electrical JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 372 of 521

Electrical rl

Key to Fig 1, Motors & Solenoids, page 36.

Filler Cap (Solenoid)

X300 VSM ~~ Issue 1 August 31

- 1994

Page 373 of 521

rl Electrical

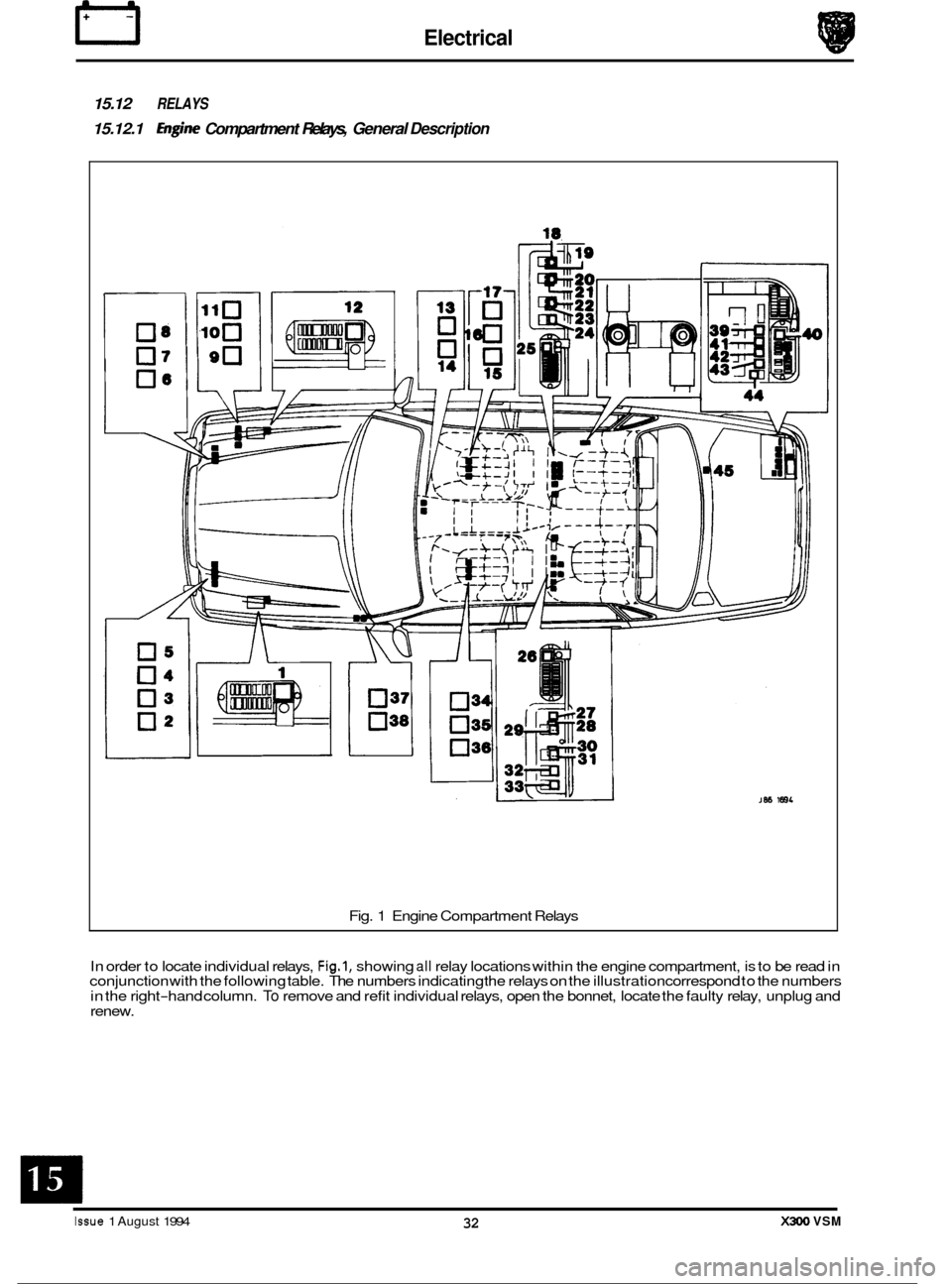

15.12 RELAYS

15.12.1 €@ne Compartment Relays, General Description

05

04

03

02

Fig. 1 Engine Compartment Relays

In order to locate individual relays,

Fig.1, showing all relay locations within the engine compartment, is to be read in

conjunction with the following table. The numbers indicating the relays on the illustration correspond to the numbers

in the right

-hand column. To remove and refit individual relays, open the bonnet, locate the faulty relay, unplug and

renew.

Issue 1 August 1994 32 X300 VSM

Page 377 of 521

rl Electrical

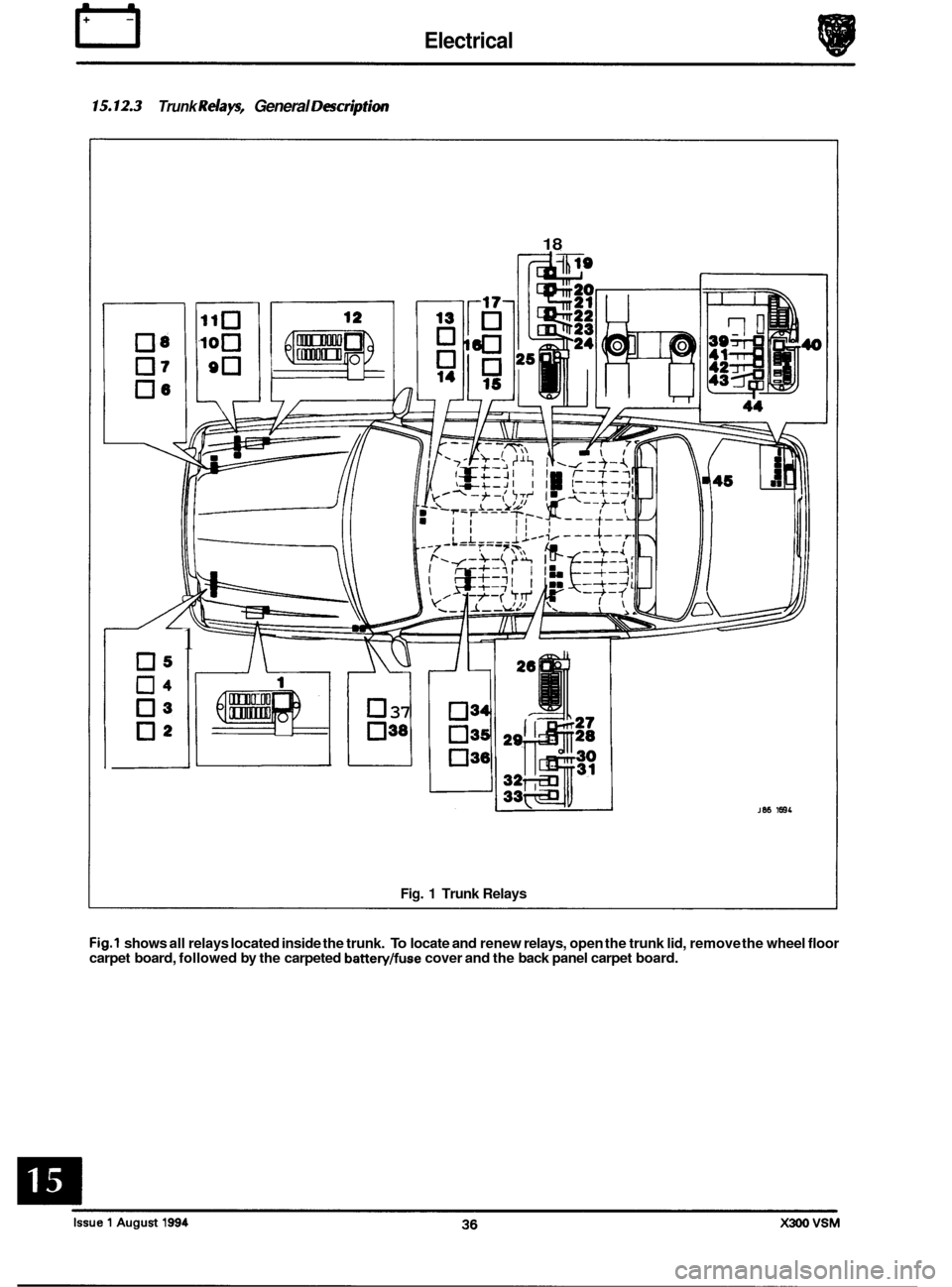

'5.12.3 Trunk Relays, General DescrptiOn

05

04

03

02

1

18

I

2-

U 37

038

Fig. 1 Trunk Relays

JW 1681

Fig.1 shows all relays located inside the trunk. To locate and renew relays, open the trunk lid, remove the wheel floor

carpet board, followed by the carpeted battery/fuse cover and the back panel carpet board.

Page 378 of 521

Electrical IT

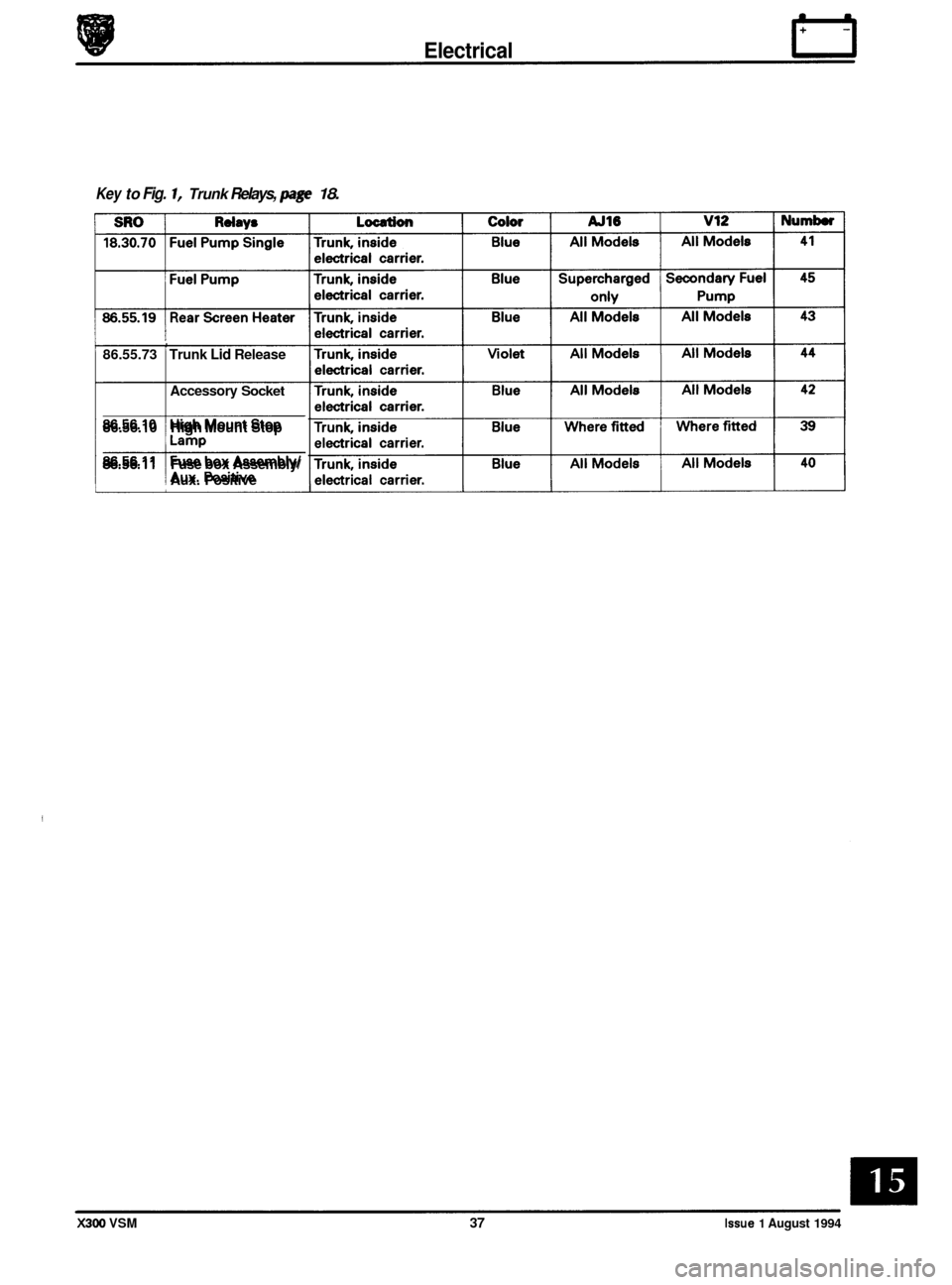

Key to Fig. 1, Trunk Relays, page 18.

, 86.55.73 Trunk Lid Release

Accessory

Socket

86.56.10 High Mount Stop

86.56.11 Fuse box Assembly/

! Aux. Positive

X300 VSM 37 Issue 1 August 1994

Page 380 of 521

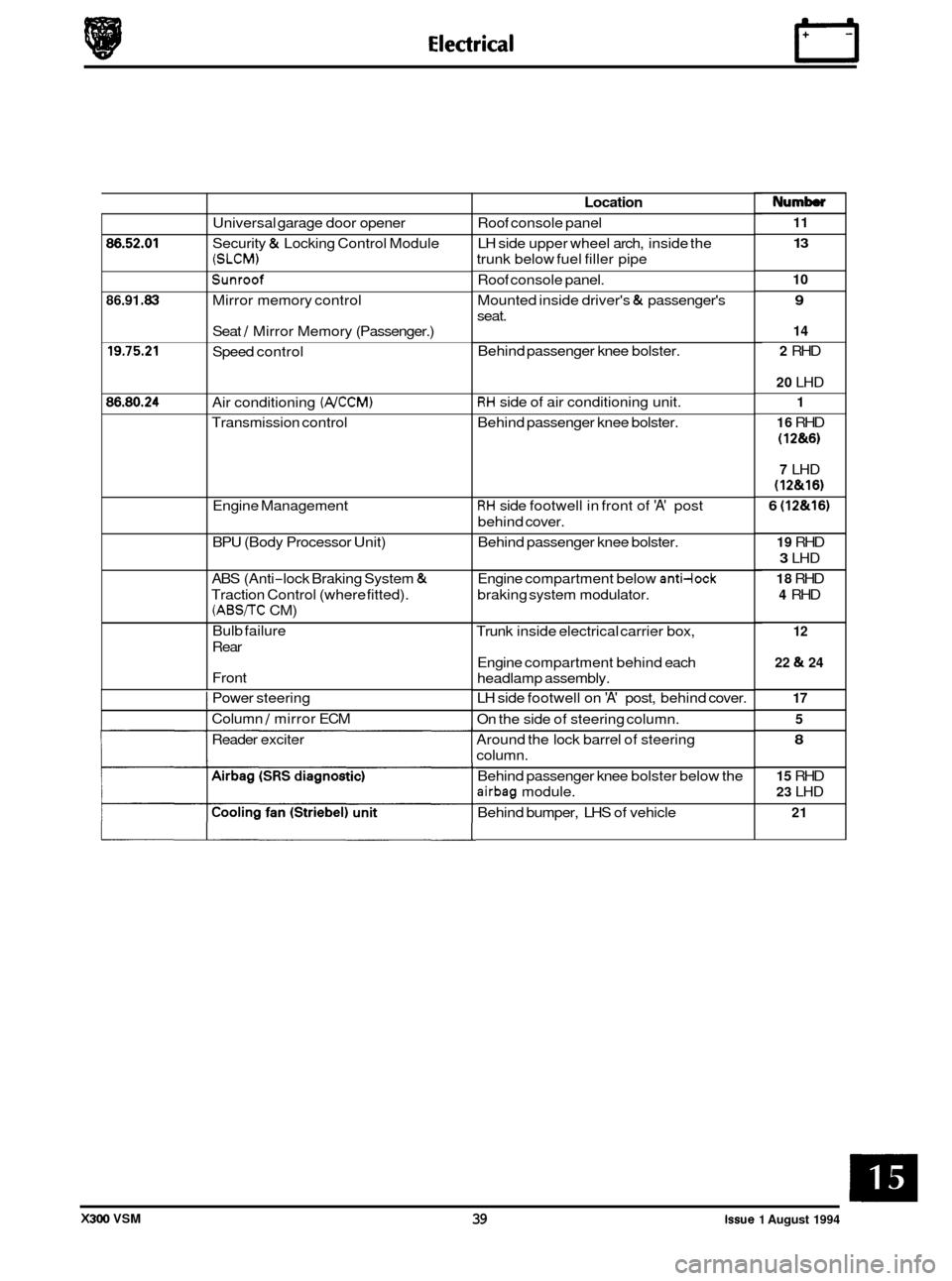

86.52.01

86.91 -83

19.75.21

86.80.24

Universal garage door opener

Security

& Locking Control Module

(SLCM)

Sunroof

Mirror memory control

Seat

/ Mirror Memory (Passenger.)

Speed control

Air conditioning

(NCCM)

Transmission control

Engine Management

BPU (Body Processor Unit)

ABS (Anti

-lock Braking System &

Traction Control (where fitted).

(ABS/TC CM)

Bulb failure

Rear

Front

I Power steering

I Column / mirror ECM

Reader exciter

Location

Roof console panel

LH side upper wheel arch, inside the

trunk below fuel filler pipe

Roof console panel.

Mounted inside driver's

& passenger's

seat.

Behind passenger knee bolster.

RH side of air conditioning unit.

Behind passenger knee bolster.

RH side footwell in front of 'A' post

behind cover.

Behind passenger knee bolster.

Engine compartment below

anti-lock

braking system modulator.

Trunk inside electrical carrier box,

Engine compartment behind each

headlamp assembly.

LH side footwell on

'A' post, behind cover.

On the side of steering column.

Around the lock barrel of steering

column.

Behind passenger knee bolster below the

airbag module.

Behind bumper, LHS of vehicle

Numb

11

13

10

9

14

2

RHD

20 LHD

1

16

RHD

(1 2&6)

7 LHD

(12&16)

6 (12&16)

19 RHD

3 LHD

18 RHD

4 RHD

12

22

& 24

17 5

8

15 RHD

23 LHD

21

X300 VSM 39 issue 1 August 1994

Page 382 of 521

Snecif icat ion W -I- ..........

e

0

CON TENTS

Title Page

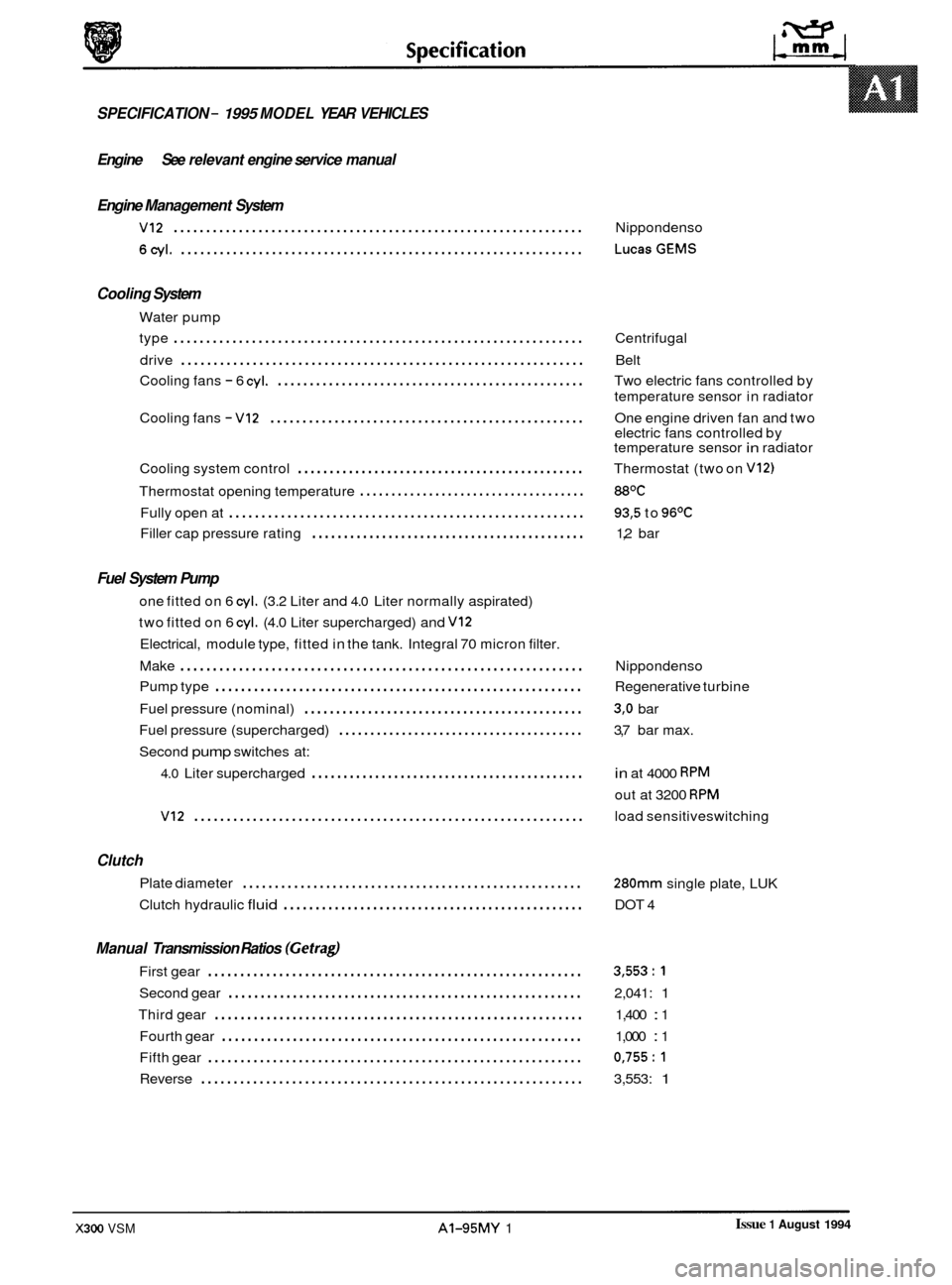

Specification. 1995 Model Year Vehicles ................................................................... 1

EngineManagementSystem ........................................................................\

. 1

Cooling System ........................................................................\

............ 7

Fuelsystem Pump ........................................................................\

......... 7

Clutch ........................................................................\

................... 7

Manual Transmission Ratios ........................................................................\

. 1

Automatic Transmission Ratios ....................................................................... \

2

Final Drive Unit Ratios ........................................................................\

..... 2

Climate Control System ........................................................................\

..... 2

Braking System ........................................................................\

............ 3

Steering&Suspension ........................................................................\

...... 4

Electrical Equipment ........................................................................\

....... 5

Lubricants & Fluids ........................................................................\

......... 7

Vehicle Weights ........................................................................\

........... 9

Tires ........................................................................\

.................... 10

Snowchains ........................................................................\

............. 17

Bulbs ........................................................................\

................... 12

Fuses ........................................................................\

................... 14

Issue 1 August 1994 AI-95MY i X300 VSM

Page 384 of 521

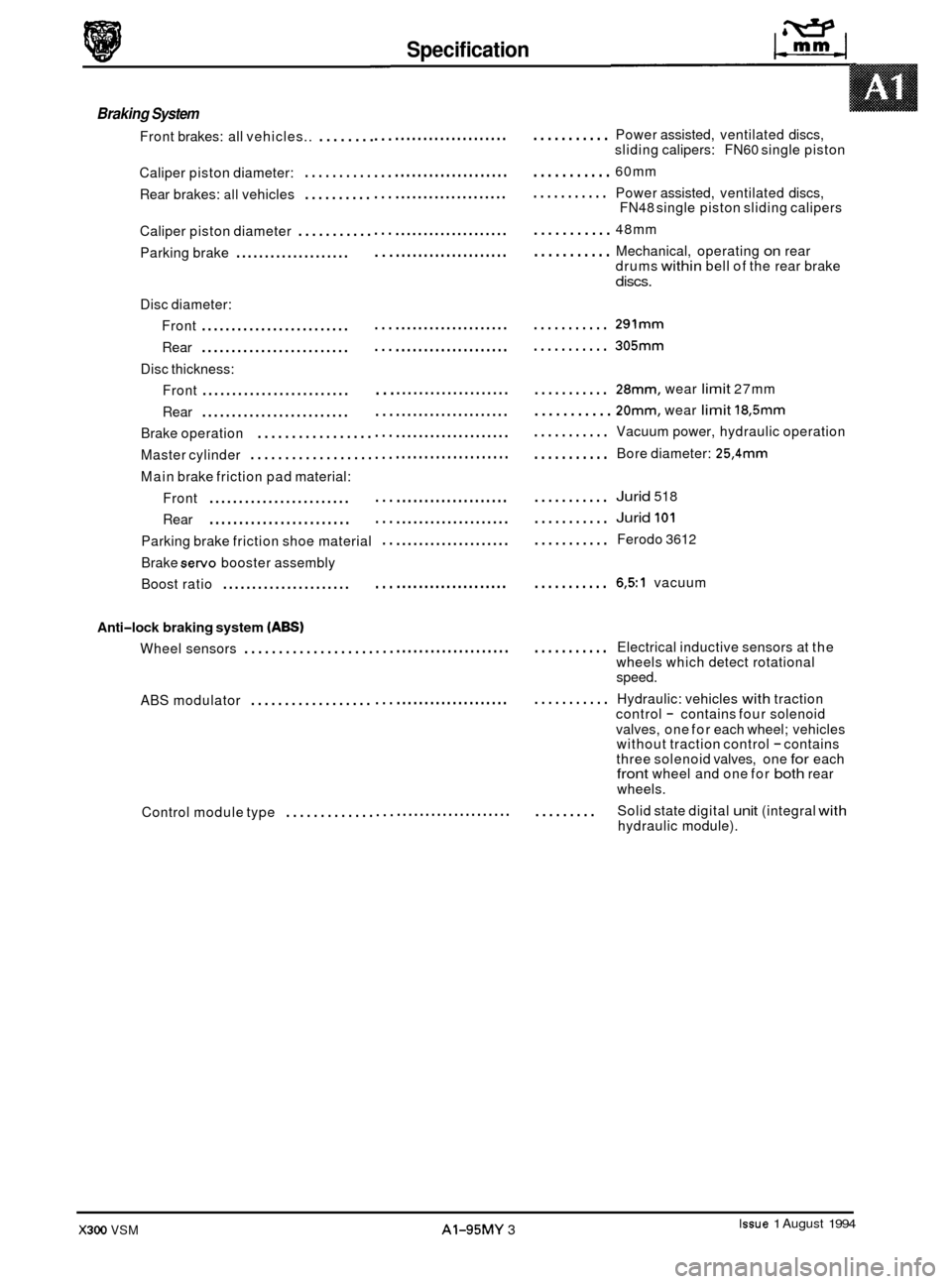

SPECIFICATION - 1995 MODEL YEAR VEHICLES

Engine See relevant engine service manual

Engine Management System

VI2 ............................................................... Nippondenso

6cyl. .............................................................. LucasGEMS

Cooling System

Water pump

type

............................................................... Centrifugal

Cooling fans

- 6 cyl. ................................................ Two electric fans controlled by

Cooling fans

- VI2 ................................................. One engine driven fan and two

Cooling system control

............................................. Thermostat (two on V12)

Thermostat opening temperature .................................... 88OC

Fully open at ....................................................... 93,5 to 96OC

Filler cap pressure rating ........................................... 1,2 bar

drive

.............................................................. Belt

temperature sensor in radiator

electric fans controlled by

temperature sensor

in radiator

Fuel System Pump

one fitted on 6 cyl. (3.2 Liter and 4.0 Liter normally aspirated)

two fitted on 6

cyl. (4.0 Liter supercharged) and VI2

Electrical, module type, fitted in the tank. Integral 70 micron filter.

Make

.............................................................. Nippondenso

Fuel pressure (nominal)

............................................ 3,O bar

Second

pump switches at:

Pump

type

......................................................... Regenerative turbine

Fuel pressure (supercharged)

....................................... 3,7 bar max.

4.0 Liter supercharged ........................................... in at 4000 RPM

out at 3200 RPM

VI2 ............................................................ load sensitiveswitching

Clutch

Plate diameter .....................................................

Clutch hydraulic fluid ............................................... DOT 4

280mm single plate, LUK

Manual Transmission Ratios (Gefragl

First gear .......................................................... 3,553:l

Second gear ....................................................... 2,041: 1

Third gear ......................................................... 1,400 : 1

Fourth gear

........................................................ 1,000 : 1

Fifth gear

.......................................................... 0,755:l

Reverse ........................................................... 3,553: 1

Issue 1 August 1994 X300 VSM AI-95MY 1

Page 386 of 521

e LmmJ

Power assisted, ventilated discs,

sliding calipers: FN60 single piston

60mm Power assisted, ventilated discs,

FN48 single piston sliding calipers

48mm Mechanical, operating

on rear

drums within bell of the rear brake

discs.

291mm

305mm

28mm. wear limit 27mm

20mm, wear limit 18,5mm

Vacuum power, hydraulic operation

Bore diameter:

25,4mm

Jurid 518

Jurid 101

Ferodo 3612

6,51 vacuum

Electrical inductive sensors at the

wheels which detect rotational

speed.

Hydraulic: vehicles

with traction

control - contains four solenoid

valves, one for each wheel; vehicles

without traction control

- contains

three solenoid valves, one for each front wheel and one for both rear

wheels.

Solid state digital

unit (integral with hydraulic module).

Specification

Braking System

Front brakes: all vehicles.. ........ .................... ........... ...

Caliper piston diameter: ..........

Rear brakes: all vehicles ..........

...

...

....................

....................

...........

...........

Caliper piston diameter ...........

Parking brake ....................

...

...

....................

....................

...........

...........

Disc diameter:

Front

.........................

Rear .........................

Front .........................

Rear .........................

Brake operation .................

Master cylinder ..................

Main brake friction pad material:

Front

........................

Rear ........................

Parking brake friction shoe material

Brake

servo booster assembly

Boost ratio

......................

Disc thickness:

...

... ....................

....................

...........

...........

...

...

...

...

....................

....................

....................

....................

...........

...........

...........

...........

...

...

.. ....................

....................

....................

...........

...........

...........

... .................... ...........

Anti-lock braking system (ABSI

Wheel sensors ................... ... .................... ...........

ABS modulator .................. ... .................... ...........

0

0

Control module type ............. ... .................... .........

Issue 1 August 1994 X300 VSM AI-95MY 3

Page 388 of 521

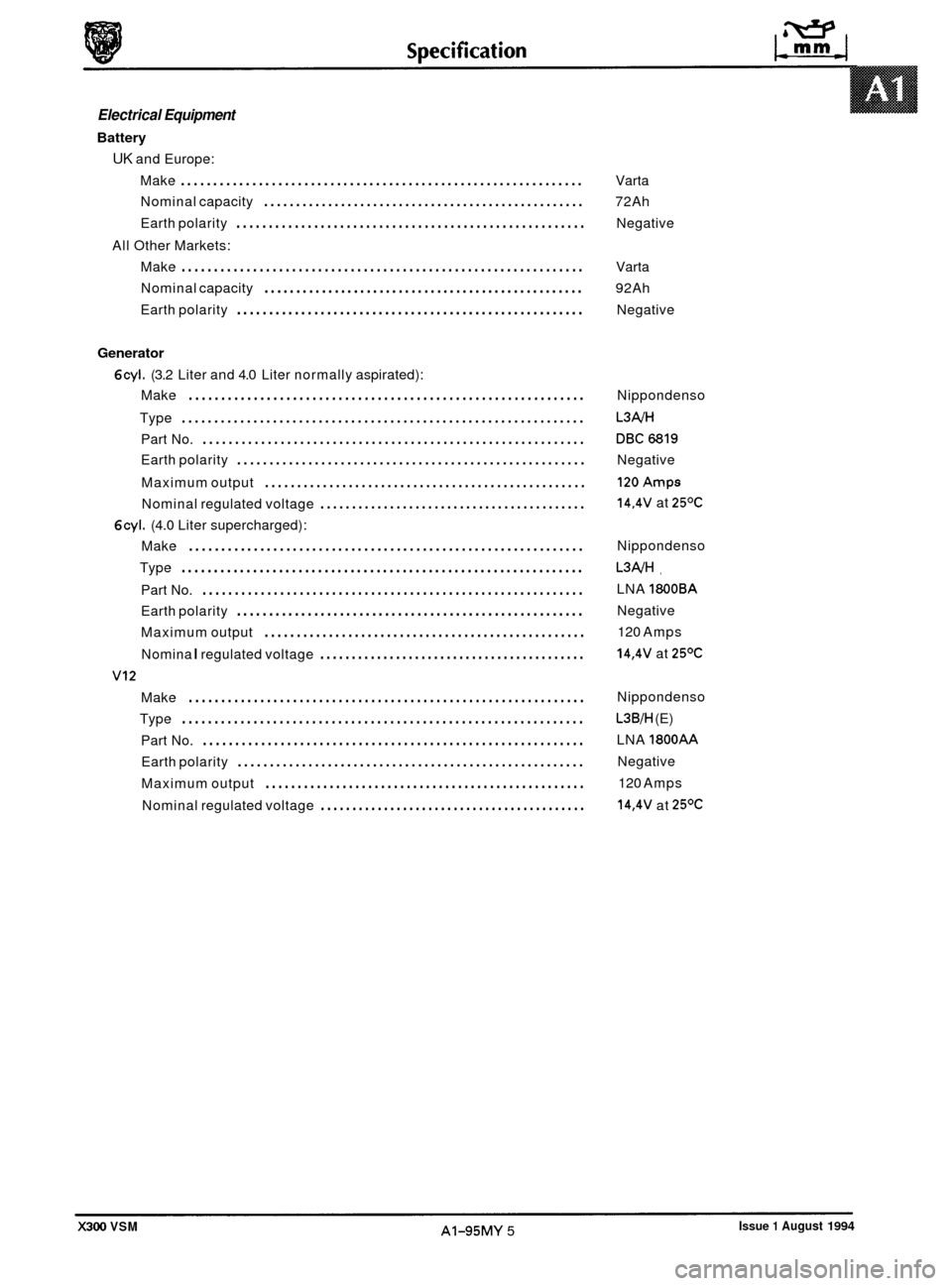

e Electrical Equipment

Battery

UK and Europe:

Make

.............................................................. Varta

Nominal capacity

.................................................. 72Ah

Earth polarity

...................................................... Negative

All Other Markets:

Make

.............................................................. Varta

Nominal capacity

.................................................. 92Ah

Earth polarity

...................................................... Negative

Generator

6 cyl. (3.2 Liter and 4.0 Liter normally aspirated):

Make

............................................................. Nippondenso

Type

.............................................................. L3NH

Part No. ........................................................... DBC6819

Maximum output .................................................. 120Amps

Earth polarity ...................................................... Negative

Nominal regulated voltage

..........................................

Make .............................................................

Type ..............................................................

Part No. ...........................................................

Earth polarity ......................................................

Maximum output ..................................................

Nomina I regulated voltage ..........................................

Make .............................................................

Type ..............................................................

Part No. ...........................................................

Earth polarity ......................................................

Maximum output ..................................................

6 cyl. (4.0 Liter supercharged):

VI2

14.4V at 25OC

Nippondenso

L3NH ,

LNA 1800BA

Negative

120 Amps

14,4V at 25OC

Nippondenso

L3B/H (E)

LNA

1800AA

Negative

120 Amps

0

X300 VSM

Nominal regulated voltage .......................................... 14,4V at 25OC

AI-95MY 5 Issue 1 August 1994

Page 389 of 521

Specificat ion

Electrical Equipment (continued)

Starter

Make and type ..................................................... Bosch DW 1,7K

Free spin speed .................................................... 3000 RPM

Free spin current ................................................... 90A maximum

Load

running current ............................................... 420A maximum

Stall

............................................................... 1050A

Make and type ..................................................... Magneti Marelli M80R

Free spin speed .................................................... 2650 RPM

Free spin current ................................................... 75A maximum

Load

running current ............................................... 375A maximum

Stall

............................................................... 1000A

lindshield Wiper Motor

Make ............................................................. Trico

Light running speed: (after 60 seconds from cold)

Slowspeed

....................................................... 40-48cycles

Fast speed ........................................................ 57 -67 cycles

Light

running current:

Fastspeed

......................................................... 5A max.

Slow speed ........................................................ 2.5A max.