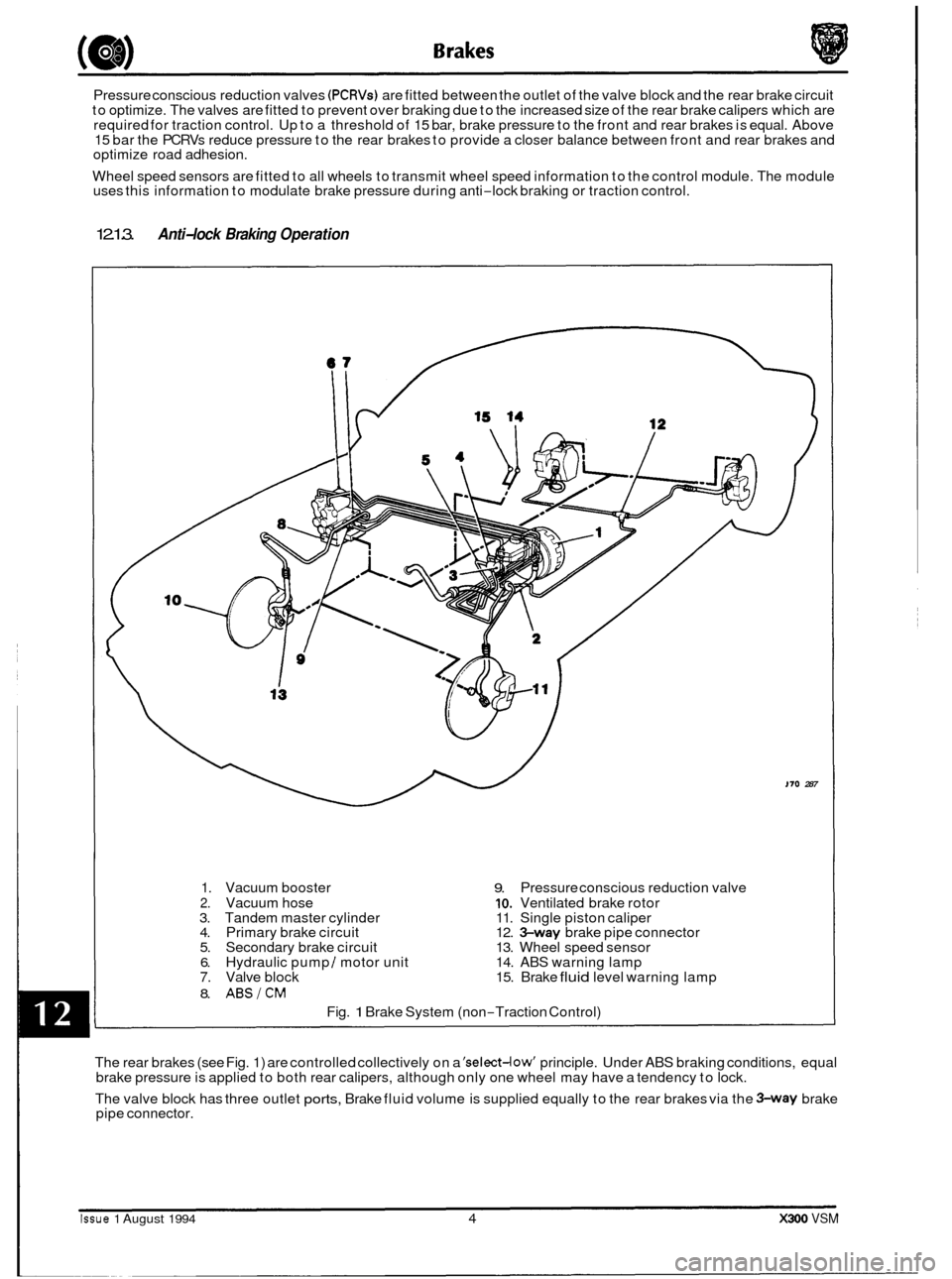

12.1.3. Anti-lock Braking Operation

170 287

1. Vacuum booster 9. Pressure conscious reduction valve

2. Vacuum hose 10. Ventilated brake rotor

3. Tandem master cylinder 11. Single piston caliper

4. Primary brake circuit 12.

%way brake pipe connector

5. Secondary brake circuit 13. Wheel speed sensor

6. Hydraulic pump I motor unit 14. ABS warning lamp 7. Valve block 15. Brake fluid level warning lamp

8. ABSICM

Fig. 1 Brake System (non-Traction Control)

The rear brakes (see Fig. 1) are controlled collectively on a

'select-low' principle. Under ABS braking conditions, equal

brake pressure is applied to both rear calipers, although only one wheel may have a tendency to lock.

The valve block has three outlet

ports, Brake fluid volume is supplied equally to the rear brakes via the %way brake

pipe connector.

Issue 1 August 1994 4 X300 VSM

Page 229 of 521

12.1.5. ABS Components

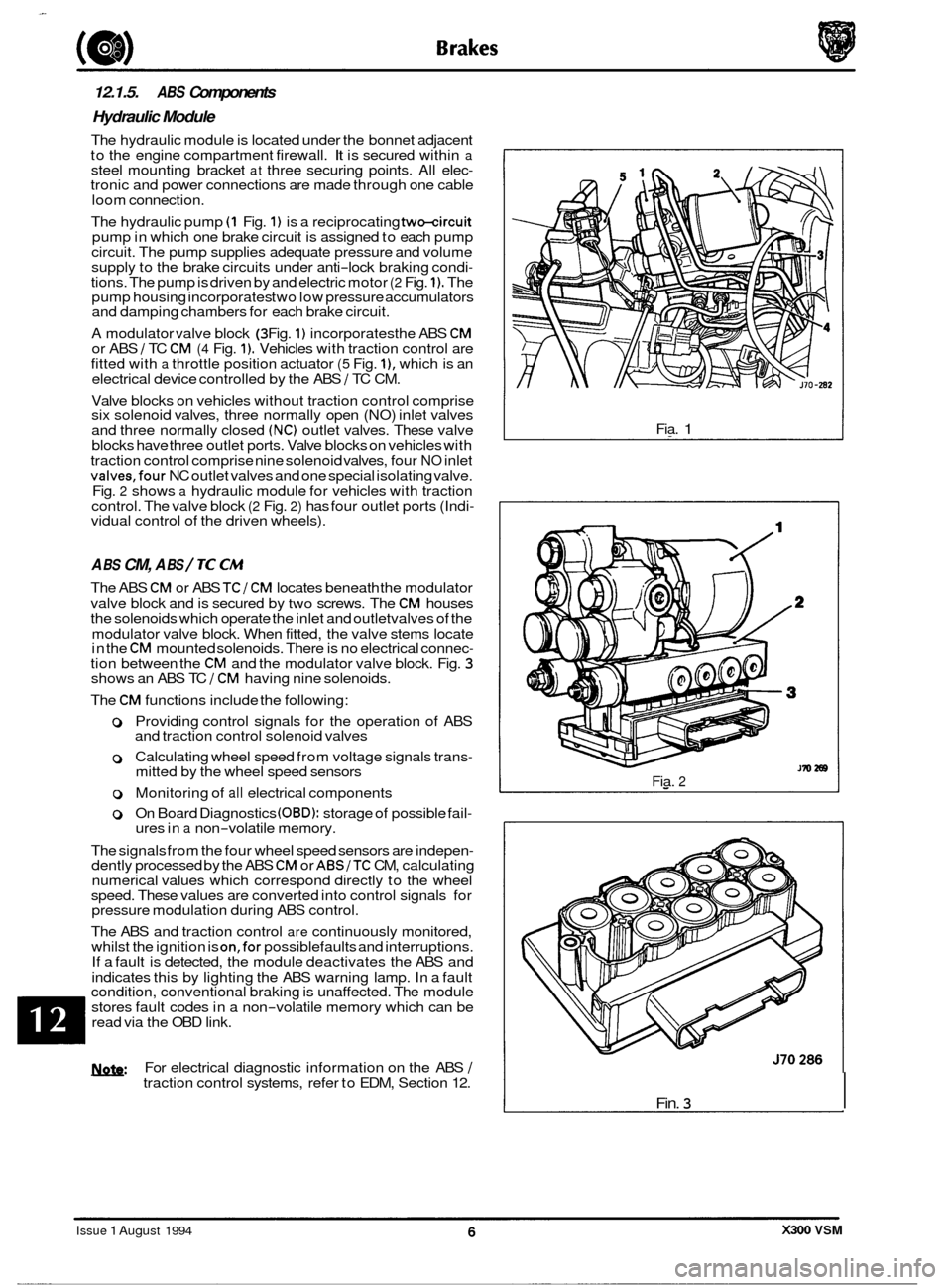

Hydraulic Module

The hydraulic module is located under the bonnet adjacent

to the engine compartment firewall. It is secured within a steel mounting bracket at three securing points. All elec- tronic and power connections are made through one cable

loom connect ion.

The hydraulic pump

(1 Fig. 1) is a reciprocating two-circuit pump in which one brake circuit is assigned to each pump

circuit. The pump supplies adequate pressure and volume

supply to the brake circuits under anti

-lock braking condi- tions. The pump is driven by and electric motor (2 Fig. 1). The

pump housing incorporates two low pressure accumulators

and damping chambers for each brake circuit.

A modulator valve block

(3 Fig. 1) incorporates the ABS CM or ABS / TC CM (4 Fig. 1). Vehicles with traction control are

fitted with a throttle position actuator (5 Fig. I), which is an

electrical device controlled by the ABS 1 TC CM.

Valve blocks on vehicles without traction control comprise

six solenoid valves, three normally open (NO) inlet valves

and three normally closed

(NC) outlet valves. These valve

blocks have three outlet ports. Valve blocks on vehicles with

traction control comprise nine solenoid valves, four

NO inlet valves,four NC outlet valves and one special isolating valve.

Fig. 2 shows a hydraulic module for vehicles with traction

control. The valve block (2 Fig. 2) has four outlet ports (Indi- vidual control of the driven wheels).

A BS CM, A BS / TC CM

The ABS CM or ABS TCI CM locates beneath the modulator

valve block and is secured by

two screws. The CM houses

the solenoids which operate the inlet and outletvalves of the

modulator valve block. When fitted, the valve stems locate

in the

CM mounted solenoids. There is no electrical connec- tion between the CM and the modulator valve block. Fig. 3 shows an ABS TC 1 CM having nine solenoids.

The

CM functions include the following:

0 Providing control signals for the operation of ABS

and traction control solenoid valves

0 Calculating wheel speed from voltage signals trans- mitted by the wheel speed sensors

0 Monitoring of all electrical components

0 On Board Diagnostics (OBD): storage of possible fail- ures in a non-volatile memory.

The signals from the four wheel speed sensors are indepen

- dently processed by the ABS CM or ABSITC CM, calculating

numerical values which correspond directly to the wheel

speed. These values are converted into control signals for

pressure modulation during ABS control.

The ABS and traction control

are continuously monitored,

whilst the ignition is on,for possiblefaults and interruptions.

If a fault is detected, the module deactivates the ABS and

indicates this by lighting the ABS warning lamp. In a fault

condition, conventional braking is unaffected. The module

stores fault codes in a non

-volatile memory which can be

read via the OBD link.

U: For electrical diagnostic information on the ABS I traction control systems, refer to EDM, Section 12. Fia.

1

Fia. 2

Fin. 3 I

J70286

Issue 1 August 1994 X300 VSM

Page 232 of 521

Brakes (e#

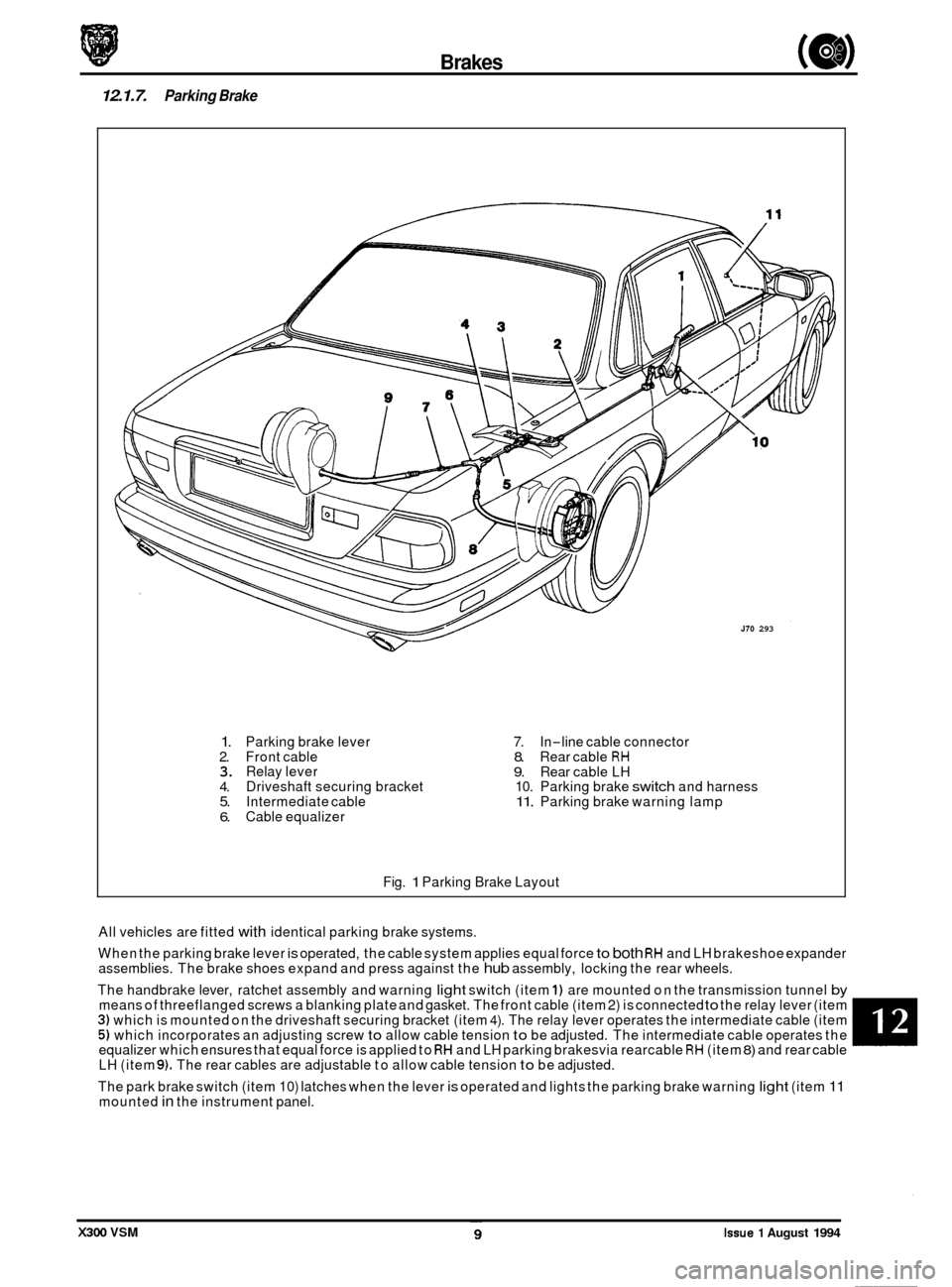

12.1.7. Parking Brake

J70 293

W

1. Parking brake lever 2. Front cable 3. Relay lever 4. Driveshaft securing bracket 5. Intermediate cable 6. Cable equalizer

7. In-line cable connector 8. Rear cable RH 9. Rear cable LH

10. Parking brake switch and harness 11. Parking brake warning lamp

Fig.

1 Parking Brake Layout

All vehicles are fitted with identical parking brake systems.

When the parking brake lever

is operated, the cable system applies equal force to both RH and LH brakeshoe expander

assemblies. The brake shoes expand and press against the hub assembly, locking the rear wheels.

The handbrake lever, ratchet assembly and warning

light switch (item 1) are mounted on the transmission tunnel by means of threeflanged screws a blanking plate and gasket. The front cable (item 2) is connected to the relay lever (item 3) which is mounted on the driveshaft securing bracket (item 4). The relay lever operates the intermediate cable (item 5) which incorporates an adjusting screw to allow cable tension to be adjusted. The intermediate cable operates the

equalizer which ensures that equal force is applied to RH and LH parking brakesvia rearcable RH (item 8) and rear cable

LH (item 9). The rear cables are adjustable to allow cable tension to be adjusted.

The park brake switch (item 10) latches when the lever

is operated and lights the parking brake warning light (item 11 mounted in the instrument panel.

X300 VSM Issue 1 August 1994

Page 234 of 521

Brakes

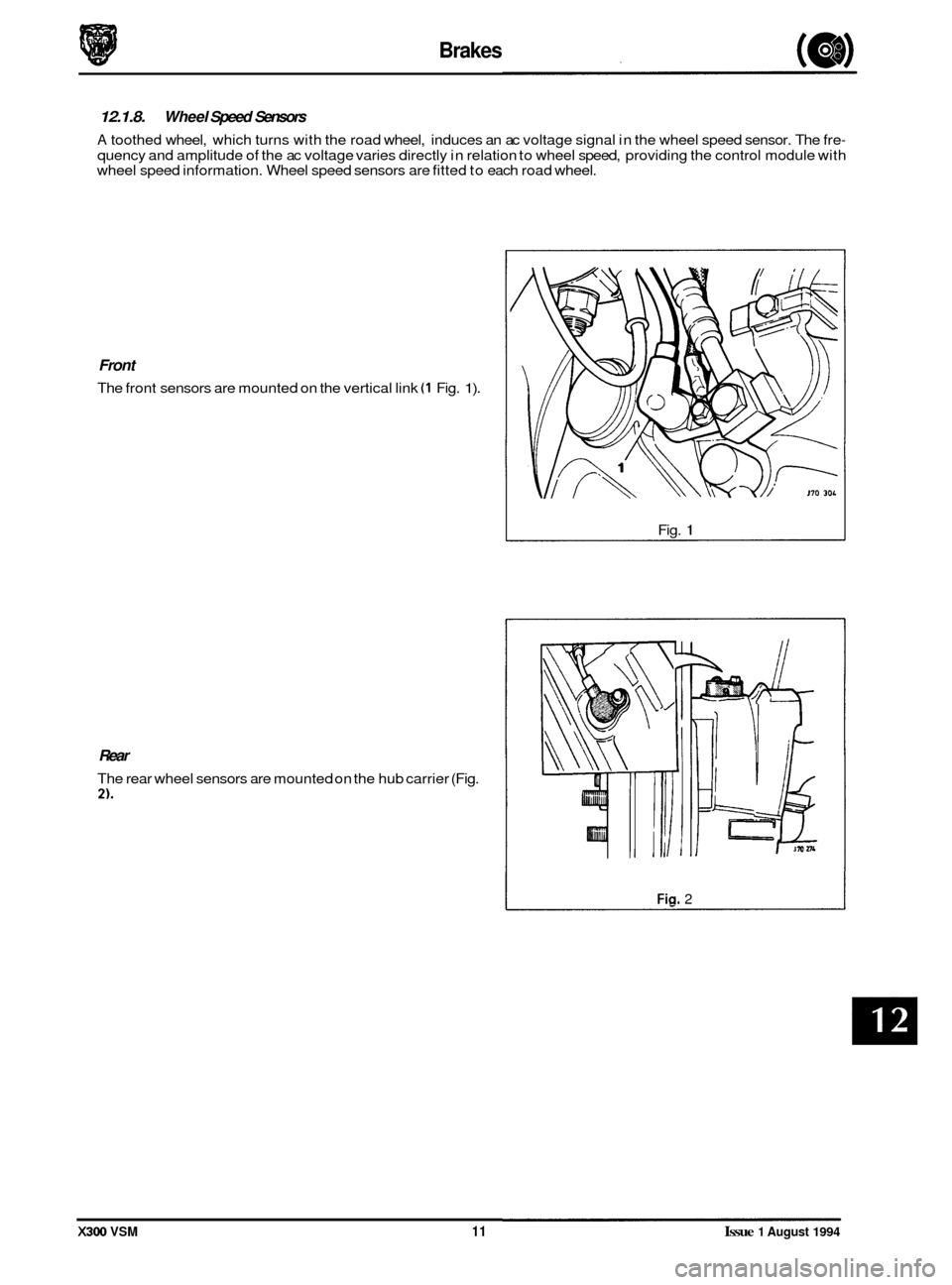

12.1.8. Wheel Speed Sensors

A toothed wheel, which turns with the road wheel, induces an ac voltage signal in the wheel speed sensor. The fre-

quency and amplitude of the ac voltage varies directly in relation to wheel speed, providing the control module with

wheel speed information. Wheel speed sensors are fitted to each road wheel.

Front

The front sensors are mounted on the vertical link (1 Fig. 1).

Fig. 1

Rear

The rear wheel sensors are mounted on the hub carrier (Fig.

2).

Fin. 2

X300 VSM 11 Issue 1 August 1994

Page 235 of 521

12.1.9

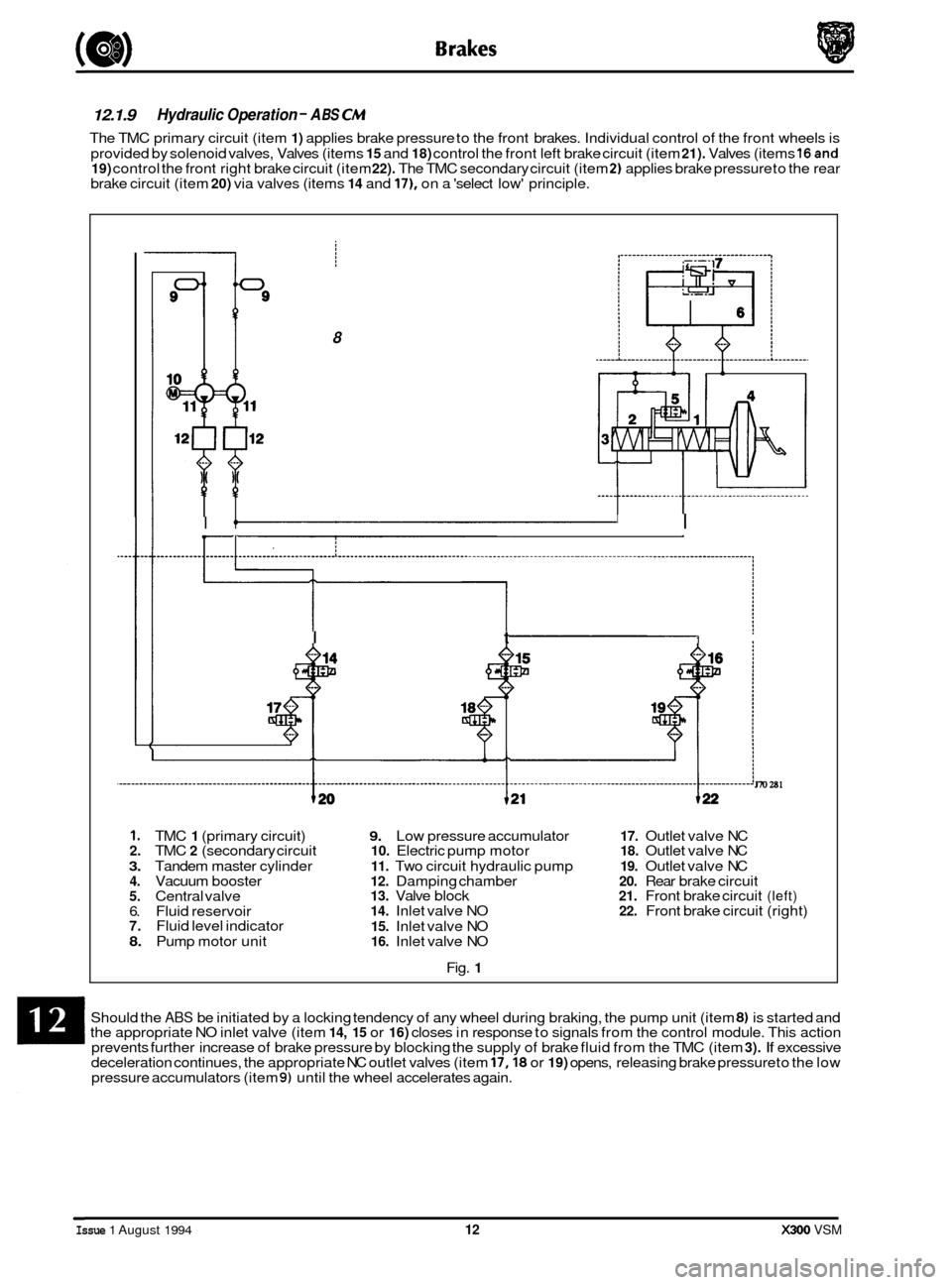

The TMC primary circuit (item 1) applies brake pressure to the front brakes. Individual control of the front wheels is

provided by solenoid valves, Valves (items

15 and 18) control the front left brake circuit (item 21). Valves (items 16and 19) control the front right brake circuit (item 22). The TMC secondary circuit (item 2) applies brake pressure to the rear

brake circuit (item 20) via valves (items 14 and 17), on a 'select low' principle.

Hydraulic Operation - A BS CM

8

I I + I

I t 1

'0281

1. TMC 1 (primary circuit) 9. Low pressure accumulator 17. Outlet valve NC 2. TMC 2 (secondary circuit 10. Electric pump motor 18. Outlet valve NC

3. Tandem master cylinder 11. Two circuit hydraulic pump 19. Outlet valve NC 4. Vacuum booster 12. Damping chamber 20. Rear brake circuit 5. Central valve 13. Valve block 21. Front brake circuit (left)

6. Fluid reservoir 14. Inlet valve NO 22. Front brake circuit (right) 7. Fluid level indicator 15. Inlet valve NO 8. Pump motor unit 16. Inlet valve NO

Fig.

1

Should the ABS be initiated by a locking tendency of any wheel during braking, the pump unit (item 8) is started and

the appropriate NO inlet valve (item 14, 15 or 16) closes in response to signals from the control module. This action

prevents further increase of brake pressure by blocking the supply of brake fluid from the TMC (item 3). If excessive

deceleration continues, the appropriate NC outlet valves (item 17,18 or 19) opens, releasing brake pressure to the low

pressure accumulators (item 9) until the wheel accelerates again.

Issue 1 August 1994 12 X300 VSM

Page 237 of 521

12.1.1 0 Hydrauric Operation - ABS 1 TC CM

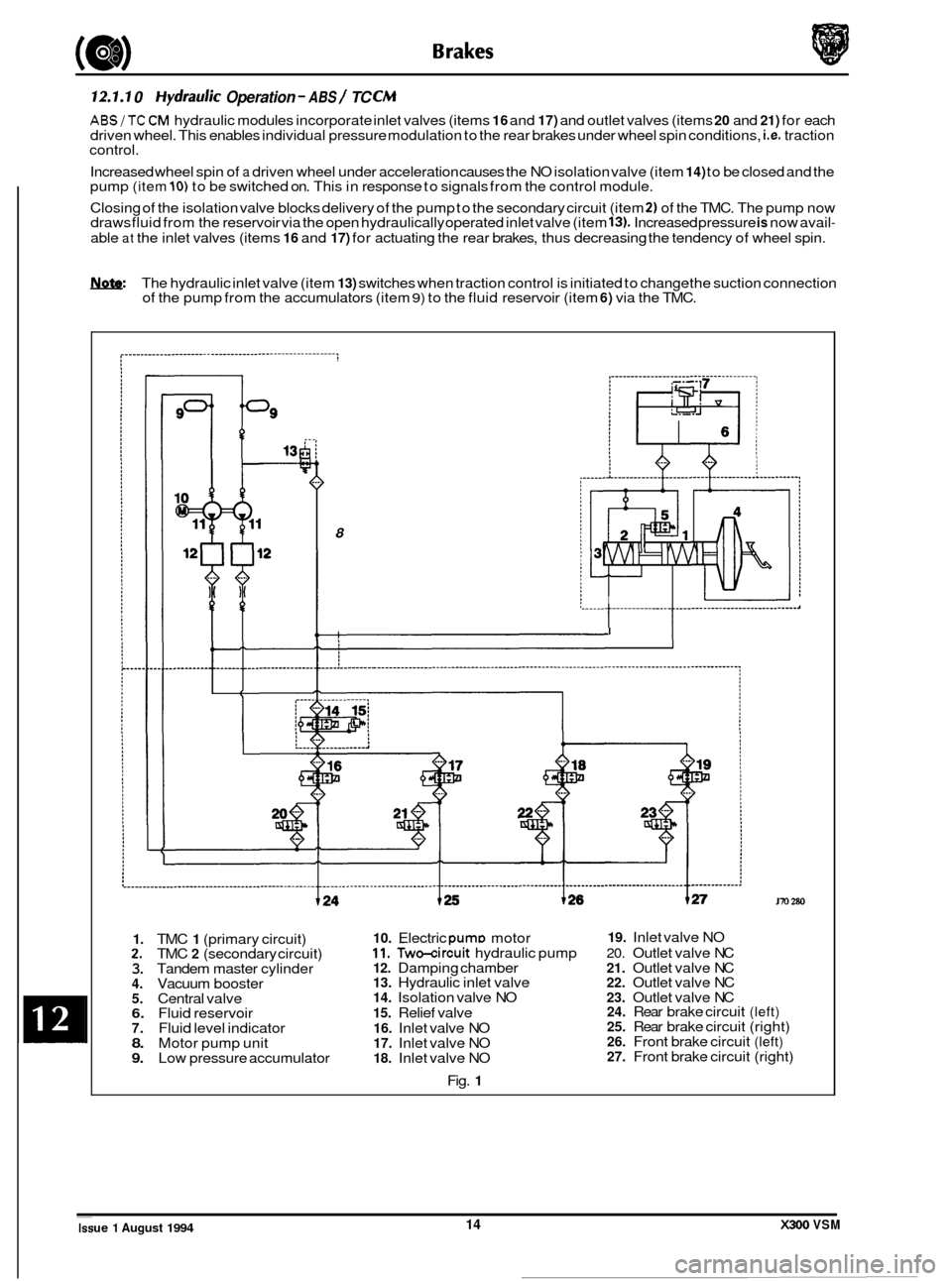

ABS/TC CM hydraulic modules incorporate inlet valves (items 16 and 17) and outlet valves (items 20 and 21) for each

driven wheel. This enables individual pressure modulation to the rear brakes under wheel spin conditions, i.e. traction

control.

Increased wheel spin of

a driven wheel under acceleration causes the NO isolation valve (item 14) to be closed and the

pump (item 10) to be switched on. This in response to signals from the control module.

Closing of the isolation valve blocks delivery of the pump to the secondary circuit (item

2) of the TMC. The pump now

draws fluid from the reservoir via the open hydraulically operated inlet valve (item 13). Increased pressure is now avail-

able at the inlet valves (items 16 and 17) for actuating the rear brakes, thus decreasing the tendency of wheel spin.

The hydraulic inlet valve (item

13) switches when traction control is initiated to change the suction connection

of the pump from the accumulators (item 9) to the fluid reservoir (item 6) via the TMC.

1. TMC 1 (primary circuit)

8

I 1-

I

10. Electric DumD motor 19. Inlet valve NO

170 280

2. TMC 2 (secondary circuit) 11. Two-cirh hydraulic pump 20. Outlet valve NC

3. Tandem master cylinder 12. Damping chamber 21. Outlet valve NC

4. Vacuum booster 13. Hydraulic inlet valve 22. Outlet valve NC

5. Central valve 14. Isolation valve NO 23. Outlet valve NC

6. Fluid reservoir 15. Relief valve 7. Fluid level indicator 16. Inlet valve NO 8. Motor pump unit 17. Inlet valve NO 9. Low pressure accumulator 18. Inlet valve NO

Fig.

1 24.

Rear

brake circuit (left) 25. Rear brake circuit (right) 26. Front brake circuit (left) 27. Front brake circuit (right) ~

Issue 1 August 1994 14 X300 VSM

Page 238 of 521

Brakes

The pressure at the inlet valves corresponds to the opening pressure of the relief valve (item 15) incorporated in the

isolation valve. Excess brake fluid is drained to the suction side of the pump via the relief valve and returns either to

the TMC secondary circuit and on to the

fluid reservoir, or is directly drawn on by the pump.

As soon as the spinning wheel has been braked down into the normal range of wheel spin, the NO valves (items

16 or 17) close to prevent any further increase in brake pressure. Depending upon the acceleration of the wheel, the NC

valve (item

20 or 21) may open to decrease thesecondary circuit brake pressure. NCvalves (item 17 or 18) may remain

closed in orderto achieve a brake pressure holding phase. If the pressure in the secondarycircuit needs to be increased

again, the NC valve closes again (if open) and the NO valve opens, diverting the necessary volume flow. This control

action, keeps the wheel in the range of optimum slip until the spinning tendency ceases.

The NO isolation valve

(14) remains closed throughout the traction control cycle.

An actuation of the brake, sensed by the control module, causes the traction control mode to be terminated and the

isolation valve (item

14) to be opened. The TMC pressure simultaneously closes the hydraulic inlet valve (item 13) so that the pump can no longer draw fluid from it. The ABS / TC CM now operates in normal ABS mode.

m: When traction control is initiated, speed control is deactivated (if in operation) and requires re-setting after

the traction control mode has terminated. Gear shift is inhibited on automatic transmission vehicles; no down- shifts are allowed and upshifts occur at 4800 RPM.

X300 VSM 15 Issue 1 August 1994

Page 239 of 521

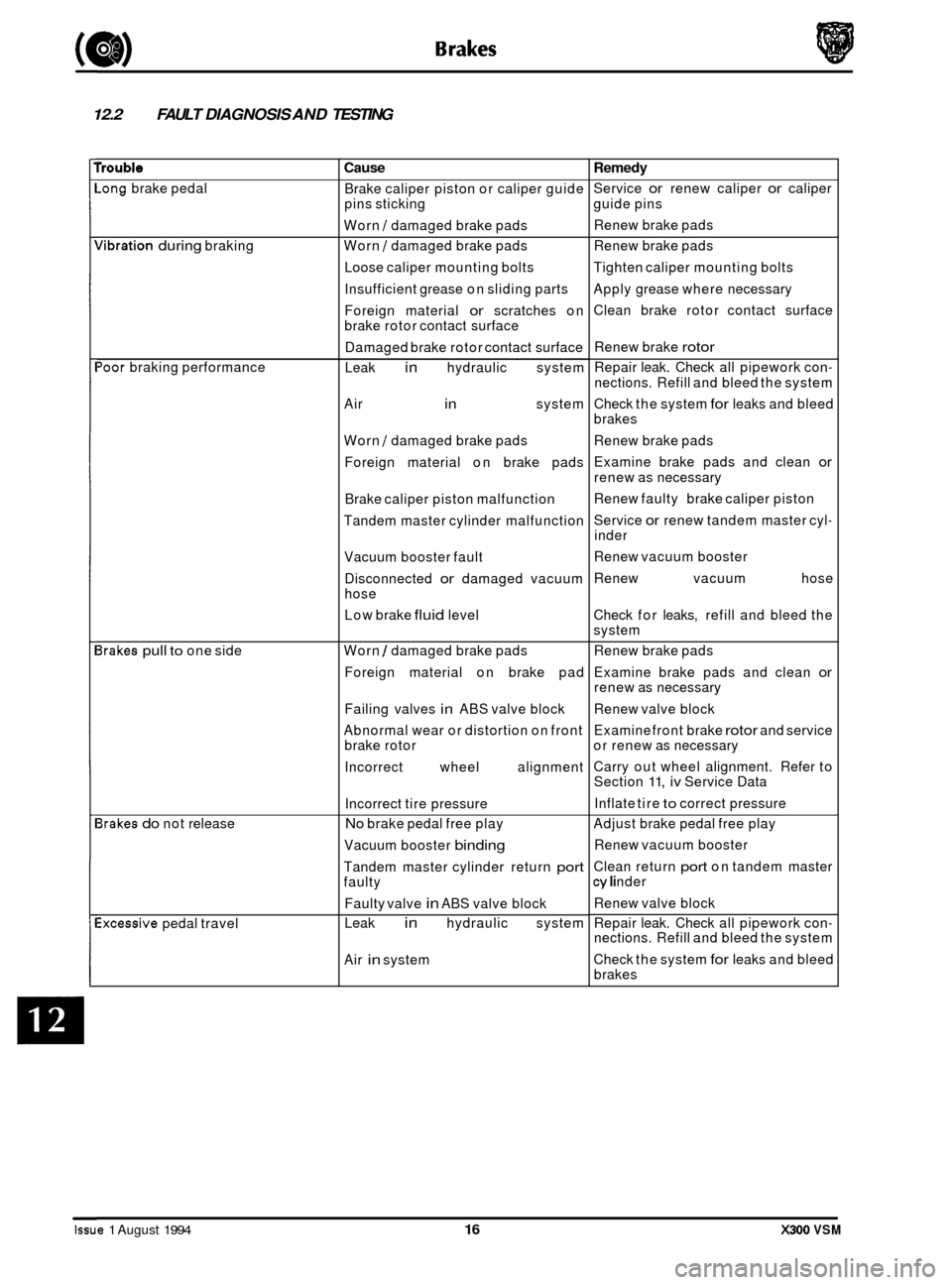

12.2 FAULT DIAGNOSIS AND TESTING

rrouble

-ong brake pedal

dibration during braking

'oor braking performance

3rakes pull to one side

3rakes do not release

ixcessive pedal travel

Cause

Brake caliper piston or caliper guide

pins sticking

Worn

I damaged brake pads

Worn

1 damaged brake pads

Loose caliper mounting bolts

Insufficient grease on sliding parts

Foreign material

or scratches on

brake rotor contact surface

Damaged brake rotor contact surface

Leak

in hydraulic system

Air

in system

Worn

I damaged brake pads

Foreign material on brake pads

Brake caliper piston malfunction

Tandem master cylinder malfunction

Vacuum booster fault

Disconnected

or damaged vacuum

hose

Low brake

fluid level

Worn

I damaged brake pads

Foreign material on brake pad

Failing valves

in ABS valve block

Abnormal wear or distortion on front

brake rotor

Incorrect wheel alignment

Incorrect tire pressure

No brake pedal free play

Vacuum booster

binding

Tandem master cylinder return port faulty

Faulty valve

in ABS valve block

Leak

in hydraulic system

Air

in system

Remedy

Service or renew caliper or caliper

guide pins

Renew brake pads

Renew brake pads

Tighten caliper mounting bolts

Apply grease where necessary

Clean brake rotor contact surface

Renew brake

rotor

Repair leak. Check all pipework con-

nections. Refill and bleed the system

Check the system

for leaks and bleed

brakes

Renew brake pads

Examine brake pads and clean

or

renew as necessary

Renew faulty brake caliper piston

Service

or renew tandem master cyl- inder

Renew vacuum booster

Renew vacuum hose

Check for leaks, refill and bleed the

system

Renew brake pads

Examine brake pads and clean

or renew as necessary

Renew valve block

Examine front brake

rotor and service

or renew as necessary

Carry out wheel alignment. Refer to

Section

11, iv Service Data

Inflate tire

to correct pressure

Adjust brake pedal free play

Renew vacuum booster

Clean return

port on tandem master cy I i nder

Renew valve block

Repair leak. Check all pipework con

- nections. Refill and bleed the system

Check the system

for leaks and bleed

brakes

0

0

0

Issue 1 August 1994 16 X300 VSM

Page 240 of 521

12.2 (continued)

rrouble

Excessive pedal travel (Cont'd)

Brakes grab

Brakes drag

Hard brake pedal when pressed

Excessive brake noise

Cause

Worn tandem master cylinder piston

seals or scored cylinder bore

'knock back'. Excessive brake rotor

run

-out or loose wheel bearings

Brake pads contaminated by grease

or brake fluid

Brake pads distorted, cracked or

loose

Loose caliper mounting bolts or

guide pins

Seized or incorrectly adjusted parking

brake or cable

Broken or weak parking brake return

springs

Caliper pistons seized

Brake pedal binding

at pivot points

Vacuum booster binding

Tandem master cylinder faulty

Lack of vacuum

at the vacuum

booster

Tandem master cylinder

pushrod

binding

Frozen tandem master cylinder pis

-

ton

Brake caliper piston or caliper guide

pins seized

Worn brake pads

Bent or cracked parking brake shoes

Foreign objects in brake pads or

park- ing brake shoes

Broken

/ loose parking brake hold

down springs or return springs

Loose caliper mounting bolts

Remedy

Renew tandem master cylinder

Check brake rotor run

-out and renew

as necessary. Adjust wheel bearing

Renew brake pads. Check

pipework for leaks

Renew brake pads

Check caliper and repair

/ renew as

necessary

Examine parking brake and repair

/

renew as necessary

Renew parking brake return springs

Examine calipers and repair

/ renew

as necessary

Examine brake pedal bushings and

repair

/ renew as necessary

Renew vacuum booster

Examine tandem master cylinder and

repair

/ renew as necessary

Check vacuum hose. Repair or renew

as necessary

Renew tandem master cylinder

Renew tandem master cylinder

Examine caliper and renew/ repair as

necessary

Renew brake pads

Renew parking brake shoes

Examine brake pads and and parking

brake shoes. Clean or renew as

necessary

Examine parking brake assembly.

Re- pair or renew as necessary

Re

-torque caliper mounting bolts

Page 245 of 521

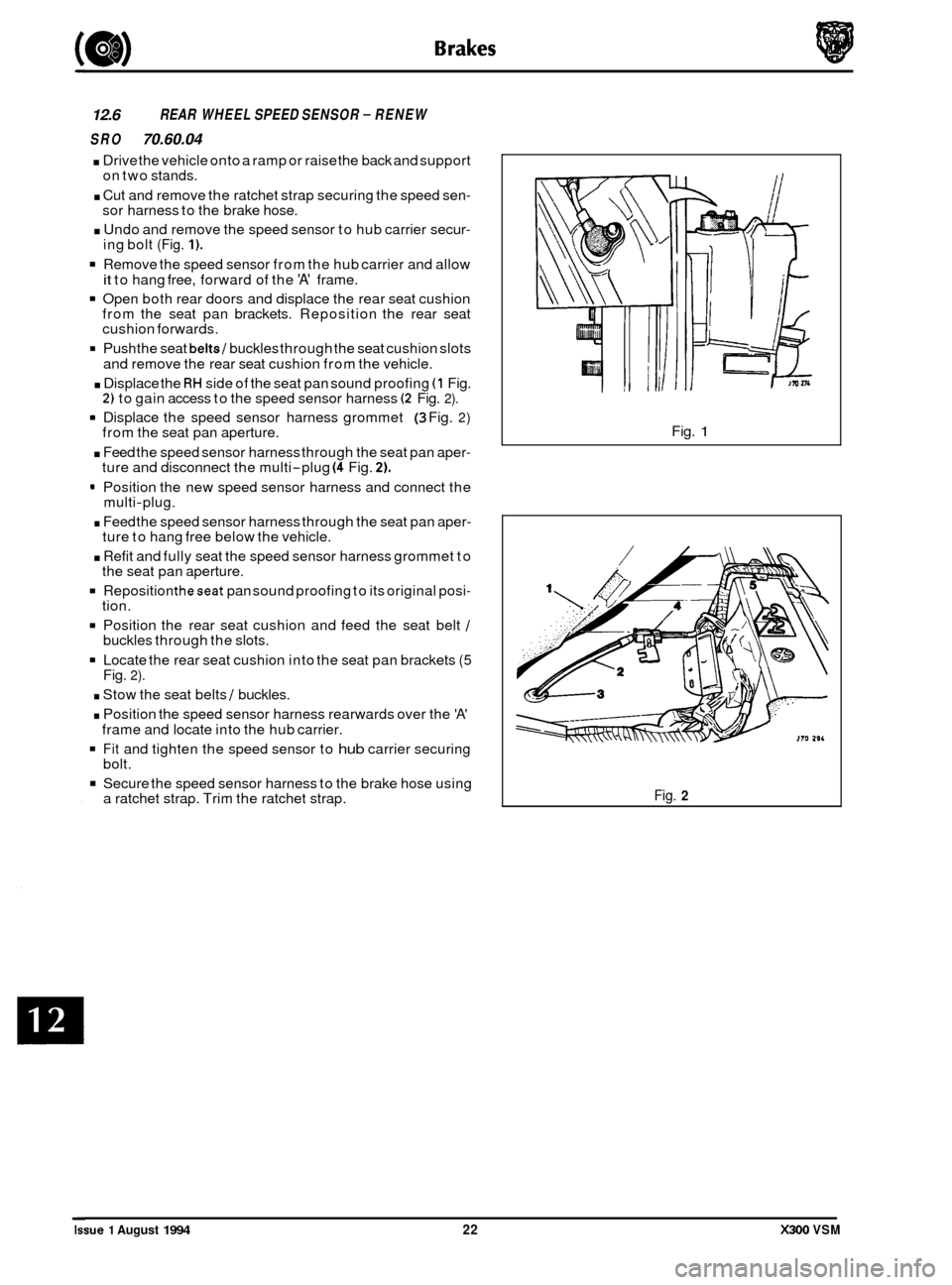

12.6 REAR WHEEL SPEED SENSOR - RENEW

SRO

70.60.04

. Drive the vehicle onto a ramp or raise the back and support

on two stands.

. Cut and remove the ratchet strap securing the speed sen- sor harness to the brake hose.

. Undo and remove the speed sensor to hub carrier secur- ing bolt (Fig. 1).

Remove the speed sensor from the hub carrier and allow

it to hang free, forward of the 'A' frame.

Open both rear doors and displace the rear seat cushion

from the seat pan brackets. Reposition the rear seat

cushion forwards.

9 Push the seat belts/ buckles through the seat cushion slots

and remove the rear seat cushion from the vehicle.

. Displace the RH side of the seat pan sound proofing (1 Fig. 2) to gain access to the speed sensor harness (2 Fig. 2).

9 Displace the speed sensor harness grommet (3 Fig. 2) from the seat pan aperture.

. Feed the speed sensor harness through the seat pan aper- ture and disconnect the multi-plug (4 Fig. 2).

9 Position the new speed sensor harness and connect the

multi-plug.

. Feed the speed sensor harness through the seat pan aper- ture to hang free below the vehicle.

. Refit and fully seat the speed sensor harness grommet to

the seat pan aperture.

Reposition theseat pan sound proofing to its original posi- tion.

Position the rear seat cushion and feed the seat belt / buckles through the slots.

Locate the rear seat cushion into the seat pan brackets (5 Fig. 2).

. Stow the seat belts / buckles.

. Position the speed sensor harness rearwards over the 'A'

Fit and tighten the speed sensor to hub carrier securing

Secure the speed sensor harness to the brake hose using

frame

and locate into the hub carrier.

bolt.

a ratchet strap. Trim the ratchet strap. Fig.

1

Fig. 2

Issue 1 August 1994 22 X300 VSM

0

0

0