lock JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 206 of 521

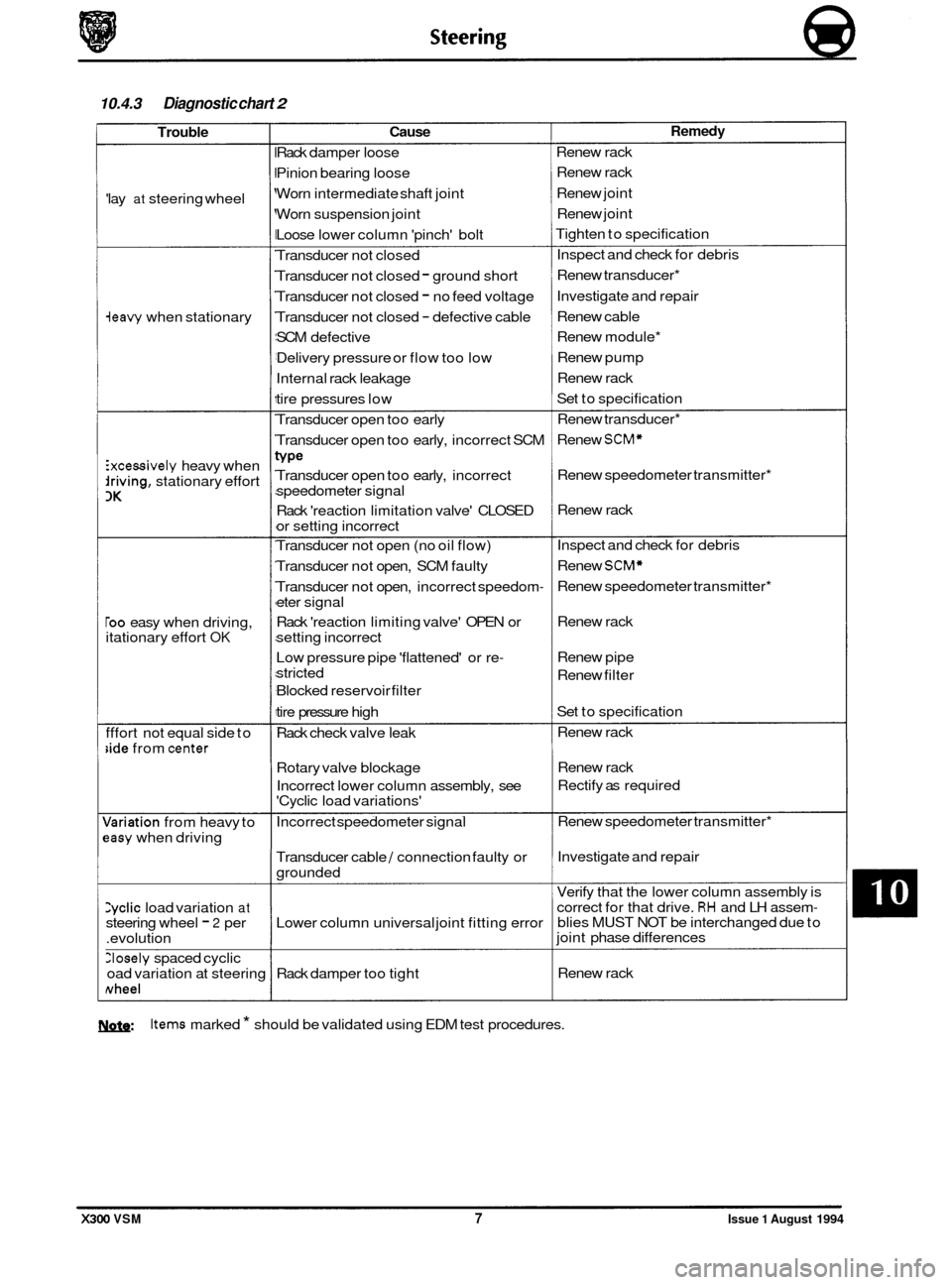

10.4.3 Diagnostic chart 2

0 Trouble

'lay at steering wheel

ieavy when stationary

Excessively heavy when

hiving, stationary effort

3K

Too easy when driving,

itationary effort OK

fffort not equal side to

;ide from center

dariation from heavy to

?asy when driving

:yclic load variation at steering wheel - 2 per

.evolution

:losely spaced cyclic

oad variation at steering

Nheel

Cause

Rack damper loose

Pinion bearing loose

Worn intermediate shaft joint

Worn suspension joint

Loose lower column 'pinch' bolt

Transducer not closed

Transducer not closed

- ground short

Transducer not closed

- no feed voltage

Transducer not closed

- defective cable

SCM defective

Delivery pressure or flow too low

Internal rack leakage

tire pressures low

Transducer open too early

Transducer open too early, incorrect SCM

h/Pe

Transducer open too early, incorrect

speedometer signal

Rack 'reaction limitation valve' CLOSED

or setting incorrect

Transducer not open (no oil flow)

Transducer not open, SCM faulty

Transducer not open, incorrect speedom

-

eter signal

Rack 'reaction limiting valve' OPEN or

setting incorrect

Low pressure pipe 'flattened' or re

-

stricted

Blocked reservoir filter

tire pressure high

Rack check valve leak

Rotary valve blockage Incorrect lower column assembly, see

'Cyclic load variations'

Incorrect speedometer signal

Transducer cable

/ connection faulty or

grounded

Lower column universal joint fitting error

Rack damper too tight

Remedy

Renew rack

Renew rack

Renew joint

Renew joint

Tighten to specification

Inspect and check for debris

Renew transducer*

Investigate and repair

Renew cable

Renew module*

Renew pump

Renew rack

Set to specification

Renew transducer*

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Inspect and check for debris

Renew

SCM*

Renew speedometer transmitter*

Renew rack

Renew pipe

Renew filter

Set to specification

Renew rack

Renew rack

Rectify as required

Renew speedometer transmitter*

Investigate and repair

Verify that the lower column assembly is

correct for that drive.

RH and LH assem- blies MUST NOT be interchanged due to

joint phase differences

Renew rack

W: Items marked * should be validated using EDM test procedures.

X300 VSM 7 Issue 1 August 1994

Page 207 of 521

@ Steering

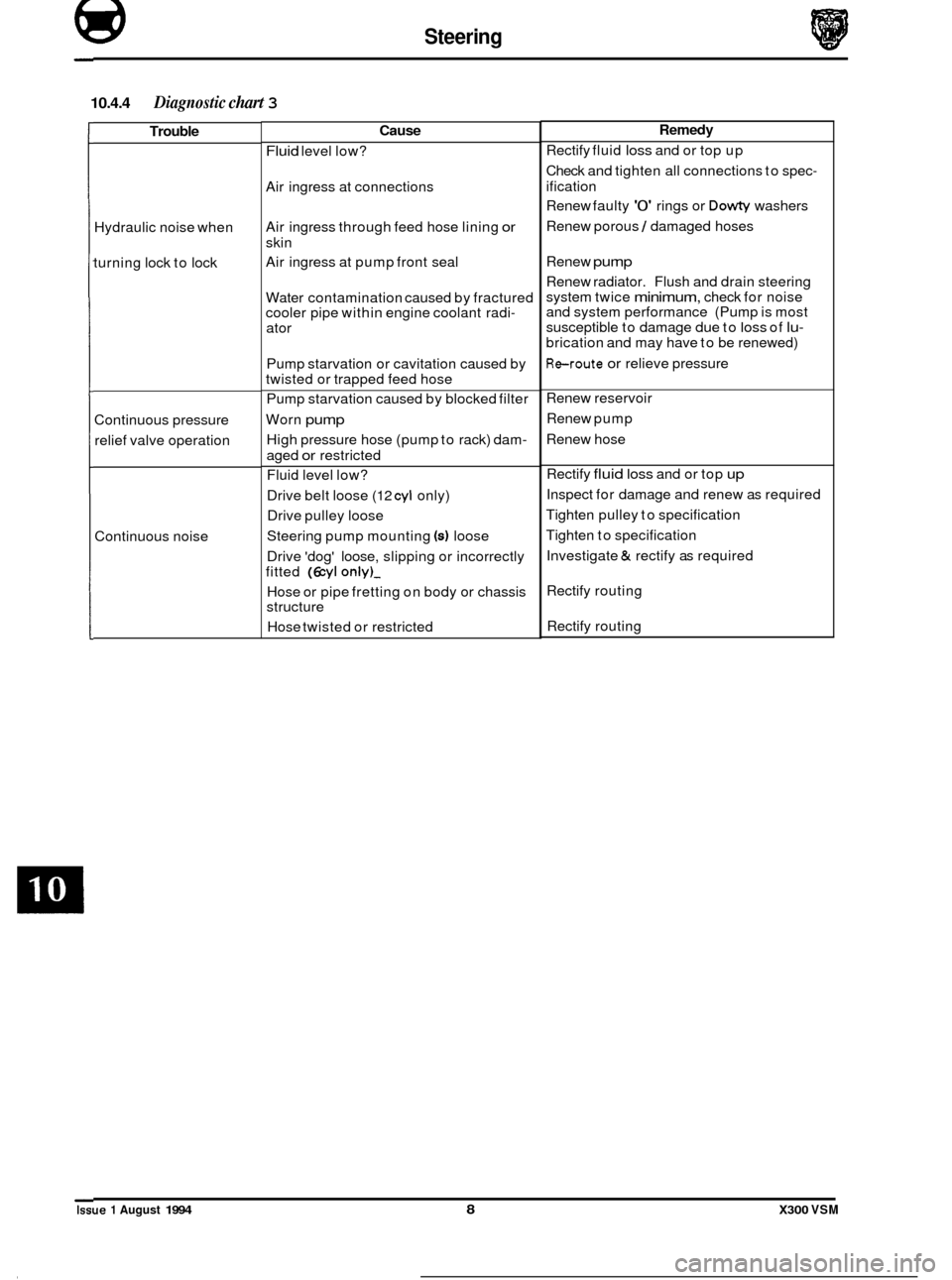

10.4.4 Diagnostic chart 3

Trouble

Hydraulic noise when

turning lock to lock

Continuous pressure

relief valve operation

Continuous noise

Cause

Fluid level low?

Air ingress at connections

Air ingress through feed hose lining

or

skin

Air ingress at pump front seal

Water contamination caused by fractured

cooler pipe within engine coolant radi

-

ator

Pump starvation or cavitation caused by

twisted or trapped feed hose

Pump starvation caused by blocked filter

Worn

pump

High pressure hose (pump to rack) dam-

aged or restricted

Fluid level low?

Drive belt loose

(12 cyl only)

Drive pulley loose

Steering pump mounting

(4 loose

Drive 'dog' loose, slipping or incorrectly

fitted

(6 cyl only)-

Hose or pipe fretting on body or chassis

structure

Hose twisted or restricted

Remedy

Rectify fluid loss and or top up

Check and tighten all connections to spec

-

ification

Renew faulty

'0' rings or Dowty washers

Renew porous

1 damaged hoses

Renew

pump

Renew radiator. Flush and drain steering

system twice

minimum, check for noise

and system performance (Pump is most

susceptible to damage due to

loss of lu-

brication and may have to be renewed)

Reroute or relieve pressure

Renew reservoir

Renew pump

Renew hose

Rectify

fluid loss and or top up

Inspect for damage and renew as required

Tighten pulley to specification

Tighten to specification

Investigate

& rectify as required

Rectify routing

Rectify routing

Issue 1 August 1994 8 X300 VSM

Page 208 of 521

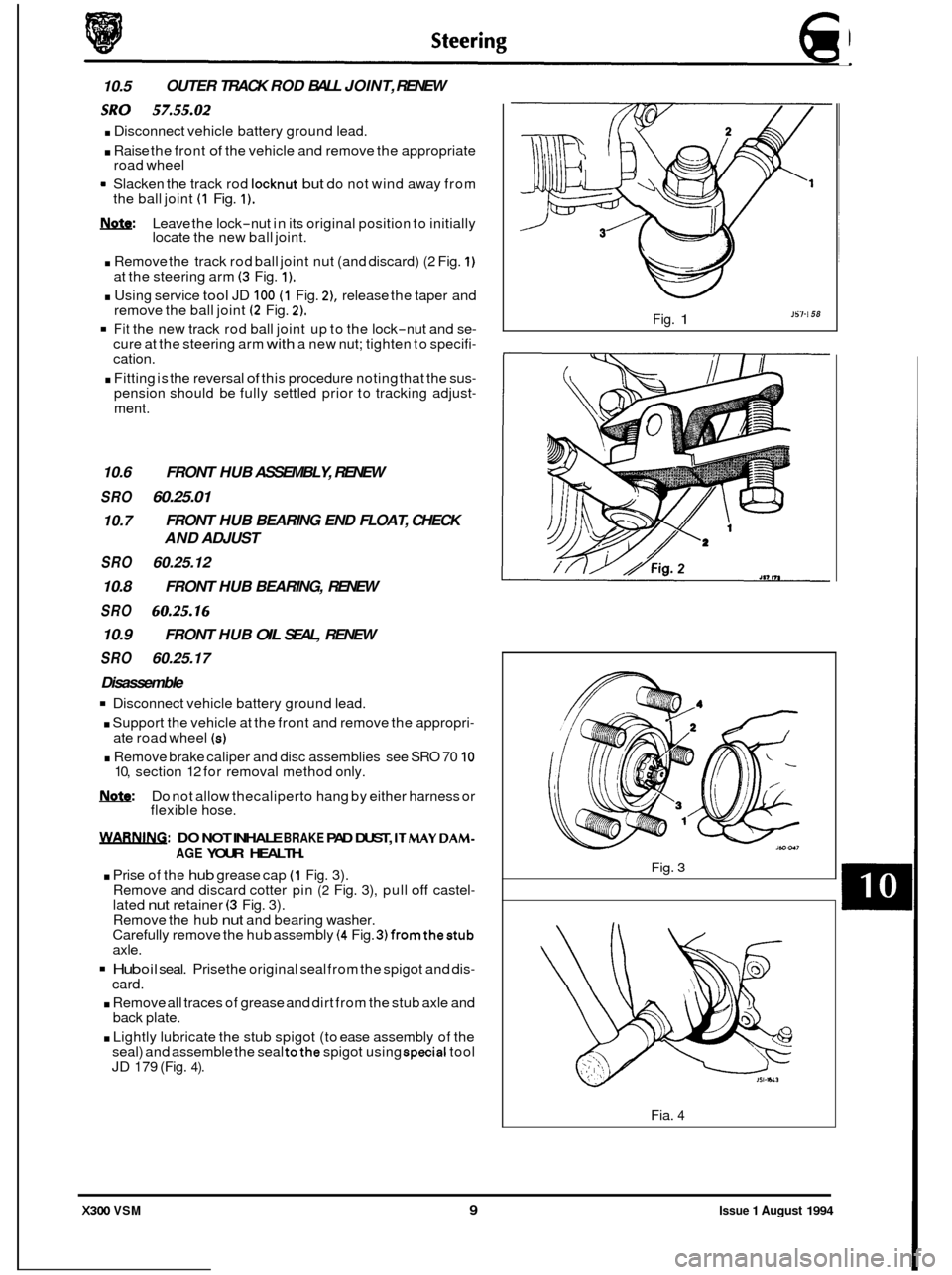

10.5 OUTER

TRACK ROD BALL JOINT, RENEW

sRo . Disconnect 57.55.02 vehicle battery ground lead.

. Raise the front of the vehicle and remove the appropriate

road wheel

Slacken the track rod

locknut but do not wind away from

the ball joint (1 Fig. 1).

m: Leave the lock-nut in its original position to initially

locate the new ball joint.

. Remove the track rod ball joint nut (and discard) (2 Fig. 1)

at the steering arm (3 Fig. 1).

. Using service tool JD 100 (1 Fig. 2), release the taper and

remove the ball joint (2 Fig. 2).

Fit the new track rod ball joint up to the lock-nut and se- cure at the steering arm with a new nut; tighten to specifi- cation.

. Fitting is the reversal of this procedure noting that the sus- pension should be fully settled prior to tracking adjust-

ment.

0 10.6 FRONT HUB ASSEMBLY, RENEW

SRO 60.25.01

10.7

SRO 60.25.12

10.8 FRONT HUB BEARING, RENEW

SRO 60.25.16

10.9

SRO 60.25.17

Disassemble

Disconnect vehicle battery ground lead.

. Support the vehicle at the front and remove the appropri-

. Remove brake caliper and disc assemblies see SRO 70 10

IWQ: Do not allow thecaliperto hang by either harness or

flexible hose.

FRONT HUB BEARING END FLOAT, CHECK

AND ADJUST

FRONT HUB

OIL SEAL, RENEW

ate road wheel (s)

10, section 12 for removal method only.

WARNIM: DO NOT INHALE BRAKE PAD DUST, ITMAY DAM-

0

AGE YOUR HEALTH.

. Prise of the hub grease cap (1 Fig. 3).

Remove and discard cotter pin (2 Fig. 3), pull off castel- lated nut retainer (3 Fig. 3).

Remove the hub nut and bearing washer.

Carefully remove the hub assembly (4 Fig. 3)fromthestub axle.

Hub oil seal. Prise the original seal from the spigot and dis-

card.

. Remove all traces of grease and dirt from the stub axle and

back plate.

. Lightly lubricate the stub spigot (to ease assembly of the

seal) and assemble the seal tothe spigot using special tool JD 179 (Fig. 4).

JS7-i 58 Fig. 1

Fig. 3

Fia.

4

X300 VSM 9 Issue 1 August 1994

Page 214 of 521

Suspension Systems

11.1 INTRODUCTION

This section describes the front and rear suspension systems, and also covers diagnostic procedures.

Fig. 1 Front Suspension Layout

11.2 FRONT SUSPENSION, DESCRIPTION

Theupperrearwishbone(1 Fig.l)andthe upperfrontwishbone(2 Fig.1)arepivotedon the upperfulcrum bolt (3Fig.l), passing through the front cross beam assembly. They are also fitted via an upper ball joint assembly (4 Fig.1) to a verti- cal linkaccommodating the stub axle (5 Fig.l), whereas the vertical linkisfittedvia a lower ball joint assembly (6 Fig.1) to the lower wishbone assembly.

The lower wishbone assembly comprises

a lower rear wishbone (7 Fig.l), lower front wishbone (8 Fig.l), damper (9 Fig.1) (incorporating damper bush 10 Fig.1) and spring pan (1 1 Fig.1) supporting the road spring (12 Fig.1). The lower

wishbone assembly is pivoted on the bushed lower fulcrum shaft (13 Fig.1) which also passes through thecross beam

assembly.

Both independent front suspension assemblies are linked by a stabilizer bar (14 Fig.1) which is secured to the cross

member using a fixing arrangement of mounting rubbers (15 Fig.1, clamps (16 Fig.l), nuts bolts, washers (17 Fig.1) and two link arm assemblies (18 Fig.1). Each link arm assembly is fitted to one end of the stabilizer bar and to one end

of the lower front wishbone using a fixing arrangement of bolts washers and self locking nuts.

All suspension loads, except the damper, are fed into a pressed steel crossbeam which is isolated from the body by

rubber bushes. This mounting method allows the necessary amount of compliance.

The degree

of caster is adjustable via shims positioned on either side of the upper ball joint assembly but camber is facton/ set and is not adjustable. The vertical link and the steering arm form a single forging. Cast iron hubs rotate

on twin tapered roller bearings.

X300 VSM 1 Issue 1 August 1994

Page 222 of 521

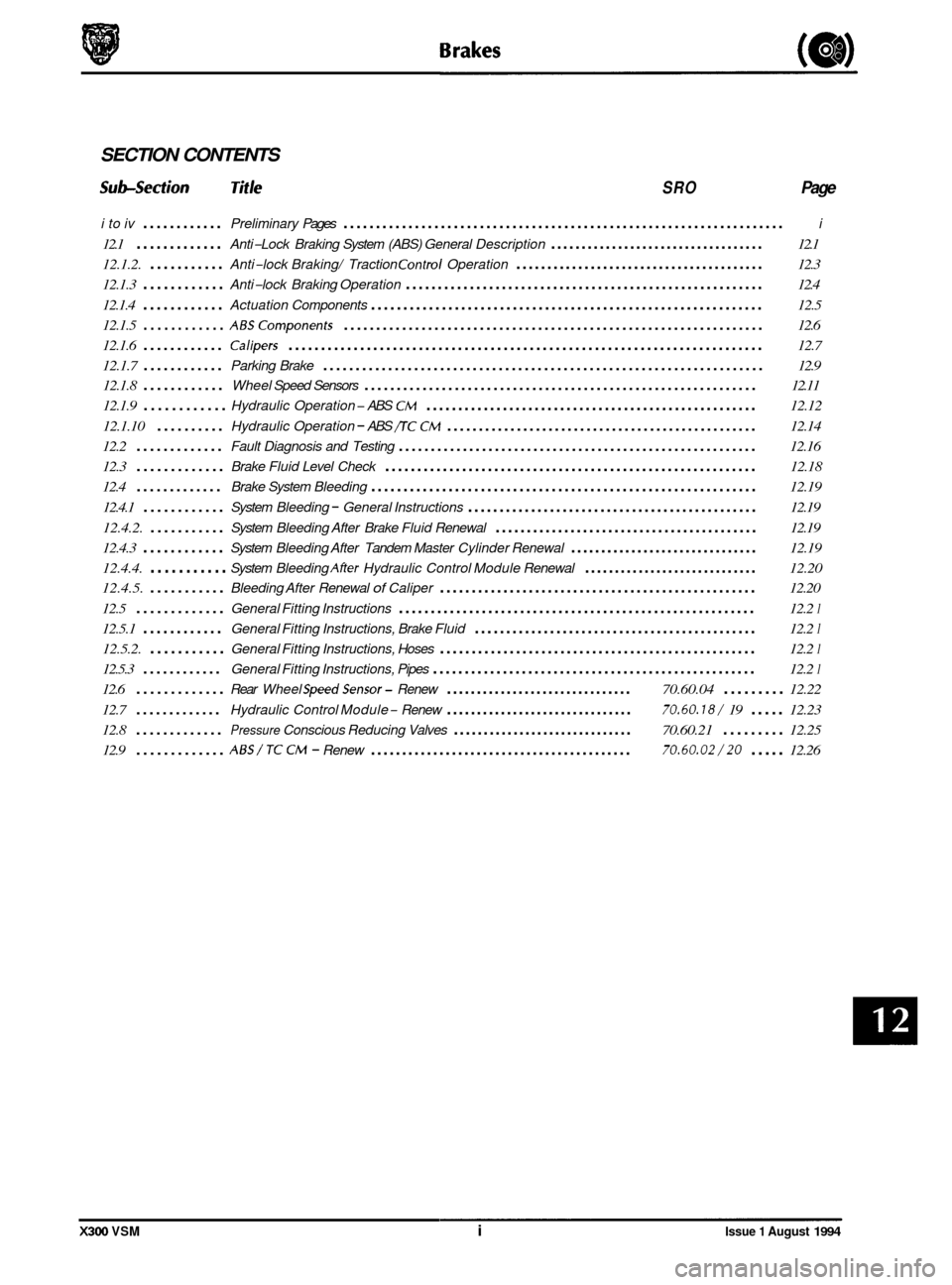

SECTION CONTENTS

Subsection Tit/e SRO Page

i to iv ............ Preliminary Pages .................................................................... i

12.1 ............. Anti-Lock Braking System (ABS) General Description ................................... 12.1

12.1.2.

........... Anti-lock Braking/ Traction Contd Operation ........................................ 12.3

12.1.3

............ Anti-lock Braking Operation ........................................................ 12.4

12.1.4

............ Actuation Components ............................................................. 12.5

12.1.5

............ ABSComponents ................................................................. 12.6

12.1.6

............ Calipers ........................................................................\

. 12.7

12.1.7

............ Parking Brake .................................................................... 12.9

12.1.8

............ Wheel Speed Sensors ............................................................. 12.11

12.1.9

............ Hydraulic Operation - ABS CM .................................................... 12.12

12.2

............. Fault Diagnosis and Testing ........................................................ 12.16

12.4

............. Brake System Bleeding ............................................................ 12.19

12.1.10

.......... Hydraulic Operation - ABS /TC CM ................................................. 12.14

12.3

............. Brake Fluid Level Check .......................................................... 12.18

12.4.1

............ System Bleeding - General Instructions .............................................. 12.19

12.4.2.

........... System Bleeding After Brake Fluid Renewal .......................................... 12.19

12.4.3

............ System Bleeding After Tandem Master Cylinder Renewal ............................... 12.19

12.4.4.

........... System Bleeding Afier Hydraulic Control Module Renewal ............................. 12.20

12.4.5.

........... Bleeding After Renewal of Caliper .................................................. 12.20

12.5

............. General Fitting Instructions ........................................................ 12.2 1

12.5.1 ............ General Fitting Instructions, Brake Fluid ............................................. 12.2 1

12.5.2. ........... General Fitting Instructions, Hoses .................................................. 12.2 1

12.5.3 ............ General Fitting Instructions, Pipes ................................................... 12.2 1

12.6 ............. Rear Wheel Speedsensor- Renew ............................... 70.60.04 ......... 12.22

12.7

............. Hydraulic Control Module- Renew ............................... 70.60.18/ 19 ..... 12.23

12.8

............. Pressure Conscious Reducing Valves .............................. 70.60.21 ......... 12.25

12.9

............. ABS/TCCM - Renew .......................................... 70.60.02/20 ..... 12.26

X300 VSM i Issue 1 August 1994

Page 224 of 521

12.1 ANTI-LOCK BRAKING SYSTEM (ASS), GENERAL DESCRIPTION

The anti-lock braking system (ABS) components are combined with a hydraulic booster and tandem master cylinder (TMC) to provide a two-circuit braking system. The anti-lock braking system comprises the following components:

0 Four inductive wheel speed sensors, hub end mounted

0 ABS warning light

0 Hydraulic module.

The hydraulic module consists of an electric motor driven pump,

two low pressure accumulators, valve block and an

ABS electronic control module.

m: Electronic control modules for vehicles without traction control are designated ABS CM. Control modules for

vehicles with traction control are designated ABS /TC CM.

The valve block houses solenoid operated valves which are activated by voltage signals from the control module. The

signals are generated using wheel speed information received from the wheel speed sensors.

For vehicles without traction control the valves operate on three circuits, two front and one rear, as necessary to pre

- vent wheel locking during braking. Brake pressure is modulated individually at thefront wheels and collectively at the

rear. Rear wheel control operates on a 'select low' principle i.e. locking in either wheel is sensed, and controlled brake

pressure is applied to both wheels.

For vehicles with traction control the valves operate on four circuits. During ABS control the rear wheel are controlled

on a 'select low' principle (as above), but during traction control operation the rear wheels are controlled individually.

0

1yQfB: Functional and diagnostic information for the ABS CM and the ABS/TC CM is contained in the Electrical Diag-

nostic Manual (EDM), Section 12.

ABS Warning lamp / Traction Control Warning lamp /Fluid level Indicator

The ABS and traction control warning lamps, mounted in the instrument panel, indicate a fault in the ABS or traction

control. These systems are inhibited or disabled when the lamps are lit, although conventional braking is unaffected.

When the ignition is switched on, an ABS self test is initiated. During this test, the ABS and traction control warning

lamps are

lit for approximately 1.7 seconds and then extinguish. A fault is indicated if the warning lamps remain lit or

come on whilst the vehicle is being driven.

W: The ABS self test is masked by the 5 second lamp test initiated when the ignition is switched on.

The fluid level indicator lamp, mounted in the instrument panel, is

lit when the brake fluid falls below the minimum

mark on the brake fluid reservoir.

ABS / Traction Control - Inhibit / Disable

Faults conditions are detected by the ABS/TC CM which disables the ABS and traction control until the fault is rectified.

The ABS and traction control warning lights on the instrument pack remains lit whilst a fault exists. The system will

be disabled when the following conditions occur:

0

0 Valve failure

0 Sensor failure

0 Main driver failure (internal ABS /TC CM fault)

0 Redundancy error (internal ABS JTC CM fault)

0 Overvoltage J undervoltage

0 Pump motor failure.

0 Throttle valve actuator motor failure (traction control vehicles only).

0 Throttle valve actuator potentiometer failure (traction control warning light only).

X300 VSM 1 Issue 1 August 1994

Page 226 of 521

Brakes (a)

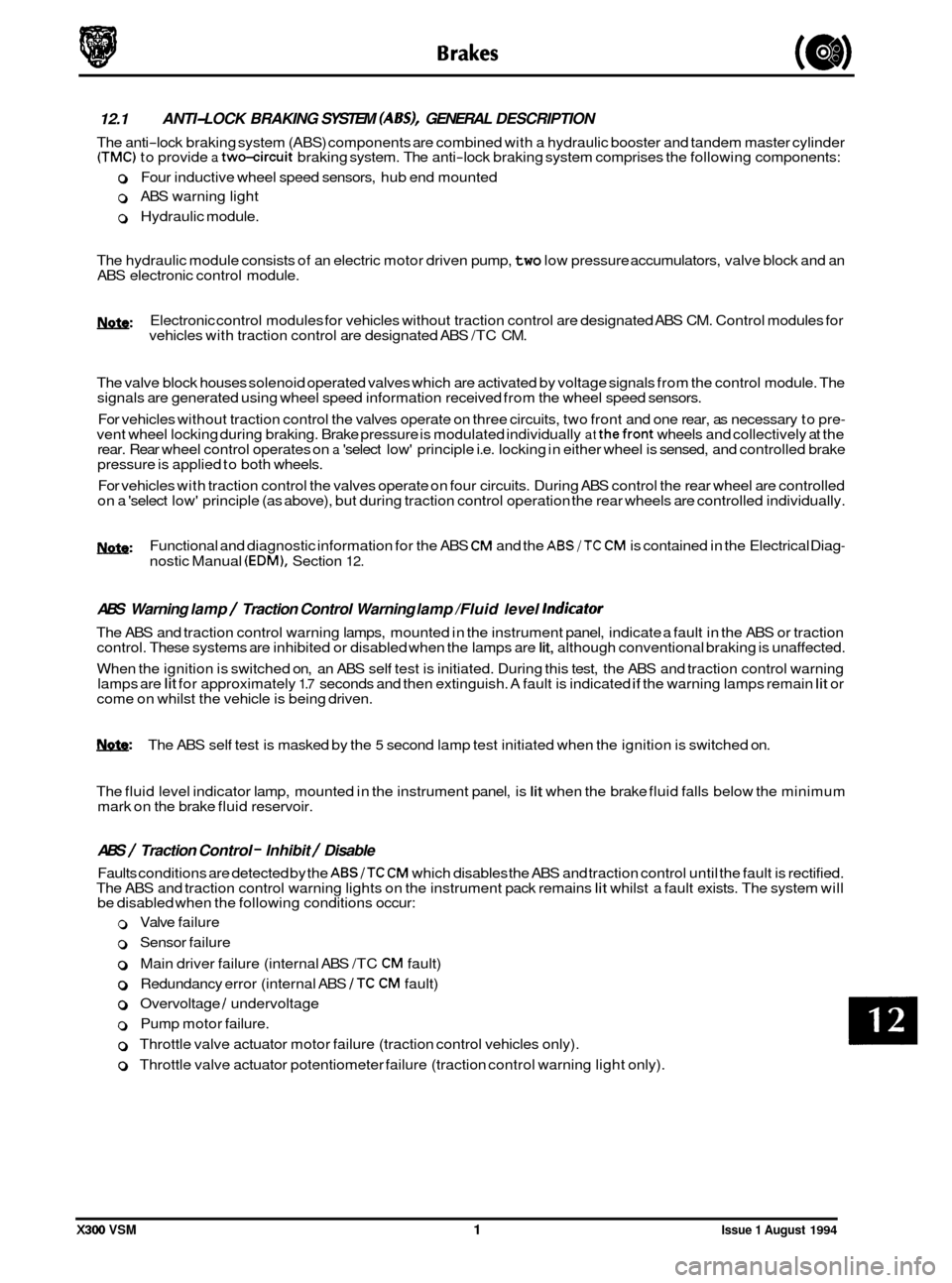

12.1.2. Anti-lock Braking / Traction Control Operation

The rear wheels are controlled collectively on a 'select-low' principle during ABS operation. During traction control,

separate circuits allow individual control of the rear wheels. To facilitate this the valve block has four outlet ports.

The

ABS/TC CM is integrated with the valve block. The pump, motor, valve block and control module are supplied as

a unit and are non-sewiceable. Faulty units must be renewed as a whole.

Both front and rear brakes on

all vehicles are fitted with single piston caliper assemblies. Ventilated brake rotors, with

provision for parking brake shoes at the rear, are fitted all round.

0

Issue 1 August 1994 X300 VSM 3

1. Vacuum booster 9. Pressure conscious reduction valve 2. Vacuum hose 10. Ventilated brake rotor 3. Tandem master cylinder 11. Single piston caliper 4. Primary brake circuit 12. %way brake pipe connector

5. Secondary brake circuit 13. Wheel speed sensor

6. Hydraulic pump / motor unit 14. ABS warning lamp 7. Valve block 15. Brake fluid level warning lamp

8. ABS/TCCM

Fig. 1 ABS / Traction Control System

The vacuum booster (see Fig.

1) is mounted on the brake pedal box and secured by three bolts. Brake pedal force is

increased by the vacuum booster which activates the Tandem Master Cylinder (TMC) intermediate piston. Brake fluid

is supplied to the pump inlet ports on two separate circuits. The primary circuit supplies the front brakes whilst the

secondary circuit supplies the rear brakes.

Page 227 of 521

Pressure conscious reduction valves (PCRVs) are fitted between the outlet of the valve block and the rear brake circuit

to optimize. The valves are fitted to prevent over braking due to the increased size of the rear brake calipers which are

required for traction control. Up to a threshold of 15 bar, brake pressure to the front and rear brakes is equal. Above

15 bar the PCRVs reduce pressure to the rear brakes to provide a closer balance between front and rear brakes and

optimize road adhesion.

Wheel speed sensors are fitted to all wheels to transmit wheel speed information to the control module. The module

uses this information to modulate brake pressure during anti

-lock braking or traction control.

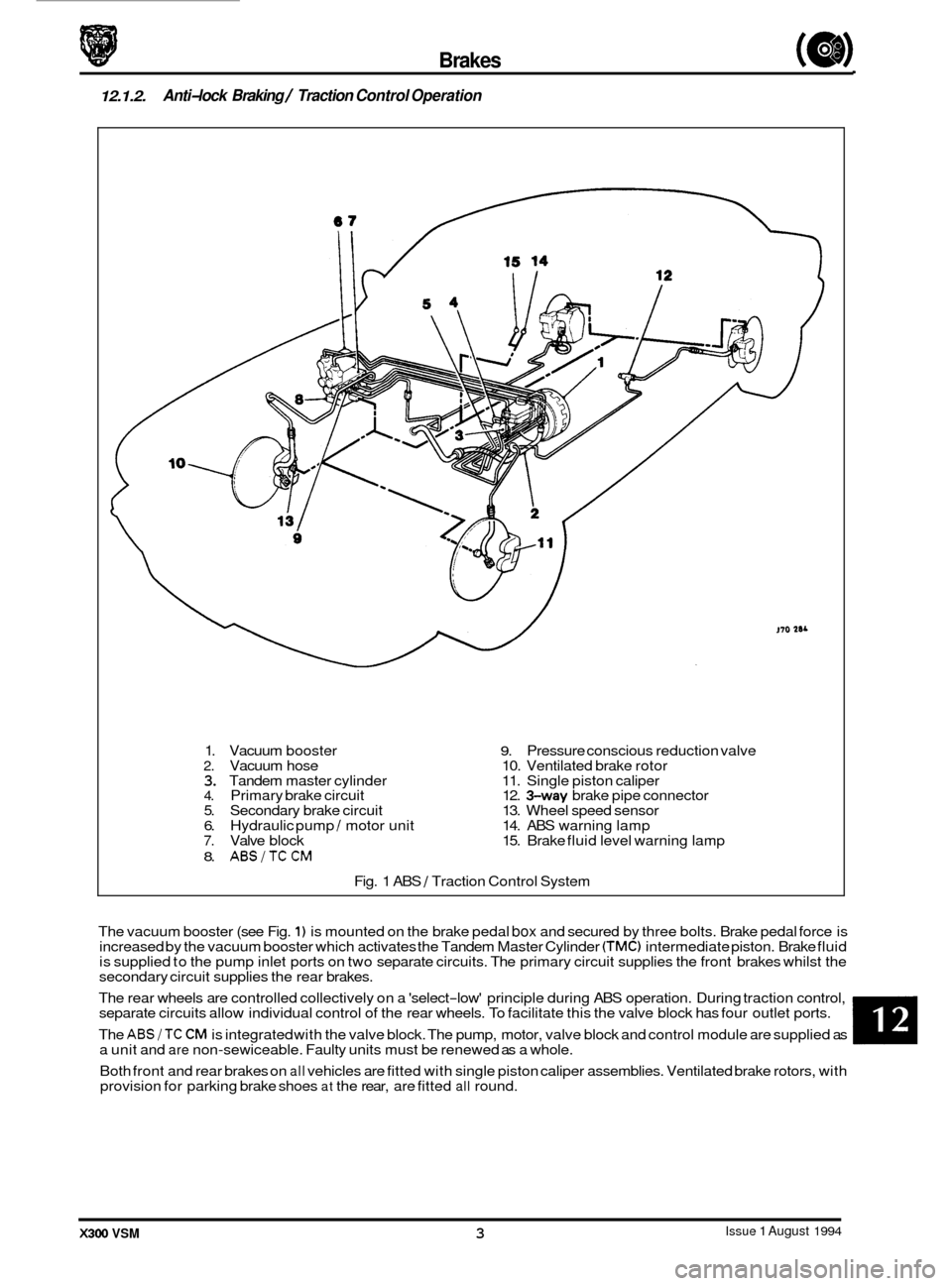

12.1.3. Anti-lock Braking Operation

170 287

1. Vacuum booster 9. Pressure conscious reduction valve

2. Vacuum hose 10. Ventilated brake rotor

3. Tandem master cylinder 11. Single piston caliper

4. Primary brake circuit 12.

%way brake pipe connector

5. Secondary brake circuit 13. Wheel speed sensor

6. Hydraulic pump I motor unit 14. ABS warning lamp 7. Valve block 15. Brake fluid level warning lamp

8. ABSICM

Fig. 1 Brake System (non-Traction Control)

The rear brakes (see Fig. 1) are controlled collectively on a

'select-low' principle. Under ABS braking conditions, equal

brake pressure is applied to both rear calipers, although only one wheel may have a tendency to lock.

The valve block has three outlet

ports, Brake fluid volume is supplied equally to the rear brakes via the %way brake

pipe connector.

Issue 1 August 1994 4 X300 VSM

Page 229 of 521

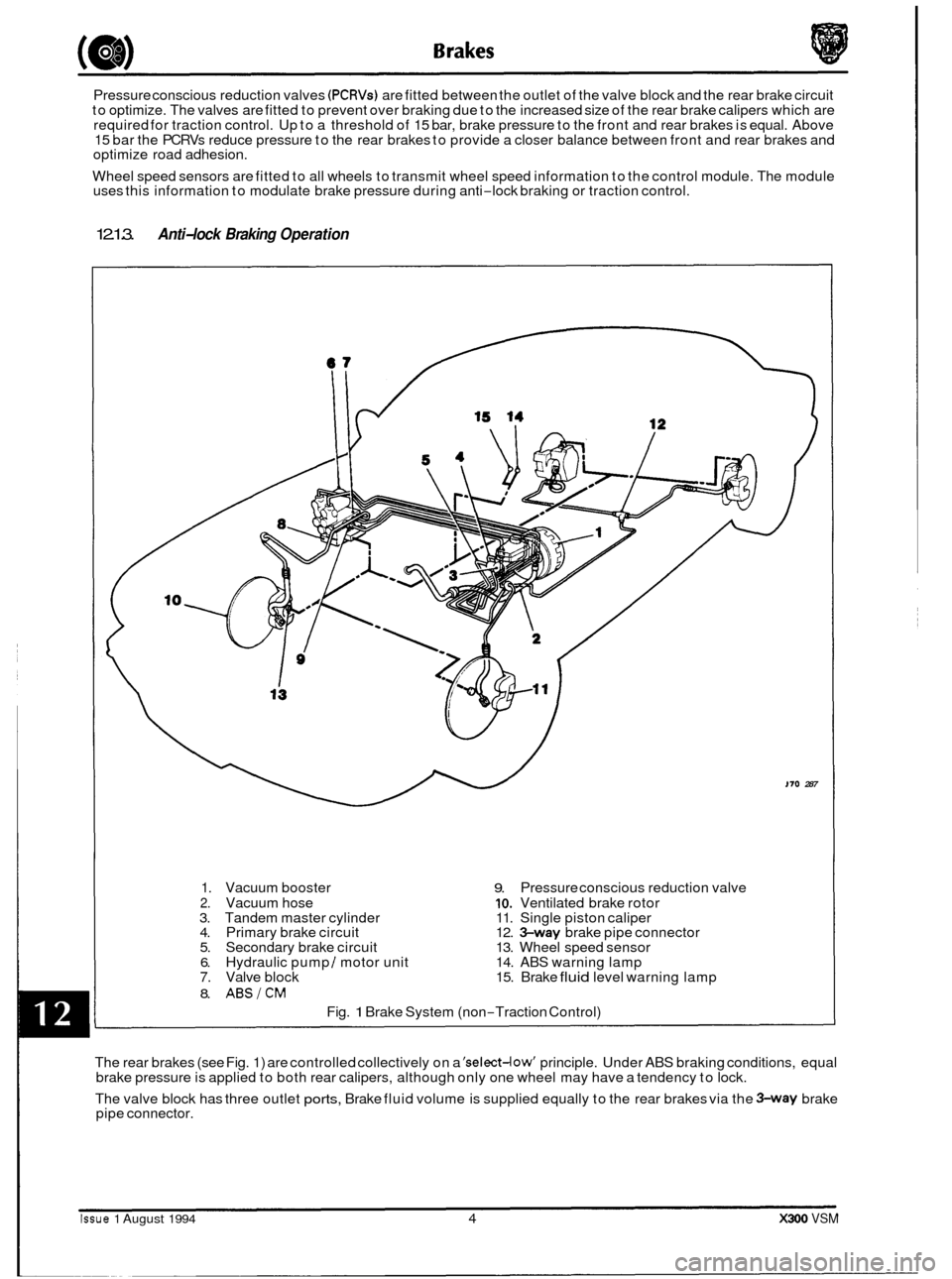

12.1.5. ABS Components

Hydraulic Module

The hydraulic module is located under the bonnet adjacent

to the engine compartment firewall. It is secured within a steel mounting bracket at three securing points. All elec- tronic and power connections are made through one cable

loom connect ion.

The hydraulic pump

(1 Fig. 1) is a reciprocating two-circuit pump in which one brake circuit is assigned to each pump

circuit. The pump supplies adequate pressure and volume

supply to the brake circuits under anti

-lock braking condi- tions. The pump is driven by and electric motor (2 Fig. 1). The

pump housing incorporates two low pressure accumulators

and damping chambers for each brake circuit.

A modulator valve block

(3 Fig. 1) incorporates the ABS CM or ABS / TC CM (4 Fig. 1). Vehicles with traction control are

fitted with a throttle position actuator (5 Fig. I), which is an

electrical device controlled by the ABS 1 TC CM.

Valve blocks on vehicles without traction control comprise

six solenoid valves, three normally open (NO) inlet valves

and three normally closed

(NC) outlet valves. These valve

blocks have three outlet ports. Valve blocks on vehicles with

traction control comprise nine solenoid valves, four

NO inlet valves,four NC outlet valves and one special isolating valve.

Fig. 2 shows a hydraulic module for vehicles with traction

control. The valve block (2 Fig. 2) has four outlet ports (Indi- vidual control of the driven wheels).

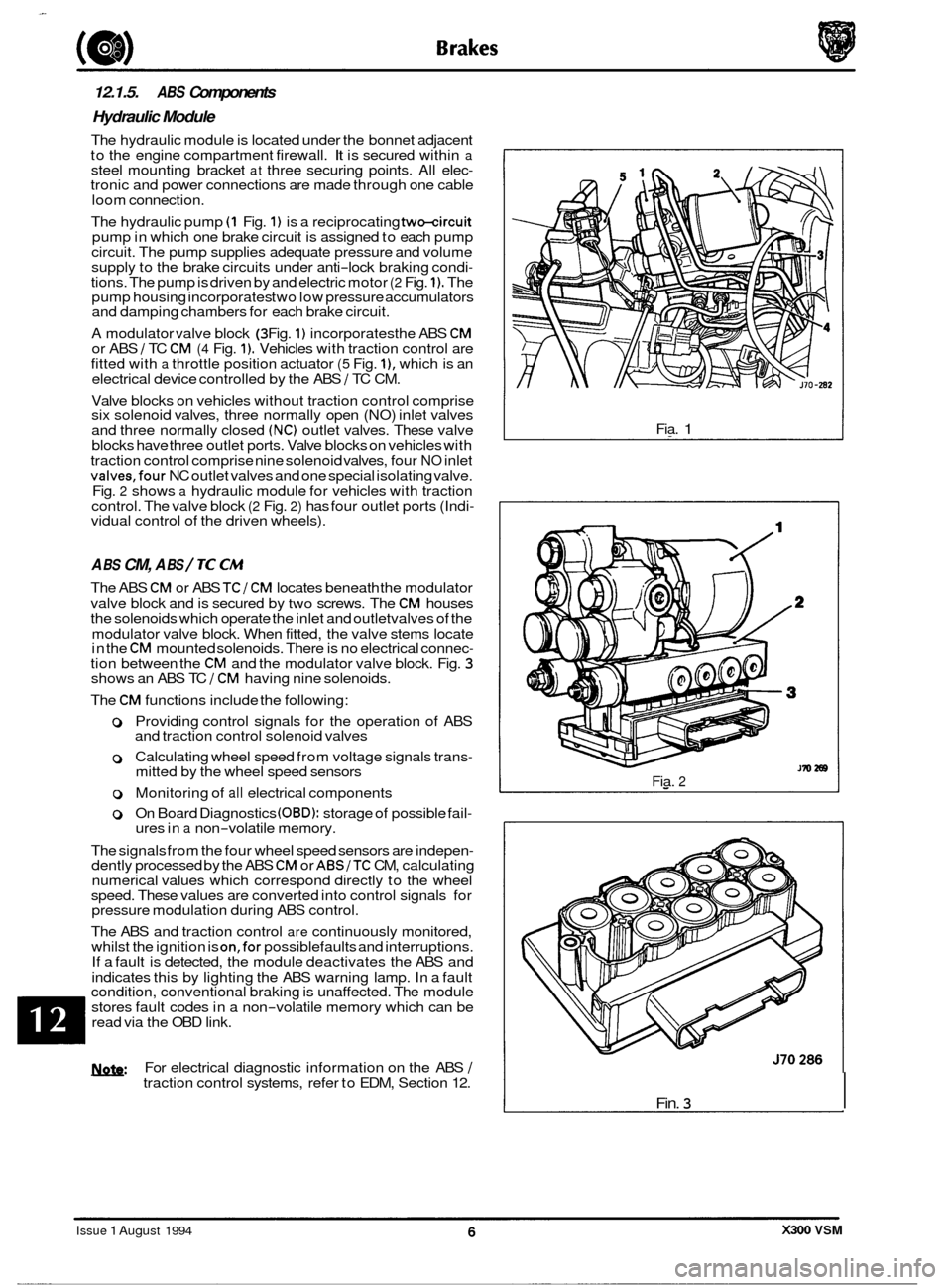

A BS CM, A BS / TC CM

The ABS CM or ABS TCI CM locates beneath the modulator

valve block and is secured by

two screws. The CM houses

the solenoids which operate the inlet and outletvalves of the

modulator valve block. When fitted, the valve stems locate

in the

CM mounted solenoids. There is no electrical connec- tion between the CM and the modulator valve block. Fig. 3 shows an ABS TC 1 CM having nine solenoids.

The

CM functions include the following:

0 Providing control signals for the operation of ABS

and traction control solenoid valves

0 Calculating wheel speed from voltage signals trans- mitted by the wheel speed sensors

0 Monitoring of all electrical components

0 On Board Diagnostics (OBD): storage of possible fail- ures in a non-volatile memory.

The signals from the four wheel speed sensors are indepen

- dently processed by the ABS CM or ABSITC CM, calculating

numerical values which correspond directly to the wheel

speed. These values are converted into control signals for

pressure modulation during ABS control.

The ABS and traction control

are continuously monitored,

whilst the ignition is on,for possiblefaults and interruptions.

If a fault is detected, the module deactivates the ABS and

indicates this by lighting the ABS warning lamp. In a fault

condition, conventional braking is unaffected. The module

stores fault codes in a non

-volatile memory which can be

read via the OBD link.

U: For electrical diagnostic information on the ABS I traction control systems, refer to EDM, Section 12. Fia.

1

Fia. 2

Fin. 3 I

J70286

Issue 1 August 1994 X300 VSM

Page 230 of 521

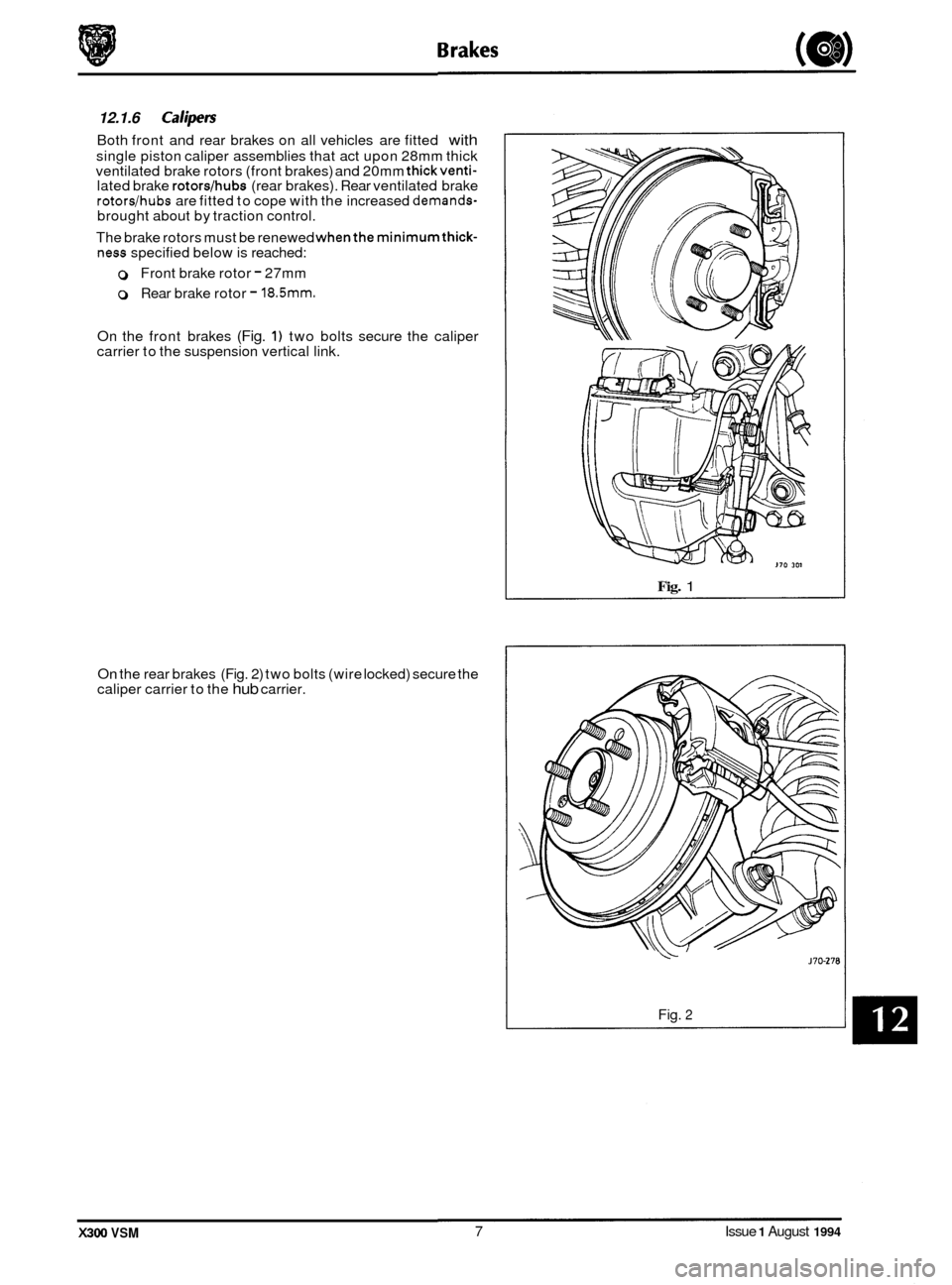

0 12.1.6 Calipers

Both front and rear brakes on all vehicles are fitted with

single piston caliper assemblies that act upon 28mm thick

ventilated brake rotors (front brakes) and 20mm thickventi- lated brake rotors/hubs (rear brakes). Rear ventilated brake rotordhubs are fitted to cope with the increased demands- brought about by traction control.

The brake rotors must be renewed

whenthe minimumthick- ness specified below is reached:

0 Front brake rotor - 27mm

0 Rear brake rotor - 18.5mm.

On the front brakes (Fig. 1) two bolts secure the caliper

carrier to the suspension vertical link.

On the rear brakes (Fig. 2) two bolts (wire locked) secure the

caliper carrier to the hub carrier.

Fig. 1

\

Fig. 2

J70-278

X300 VSM 7 Issue 1 August 1994