JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1631 of 1784

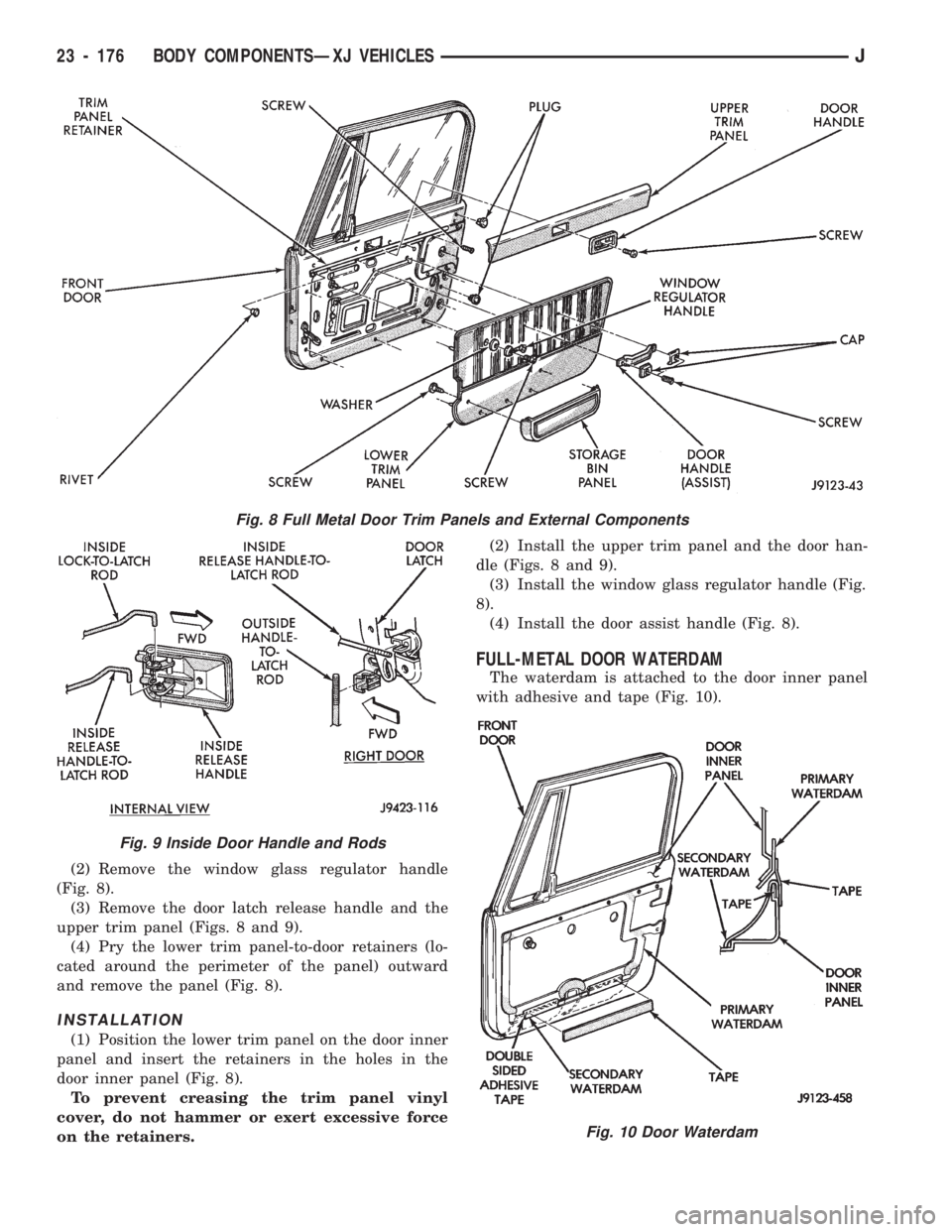

(2) Remove the window glass regulator handle

(Fig. 8).

(3) Remove the door latch release handle and the

upper trim panel (Figs. 8 and 9).

(4) Pry the lower trim panel-to-door retainers (lo-

cated around the perimeter of the panel) outward

and remove the panel (Fig. 8).

INSTALLATION

(1) Position the lower trim panel on the door inner

panel and insert the retainers in the holes in the

door inner panel (Fig. 8).

To prevent creasing the trim panel vinyl

cover, do not hammer or exert excessive force

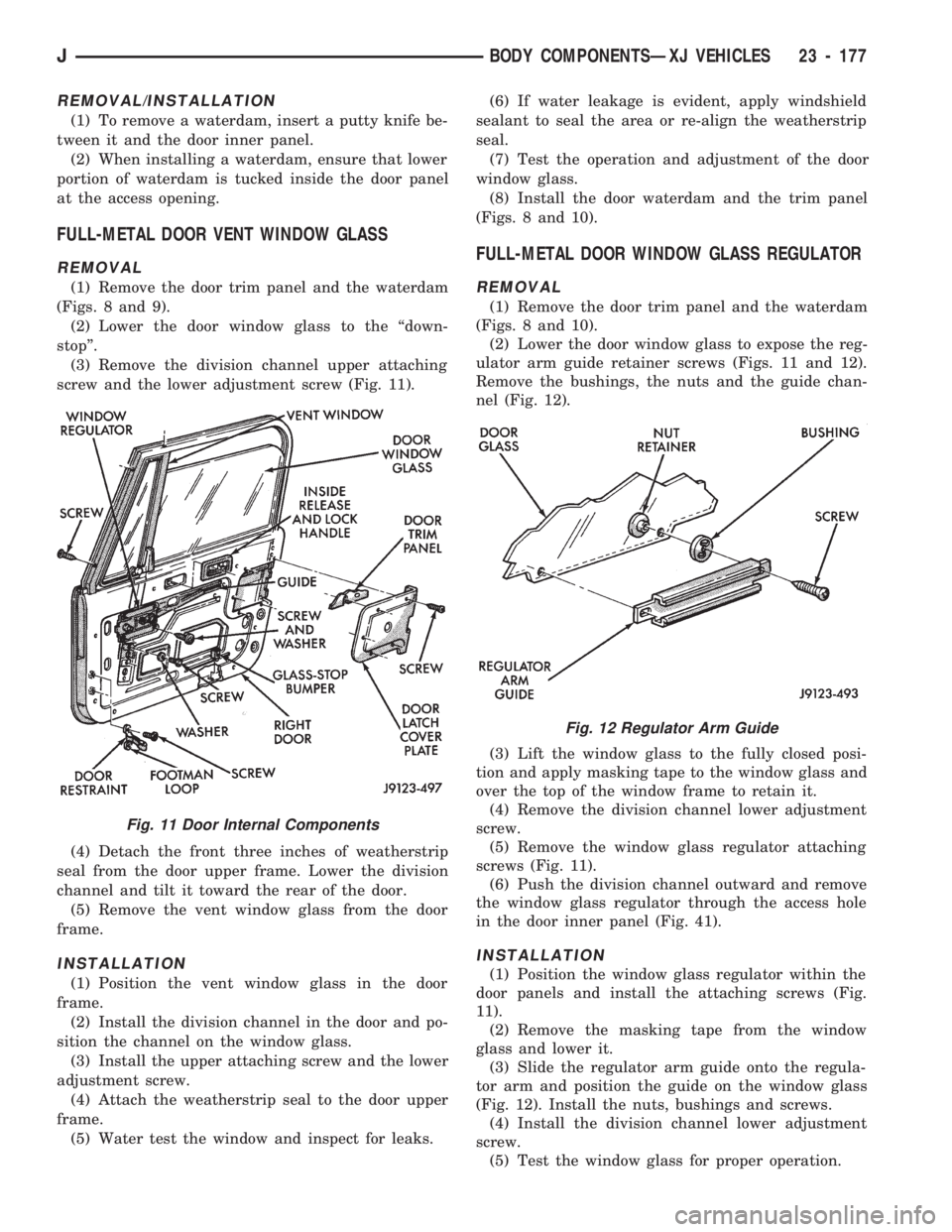

on the retainers.(2) Install the upper trim panel and the door han-

dle (Figs. 8 and 9).

(3) Install the window glass regulator handle (Fig.

8).

(4) Install the door assist handle (Fig. 8).

FULL-METAL DOOR WATERDAM

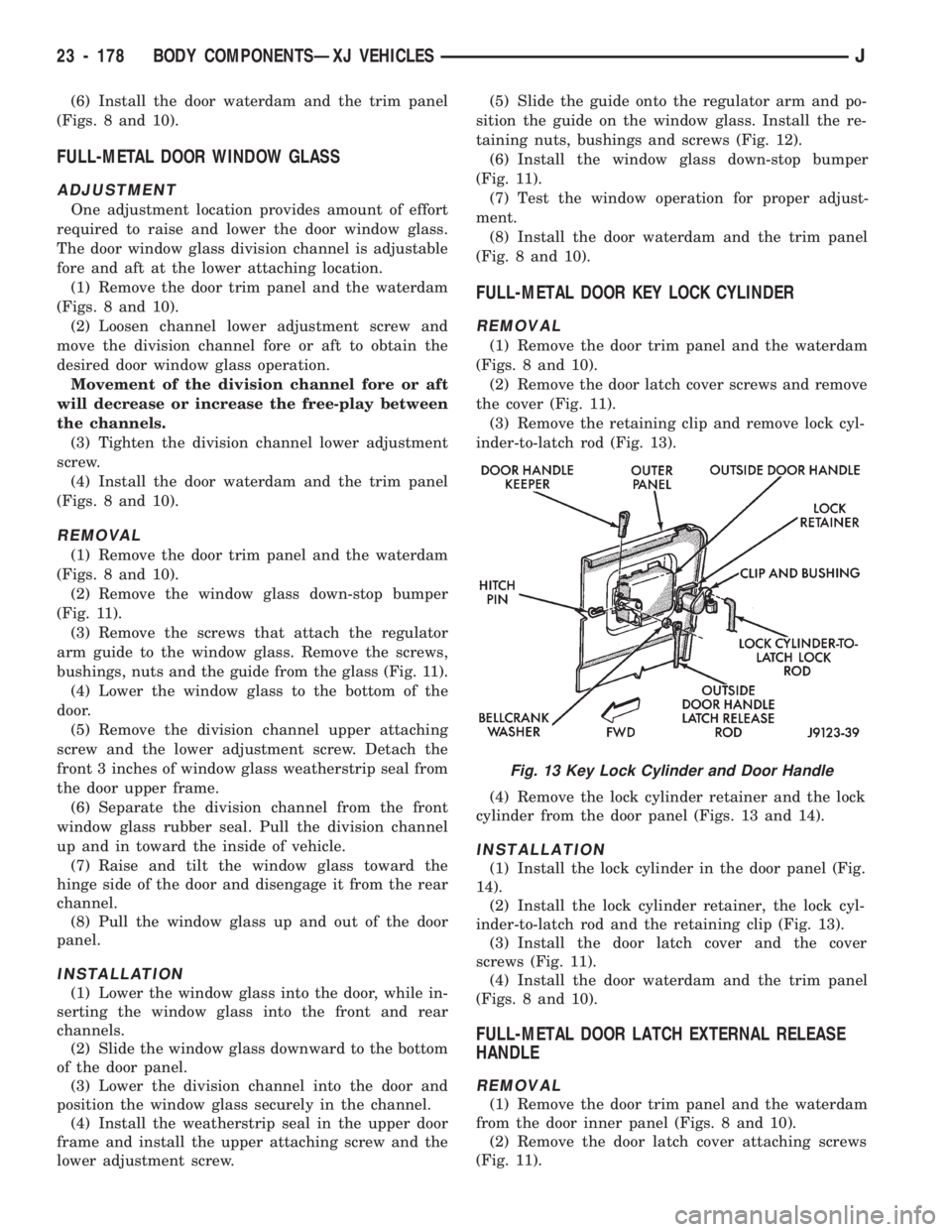

The waterdam is attached to the door inner panel

with adhesive and tape (Fig. 10).

Fig. 10 Door Waterdam

Fig. 8 Full Metal Door Trim Panels and External Components

Fig. 9 Inside Door Handle and Rods

23 - 176 BODY COMPONENTSÐXJ VEHICLESJ

Page 1632 of 1784

REMOVAL/INSTALLATION

(1) To remove a waterdam, insert a putty knife be-

tween it and the door inner panel.

(2) When installing a waterdam, ensure that lower

portion of waterdam is tucked inside the door panel

at the access opening.

FULL-METAL DOOR VENT WINDOW GLASS

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 9).

(2) Lower the door window glass to the ``down-

stop''.

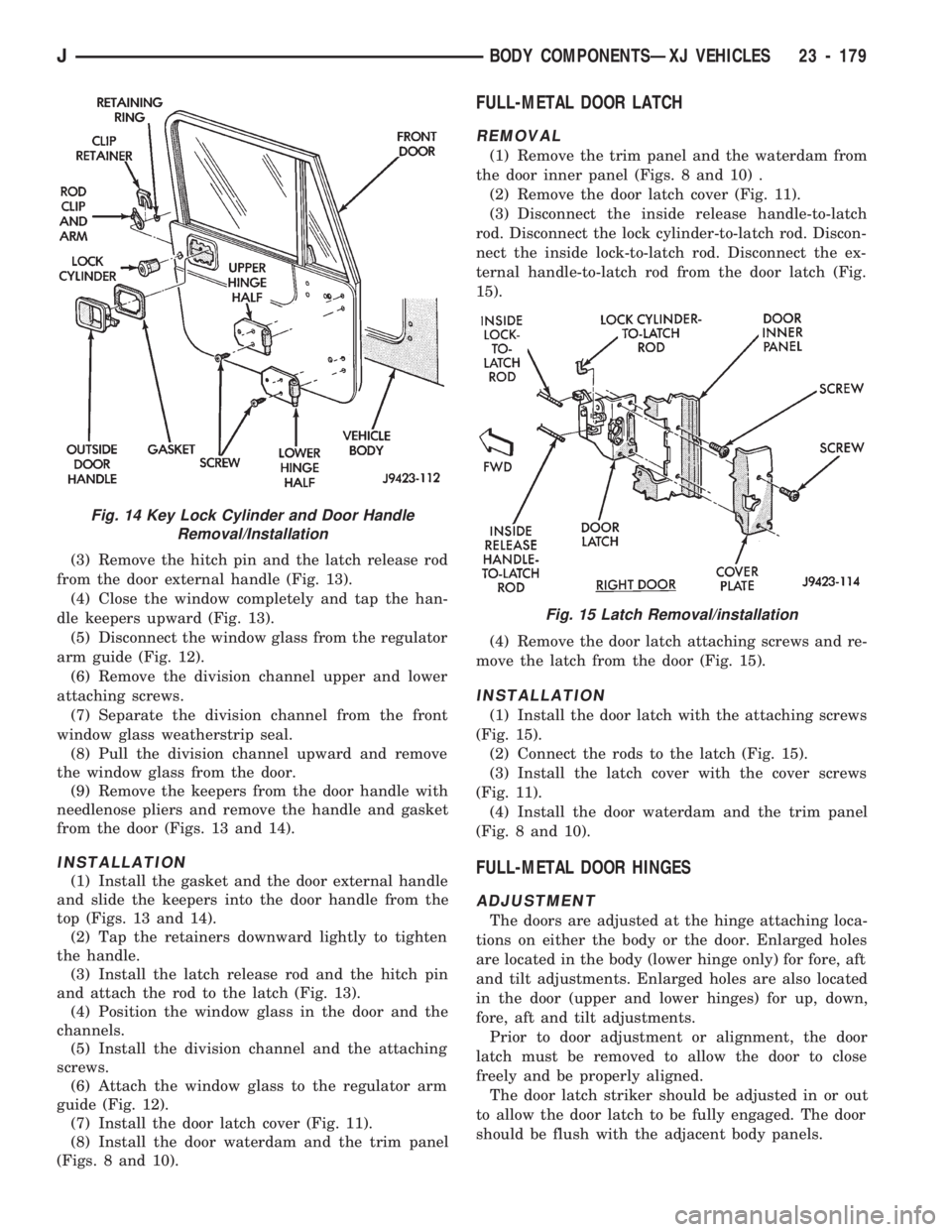

(3) Remove the division channel upper attaching

screw and the lower adjustment screw (Fig. 11).

(4) Detach the front three inches of weatherstrip

seal from the door upper frame. Lower the division

channel and tilt it toward the rear of the door.

(5) Remove the vent window glass from the door

frame.

INSTALLATION

(1) Position the vent window glass in the door

frame.

(2) Install the division channel in the door and po-

sition the channel on the window glass.

(3) Install the upper attaching screw and the lower

adjustment screw.

(4) Attach the weatherstrip seal to the door upper

frame.

(5) Water test the window and inspect for leaks.(6) If water leakage is evident, apply windshield

sealant to seal the area or re-align the weatherstrip

seal.

(7) Test the operation and adjustment of the door

window glass.

(8) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR WINDOW GLASS REGULATOR

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Lower the door window glass to expose the reg-

ulator arm guide retainer screws (Figs. 11 and 12).

Remove the bushings, the nuts and the guide chan-

nel (Fig. 12).

(3) Lift the window glass to the fully closed posi-

tion and apply masking tape to the window glass and

over the top of the window frame to retain it.

(4) Remove the division channel lower adjustment

screw.

(5) Remove the window glass regulator attaching

screws (Fig. 11).

(6) Push the division channel outward and remove

the window glass regulator through the access hole

in the door inner panel (Fig. 41).

INSTALLATION

(1) Position the window glass regulator within the

door panels and install the attaching screws (Fig.

11).

(2) Remove the masking tape from the window

glass and lower it.

(3) Slide the regulator arm guide onto the regula-

tor arm and position the guide on the window glass

(Fig. 12). Install the nuts, bushings and screws.

(4) Install the division channel lower adjustment

screw.

(5) Test the window glass for proper operation.

Fig. 11 Door Internal Components

Fig. 12 Regulator Arm Guide

JBODY COMPONENTSÐXJ VEHICLES 23 - 177

Page 1633 of 1784

(6) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR WINDOW GLASS

ADJUSTMENT

One adjustment location provides amount of effort

required to raise and lower the door window glass.

The door window glass division channel is adjustable

fore and aft at the lower attaching location.

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Loosen channel lower adjustment screw and

move the division channel fore or aft to obtain the

desired door window glass operation.

Movement of the division channel fore or aft

will decrease or increase the free-play between

the channels.

(3) Tighten the division channel lower adjustment

screw.

(4) Install the door waterdam and the trim panel

(Figs. 8 and 10).

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Remove the window glass down-stop bumper

(Fig. 11).

(3) Remove the screws that attach the regulator

arm guide to the window glass. Remove the screws,

bushings, nuts and the guide from the glass (Fig. 11).

(4) Lower the window glass to the bottom of the

door.

(5) Remove the division channel upper attaching

screw and the lower adjustment screw. Detach the

front 3 inches of window glass weatherstrip seal from

the door upper frame.

(6) Separate the division channel from the front

window glass rubber seal. Pull the division channel

up and in toward the inside of vehicle.

(7) Raise and tilt the window glass toward the

hinge side of the door and disengage it from the rear

channel.

(8) Pull the window glass up and out of the door

panel.

INSTALLATION

(1) Lower the window glass into the door, while in-

serting the window glass into the front and rear

channels.

(2) Slide the window glass downward to the bottom

of the door panel.

(3) Lower the division channel into the door and

position the window glass securely in the channel.

(4) Install the weatherstrip seal in the upper door

frame and install the upper attaching screw and the

lower adjustment screw.(5) Slide the guide onto the regulator arm and po-

sition the guide on the window glass. Install the re-

taining nuts, bushings and screws (Fig. 12).

(6) Install the window glass down-stop bumper

(Fig. 11).

(7) Test the window operation for proper adjust-

ment.

(8) Install the door waterdam and the trim panel

(Fig. 8 and 10).

FULL-METAL DOOR KEY LOCK CYLINDER

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Remove the door latch cover screws and remove

the cover (Fig. 11).

(3) Remove the retaining clip and remove lock cyl-

inder-to-latch rod (Fig. 13).

(4) Remove the lock cylinder retainer and the lock

cylinder from the door panel (Figs. 13 and 14).

INSTALLATION

(1) Install the lock cylinder in the door panel (Fig.

14).

(2) Install the lock cylinder retainer, the lock cyl-

inder-to-latch rod and the retaining clip (Fig. 13).

(3) Install the door latch cover and the cover

screws (Fig. 11).

(4) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR LATCH EXTERNAL RELEASE

HANDLE

REMOVAL

(1) Remove the door trim panel and the waterdam

from the door inner panel (Figs. 8 and 10).

(2) Remove the door latch cover attaching screws

(Fig. 11).

Fig. 13 Key Lock Cylinder and Door Handle

23 - 178 BODY COMPONENTSÐXJ VEHICLESJ

Page 1634 of 1784

(3) Remove the hitch pin and the latch release rod

from the door external handle (Fig. 13).

(4) Close the window completely and tap the han-

dle keepers upward (Fig. 13).

(5) Disconnect the window glass from the regulator

arm guide (Fig. 12).

(6) Remove the division channel upper and lower

attaching screws.

(7) Separate the division channel from the front

window glass weatherstrip seal.

(8) Pull the division channel upward and remove

the window glass from the door.

(9) Remove the keepers from the door handle with

needlenose pliers and remove the handle and gasket

from the door (Figs. 13 and 14).

INSTALLATION

(1) Install the gasket and the door external handle

and slide the keepers into the door handle from the

top (Figs. 13 and 14).

(2) Tap the retainers downward lightly to tighten

the handle.

(3) Install the latch release rod and the hitch pin

and attach the rod to the latch (Fig. 13).

(4) Position the window glass in the door and the

channels.

(5) Install the division channel and the attaching

screws.

(6) Attach the window glass to the regulator arm

guide (Fig. 12).

(7) Install the door latch cover (Fig. 11).

(8) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR LATCH

REMOVAL

(1) Remove the trim panel and the waterdam from

the door inner panel (Figs. 8 and 10) .

(2) Remove the door latch cover (Fig. 11).

(3) Disconnect the inside release handle-to-latch

rod. Disconnect the lock cylinder-to-latch rod. Discon-

nect the inside lock-to-latch rod. Disconnect the ex-

ternal handle-to-latch rod from the door latch (Fig.

15).

(4) Remove the door latch attaching screws and re-

move the latch from the door (Fig. 15).

INSTALLATION

(1) Install the door latch with the attaching screws

(Fig. 15).

(2) Connect the rods to the latch (Fig. 15).

(3) Install the latch cover with the cover screws

(Fig. 11).

(4) Install the door waterdam and the trim panel

(Fig. 8 and 10).

FULL-METAL DOOR HINGES

ADJUSTMENT

The doors are adjusted at the hinge attaching loca-

tions on either the body or the door. Enlarged holes

are located in the body (lower hinge only) for fore, aft

and tilt adjustments. Enlarged holes are also located

in the door (upper and lower hinges) for up, down,

fore, aft and tilt adjustments.

Prior to door adjustment or alignment, the door

latch must be removed to allow the door to close

freely and be properly aligned.

The door latch striker should be adjusted in or out

to allow the door latch to be fully engaged. The door

should be flush with the adjacent body panels.

Fig. 15 Latch Removal/installation

Fig. 14 Key Lock Cylinder and Door Handle

Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 179

Page 1635 of 1784

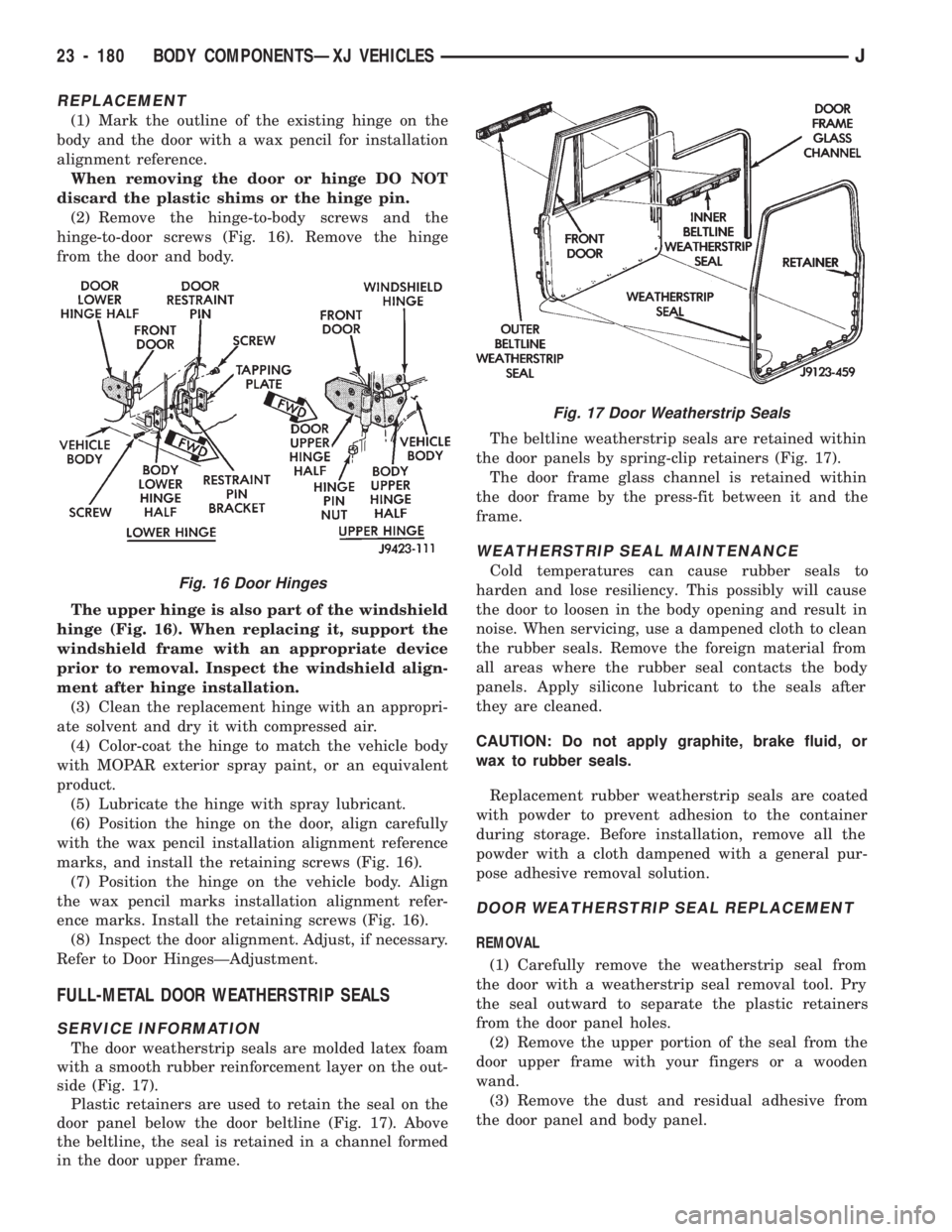

REPLACEMENT

(1) Mark the outline of the existing hinge on the

body and the door with a wax pencil for installation

alignment reference.

When removing the door or hinge DO NOT

discard the plastic shims or the hinge pin.

(2) Remove the hinge-to-body screws and the

hinge-to-door screws (Fig. 16). Remove the hinge

from the door and body.

The upper hinge is also part of the windshield

hinge (Fig. 16). When replacing it, support the

windshield frame with an appropriate device

prior to removal. Inspect the windshield align-

ment after hinge installation.

(3) Clean the replacement hinge with an appropri-

ate solvent and dry it with compressed air.

(4) Color-coat the hinge to match the vehicle body

with MOPAR exterior spray paint, or an equivalent

product.

(5) Lubricate the hinge with spray lubricant.

(6) Position the hinge on the door, align carefully

with the wax pencil installation alignment reference

marks, and install the retaining screws (Fig. 16).

(7) Position the hinge on the vehicle body. Align

the wax pencil marks installation alignment refer-

ence marks. Install the retaining screws (Fig. 16).

(8) Inspect the door alignment. Adjust, if necessary.

Refer to Door HingesÐAdjustment.

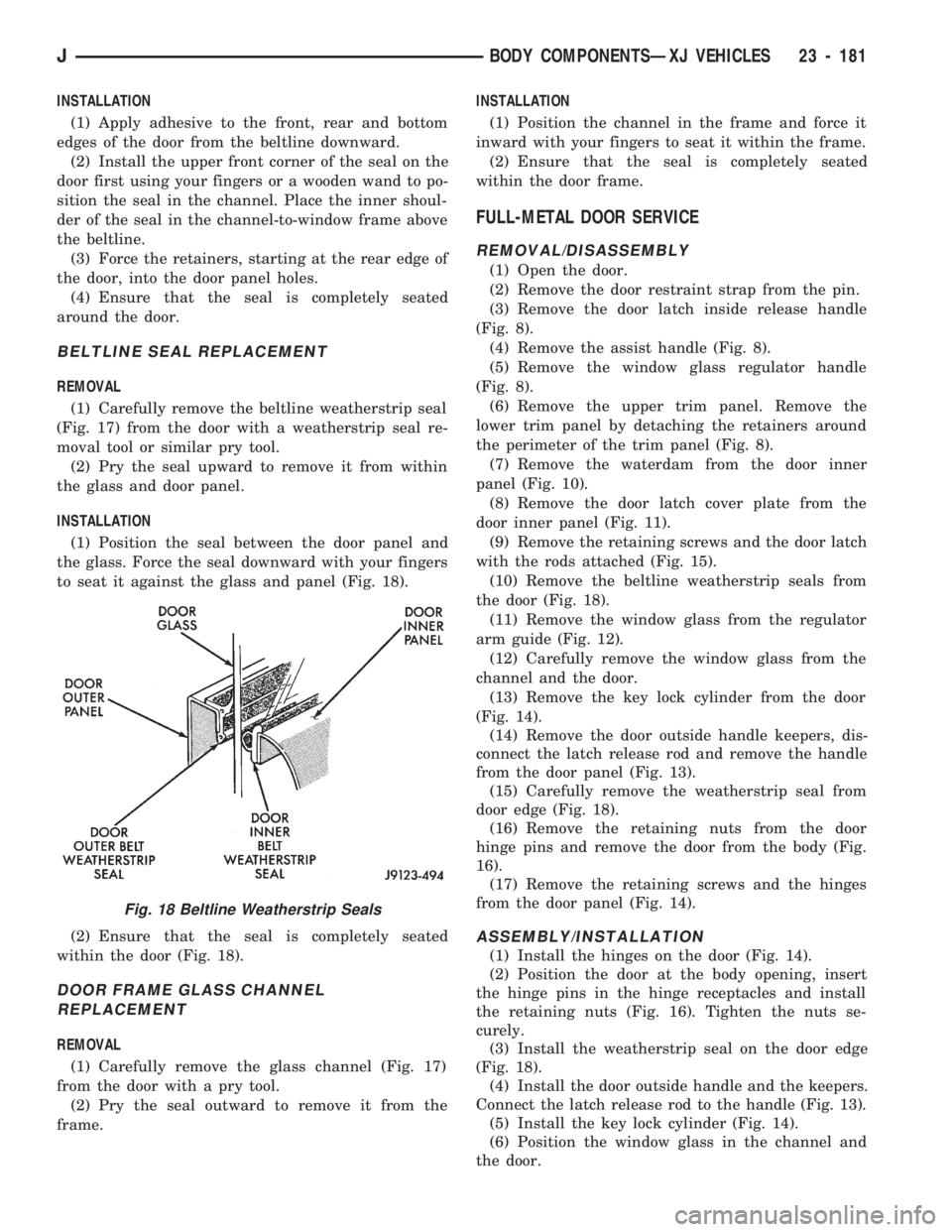

FULL-METAL DOOR WEATHERSTRIP SEALS

SERVICE INFORMATION

The door weatherstrip seals are molded latex foam

with a smooth rubber reinforcement layer on the out-

side (Fig. 17).

Plastic retainers are used to retain the seal on the

door panel below the door beltline (Fig. 17). Above

the beltline, the seal is retained in a channel formed

in the door upper frame.The beltline weatherstrip seals are retained within

the door panels by spring-clip retainers (Fig. 17).

The door frame glass channel is retained within

the door frame by the press-fit between it and the

frame.

WEATHERSTRIP SEAL MAINTENANCE

Cold temperatures can cause rubber seals to

harden and lose resiliency. This possibly will cause

the door to loosen in the body opening and result in

noise. When servicing, use a dampened cloth to clean

the rubber seals. Remove the foreign material from

all areas where the rubber seal contacts the body

panels. Apply silicone lubricant to the seals after

they are cleaned.

CAUTION: Do not apply graphite, brake fluid, or

wax to rubber seals.

Replacement rubber weatherstrip seals are coated

with powder to prevent adhesion to the container

during storage. Before installation, remove all the

powder with a cloth dampened with a general pur-

pose adhesive removal solution.

DOOR WEATHERSTRIP SEAL REPLACEMENT

REMOVAL

(1) Carefully remove the weatherstrip seal from

the door with a weatherstrip seal removal tool. Pry

the seal outward to separate the plastic retainers

from the door panel holes.

(2) Remove the upper portion of the seal from the

door upper frame with your fingers or a wooden

wand.

(3) Remove the dust and residual adhesive from

the door panel and body panel.

Fig. 17 Door Weatherstrip Seals

Fig. 16 Door Hinges

23 - 180 BODY COMPONENTSÐXJ VEHICLESJ

Page 1636 of 1784

INSTALLATION

(1) Apply adhesive to the front, rear and bottom

edges of the door from the beltline downward.

(2) Install the upper front corner of the seal on the

door first using your fingers or a wooden wand to po-

sition the seal in the channel. Place the inner shoul-

der of the seal in the channel-to-window frame above

the beltline.

(3) Force the retainers, starting at the rear edge of

the door, into the door panel holes.

(4) Ensure that the seal is completely seated

around the door.

BELTLINE SEAL REPLACEMENT

REMOVAL

(1) Carefully remove the beltline weatherstrip seal

(Fig. 17) from the door with a weatherstrip seal re-

moval tool or similar pry tool.

(2) Pry the seal upward to remove it from within

the glass and door panel.

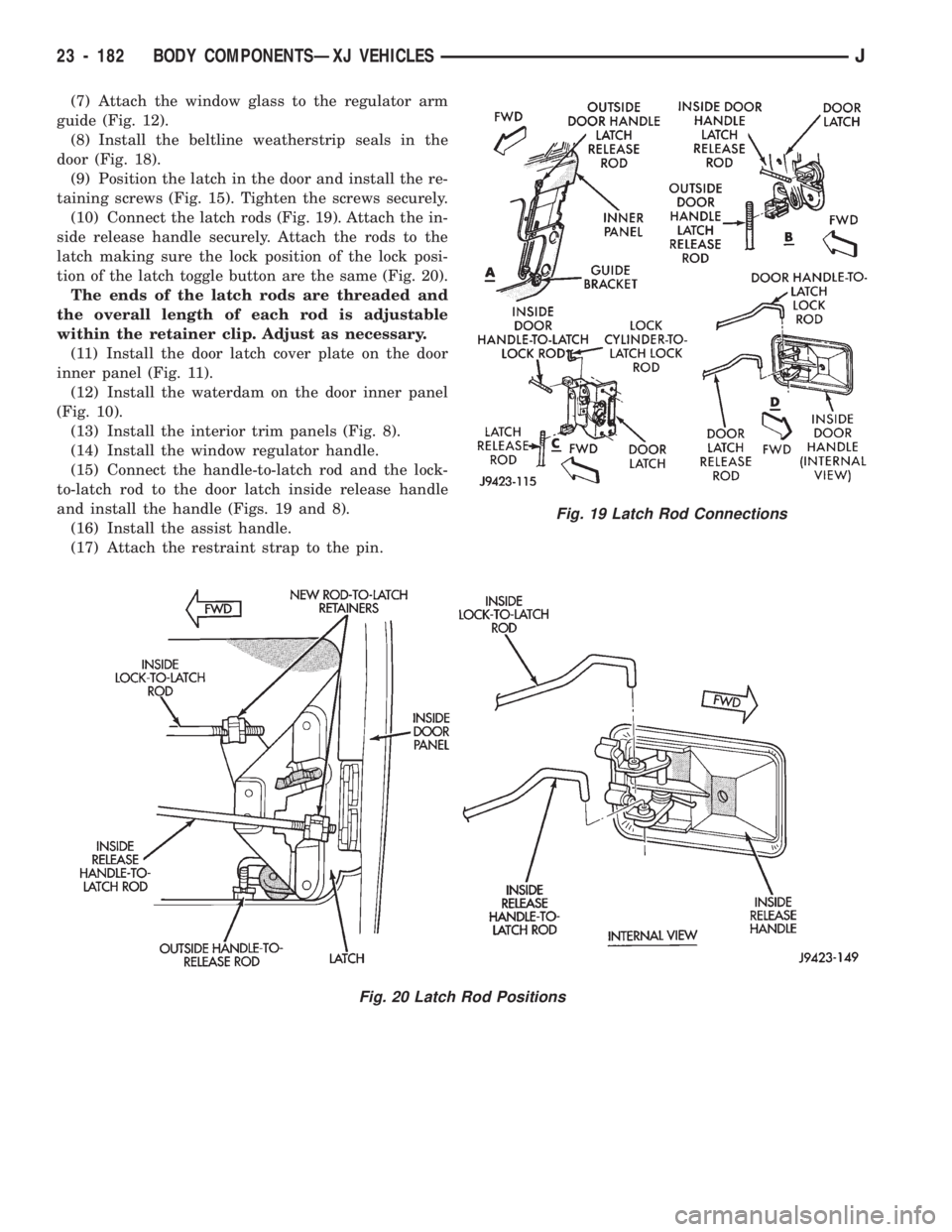

INSTALLATION

(1) Position the seal between the door panel and

the glass. Force the seal downward with your fingers

to seat it against the glass and panel (Fig. 18).

(2) Ensure that the seal is completely seated

within the door (Fig. 18).

DOOR FRAME GLASS CHANNEL

REPLACEMENT

REMOVAL

(1) Carefully remove the glass channel (Fig. 17)

from the door with a pry tool.

(2) Pry the seal outward to remove it from the

frame.INSTALLATION

(1) Position the channel in the frame and force it

inward with your fingers to seat it within the frame.

(2) Ensure that the seal is completely seated

within the door frame.

FULL-METAL DOOR SERVICE

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Remove the door restraint strap from the pin.

(3) Remove the door latch inside release handle

(Fig. 8).

(4) Remove the assist handle (Fig. 8).

(5) Remove the window glass regulator handle

(Fig. 8).

(6) Remove the upper trim panel. Remove the

lower trim panel by detaching the retainers around

the perimeter of the trim panel (Fig. 8).

(7) Remove the waterdam from the door inner

panel (Fig. 10).

(8) Remove the door latch cover plate from the

door inner panel (Fig. 11).

(9) Remove the retaining screws and the door latch

with the rods attached (Fig. 15).

(10) Remove the beltline weatherstrip seals from

the door (Fig. 18).

(11) Remove the window glass from the regulator

arm guide (Fig. 12).

(12) Carefully remove the window glass from the

channel and the door.

(13) Remove the key lock cylinder from the door

(Fig. 14).

(14) Remove the door outside handle keepers, dis-

connect the latch release rod and remove the handle

from the door panel (Fig. 13).

(15) Carefully remove the weatherstrip seal from

door edge (Fig. 18).

(16) Remove the retaining nuts from the door

hinge pins and remove the door from the body (Fig.

16).

(17) Remove the retaining screws and the hinges

from the door panel (Fig. 14).

ASSEMBLY/INSTALLATION

(1) Install the hinges on the door (Fig. 14).

(2) Position the door at the body opening, insert

the hinge pins in the hinge receptacles and install

the retaining nuts (Fig. 16). Tighten the nuts se-

curely.

(3) Install the weatherstrip seal on the door edge

(Fig. 18).

(4) Install the door outside handle and the keepers.

Connect the latch release rod to the handle (Fig. 13).

(5) Install the key lock cylinder (Fig. 14).

(6) Position the window glass in the channel and

the door.

Fig. 18 Beltline Weatherstrip Seals

JBODY COMPONENTSÐXJ VEHICLES 23 - 181

Page 1637 of 1784

(7) Attach the window glass to the regulator arm

guide (Fig. 12).

(8) Install the beltline weatherstrip seals in the

door (Fig. 18).

(9) Position the latch in the door and install the re-

taining screws (Fig. 15). Tighten the screws securely.

(10) Connect the latch rods (Fig. 19). Attach the in-

side release handle securely. Attach the rods to the

latch making sure the lock position of the lock posi-

tion of the latch toggle button are the same (Fig. 20).

The ends of the latch rods are threaded and

the overall length of each rod is adjustable

within the retainer clip. Adjust as necessary.

(11) Install the door latch cover plate on the door

inner panel (Fig. 11).

(12) Install the waterdam on the door inner panel

(Fig. 10).

(13) Install the interior trim panels (Fig. 8).

(14) Install the window regulator handle.

(15) Connect the handle-to-latch rod and the lock-

to-latch rod to the door latch inside release handle

and install the handle (Figs. 19 and 8).

(16) Install the assist handle.

(17) Attach the restraint strap to the pin.

Fig. 20 Latch Rod Positions

Fig. 19 Latch Rod Connections

23 - 182 BODY COMPONENTSÐXJ VEHICLESJ

Page 1638 of 1784

FIXED WINDOW GLASS

INDEX

page page

Fixed Glass Water Leak Detection and Repair . 189

Hard Top Quarter Window Glass............ 188

Rearview Mirror......................... 183

Rearview Mirror Retaining Bracket........... 183

Service Information...................... 183Windshield Frame....................... 184

Windshield Frame Weatherstrip Seal......... 185

Windshield Glass........................ 185

Windshield Reveal Moulding............... 183

SERVICE INFORMATION

The following fixed window service information in-

cludes removal/installation procedures for the:

²windshield reveal moulding,

²rearview mirror,

²windshield frame,

²windshield frame weatherstrip seal,

²windshield glass (using both the short and the ex-

tended installation method), and

²hard top quarter (side) window glass.

WINDSHIELD REVEAL MOULDING

REMOVAL

(1) Disengage the reveal moulding around the pe-

rimeter of the windshield glass with an appropriate

tool.

(2) Remove the mouldings from the windshield

frame.

(3) Inspect the reveal moulding retainers. Replace

the moulding if it has broken, distorted or ineffective

retainers.

INSTALLATION

(1) Position the reveal mouldings on the wind-

shield frame.

(2) Attach the mouldings to the frame by tapping

each moulding with a rubber mallet to seat the re-

tainers.

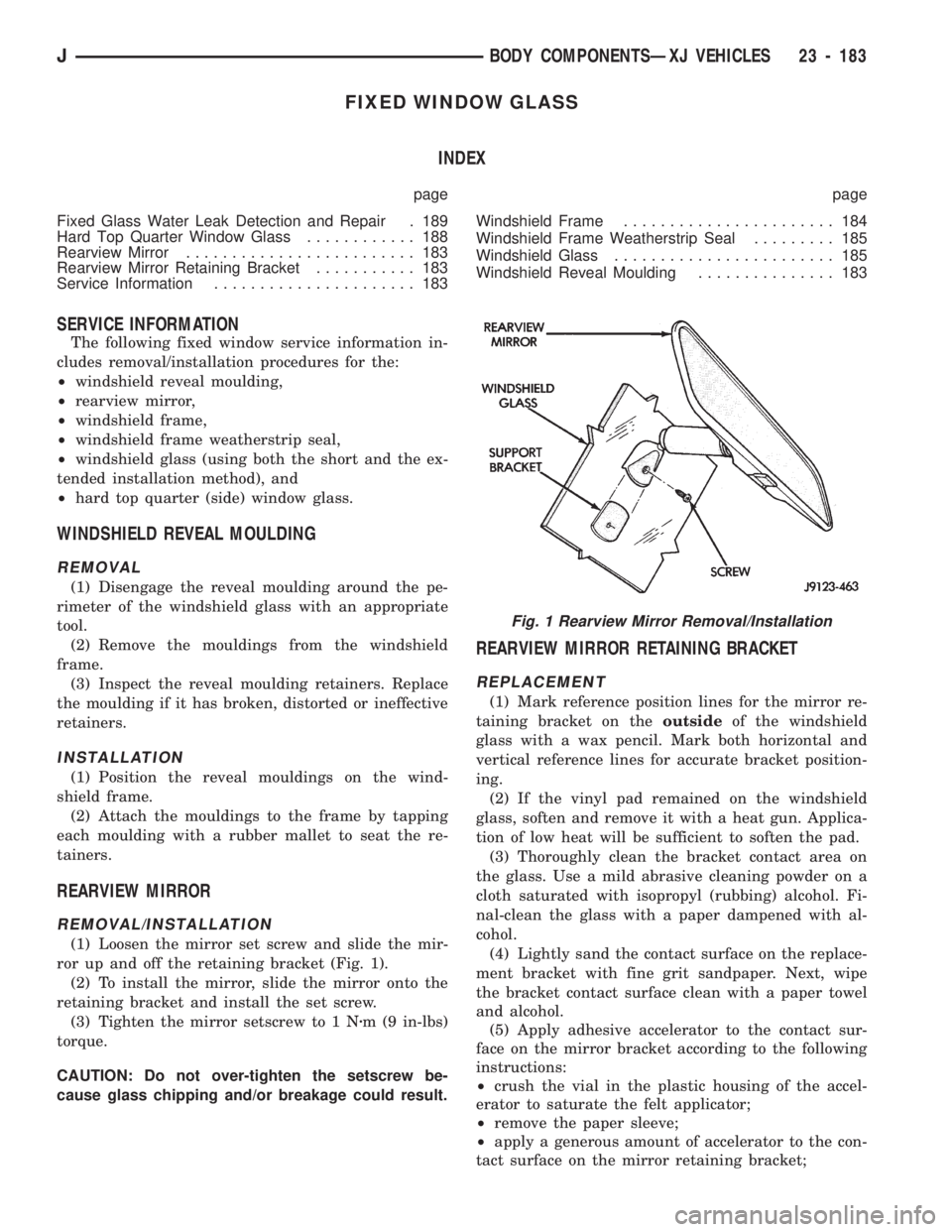

REARVIEW MIRROR

REMOVAL/INSTALLATION

(1) Loosen the mirror set screw and slide the mir-

ror up and off the retaining bracket (Fig. 1).

(2) To install the mirror, slide the mirror onto the

retaining bracket and install the set screw.

(3) Tighten the mirror setscrew to 1 Nzm (9 in-lbs)

torque.

CAUTION: Do not over-tighten the setscrew be-

cause glass chipping and/or breakage could result.

REARVIEW MIRROR RETAINING BRACKET

REPLACEMENT

(1) Mark reference position lines for the mirror re-

taining bracket on theoutsideof the windshield

glass with a wax pencil. Mark both horizontal and

vertical reference lines for accurate bracket position-

ing.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun. Applica-

tion of low heat will be sufficient to soften the pad.

(3) Thoroughly clean the bracket contact area on

the glass. Use a mild abrasive cleaning powder on a

cloth saturated with isopropyl (rubbing) alcohol. Fi-

nal-clean the glass with a paper dampened with al-

cohol.

(4) Lightly sand the contact surface on the replace-

ment bracket with fine grit sandpaper. Next, wipe

the bracket contact surface clean with a paper towel

and alcohol.

(5) Apply adhesive accelerator to the contact sur-

face on the mirror bracket according to the following

instructions:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator;

²remove the paper sleeve;

²apply a generous amount of accelerator to the con-

tact surface on the mirror retaining bracket;

Fig. 1 Rearview Mirror Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 183

Page 1639 of 1784

²do not touch the retaining bracket contact surface

after the accelerator has been applied.

²allow the accelerator to dry for at least five min-

utes; and

(6) Apply accelerator to bracket contact surface on

the windshield glass. Allow the accelerator to dry for

one minute. Do not touch the glass contact surface

after the accelerator has been applied.

(7) Install the mirror retaining bracket according

to the following instructions:

²apply one drop of adhesive at the center of the re-

taining bracket contact surface on the windshield

glass;

²immediately apply an even coat of adhesive to the

contact surface on the retaining bracket;

²align the retaining bracket with the position refer-

ence lines on the windshield glass, then

²press and hold the retaining bracket in-place for at

least one minute.

Ensure that the mirror retaining bracket is

correctly aligned because the adhesive will

cure rapidly.

(8) Allow the adhesive to cure for 8-10 minutes,

then remove any residue adhesive with an alcohol

dampened cloth.

(9) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror on the re-

taining bracket (Fig. 1).

WINDSHIELD FRAME

SERVICE INFORMATION

The windshield frame and glass can be removed as

a unit for service access (Fig. 2). The windshield

frame can also be tilted forward to a full horizontal

position and retained in-place with the strap when

complete removal is not necessary.

REMOVAL

(1) Remove the windshield wipers. Refer to the re-

moval procedure.

(2) For vehicles equipped with a soft top, discon-

nect the fabric top from the windshield frame re-

tainer rail. If necessary, refer to the soft top removal

procedure.

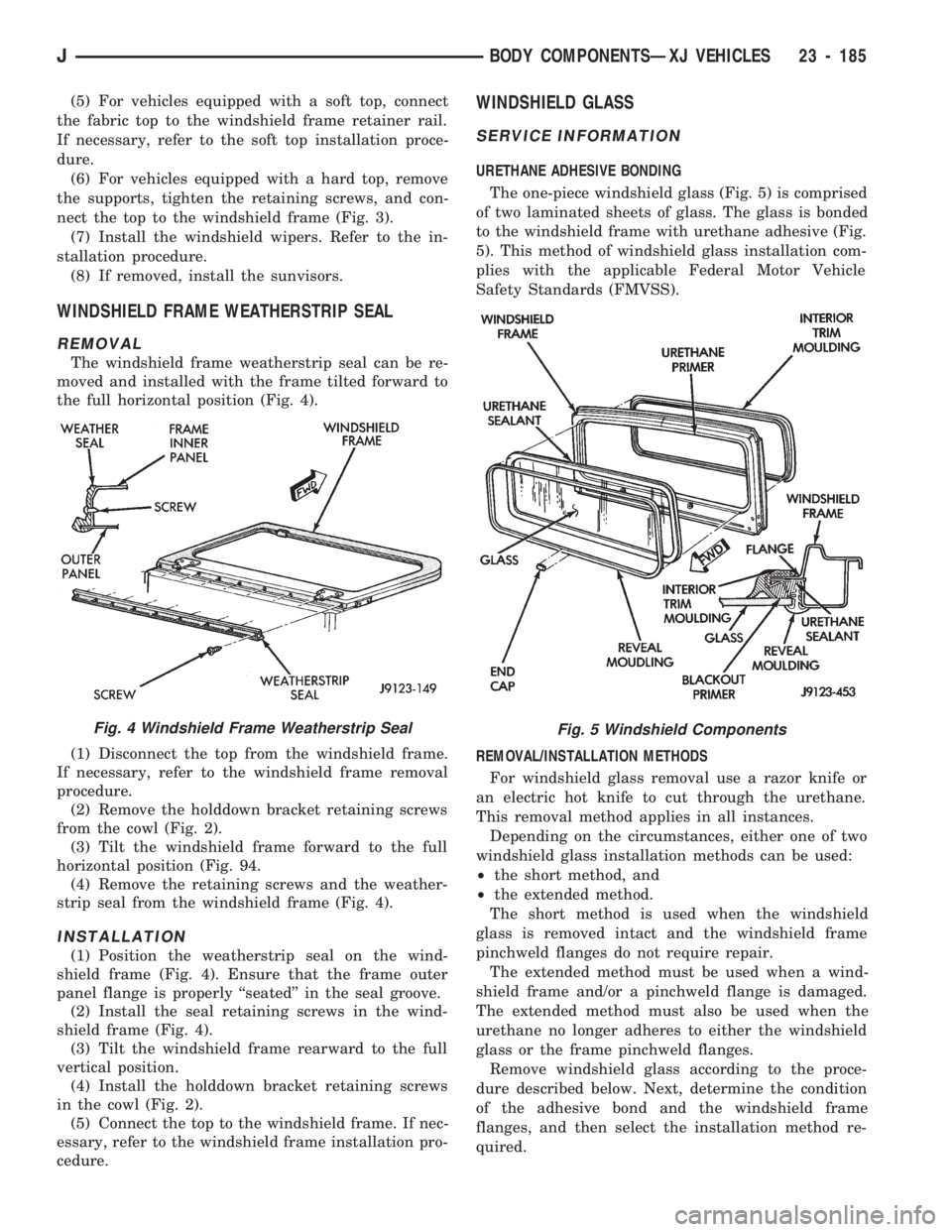

(3) For vehicles equipped with a hard top, discon-

nect the top from the windshield frame. Loosen the

retaining screws, tilt the top rearward and support

the top away from the windshield frame (Fig. 3).

(4) Remove the retaining screws and the wind-

shield/door hinges from the cowl (Fig. 2).

(5) Remove the holddown bracket retaining screws

from the cowl (Fig. 2).

(6) Remove the windshield frame and glass from

the cowl as a unit (Fig. 2).

(7) If necessary, remove the sunvisors.

INSTALLATION

(1) Position the windshield frame on the cowl (Fig.

2).

(2) Install the holddown bracket retaining screws

in the cowl (Fig. 2).

(3) Install the windshield/door hinge retaining

screws (Fig. 2).

(4) Connect the top to the windshield frame. If nec-

essary, refer to the applicable top installation proce-

dure.

Fig. 2 Windshield Frame Removal/Installation

Fig. 3 Hard Top Detached From Windshield Frame

23 - 184 BODY COMPONENTSÐXJ VEHICLESJ

Page 1640 of 1784

(5) For vehicles equipped with a soft top, connect

the fabric top to the windshield frame retainer rail.

If necessary, refer to the soft top installation proce-

dure.

(6) For vehicles equipped with a hard top, remove

the supports, tighten the retaining screws, and con-

nect the top to the windshield frame (Fig. 3).

(7) Install the windshield wipers. Refer to the in-

stallation procedure.

(8) If removed, install the sunvisors.

WINDSHIELD FRAME WEATHERSTRIP SEAL

REMOVAL

The windshield frame weatherstrip seal can be re-

moved and installed with the frame tilted forward to

the full horizontal position (Fig. 4).

(1) Disconnect the top from the windshield frame.

If necessary, refer to the windshield frame removal

procedure.

(2) Remove the holddown bracket retaining screws

from the cowl (Fig. 2).

(3) Tilt the windshield frame forward to the full

horizontal position (Fig. 94.

(4) Remove the retaining screws and the weather-

strip seal from the windshield frame (Fig. 4).

INSTALLATION

(1) Position the weatherstrip seal on the wind-

shield frame (Fig. 4). Ensure that the frame outer

panel flange is properly ``seated'' in the seal groove.

(2) Install the seal retaining screws in the wind-

shield frame (Fig. 4).

(3) Tilt the windshield frame rearward to the full

vertical position.

(4) Install the holddown bracket retaining screws

in the cowl (Fig. 2).

(5) Connect the top to the windshield frame. If nec-

essary, refer to the windshield frame installation pro-

cedure.

WINDSHIELD GLASS

SERVICE INFORMATION

URETHANE ADHESIVE BONDING

The one-piece windshield glass (Fig. 5) is comprised

of two laminated sheets of glass. The glass is bonded

to the windshield frame with urethane adhesive (Fig.

5). This method of windshield glass installation com-

plies with the applicable Federal Motor Vehicle

Safety Standards (FMVSS).

REMOVAL/INSTALLATION METHODS

For windshield glass removal use a razor knife or

an electric hot knife to cut through the urethane.

This removal method applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used:

²the short method, and

²the extended method.

The short method is used when the windshield

glass is removed intact and the windshield frame

pinchweld flanges do not require repair.

The extended method must be used when a wind-

shield frame and/or a pinchweld flange is damaged.

The extended method must also be used when the

urethane no longer adheres to either the windshield

glass or the frame pinchweld flanges.

Remove windshield glass according to the proce-

dure described below. Next, determine the condition

of the adhesive bond and the windshield frame

flanges, and then select the installation method re-

quired.

Fig. 4 Windshield Frame Weatherstrip SealFig. 5 Windshield Components

JBODY COMPONENTSÐXJ VEHICLES 23 - 185