lock JAGUAR XJ6 1994 2.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 302 of 521

Body Components & Trim

la 'Fi brefresh'

Ib '1001 Foam Shampoo'

Ic 'Novatreat'

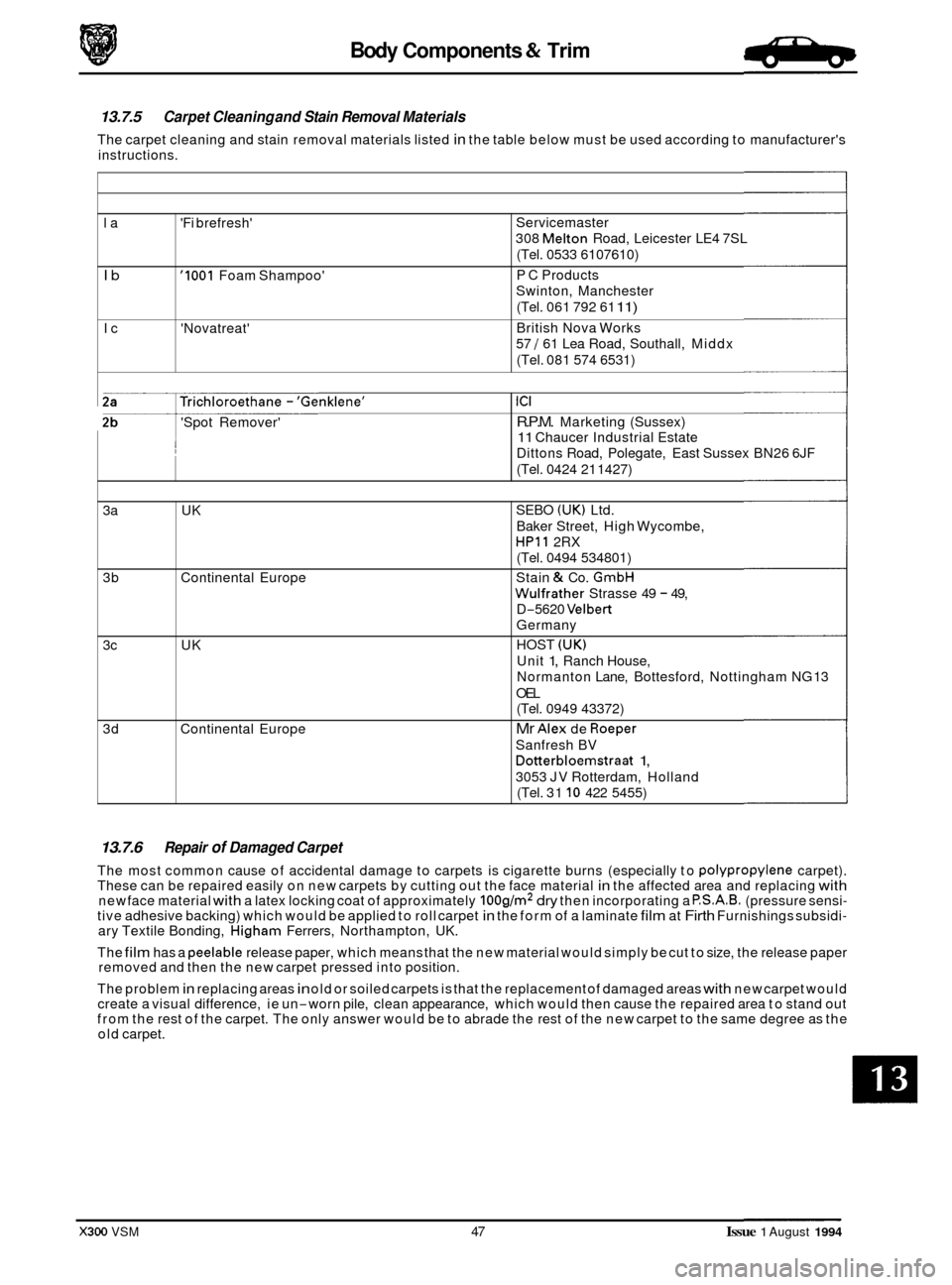

13.7.5 Carpet Cleaning and Stain Removal Materials

The carpet cleaning and stain removal materials listed in the table below must be used according to manufacturer's

instructions.

Servicemaster

308

Melton Road, Leicester LE4 7SL

(Tel. 0533 6107610)

P C Products

Swinton, Manchester

(Tel. 061 792 61

11)

British Nova Works

57

/ 61 Lea Road, Southall, Middx

(Tel. 081 574 6531)

Trichloroethane - 'Genklene'

'Spot Remover' ~

ICI

R.P.M. Marketing

(Sussex)

11 Chaucer Industrial Estate

Dittons Road, Polegate, East Sussex BN26 6JF

(Tel. 0424 21 1427)

13.7.6 Repair of Damaged Carpet

The most common cause of accidental damage to carpets is cigarette burns (especially to polypropylene carpet).

These can be repaired easily on new carpets by cutting out the face material in the affected area and replacing with new face material with a latex locking coat of approximately 100g/m2 dry then incorporating a P.S.A.B. (pressure sensi- tive adhesive backing) which would be applied to roll carpet in the form of a laminate film at Firth Furnishings subsidi- ary Textile Bonding, Higham Ferrers, Northampton, UK.

The

film has a peelable release paper, which means that the new material would simply be cut to size, the release paper

removed and then the new carpet pressed into position.

The problem

in replacing areas in old or soiled carpets is that the replacement of damaged areas with new carpet would

create a visual difference, ie un-worn pile, clean appearance, which would then cause the repaired area to stand out

from the rest of the carpet. The only answer would be to abrade the rest of the new carpet to the same degree as the

old carpet.

3a

UK

3b Continental Europe

3c UK

3d Continental Europe

X300 VSM 47 Issue 1 August 1994

SEBO (UK) Ltd.

Baker Street, High Wycombe,

HPll 2RX

(Tel. 0494 534801)

Stain

& Co. GmbH

Wulfrather Strasse 49 - 49,

D

-5620 Velbert

Germany

HOST

(UK)

Unit 1, Ranch House,

Normanton Lane, Bottesford, Nottingham NG 13

OEL (Tel. 0949 43372)

Mr Alex de Roeper

Sanfresh BV

Dotterbloemstraat 1,

3053 JV Rotterdam, Holland

(Tel. 31

10 422 5455)

Page 304 of 521

Body Components & Trim

13.8.5

Renew

Front Seaf Head Restraint (Power Operated),

. Recline the seat to give access to the head restraint from

. Disengage the head restraint from its retainers with a

= To refit, carry out reversal of the above procedure, ensur-

the rear.

sharp upward

pull.

ing that the restraint is fully locked in position.

13.8.6 Rear Seaf Cushion, Renew

. Release the seat cushion quick release fittings.

. Remove the seat cushion from the vehicle.

To refit, carry out reversal of the above procedure.

13.8.7 Rear Seat Squab, Renew

. Release the rear seat cushion quick release fittings and re-

. Release the rear squab fixings and remove the squab.

. Move the rear seat belts aside and remove the squab as-

. Remove the armrest from the squab assembly.

. Remove the seat belt stowage pocket.

To refit, carry out reversal of the above procedure.

move

the cushion.

sembly from the vehicle.

Issue 1 August 1994 X300 VSM 49

Page 305 of 521

Body Components & Trim .Birpa,

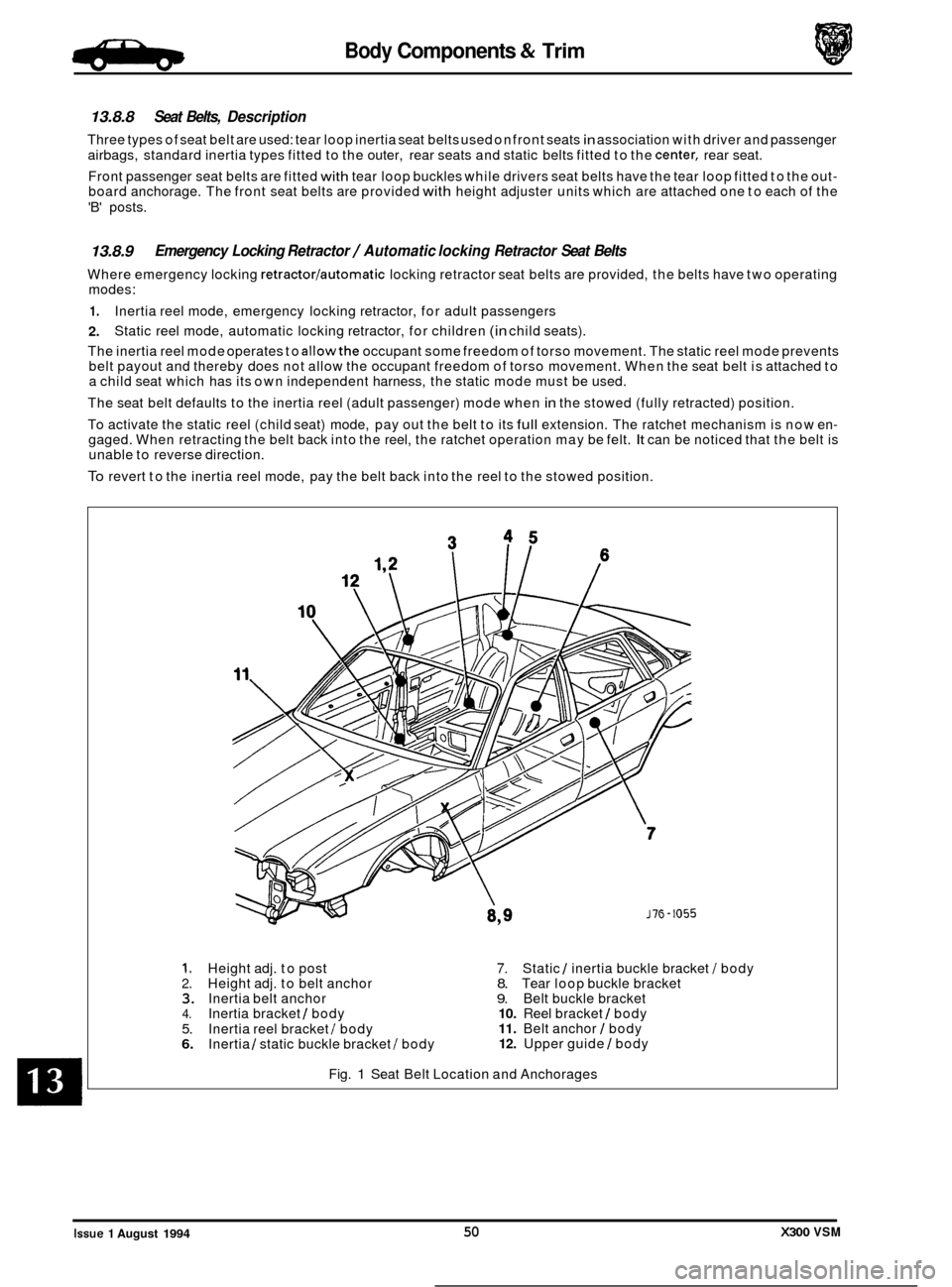

13.8.8 Seat Belts, Description

Three types of seat belt are used: tear loop inertia seat belts used on front seats in association with driver and passenger

airbags, standard inertia types fitted to the outer, rear seats and static belts fitted to the

center, rear seat.

Front passenger seat belts are fitted

with tear loop buckles while drivers seat belts have the tear loop fitted to the out- board anchorage. The front seat belts are provided with height adjuster units which are attached one to each of the

'B' posts.

13.8.9

Where emergency locking retractorlautomatic locking retractor seat belts are provided, the belts have two operating

modes:

1.

2.

The inertia reel mode operates to allowthe occupant some freedom of torso movement. The static reel mode prevents

belt payout and thereby does not allow the occupant freedom of torso movement. When the seat belt is attached to

a child seat which has its own independent harness, the static mode must be used.

The seat belt defaults to the inertia reel (adult passenger) mode when

in the stowed (fully retracted) position.

To activate the static reel (child seat) mode, pay out the belt to its

full extension. The ratchet mechanism is now en- gaged. When retracting the belt back into the reel, the ratchet operation may be felt. It can be noticed that the belt is

unable to reverse direction.

To revert to the inertia reel mode, pay the belt back into the reel to the stowed position.

Emergency Locking Retractor / Automatic locking Retractor Seat Belts

Inertia reel mode, emergency locking retractor, for adult passengers

Static reel mode, automatic locking retractor, for children

(in child seats).

1. Height adj. to post 7. Static 1 inertia buckle bracket I body 2. Height adj. to belt anchor 8. Tear loop buckle bracket 3. Inertia belt anchor 9. Belt buckle bracket 4. Inertia bracket / body 10. Reel bracket 1 body

5. 11. Belt anchor I body

6. 12. Upper guide I body

Inertia

reel bracket I body

Inertia 1 static buckle bracket I body

Fig.

1 Seat Belt Location and Anchorages

0

0

Issue 1 August 1994 50 X300 VSM

Page 317 of 521

Climate Control Systems

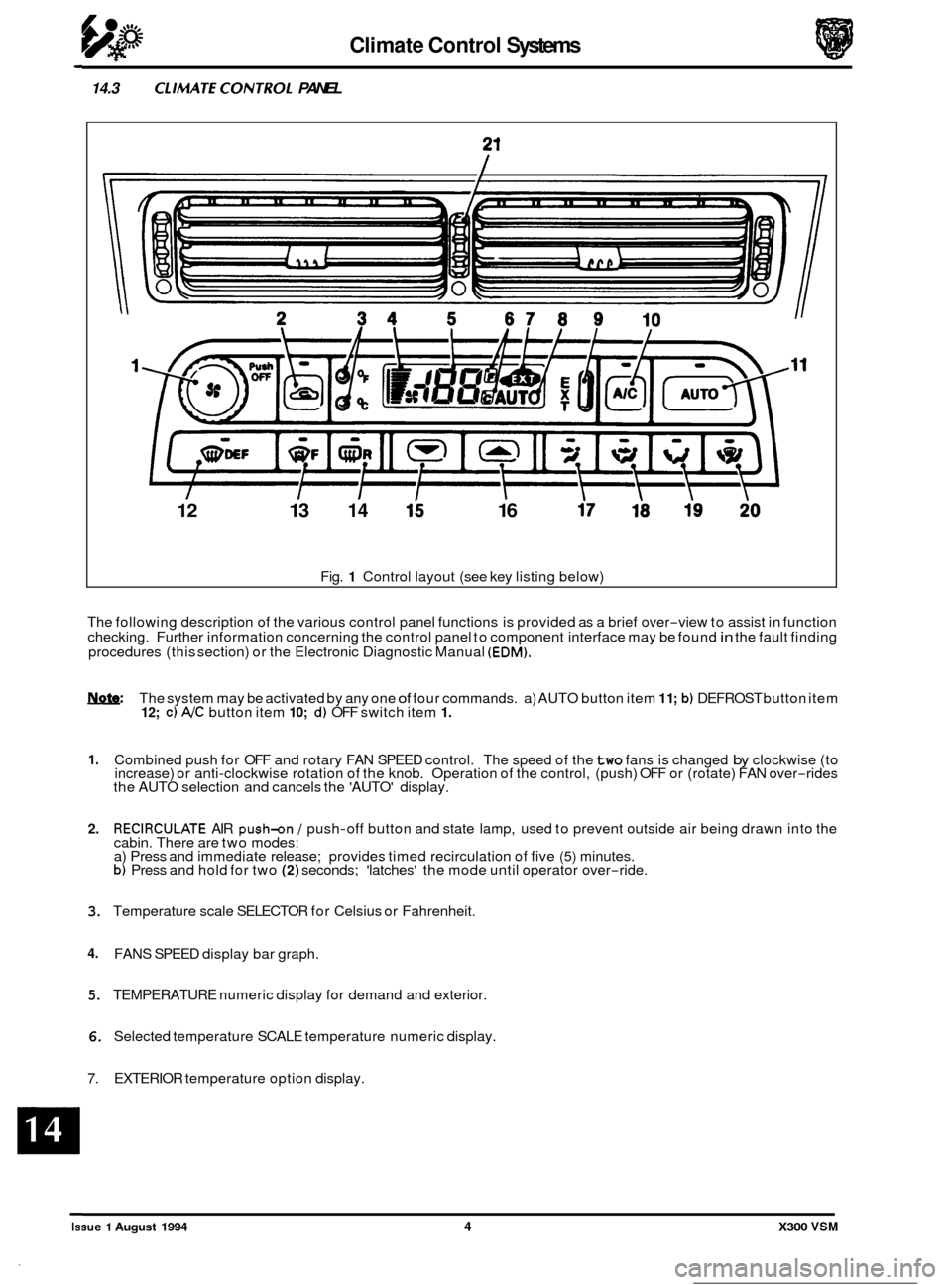

14.3 CLIMATECONTROL PANEL

12 13 14 15 16

Fig. 1 Control layout (see key listing below)

The following description of the various control panel functions is provided as a brief over

-view to assist in function

checking. Further information concerning the control panel to component interface may be found in the fault finding

procedures (this section) or the Electronic Diagnostic Manual (EDM).

Iynfe: The system may be activated by any one of four commands. a) AUTO button item 1 1; b) DEFROST button item 12; c) NC button item 10; d) OFF switch item 1.

1. Combined push for OFF and rotary FAN SPEED control. The speed of the two fans is changed by clockwise (to

increase) or anti-clockwise rotation of the knob. Operation of the control, (push) OFF or (rotate) FAN over-rides

the AUTO selection and cancels the 'AUTO' display.

2. RECIRCULATE AIR push-on / push-off button and state lamp, used to prevent outside air being drawn into the

cabin. There are two modes:

a) Press and immediate release; provides timed recirculation of five

(5) minutes. b) Press and hold for two (2) seconds; 'latches' the mode until operator over-ride.

3. Temperature scale SELECTOR for Celsius or Fahrenheit.

4. FANS SPEED display bar graph.

5. TEMPERATURE numeric display for demand and exterior.

6. Selected temperature SCALE temperature numeric display.

7. EXTERIOR temperature option display.

Issue 1 August 1994 4 X300 VSM

Page 320 of 521

Climate Control Systems

Manual Inputs

Automatic inputs

outputs

14.5 AIR CONDITIONING CONTROL MODULE (A/CCM)

14.5.1 Description

Theclimate control system peripheralscommunicate with theA/CCMvia three main devicecategories, plusthevehicle

power supply and ground connections.

Control panel Face Vent Temperature Control

Temperature and solar sensors

Flap

servo motor potentiometers

Circulation pump

& coolant flow valve

Power

transistor(fan speed control)

Compressor lock sensor

(12 cylinder only)

Instrument pack (coolant temp

& road speed) (engine revolutions via engine control module)

Blower motors (Left

& Right) & associated relays

Flap

servo motors

Heated front

/ rear screens & exterior mirror relays

Motorized in

-car aspirator

Compressor clutch request to engine control module (not

heater-only cars)

Circulation pump relay

Coolant flow valve

X300 VSM Issue 1 August 1994 7

Page 321 of 521

Climate Control Systems

. Centre vent flap

Foot flap

Defrost flap

I I

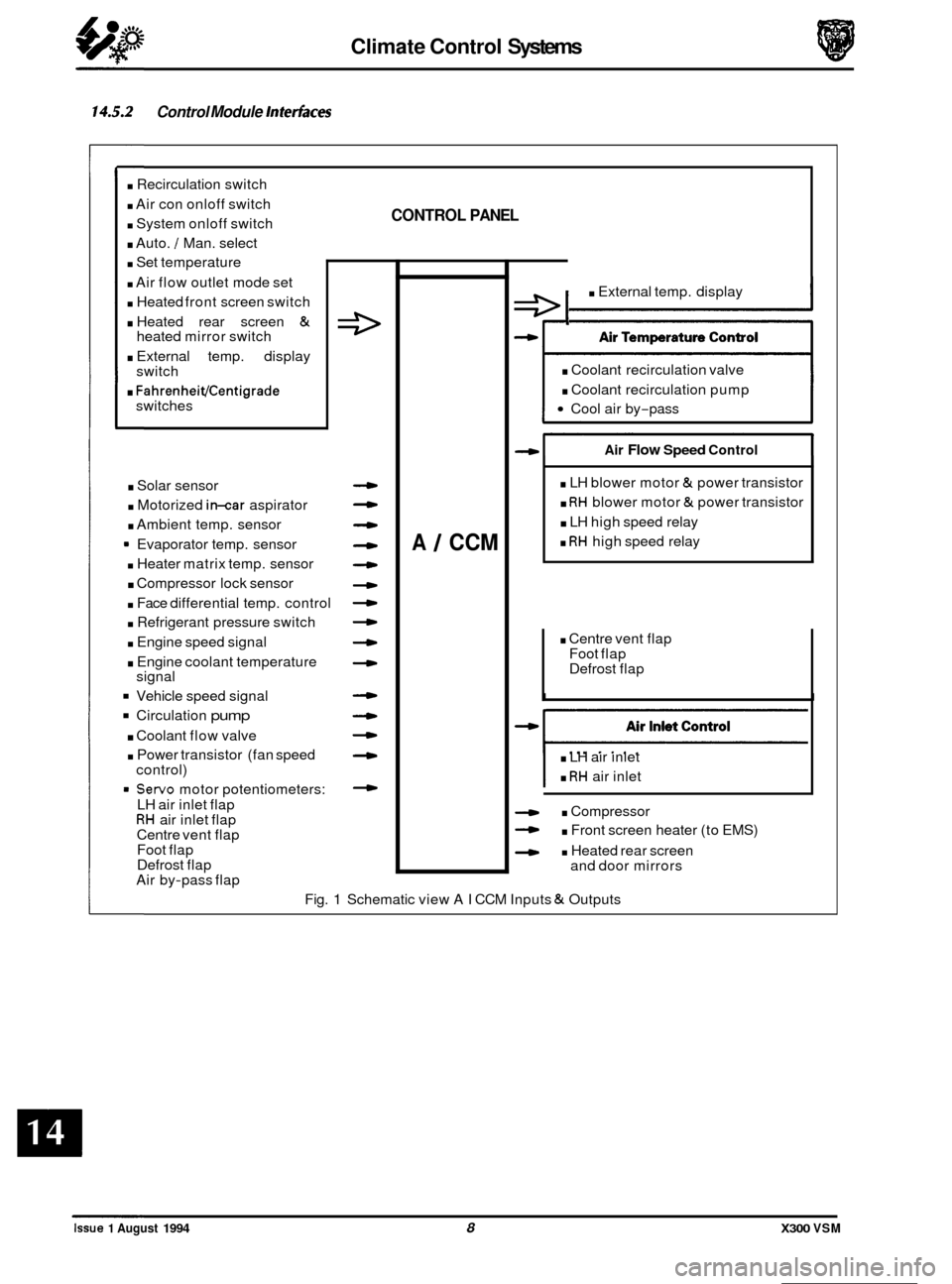

14.5.2 Control Module Interfaces

. Recirculation switch

. Air con onloff switch

. System onloff switch

. Auto. / Man. select

. Set temperature

. Air flow outlet mode set

. Heated front screen switch

. Heated rear screen &

. External temp. display

. FahrenheiVCentigrade

heated mirror switch

switch

switches

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

9 Evaporator temp. sensor

. Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

. Engine coolant temperature

Vehicle speed signal

Circulation pump

. Coolant flow valve

. Power transistor (fan speed

= Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

CONTROL PANEL

4

-

4

4

4

4

4

4

A 1 CCM

e I . External temp. display

. Coolant recirculation valve

. Coolant recirculation pump

Cool air by-pass

Air Flow Speed Control

. LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

. RH high speed relay

. LH air inlet

. RH air inlet

. Compressor

- . Front screen heater (to EMS)

- . Heated rear screen

and door mirrors

Fig.

1 Schematic view AI CCM Inputs & Outputs

0

0

0

0

Issue 1 August 1994 8 X300 VSM

Page 322 of 521

Climate Control Systems

CONTROL MODULE FAULT & CONDITION SELF-ANALYSIS

0 14.6 14.6.1 System Health

The climate control system has a 'self-test' facility, accessible from the control panel. The self test sequence has two

basic modes:

0 System error information is stored in the A/CCM up to a maximum of five faults. Should a fault occur there will

be an audible 'beep' and the message 'Er' will be displayed on the control panel LCD for approximately five (5)

seconds after ignition on. Please note that this will happen only once in any ignition switch cycle. The error

source may be accessed by the procedure described in 'Self Test System Diagnosis', this section.

0 Panel communication check may be initiated by following the instruction in 'Self Test System Diagnosis', this

section.

Nsfe: Displayed error codes are NOT directly related to Jaguar Diagnostic Equipment (JDE) but more detailed fault

related information may be accessed using Portable Diagnostic Unit (PDU).

14.6.2 System Protection

Power to the compressor clutch may be cut should either the engine management or air conditioning control systems

detect certain conditions; these conditions may be caused by Fault or Demand and can be classified thus:

0 Engine coolant overheat,

0 Refrigerant excessive pressure.

0 Refrigerant, insufficient pressure or low charge weight.

0 Speed differential between compressor and crankshaft caused by belt slippage or compressor seizure (indi-

cated by A/C state lamp flashing once per second) - 12 cylinder engine only. This feature, 'lock sensing' is fully

explained

in the EDM.

Demand

0 Engine maximum power requirement

0 Electrical system drain at engine idle.

X300 VSM 9 Issue 1 August 1994

Page 326 of 521

Climate Control Systems

0 14.9 GENERAL SYSTEM PROCEDURES

14.9.1 Leak Test

Faults associated with low refrigerant charge weight and low pressure may be caused by leakage. Leaks traced to

mechanical connections may be caused by torque relaxation or joint face contamination. Evidence of oil around such

areas is an indicator of leakage. When checking for non visible leaks use only

a dedicated HFC 134A electronic analyzer

and apply the probe all round the joint / connection.

Should a leak betraced to a joint,checkthatthefixing issecuredtothecorrecttightening torque before any other action

is taken.

Do not forget to check the compressor shaft seal and evaporator.

CAUTION : Never use a dedicated CFC 12 or naked flame type analyzer.

14.9.2 Charge Recovery (System depressurization)

The process of HFC 134A recovery will depend on the basic characteristics of your chosen recovery/ recycle I recharge

equipment, therefore, follow the manufacturer's instructions carefully.

Remember that compressor oil may be drawn

out of the system by this process, take note of the quantity recovered

so that it may be replaced.

CAUTION: Observe all relevant safety requirements.

Wear suitable eye and skin protection

Do not mix HFC 134A with CFC 12. Do not vent refrigerant directly to atmosphere and always use Jaguar approved recovery I recycle I re- charge equipment.

Take note of the amount of recovered refrigerant, it will indicate the state of the system. 0

14.9.3 Evacuating the System

This process, the removal of unwanted air and moisture, is critical to the correct operation of the air conditioning sys-

tem. The specific procedures will vary depending on the individual characteristics of your chosen recovery I recycle / recharge equipment and must be carried out exactly in accordance with the manufacturers instructions. However,

it is recommended that the initially only the HIGH side valve be opened at the start of the procedure. After a short time a small depression should be seen on the LOW side, at which point the LOW side valve may be opened and the evacu- ation process completed. If a vacuum is not registered on the LOW side it may indicate that the expansion valve is

jammed closed or that the system is blocked. This simple check may save time and effort when the system is re- charged.

Moisture can be highly destructive and may cause internal blockages due to freezing, but more importantly, water sus- pended in the PAG oil will damage the compressor. Once the system has been opened for repairs, or the refrigerant

charge recovered, all traces of moisture MUST be removed before recharging.

14.9.4

The amount of oil drawn out during a recovery procedure will be dependent on the state of the system and the rate

of recovery. The quantity will be approximately 30 to 40 ml; this may vary, and the figure is given only for guidance.

The oil separator vessel in the recovery equipment must be clean and empty

at the start of the process so that the quan- tity of oil which is drawn out may be accurately measured.

Oil may be added by three methods,

1 and 2 being direct into the system and 3 with the compressor off the vehicle;

1. Via the recovery I recycle 1 recharge station.

2. Proprietary oil injector.

Adding Lubricating Oil - Compressor Related

1ynfa: Equipment manufacturer's instructions must be adhered to when using direct oil introduction.

3. Directly into the original, or new unit, because of rectification work to the existing compressor, or the need to fit a new compressor.

Original

From an existing compressor, drain the oil into a measuring cylinder and record the amount. Flush the unit out

with fresh PAG oil and drain thoroughly, Replenish the compressor with the same amount of PAG oil that was

originally drained out and immediately plug all orifices ready for refitting to the vehicle.

X300 VSM 13 Issue 1 August 1994

Page 328 of 521

Climate Control Systems

14.10 FAULT DIAGNOSIS

14.10.1 Introduction

It is very important to positively identifythe area of concern before starting a rectification procedure. A little time spent

with your customer to identify the conditions under which a problem occurs will be beneficial. Relevant criteria are:

Weather conditions, ambient temperature, intermittent or continuous fault, airflow fault, temperature control fault, dis

- tribution fault and air inlet problem.

14.10.2 Functional Check

This simple 'first line check' will allow you to ascertain whether the system is operating within its design parameters,

without recourse to (JDE). Please carry out the following, in order.

0 Start engine and attain normal running temperature.

0 Presss AUTO to display selected temperature and illuminate AUTO & AJC state lamps.

0 Rotate FAN to increase or decrease lower speed, verify bar graph representation.

0 Operate AJC to toggle on or off. Because the compressor can be inhibited by the engine management system,

ensure that the engine temperature is normal and that the ambient is above 5O C.

0 Operate RECIRC, state lamp should be lit and the flap behind the blower grille open.

0 Operate distribution buttons in turn, verify correct air distribution and relevant state lamp.

0 Operate DEFROST, check max fans and air to front screen.

0 Cycle TEMPERATURE to 'Hi' and 'Lo' to verify demanded variations and display operation. Note that extremes

will provide max heat or cold independent of in-car temperature.

0 Operate EX to toggle between ambient and control temperatures.

0 Operate HFS and HRW to note timer and mirror operation.

0 Initiate System Self Test to check for, and extract, stored faults should any of the above not perform as stated.

14.10.3 System symptoms

There are five basic symptoms associated with air conditioning fault diagnosis. The following conditions are not in order of priority.

No Cooling

0 Is the electrical circuit to the compressor clutch functional?

0 Is the electrical circuit to the blower motor(s) functional?

0 Slack or broken compressor drive belt.

0 Compressor partially or completely seized.

0 Compressor shaft seal leak.

0 Compressor valve or piston damage (may be indicated by small variation between HIGH &LOW side pressures

relative to engine speed).

0 Broken refrigerant pipe (causing total loss of refrigerant).

0 Leak in system (causing total loss of refrigerant) - possible code 23.

0 Blocked filter in the receiver drier.

0 Evaporator sensor disconnected - possible code 13.

0 Pressure switch faulty - possible code 23.

X300 VSM Issue 1 August 1994

Page 329 of 521

Climate Control Systems

lnsufficent Cooling

0 Sluggish blower motor(s).

0 Restricted blower inlet or outlet passage

0 Blocked or partially restricted condenser matrix or fins.

0 Blocked or partially restricted evaporator matrix.

0 Blocked or partially restricted filter in the receiver drier.

0 Blocked or partially restricted expansion valve.

0 Partially collapsed flexible pipe.

0 Expansion valve temperature sensor faulty (this sensor is integral with valve and is not serviceable).

0 Excessive moisture in the system.

0 Air in the system.

0 Low refrigerant charge - possible code 23.

0 Compressor clutch slipping.

0 Blower flaps or distribution vents closed or partially seized - possible codes 41 or 46.

0 Coolant flow valve not closed.

0 Evaporator sensor incorrectly positioned

m: Should a leakor low refrigerant be established as the cause of /NSUff/C/€NTCOOL/NG,followthe procedures

Recovery / Recycle / Recharge, this section, and observe all refrigerant and oil handling instructions.

lntermiffent Cooling

0 Is the electrical circuit to the compressor clutch consistent?

0 Is the electrical circuit to the blower motor(s) consistent?

0 Compressor clutch slipping?

0 Motorized in-car aspirator or evaporator temperature sensor faulty, causing temperature variations - possible

codes 11 or 13.

0 Blocked or partially restricted evaporator or condenser.

Noisy System

0 Loose or damaged compressor drive belt.

0 Loose or damaged compressor mountings.

0 Compressor oil level low, look for evidence of leakage.

0 Compressor damage caused by low oil level or internal debris.

0 Blower motor(s) noisy.

0 Excessive refrigerant charge, witnessed by vibration and 'thumping' in the high pressure line (may be indicated

by high HIGH & high LOW side pressures).

0 Low refrigerant charge causing 'hissing' at the expansion valve (may be indicated by low HIGH side pressure).

0 Excessive moisture in the system causing expansion valve noise.

0 Air-lock in water pump*.

lnsufficent Heating

0 Coolant flow valve stuck in the closed position.

0 Motorized in-car aspirator seized.

0 Cool air by-pass damper stuck or seized - possible code 43.

0 Blocked or restricted blower inlet or outlet.

0 Low coolant level.

0 Blower fan speed low.

0 Coolant thermostat faulty or seized open.

0 Water pump inoperative or blocked

0 Air-lock in matrix*.

m: * Please see Sections 4.1 and 4.2 for specific coolant fill / bleed procedures.

Electrical faults may be more rapidly traced using

(JDE), please refer to the (EDM).

Issue 1 August 1994 16 X300 VSM