electrical JAGUAR XJ6 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 254 of 521

Body Components & Trim -

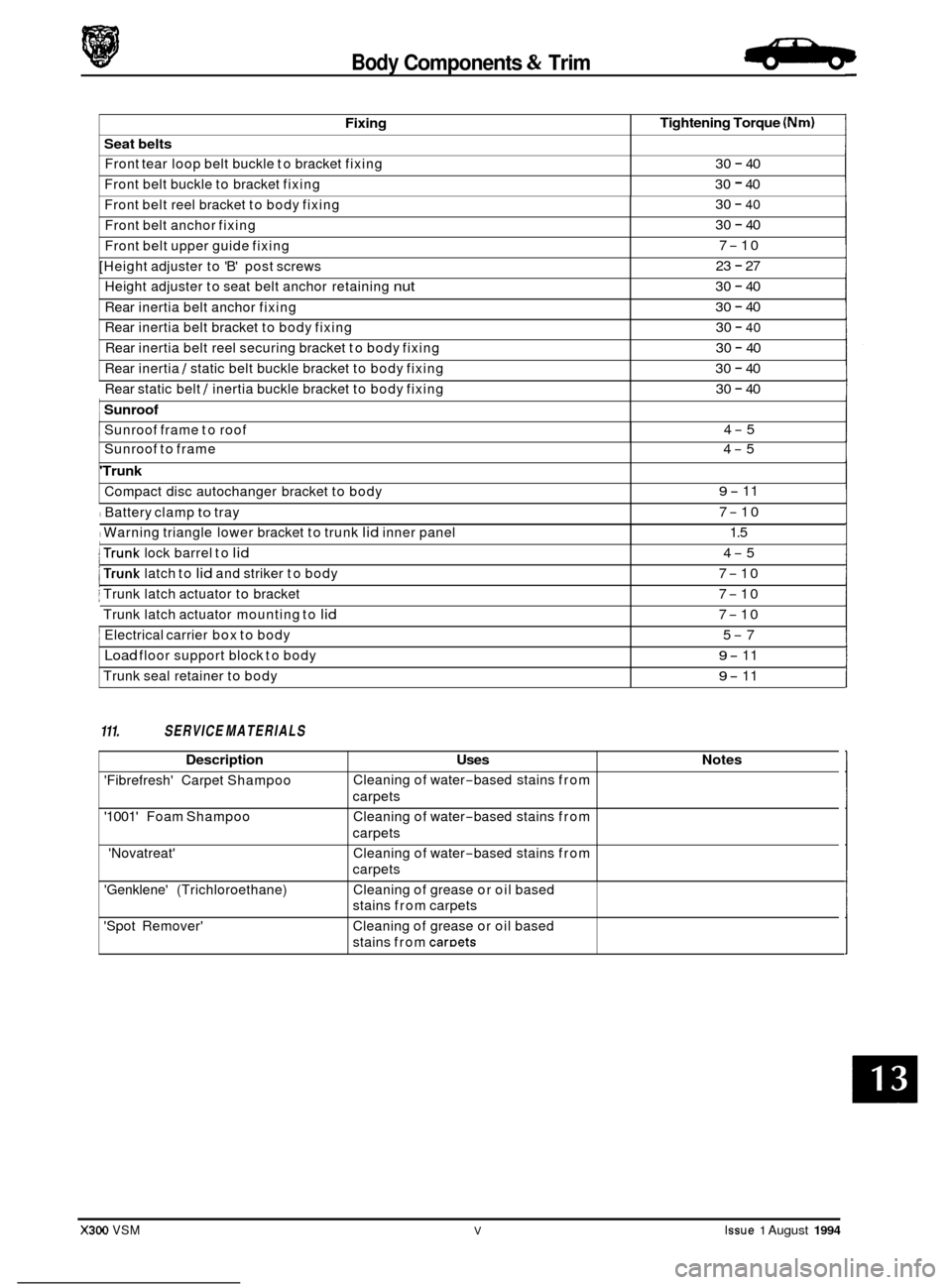

Fixing

Seat belts

Front tear loop belt buckle to bracket fixing

Front belt buckle to bracket fixing

Tightening Torque (Nm)

30 - 40

30

- 40

Front belt reel bracket to body fixing

Front belt anchor fixing 30 - 40

30 - 40

7

-10

23

- 27

30

- 40

30 - 40

30

- 40

30 - 40

30

- 40

Front belt upper guide fixing

[Height adjuster to 'B' post screws

Height adjuster to seat belt anchor retaining

nut

Rear inertia belt anchor fixing

Rear inertia belt bracket to body fixing

Rear inertia belt reel securing bracket to body fixing

Rear inertia

/ static belt buckle bracket to body fixing ~

Rear

static belt / inertia buckle bracket to body fixing

: Sunroof ~

Sunroof frame

to roof

30 - 40

4

-5

111. SERVICE MATERIALS

Sunroof to frame 4-5

'Trunk

Compact disc autochanger bracket to body

I Battery clamp to tray

I Warning triangle lower bracket to trunk lid inner panel

9- 11

7

-10

1.5

X300 VSM V Issue 1 August 1994

I trunk lock barrel to lid

j Trunk latch actuator to bracket

Trunk latch actuator mounting to

lid

j Electrical carrier box to body

Load floor support block to body

Trunk seal retainer to body

trunk latch to lid and striker to body

4-5

7

-10

7

-10

7

-10

5

-7

9- 11

9- 11

Description Uses

'Fibrefresh' Carpet Shampoo

'1001' Foam Shampoo

'Novatreat' Cleaning

of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Notes

'Genklene' (Trichloroethane)

'Spot Remover' Cleaning

of grease or oil based

stains from carpets

Cleaning of grease or oil based

stains from

caroets

Page 256 of 521

Body Components & Trim

13.1 GENERAL DESCRIPTION

This section covers the following areas of the vehicle body:

0 Battery cover

0 Carpets - passenger compartment, trunk

0 Console - including radio, glovebox

0 Doors -frames, sealing, locks, trim, glazing

0 Fascia

0 Fuel filler flap assembly

0 Footrest

0 Hood - liners, gas strut, locking,

0 Illuminated sunvisor - inc mirror

0 Interior trim - trim pads, finishers, veneers

0 Mirrors - internal, external

0 Rear parcel tray

0 Roof console

0 Roof lining (headlining)

o Seats -front, rear -

0 Seat belts - front, rear

0 Sliding roof

0 Steering column cowl

0 Underscuttle pad

Refer to Appendix

A4 - Body Systems & Body Repair for information relating to crash-damage repairs and to the fol- lowing external components: exterior trim, bumpers, windscreen and rear screen, closures and sealing.

Refer to Section 15, Electrical for details of the following motors and solenoids: driver's and interior mirrors, window

lift, sunroof, seat / headrest and locking mechanisms (doors, trunk and filler cap).

Refer to Section 15, Electrical and Electrical Diagnostic Manual (EDM) for details of the passenger and driver airbags.

X300 VSM 1 Issue 1 August 1994

Page 293 of 521

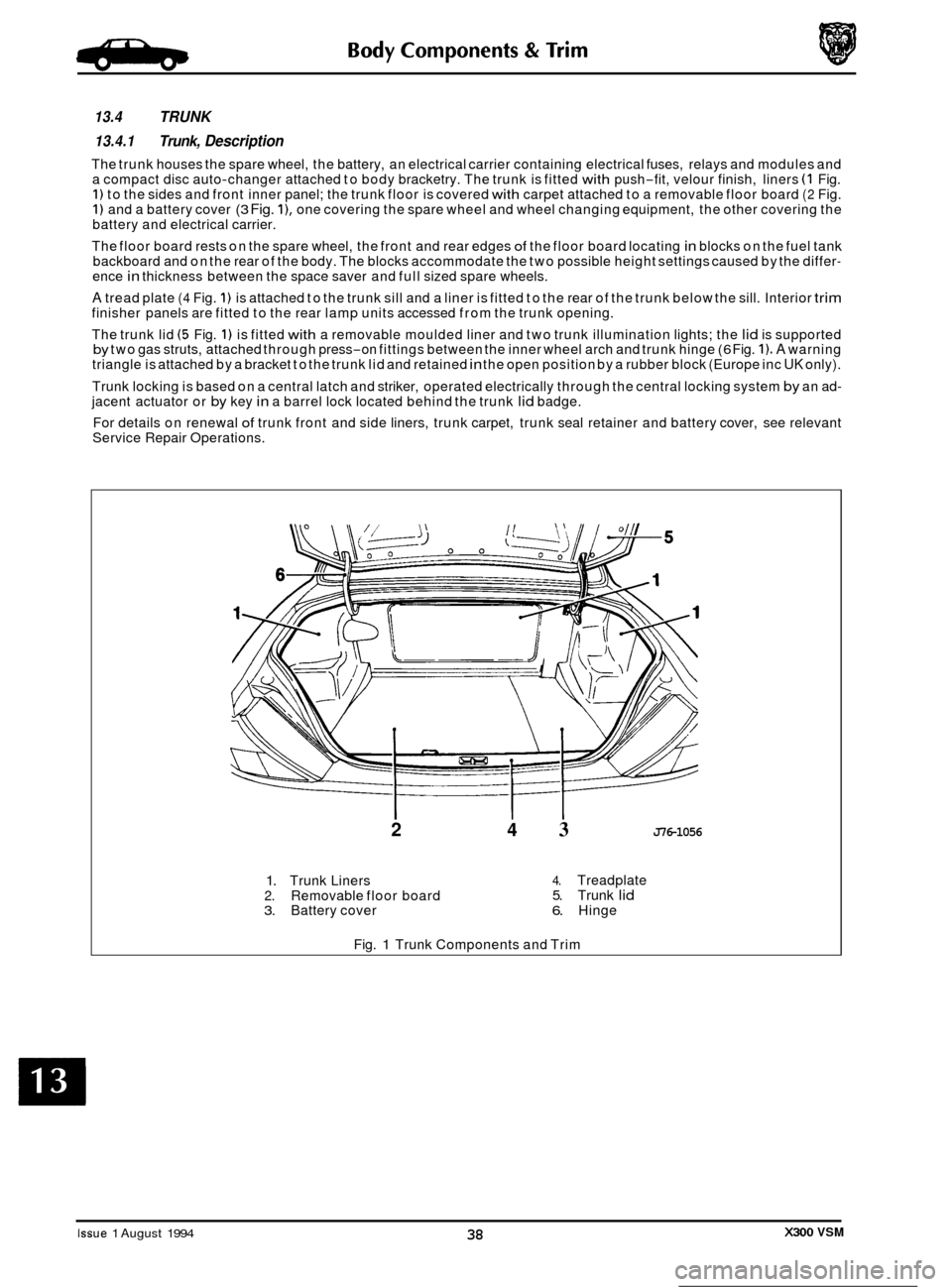

13.4 TRUNK

13.4.1 Trunk, Description

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and

a compact disc auto-changer attached to body bracketry. The trunk is fitted with push-fit, velour finish, liners (1 Fig. 1) to the sides and front inner panel; the trunk floor is covered with carpet attached to a removable floor board (2 Fig. 1) and a battery cover (3 Fig. I), one covering the spare wheel and wheel changing equipment, the other covering the

battery and electrical carrier.

The floor board rests on the spare wheel, the front and rear edges

of the floor board locating in blocks on the fuel tank

backboard and on the rear of the body. The blocks accommodate the two possible height settings caused by the differ- ence in thickness between the space saver and full sized spare wheels.

A tread plate (4 Fig. 1) is attached to the trunk sill and a liner is fitted to the rear of the trunk below the sill. Interior trim finisher panels are fitted to the rear lamp units accessed from the trunk opening.

The trunk lid

(5 Fig. 1) is fitted with a removable moulded liner and two trunk illumination lights; the lid is supported by two gas struts, attached through press-on fittings between the inner wheel arch and trunk hinge (6 Fig. 1). A warning

triangle is attached by a bracket to the trunk lid and retained in the open position by a rubber block (Europe inc UK only).

Trunk locking is based on a central latch and striker, operated electrically through the central locking system

by an ad- jacent actuator or by key in a barrel lock located behind the trunk lid badge.

For details on renewal

of trunk front and side liners, trunk carpet, trunk seal retainer and battery cover, see relevant

Service Repair Operations.

2 4 3 J76-1056

1. Trunk Liners 2. Removable floor board 3. Battery cover

4. Treadplate 5. Trunk lid 6. Hinge

Fig.

1 Trunk Components and Trim

Issue 1 August 1994 X300 VSM 38

Page 303 of 521

Body Components & Trim a

13.8 SEATING AND SEAT BELTS

13.8.1 Seating, Description

The front seats are available in a range of materials consisting of sculptured fabric / leather, leather, sports cloth / leather, embossed leather / leather and autolux. Both seats are available as 'manual', ie manually adjustable with elec- tric rise and fall, manual height adjustment headrests, 'power', ie 12-way electric adjustment, 'power with memory', ie memory controlled, 12-way electric adjustment of seat, steering column and exterior rear view mirrors and 'heated',

ie with integral heating.

Front seats are based on a non

-handed, one-piece frame which includes cushion and squab frames and seat adjuster

mechanisms. The seat switchpacks (powerseats) are fitted to the outboard side of driver and passenger seats; on 'man- ual'seats, the seat height adjustment switch is similarly located. Seat control modules SCMs are contained within the

seat assemblies. The seats are secured through four mounting points to the vehicle floor.

Rear seats are of the bench type with

full width removable cushion and individual seat squabs.

Electrical components installed on the heel board below the rear passenger seat are protected

by two covers secured

by two locating brackets on the floor and by two latches on the cover. The latches are released by pushing down on

the two recesses in the top edge of the cover.

13.8.2 Front Manual Seat, Renew

. Disconnect vehicle battery ground lead.

. Disconnect electrical connections as required.

. Remove the seat forward fixings.

Move the seat fully forward.

. Remove the rear fixing / slide covers.

. Remove the seat rear fixings.

. Reposition seat for access and remove seat from vehicle.

. To refit seat, carry out reversal of above procedure.

13.8.3

. Disconnect vehicle battery ground lead.

. Move the seat fully forward to gain access to squab back

Remove squab side fixings, disconnect lamp harness and

. To refit, carry out reversal of the above procedure.

Front Seat (Power Operated) Squab Back

Cover, Renew

cover outer fixings.

remove squab back cover.

13.8.4

. Position seat as required for access.

. Disconnect vehicle battery ground lead.

. Release sound insulation retainers and displace insula-

. Remove SCM cover, move SCM aside and remove seat

. Remove the seat forward fixings and move the seat fully

. Remove the seat rearward fixing covers and remove the

. Disconnect multi-plugs, seat switch and motor harness to

. Release harness tie strap and remove seat assembly from

Front Seat (Power Operated), Renew

tion.

switch

multi-plug from its mounting bracket.

forward. seat rearward fixings.

SCM.

vehicle.

. To refit, carry out reversal of the above procedure, ensur- ing that fixings are tightened to the correct torque.

Issue 1 August 1994 48 X300 VSM

0

0

0

Page 306 of 521

Body Components & Trim

13.8.10 Tear loop Seat Belts, Description

The tear loop seat belt (Fig.1) is used to control the rate of forward travel of the occupant towards the deployed airbag

(the airbag is covered in Section 15, Electrical). The tear loop assembly is designed to release additional webbing when

the stitching, which retains the webbing loops, breaks under

a predetermined load. The wires (1 Fig. 1) within the as- sembly have the following functions:

0 To protect the stitching from 'normal' loads such as heavy braking or cornering.

o To control the rate of deployment.

0 To support the extended head following deployment.

When the passenger unit has been activated, the buckle will extend from the shroud and reveal

a warning label (2 Fig. 1); the extent of deployment will depend upon the severity of the load.

-: IF THE LABEL IS VISIBLE AT ALL (3 FIG. 3). THE COMPLETE ASSEMBLY MUST BE RENEWED, AS MUST

ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT.

2

Fia. 1 Tear LOOO Seat Belt

X300 VSM 51 Issue 1 August 1994 ~~

Page 318 of 521

Climate Control Systems

8. AUTO selection display.

9. EXTERIOR temperature selection button. There are two modes:

a) Press and immediate release; provides timed display of four (4) seconds.

b) Press and hold for two (2) seconds; 'latches' the mode until operator over-ride.

10. A/C push-on / push-off button will either engage or disengage (as indicated by the state lamp) the refrigeration

system compressor. The state lamp is also used as a compressor speed fault indicator,see System protection, this

section.

11. AUTO push-on button and state lamp. When selected and the state lamp lit, the A/C mode is selected and control

of demand temperature, fans speed, and air distribution is automatic. AUTO is cancelled by selection of any 'dis- tribution' button, A/C off, or manual FANS SPEED.

12. DEFROST push

-on / push-off button and state lamp. When engaged, air is distributed to the screen at maximum

fans speed and the heated front screen elements (where fitted) are ener ized. The heated front screen is automati- cally timed for a six (6) minute cycle but may be cancelled by pressing tfe HEATED FRONT SCREEN button. Auto- matic temperature control is retained and the fans speed may be manually reduced. Deselection will return the

system to the previous state and selection of AUTO will resume automatic system control.

13. The push

-on / push-off (F) button with state lamp manually controls the HEATED FRONT SCREEN (where fitted).

This facility allows rapid screen de-icing using laminated electrical heating elements to supplement the hot air

defrost.

14. The push-on / push-off (R) button with state lamp manually controls the HEATED REAR SCREEN and door mirror

glass heating elements for a timed cycle of; screen twenty (20) minutes and mirrors eleven (1 1) minutes.

m: The state lamp will remain lit after the mirror timer has gone through its 11 minute cycle and will not go out

until either completion of the 20 minute screen cycle or manual override.

15. TEMPERATURE decrease button

in IoC or I0F steps.

16. TEMPERATURE increase button in

IoC or I0F steps.

w: Automatic temperature control operates over the range 17OC to 31OC (61OF to 90OF). Extreme limits selected

by items 15 and 16 ('Lo' and 'Hi') provide maximum cooling or heating at maximum fans speed.

17. FACE level manual distribution over

-ride push-on / push-off button and state lamp.

0 18. Bi LEVEL (foot and face) manual distribution over-ride push-on / push-off button and state lamp.

19. FOOT level manual distribution over

-ride push-on / push-off button and state lamp.

20. DEMIST (screen and foot) level manual distribution over

-ride push-on / push-off button and state lamp.

!Y&Q: Selection of AUTO will over-ride any manual setting and deselection of any manual distribution will revertthe

system to AUTO distribution.

21. FACE VENTTEMPERATURE CONTROL thumb

-wheel. Situated between dash centre face level vents to reduce face

air outlet temperature relative to that of the foot-well.

Issue 1 August 1994 X300 VSM 5

Page 319 of 521

Climate Control Systems

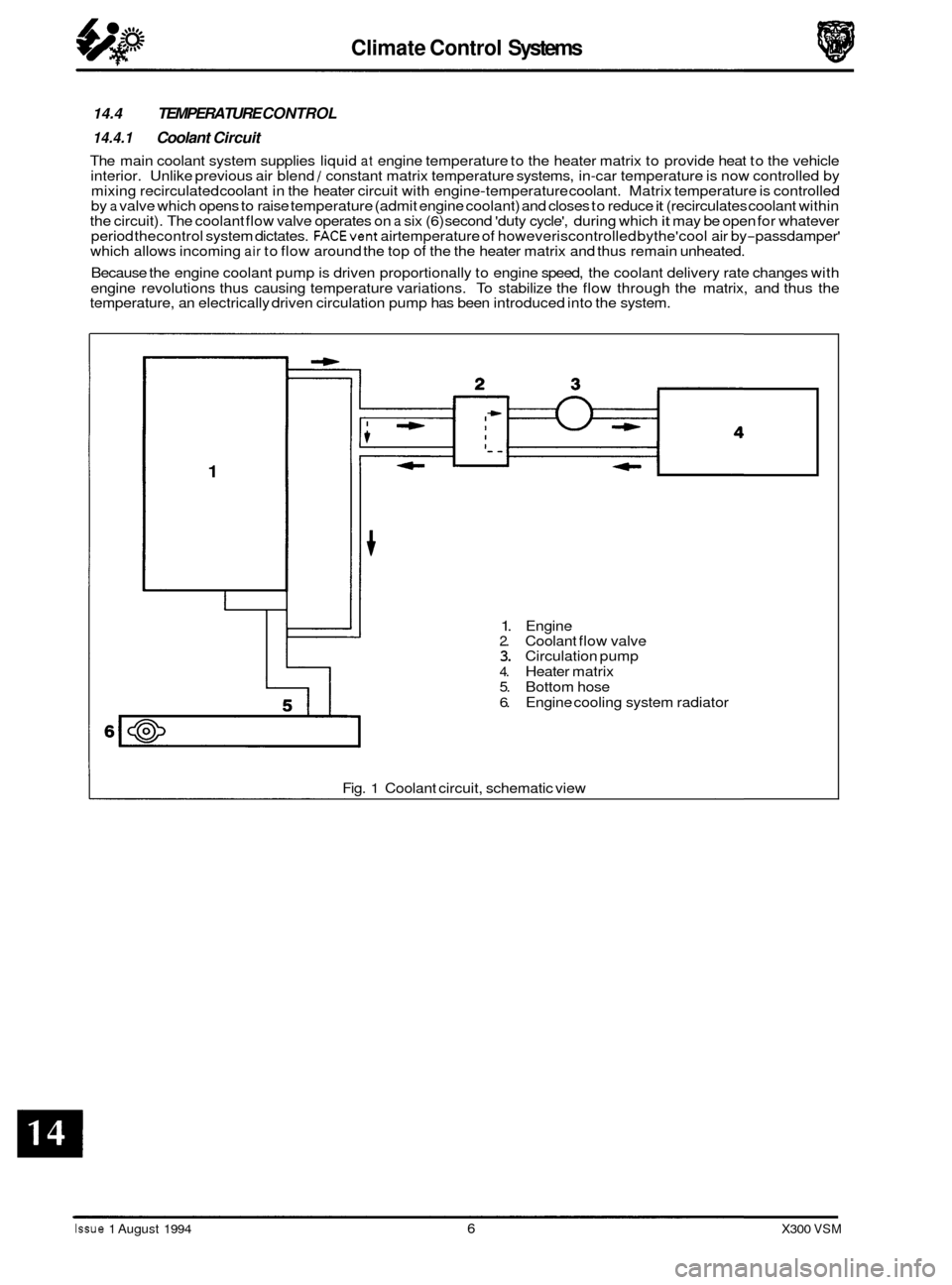

14.4 TEMPERATURE CONTROL

14.4.1 Coolant Circuit

The main coolant system supplies liquid at engine temperature to the heater matrix to provide heat to the vehicle

interior. Unlike previous air blend / constant matrix temperature systems, in-car temperature is now controlled by

mixing recirculated coolant in the heater circuit with engine-temperature coolant. Matrix temperature is controlled

by a valve which opens to raise temperature (admit engine coolant) and closes to reduce it (recirculates coolant within

the circuit). The coolant flow valve operates on a six (6) second 'duty cycle', during which it may be open for whatever

period thecontrol system dictates. FACEvent airtemperature of howeveriscontrolled bythe'cool air by-passdamper'

which allows incoming air to flow around the top of the the heater matrix and thus remain unheated.

Because the engine coolant pump is driven proportionally to engine speed, the coolant delivery rate changes with

engine revolutions thus causing temperature variations. To stabilize the flow through the matrix, and thus the

temperature, an electrically driven circulation pump has been introduced into the system.

1

1. Engine 2. Coolant flow valve 3. Circulation pump

4. Heater matrix

5. Bottom hose

6. Engine cooling system radiator

Fig.

1 Coolant circuit, schematic view

Issue 1 August 1994 6 X300 VSM

Page 322 of 521

Climate Control Systems

CONTROL MODULE FAULT & CONDITION SELF-ANALYSIS

0 14.6 14.6.1 System Health

The climate control system has a 'self-test' facility, accessible from the control panel. The self test sequence has two

basic modes:

0 System error information is stored in the A/CCM up to a maximum of five faults. Should a fault occur there will

be an audible 'beep' and the message 'Er' will be displayed on the control panel LCD for approximately five (5)

seconds after ignition on. Please note that this will happen only once in any ignition switch cycle. The error

source may be accessed by the procedure described in 'Self Test System Diagnosis', this section.

0 Panel communication check may be initiated by following the instruction in 'Self Test System Diagnosis', this

section.

Nsfe: Displayed error codes are NOT directly related to Jaguar Diagnostic Equipment (JDE) but more detailed fault

related information may be accessed using Portable Diagnostic Unit (PDU).

14.6.2 System Protection

Power to the compressor clutch may be cut should either the engine management or air conditioning control systems

detect certain conditions; these conditions may be caused by Fault or Demand and can be classified thus:

0 Engine coolant overheat,

0 Refrigerant excessive pressure.

0 Refrigerant, insufficient pressure or low charge weight.

0 Speed differential between compressor and crankshaft caused by belt slippage or compressor seizure (indi-

cated by A/C state lamp flashing once per second) - 12 cylinder engine only. This feature, 'lock sensing' is fully

explained

in the EDM.

Demand

0 Engine maximum power requirement

0 Electrical system drain at engine idle.

X300 VSM 9 Issue 1 August 1994

Page 323 of 521

Climate Control Systems

14.7 AIR DlSTRlBUTlON

(Refer to illustrations on this and next page)

Air is drawn from the plenum chamber into the heater/cooler case at the lower front right and left hand sides. All air must first pass through the evaporator (not fitted to heater only cars) and then through the heater matrix for in-car distribution.

When cooler air than that available from the other outlets is desired at the FACE vents, air by

-passes the matrix via

the 'cool air by-pass damper' within the range cold to hot.

The flaps for FOOT, COOL AIR, CENTRE VENT, RH & LH RECIRCULATION and DEFROST are electrically driven by indi- vidual motor / potentiometer units.

1. Face outlet

2. Defrost outlet

3. End-of-dash outlet 4. Cool air by-pass damper

5. Evaporator

6. Air in 7. Foot outlet (front)

8. Foot outlet (rear)

9. Rear face outlet 10. Heater matrix

J82-49L

Fig. 1

\d J82-495 \d J82-L96

(Solid arrow = Hot, Line arrow = Cold)

Fig. 2

0

0

0

0

Issue 1 August 1994 10 X300 VSM

Page 325 of 521

Climate Control Systems

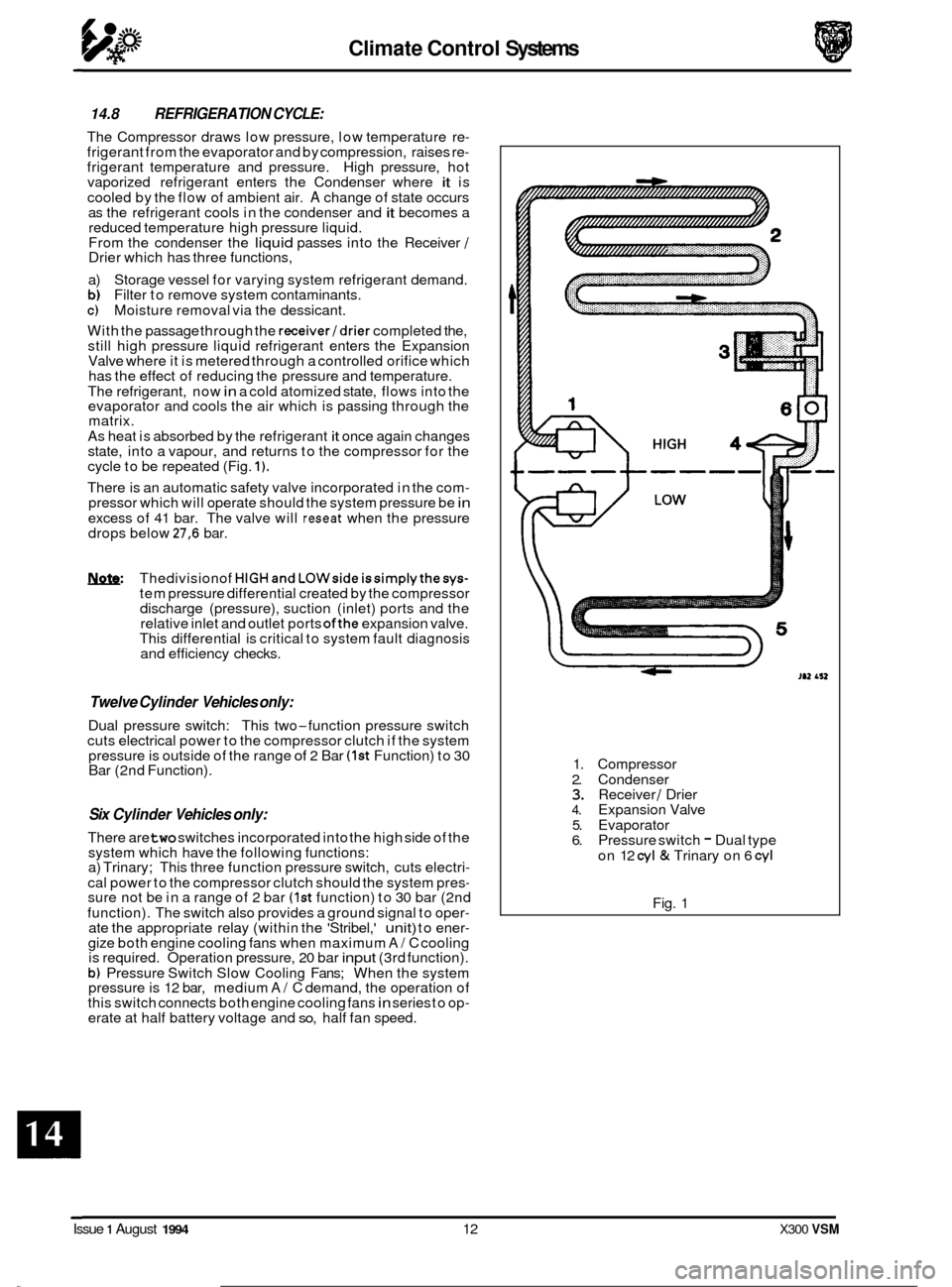

14.8 REFRIGERATION CYCLE:

The Compressor draws low pressure, low temperature re- frigerant from the evaporator and by compression, raises re- frigerant temperature and pressure. High pressure, hot

vaporized refrigerant enters the Condenser where it is

cooled by the flow of ambient air.

A change of state occurs

as the refrigerant cools in the condenser and it becomes a

reduced temperature high pressure liquid.

From the condenser the

liquid passes into the Receiver / Drier which has three functions,

a) Storage vessel for varying system refrigerant demand.

b) Filter to remove system contaminants. c) Moisture removal via the dessicant.

With the passage through the

receiver/drier completed the,

still high pressure liquid refrigerant enters the Expansion

Valve where it is metered through a controlled orifice which

has the effect of reducing the pressure and temperature.

The refrigerant, now

in a cold atomized state, flows into the

evaporator and cools the air which is passing through the

matrix.

As heat is absorbed by the refrigerant

it once again changes

state, into a vapour, and returns to the compressor for the

cycle to be repeated (Fig.

1).

There is an automatic safety valve incorporated in the com- pressor which will operate should the system pressure be in

excess of 41 bar. The valve will reseat when the pressure

drops below 27,6 bar.

W Thedivisionof HIGHandLOWsideissimplythesys- tem pressure differential created by the compressor

discharge (pressure), suction (inlet) ports and the

relative inlet and outlet ports

ofthe expansion valve.

This differential is critical to system fault diagnosis

and efficiency checks.

Twelve Cylinder Vehicles only:

Dual pressure switch: This two-function pressure switch

cuts electrical power to the compressor clutch if the system

pressure is outside of the range

of 2 Bar (1st Function) to 30

Bar (2nd Function).

Six Cylinder Vehicles only:

There are two switches incorporated into the high side of the

system which have the following functions:

a) Trinary; This three function pressure switch, cuts electri

-

cal power to the compressor clutch should the system pres- sure not be in a range of 2 bar (1st function) to 30 bar (2nd

function). The switch also provides a ground signal to oper

- ate the appropriate relay (within the 'Stribel,' unit) to ener- gize both engine cooling fans when maximum A/ C cooling

is required. Operation pressure, 20 bar input (3rd function).

b) Pressure Switch Slow Cooling Fans; When the system

pressure is 12 bar, medium A/ C demand, the operation of

this switch connects both engine cooling fans in series to op- erate at half battery voltage and so, half fan speed. 1.

Compressor

2. Condenser

3. Receiver / Drier 4. Expansion Valve

5. Evaporator

6. Pressure switch - Dual type

on 12

cyl & Trinary on 6 cyl

Fig. 1

0

0

Issue 1 August 1994 12 X300 VSM