damper JAGUAR XJ6 1997 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 39 of 227

Torque wrench settings*Nm lbf ft

Camshaft bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Camshaft sprocket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft damper-to-crankshaft bolt

3.2 and 3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204 151

4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 to 220 133 to 162

Crankshaft pulley to damper bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft rear oil seal retainer bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft sensor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Cylinder head bolts

Step 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 44

Step 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten an additional 90° (1/4 turn)

Driveplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 to 149 91 to 110

Engine mounts

To engine block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 to 66 36 to 39

To chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24 16 to 18

Exhaust manifold heat shield fasteners . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Exhaust manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Intake manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Sump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Sump bolts, adapter to pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 to 54 36 to 40

Timing chain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Valve cover screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 to 12 7 to 9

*Note:Refer to Part B for additional specifications

2A•2 Engine in-car repair procedures

3261 Jaguar XJ6

1 General information

This Part of Chapter 2 is devoted to in-car

repair procedures for the in-line six-cylinder

engines. All information concerning engine

removal and refitting and engine block and

cylinder head overhaul can be found in Part B

of this Chapter.

The following repair procedures are based

on the assumption that the engine is installed

in the car. If the engine has been removed

from the car and mounted on a stand, many of

the steps outlined in this Part of Chapter 2 will

not apply. We have photographed some in-

car engine procedures with the engine on a

stand for photographic purposes.

The Specifications included in this Part of

Chapter 2 apply only to the procedures

contained in this Part. Part B of Chapter 2

includes the Specifications necessary for

cylinder head and engine block rebuilding.

2 Repair operations possible

with the engine in the car

Many repair operations can be

accomplished without removing the engine

from the car.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier and help keep dirt out of

the internal areas of the engine.

Depending on the components involved, itmay be helpful to remove the bonnet to

improve access to the engine as repairs are

performed (refer to Chapter 11 if necessary).

Cover the wings to prevent damage to the

paint. Special pads are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for gasket or seal

renewal, the repairs can generally be made

with the engine in the car. The intake and

exhaust manifold gaskets, crankshaft oil seals

and cylinder head gasket are all accessible

with the engine in place (although rear oil seal

renewal involves removal of the transmission).

The sump is difficult for a home mechanic to

replace without a hoist and other specialised

equipment, since the front suspension,

steering and crossmember must be lowered

to allow enough clearance for sump removal.

If such equipment is not available, the

alternative would be to remove the engine for

renewal of the sump or oil pump. Note:We

assume that the home mechanic does not

have access to the specialised equipment,

and have photographed our subject engine

out of the car for some procedures.

Exterior engine components, such as the

intake and exhaust manifolds, the water

pump, the starter motor, the alternator, the

distributor and the fuel system components

can be removed for repair with the engine in

place.

Since the cylinder head can be removed

with the engine in-car, camshaft and valve

component servicing can also be

accomplished. Renewal of the timing chains

and sprockets is also possible with the engine

in-car.

3 Top Dead Centre (TDC) for

number one piston- locating

1

Note:The following procedure is based on the

assumption that the distributor is correctly

installed. If you are trying to locate TDC to refit

the distributor correctly, piston position must

be determined by feeling for compression at

the number one spark plug hole, then aligning

the ignition timing marks (see paragraph 8).

1Top Dead Centre (TDC) is the highest point

in the cylinder that each piston reaches as it

travels up the cylinder bore. Each piston

reaches TDC on the compression stroke and

again on the exhaust stroke, but TDC

generally refers to piston position on the

compression stroke.

2Positioning the piston(s) at TDC is an

essential part of many procedures such as

camshaft and timing chain/sprocket removal

and distributor removal.

3Before beginning this procedure, be sure to

place the transmission in Neutral and apply

the handbrake or block the rear wheels. Also,

disable the ignition system by detaching the

coil wire from the centre terminal of the

distributor cap and grounding it on the engine

block with a jumper wire. Remove the spark

plugs (see Chapter 1).

4In order to bring any piston to TDC, the

crankshaft must be turned using one of the

methods outlined below. When looking at the

timing chain end of the engine, normal

crankshaft rotation is clockwise.

a) The preferred method is to turn the

crankshaft with a socket and ratchet

Page 42 of 227

Refitting

7Use a scraper to remove all traces of old

gasket material and carbon deposits from the

manifold and cylinder head mating surfaces. If

the gasket was leaking, have the manifold

checked for warpage at an automotive

machine workshop and resurfaced if

necessary.

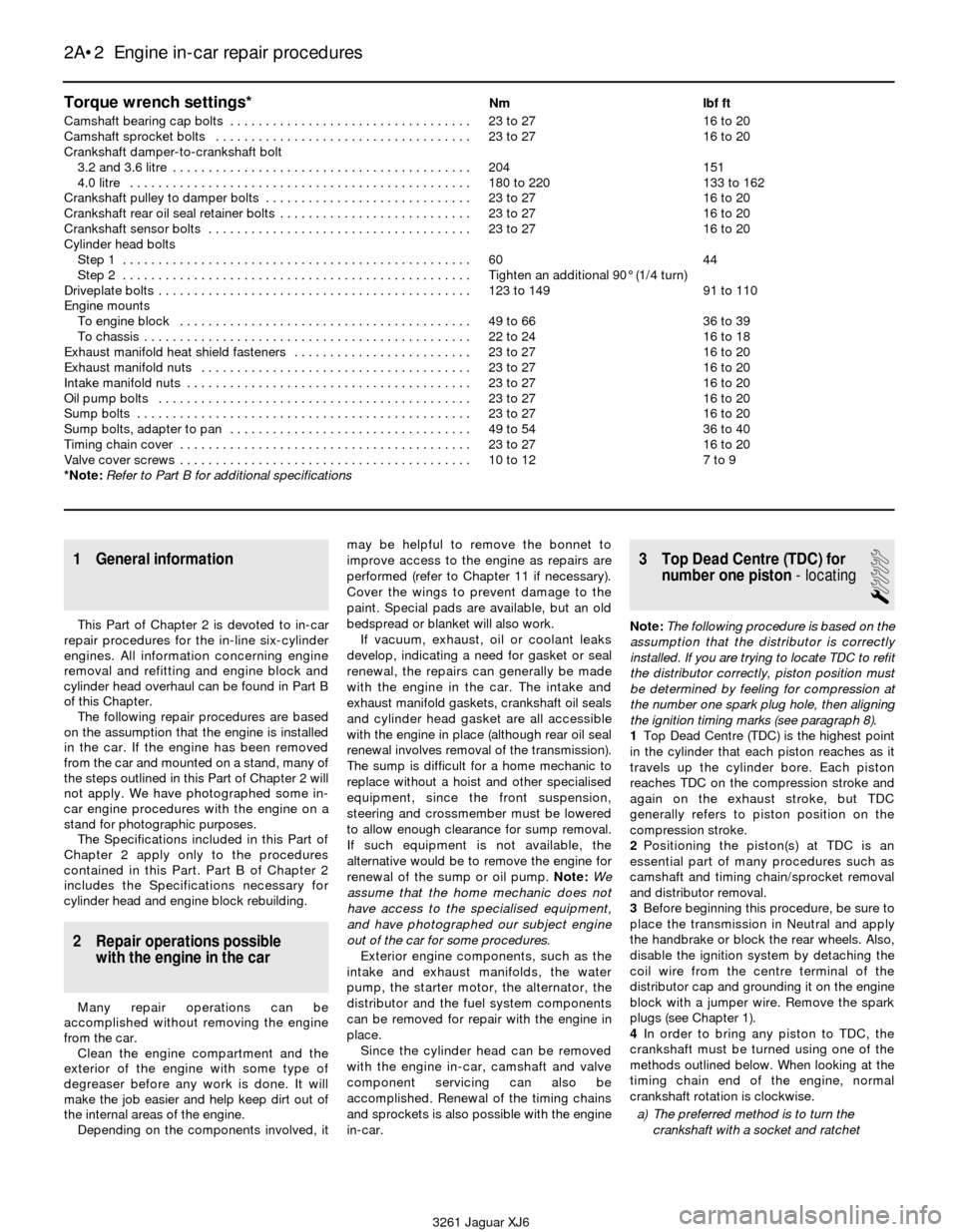

8Position new gaskets over the cylinder

head studs (see illustration). Note:The

marks on the gasket should face out (away

from the cylinder head) and the arrow should

point toward the rear of the engine.

9Refit the manifolds and thread the mounting

nuts/bolts into place.

10Working from the centre out, tighten the

nuts/bolts to the torque listed in this Chapter’s

Specifications in three or four equal steps.

11Refit the remaining parts in the reverse

order of removal.

12Run the engine and check for exhaust

leaks.

7 Crankshaft front oil seal-

renewal

3

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle isequipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Chapter 1 and remove the

accessory drive belts.

3Refer to Chapter 3 and remove the fan

shroud and fan clutch assembly.

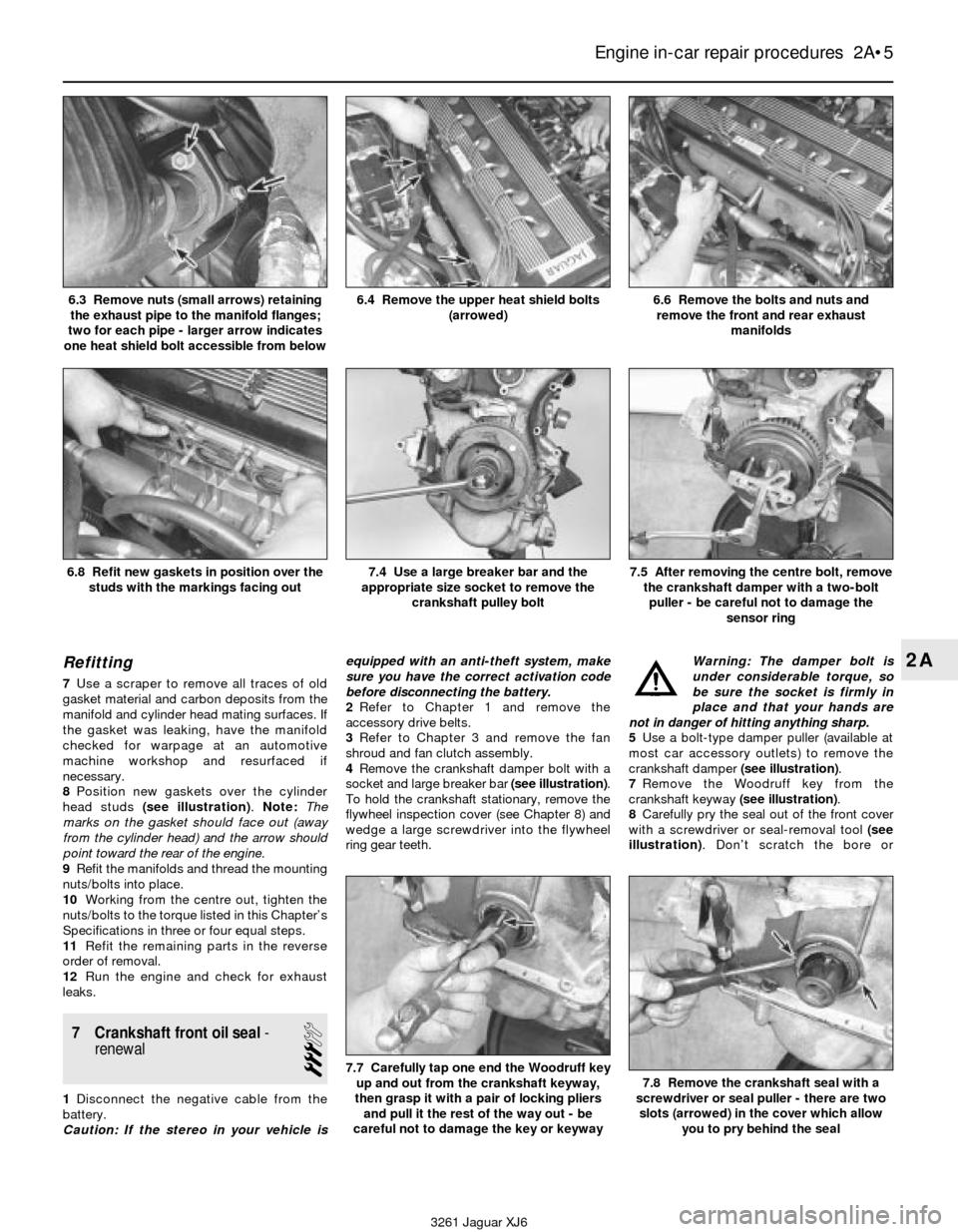

4Remove the crankshaft damper bolt with a

socket and large breaker bar (see illustration).

To hold the crankshaft stationary, remove the

flywheel inspection cover (see Chapter 8) and

wedge a large screwdriver into the flywheel

ring gear teeth. Warning: The damper bolt is

under considerable torque, so

be sure the socket is firmly in

place and that your hands are

not in danger of hitting anything sharp.

5Use a bolt-type damper puller (available at

most car accessory outlets) to remove the

crankshaft damper (see illustration).

7Remove the Woodruff key from the

crankshaft keyway (see illustration).

8Carefully pry the seal out of the front cover

with a screwdriver or seal-removal tool(see

illustration). Don’t scratch the bore or

Engine in-car repair procedures 2A•5

2A

6.3 Remove nuts (small arrows) retaining

the exhaust pipe to the manifold flanges;

two for each pipe - larger arrow indicates

one heat shield bolt accessible from below6.4 Remove the upper heat shield bolts

(arrowed)6.6 Remove the bolts and nuts and

remove the front and rear exhaust

manifolds

6.8 Refit new gaskets in position over the

studs with the markings facing out

7.7 Carefully tap one end the Woodruff key

up and out from the crankshaft keyway,

then grasp it with a pair of locking pliers

and pull it the rest of the way out - be

careful not to damage the key or keyway7.8 Remove the crankshaft seal with a

screwdriver or seal puller - there are two

slots (arrowed) in the cover which allow

you to pry behind the seal

7.4 Use a large breaker bar and the

appropriate size socket to remove the

crankshaft pulley bolt7.5 After removing the centre bolt, remove

the crankshaft damper with a two-bolt

puller - be careful not to damage the

sensor ring

3261 Jaguar XJ6

Page 43 of 227

damage the crankshaft in the process (if the

crankshaft is damaged, the new seal will end

up leaking).

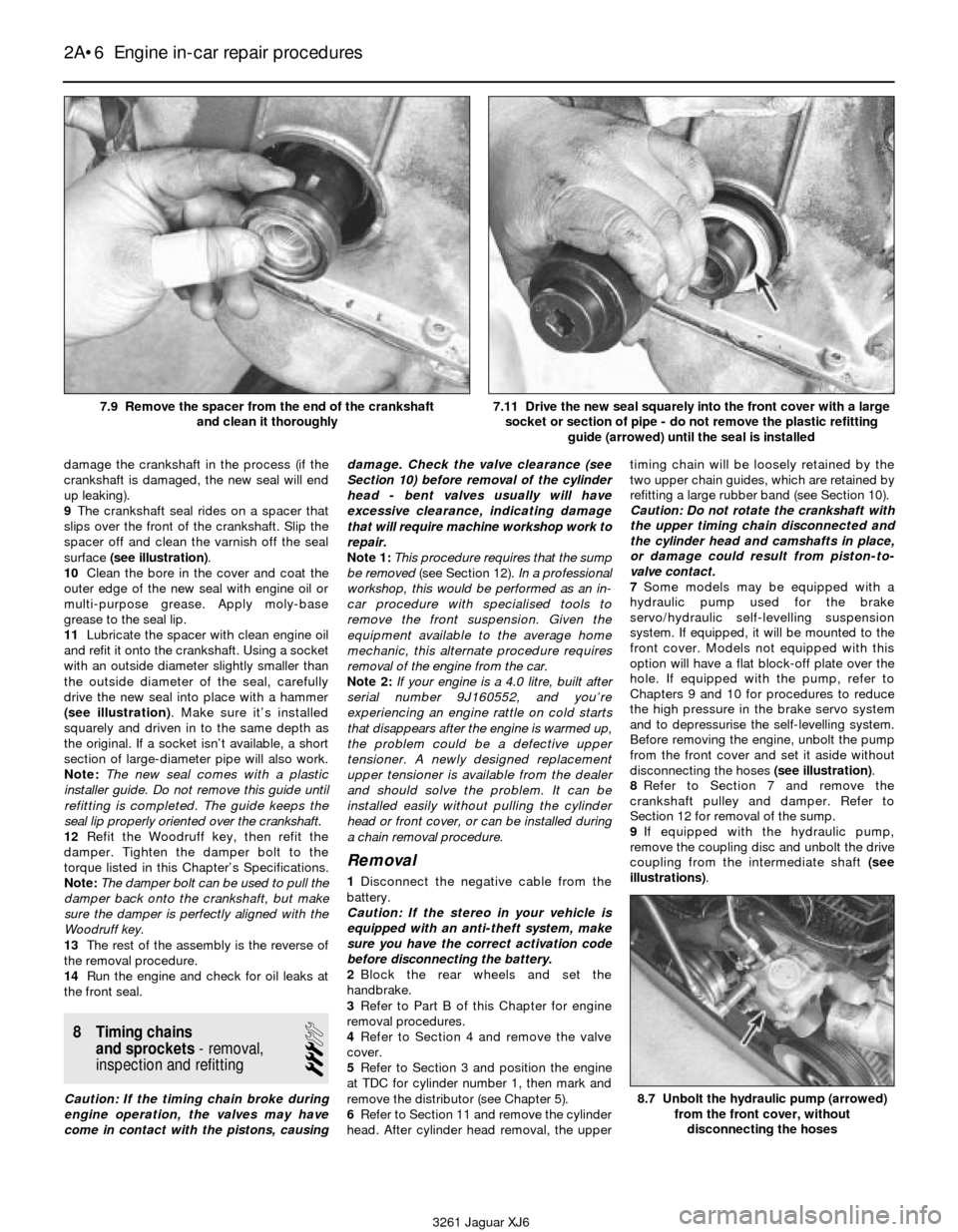

9The crankshaft seal rides on a spacer that

slips over the front of the crankshaft. Slip the

spacer off and clean the varnish off the seal

surface (see illustration).

10Clean the bore in the cover and coat the

outer edge of the new seal with engine oil or

multi-purpose grease. Apply moly-base

grease to the seal lip.

11Lubricate the spacer with clean engine oil

and refit it onto the crankshaft. Using a socket

with an outside diameter slightly smaller than

the outside diameter of the seal, carefully

drive the new seal into place with a hammer

(see illustration). Make sure it’s installed

squarely and driven in to the same depth as

the original. If a socket isn’t available, a short

section of large-diameter pipe will also work.

Note:The new seal comes with a plastic

installer guide. Do not remove this guide until

refitting is completed. The guide keeps the

seal lip properly oriented over the crankshaft.

12Refit the Woodruff key, then refit the

damper. Tighten the damper bolt to the

torque listed in this Chapter’s Specifications.

Note:The damper bolt can be used to pull the

damper back onto the crankshaft, but make

sure the damper is perfectly aligned with the

Woodruff key.

13The rest of the assembly is the reverse of

the removal procedure.

14Run the engine and check for oil leaks at

the front seal.

8 Timing chains

and sprockets- removal,

inspection and refitting

3

Caution: If the timing chain broke during

engine operation, the valves may have

come in contact with the pistons, causingdamage. Check the valve clearance (see

Section 10) before removal of the cylinder

head - bent valves usually will have

excessive clearance, indicating damage

that will require machine workshop work to

repair.

Note 1:This procedure requires that the sump

be removed (see Section 12).In a professional

workshop, this would be performed as an in-

car procedure with specialised tools to

remove the front suspension. Given the

equipment available to the average home

mechanic, this alternate procedure requires

removal of the engine from the car.

Note 2:If your engine is a 4.0 litre, built after

serial number 9J160552, and you’re

experiencing an engine rattle on cold starts

that disappears after the engine is warmed up,

the problem could be a defective upper

tensioner. A newly designed replacement

upper tensioner is available from the dealer

and should solve the problem. It can be

installed easily without pulling the cylinder

head or front cover, or can be installed during

a chain removal procedure.

Removal

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Block the rear wheels and set the

handbrake.

3Refer to Part B of this Chapter for engine

removal procedures.

4Refer to Section 4 and remove the valve

cover.

5Refer to Section 3 and position the engine

at TDC for cylinder number 1, then mark and

remove the distributor (see Chapter 5).

6Refer to Section 11 and remove the cylinder

head. After cylinder head removal, the uppertiming chain will be loosely retained by the

two upper chain guides, which are retained by

refitting a large rubber band (see Section 10).

Caution: Do not rotate the crankshaft with

the upper timing chain disconnected and

the cylinder head and camshafts in place,

or damage could result from piston-to-

valve contact.

7Some models may be equipped with a

hydraulic pump used for the brake

servo/hydraulic self-levelling suspension

system. If equipped, it will be mounted to the

front cover. Models not equipped with this

option will have a flat block-off plate over the

hole. If equipped with the pump, refer to

Chapters 9 and 10 for procedures to reduce

the high pressure in the brake servo system

and to depressurise the self-levelling system.

Before removing the engine, unbolt the pump

from the front cover and set it aside without

disconnecting the hoses (see illustration).

8Refer to Section 7 and remove the

crankshaft pulley and damper. Refer to

Section 12 for removal of the sump.

9If equipped with the hydraulic pump,

remove the coupling disc and unbolt the drive

coupling from the intermediate shaft (see

illustrations).

2A•6 Engine in-car repair procedures

8.7 Unbolt the hydraulic pump (arrowed)

from the front cover, without

disconnecting the hoses

3261 Jaguar XJ6 7.9 Remove the spacer from the end of the crankshaft

and clean it thoroughly

7.11 Drive the new seal squarely into the front cover with a large

socket or section of pipe - do not remove the plastic refitting

guide (arrowed) until the seal is installed

Page 45 of 227

23Clean and lubricate the lower tensioner.

Fill the lower tensioner oil reservoir with engine

oil and refit it on the engine block, aligning the

notch in the tensioner with the lug on the back

of the guide (see illustrations). This should

remove all slack from the lower timing chain. If

not, push the lower tensioner guide back and

forth a few times to prime the tensioner.

24Refit the upper chain tensioner guide and

mounting bracket to the engine block.

Caution: Before fully tightening the

mounting bracket to the engine block,

make sure the mount and chain guide are

clear of the lower chain, auxiliary sprocket

and intermediate sprocket. If necessary,

position the mount for clearance before

tightening the mounting bolts.

25Refit the oil pump drive chain and

sprocket to the crankshaft (see Section 13).

26Refit the upper chain fixed guide to the

engine block and place the upper timing chain

over the intermediate sprocket and auxiliary

shaft sprocket, draping the excess chain over

the top of the fixed guide. Lubricate the chain

and sprockets with clean engine oil.27Gather the loose portion of the upper

timing chain and place it between the upper

guides. Use a large rubber band to hold the

two guides snugly around the chain (see

Section 11).

28If necessary, renew the intermediate shaft

seal (see illustrations).

29Apply a thin coat of RTV sealant to the

engine side of the front cover and RTV sealant

to the oil-pan mating surface (bottom of the

front cover), then refit the front cover. Note:

Make sure the top surface of the cover aligns

with the top surface of the engine block, by

checking with a straightedge(see illustration).

30Refer to Section 11 for refitting of the

cylinder head and Section 10 for refitting of

the camshafts and connection of the upper

timing chain to the two camshaft sprockets.

31The remainder of the refitting is the

reverse of the removal procedure. If your car

is equipped with the hydraulic/self-levelling

suspension, refit the drive coupling and

coupling disc to the intermediate shaft (see

illustrations 8.9a and 8.9b). Coat the

mounting surface of the pump with RTVsealant and make sure the tang on the pump

aligns with the slot in the intermediate shaft

before bolting the pump to the front cover.

Refer to Section 7 for refitting of the

crankshaft spacer, damper and puller.

Caution: DO NOT start the engine until

you’re absolutely certain that the timing

chains are installed correctly. Serious and

costly engine damage could occur if the

chains are installed wrong.

32Run the engine and check for proper

operation.

9 Auxiliary shaft- renewal

3

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Refer to Chapter 10 and remove the power

steering pump, without disconnecting the

hoses. Remove the plastic power steering

pump drive coupling disc.

2A•8 Engine in-car repair procedures

8.28a Drill a small hole in the intermediate

shaft seal, thread a sheet metal screw into

it and use a small slide-hammer pull the

seal out of the cover8.28b Drive the new seal in with a seal-

driver or socket, to the same depth as the

original seal8.29 Bolt the front cover on hand tight, use

a straightedge to make sure the cover’s

top surface is level with the top of the

engine block, then tighten the cover bolts

3261 Jaguar XJ6 8.23a Add oil to the reservoir in the lower tensioner . . .

8.23b . . . and refit the tensioner against the guide -

after it’s installed, push the tensioner guide back and forth

a few times to prime the tensioner

Page 59 of 227

6Refit the compression gauge in the spark

plug hole (see illustration).

7Crank the engine over at least seven

compression strokes and watch the gauge.

The compression should build up quickly in a

healthy engine. Low compression on the first

stroke, followed by gradually increasing

pressure on successive strokes, indicates

worn piston rings. A low compression reading

on the first stroke, which doesn’t build up

during successive strokes, indicates leaking

valves or a blown cylinder head gasket (a

cracked cylinder head could also be the

cause). Deposits on the undersides of the

valve heads can also cause low compression.

Record the highest gauge reading obtained.

8Repeat the procedure for the remaining

cylinders and compare the results to this

Chapter’s Specifications.

9Add some engine oil (about three squirts

from a plunger-type oil can) to each cylinder,

through the spark plug hole, and repeat the

test.

10If the compression increases after the oil

is added, the piston rings are definitely worn.

If the compression doesn’t increase

significantly, the leakage is occurring at the

valves or cylinder head gasket. Leakage past

the valves may be caused by burned valve

seats and/or faces or warped, cracked or bent

valves.

11If two adjacent cylinders have equally low

compression, there’s a strong possibility that

the cylinder head gasket between them is

blown. The appearance of coolant in the

combustion chambers or the crankcase

would verify this condition.

12If one cylinder is 20 percent lower than the

others, and the engine has a slightly rough

idle, a worn exhaust lobe on the camshaft

could be the cause.

13If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If that’s the case, the

cylinder head(s) should be removed and

decarbonised.

14If compression is way down or varies

greatly between cylinders, it would be a goodidea to have a leak-down test performed by

an automotive repair workshop. This test will

pinpoint exactly where the leakage is

occurring and how severe it is.

5 Engine removal-

methods and precautions

If you’ve decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the vehicle, will

be needed. If a workshop or garage isn’t

available, at the very least a flat, level, clean

work surface made of concrete or asphalt is

required.

Cleaning the engine compartment and

engine before beginning the removal

procedure will help keep tools clean and

organised.

An engine hoist or A-frame will also be

necessary. Make sure the equipment is rated

in excess of the combined weight of the

engine and transmission. Safety is of primary

importance, considering the potential hazards

involved in lifting the engine out of the vehicle.

If the engine is being removed by a novice,

a helper should be available. Advice and aid

from someone more experienced would also

be helpful. There are many instances when

one person cannot simultaneously perform all

of the operations required when lifting the

engine out of the vehicle.

Plan the operation ahead of time. Arrange

for or obtain all of the tools and equipment

you’ll need prior to beginning the job. Some of

the equipment necessary to perform engine

removal and refitting safely and with relative

ease are (in addition to an engine hoist) a

heavy duty trolley jack, complete sets of

spanners and sockets as described in the

front of this manual, wooden blocks and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and petrol. If

the hoist must be rented, make sure that you

arrange for it in advance and perform all of the

operations possible without it beforehand.

This will save you money and time.

Plan for the vehicle to be out of use for

quite a while. A machine workshop will be

required to perform some of the work which

the do-it-yourselfer can’t accomplish without

special equipment. These shops often have a

busy schedule, so it would be a good idea to

consult them before removing the engine in

order to accurately estimate the amount of

time required to rebuild or repair components

that may need work.

Always be extremely careful when removing

and refitting the engine. Serious injury can

result from careless actions. Plan ahead, take

your time and a job of this nature, although

major, can be accomplished successfully.

6 Engine- removal and refitting

3

Note:Read through the entire Section before

beginning this procedure. It is recommended

to remove the engine and transmission from

the top as a unit, then separate the engine

from the transmission on the workshop floor. If

the transmission is not being serviced, it is

possible to leave the transmission in the

vehicle and remove the engine from the top by

itself, by removing the crankshaft damper and

tilting up the front end of the engine for

clearance,but access to the upper

bellhousing bolts is only practical when the

rear transmission mount and driveshaft have

been removed and the transmission is angled

down with a trolley jack.

Removal

1Relieve the fuel system pressure (see

Chapter 4).

2Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

3Place protective covers on the wings and

cowl and remove the bonnet (see Chapter 11).

4Remove the battery and battery tray.

5Remove the air cleaner assembly (see

Chapter 4).

6Raise the vehicle and support it securely on

axle stands. Drain the cooling system and

engine oil and remove the drivebelts (see

Chapter 1).

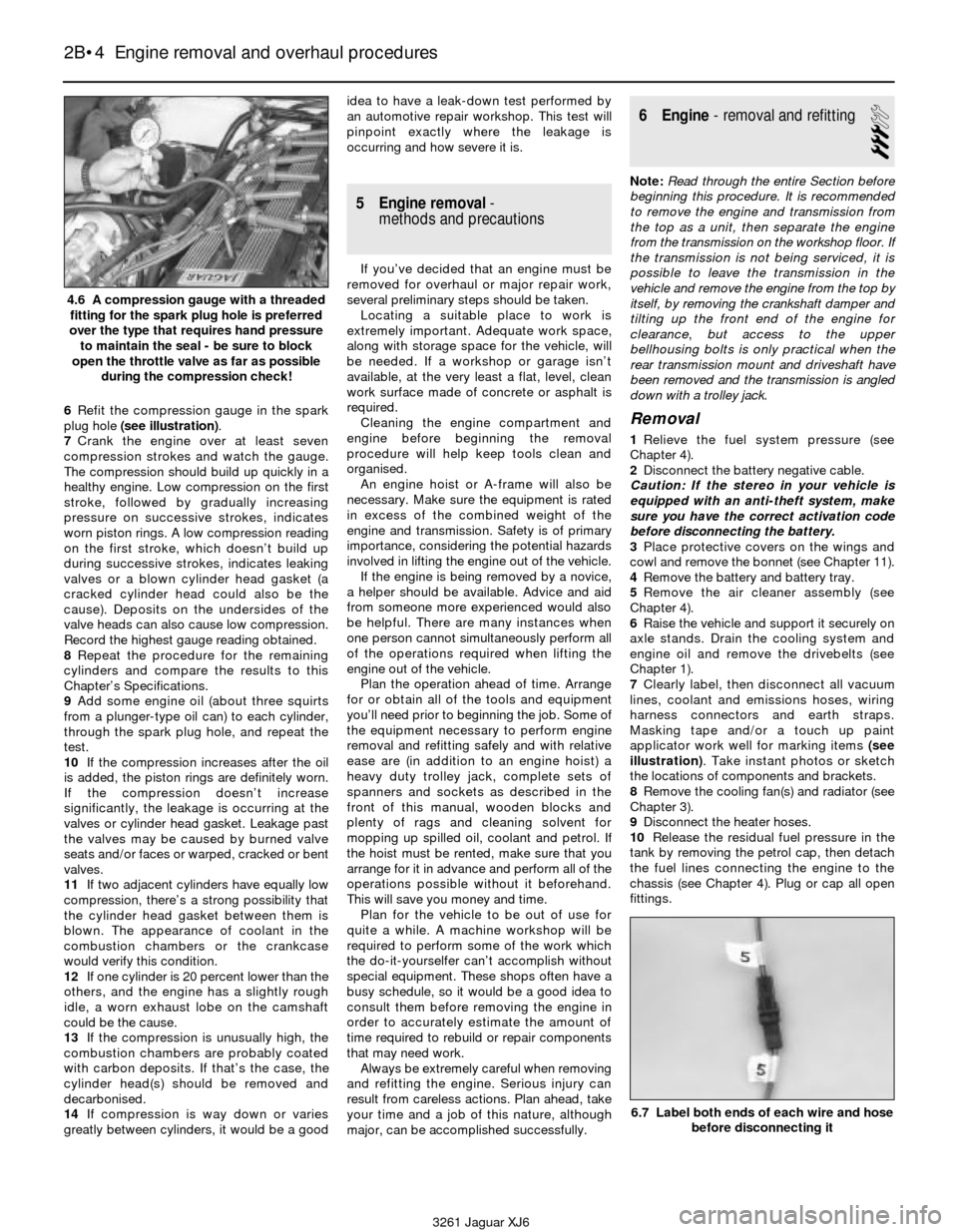

7Clearly label, then disconnect all vacuum

lines, coolant and emissions hoses, wiring

harness connectors and earth straps.

Masking tape and/or a touch up paint

applicator work well for marking items (see

illustration). Take instant photos or sketch

the locations of components and brackets.

8Remove the cooling fan(s) and radiator (see

Chapter 3).

9Disconnect the heater hoses.

10Release the residual fuel pressure in the

tank by removing the petrol cap, then detach

the fuel lines connecting the engine to the

chassis (see Chapter 4). Plug or cap all open

fittings.

2B•4 Engine removal and overhaul procedures

4.6 A compression gauge with a threaded

fitting for the spark plug hole is preferred

over the type that requires hand pressure

to maintain the seal - be sure to block

open the throttle valve as far as possible

during the compression check!

6.7 Label both ends of each wire and hose

before disconnecting it

3261 Jaguar XJ6

Page 61 of 227

incorporated throughout. The refitting of

manifolds and external parts is all that’s

necessary. Engines in this rebuilt form are

available from Jaguar dealers, and some

independent rebuilders.

Give careful thought to which alternative is

best for you and discuss the situation with

local automotive machine shops, auto parts

dealers and experienced rebuilders before

ordering or purchasing replacement parts.

8 Engine overhaul-

dismantling sequence

1It’s much easier to dismantle and work on

the engine if it’s mounted on a portable

engine stand. A stand can often be rented

quite cheaply from an equipment rental yard.

Before the engine is mounted on a stand, the

driveplate and rear oil seal retainer should be

removed from the engine.

2If a stand isn’t available, it’s possible to

dismantle the engine with it blocked up on the

floor. Be extra careful not to tip or drop the

engine when working without a stand.

3If you’re going to obtain a rebuilt engine, all

external components must come off first, to

be transferred to the replacement engine, just

as they will if you’re doing a complete engine

overhaul yourself. These include:

Alternator and brackets

Emissions control components

Distributor, spark plug leads and spark

plugs

Thermostat and housing cover

Water pump

EFI components

Intake/exhaust manifolds

Oil filter

Engine mounts

Driveplate

Transmission adapter plate

Note:When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the installed

position of gaskets, seals, spacers, pins,

brackets, washers, bolts and other small items.

4If you’re obtaining a short block, which

consists of the engine block, crankshaft,

pistons and connecting rods all assembled,

then the cylinder head, sump and oil pump will

have to be removed as well from your engine

so that your short-block can be turned in to

the rebuilder as a core. See Engine rebuilding

alternativesfor additional information

regarding the different possibilities to be

considered.

5If you’re planning a complete overhaul, the

engine must be dismantled and the internal

components removed in the following order:

Intake and exhaust manifolds

Valve cover

Upper timing chain and camshaft

sprocketsCamshafts

Timing chain cover

Cylinder head

Sump

Oil pump

Piston/connecting rod assemblies

Crankshaft rear oil seal retainer

Crankshaft and main bearings

6Before beginning the dismantling and

overhaul procedures, make sure the following

items are available. Also, refer to Section 21

for a list of tools and materials needed for

engine reassembly.

Common hand tools

Small cardboard boxes or plastic bags for

storing parts

Gasket scraper

Ridge reamer

Micrometers

Telescoping gauges

Dial indicator set

Valve spring compressor

Cylinder surfacing hone

Piston ring groove-cleaning tool

Electric drill motor

Tap and die set

Wire brushes

Oil gallery brushes

Cleaning solvent

Special Jaguar tools

Engine lifting brackets (18G 1465)

Timing damper simulator (18E 1436)

Camshaft TDC tool (18G 1433)

9 Cylinder head- dismantling

2

Note: New and rebuilt cylinder heads are

available from Jaguar and some independent

rebuilders. Due to the fact that some

specialised tools are necessary for the

dismantling and inspection procedures, and

replacement parts may not be readily

available, it may be more practical and

economical for the home mechanic to

purchase a replacement cylinder head rather

than taking the time to dismantle, inspect and

recondition the original.1Cylinder head dismantling involves removal

of the intake and exhaust valves and related

components. It’s assumed that the lifters and

camshafts have already been removed (see

Part A as needed).

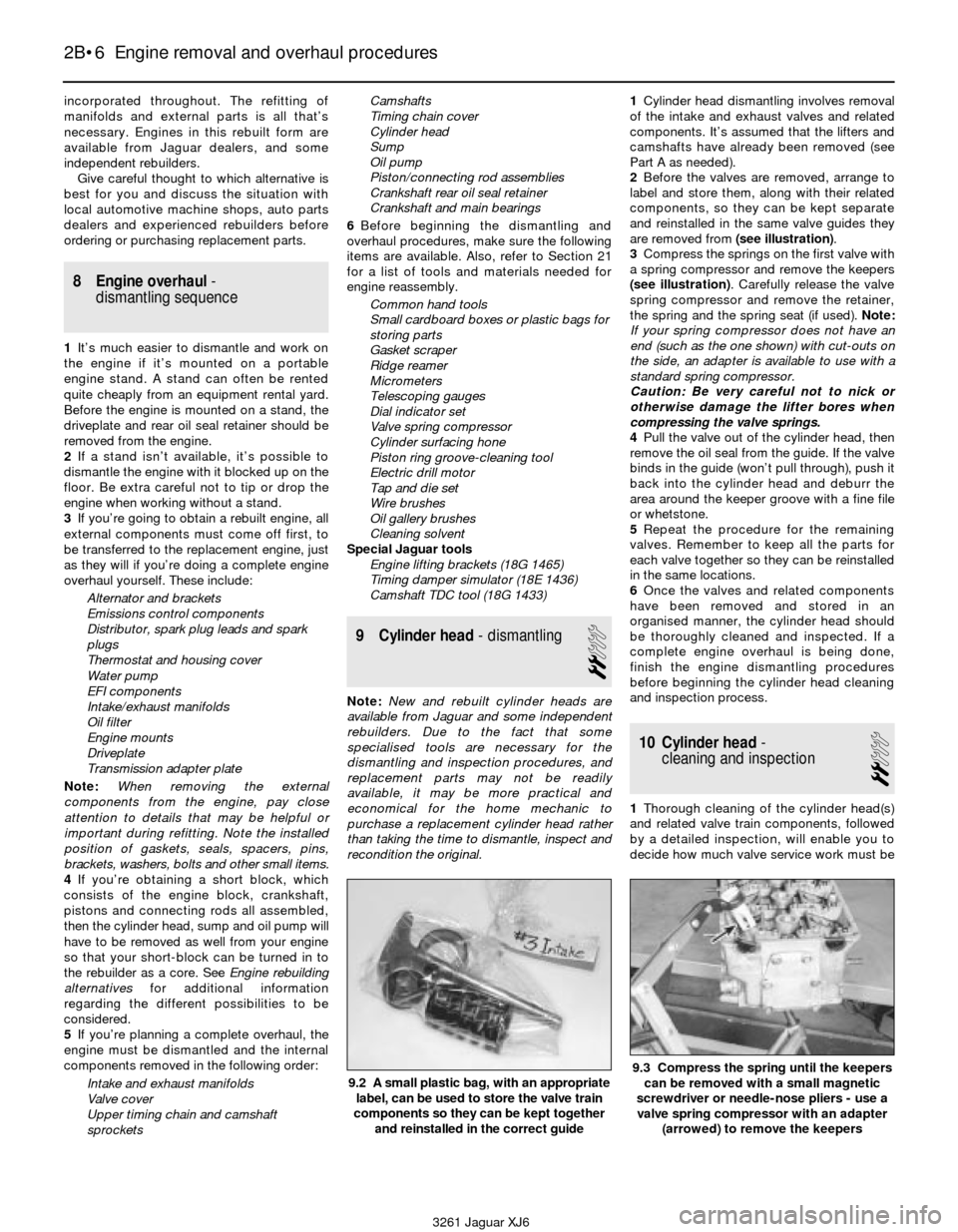

2Before the valves are removed, arrange to

label and store them, along with their related

components, so they can be kept separate

and reinstalled in the same valve guides they

are removed from (see illustration).

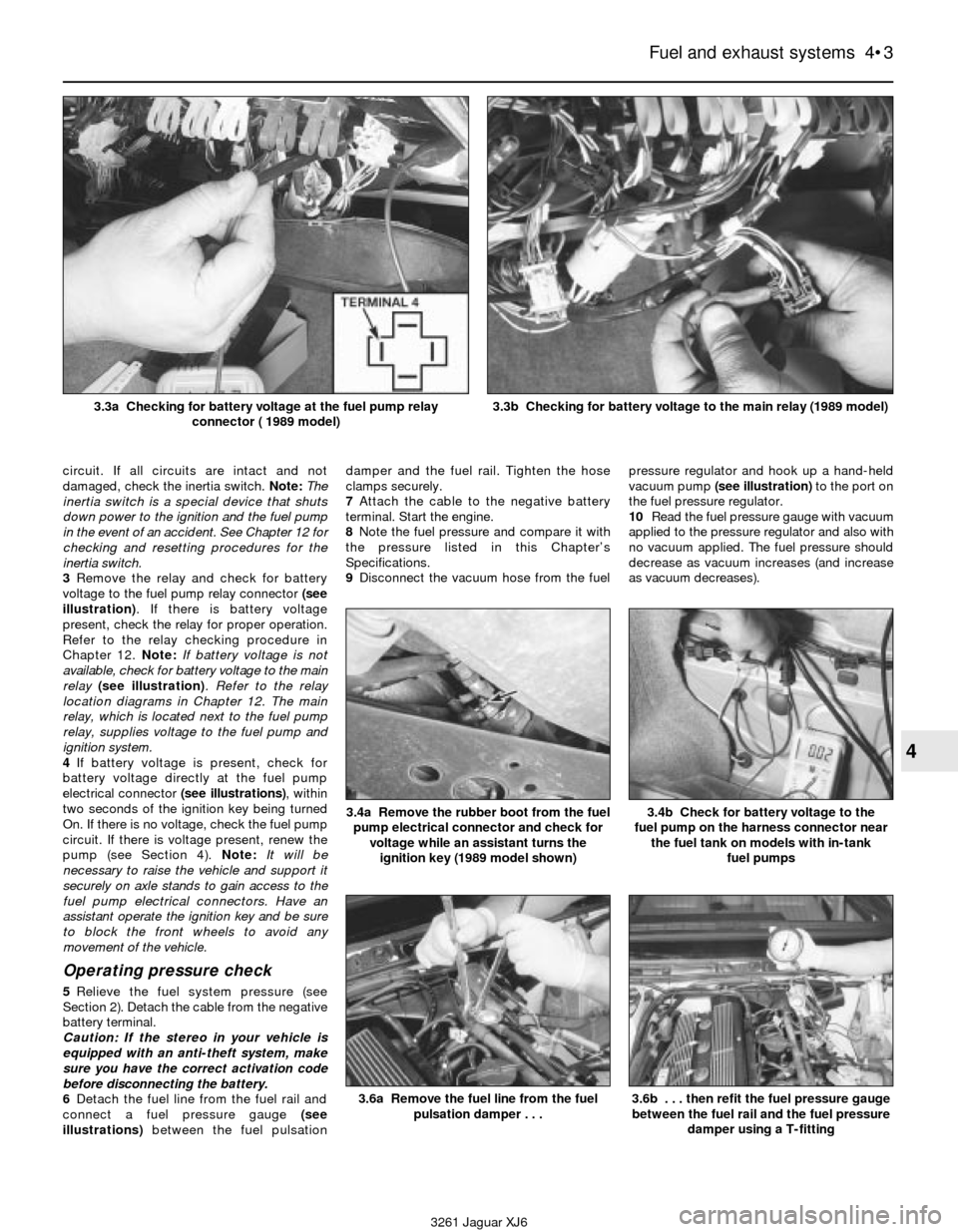

3Compress the springs on the first valve with

a spring compressor and remove the keepers

(see illustration). Carefully release the valve

spring compressor and remove the retainer,

the spring and the spring seat (if used). Note:

If your spring compressor does not have an

end (such as the one shown) with cut-outs on

the side, an adapter is available to use with a

standard spring compressor.

Caution: Be very careful not to nick or

otherwise damage the lifter bores when

compressing the valve springs.

4Pull the valve out of the cylinder head, then

remove the oil seal from the guide. If the valve

binds in the guide (won’t pull through), push it

back into the cylinder head and deburr the

area around the keeper groove with a fine file

or whetstone.

5Repeat the procedure for the remaining

valves. Remember to keep all the parts for

each valve together so they can be reinstalled

in the same locations.

6Once the valves and related components

have been removed and stored in an

organised manner, the cylinder head should

be thoroughly cleaned and inspected. If a

complete engine overhaul is being done,

finish the engine dismantling procedures

before beginning the cylinder head cleaning

and inspection process.

10 Cylinder head-

cleaning and inspection

2

1Thorough cleaning of the cylinder head(s)

and related valve train components, followed

by a detailed inspection, will enable you to

decide how much valve service work must be

2B•6 Engine removal and overhaul procedures

9.2 A small plastic bag, with an appropriate

label, can be used to store the valve train

components so they can be kept together

and reinstalled in the correct guide

3261 Jaguar XJ6

9.3 Compress the spring until the keepers

can be removed with a small magnetic

screwdriver or needle-nose pliers - use a

valve spring compressor with an adapter

(arrowed) to remove the keepers

Page 70 of 227

21 Engine overhaul-

reassembly sequence

1Before beginning engine reassembly, make

sure you have all the necessary new parts,

gaskets and seals as well as the following

items on hand:

Common hand tools

A 1/2-inch drive torque wrench

Piston ring refitting tool

Piston ring compressor

Short lengths of rubber or plastic hose to

fit over connecting rod bolts

Plastigauge

Feeler gauges

A fine-tooth file

New engine oil

Engine assembly lube or moly-base

grease

Gasket sealer

Thread locking compound

Special Jaguar tools:

Engine lifting brackets (18G 1465)

Timing damper simulator (18E 1436)

Camshaft TDC tool (18G 1433)

2In order to save time and avoid problems,

engine reassembly must be done in the

following general order:

Piston rings (Part B)

Crankshaft and main bearings (Part B)

Piston/connecting rod assemblies (Part B)

Rear main (crankshaft) oil seal (Part B)

Auxiliary shaft (Part A)

Timing chains and sprockets (Part A)

Oil pump (Part A)

Timing chain cover (Part A)

Cylinder head and lifters (Part A)

Camshafts (Part A)

Oil pick-up (Part A)

Sump (Part A)

Intake and exhaust manifolds (Part A)

Valve cover (Part A)

Flywheel/driveplate (Part A)

22 Piston rings- refitting

3

1Before refitting the new piston rings, the ring

end gaps must be checked. It’s assumed that

the piston ring groove clearance has been

checked and verified correct (see Section 18).

2Lay out the piston/connecting rod

assemblies and the new ring sets so the ring

sets will be matched with the same piston and

cylinder during the end gap measurement and

engine assembly.

3Insert the top (number one) ring into the first

cylinder and square it up with the cylinder

walls by pushing it in with the top of the piston

(see illustration). The ring should be near the

bottom of the cylinder, at the lower limit of

ring travel.

4To measure the end gap, slip feeler gauges

between the ends of the ring until a gauge

equal to the gap width is found (see

illustration). The feeler gauge should slide

between the ring ends with a slight amount of

drag. Compare the measurement to that

found in this Chapter’s Specifications. If the

gap is larger or smaller than specified,

double-check to make sure you have the

correct rings before proceeding.

5If the gap is too small, it must be enlarged

or the ring ends may come in contact with

each other during engine operation, which

can cause serious damage to the engine. The

end gap can be increased by filing the ring

ends very carefully with a fine file. Mount thefile in a vice equipped with soft jaws, slip the

ring over the file with the ends contacting the

file face and slowly move the ring to remove

material from the ends(see illustration).

Caution: When performing this operation,

file only from the outside in, and after the

correct gap is achieved, deburr the filed

ends of the rings with a fine whetstone.

6Excess end gap isn’t critical unless it’s

greater than Specifications. Again, double-

check to make sure you have the correct rings

for your engine.

7Repeat the procedure for each ring that will

be installed in the first cylinder and for each

ring in the remaining cylinders. Remember to

keep rings, pistons and cylinders matched.

8Once the ring end gaps have been

checked/corrected, the rings can be installed

on the pistons.

9The oil control ring (lowest one on the

piston) is usually installed first. It’s composed

of three separate components. Slip the

spacer/expander into the groove (see

illustration). If an anti-rotation tang is used,

make sure it’s inserted into the drilled hole in

the ring groove. Next, refit the lower side rail.

Don’t use a piston ring refitting tool on the oil

ring side rails, as they may be damaged.

Instead, place one end of the side rail into the

groove between the spacer/expander and the

ring land, hold it firmly in place and slide a

finger around the piston while pushing the rail

into the groove (see illustrations). Next, refit

the upper side rail in the same manner.

10After the three oil ring components have

been installed, check to make sure that both

Engine removal and overhaul procedures 2B•15

2B

22.3 When checking piston ring end gap,

the ring must be square in the cylinder

bore (this is done by pushing the ring down

with the top of a piston as shown)22.4 With the ring square in the cylinder,

measure the end gap with a feeler gauge22.5 If the end gap is too small, clamp a

file in a vice and file the ring ends (from the

outside in only) to enlarge the gap slightly

22.9a Refit the spacer/expander in the oil

control ring groove22.9b DO NOT use a piston ring refitting

tool when refitting the oil ring side rails

3261 Jaguar XJ6

Page 91 of 227

circuit. If all circuits are intact and not

damaged, check the inertia switch. Note: The

inertia switch is a special device that shuts

down power to the ignition and the fuel pump

in the event of an accident. See Chapter 12 for

checking and resetting procedures for the

inertia switch.

3Remove the relay and check for battery

voltage to the fuel pump relay connector (see

illustration). If there is battery voltage

present, check the relay for proper operation.

Refer to the relay checking procedure in

Chapter 12. Note:If battery voltage is not

available, check for battery voltage to the main

relay(see illustration). Refer to the relay

location diagrams in Chapter 12. The main

relay, which is located next to the fuel pump

relay, supplies voltage to the fuel pump and

ignition system.

4If battery voltage is present, check for

battery voltage directly at the fuel pump

electrical connector (see illustrations), within

two seconds of the ignition key being turned

On. If there is no voltage, check the fuel pump

circuit. If there is voltage present, renew the

pump (see Section 4). Note:It will be

necessary to raise the vehicle and support it

securely on axle stands to gain access to the

fuel pump electrical connectors. Have an

assistant operate the ignition key and be sure

to block the front wheels to avoid any

movement of the vehicle.

Operating pressure check

5Relieve the fuel system pressure (see

Section 2). Detach the cable from the negative

battery terminal.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

6Detach the fuel line from the fuel rail and

connect a fuel pressure gauge(see

illustrations)between the fuel pulsationdamper and the fuel rail. Tighten the hose

clamps securely.

7Attach the cable to the negative battery

terminal. Start the engine.

8Note the fuel pressure and compare it with

the pressure listed in this Chapter’s

Specifications.

9Disconnect the vacuum hose from the fuelpressure regulator and hook up a hand-held

vacuum pump (see illustration)to the port on

the fuel pressure regulator.

10Read the fuel pressure gauge with vacuum

applied to the pressure regulator and also with

no vacuum applied. The fuel pressure should

decrease as vacuum increases (and increase

as vacuum decreases).

Fuel and exhaust systems 4•3

4

3261 Jaguar XJ6 3.3a Checking for battery voltage at the fuel pump relay

connector ( 1989 model)

3.3b Checking for battery voltage to the main relay (1989 model)

3.6a Remove the fuel line from the fuel

pulsation damper . . .

3.4b Check for battery voltage to the

fuel pump on the harness connector near

the fuel tank on models with in-tank

fuel pumps3.4a Remove the rubber boot from the fuel

pump electrical connector and check for

voltage while an assistant turns the

ignition key (1989 model shown)

3.6b . . . then refit the fuel pressure gauge

between the fuel rail and the fuel pressure

damper using a T-fitting

Page 97 of 227

13Allow the bellcrank to return to the idle

position and test the adjustment once again

until the correct adjustment has been attained.

11 Electronic Fuel Injection

(EFI) system-

general information

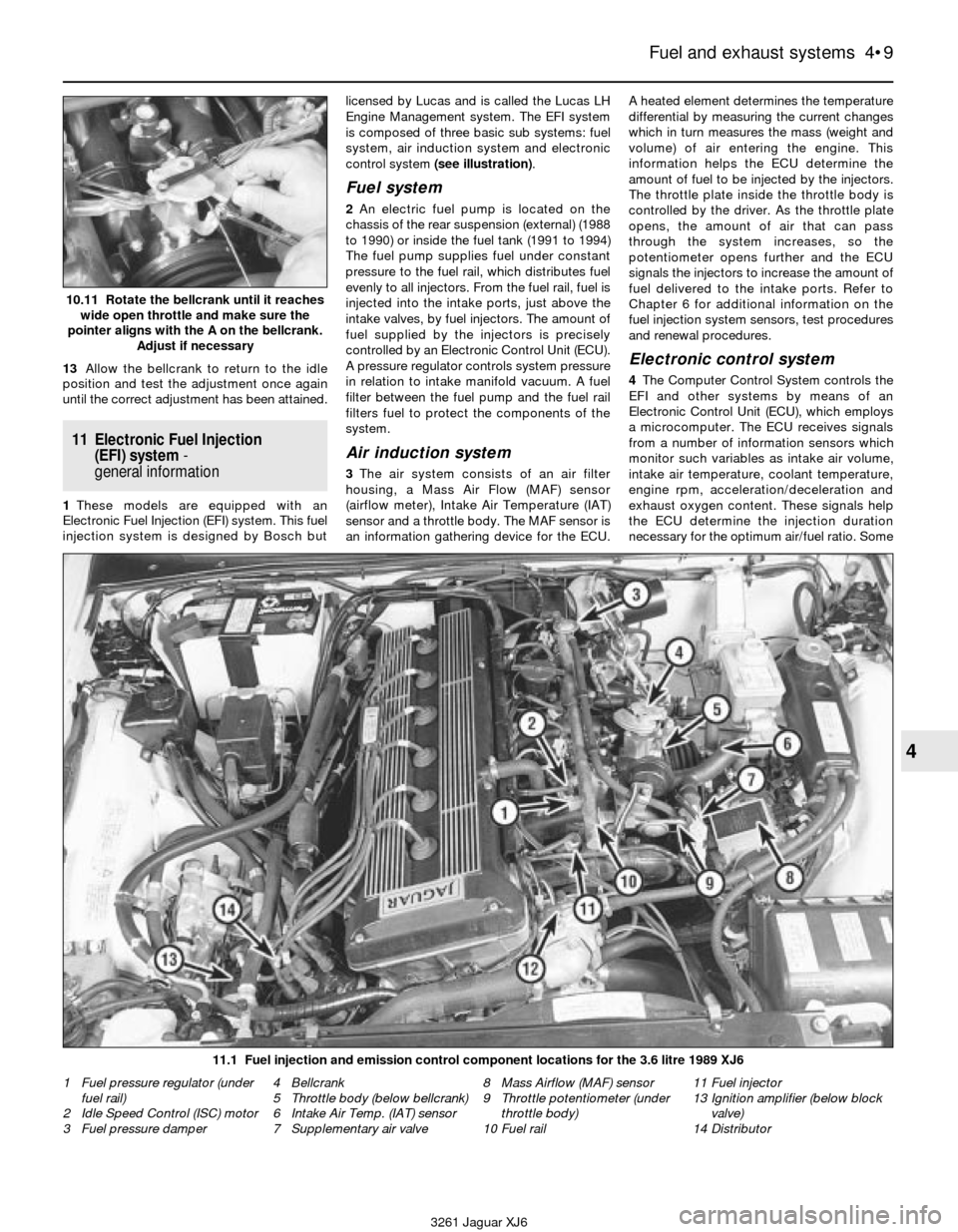

1These models are equipped with an

Electronic Fuel Injection (EFI) system. This fuel

injection system is designed by Bosch butlicensed by Lucas and is called the Lucas LH

Engine Management system. The EFI system

is composed of three basic sub systems: fuel

system, air induction system and electronic

control system (see illustration).

Fuel system

2An electric fuel pump is located on the

chassis of the rear suspension (external) (1988

to 1990) or inside the fuel tank (1991 to 1994)

The fuel pump supplies fuel under constant

pressure to the fuel rail, which distributes fuel

evenly to all injectors. From the fuel rail, fuel is

injected into the intake ports, just above the

intake valves, by fuel injectors. The amount of

fuel supplied by the injectors is precisely

controlled by an Electronic Control Unit (ECU).

A pressure regulator controls system pressure

in relation to intake manifold vacuum. A fuel

filter between the fuel pump and the fuel rail

filters fuel to protect the components of the

system.

Air induction system

3The air system consists of an air filter

housing, a Mass Air Flow (MAF) sensor

(airflow meter), Intake Air Temperature (IAT)

sensor and a throttle body. The MAF sensor is

an information gathering device for the ECU.A heated element determines the temperature

differential by measuring the current changes

which in turn measures the mass (weight and

volume) of air entering the engine. This

information helps the ECU determine the

amount of fuel to be injected by the injectors.

The throttle plate inside the throttle body is

controlled by the driver. As the throttle plate

opens, the amount of air that can pass

through the system increases, so the

potentiometer opens further and the ECU

signals the injectors to increase the amount of

fuel delivered to the intake ports. Refer to

Chapter 6 for additional information on the

fuel injection system sensors, test procedures

and renewal procedures.

Electronic control system

4The Computer Control System controls the

EFI and other systems by means of an

Electronic Control Unit (ECU), which employs

a microcomputer. The ECU receives signals

from a number of information sensors which

monitor such variables as intake air volume,

intake air temperature, coolant temperature,

engine rpm, acceleration/deceleration and

exhaust oxygen content. These signals help

the ECU determine the injection duration

necessary for the optimum air/fuel ratio. Some

Fuel and exhaust systems 4•9

4

10.11 Rotate the bellcrank until it reaches

wide open throttle and make sure the

pointer aligns with the A on the bellcrank.

Adjust if necessary

11.1 Fuel injection and emission control component locations for the 3.6 litre 1989 XJ6

3261 Jaguar XJ6 1 Fuel pressure regulator (under

fuel rail)

2 Idle Speed Control (ISC) motor

3 Fuel pressure damper4 Bellcrank

5 Throttle body (below bellcrank)

6 Intake Air Temp. (IAT) sensor

7 Supplementary air valve8 Mass Airflow (MAF) sensor

9 Throttle potentiometer (under

throttle body)

10 Fuel rail11 Fuel injector

13 Ignition amplifier (below block

valve)

14 Distributor

Page 204 of 227

3261 Jaguar XJ6

Use of EnglishREF•3

As the main part of this book has been written in the US, it uses the appropriate US component names, phrases, and spelling. Some of these

differ from those used in the UK. Normally, these cause no difficulty, but to make sure, a glossary is printed below. When ordering spare parts,

remember the parts list may use some of these words:

AMERICAN ENGLISH

Aluminum Aluminium

Antenna Aerial

Authorized Authorised

Auto parts stores Motor factors

Axleshaft Halfshaft

Back-up Reverse

Barrel Choke/venturi

Block Chock

Box-end wrench Ring spanner

Bushing Bush

Carburetor Carburettor

Center Centre

Coast Freewheel

Color Colour

Convertible Drop head coupe

Cotter pin Split pin

Counterclockwise Anti-clockwise

Countershaft (of gearbox) Layshaft

Dashboard Facia

Denatured alcohol Methylated spirit

Dome lamp Interior light

Driveaxle Driveshaft

Driveshaft Propeller shaft

Fender Wing/mudguard

Firewall Bulkhead

Flashlight Torch

Float bowl Float chamber

Floor jack Trolley jack

Freeway, turnpike etc Motorway

Freeze plug Core plug

Frozen Seized

Gas tank Petrol tank

Gasoline (gas) Petrol

Gearshift Gearchange

Generator (DC) Dynamo

Ground (electrical) Earth

Header Exhaust manifold

Heat riser Hot spot

High Top gear

Hood (engine cover) Bonnet

Installation Refitting

Intake Inlet

Jackstands Axle stands

Jumper cable Jump lead

Keeper Collet

Kerosene Paraffin

Knock pin Roll pin

Lash Clearance

Lash Free-play

Latch Catch

Latches Locks

License plate Number plate

Light Lamp

Lock (for valve spring retainer) Split cotter (for valve spring cap)

Lopes Hunts

Lug nut/bolt Wheel nut/bolt

Metal chips or debris Swarf

Misses Misfires

AMERICAN ENGLISH

Muffler Silencer

Odor Odour

Oil pan Sump

Open flame Naked flame

Panel wagon/van Van

Parking brake Handbrake

Parking light Sidelight

Pinging Pinking

Piston pin or wrist pin Gudgeon pin

Piston pin or wrist pin Small end, little end

Pitman arm Drop arm

Power brake booster Servo unit

Primary shoe (of brake) Leading shoe (of brake)

Prussian blue Engineer’s blue

Pry Prise (force apart)

Prybar Lever

Prying Levering

Quarter window Quarterlight

Recap Retread

Release cylinder Slave cylinder

Repair shop Garage

Replacement Renewal

Ring gear (of differential) Crownwheel

Rocker panel (beneath doors) Sill panel (beneath doors)

Rod bearing Big-end bearing

Rotor/disk Disc (brake)

Secondary shoe (of brake) Trailing shoe (of brake)

Sedan Saloon

Setscrew, Allen screw Grub screw

Shock absorber, shock Damper

Snap-ring Circlip

Soft top Hood

Spacer Distance piece

Spare tire Spare wheel

Spark plug wires HT leads

Spindle arm Steering arm

Stabilizer or sway bar Anti-roll bar

Station wagon Estate car

Stumbles Hesitates

Tang or lock Tab washer

Throw-out bearing Thrust bearing

Tie-rod or connecting rod (of steering) Trackrod

Tire Tyre

Transmission Gearbox

Troubleshooting Fault finding/diagnosis

Trunk Boot (luggage compartment)

Turn signal Indicator

TV (throttle valve) cable Kickdown cable

Unpublicized Unpublicised

Valve cover Rocker cover

Valve lifter Tappet

Valve lifter or tappet Cam follower or tappet

Vapor Vapour

Vise Vice

Wheel cover Roadwheel trim

Whole drive line Transmission

Windshield Windscreen

Wrench Spanner