ESP JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 65 of 227

8Repeat the procedure for the remaining

cylinders. Note:Turn the crankshaft as

needed to position the piston/connecting rod

assembly to be removed close to parallel with

the cylinder bore - i.e. don’t try to drive it out

while at a large angle to the bore.

9After removal, reassemble the connecting

rod caps and bearing inserts in their

respective connecting rods and refit the cap

nuts/bolts finger tight. Leaving the old bearing

inserts in place until reassembly will help

prevent the big-end bearing surfaces from

being accidentally nicked or gouged.

10Don’t separate the pistons from the

connecting rods (see Section 18 for additional

information).

14 Crankshaft- removal

3

Note:The rear main oil seal and retainer must

be removed from the engine block before

proceeding with crankshaft removal (see Part

A of this Chapter).

1Before the crankshaft is removed, check

the endplay. Mount a dial indicator to the front

of the engine with the stem in line with, and

just touching, the end of the crankshaft (see

illustration).2Push the crankshaft all the way to the rear

and zero the dial indicator. Next, pry the

crankshaft to the front as far as possible and

check the reading on the dial indicator. The

distance that it moves is the endplay. If it’s

greater than that specified in this Chapter’s

Specifications, check the crankshaft thrust

surfaces for wear. If no wear is evident, new

thrust washers should correct the endplay.

3If a dial indicator isn’t available, feeler

gauges can be used. Gently pry or push the

crankshaft all the way to the front of the

engine. Slip feeler gauges between the

crankshaft and the front face of the number 4

(thrust) main bearing to determine the

clearance (see illustration).

4Check the main bearing caps to see if

they’re marked to indicate their locations.

They should be numbered consecutively from

the front of the engine to the rear. If they

aren’t, mark them with number stamping dies

or a centre punch. Main bearing caps

generally have a cast-in arrow, which points

to the front of the engine. Loosen the main

bearing cap bolts 1/4-turn at a time each,

stating at the ends and working toward the

centre, until they can be removed by hand.

5The main bearing caps are numbered on

the right side with corresponding numbers

stamped into the sump rail on the same side

(see illustration). Gently tap the caps with asoft-face hammer, then separate them from

the engine block. If necessary, use the bolts

as levers to remove the main bearing caps.

Try not to drop the bearing inserts if they

come out with the caps. Note:The number

four main bearing is the thrust bearing and is

not numbered.

6Carefully lift the crankshaft out of the

engine. It may be a good idea to have an

assistant available, since the crankshaft is

quite heavy. With the bearing inserts in place

in the engine block and main bearing caps,

return the main bearing caps to their

respective locations on the engine block and

tighten the bolts finger tight.

15 Engine block- cleaning

2

Caution: The core plugs (also known as

freeze or soft plugs) may be difficult or

impossible to retrieve if they’re driven

completely into the engine block coolant

passages.

1Using the blunt end of a punch, tap in on

the outer edge of the core plug to turn the

plug sideways in the bore. Then using pliers,

pull the core plug from the engine block (see

illustrations).

2B•10 Engine removal and overhaul procedures

14.5 The right side of each main bearing

cap is stamped with a number (left arrow)

that corresponds to the stamped number

on the pan rail (right arrow)15.1a A hammer and a large punch can be

used to knock the core plugs sideways in

their bores15.1b Pull the core plugs from the engine

block with pliers

3261 Jaguar XJ6 14.1 Checking crankshaft endplay with a dial indicator

14.3 Checking crankshaft endplay with a feeler gauge

Page 66 of 227

2Using a gasket scraper, remove all traces of

gasket material from the engine block. Be very

careful not to nick or gouge the gasket sealing

surfaces.

3Remove the main bearing caps and

separate the bearing inserts from the caps

and the engine block. Tag the bearings,

indicating which cylinder they were removed

from and whether they were in the cap or the

engine block, then set them aside.

4Remove all of the threaded oil gallery plugs

from the engine block. The plugs are usually

very tight - they may have to be drilled out and

the holes retapped. Use new plugs when the

engine is reassembled.

5If the engine is extremely dirty, it should be

taken to an automotive machine workshop to

be steam cleaned or hot tanked.

6After the engine block is returned, clean all

oil holes and oil galleries one more time.

Brushes specifically designed for this purpose

are available at most car accessory outlets.

Flush the passages with warm water until the

water runs clear, dry the engine block

thoroughly and wipe all machined surfaces

with a light, rust preventive oil. If you have

access to compressed air, use it to speed the

drying process and to blow out all the oil

holes and galleries. Warning: Wear eye protection

when using compressed air!

7If the engine block isn’t extremely dirty or

sludged up, you can do an adequate cleaning

job with hot soapy water and a stiff brush.

Take plenty of time and do a thorough job.

Regardless of the cleaning method used, be

sure to clean all oil holes and galleries very

thoroughly, dry the engine block completely

and coat all machined surfaces with light oil.

8The threaded holes in the engine block

must be clean to ensure accurate torque

readings during reassembly. Run the proper

size tap into each of the holes to remove rust,

corrosion, thread sealant or sludge and

restore damaged threads (see illustration). If

possible, use compressed air to clear the

holes of debris produced by this operation.

9Refit the main bearing caps and tighten the

bolts finger tight.

10After coating the sealing surfaces of the

new core plugs with suitable sealant, refit

them in the engine block (see illustration).

Make sure they’re driven in straight and

seated properly or leakage could result.

Special tools are available for this purpose,

but a large socket, with an outside diameter

that will just slip into the core plug, a 1/2-inchdrive extension and a hammer will work just

as well.

11Apply non-hardening sealant (such as

Permatex no. 2 or Teflon pipe sealant) to the

new oil gallery plugs and thread them into the

holes in the engine block. Make sure they’re

tightened securely.

12If the engine isn’t going to be

reassembled right away, cover it with a large

plastic trash bag to keep it clean.

16 Engine block- inspection

2

1Before the engine block is inspected, it

should be cleaned as described in Section 15.

2Visually check the engine block for cracks,

rust and corrosion (see illustration 10.12).

Look for stripped threads in the threaded

holes. It’s also a good idea to have the engine

block checked for hidden cracks by an

automotive machine workshop that has the

special equipment to do this type of work,

especially if the vehicle had a history of

overheating or using coolant. If defects are

found, have the engine block repaired, if

possible, or renewed. If the top of the engine

block has been eroded by coolant leakage

and the erosion is near the cylinder bores, the

engine block must be renewed.

3Check the cylinder bores for scuffing and

scoring.

4Check the cylinders for taper and out-of-

round conditions as follows (see illustrations):

5Measure the diameter of each cylinder at

the top (just under the ridge area), centre and

bottom of the cylinder bore, parallel to the

crankshaft axis.

6Next, measure each cylinder’s diameter at

the same three locations perpendicular to the

crankshaft axis.

7The taper of each cylinder is the difference

between the bore diameter at the top of the

cylinder and the diameter at the bottom. The

out-of-round specification of the cylinder bore

Engine removal and overhaul procedures 2B•11

2B

16.4a Measure the diameter of each

cylinder at 90° to engine centreline (A), and

parallel to engine centreline (B) - out-of-

round is the difference between A and B;

taper is the difference between A and B at

the top of the cylinder and A and B at the

bottom of the cylinder16.4b The ability to “feel” when the

telescoping gauge is at the correct point

will be developed over time, so work

slowly and repeat the check until you’re

satisfied that the bore measurement is

accurate

3261 Jaguar XJ6

15.8 All bolt holes in the engine block -

particularly the main bearing cap and

cylinder head bolt holes - should be

cleaned and restored with a tap (remove

debris from holes after this is done)15.10 A large socket on an extension can

be used to drive the new core plugs into

the bores

16.4c The gauge is then measured with a

micrometer to determine the bore size

Page 69 of 227

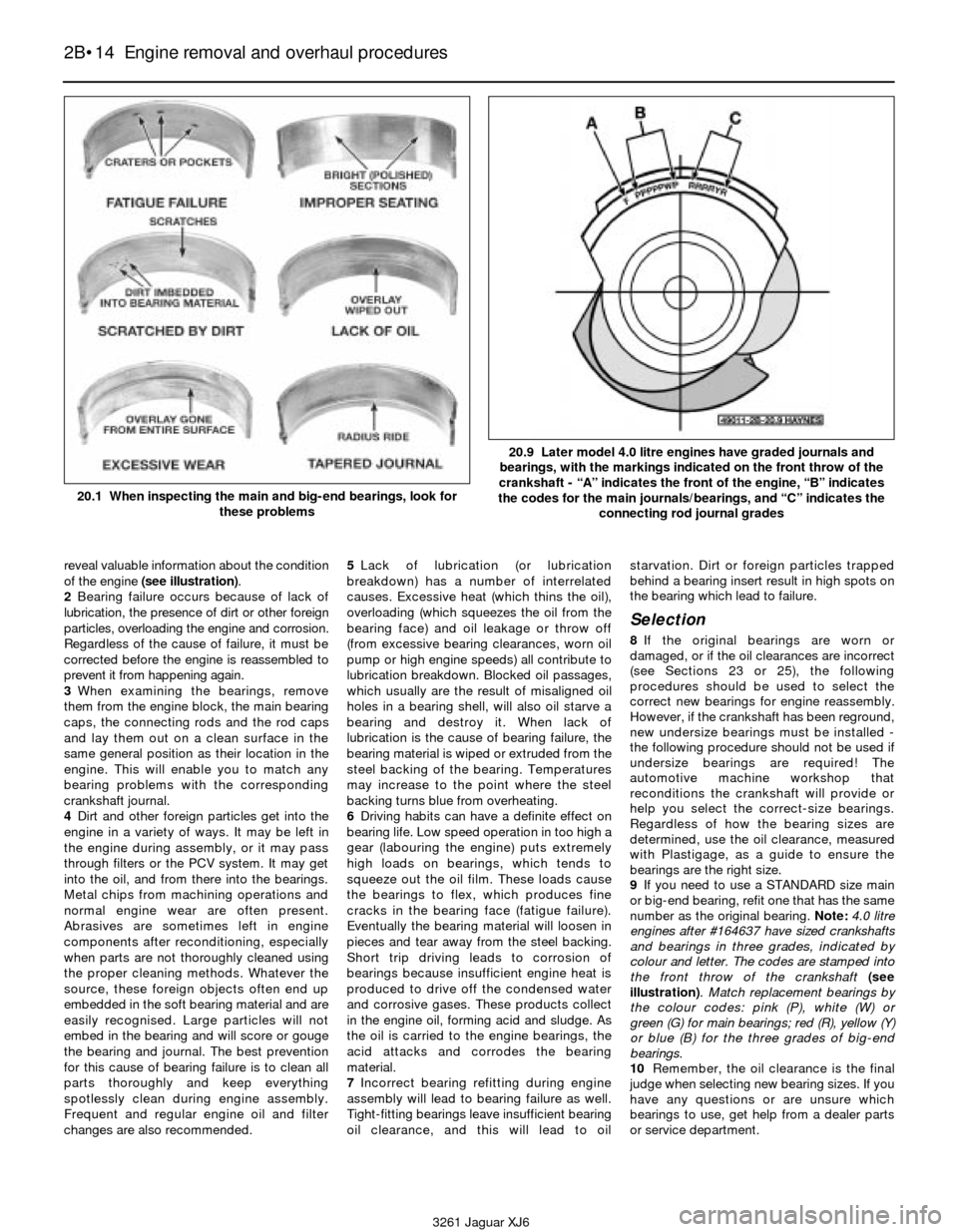

reveal valuable information about the condition

of the engine (see illustration).

2Bearing failure occurs because of lack of

lubrication, the presence of dirt or other foreign

particles, overloading the engine and corrosion.

Regardless of the cause of failure, it must be

corrected before the engine is reassembled to

prevent it from happening again.

3When examining the bearings, remove

them from the engine block, the main bearing

caps, the connecting rods and the rod caps

and lay them out on a clean surface in the

same general position as their location in the

engine. This will enable you to match any

bearing problems with the corresponding

crankshaft journal.

4Dirt and other foreign particles get into the

engine in a variety of ways. It may be left in

the engine during assembly, or it may pass

through filters or the PCV system. It may get

into the oil, and from there into the bearings.

Metal chips from machining operations and

normal engine wear are often present.

Abrasives are sometimes left in engine

components after reconditioning, especially

when parts are not thoroughly cleaned using

the proper cleaning methods. Whatever the

source, these foreign objects often end up

embedded in the soft bearing material and are

easily recognised. Large particles will not

embed in the bearing and will score or gouge

the bearing and journal. The best prevention

for this cause of bearing failure is to clean all

parts thoroughly and keep everything

spotlessly clean during engine assembly.

Frequent and regular engine oil and filter

changes are also recommended.5Lack of lubrication (or lubrication

breakdown) has a number of interrelated

causes. Excessive heat (which thins the oil),

overloading (which squeezes the oil from the

bearing face) and oil leakage or throw off

(from excessive bearing clearances, worn oil

pump or high engine speeds) all contribute to

lubrication breakdown. Blocked oil passages,

which usually are the result of misaligned oil

holes in a bearing shell, will also oil starve a

bearing and destroy it. When lack of

lubrication is the cause of bearing failure, the

bearing material is wiped or extruded from the

steel backing of the bearing. Temperatures

may increase to the point where the steel

backing turns blue from overheating.

6Driving habits can have a definite effect on

bearing life. Low speed operation in too high a

gear (labouring the engine) puts extremely

high loads on bearings, which tends to

squeeze out the oil film. These loads cause

the bearings to flex, which produces fine

cracks in the bearing face (fatigue failure).

Eventually the bearing material will loosen in

pieces and tear away from the steel backing.

Short trip driving leads to corrosion of

bearings because insufficient engine heat is

produced to drive off the condensed water

and corrosive gases. These products collect

in the engine oil, forming acid and sludge. As

the oil is carried to the engine bearings, the

acid attacks and corrodes the bearing

material.

7Incorrect bearing refitting during engine

assembly will lead to bearing failure as well.

Tight-fitting bearings leave insufficient bearing

oil clearance, and this will lead to oilstarvation. Dirt or foreign particles trapped

behind a bearing insert result in high spots on

the bearing which lead to failure.

Selection

8If the original bearings are worn or

damaged, or if the oil clearances are incorrect

(see Sections 23 or 25), the following

procedures should be used to select the

correct new bearings for engine reassembly.

However, if the crankshaft has been reground,

new undersize bearings must be installed -

the following procedure should not be used if

undersize bearings are required! The

automotive machine workshop that

reconditions the crankshaft will provide or

help you select the correct-size bearings.

Regardless of how the bearing sizes are

determined, use the oil clearance, measured

with Plastigage, as a guide to ensure the

bearings are the right size.

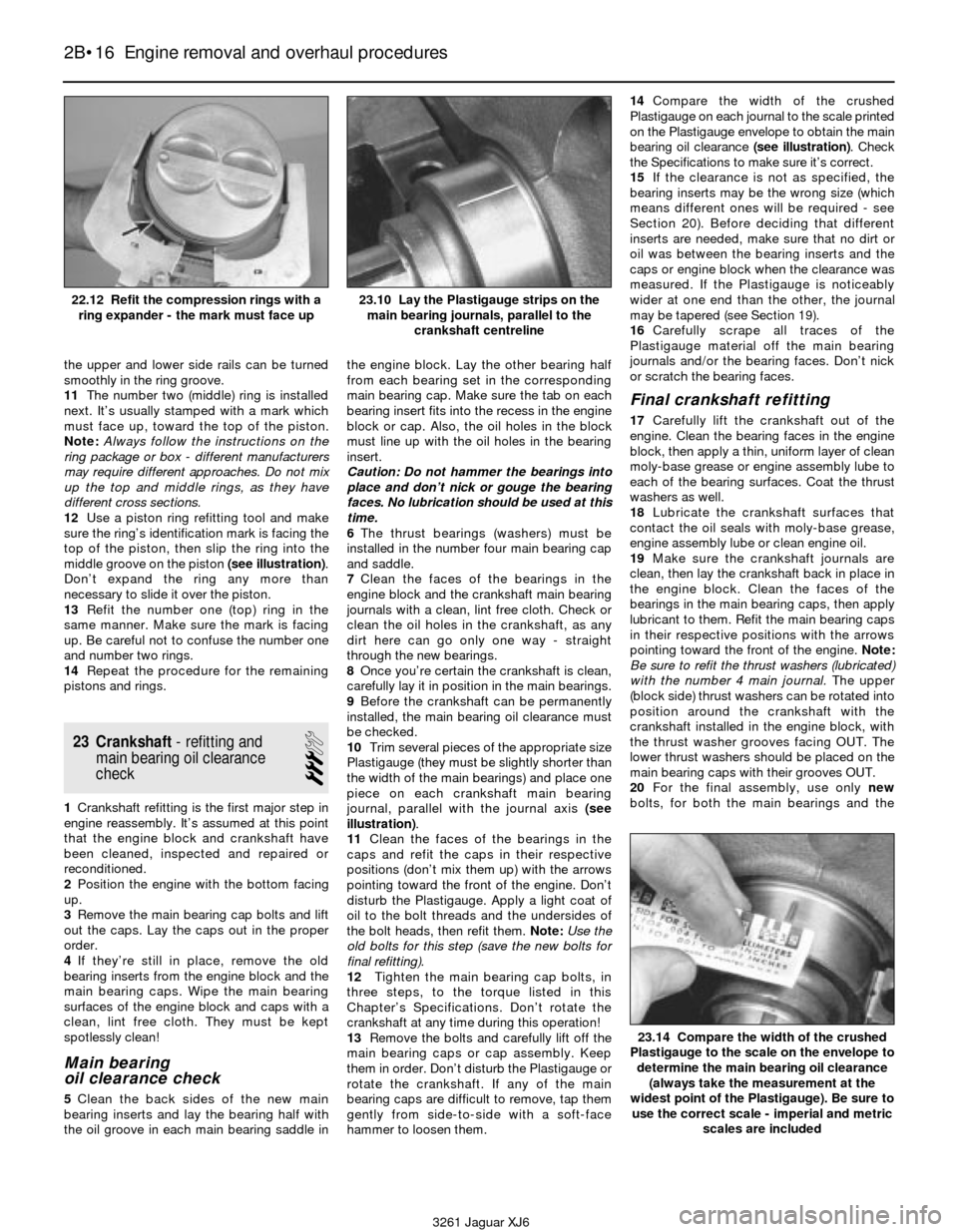

9If you need to use a STANDARD size main

or big-end bearing, refit one that has the same

number as the original bearing. Note:4.0 litre

engines after #164637 have sized crankshafts

and bearings in three grades, indicated by

colour and letter. The codes are stamped into

the front throw of the crankshaft(see

illustration). Match replacement bearings by

the colour codes: pink (P), white (W) or

green (G) for main bearings; red (R), yellow (Y)

or blue (B) for the three grades of big-end

bearings.

10Remember, the oil clearance is the final

judge when selecting new bearing sizes. If you

have any questions or are unsure which

bearings to use, get help from a dealer parts

or service department.

2B•14 Engine removal and overhaul procedures

3261 Jaguar XJ6 20.1 When inspecting the main and big-end bearings, look for

these problems

20.9 Later model 4.0 litre engines have graded journals and

bearings, with the markings indicated on the front throw of the

crankshaft - “A” indicates the front of the engine, “B” indicates

the codes for the main journals/bearings, and “C” indicates the

connecting rod journal grades

Page 71 of 227

the upper and lower side rails can be turned

smoothly in the ring groove.

11The number two (middle) ring is installed

next. It’s usually stamped with a mark which

must face up, toward the top of the piston.

Note:Always follow the instructions on the

ring package or box - different manufacturers

may require different approaches. Do not mix

up the top and middle rings, as they have

different cross sections.

12Use a piston ring refitting tool and make

sure the ring’s identification mark is facing the

top of the piston, then slip the ring into the

middle groove on the piston (see illustration).

Don’t expand the ring any more than

necessary to slide it over the piston.

13Refit the number one (top) ring in the

same manner. Make sure the mark is facing

up. Be careful not to confuse the number one

and number two rings.

14Repeat the procedure for the remaining

pistons and rings.

23 Crankshaft- refitting and

main bearing oil clearance

check

3

1Crankshaft refitting is the first major step in

engine reassembly. It’s assumed at this point

that the engine block and crankshaft have

been cleaned, inspected and repaired or

reconditioned.

2Position the engine with the bottom facing

up.

3Remove the main bearing cap bolts and lift

out the caps. Lay the caps out in the proper

order.

4If they’re still in place, remove the old

bearing inserts from the engine block and the

main bearing caps. Wipe the main bearing

surfaces of the engine block and caps with a

clean, lint free cloth. They must be kept

spotlessly clean!

Main bearing

oil clearance check

5Clean the back sides of the new main

bearing inserts and lay the bearing half with

the oil groove in each main bearing saddle inthe engine block. Lay the other bearing half

from each bearing set in the corresponding

main bearing cap. Make sure the tab on each

bearing insert fits into the recess in the engine

block or cap. Also, the oil holes in the block

must line up with the oil holes in the bearing

insert.

Caution: Do not hammer the bearings into

place and don’t nick or gouge the bearing

faces. No lubrication should be used at this

time.

6The thrust bearings (washers) must be

installed in the number four main bearing cap

and saddle.

7Clean the faces of the bearings in the

engine block and the crankshaft main bearing

journals with a clean, lint free cloth. Check or

clean the oil holes in the crankshaft, as any

dirt here can go only one way - straight

through the new bearings.

8Once you’re certain the crankshaft is clean,

carefully lay it in position in the main bearings.

9Before the crankshaft can be permanently

installed, the main bearing oil clearance must

be checked.

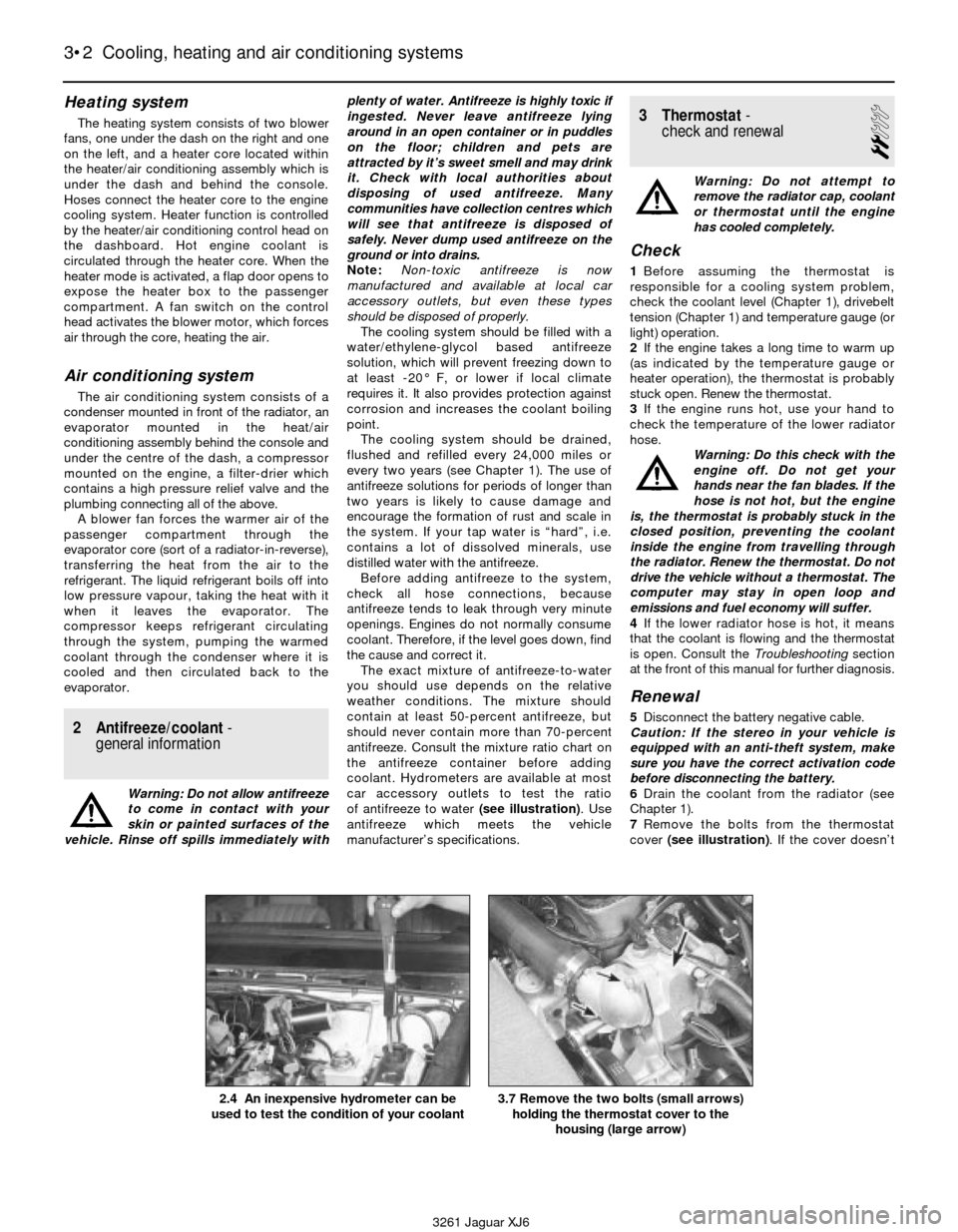

10Trim several pieces of the appropriate size

Plastigauge (they must be slightly shorter than

the width of the main bearings) and place one

piece on each crankshaft main bearing

journal, parallel with the journal axis (see

illustration).

11Clean the faces of the bearings in the

caps and refit the caps in their respective

positions (don’t mix them up) with the arrows

pointing toward the front of the engine. Don’t

disturb the Plastigauge. Apply a light coat of

oil to the bolt threads and the undersides of

the bolt heads, then refit them. Note:Use the

old bolts for this step (save the new bolts for

final refitting).

12Tighten the main bearing cap bolts, in

three steps, to the torque listed in this

Chapter’s Specifications. Don’t rotate the

crankshaft at any time during this operation!

13Remove the bolts and carefully lift off the

main bearing caps or cap assembly. Keep

them in order. Don’t disturb the Plastigauge or

rotate the crankshaft. If any of the main

bearing caps are difficult to remove, tap them

gently from side-to-side with a soft-face

hammer to loosen them.14Compare the width of the crushed

Plastigauge on each journal to the scale printed

on the Plastigauge envelope to obtain the main

bearing oil clearance (see illustration). Check

the Specifications to make sure it’s correct.

15If the clearance is not as specified, the

bearing inserts may be the wrong size (which

means different ones will be required - see

Section 20). Before deciding that different

inserts are needed, make sure that no dirt or

oil was between the bearing inserts and the

caps or engine block when the clearance was

measured. If the Plastigauge is noticeably

wider at one end than the other, the journal

may be tapered (see Section 19).

16Carefully scrape all traces of the

Plastigauge material off the main bearing

journals and/or the bearing faces. Don’t nick

or scratch the bearing faces.

Final crankshaft refitting

17Carefully lift the crankshaft out of the

engine. Clean the bearing faces in the engine

block, then apply a thin, uniform layer of clean

moly-base grease or engine assembly lube to

each of the bearing surfaces. Coat the thrust

washers as well.

18Lubricate the crankshaft surfaces that

contact the oil seals with moly-base grease,

engine assembly lube or clean engine oil.

19Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the engine block. Clean the faces of the

bearings in the main bearing caps, then apply

lubricant to them. Refit the main bearing caps

in their respective positions with the arrows

pointing toward the front of the engine. Note:

Be sure to refit the thrust washers (lubricated)

with the number 4 main journal.The upper

(block side) thrust washers can be rotated into

position around the crankshaft with the

crankshaft installed in the engine block, with

the thrust washer grooves facing OUT. The

lower thrust washers should be placed on the

main bearing caps with their grooves OUT.

20For the final assembly, use only new

bolts, for both the main bearings and the

2B•16 Engine removal and overhaul procedures

23.10 Lay the Plastigauge strips on the

main bearing journals, parallel to the

crankshaft centreline

23.14 Compare the width of the crushed

Plastigauge to the scale on the envelope to

determine the main bearing oil clearance

(always take the measurement at the

widest point of the Plastigauge). Be sure to

use the correct scale - imperial and metric

scales are included

3261 Jaguar XJ6

22.12 Refit the compression rings with a

ring expander - the mark must face up

Page 75 of 227

Heating system

The heating system consists of two blower

fans, one under the dash on the right and one

on the left, and a heater core located within

the heater/air conditioning assembly which is

under the dash and behind the console.

Hoses connect the heater core to the engine

cooling system. Heater function is controlled

by the heater/air conditioning control head on

the dashboard. Hot engine coolant is

circulated through the heater core. When the

heater mode is activated, a flap door opens to

expose the heater box to the passenger

compartment. A fan switch on the control

head activates the blower motor, which forces

air through the core, heating the air.

Air conditioning system

The air conditioning system consists of a

condenser mounted in front of the radiator, an

evaporator mounted in the heat/air

conditioning assembly behind the console and

under the centre of the dash, a compressor

mounted on the engine, a filter-drier which

contains a high pressure relief valve and the

plumbing connecting all of the above.

A blower fan forces the warmer air of the

passenger compartment through the

evaporator core (sort of a radiator-in-reverse),

transferring the heat from the air to the

refrigerant. The liquid refrigerant boils off into

low pressure vapour, taking the heat with it

when it leaves the evaporator. The

compressor keeps refrigerant circulating

through the system, pumping the warmed

coolant through the condenser where it is

cooled and then circulated back to the

evaporator.

2 Antifreeze/coolant-

general information

Warning: Do not allow antifreeze

to come in contact with your

skin or painted surfaces of the

vehicle. Rinse off spills immediately withplenty of water. Antifreeze is highly toxic if

ingested. Never leave antifreeze lying

around in an open container or in puddles

on the floor; children and pets are

attracted by it’s sweet smell and may drink

it. Check with local authorities about

disposing of used antifreeze. Many

communities have collection centres which

will see that antifreeze is disposed of

safely. Never dump used antifreeze on the

ground or into drains.

Note:Non-toxic antifreeze is now

manufactured and available at local car

accessory outlets, but even these types

should be disposed of properly.

The cooling system should be filled with a

water/ethylene-glycol based antifreeze

solution, which will prevent freezing down to

at least -20° F, or lower if local climate

requires it. It also provides protection against

corrosion and increases the coolant boiling

point.

The cooling system should be drained,

flushed and refilled every 24,000 miles or

every two years (see Chapter 1). The use of

antifreeze solutions for periods of longer than

two years is likely to cause damage and

encourage the formation of rust and scale in

the system. If your tap water is “hard”, i.e.

contains a lot of dissolved minerals, use

distilled water with the antifreeze.

Before adding antifreeze to the system,

check all hose connections, because

antifreeze tends to leak through very minute

openings. Engines do not normally consume

coolant. Therefore, if the level goes down, find

the cause and correct it.

The exact mixture of antifreeze-to-water

you should use depends on the relative

weather conditions. The mixture should

contain at least 50-percent antifreeze, but

should never contain more than 70-percent

antifreeze. Consult the mixture ratio chart on

the antifreeze container before adding

coolant. Hydrometers are available at most

car accessory outlets to test the ratio

of antifreeze to water (see illustration). Use

antifreeze which meets the vehicle

manufacturer’s specifications.

3 Thermostat-

check and renewal

2

Warning: Do not attempt to

remove the radiator cap, coolant

or thermostat until the engine

has cooled completely.

Check

1Before assuming the thermostat is

responsible for a cooling system problem,

check the coolant level (Chapter 1), drivebelt

tension (Chapter 1) and temperature gauge (or

light) operation.

2If the engine takes a long time to warm up

(as indicated by the temperature gauge or

heater operation), the thermostat is probably

stuck open. Renew the thermostat.

3If the engine runs hot, use your hand to

check the temperature of the lower radiator

hose.

Warning: Do this check with the

engine off. Do not get your

hands near the fan blades. If the

hose is not hot, but the engine

is, the thermostat is probably stuck in the

closed position, preventing the coolant

inside the engine from travelling through

the radiator. Renew the thermostat. Do not

drive the vehicle without a thermostat. The

computer may stay in open loop and

emissions and fuel economy will suffer.

4If the lower radiator hose is hot, it means

that the coolant is flowing and the thermostat

is open. Consult the Troubleshootingsection

at the front of this manual for further diagnosis.

Renewal

5Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

6Drain the coolant from the radiator (see

Chapter 1).

7Remove the bolts from the thermostat

cover (see illustration). If the cover doesn’t

3•2 Cooling, heating and air conditioning systems

3261 Jaguar XJ6 2.4 An inexpensive hydrometer can be

used to test the condition of your coolant

3.7 Remove the two bolts (small arrows)

holding the thermostat cover to the

housing (large arrow)

Page 80 of 227

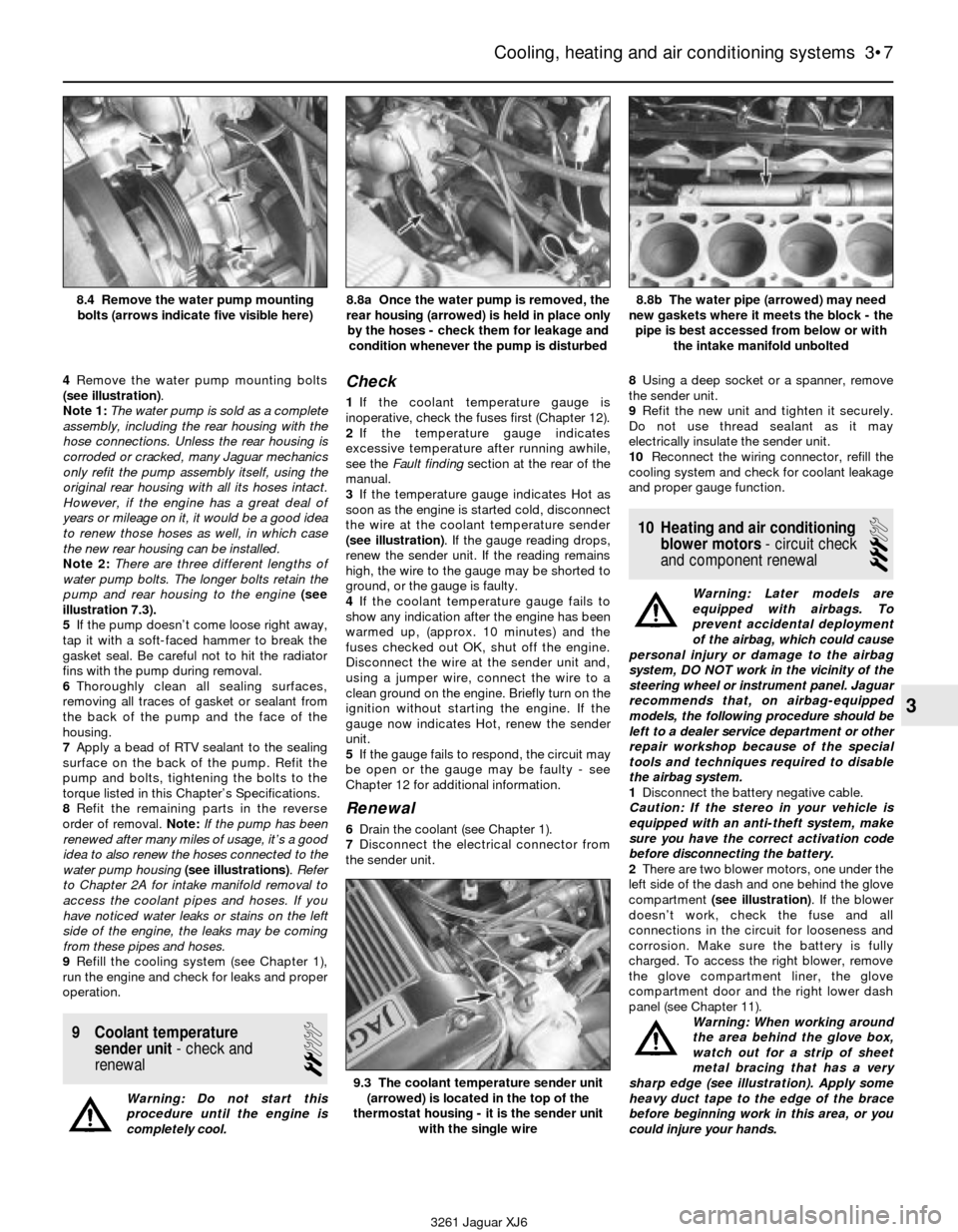

4Remove the water pump mounting bolts

(see illustration).

Note 1:The water pump is sold as a complete

assembly, including the rear housing with the

hose connections. Unless the rear housing is

corroded or cracked, many Jaguar mechanics

only refit the pump assembly itself, using the

original rear housing with all its hoses intact.

However, if the engine has a great deal of

years or mileage on it, it would be a good idea

to renew those hoses as well, in which case

the new rear housing can be installed.

Note 2:There are three different lengths of

water pump bolts. The longer bolts retain the

pump and rear housing to the engine(see

illustration 7.3).

5If the pump doesn’t come loose right away,

tap it with a soft-faced hammer to break the

gasket seal. Be careful not to hit the radiator

fins with the pump during removal.

6Thoroughly clean all sealing surfaces,

removing all traces of gasket or sealant from

the back of the pump and the face of the

housing.

7Apply a bead of RTV sealant to the sealing

surface on the back of the pump. Refit the

pump and bolts, tightening the bolts to the

torque listed in this Chapter’s Specifications.

8Refit the remaining parts in the reverse

order of removal. Note:If the pump has been

renewed after many miles of usage, it’s a good

idea to also renew the hoses connected to the

water pump housing(see illustrations). Refer

to Chapter 2A for intake manifold removal to

access the coolant pipes and hoses. If you

have noticed water leaks or stains on the left

side of the engine, the leaks may be coming

from these pipes and hoses.

9Refill the cooling system (see Chapter 1),

run the engine and check for leaks and proper

operation.

9 Coolant temperature

sender unit- check and

renewal

2

Warning: Do not start this

procedure until the engine is

completely cool.

Check

1If the coolant temperature gauge is

inoperative, check the fuses first (Chapter 12).

2If the temperature gauge indicates

excessive temperature after running awhile,

see the Fault finding section at the rear of the

manual.

3If the temperature gauge indicates Hot as

soon as the engine is started cold, disconnect

the wire at the coolant temperature sender

(see illustration). If the gauge reading drops,

renew the sender unit. If the reading remains

high, the wire to the gauge may be shorted to

ground, or the gauge is faulty.

4If the coolant temperature gauge fails to

show any indication after the engine has been

warmed up, (approx. 10 minutes) and the

fuses checked out OK, shut off the engine.

Disconnect the wire at the sender unit and,

using a jumper wire, connect the wire to a

clean ground on the engine. Briefly turn on the

ignition without starting the engine. If the

gauge now indicates Hot, renew the sender

unit.

5If the gauge fails to respond, the circuit may

be open or the gauge may be faulty - see

Chapter 12 for additional information.

Renewal

6Drain the coolant (see Chapter 1).

7Disconnect the electrical connector from

the sender unit.8Using a deep socket or a spanner, remove

the sender unit.

9Refit the new unit and tighten it securely.

Do not use thread sealant as it may

electrically insulate the sender unit.

10Reconnect the wiring connector, refill the

cooling system and check for coolant leakage

and proper gauge function.

10 Heating and air conditioning

blower motors- circuit check

and component renewal

3

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering wheel or instrument panel. Jaguar

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department or other

repair workshop because of the special

tools and techniques required to disable

the airbag system.

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2There are two blower motors, one under the

left side of the dash and one behind the glove

compartment (see illustration). If the blower

doesn’t work, check the fuse and all

connections in the circuit for looseness and

corrosion. Make sure the battery is fully

charged. To access the right blower, remove

the glove compartment liner, the glove

compartment door and the right lower dash

panel (see Chapter 11).

Warning: When working around

the area behind the glove box,

watch out for a strip of sheet

metal bracing that has a very

sharp edge (see illustration). Apply some

heavy duct tape to the edge of the brace

before beginning work in this area, or you

could injure your hands.

Cooling, heating and air conditioning systems 3•7

3

8.4 Remove the water pump mounting

bolts (arrows indicate five visible here)8.8a Once the water pump is removed, the

rear housing (arrowed) is held in place only

by the hoses - check them for leakage and

condition whenever the pump is disturbed8.8b The water pipe (arrowed) may need

new gaskets where it meets the block - the

pipe is best accessed from below or with

the intake manifold unbolted

9.3 The coolant temperature sender unit

(arrowed) is located in the top of the

thermostat housing - it is the sender unit

with the single wire

3261 Jaguar XJ6

Page 84 of 227

4Refitting is the reverse of the removal

procedure.

5Run the engine and check for proper

functioning of the heater (and air conditioning,

if equipped).

Control checks

6The climate-control system uses an all-

electronic control panel that sends digital

information to the climate control computer.

There is little the home mechanic can do to

troubleshoot or test the system. The factory

recommends that diagnosis be performed at a

dealership.

7If there is a problem in just one area of

climate control, put the controls through their

entire range of operation and check the

system responses, i.e. set the controls to

COLD, the fan to low and the temperature to

65° F. In this mode the Manual LED should be

lit and the air conditioning compressor should

engage. Try all of the fan speeds and try the

temperature on HOT, then feel for warm air

coming from the ducts. Note:Between each

try of the different controls, wait 20 seconds or

so for the heater/air conditioning system to

adjust before checking for a response.

8When each control button is pushed two

times, its LED light should go on or off. Renew

the control assembly if any of the warning

lights don’t work.

9On 1988 and 1989 models, if the climate

controls do not respond to any driver input,

check with your Jaguar dealer before

renewing the ECU or control panel. A service

part is available (a resistor, #JLM 1901) that

can be installed at one of the control panel

terminals that may fix the problem without any

other parts being renewed. Instructions are

included with the part.

10Check the vacuum lines to the several

vacuum motors that operate the heater/air

conditioning functions. Look for pinched or

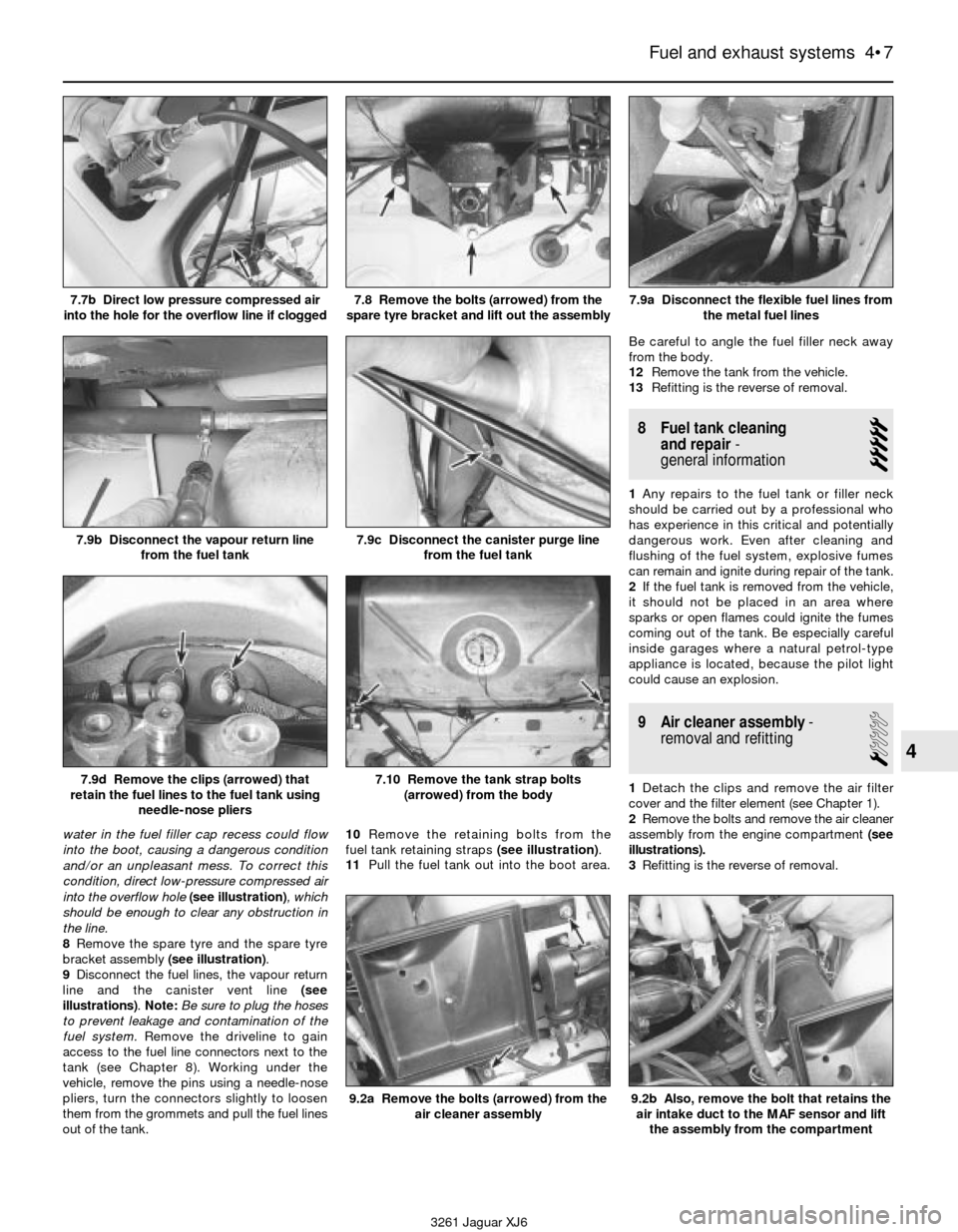

blocked hoses and leaks.11Each of the vacuum “servo motors” in the

system can be checked with a hand-held

vacuum pump (see illustration). Apply vacuum

and watch that the door or control it operates is

working.

12Further diagnosis of the controls or

climate control ECU are best left to a Jaguar

dealership or other qualified repair facility.

13 Air conditioning and heating

system- check and

maintenance

1

Air conditioning system

Warning: The air conditioning

system is under high pressure.

Do not loosen any hose fittings

or remove any components until

the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an EPA-approved

recovery/recycling unit by a dealer service

department or an automotive air

conditioning repair facility. Always wear

eye protection when working near air

conditioning system fittings.

1The following maintenance checks should

be performed on a regular basis to ensure that

the air conditioner continues to operate at

peak efficiency:

a) Inspect the condition of the compressor

drivebelt. If it is worn or deteriorated,

renew it (see Chapter 1).

b) Check the drivebelt tension and, if

necessary, adjust it (see Chapter 1).

c) Inspect the system hoses. Look for

cracks, bubbles, hardening and

deterioration. Inspect the hoses and all

fittings for oil bubbles or seepage. If there

is any evidence of wear, damage or

leakage, renew the hose(s).d) Inspect the condenser fins for leaves,

bugs and any other foreign material that

may have embedded itself in the fins. Use

a “fin comb” or compressed air to remove

debris from the condenser.

e) Make sure the system has the correct

refrigerant charge.

2It’s a good idea to operate the system for

about ten minutes at least once a month. This

is particularly important during the winter

months because long term non-use can

cause hardening, and subsequent failure, of

the seals.

3Leaks in the air conditioning system are

best spotted when the system is brought up

to operating temperature and pressure, by

running the engine with the air conditioning

ON for five minutes. Shut the engine off and

inspect the air conditioning hoses and

connections. Traces of oil usually indicate

refrigerant leaks.

4Because of the complexity of the air

conditioning system and the special

equipment required to effectively work on it,

accurate troubleshooting of the system

should be left to a professional technician.

5If the air conditioning system doesn’t

operate at all, check the fuse panel and the air

conditioning relay (refer to Chapter 12 for

relay locations and testing). See Sections 4, 9

and 12 for electrical checks of heating/air

conditioning system components.

6The most common cause of poor cooling is

simply a low system refrigerant charge. If a

noticeable drop in cool air output occurs, the

following quick check will help you determine

if the refrigerant level is low.

Checking the refrigerant charge

7Warm the engine up to normal operating

temperature.

8Place the air conditioning temperature

selector at the coldest setting and put the

Cooling, heating and air conditioning systems 3•11

3

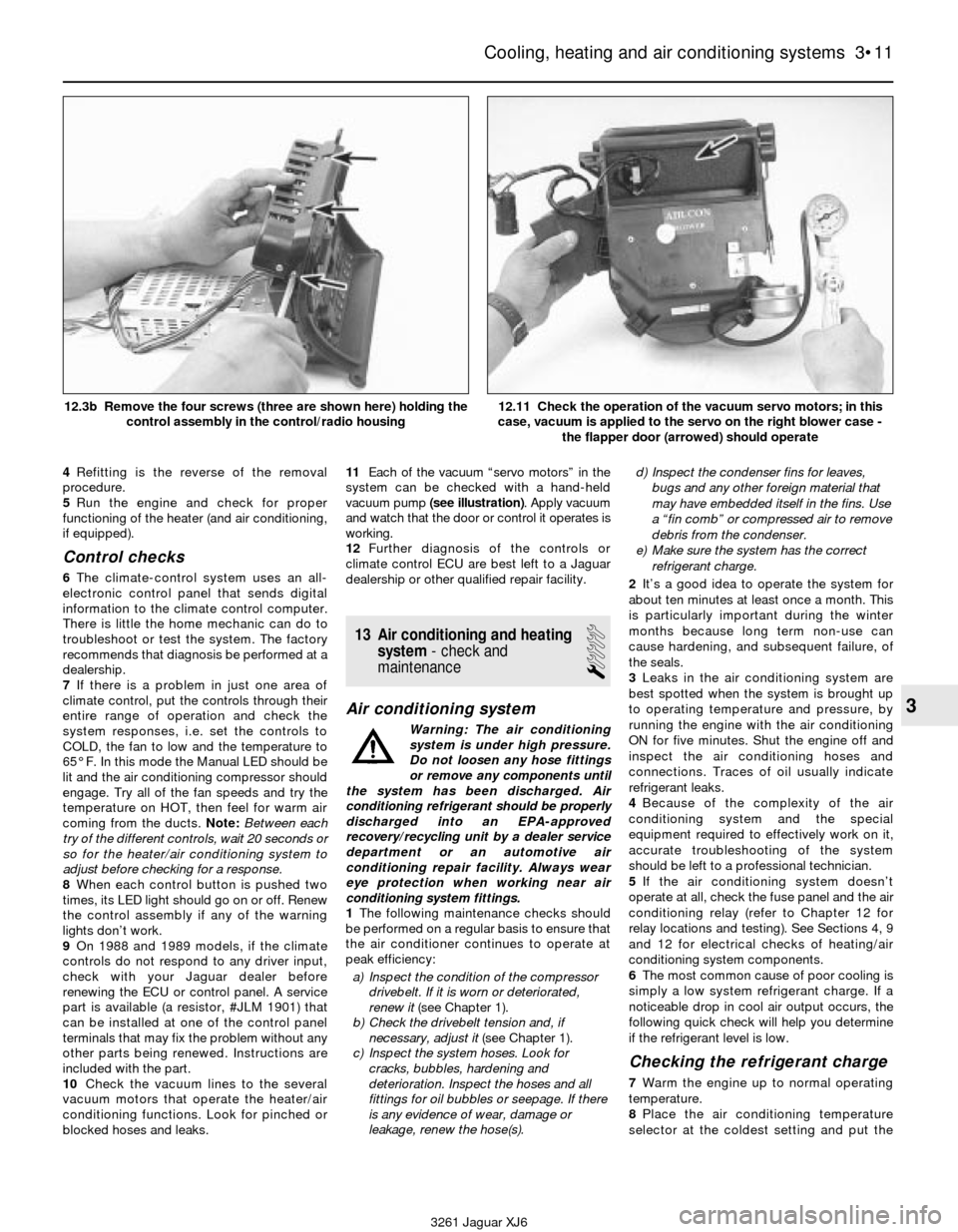

3261 Jaguar XJ6 12.3b Remove the four screws (three are shown here) holding the

control assembly in the control/radio housing

12.11 Check the operation of the vacuum servo motors; in this

case, vacuum is applied to the servo on the right blower case -

the flapper door (arrowed) should operate

Page 85 of 227

blower at the highest setting. Open the doors

(to make sure the air conditioning system

doesn’t cycle off as soon as it cools the

passenger compartment).

9With the compressor engaged - the clutch

will make an audible click and the centre of

the clutch will rotate. After the system reaches

operating temperature, feel the two pipes

connected to the evaporator at the bulkhead

(see illustration).

10The pipe (thinner tubing) leading from the

condenser outlet to the evaporator should be

cold, and the evaporator outlet line (the

thicker tubing that leads back to the

compressor) should be slightly colder (3 to

10° F). If the evaporator outlet is considerably

warmer than the inlet, the system needs a

charge. Insert a thermometer in the centre air

distribution duct while operating the air

conditioning system - the temperature of the

output air should be 35 to 40° F below the

ambient air temperature (down to approxi-

mately 40° F). If the ambient (outside) air

temperature is very high, say 110° F, the duct

air temperature may be as high as 60° F, but

generally the air conditioning is 30 to 50° F

cooler than the ambient air. If the air isn’t as

cold as it used to be, the system probably

needs a charge. Further inspection or testing

of the system is beyond the scope of the

home mechanic and should be left to a

professional.

11Inspect the sight glass (see illustration).

If the refrigerant looks foamy when running,

it’s low. When ambient temperatures are very

hot, bubbles may show in the sight glass even

with the proper amount of refrigerant. With the

proper amount of refrigerant, when the air

conditioning is turned off, the sight glass

should show refrigerant that foams, then

clears. Note:1993 and 1994 models are

equipped with R-134a refrigerant systems and

do not have a sight glass.Heating systems

12If the air coming out of the heater vents

isn’t hot, the problem could stem from any of

the following causes:

a) The thermostat is stuck open, preventing

the engine coolant from warming up

enough to carry heat to the heater core.

Renew the thermostat (see Section 3).

b) A heater hose is blocked, preventing the

flow of coolant through the heater core.

Feel both heater hoses at the bulkhead.

They should be hot. If one of them is cold,

there is an obstruction in one of the hoses

or in the heater core, or the heater control

valve is shut. Detach the hoses and back

flush the heater core with a water hose. If

the heater core is clear but circulation is

impeded, remove the two hoses and flush

them out with a water hose.

c) If flushing fails to remove the blockage

from the heater core, the core must be

renewed.(see Section 11).

13If the blower motor speed does not

correspond to the setting selected on the

blower switch, the problem could be a badfuse, circuit, control panel or climate control

computer (see Sections 10 and 12).

14If there isn’t any air coming out of the

vents:

a) Turn the ignition ON and activate the fan

control. Place your ear at the heating/air

conditioning register (vent) and listen.

Most motors are audible. Can you hear

the motor running?

b) If you can’t (and have already verified that

the blower switch and the blower motor

resistor are good), the blower motor itself

is probably bad (see Section 10).

15If the carpet under the heater core is

damp, or if antifreeze vapour or steam is

coming through the vents, the heater core is

leaking. Remove it (see Section 11) and refit a

new unit (most radiator shops will not repair a

leaking heater core).

16Inspect the drain hose from the heat/AC

assembly at the right side of the bulkhead,

make sure it is not clogged (see illustration).

If there is a humid mist coming from the

system ducts, this hose may be plugged. In

some early models, the hose may have been

pinched during assembly or blocked with

insulation or underseal.

14 Air conditioning

receiver/drier-

removal and refitting

4

Warning: The air conditioning

system is under high pressure.

Do not loosen any hose fittings

or remove any components until

the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an EPA-approved recovery/

recycling unit by a dealer service depart-

ment or an automotive air conditioning

3•12 Cooling, heating and air conditioning systems

13.16 This drain hose (arrowed) from the

heater/air conditioning unit should be kept

clear to allow drainage of condensation

3261 Jaguar XJ6 13.9 Feel the inlet (small arrow) and outlet (large arrow) pipes at

the bulkhead leading to the air conditioning evaporator (battery

removed here for clarity only)

13.11 The sight glass (arrowed) is located on the top of the

receiver/drier, to the right of the radiator

Page 95 of 227

water in the fuel filler cap recess could flow

into the boot, causing a dangerous condition

and/or an unpleasant mess. To correct this

condition, direct low-pressure compressed air

into the overflow hole (see illustration), which

should be enough to clear any obstruction in

the line.

8Remove the spare tyre and the spare tyre

bracket assembly (see illustration).

9Disconnect the fuel lines, the vapour return

line and the canister vent line (see

illustrations). Note:Be sure to plug the hoses

to prevent leakage and contamination of the

fuel system.Remove the driveline to gain

access to the fuel line connectors next to the

tank (see Chapter 8). Working under the

vehicle, remove the pins using a needle-nose

pliers, turn the connectors slightly to loosen

them from the grommets and pull the fuel lines

out of the tank.10Remove the retaining bolts from the

fuel tank retaining straps (see illustration).

11Pull the fuel tank out into the boot area.Be careful to angle the fuel filler neck away

from the body.

12Remove the tank from the vehicle.

13Refitting is the reverse of removal.

8 Fuel tank cleaning

and repair-

general information

5

1Any repairs to the fuel tank or filler neck

should be carried out by a professional who

has experience in this critical and potentially

dangerous work. Even after cleaning and

flushing of the fuel system, explosive fumes

can remain and ignite during repair of the tank.

2If the fuel tank is removed from the vehicle,

it should not be placed in an area where

sparks or open flames could ignite the fumes

coming out of the tank. Be especially careful

inside garages where a natural petrol-type

appliance is located, because the pilot light

could cause an explosion.

9 Air cleaner assembly-

removal and refitting

1

1Detach the clips and remove the air filter

cover and the filter element (see Chapter 1).

2Remove the bolts and remove the air cleaner

assembly from the engine compartment (see

illustrations).

3Refitting is the reverse of removal.

Fuel and exhaust systems 4•7

4

7.7b Direct low pressure compressed air

into the hole for the overflow line if clogged7.8 Remove the bolts (arrowed) from the

spare tyre bracket and lift out the assembly7.9a Disconnect the flexible fuel lines from

the metal fuel lines

7.9b Disconnect the vapour return line

from the fuel tank7.9c Disconnect the canister purge line

from the fuel tank

7.9d Remove the clips (arrowed) that

retain the fuel lines to the fuel tank using

needle-nose pliers

3261 Jaguar XJ6

7.10 Remove the tank strap bolts

(arrowed) from the body

9.2a Remove the bolts (arrowed) from the

air cleaner assembly9.2b Also, remove the bolt that retains the

air intake duct to the MAF sensor and lift

the assembly from the compartment

Page 98 of 227

of these sensors and their corresponding

ECU-controlled relays are not contained

within EFI components, but are located

throughout the engine compartment. For

further information regarding the ECU and its

relationship to the engine electrical and

ignition system, see Chapter 6.

12 Electronic Fuel Injection

(EFI) system- check

2

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor grounds

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully

charged, as the control unit and sensors

depend on an accurate supply voltage in

order to properly meter the fuel.

3Check the air filter element - a dirty or

partially blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a shorted

wire in the harness related to the system.

5Check the air intake duct from the MAF

sensor to the intake manifold for leaks, which

will result in an excessively lean mixture. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body and check for carbon and residue build-

up. If it’s dirty, clean with aerosol carburettor

cleaner (make sure the can says it’s safe for

use with oxygen sensors and catalytic

converters) and a toothbrush.

7With the engine running, place a

stethoscope against each injector, one at a

time, and listen for a clicking sound, indicating

operation (see illustration).8If there is a problem with an injector,

purchase a special injector test light (noid

light) and refit it into the injector electrical

connector (see illustration). Start the engine

and make sure that each injector connector

flashes the noid light. This will test for the

proper voltage signal to the injector.Caution:

If the engine will not start and the noid

light indicates that each injector is

receiving the proper signal, there is a good

possibility that the injector(s) is stuck open

and allowing fuel into the combustion

chamber in excessive amounts. If the spark

plugs are fouled, detach the primary (low

voltage) wires from the ignition coil, disable

the fuel pump by removing the fuel pump

relay (see Section 2), remove the spark plugs

and crank the engine over. If fuel sprays from

the spark plug holes, the engine is flooded

and the fuel must be removed from the

combustion chambers.

9With the engine OFF and the fuel injector

electrical connectors disconnected, measure

the resistance of each injector (see

illustration). Each injector should measure

about 2.0 to 3.0 ohms. If not, the injector is

probably faulty.10The remainder of the system checks

should be left to a Jaguar service department

or other qualified repair workshop, as there is

a chance that the control unit may be

damaged if not performed properly.

13 Electronic Fuel Injection

(EFI) system- component

check and renewal

3

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

Throttle body

Check

1Verify that the throttle linkage operates

smoothly.

2Start the engine, detach each vacuum hose

and, using your finger, check the vacuum at

each port on the throttle body with the engine

at idle and above idle. The vacuum available

from the throttle body is ported. Raise the

engine rpm and watch as vacuum increases.

It may be necessary to use a vacuum gauge.

Refer to Chapter 2B for additional information

concerning vacuum checks.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

3Detach the cable from the negative terminal

of the battery (see the Cautionat the

beginning of this Section).

4Drain the radiator (see Chapter 1).

4•10 Fuel and exhaust systems

12.9 Using an ohmmeter, measure the

resistance across both terminals

of the injector

3261 Jaguar XJ6 12.7 Use a stethoscope or a screwdriver to determine if the

injectors are working properly - they should make a steady

clicking sound that rises and falls with engine speed changes

12.8 Refit the “noid” light into the fuel injector electrical

connector and check to see that it blinks with the engine running