JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1601 of 1784

panel (Fig. 40). Install and tighten the support

bracket retaining bolt to 11 Nzm (96 in-lbs) torque.

Install and tighten the support platform retaining

screws to 41 Nzm (30 ft-lbs) torque.

(2) Install the side step moulding and applique on

the cowl side panel/rocker panel (Fig. 39). Install and

tighten the moulding retaining bolts to 11 Nzm (96

in-lbs) torque. Install and tighten the applique re-

taining screws to 41 Nzm (30 ft-lbs) torque.(3) Install the lower body moulding on the support

bracket and cowl side panel with the retaining bolts

and (Fig. 39). Tighten the moulding retaining bolts to

11 Nzm (96 in-lbs) torque.

(4) Tighten the fender flare retaining screws (Figs.

36, 37 and 38) to 11 Nzm (96 in-lbs) torque.

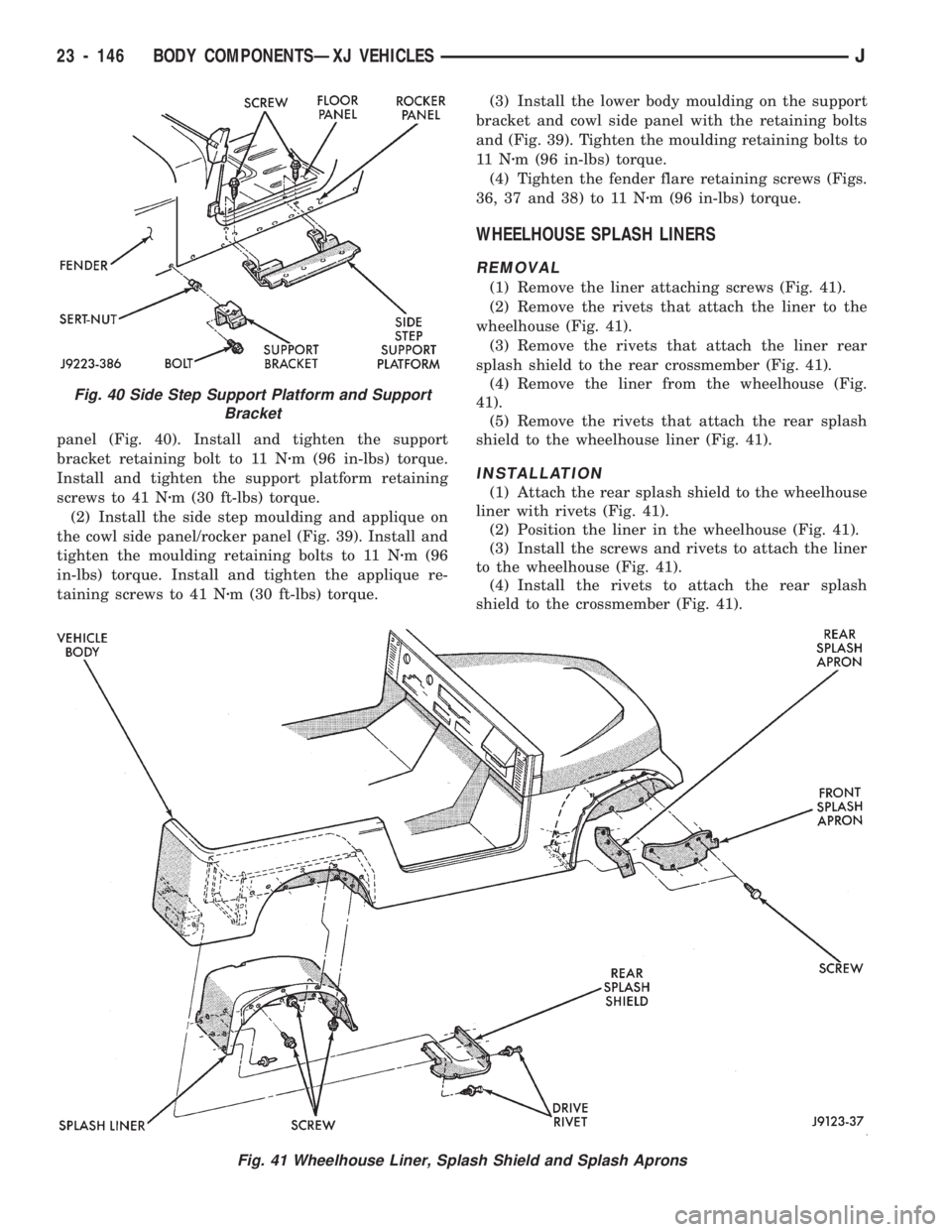

WHEELHOUSE SPLASH LINERS

REMOVAL

(1) Remove the liner attaching screws (Fig. 41).

(2) Remove the rivets that attach the liner to the

wheelhouse (Fig. 41).

(3) Remove the rivets that attach the liner rear

splash shield to the rear crossmember (Fig. 41).

(4) Remove the liner from the wheelhouse (Fig.

41).

(5) Remove the rivets that attach the rear splash

shield to the wheelhouse liner (Fig. 41).

INSTALLATION

(1) Attach the rear splash shield to the wheelhouse

liner with rivets (Fig. 41).

(2) Position the liner in the wheelhouse (Fig. 41).

(3) Install the screws and rivets to attach the liner

to the wheelhouse (Fig. 41).

(4) Install the rivets to attach the rear splash

shield to the crossmember (Fig. 41).

Fig. 41 Wheelhouse Liner, Splash Shield and Splash Aprons

Fig. 40 Side Step Support Platform and Support

Bracket

23 - 146 BODY COMPONENTSÐXJ VEHICLESJ

Page 1602 of 1784

FENDER SPLASH APRONS

REMOVAL

(1) Remove the splash apron attaching screws (Fig.

41).

(2) Remove the aprons from the fender well (Fig.

41).

INSTALLATION

(1) Position the aprons in the fender well (Fig. 41).

(2) Install the screws to attach the splash aprons

to the fender well (Fig. 41).

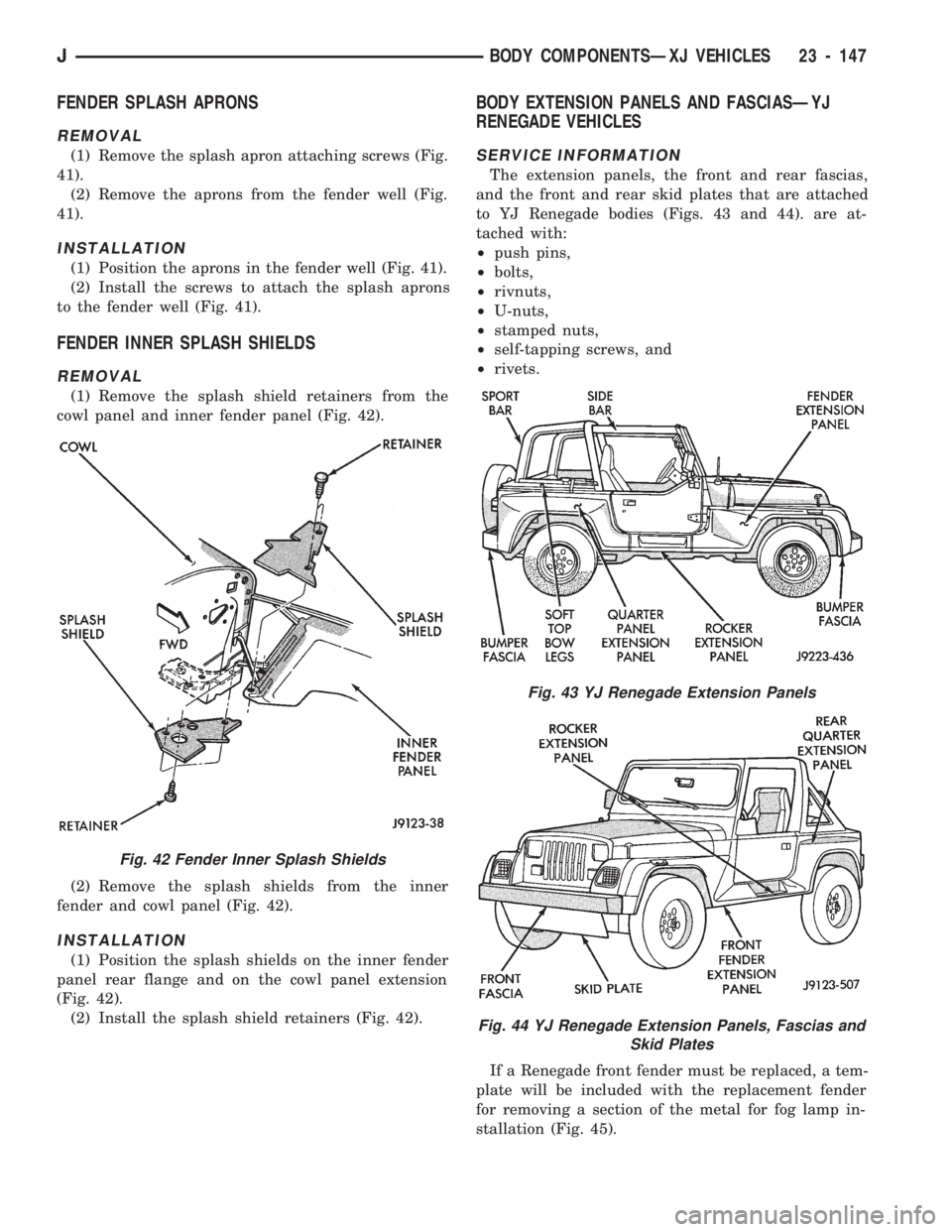

FENDER INNER SPLASH SHIELDS

REMOVAL

(1) Remove the splash shield retainers from the

cowl panel and inner fender panel (Fig. 42).

(2) Remove the splash shields from the inner

fender and cowl panel (Fig. 42).

INSTALLATION

(1) Position the splash shields on the inner fender

panel rear flange and on the cowl panel extension

(Fig. 42).

(2) Install the splash shield retainers (Fig. 42).

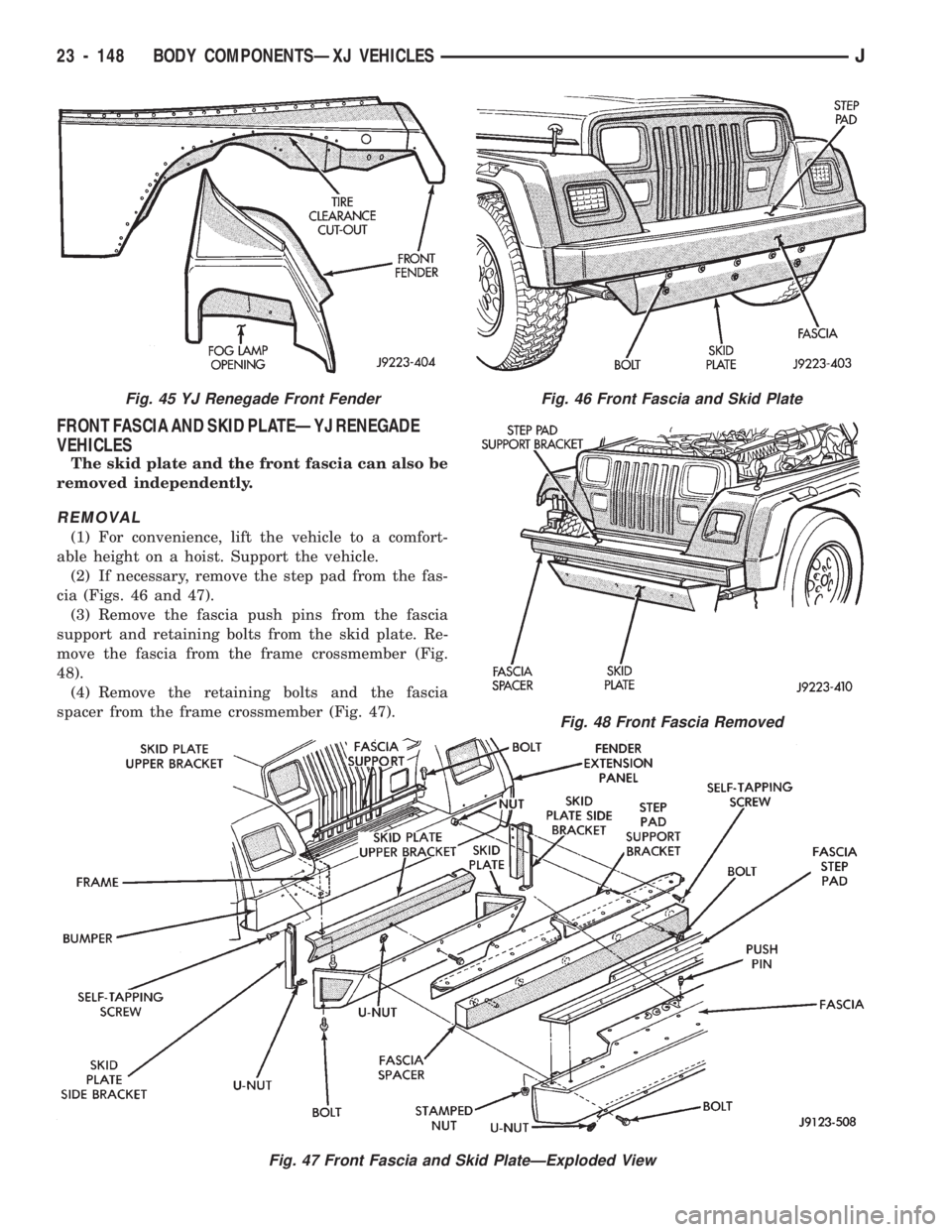

BODY EXTENSION PANELS AND FASCIASÐYJ

RENEGADE VEHICLES

SERVICE INFORMATION

The extension panels, the front and rear fascias,

and the front and rear skid plates that are attached

to YJ Renegade bodies (Figs. 43 and 44). are at-

tached with:

²push pins,

²bolts,

²rivnuts,

²U-nuts,

²stamped nuts,

²self-tapping screws, and

²rivets.

If a Renegade front fender must be replaced, a tem-

plate will be included with the replacement fender

for removing a section of the metal for fog lamp in-

stallation (Fig. 45).

Fig. 42 Fender Inner Splash Shields

Fig. 43 YJ Renegade Extension Panels

Fig. 44 YJ Renegade Extension Panels, Fascias and

Skid Plates

JBODY COMPONENTSÐXJ VEHICLES 23 - 147

Page 1603 of 1784

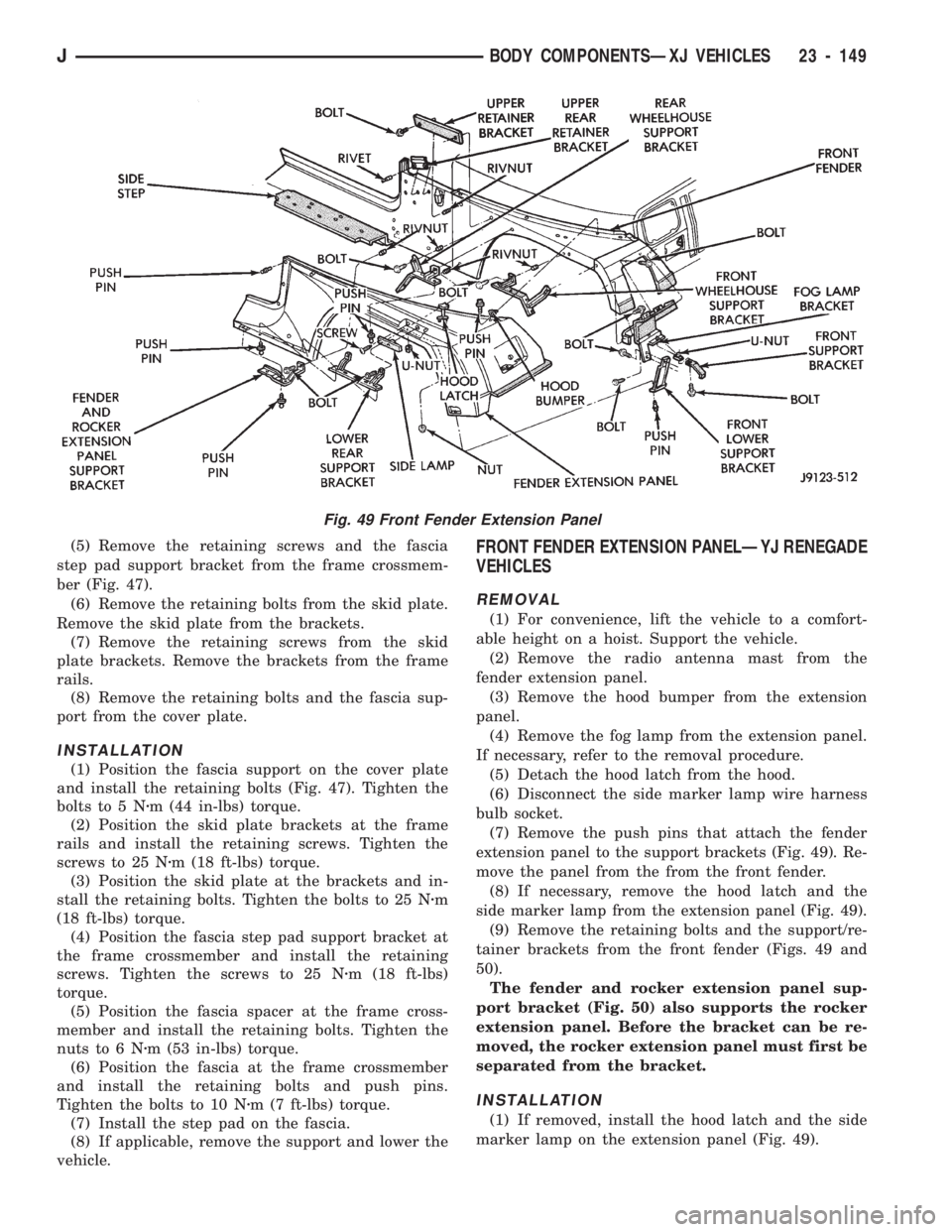

FRONT FASCIA AND SKID PLATEÐYJ RENEGADE

VEHICLES

The skid plate and the front fascia can also be

removed independently.

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) If necessary, remove the step pad from the fas-

cia (Figs. 46 and 47).

(3) Remove the fascia push pins from the fascia

support and retaining bolts from the skid plate. Re-

move the fascia from the frame crossmember (Fig.

48).

(4) Remove the retaining bolts and the fascia

spacer from the frame crossmember (Fig. 47).

Fig. 46 Front Fascia and Skid Plate

Fig. 47 Front Fascia and Skid PlateÐExploded View

Fig. 48 Front Fascia Removed

Fig. 45 YJ Renegade Front Fender

23 - 148 BODY COMPONENTSÐXJ VEHICLESJ

Page 1604 of 1784

(5) Remove the retaining screws and the fascia

step pad support bracket from the frame crossmem-

ber (Fig. 47).

(6) Remove the retaining bolts from the skid plate.

Remove the skid plate from the brackets.

(7) Remove the retaining screws from the skid

plate brackets. Remove the brackets from the frame

rails.

(8) Remove the retaining bolts and the fascia sup-

port from the cover plate.

INSTALLATION

(1) Position the fascia support on the cover plate

and install the retaining bolts (Fig. 47). Tighten the

bolts to 5 Nzm (44 in-lbs) torque.

(2) Position the skid plate brackets at the frame

rails and install the retaining screws. Tighten the

screws to 25 Nzm (18 ft-lbs) torque.

(3) Position the skid plate at the brackets and in-

stall the retaining bolts. Tighten the bolts to 25 Nzm

(18 ft-lbs) torque.

(4) Position the fascia step pad support bracket at

the frame crossmember and install the retaining

screws. Tighten the screws to 25 Nzm (18 ft-lbs)

torque.

(5) Position the fascia spacer at the frame cross-

member and install the retaining bolts. Tighten the

nuts to 6 Nzm (53 in-lbs) torque.

(6) Position the fascia at the frame crossmember

and install the retaining bolts and push pins.

Tighten the bolts to 10 Nzm (7 ft-lbs) torque.

(7) Install the step pad on the fascia.

(8) If applicable, remove the support and lower the

vehicle.

FRONT FENDER EXTENSION PANELÐYJ RENEGADE

VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the radio antenna mast from the

fender extension panel.

(3) Remove the hood bumper from the extension

panel.

(4) Remove the fog lamp from the extension panel.

If necessary, refer to the removal procedure.

(5) Detach the hood latch from the hood.

(6) Disconnect the side marker lamp wire harness

bulb socket.

(7) Remove the push pins that attach the fender

extension panel to the support brackets (Fig. 49). Re-

move the panel from the from the front fender.

(8) If necessary, remove the hood latch and the

side marker lamp from the extension panel (Fig. 49).

(9) Remove the retaining bolts and the support/re-

tainer brackets from the front fender (Figs. 49 and

50).

The fender and rocker extension panel sup-

port bracket (Fig. 50) also supports the rocker

extension panel. Before the bracket can be re-

moved, the rocker extension panel must first be

separated from the bracket.

INSTALLATION

(1) If removed, install the hood latch and the side

marker lamp on the extension panel (Fig. 49).

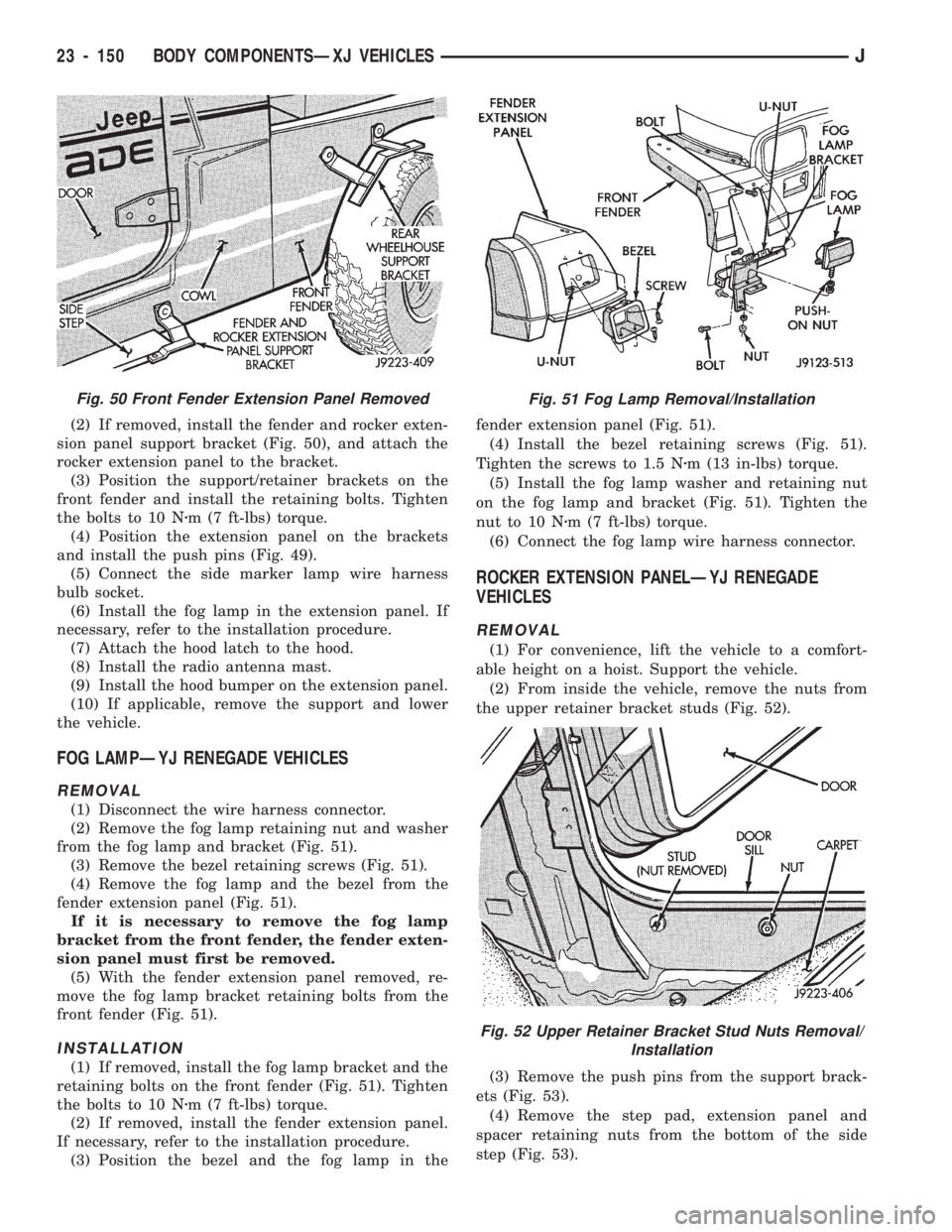

Fig. 49 Front Fender Extension Panel

JBODY COMPONENTSÐXJ VEHICLES 23 - 149

Page 1605 of 1784

(2) If removed, install the fender and rocker exten-

sion panel support bracket (Fig. 50), and attach the

rocker extension panel to the bracket.

(3) Position the support/retainer brackets on the

front fender and install the retaining bolts. Tighten

the bolts to 10 Nzm (7 ft-lbs) torque.

(4) Position the extension panel on the brackets

and install the push pins (Fig. 49).

(5) Connect the side marker lamp wire harness

bulb socket.

(6) Install the fog lamp in the extension panel. If

necessary, refer to the installation procedure.

(7) Attach the hood latch to the hood.

(8) Install the radio antenna mast.

(9) Install the hood bumper on the extension panel.

(10) If applicable, remove the support and lower

the vehicle.

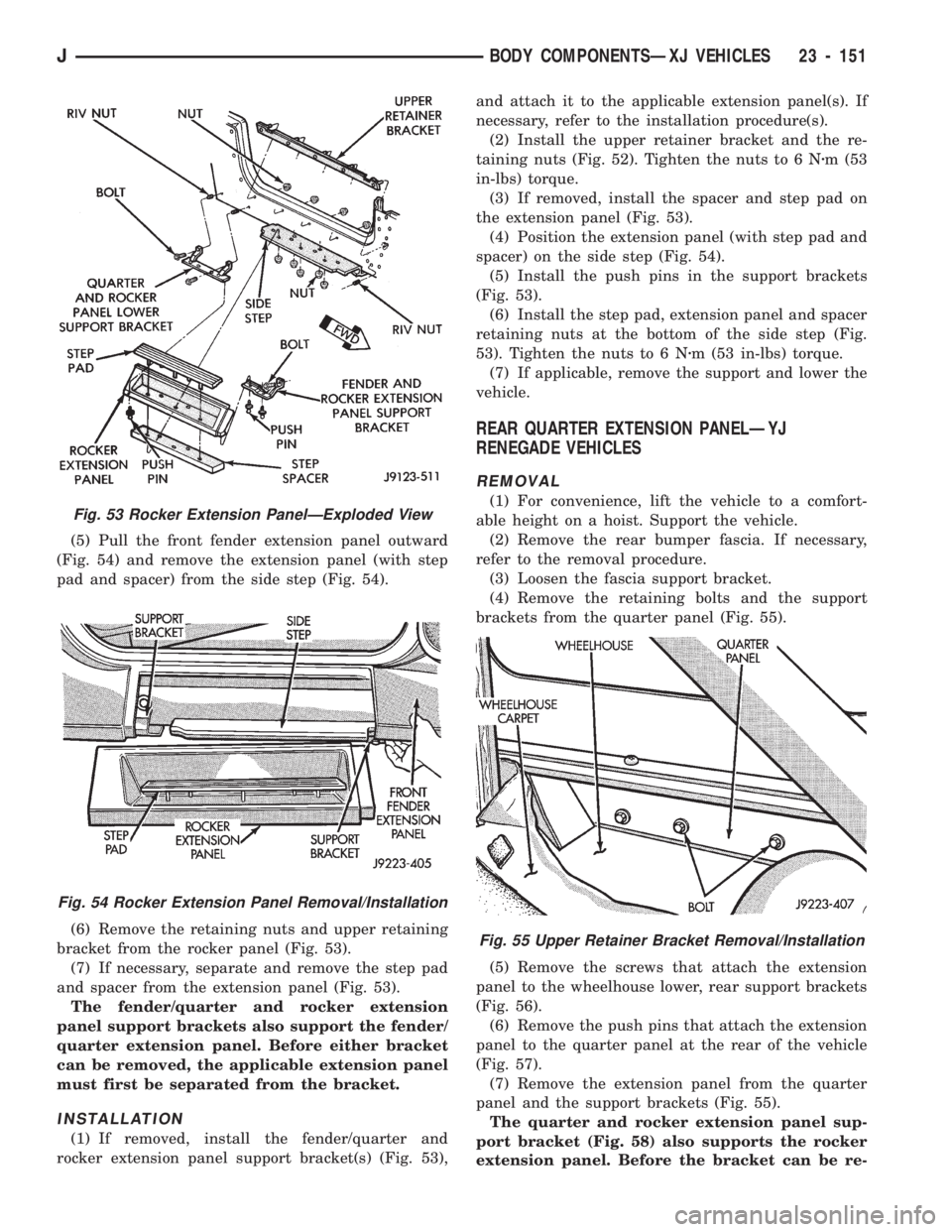

FOG LAMPÐYJ RENEGADE VEHICLES

REMOVAL

(1) Disconnect the wire harness connector.

(2) Remove the fog lamp retaining nut and washer

from the fog lamp and bracket (Fig. 51).

(3) Remove the bezel retaining screws (Fig. 51).

(4) Remove the fog lamp and the bezel from the

fender extension panel (Fig. 51).

If it is necessary to remove the fog lamp

bracket from the front fender, the fender exten-

sion panel must first be removed.

(5) With the fender extension panel removed, re-

move the fog lamp bracket retaining bolts from the

front fender (Fig. 51).

INSTALLATION

(1) If removed, install the fog lamp bracket and the

retaining bolts on the front fender (Fig. 51). Tighten

the bolts to 10 Nzm (7 ft-lbs) torque.

(2) If removed, install the fender extension panel.

If necessary, refer to the installation procedure.

(3) Position the bezel and the fog lamp in thefender extension panel (Fig. 51).

(4) Install the bezel retaining screws (Fig. 51).

Tighten the screws to 1.5 Nzm (13 in-lbs) torque.

(5) Install the fog lamp washer and retaining nut

on the fog lamp and bracket (Fig. 51). Tighten the

nut to 10 Nzm (7 ft-lbs) torque.

(6) Connect the fog lamp wire harness connector.

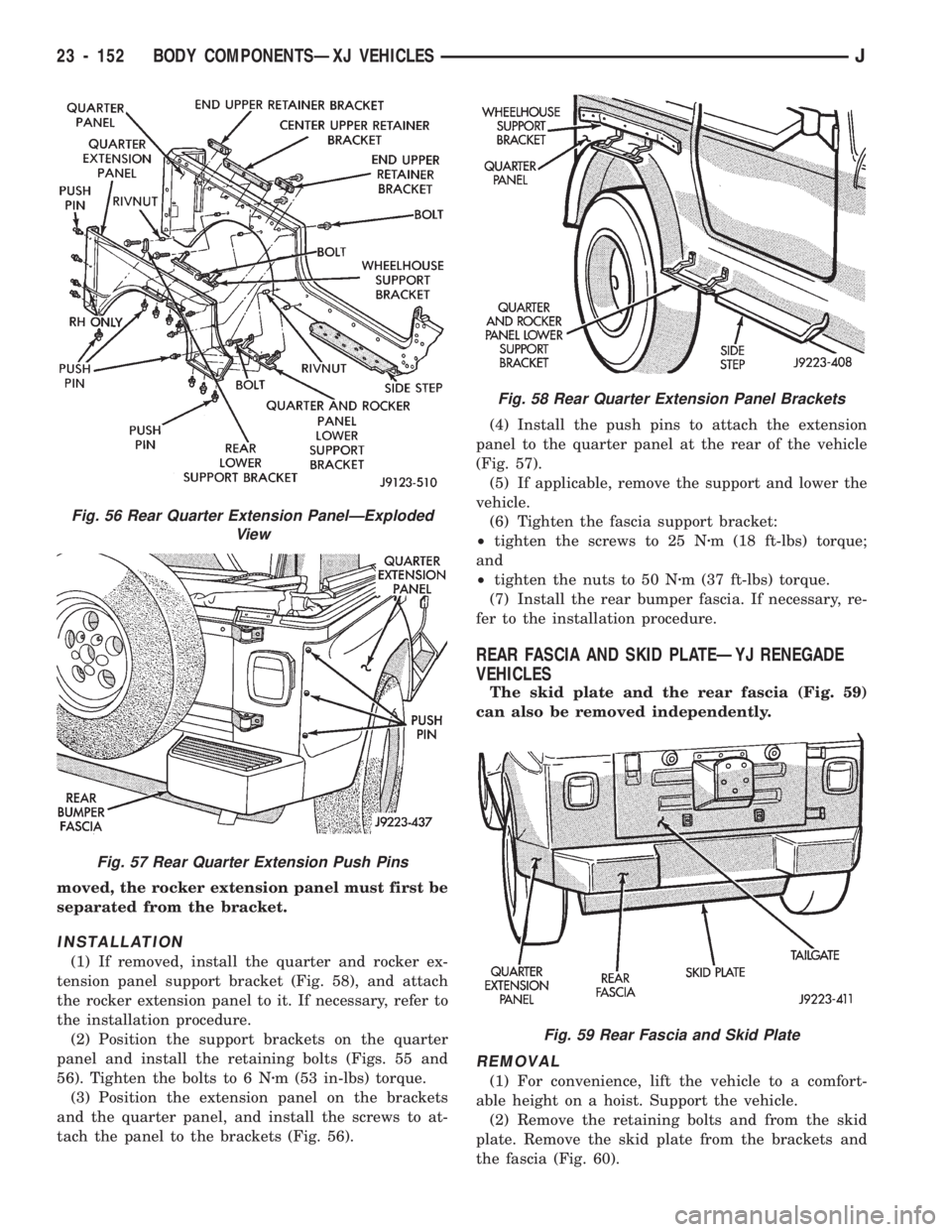

ROCKER EXTENSION PANELÐYJ RENEGADE

VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) From inside the vehicle, remove the nuts from

the upper retainer bracket studs (Fig. 52).

(3) Remove the push pins from the support brack-

ets (Fig. 53).

(4) Remove the step pad, extension panel and

spacer retaining nuts from the bottom of the side

step (Fig. 53).

Fig. 50 Front Fender Extension Panel RemovedFig. 51 Fog Lamp Removal/Installation

Fig. 52 Upper Retainer Bracket Stud Nuts Removal/

Installation

23 - 150 BODY COMPONENTSÐXJ VEHICLESJ

Page 1606 of 1784

(5) Pull the front fender extension panel outward

(Fig. 54) and remove the extension panel (with step

pad and spacer) from the side step (Fig. 54).

(6) Remove the retaining nuts and upper retaining

bracket from the rocker panel (Fig. 53).

(7) If necessary, separate and remove the step pad

and spacer from the extension panel (Fig. 53).

The fender/quarter and rocker extension

panel support brackets also support the fender/

quarter extension panel. Before either bracket

can be removed, the applicable extension panel

must first be separated from the bracket.

INSTALLATION

(1) If removed, install the fender/quarter and

rocker extension panel support bracket(s) (Fig. 53),and attach it to the applicable extension panel(s). If

necessary, refer to the installation procedure(s).

(2) Install the upper retainer bracket and the re-

taining nuts (Fig. 52). Tighten the nuts to 6 Nzm (53

in-lbs) torque.

(3) If removed, install the spacer and step pad on

the extension panel (Fig. 53).

(4) Position the extension panel (with step pad and

spacer) on the side step (Fig. 54).

(5) Install the push pins in the support brackets

(Fig. 53).

(6) Install the step pad, extension panel and spacer

retaining nuts at the bottom of the side step (Fig.

53). Tighten the nuts to 6 Nzm (53 in-lbs) torque.

(7) If applicable, remove the support and lower the

vehicle.

REAR QUARTER EXTENSION PANELÐYJ

RENEGADE VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the rear bumper fascia. If necessary,

refer to the removal procedure.

(3) Loosen the fascia support bracket.

(4) Remove the retaining bolts and the support

brackets from the quarter panel (Fig. 55).

(5) Remove the screws that attach the extension

panel to the wheelhouse lower, rear support brackets

(Fig. 56).

(6) Remove the push pins that attach the extension

panel to the quarter panel at the rear of the vehicle

(Fig. 57).

(7) Remove the extension panel from the quarter

panel and the support brackets (Fig. 55).

The quarter and rocker extension panel sup-

port bracket (Fig. 58) also supports the rocker

extension panel. Before the bracket can be re-

Fig. 55 Upper Retainer Bracket Removal/Installation

Fig. 53 Rocker Extension PanelÐExploded View

Fig. 54 Rocker Extension Panel Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 151

Page 1607 of 1784

moved, the rocker extension panel must first be

separated from the bracket.

INSTALLATION

(1) If removed, install the quarter and rocker ex-

tension panel support bracket (Fig. 58), and attach

the rocker extension panel to it. If necessary, refer to

the installation procedure.

(2) Position the support brackets on the quarter

panel and install the retaining bolts (Figs. 55 and

56). Tighten the bolts to 6 Nzm (53 in-lbs) torque.

(3) Position the extension panel on the brackets

and the quarter panel, and install the screws to at-

tach the panel to the brackets (Fig. 56).(4) Install the push pins to attach the extension

panel to the quarter panel at the rear of the vehicle

(Fig. 57).

(5) If applicable, remove the support and lower the

vehicle.

(6) Tighten the fascia support bracket:

²tighten the screws to 25 Nzm (18 ft-lbs) torque;

and

²tighten the nuts to 50 Nzm (37 ft-lbs) torque.

(7) Install the rear bumper fascia. If necessary, re-

fer to the installation procedure.

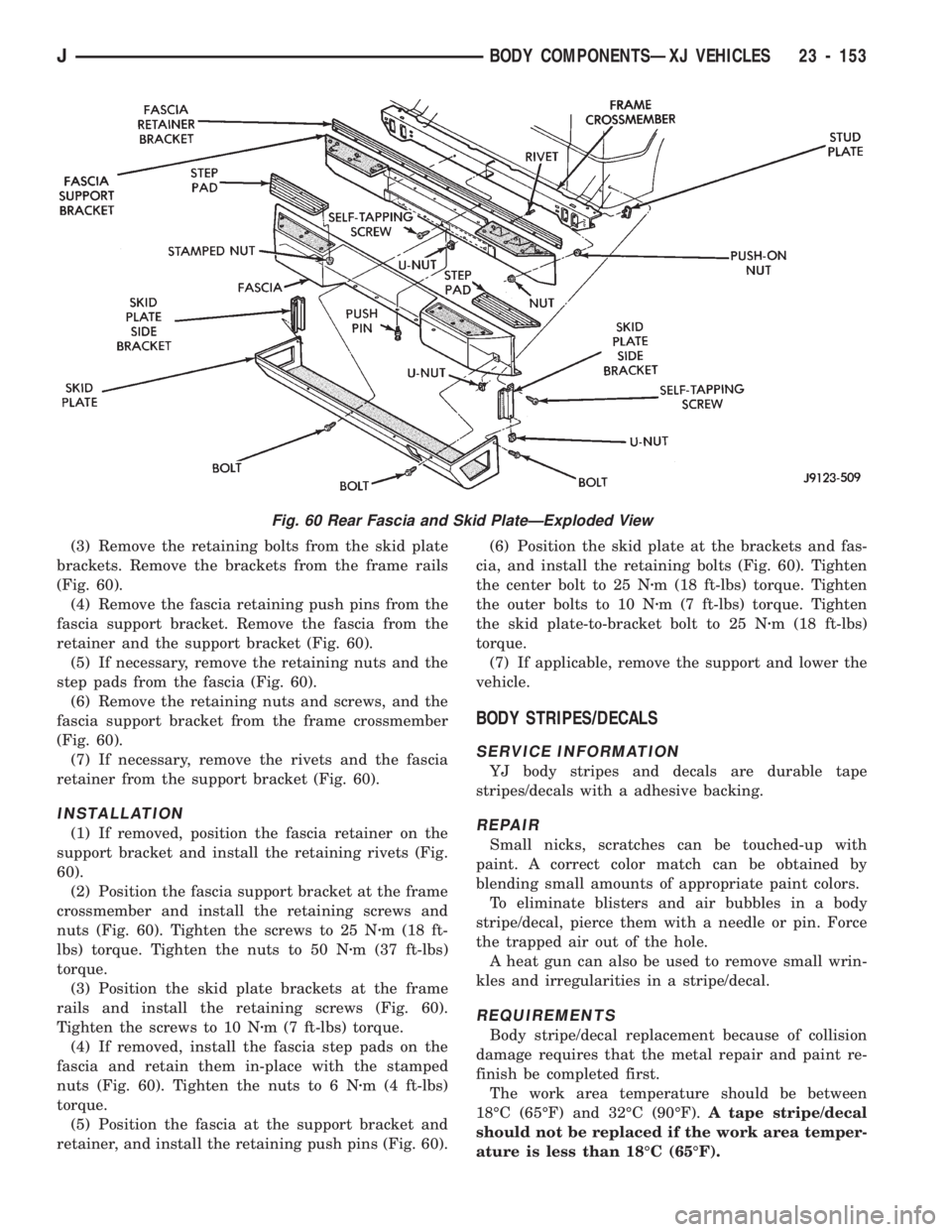

REAR FASCIA AND SKID PLATEÐYJ RENEGADE

VEHICLES

The skid plate and the rear fascia (Fig. 59)

can also be removed independently.

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the retaining bolts and from the skid

plate. Remove the skid plate from the brackets and

the fascia (Fig. 60).

Fig. 56 Rear Quarter Extension PanelÐExploded

View

Fig. 57 Rear Quarter Extension Push Pins

Fig. 58 Rear Quarter Extension Panel Brackets

Fig. 59 Rear Fascia and Skid Plate

23 - 152 BODY COMPONENTSÐXJ VEHICLESJ

Page 1608 of 1784

(3) Remove the retaining bolts from the skid plate

brackets. Remove the brackets from the frame rails

(Fig. 60).

(4) Remove the fascia retaining push pins from the

fascia support bracket. Remove the fascia from the

retainer and the support bracket (Fig. 60).

(5) If necessary, remove the retaining nuts and the

step pads from the fascia (Fig. 60).

(6) Remove the retaining nuts and screws, and the

fascia support bracket from the frame crossmember

(Fig. 60).

(7) If necessary, remove the rivets and the fascia

retainer from the support bracket (Fig. 60).

INSTALLATION

(1) If removed, position the fascia retainer on the

support bracket and install the retaining rivets (Fig.

60).

(2) Position the fascia support bracket at the frame

crossmember and install the retaining screws and

nuts (Fig. 60). Tighten the screws to 25 Nzm (18 ft-

lbs) torque. Tighten the nuts to 50 Nzm (37 ft-lbs)

torque.

(3) Position the skid plate brackets at the frame

rails and install the retaining screws (Fig. 60).

Tighten the screws to 10 Nzm (7 ft-lbs) torque.

(4) If removed, install the fascia step pads on the

fascia and retain them in-place with the stamped

nuts (Fig. 60). Tighten the nuts to 6 Nzm (4 ft-lbs)

torque.

(5) Position the fascia at the support bracket and

retainer, and install the retaining push pins (Fig. 60).(6) Position the skid plate at the brackets and fas-

cia, and install the retaining bolts (Fig. 60). Tighten

the center bolt to 25 Nzm (18 ft-lbs) torque. Tighten

the outer bolts to 10 Nzm (7 ft-lbs) torque. Tighten

the skid plate-to-bracket bolt to 25 Nzm (18 ft-lbs)

torque.

(7) If applicable, remove the support and lower the

vehicle.

BODY STRIPES/DECALS

SERVICE INFORMATION

YJ body stripes and decals are durable tape

stripes/decals with a adhesive backing.

REPAIR

Small nicks, scratches can be touched-up with

paint. A correct color match can be obtained by

blending small amounts of appropriate paint colors.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin. Force

the trapped air out of the hole.

A heat gun can also be used to remove small wrin-

kles and irregularities in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement because of collision

damage requires that the metal repair and paint re-

finish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

Fig. 60 Rear Fascia and Skid PlateÐExploded View

JBODY COMPONENTSÐXJ VEHICLES 23 - 153

Page 1609 of 1784

The following equipment and material are neces-

sary for body stripe/decal removal and installation:

²a commercial tape stripe/decal removal solution;

²a commercial adhesive removal solution;

²liquid dish detergent (for the wetting solution);

²a mixture of wetting solution;

²a commercial wax and silicone removal solution;

²isopropyl (rubbing) alcohol;

²a small squeegee (plastic or hard rubber);

²a water bucket and sponge;

²clean wiping rags or paper towels;

²a heat gun (or infra-red heat bulb);

²a wax pencil;

²a sharp knife, single edge razor blade or X-acto

knife;

²a pair of scissors; and

²a needle or pin.

A wetting solution assures a better bond between

the painted surface of the body and the tape stripe/

decal. Prepare a supply of wetting solution by mixing

two or three teaspoons of dish detergent with 1 gal-

lon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

The key to successful tape stripe/decal re-

moval is to apply heat to area and slowly peel

stripe/decal from panel.

(1) Clean the repaired surface, adjacent panels and

door openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from the panel.

WARNING: USE THE TAPE STRIPE/DECAL RE-

MOVAL SOLUTION IN A WELL-VENTILATED AREA

ONLY.

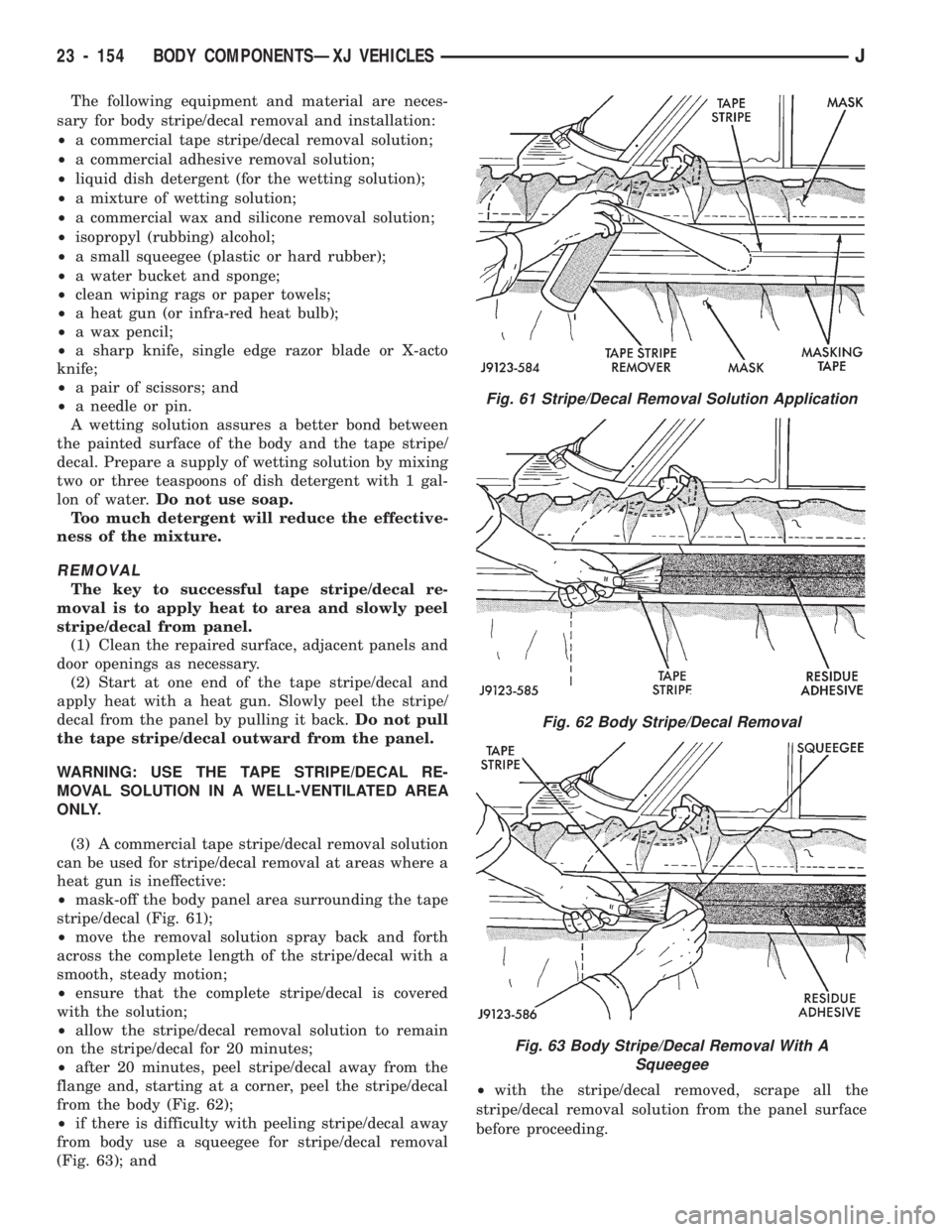

(3) A commercial tape stripe/decal removal solution

can be used for stripe/decal removal at areas where a

heat gun is ineffective:

²mask-off the body panel area surrounding the tape

stripe/decal (Fig. 61);

²move the removal solution spray back and forth

across the complete length of the stripe/decal with a

smooth, steady motion;

²ensure that the complete stripe/decal is covered

with the solution;

²allow the stripe/decal removal solution to remain

on the stripe/decal for 20 minutes;

²after 20 minutes, peel stripe/decal away from the

flange and, starting at a corner, peel the stripe/decal

from the body (Fig. 62);

²if there is difficulty with peeling stripe/decal away

from body use a squeegee for stripe/decal removal

(Fig. 63); and²with the stripe/decal removed, scrape all the

stripe/decal removal solution from the panel surface

before proceeding.

Fig. 61 Stripe/Decal Removal Solution Application

Fig. 62 Body Stripe/Decal Removal

Fig. 63 Body Stripe/Decal Removal With A

Squeegee

23 - 154 BODY COMPONENTSÐXJ VEHICLESJ

Page 1610 of 1784

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining on body with a removal solution.

(5) After 3 to 5 minutes, use a squeegee to remove

adhesive (Fig. 64).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth with a general pur-

pose cleaning solution.

BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with an cleaning solu-

tion to remove any residue paint.

(2) Freshly painted surfaces must be thoroughly dry.

(3) Clean painted surface with a commercial wax

and silicone removal solution. Wipe surface with a

clean cloth and allow to dry.

REPLACEMENT ON ONE PANEL

For large tape stripes/decals, use a clean sponge

and apply ample wetting solution:

²to the adhesive side of the tape stripe/decal, and

²to the painted panel surface.

The wetting solution will permit ease of tape stripe/

decal movement when positioning it on the panel.

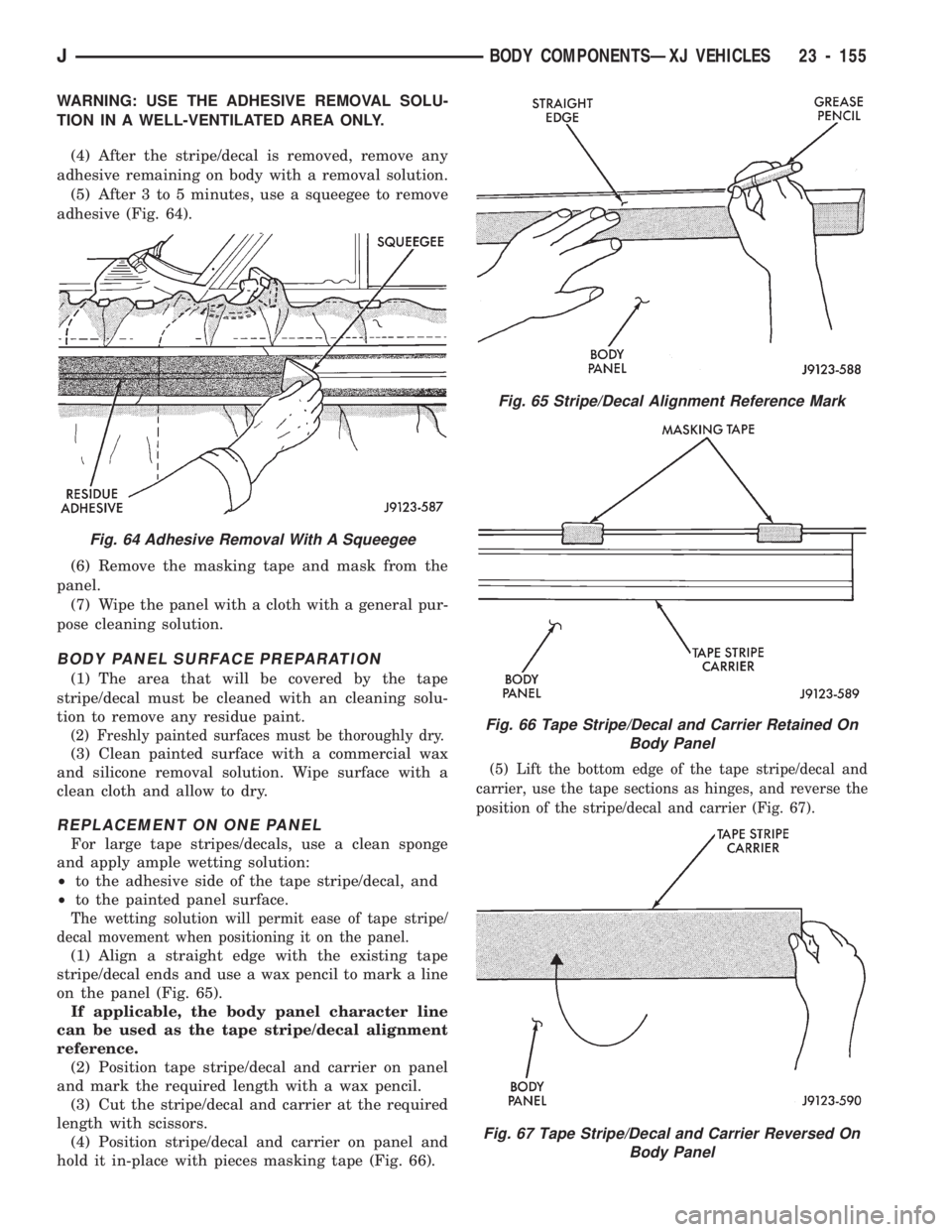

(1) Align a straight edge with the existing tape

stripe/decal ends and use a wax pencil to mark a line

on the panel (Fig. 65).

If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position tape stripe/decal and carrier on panel

and mark the required length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position stripe/decal and carrier on panel and

hold it in-place with pieces masking tape (Fig. 66).

(5) Lift the bottom edge of the tape stripe/decal and

carrier, use the tape sections as hinges, and reverse the

position of the stripe/decal and carrier (Fig. 67).

Fig. 65 Stripe/Decal Alignment Reference Mark

Fig. 66 Tape Stripe/Decal and Carrier Retained On

Body Panel

Fig. 67 Tape Stripe/Decal and Carrier Reversed On

Body Panel

Fig. 64 Adhesive Removal With A Squeegee

JBODY COMPONENTSÐXJ VEHICLES 23 - 155