electrical JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 355 of 521

15.5.8 wific Gravity Test

The specific gravity of the electrolyte determines the level of the float in the liquid. With the float in a high position

the specific gravity is high and when the specific gravity is low the float sinks to the lower position.

Using

a hydrometer the specific gravity readings are taken when the liquid level crosses the scale on float. This should

give a accurate indication of the state charge of the battery.

The volume and the specific gravity of the electrolyte varies with the change in temperature.

15.5.9 Electrolyte Temperature Correctkm

For every 10- below 15% subtract 0.007 from the hydrometer reading, and for every 10°C above 15OC add 0.007 to

the hydrometer reading.

Note: Use only distilled water for topping up electrolyte. The electrolyte must not exceed 51.66OC during charging.

If after 30 minutes charging the battery current is not equal or greater than 3A, dispose of the battery.

15.5.10 Heahh and Sakty Precautions

As batteries contain sulphuric acid and explosive mixtures of hydrogen and oxygen gases, it is strongly recommended

that protective clothing is worn.

Avoid spilling acid to prevent damage to clothing and skin bums.

If accidentalty spilled or splashed on clothing or skin, rinse with cold water. As a neutralizer, a solution of baking soda

or ammonia and water may be used.

In the event of skin or eye contact rinse the affected areas with water and should this not

be sufficient seek medical

attention.

Any trace of acid spilled or splashed on the vehicle should be rinsed with clean water.

BEFORE AND WHILST WORKING WITH THE BATTERY BE AWARE OF THE FOLLOWING SAFETY PRECAUTIONS

o particularly during charging, highly explosive hydrogen is emitted.

0 do not smoke when working near the battery.

o avoid sparks, short circuits or other sources of ignition.

o switch off current before connecting or disconnecting any electrical terminals.

o always disconnect battery ground lead first and reconnect last.

o ensure battery is charged in a well ventilated area.

o switch off the charger before disconnecting.

WARNING: WHEN PREPARING ELECTROLYTE OF A DESIRED SPECIFIC GRAVITY, ALWAYS POUR THE

CONCENTRATED ACID SLOWLY INTO THE WATER AND NOT WATER INTO THE ACID.

HEAT IS GENERATED WHEN MIXING ACID WITH WATER, HENCE ADD SMALL AMOUNTS OF ACID AND

STIR SLOWLY INTO THE WATER. ALLOW TO COOL IF NOTICEABLE HEAT DEVELOPS. EXCEPT FOR LEAD

DO NOT STORE ACID

IN EXCESSIVELY WARM LOCATIONS OR DIRECT SUN LIGHT.FUEL VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL

SYSTEM. LINED

CONTAINERS, ALWAYS USE NON

- METALLIC CONTAINERS AND / OR FUNNELS.

Issue 1 August 1994 14 X300 VSM

Page 357 of 521

15.6

15.6.1

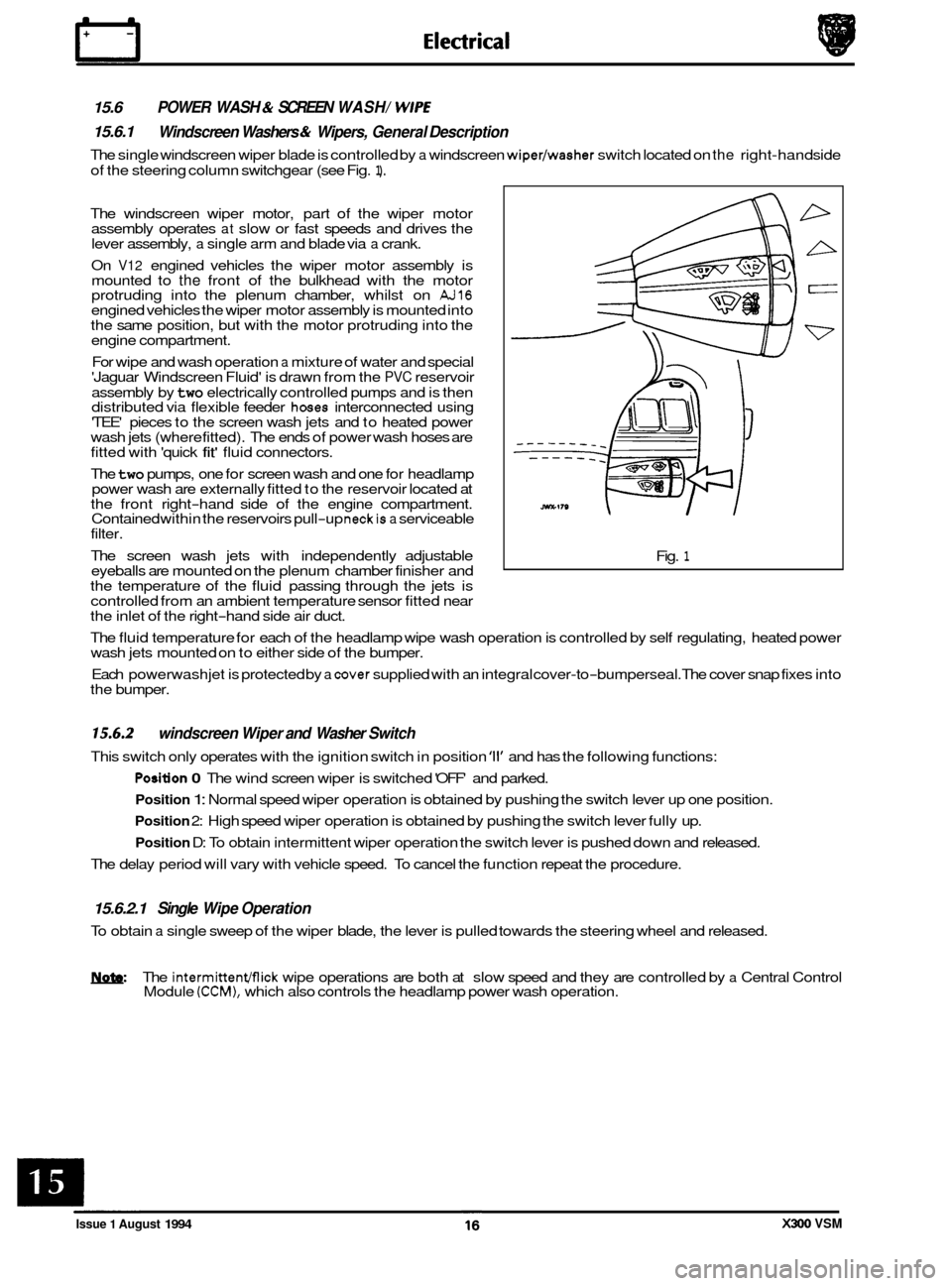

The single windscreen wiper blade is controlled by a windscreen wiper/washer switch located on the right-hand side

of the steering column switchgear (see Fig.

1).

POWER WASH & SCREEN WASH/ WlPE

Windscreen Washers & Wipers, General Description

The windscreen wiper motor, part of the wiper motor

assembly operates at slow or fast speeds and drives the

lever assembly, a single arm and blade via a crank.

On

V12 engined vehicles the wiper motor assembly is

mounted to the front of the bulkhead with the motor

protruding into the plenum chamber, whilst on AJ16 engined vehicles the wiper motor assembly is mounted into

the same position, but with the motor protruding into the

engine compartment.

For wipe and wash operation

a mixture of water and special

'Jaguar Windscreen Fluid' is drawn from the PVC reservoir

assembly by

two electrically controlled pumps and is then

distributed via flexible feeder hoses interconnected using

'TEE' pieces to the screen wash jets and to heated power

wash jets (where fitted). The ends of power wash hoses are

fitted with 'quick

fit' fluid connectors.

The

two pumps, one for screen wash and one for headlamp

power wash are externally fitted to the reservoir located at

the front right

-hand side of the engine compartment.

Contained within the reservoirs pull-up neckis a serviceable

filter.

The screen wash jets with independently adjustable

eyeballs are mounted on the plenum chamber finisher and

the temperature of the fluid passing through the jets is

controlled from an ambient temperature sensor fitted near

the inlet of the right

-hand side air duct. Fig.

1

The

fluid temperature for each of the headlamp wipe wash operation is controlled by self regulating, heated power

wash jets mounted on to either side of the bumper.

Each powerwash jet is protected by

a cover supplied with an integral cover-to-bumperseal. The cover snap fixes into

the bumper.

15.6.2

This switch only operates with the ignition switch in position '11' and has the following functions:

windscreen Wiper and Washer Switch

Position 0 The wind screen wiper is switched 'OFF' and parked.

Position 1: Normal speed wiper operation is obtained by pushing the switch lever up one position.

Position 2: High speed wiper operation is obtained by pushing the switch lever fully up.

Position D: To obtain intermittent wiper operation the switch lever is pushed down and released.

The delay period will vary with vehicle speed. To cancel the function repeat the procedure.

15.6.2.1 Single Wipe Operation

To obtain a single sweep of the wiper blade, the lever is pulled towards the steering wheel and released.

W The intermittenmick wipe operations are both at slow speed and they are controlled by a Central Control

Module (CCM), which also controls the headlamp power wash operation.

Issue 1 August 1994 X300 VSM

Page 360 of 521

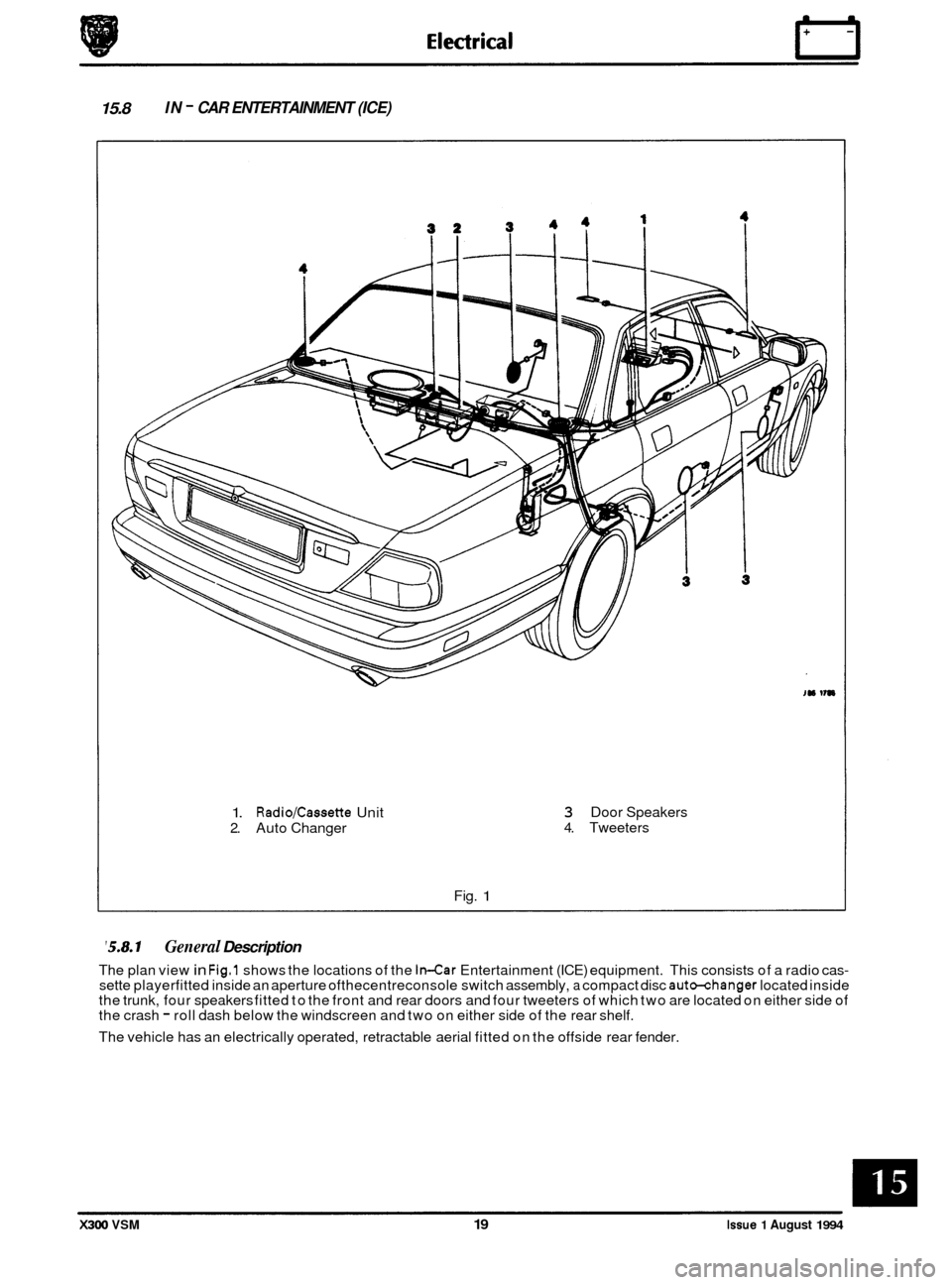

15.8 IN - CAR ENTERTAINMENT (ICE)

0

1. Radio/Cassette Unit

2. Auto Changer

Fig.

1

3 Door Speakers

4. Tweeters

'5.8.1 General Description

The plan view in Fig.1 shows the locations of the In-Car Entertainment (ICE) equipment. This consists of a radio cas- sette playerfitted inside an aperture ofthecentreconsole switch assembly, a compact disc auto-changer located inside

the trunk, four speakers fitted to the front and rear doors and four tweeters of which two are located on either side of

the crash

- roll dash below the windscreen and two on either side of the rear shelf.

The vehicle has an electrically operated, retractable aerial fitted on the offside rear fender.

X300 VSM 19 Issue 1 August 1994

Page 361 of 521

rl Electrical

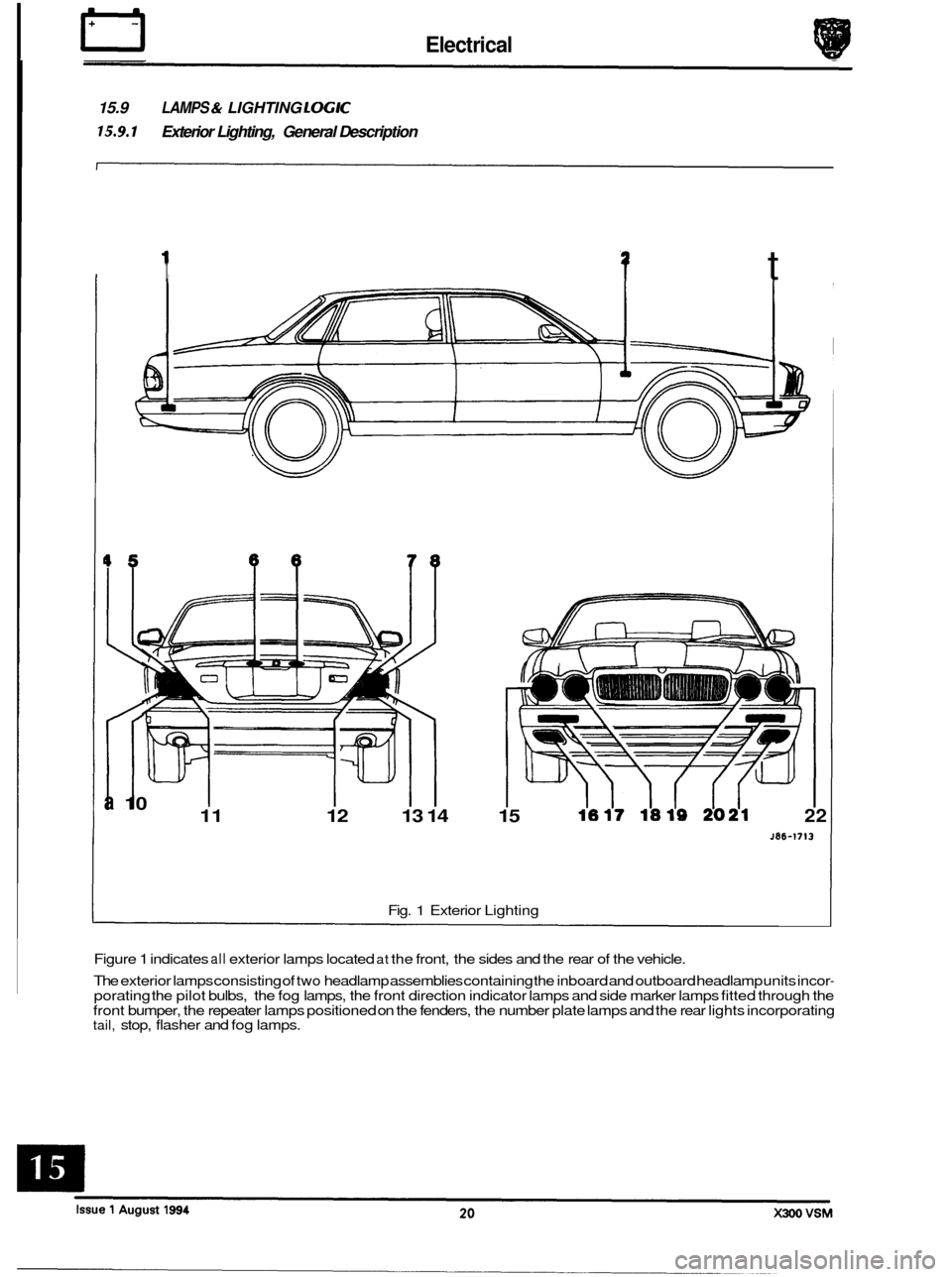

15.9 LAMPS & LIGHTING LOGIC

15.9.1 Exterior Lighting, General Description

1

I t

4

1.1

a ;7 10

11 12 13 14 15 22

J86-1713

Fig. 1 Exterior Lighting

Figure

1 indicates all exterior lamps located at the front, the sides and the rear of the vehicle.

The exterior lamps consisting of

two headlamp assemblies containing the inboard and outboard headlamp units incor- porating the pilot bulbs, the fog lamps, the front direction indicator lamps and side marker lamps fitted through the

front bumper, the repeater lamps positioned on the fenders, the number plate lamps and the rear lights incorporating

tail, stop, flasher and fog lamps.

0

0

0

Page 363 of 521

Electrical

0

15.10 HARNESSES & CABLES

15.10.1 Battery Power Distribution Cabk, General Description

1 2 8

10-

Fig.1 Battery Power Distribution Cables

Figure 1 shows

a plan view of the battery power distribution cables and their distribution points. This illustration is

to be read in conjunction with the following table. To avoid any accidents such as electric shocks, always disconnect

the battery negative lead from the battery negative terminal before disconnecting any of the listed cables.

Page 366 of 521

Electrical I3

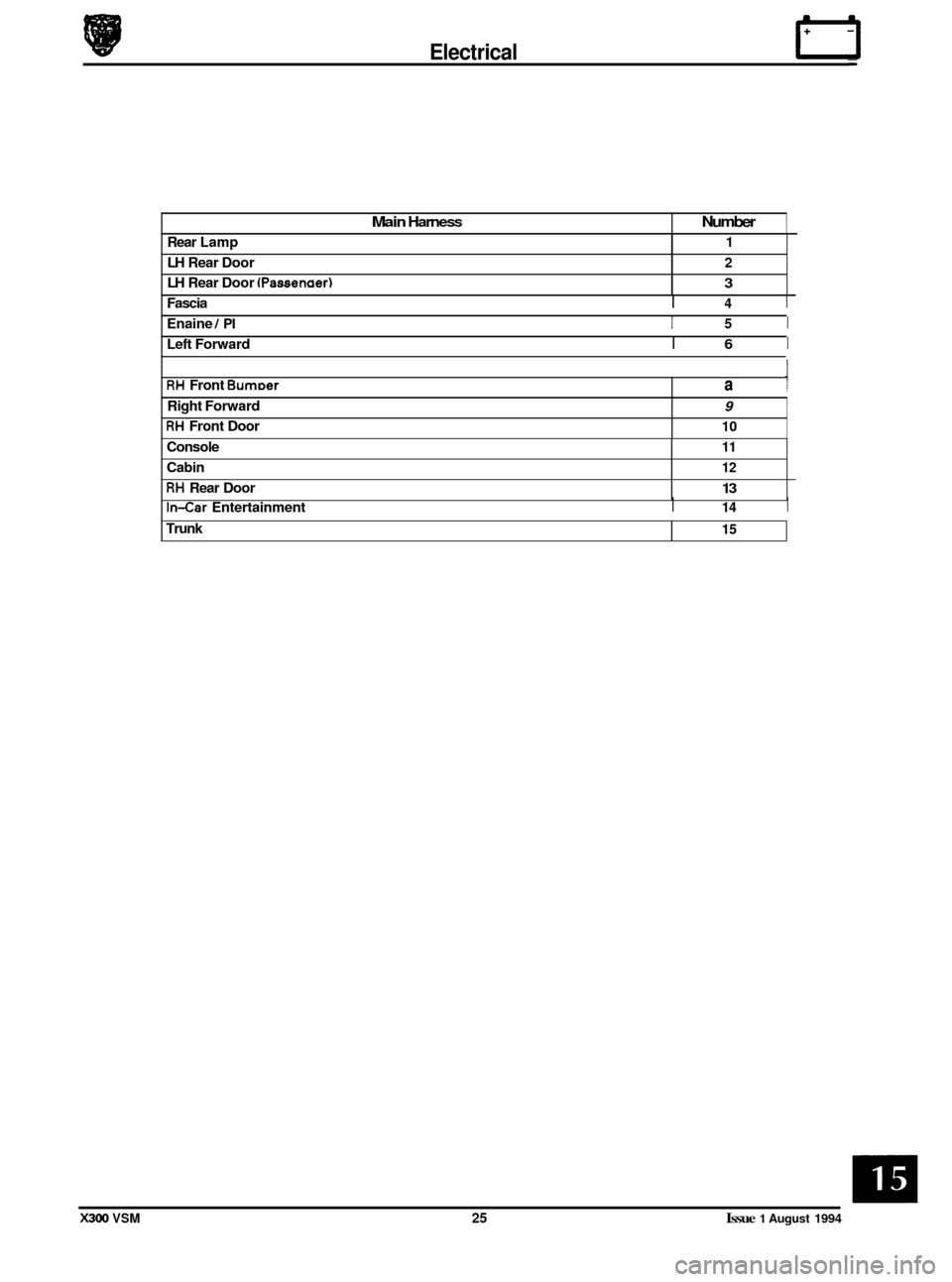

Main Harness Number

Rear Lamp

LH Rear Door

LH Rear Door

(Passenaer)

Fascia I 4 I

1

2

3

Enaine I PI I 5 I

RH Front BumDer

Left Forward I 6 I

a

Right Forward 9

RH Front Door

In-Car Entertainment I 14 I

10

Console

Cabin

RH Rear Door

X300 VSM 25 Issue 1 August 1994

11

12

13

Trunk 15

Page 367 of 521

rl Electrical

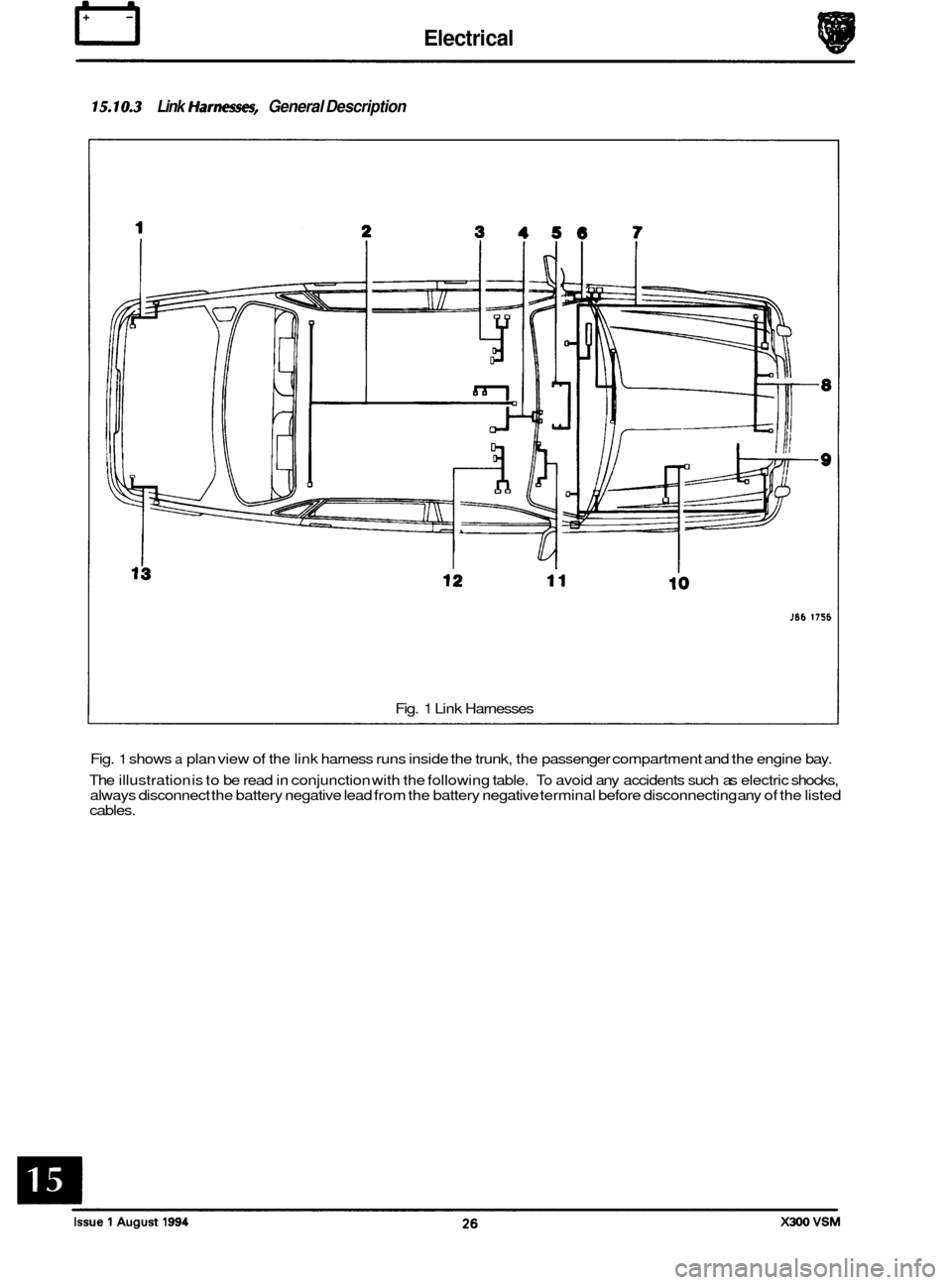

'5.10.3 Link /farnest?$, General Description

Fig. 1 Link Harnesses

Fig.

1 shows a plan view of the link harness runs inside the trunk, the passenger compartment and the engine bay.

The illustration is to be read in conjunction with the following table.

To avoid any accidents such as electric shocks,

always disconnect the battery negative lead from the battery negative terminal before disconnecting any of the listed

cables.

Page 369 of 521

I3 Electrical

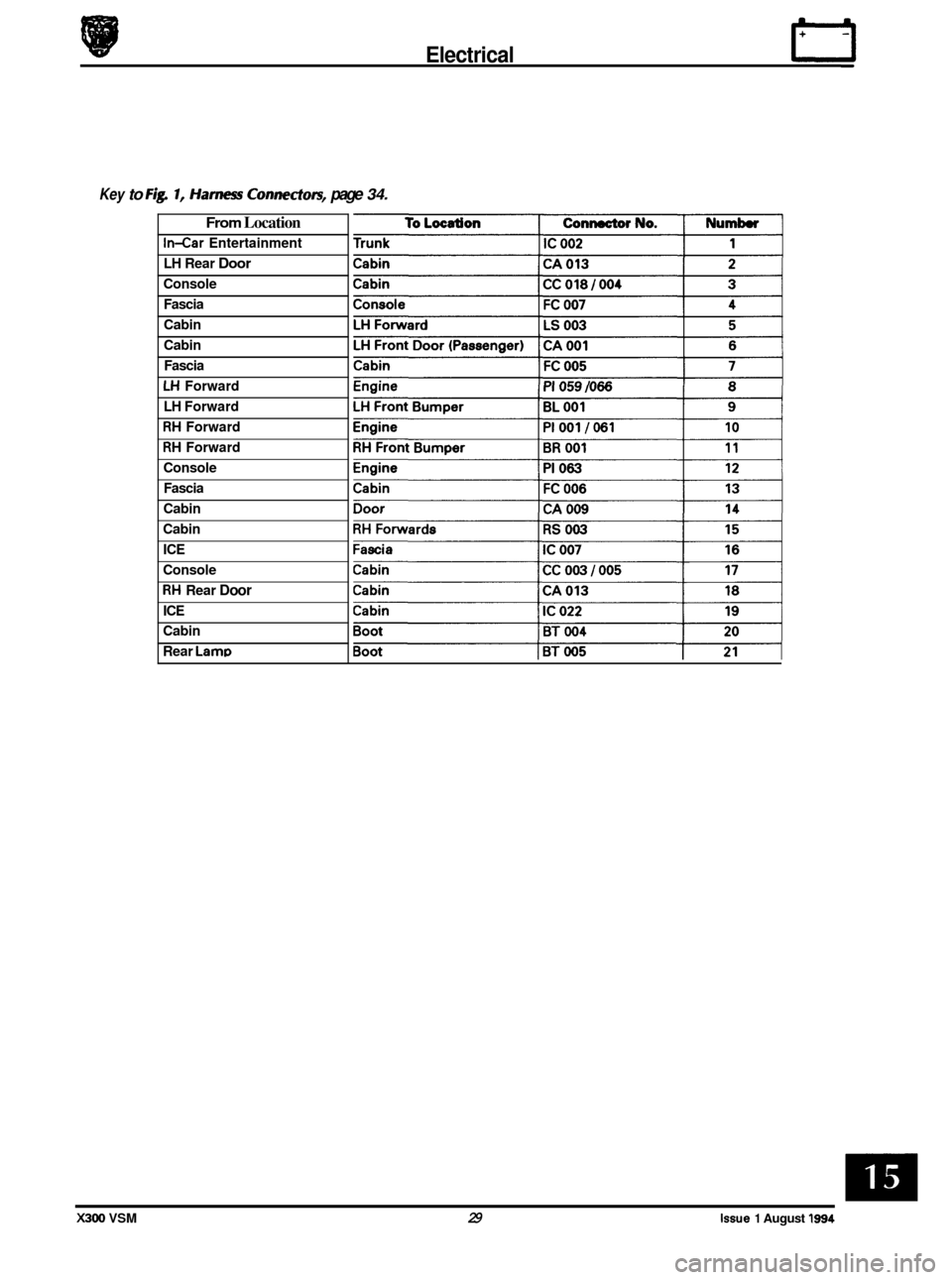

'5.10.4 Hamess Connecton, General Descriptbn

21

1 23 4 7 09

10

Fig. 1 Harness Connectors

Fig.

1 shows a plan view of the harness connectors physically linking all the harnesses located in the trunk, the passen- ger compartment and the engine bay.

The illustration

is to be read in conjunction with the following table. To avoid any accidents such as electric shocks,

always disconnect the battery negative lead from the battery negative terminal before disconnecting any of the listed

cables.

Page 370 of 521

Electrical rl

Key to Fig 1, Hamess Connecton, page 34.

From Location

In-Car Entertainment

LH Rear

Door

Console

Fascia

Cabin

Cabin

Fascia

LH Forward

LH Forward

RH Forward

RH Forward

Console Fascia

Cabin

Cabin ICE

Console

RH Rear Door

ICE

Cabin

Rear

LamD

X300 VSM 29 Issue 1 August 1994

Page 371 of 521

15.11 MOTORS & SOLENOIDS ~

5.1 1.1 General

Description

Electrical

I# b

Fig. 1 Motors & Solenoids

-

1695

Fig. 1 shows a plan view of all motors located inside the trunk, the passenger compartment and the engine bay. The

motors drive various devices to perform certain functions such wipe / wash operations, window lift operations, seat

operations etc.

In order to carry out remove and refit operations, the annotated illustration is to be read in conjunction with the table

shown on the following page. This lists

all the motors and solenoids.

Some motors can be accessed by removing the various trims, the carpet, or carpet sections, other can be located

through carrying out

a visual inspection around the engine bay, the cab and the trunk.

To avoid any accidents such as electric shocks, always disconnect the battery negative lead from the battery negative

terminal before disconnecting any of the listed cables.

Issue 1 August 1994 30 X300 VSM