JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1581 of 1784

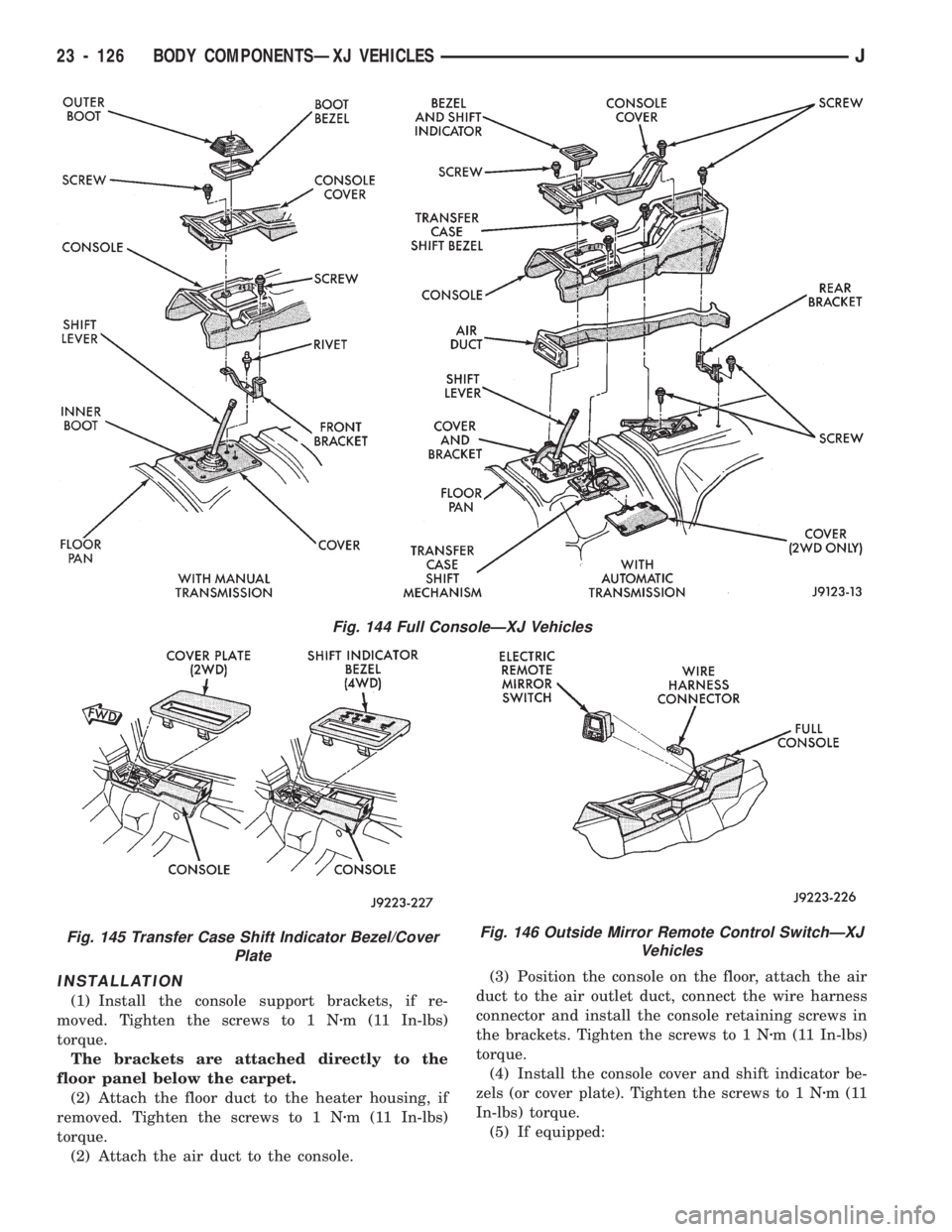

INSTALLATION

(1) Install the console support brackets, if re-

moved. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

The brackets are attached directly to the

floor panel below the carpet.

(2) Attach the floor duct to the heater housing, if

removed. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(2) Attach the air duct to the console.(3) Position the console on the floor, attach the air

duct to the air outlet duct, connect the wire harness

connector and install the console retaining screws in

the brackets. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(4) Install the console cover and shift indicator be-

zels (or cover plate). Tighten the screws to 1 Nzm(11

In-lbs) torque.

(5) If equipped:

Fig. 146 Outside Mirror Remote Control SwitchÐXJ

Vehicles

Fig. 144 Full ConsoleÐXJ Vehicles

Fig. 145 Transfer Case Shift Indicator Bezel/Cover

Plate

23 - 126 BODY COMPONENTSÐXJ VEHICLESJ

Page 1582 of 1784

²connect the wire harness connector to the outside

mirror remote control switch,

²insert the switch into the console hole, and

²push inward to engage the retaining clips.

(6) Install the shift lever handle/knob.

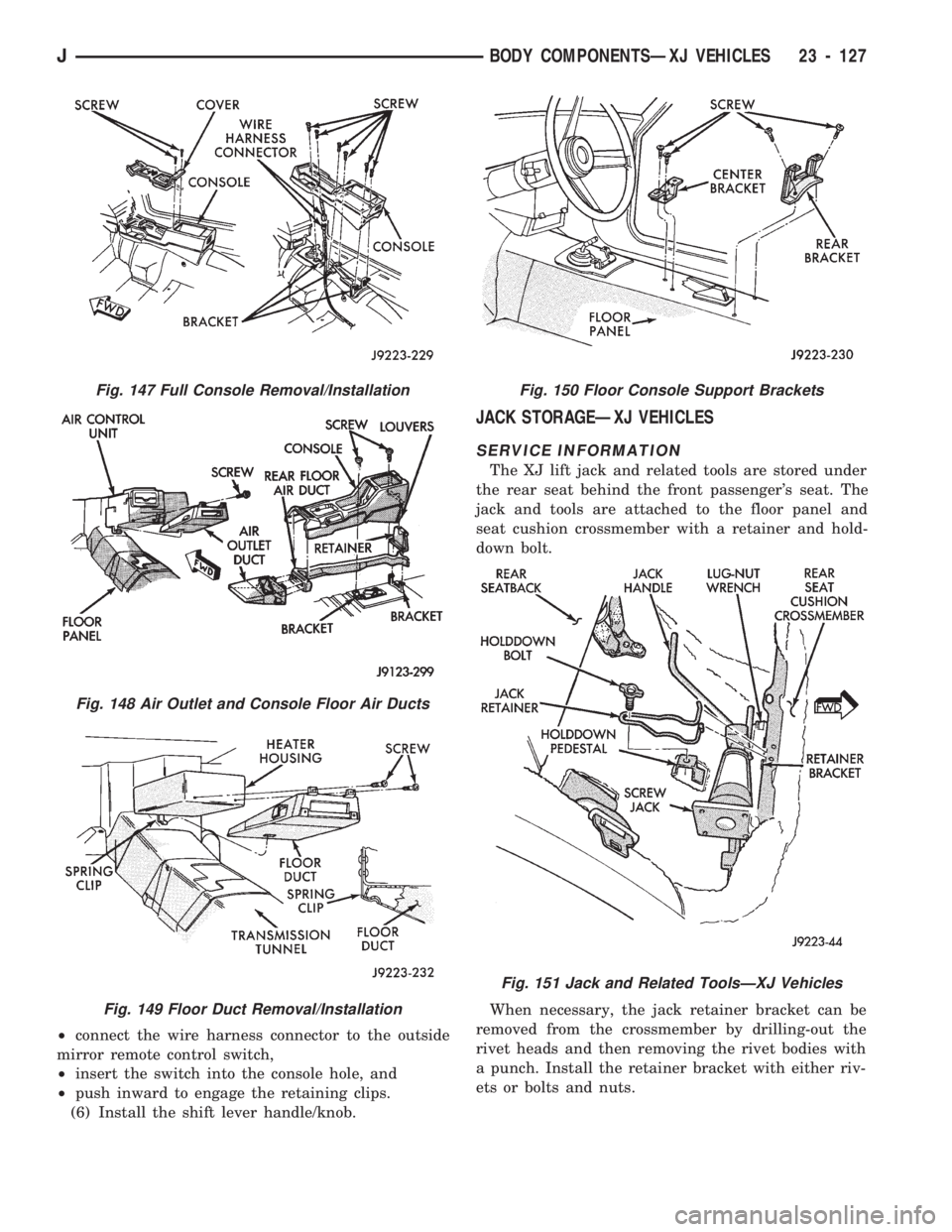

JACK STORAGEÐXJ VEHICLES

SERVICE INFORMATION

The XJ lift jack and related tools are stored under

the rear seat behind the front passenger's seat. The

jack and tools are attached to the floor panel and

seat cushion crossmember with a retainer and hold-

down bolt.

When necessary, the jack retainer bracket can be

removed from the crossmember by drilling-out the

rivet heads and then removing the rivet bodies with

a punch. Install the retainer bracket with either riv-

ets or bolts and nuts.

Fig. 147 Full Console Removal/Installation

Fig. 148 Air Outlet and Console Floor Air Ducts

Fig. 149 Floor Duct Removal/Installation

Fig. 150 Floor Console Support Brackets

Fig. 151 Jack and Related ToolsÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 127

Page 1583 of 1784

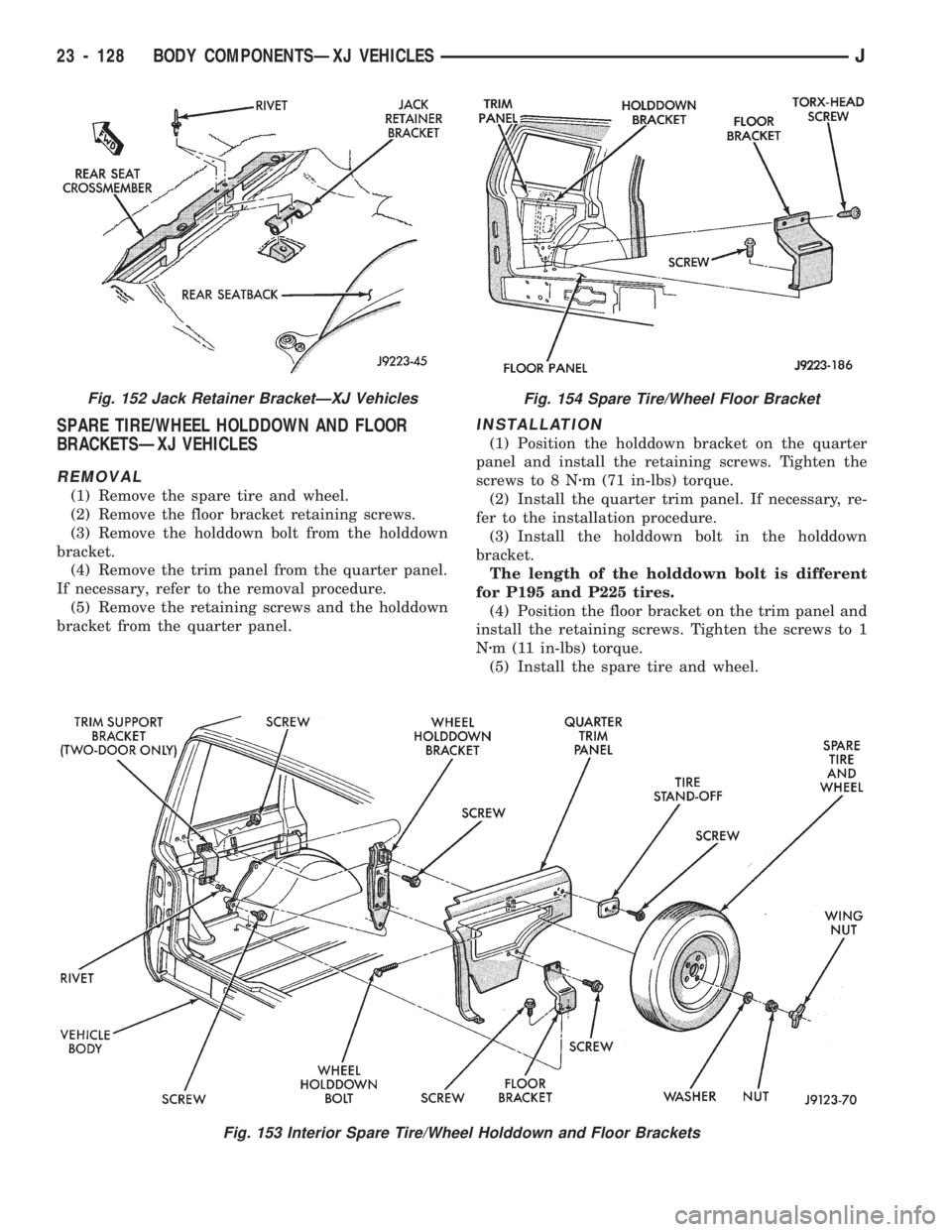

SPARE TIRE/WHEEL HOLDDOWN AND FLOOR

BRACKETSÐXJ VEHICLES

REMOVAL

(1) Remove the spare tire and wheel.

(2) Remove the floor bracket retaining screws.

(3) Remove the holddown bolt from the holddown

bracket.

(4) Remove the trim panel from the quarter panel.

If necessary, refer to the removal procedure.

(5) Remove the retaining screws and the holddown

bracket from the quarter panel.

INSTALLATION

(1) Position the holddown bracket on the quarter

panel and install the retaining screws. Tighten the

screws to 8 Nzm (71 in-lbs) torque.

(2) Install the quarter trim panel. If necessary, re-

fer to the installation procedure.

(3) Install the holddown bolt in the holddown

bracket.

The length of the holddown bolt is different

for P195 and P225 tires.

(4) Position the floor bracket on the trim panel and

install the retaining screws. Tighten the screws to 1

Nzm (11 in-lbs) torque.

(5) Install the spare tire and wheel.

Fig. 153 Interior Spare Tire/Wheel Holddown and Floor Brackets

Fig. 152 Jack Retainer BracketÐXJ VehiclesFig. 154 Spare Tire/Wheel Floor Bracket

23 - 128 BODY COMPONENTSÐXJ VEHICLESJ

Page 1584 of 1784

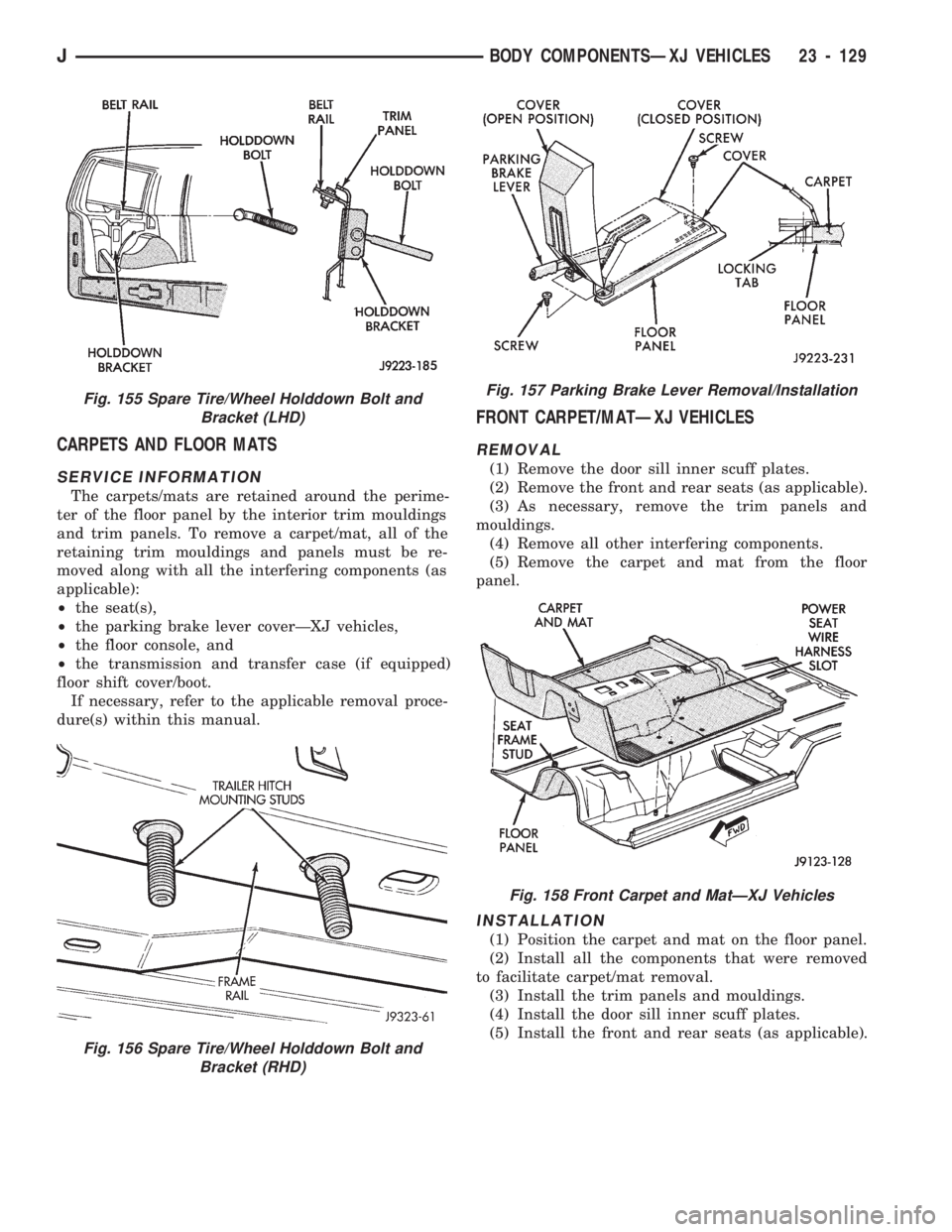

CARPETS AND FLOOR MATS

SERVICE INFORMATION

The carpets/mats are retained around the perime-

ter of the floor panel by the interior trim mouldings

and trim panels. To remove a carpet/mat, all of the

retaining trim mouldings and panels must be re-

moved along with all the interfering components (as

applicable):

²the seat(s),

²the parking brake lever coverÐXJ vehicles,

²the floor console, and

²the transmission and transfer case (if equipped)

floor shift cover/boot.

If necessary, refer to the applicable removal proce-

dure(s) within this manual.

FRONT CARPET/MATÐXJ VEHICLES

REMOVAL

(1) Remove the door sill inner scuff plates.

(2) Remove the front and rear seats (as applicable).

(3) As necessary, remove the trim panels and

mouldings.

(4) Remove all other interfering components.

(5) Remove the carpet and mat from the floor

panel.

INSTALLATION

(1) Position the carpet and mat on the floor panel.

(2) Install all the components that were removed

to facilitate carpet/mat removal.

(3) Install the trim panels and mouldings.

(4) Install the door sill inner scuff plates.

(5) Install the front and rear seats (as applicable).

Fig. 156 Spare Tire/Wheel Holddown Bolt and

Bracket (RHD)

Fig. 155 Spare Tire/Wheel Holddown Bolt and

Bracket (LHD)Fig. 157 Parking Brake Lever Removal/Installation

Fig. 158 Front Carpet and MatÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 129

Page 1585 of 1784

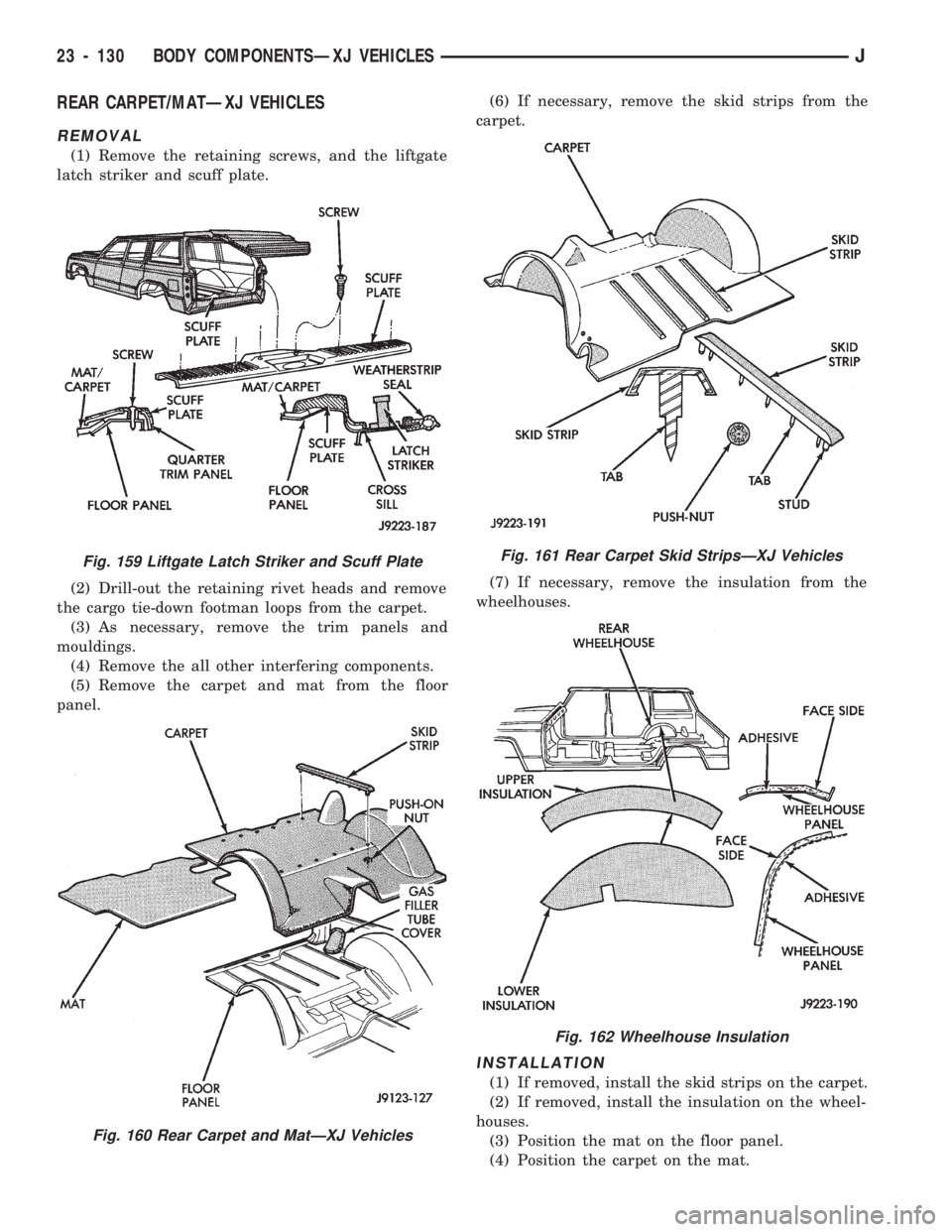

REAR CARPET/MATÐXJ VEHICLES

REMOVAL

(1) Remove the retaining screws, and the liftgate

latch striker and scuff plate.

(2) Drill-out the retaining rivet heads and remove

the cargo tie-down footman loops from the carpet.

(3) As necessary, remove the trim panels and

mouldings.

(4) Remove the all other interfering components.

(5) Remove the carpet and mat from the floor

panel.(6) If necessary, remove the skid strips from the

carpet.

(7) If necessary, remove the insulation from the

wheelhouses.

INSTALLATION

(1) If removed, install the skid strips on the carpet.

(2) If removed, install the insulation on the wheel-

houses.

(3) Position the mat on the floor panel.

(4) Position the carpet on the mat.

Fig. 159 Liftgate Latch Striker and Scuff Plate

Fig. 160 Rear Carpet and MatÐXJ Vehicles

Fig. 161 Rear Carpet Skid StripsÐXJ Vehicles

Fig. 162 Wheelhouse Insulation

23 - 130 BODY COMPONENTSÐXJ VEHICLESJ

Page 1586 of 1784

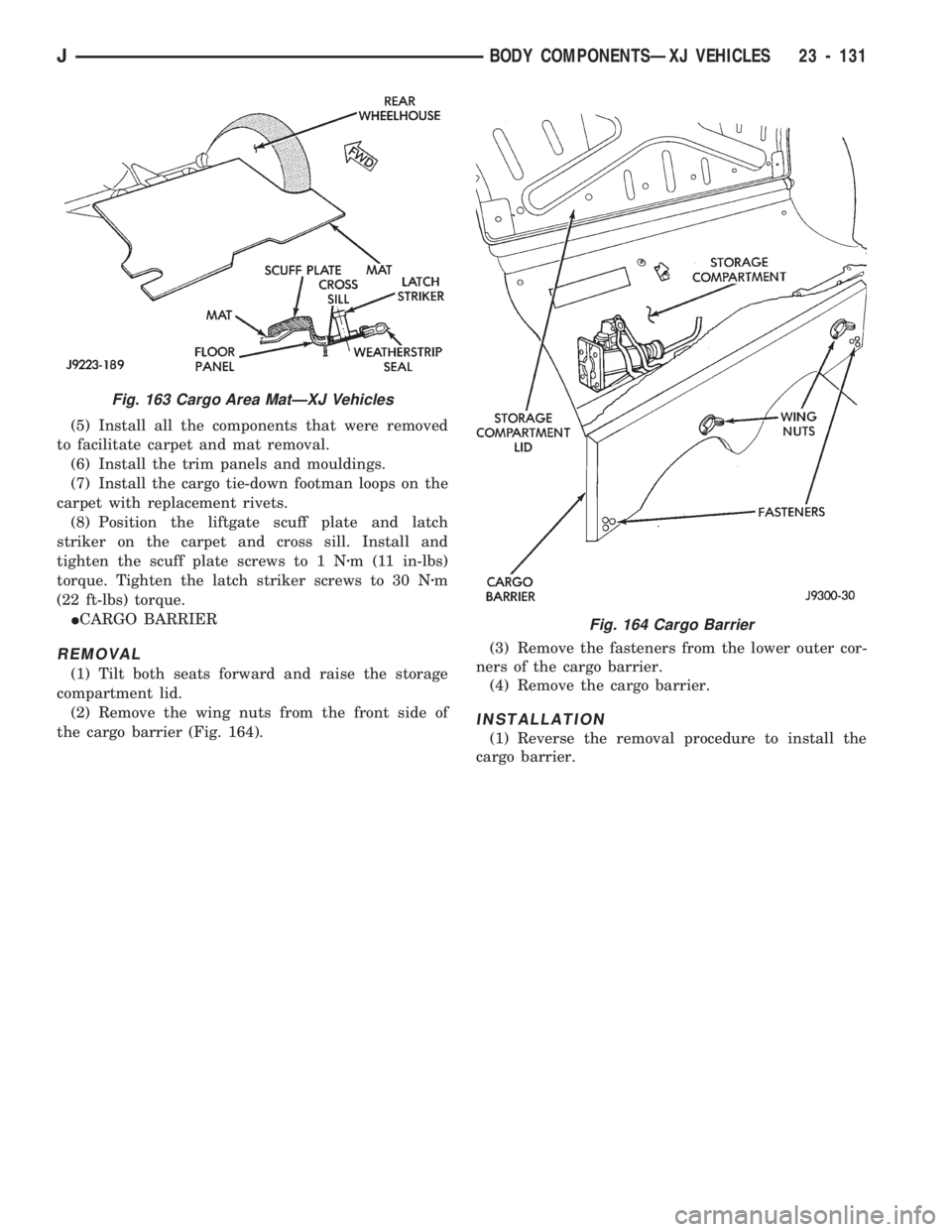

(5) Install all the components that were removed

to facilitate carpet and mat removal.

(6) Install the trim panels and mouldings.

(7) Install the cargo tie-down footman loops on the

carpet with replacement rivets.

(8) Position the liftgate scuff plate and latch

striker on the carpet and cross sill. Install and

tighten the scuff plate screws to 1 Nzm (11 in-lbs)

torque. Tighten the latch striker screws to 30 Nzm

(22 ft-lbs) torque.

ICARGO BARRIER

REMOVAL

(1) Tilt both seats forward and raise the storage

compartment lid.

(2) Remove the wing nuts from the front side of

the cargo barrier (Fig. 164).(3) Remove the fasteners from the lower outer cor-

ners of the cargo barrier.

(4) Remove the cargo barrier.

INSTALLATION

(1) Reverse the removal procedure to install the

cargo barrier.

Fig. 164 Cargo Barrier

Fig. 163 Cargo Area MatÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 131

Page 1587 of 1784

BODY COMPONENTSÐYJ VEHICLES

CONTENTS

page page

ADD-A-TRUNK........................ 198

DOORS.............................. 172

EXTERIOR COMPONENTS............... 134FIXED WINDOW GLASS................ 181

GENERAL SERVICE INFORMATION........ 132

INTERIOR COMPONENTS............... 188

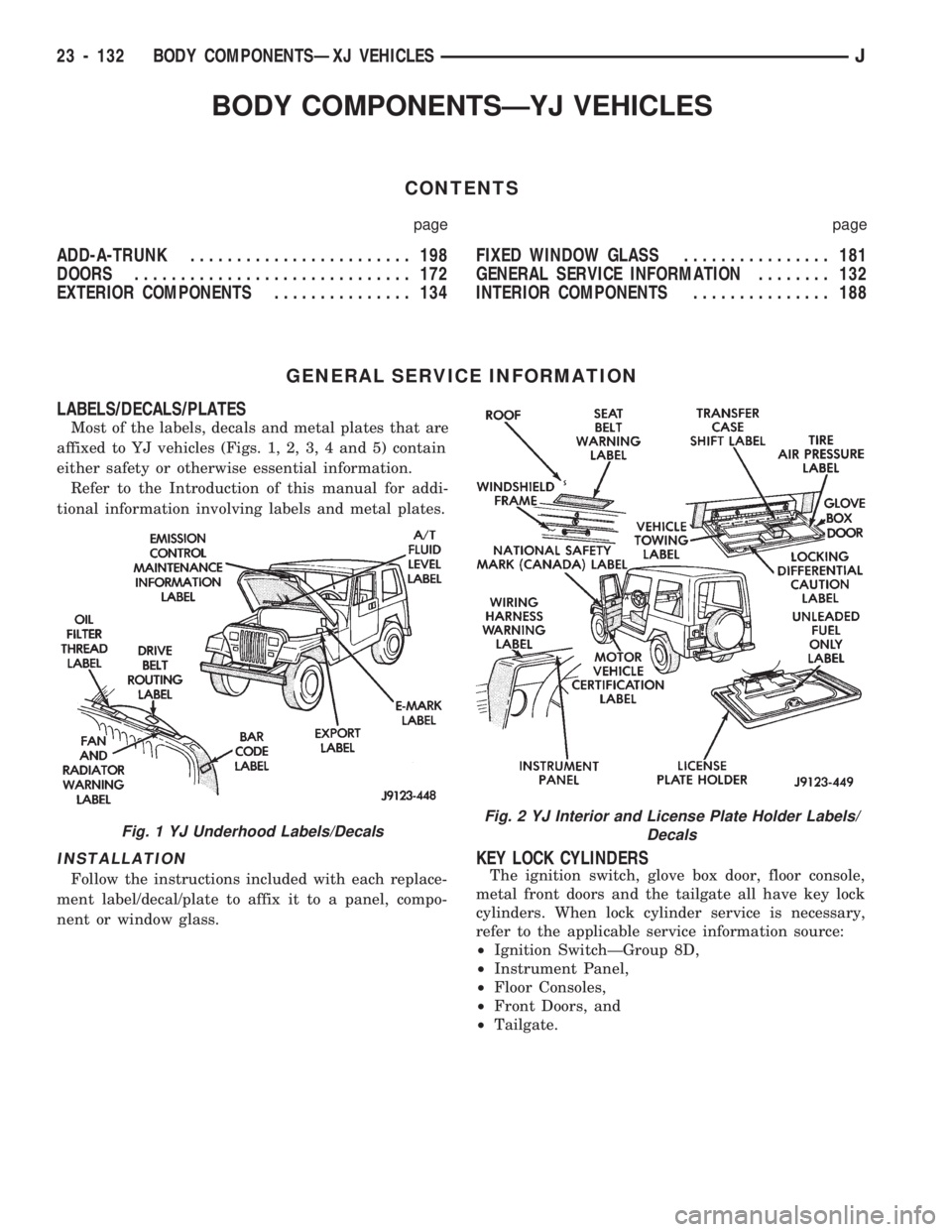

GENERAL SERVICE INFORMATION

LABELS/DECALS/PLATES

Most of the labels, decals and metal plates that are

affixed to YJ vehicles (Figs. 1, 2, 3, 4 and 5) contain

either safety or otherwise essential information.

Refer to the Introduction of this manual for addi-

tional information involving labels and metal plates.

INSTALLATION

Follow the instructions included with each replace-

ment label/decal/plate to affix it to a panel, compo-

nent or window glass.

KEY LOCK CYLINDERS

The ignition switch, glove box door, floor console,

metal front doors and the tailgate all have key lock

cylinders. When lock cylinder service is necessary,

refer to the applicable service information source:

²Ignition SwitchÐGroup 8D,

²Instrument Panel,

²Floor Consoles,

²Front Doors, and

²Tailgate.

Fig. 1 YJ Underhood Labels/DecalsFig. 2 YJ Interior and License Plate Holder Labels/

Decals

23 - 132 BODY COMPONENTSÐXJ VEHICLESJ

Page 1588 of 1784

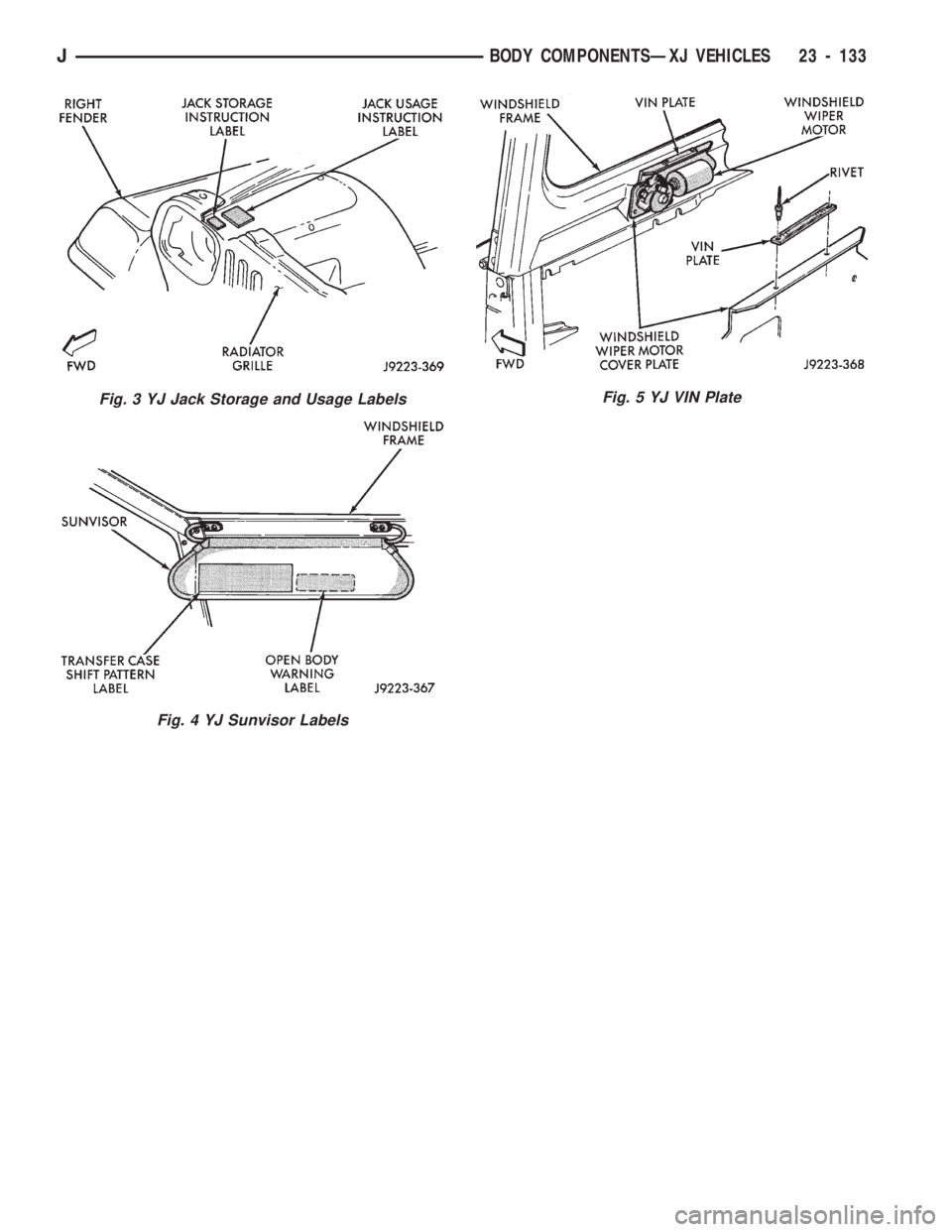

Fig. 3 YJ Jack Storage and Usage Labels

Fig. 4 YJ Sunvisor Labels

Fig. 5 YJ VIN Plate

JBODY COMPONENTSÐXJ VEHICLES 23 - 133

Page 1589 of 1784

EXTERIOR COMPONENTS

INDEX

page page

Battery Tray........................... 140

Body Extension Panels and FasciasÐYJ

Renegade Vehicles..................... 147

Body Side Step Moulding................. 145

Body Stripes/Decals..................... 153

Cowl Grille and Screen................... 139

Cowl Weatherstrip Seal................... 139

Exterior Nameplates (Adhesive-Backed)....... 158

External Spare/Wheel Tire Carrier........... 172

Fender Flare........................... 144

Fender Inner Splash Shields............... 147

Fender Splash Aprons.................... 147

Fenders............................... 141

Fog LampÐYJ Renegade Vehicles.......... 150

Front Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 148

Front Fender Extension PanelÐYJ Renegade

Vehicles............................. 149

Fuel Filler Protector/Nozzle................ 158

Half Metal Door Mirror (External)............ 158

Hard Top Liftgate Glass.................. 162

Hard Top Repair........................ 165

Hard Top Roof Vent..................... 165

Hard Top Service....................... 164

Hard Top Service Information.............. 164Hood................................. 137

Hood Alignment......................... 138

Hood Insulator Panel..................... 138

Hood Safety Latch....................... 139

Liftgate Glass Weatherstrip Seal Replacement . . 163

Radiator Grille Applique................... 134

Rear Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 152

Rear Quarter Extension PanelÐYJ Renegade

Vehicles............................. 151

Rocker Extension PanelÐYJ Renegade

Vehicles............................. 150

Soft Top Service........................ 167

Soft Top Service Information............... 166

Sport Bar............................. 171

Tailgate Adjustment...................... 160

Tailgate Hinge.......................... 159

Tailgate Latch and Release Handle.......... 160

Tailgate Latch Striker..................... 161

Tailgate Lock Cylinder.................... 160

Tailgate Service......................... 159

Tailgate Service Information................ 159

Tailgate Weatherstrip Seal................. 161

Wheelhouse Splash Liners................ 146

RADIATOR GRILLE APPLIQUE

REMOVAL

(1) Raise the hood.

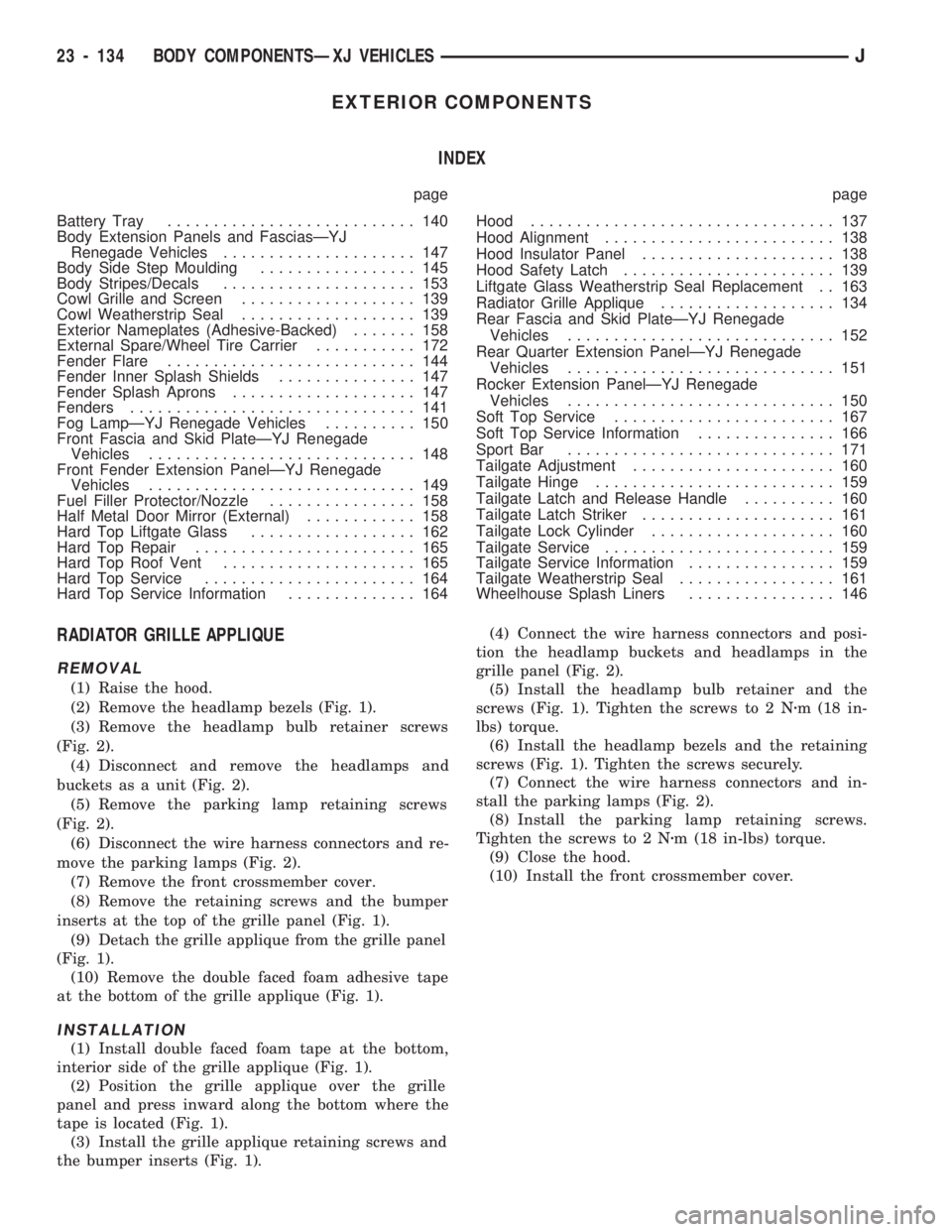

(2) Remove the headlamp bezels (Fig. 1).

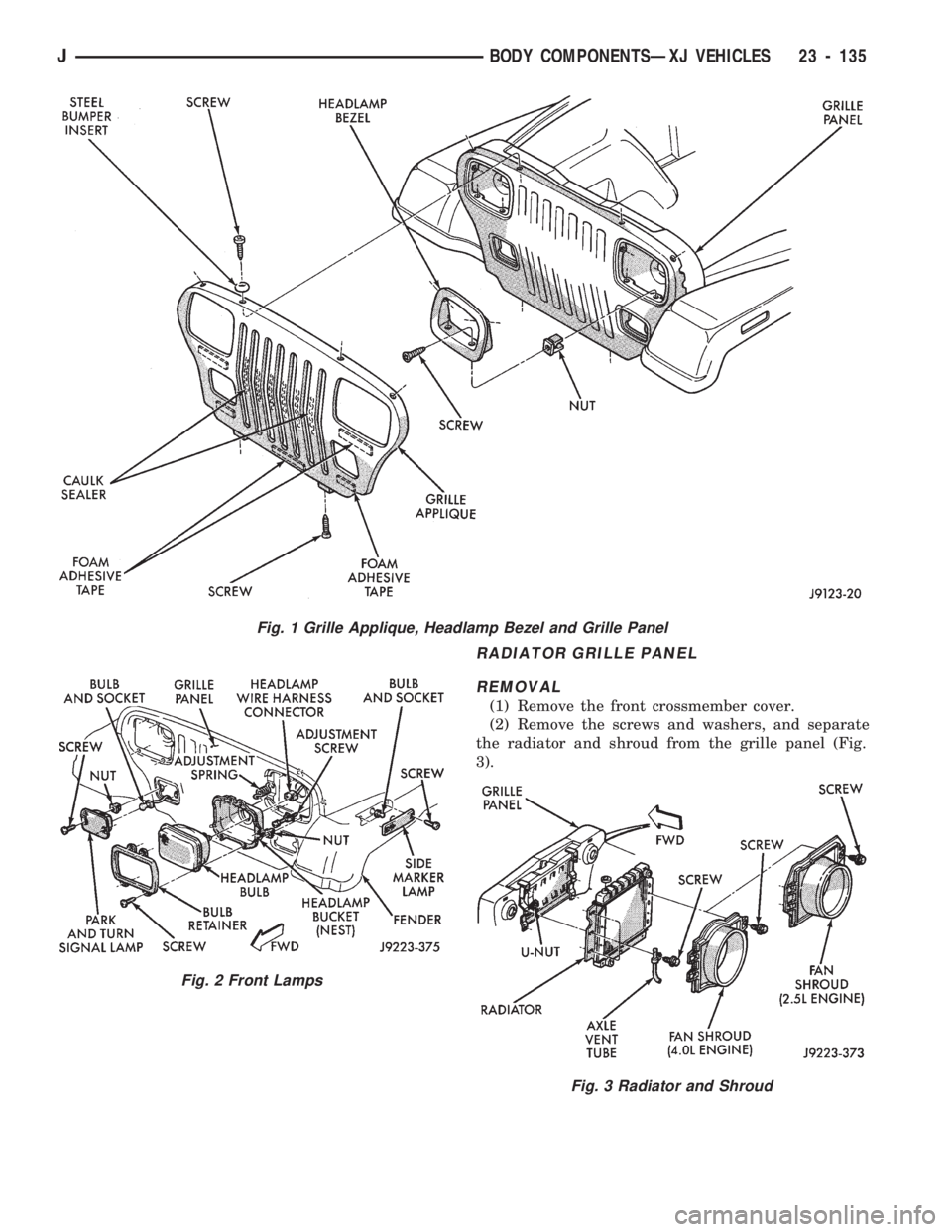

(3) Remove the headlamp bulb retainer screws

(Fig. 2).

(4) Disconnect and remove the headlamps and

buckets as a unit (Fig. 2).

(5) Remove the parking lamp retaining screws

(Fig. 2).

(6) Disconnect the wire harness connectors and re-

move the parking lamps (Fig. 2).

(7) Remove the front crossmember cover.

(8) Remove the retaining screws and the bumper

inserts at the top of the grille panel (Fig. 1).

(9) Detach the grille applique from the grille panel

(Fig. 1).

(10) Remove the double faced foam adhesive tape

at the bottom of the grille applique (Fig. 1).

INSTALLATION

(1) Install double faced foam tape at the bottom,

interior side of the grille applique (Fig. 1).

(2) Position the grille applique over the grille

panel and press inward along the bottom where the

tape is located (Fig. 1).

(3) Install the grille applique retaining screws and

the bumper inserts (Fig. 1).(4) Connect the wire harness connectors and posi-

tion the headlamp buckets and headlamps in the

grille panel (Fig. 2).

(5) Install the headlamp bulb retainer and the

screws (Fig. 1). Tighten the screws to 2 Nzm (18 in-

lbs) torque.

(6) Install the headlamp bezels and the retaining

screws (Fig. 1). Tighten the screws securely.

(7) Connect the wire harness connectors and in-

stall the parking lamps (Fig. 2).

(8) Install the parking lamp retaining screws.

Tighten the screws to 2 Nzm (18 in-lbs) torque.

(9) Close the hood.

(10) Install the front crossmember cover.

23 - 134 BODY COMPONENTSÐXJ VEHICLESJ

Page 1590 of 1784

RADIATOR GRILLE PANEL

REMOVAL

(1) Remove the front crossmember cover.

(2) Remove the screws and washers, and separate

the radiator and shroud from the grille panel (Fig.

3).

Fig. 1 Grille Applique, Headlamp Bezel and Grille Panel

Fig. 2 Front Lamps

Fig. 3 Radiator and Shroud

JBODY COMPONENTSÐXJ VEHICLES 23 - 135