JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1661 of 1784

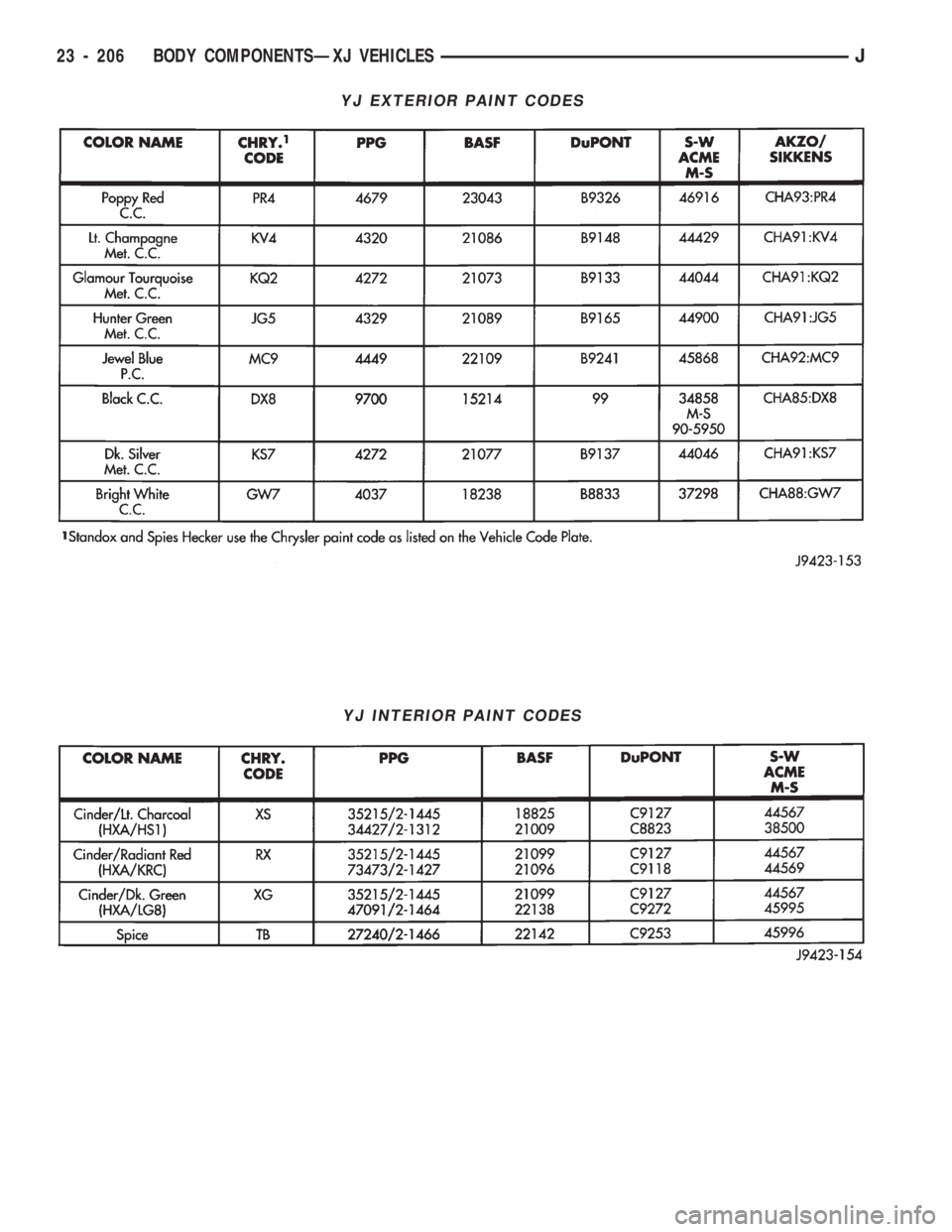

YJ EXTERIOR PAINT CODES

YJ INTERIOR PAINT CODES

23 - 206 BODY COMPONENTSÐXJ VEHICLESJ

Page 1662 of 1784

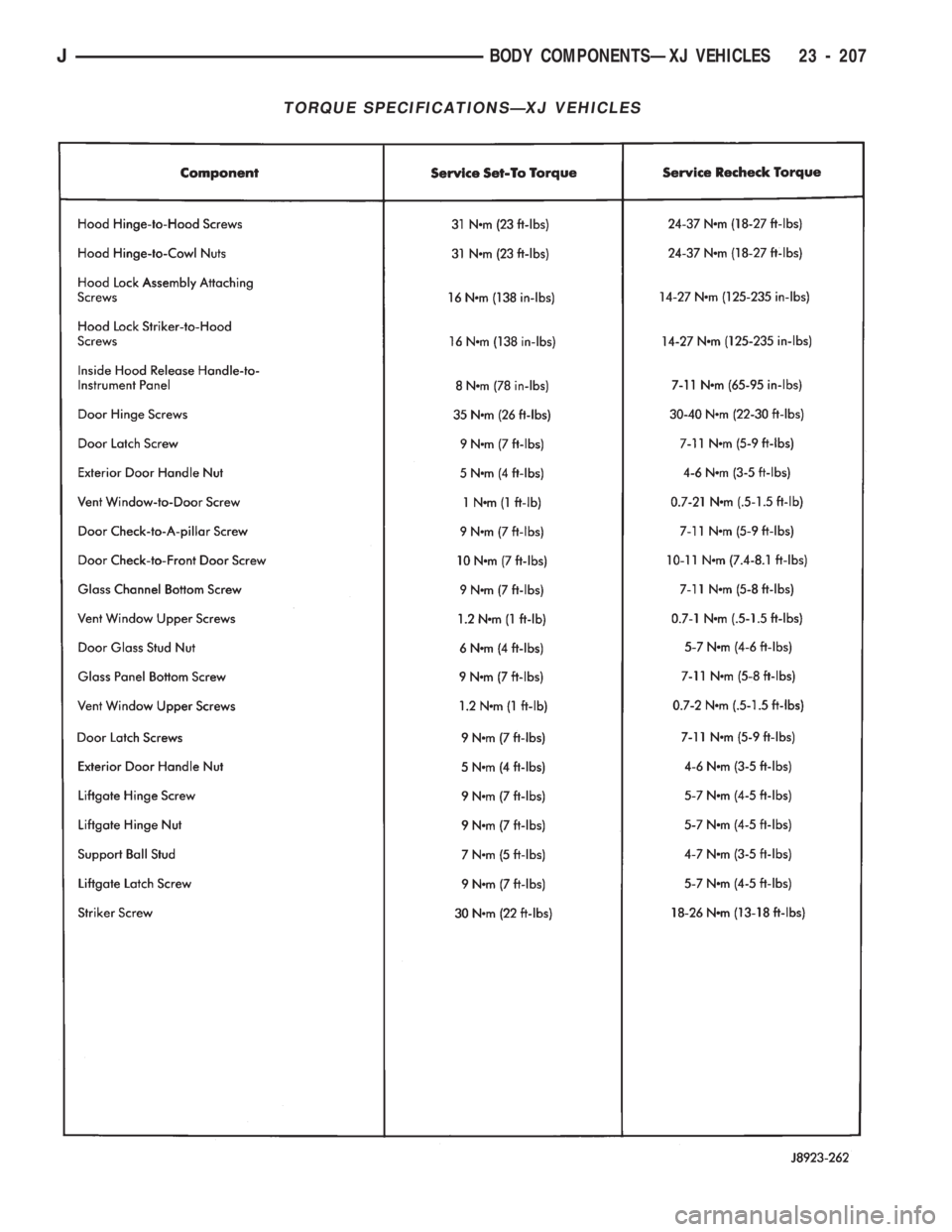

TORQUE SPECIFICATIONSÐXJ VEHICLES

JBODY COMPONENTSÐXJ VEHICLES 23 - 207

Page 1663 of 1784

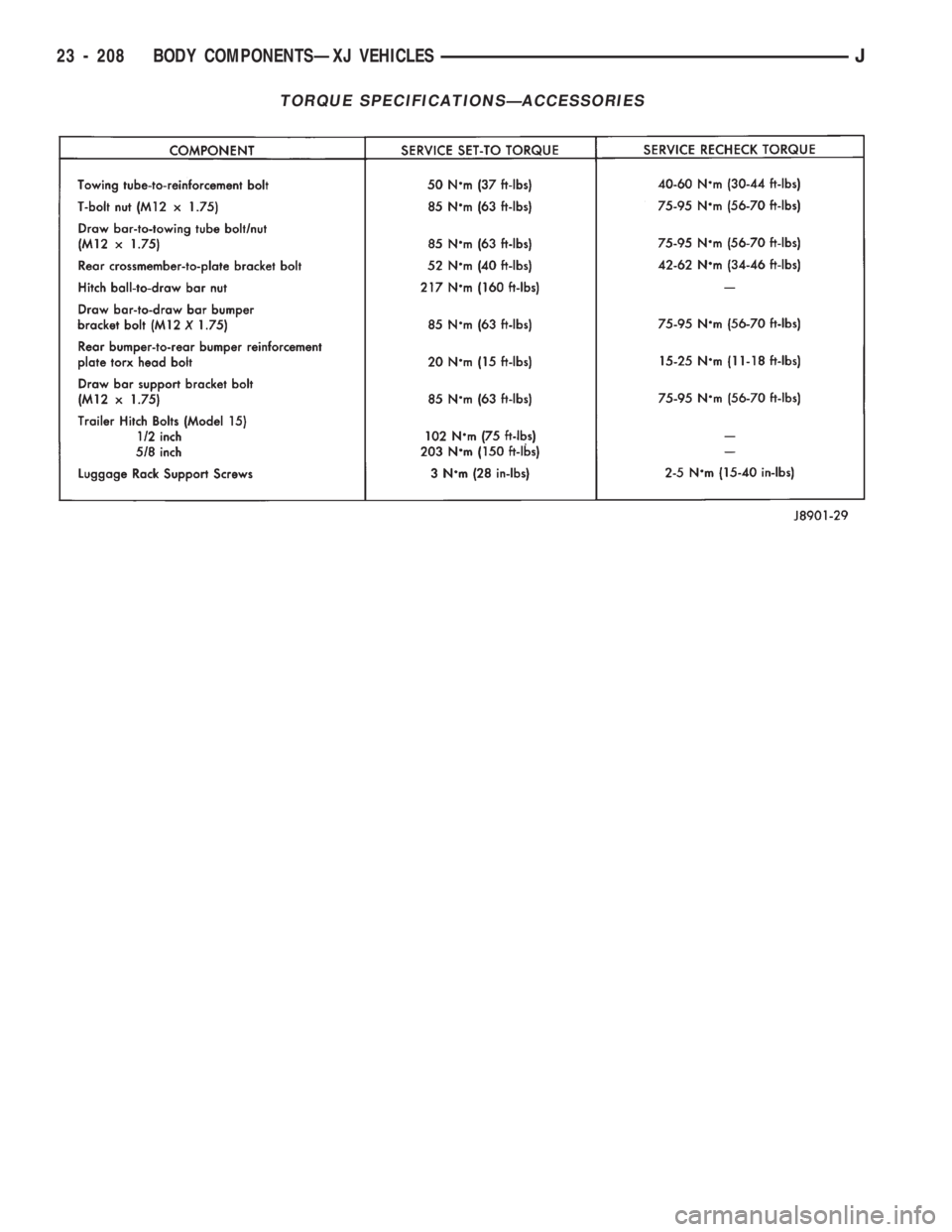

TORQUE SPECIFICATIONSÐACCESSORIES

23 - 208 BODY COMPONENTSÐXJ VEHICLESJ

Page 1664 of 1784

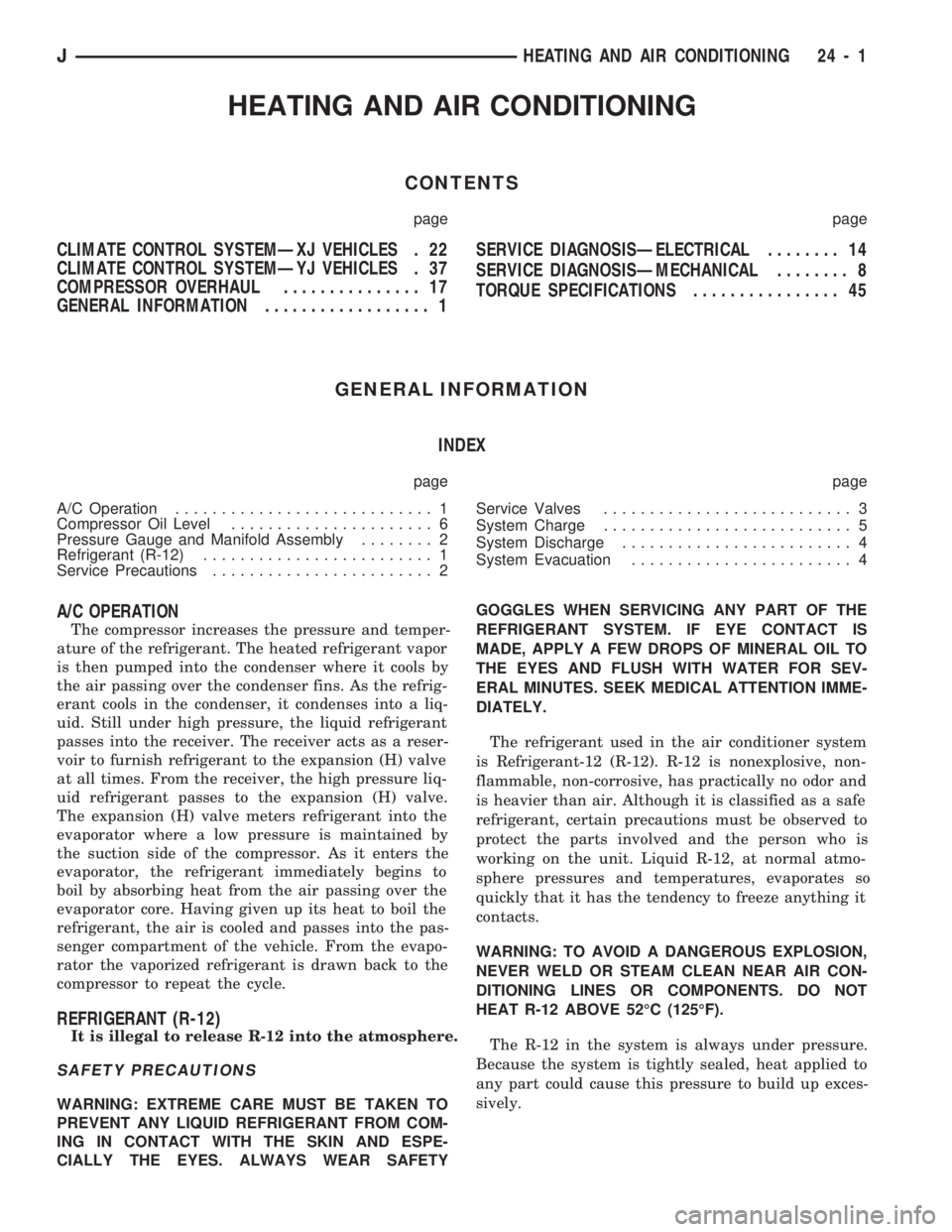

HEATING AND AIR CONDITIONING

CONTENTS

page page

CLIMATE CONTROL SYSTEMÐXJ VEHICLES . 22

CLIMATE CONTROL SYSTEMÐYJ VEHICLES . 37

COMPRESSOR OVERHAUL............... 17

GENERAL INFORMATION.................. 1SERVICE DIAGNOSISÐELECTRICAL........ 14

SERVICE DIAGNOSISÐMECHANICAL........ 8

TORQUE SPECIFICATIONS................ 45

GENERAL INFORMATION

INDEX

page page

A/C Operation............................ 1

Compressor Oil Level...................... 6

Pressure Gauge and Manifold Assembly........ 2

Refrigerant (R-12)......................... 1

Service Precautions........................ 2Service Valves........................... 3

System Charge........................... 5

System Discharge......................... 4

System Evacuation........................ 4

A/C OPERATION

The compressor increases the pressure and temper-

ature of the refrigerant. The heated refrigerant vapor

is then pumped into the condenser where it cools by

the air passing over the condenser fins. As the refrig-

erant cools in the condenser, it condenses into a liq-

uid. Still under high pressure, the liquid refrigerant

passes into the receiver. The receiver acts as a reser-

voir to furnish refrigerant to the expansion (H) valve

at all times. From the receiver, the high pressure liq-

uid refrigerant passes to the expansion (H) valve.

The expansion (H) valve meters refrigerant into the

evaporator where a low pressure is maintained by

the suction side of the compressor. As it enters the

evaporator, the refrigerant immediately begins to

boil by absorbing heat from the air passing over the

evaporator core. Having given up its heat to boil the

refrigerant, the air is cooled and passes into the pas-

senger compartment of the vehicle. From the evapo-

rator the vaporized refrigerant is drawn back to the

compressor to repeat the cycle.

REFRIGERANT (R-12)

It is illegal to release R-12 into the atmosphere.

SAFETY PRECAUTIONS

WARNING: EXTREME CARE MUST BE TAKEN TO

PREVENT ANY LIQUID REFRIGERANT FROM COM-

ING IN CONTACT WITH THE SKIN AND ESPE-

CIALLY THE EYES. ALWAYS WEAR SAFETYGOGGLES WHEN SERVICING ANY PART OF THE

REFRIGERANT SYSTEM. IF EYE CONTACT IS

MADE, APPLY A FEW DROPS OF MINERAL OIL TO

THE EYES AND FLUSH WITH WATER FOR SEV-

ERAL MINUTES. SEEK MEDICAL ATTENTION IMME-

DIATELY.

The refrigerant used in the air conditioner system

is Refrigerant-12 (R-12). R-12 is nonexplosive, non-

flammable, non-corrosive, has practically no odor and

is heavier than air. Although it is classified as a safe

refrigerant, certain precautions must be observed to

protect the parts involved and the person who is

working on the unit. Liquid R-12, at normal atmo-

sphere pressures and temperatures, evaporates so

quickly that it has the tendency to freeze anything it

contacts.

WARNING: TO AVOID A DANGEROUS EXPLOSION,

NEVER WELD OR STEAM CLEAN NEAR AIR CON-

DITIONING LINES OR COMPONENTS. DO NOT

HEAT R-12 ABOVE 52ÉC (125ÉF).

The R-12 in the system is always under pressure.

Because the system is tightly sealed, heat applied to

any part could cause this pressure to build up exces-

sively.

JHEATING AND AIR CONDITIONING 24 - 1

Page 1665 of 1784

WARNING: LARGE AMOUNTS OF REFRIGERANT

RELEASED IN A CLOSED WORK AREA WILL DIS-

PLACE THE OXYGEN AND CAUSE SUFFOCATION.

ALWAYS MAINTAIN GOOD VENTILATION SUR-

ROUNDING THE WORK AREA.

R-12 gas, under normal conditions, is non-poison-

ous.

WARNING: THE DISCHARGE OF R-12 GAS NEAR

AN OPEN FLAME CAN PRODUCE A VERY POISON-

OUS GAS CALLED PHOSGENE. PHOSGENE IS

GENERATED WHEN A FLAME-TYPE LEAK DETEC-

TOR IS USED.

CAUTION: When charging an A/C system always

keep the tank in an upright position. If the tank is

on its side or upside down, liquid refrigerant will

enter the system and may damage the compressor.

In most instances when charging or adding refrig-

erant, moderate heat is required to bring the pres-

sure of the refrigerant above the pressure of the

system. A bucket or large pan of hot water, not over

52ÉC (125ÉF), is all the heat required for this pur-

pose. DO NOT heat the refrigerant container with a

blow torch or any other means that would raise the

temperature and pressure above this temperature.

CAUTION: DO NOT allow liquid refrigerant to touch

bright metal. Refrigerant will tarnish bright metal

and chrome surfaces. Refrigerant in combination

with moisture is very corrosive and can cause ex-

tensive damage to all metal surfaces.

Avoid splashing the refrigerant on any surface.

RECYCLING

(R-12) refrigerant is a chloroflorocarbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere. Ozone filters out harmful ra-

diation from the sun. To assist in protecting the

ozone layer, Chrysler Corporation requires that an

(R-12) refrigerant recovery device that meets SAE

standard J1991 be used. Contact an automotive ser-

vice equipment supplier for refrigerant recycling

equipment that is available in your area. Refer to

the operating instructions provided with the recy-

cling equipment for proper operation.

SERVICE PRECAUTIONS

Never open or loosen a connection before discharg-

ing the system refrigerant.

A system which has been opened to replace a com-

ponent or one which has discharged through leakage

must be evacuated before charging.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.Before disconnecting a component from the system,

clean the outside of the fittings thoroughly.

DO NOT remove the sealing caps from a replace-

ment component until ready to install.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. DO NOT open an oil con-

tainer until ready to use and install the cap

immediately after using. Store the oil only in a clean

moisture-free container.

Before connecting an open fitting always install a

new seal ring. Coat the fitting and seal with clean

refrigerant oil before connecting.

When installing a refrigerant line avoid sharp

bends. Position the line away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

copper and aluminum fittings used in the A/C system

will not tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting to prevent twisting of the refrig-

erant lines or tubes.

DO NOT open a refrigerant system or uncap a re-

placement component unless it is as close as possible

to room temperature. This will prevent condensation

from forming inside of a component which is cooler

than the surrounding air.

Keep service tools and the work area clean. Con-

tamination of A/C system through careless work hab-

its must be avoided.

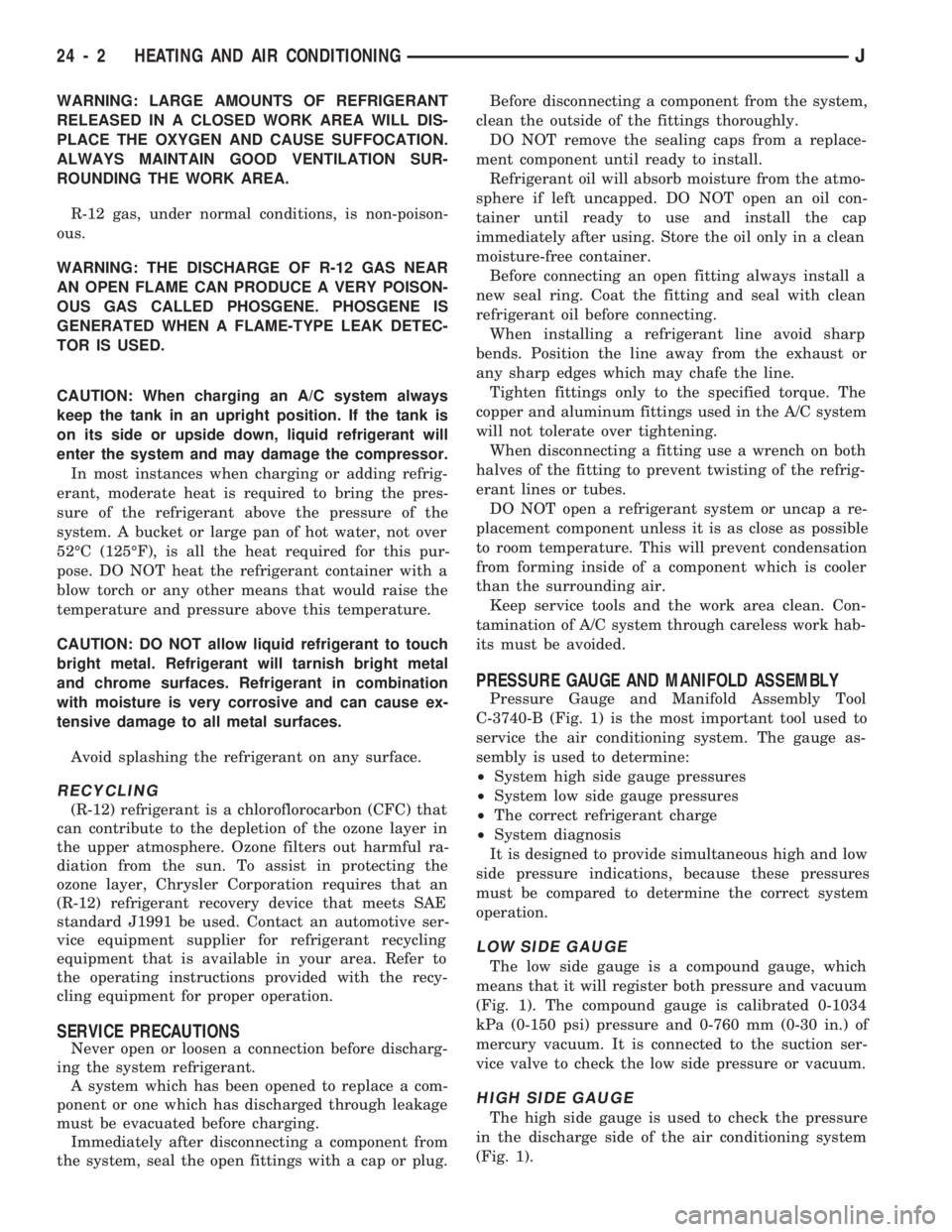

PRESSURE GAUGE AND MANIFOLD ASSEMBLY

Pressure Gauge and Manifold Assembly Tool

C-3740-B (Fig. 1) is the most important tool used to

service the air conditioning system. The gauge as-

sembly is used to determine:

²System high side gauge pressures

²System low side gauge pressures

²The correct refrigerant charge

²System diagnosis

It is designed to provide simultaneous high and low

side pressure indications, because these pressures

must be compared to determine the correct system

operation.

LOW SIDE GAUGE

The low side gauge is a compound gauge, which

means that it will register both pressure and vacuum

(Fig. 1). The compound gauge is calibrated 0-1034

kPa (0-150 psi) pressure and 0-760 mm (0-30 in.) of

mercury vacuum. It is connected to the suction ser-

vice valve to check the low side pressure or vacuum.

HIGH SIDE GAUGE

The high side gauge is used to check the pressure

in the discharge side of the air conditioning system

(Fig. 1).

24 - 2 HEATING AND AIR CONDITIONINGJ

Page 1666 of 1784

MANIFOLD

The gauges are connected into the air conditioning

systems through a manifold. The manifold has 3 con-

nections (Fig. 1). The low side hose and fitting is con-

nected directly below the low side gauge. The high

side hose and fitting is connected below the high side

gauge.

The center connection of the manifold is used for

recovery and any other necessary service (Fig. 1).

Both the high and low sides of the manifold have

hand shutoff valves. The hand shutoff valves open or

close the respective gauge connections to the center

service connection or to each other (Fig. 1). The man-

ifold is constructed so that pressure will be indicated

on the gauges regardless of the hand valve position.

CONNECTING THE PRESSURE GAUGE AND

MANIFOLD ASSEMBLY

Remove the protective caps from the service valve

gauge ports and valve stems.

Close both of the hand valves on the gauge mani-

fold set.

Connect the compound gauge hose to the compres-

sor suction service valve gauge port (low-side).

Connect the high pressure gauge hose to the dis-

charge service valve gauge port (high-side).

If necessary, to facilitate installation of the gauge

set, loosen the service valve-to-compressor fitting and

rotate the service valve slightly. DO NOT allow the

hose to contact the engine or body components.

Tighten the service valve-to-compressor fitting to 34

NIm (25 ft. lbs.) torque. Tighten the flange-type ser-

vice valve screws to 20 NIm (15 ft. lbs.) torque.

Set both the service valve stems to the mid-position

or the cracked-position. The gauges will indicate

high and low side pressure respectively.Purge any air from the high side test hose by open-

ing the high side hand valve on the manifold for 3 to

5 seconds. The center connection on the manifold

must be open.

Purge any air from the low side test hose by open-

ing the low side hand valve on the manifold for 3 to

5 seconds. The center connection on the manifold

must be open.

The air conditioning system may be operated with

the gauge manifold assembly connected in this man-

ner. The gauges will indicate respective operative

pressures.

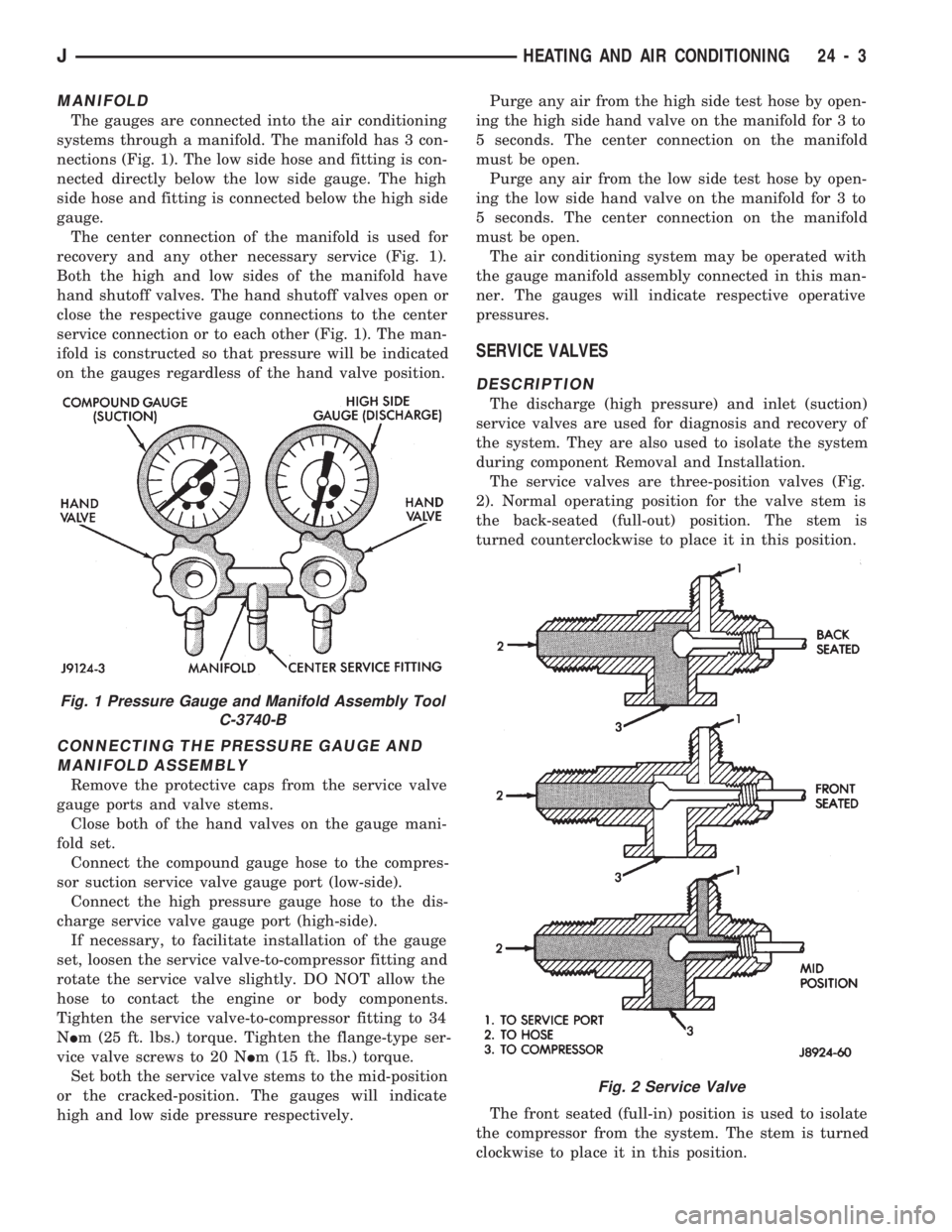

SERVICE VALVES

DESCRIPTION

The discharge (high pressure) and inlet (suction)

service valves are used for diagnosis and recovery of

the system. They are also used to isolate the system

during component Removal and Installation.

The service valves are three-position valves (Fig.

2). Normal operating position for the valve stem is

the back-seated (full-out) position. The stem is

turned counterclockwise to place it in this position.

The front seated (full-in) position is used to isolate

the compressor from the system. The stem is turned

clockwise to place it in this position.

Fig. 1 Pressure Gauge and Manifold Assembly Tool

C-3740-B

Fig. 2 Service Valve

JHEATING AND AIR CONDITIONING 24 - 3

Page 1667 of 1784

In the mid-position the gauge port is open. This po-

sition is used for pressure testing and for recovery of

the system.

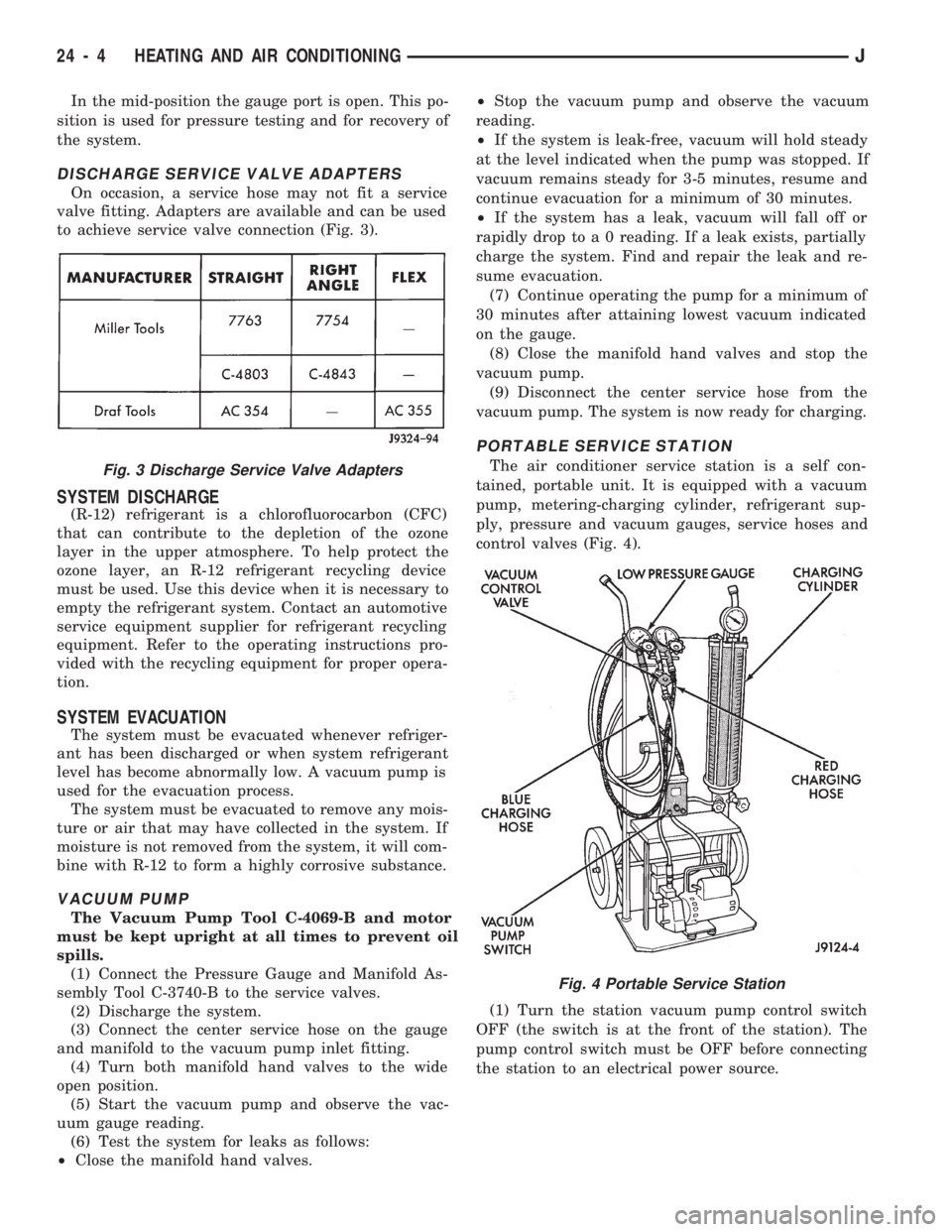

DISCHARGE SERVICE VALVE ADAPTERS

On occasion, a service hose may not fit a service

valve fitting. Adapters are available and can be used

to achieve service valve connection (Fig. 3).

SYSTEM DISCHARGE

(R-12) refrigerant is a chlorofluorocarbon (CFC)

that can contribute to the depletion of the ozone

layer in the upper atmosphere. To help protect the

ozone layer, an R-12 refrigerant recycling device

must be used. Use this device when it is necessary to

empty the refrigerant system. Contact an automotive

service equipment supplier for refrigerant recycling

equipment. Refer to the operating instructions pro-

vided with the recycling equipment for proper opera-

tion.

SYSTEM EVACUATION

The system must be evacuated whenever refriger-

ant has been discharged or when system refrigerant

level has become abnormally low. A vacuum pump is

used for the evacuation process.

The system must be evacuated to remove any mois-

ture or air that may have collected in the system. If

moisture is not removed from the system, it will com-

bine with R-12 to form a highly corrosive substance.

VACUUM PUMP

The Vacuum Pump Tool C-4069-B and motor

must be kept upright at all times to prevent oil

spills.

(1) Connect the Pressure Gauge and Manifold As-

sembly Tool C-3740-B to the service valves.

(2) Discharge the system.

(3) Connect the center service hose on the gauge

and manifold to the vacuum pump inlet fitting.

(4) Turn both manifold hand valves to the wide

open position.

(5) Start the vacuum pump and observe the vac-

uum gauge reading.

(6) Test the system for leaks as follows:

²Close the manifold hand valves.²Stop the vacuum pump and observe the vacuum

reading.

²If the system is leak-free, vacuum will hold steady

at the level indicated when the pump was stopped. If

vacuum remains steady for 3-5 minutes, resume and

continue evacuation for a minimum of 30 minutes.

²If the system has a leak, vacuum will fall off or

rapidly drop to a 0 reading. If a leak exists, partially

charge the system. Find and repair the leak and re-

sume evacuation.

(7) Continue operating the pump for a minimum of

30 minutes after attaining lowest vacuum indicated

on the gauge.

(8) Close the manifold hand valves and stop the

vacuum pump.

(9) Disconnect the center service hose from the

vacuum pump. The system is now ready for charging.

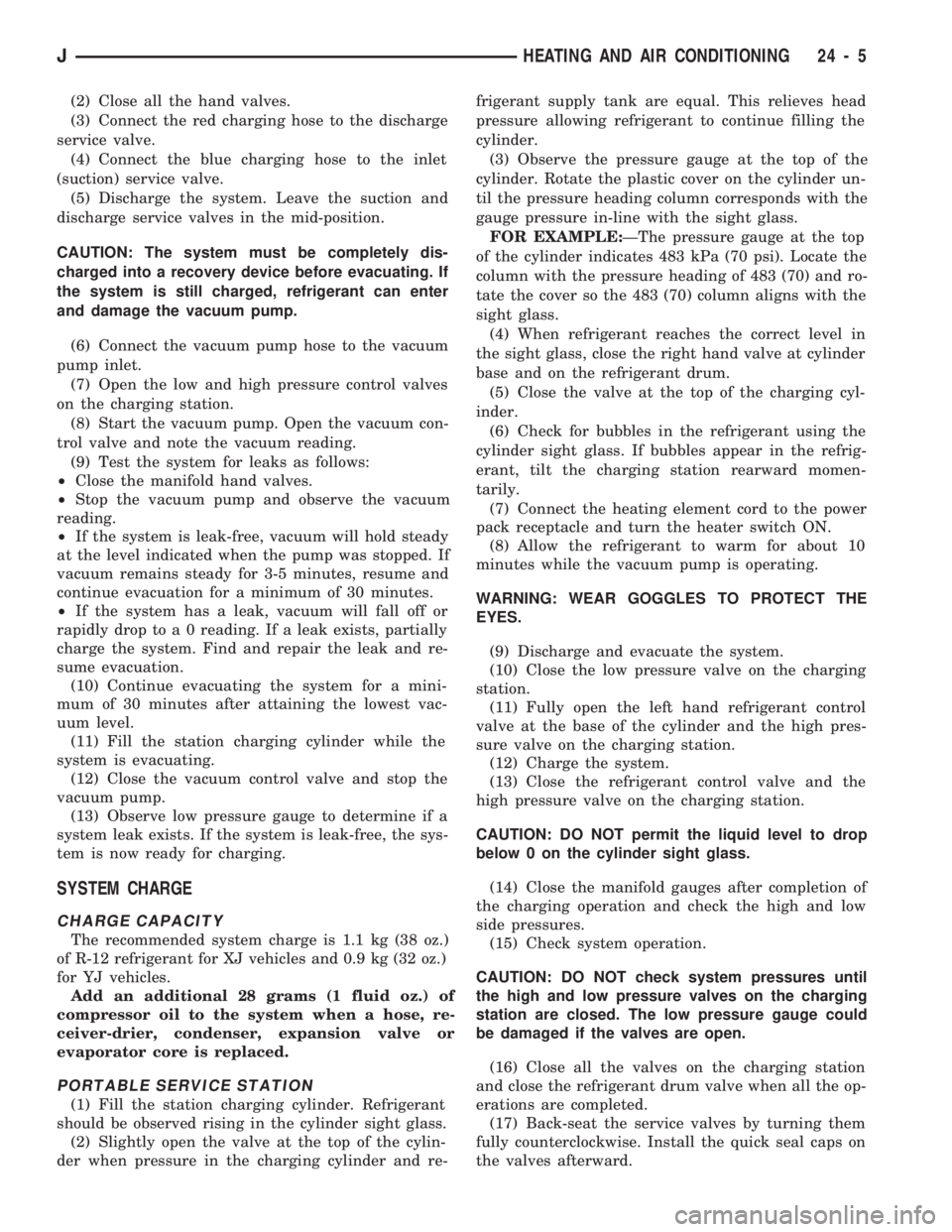

PORTABLE SERVICE STATION

The air conditioner service station is a self con-

tained, portable unit. It is equipped with a vacuum

pump, metering-charging cylinder, refrigerant sup-

ply, pressure and vacuum gauges, service hoses and

control valves (Fig. 4).

(1) Turn the station vacuum pump control switch

OFF (the switch is at the front of the station). The

pump control switch must be OFF before connecting

the station to an electrical power source.Fig. 3 Discharge Service Valve Adapters

Fig. 4 Portable Service Station

24 - 4 HEATING AND AIR CONDITIONINGJ

Page 1668 of 1784

(2) Close all the hand valves.

(3) Connect the red charging hose to the discharge

service valve.

(4) Connect the blue charging hose to the inlet

(suction) service valve.

(5) Discharge the system. Leave the suction and

discharge service valves in the mid-position.

CAUTION: The system must be completely dis-

charged into a recovery device before evacuating. If

the system is still charged, refrigerant can enter

and damage the vacuum pump.

(6) Connect the vacuum pump hose to the vacuum

pump inlet.

(7) Open the low and high pressure control valves

on the charging station.

(8) Start the vacuum pump. Open the vacuum con-

trol valve and note the vacuum reading.

(9) Test the system for leaks as follows:

²Close the manifold hand valves.

²Stop the vacuum pump and observe the vacuum

reading.

²If the system is leak-free, vacuum will hold steady

at the level indicated when the pump was stopped. If

vacuum remains steady for 3-5 minutes, resume and

continue evacuation for a minimum of 30 minutes.

²If the system has a leak, vacuum will fall off or

rapidly drop to a 0 reading. If a leak exists, partially

charge the system. Find and repair the leak and re-

sume evacuation.

(10) Continue evacuating the system for a mini-

mum of 30 minutes after attaining the lowest vac-

uum level.

(11) Fill the station charging cylinder while the

system is evacuating.

(12) Close the vacuum control valve and stop the

vacuum pump.

(13) Observe low pressure gauge to determine if a

system leak exists. If the system is leak-free, the sys-

tem is now ready for charging.

SYSTEM CHARGE

CHARGE CAPACITY

The recommended system charge is 1.1 kg (38 oz.)

of R-12 refrigerant for XJ vehicles and 0.9 kg (32 oz.)

for YJ vehicles.

Add an additional 28 grams (1 fluid oz.) of

compressor oil to the system when a hose, re-

ceiver-drier, condenser, expansion valve or

evaporator core is replaced.

PORTABLE SERVICE STATION

(1) Fill the station charging cylinder. Refrigerant

should be observed rising in the cylinder sight glass.

(2) Slightly open the valve at the top of the cylin-

der when pressure in the charging cylinder and re-frigerant supply tank are equal. This relieves head

pressure allowing refrigerant to continue filling the

cylinder.

(3) Observe the pressure gauge at the top of the

cylinder. Rotate the plastic cover on the cylinder un-

til the pressure heading column corresponds with the

gauge pressure in-line with the sight glass.

FOR EXAMPLE:ÐThe pressure gauge at the top

of the cylinder indicates 483 kPa (70 psi). Locate the

column with the pressure heading of 483 (70) and ro-

tate the cover so the 483 (70) column aligns with the

sight glass.

(4) When refrigerant reaches the correct level in

the sight glass, close the right hand valve at cylinder

base and on the refrigerant drum.

(5) Close the valve at the top of the charging cyl-

inder.

(6) Check for bubbles in the refrigerant using the

cylinder sight glass. If bubbles appear in the refrig-

erant, tilt the charging station rearward momen-

tarily.

(7) Connect the heating element cord to the power

pack receptacle and turn the heater switch ON.

(8) Allow the refrigerant to warm for about 10

minutes while the vacuum pump is operating.

WARNING: WEAR GOGGLES TO PROTECT THE

EYES.

(9) Discharge and evacuate the system.

(10) Close the low pressure valve on the charging

station.

(11) Fully open the left hand refrigerant control

valve at the base of the cylinder and the high pres-

sure valve on the charging station.

(12) Charge the system.

(13) Close the refrigerant control valve and the

high pressure valve on the charging station.

CAUTION: DO NOT permit the liquid level to drop

below 0 on the cylinder sight glass.

(14) Close the manifold gauges after completion of

the charging operation and check the high and low

side pressures.

(15) Check system operation.

CAUTION: DO NOT check system pressures until

the high and low pressure valves on the charging

station are closed. The low pressure gauge could

be damaged if the valves are open.

(16) Close all the valves on the charging station

and close the refrigerant drum valve when all the op-

erations are completed.

(17) Back-seat the service valves by turning them

fully counterclockwise. Install the quick seal caps on

the valves afterward.

JHEATING AND AIR CONDITIONING 24 - 5

Page 1669 of 1784

(18) Disconnect the charging hoses from the ser-

vice valves.

COMPRESSOR OIL LEVEL

The compressor oil level must be checked and ad-

justed if the system has been discharged rapidly, or

when a component has been replaced. If a replace-

ment compressor is being installed, it must be filled

with new compressor oil (Suniso 5GS, or equivalent).

The normal quantity of oil required for the com-

pressor and entire system is 136 ml (4.6 fluid oz.) for

SD 709 compressor. DO NOT overfill the compressor.

Excessive amounts of oil in the system will hinder

compressor operation and reduce A/C performance.

CAUTION: The compressor is a high speed unit.

Satisfactory operation is dependent on sufficient lu-

brication; however, excess oil will hinder A/C per-

formance.

Two oil level checking procedures are necessary.

Use Procedure (A) when the compressor is being re-

placed and the system was discharged properly (no

oil loss). Use Procedure (B) for routine maintenance

or when checking oil level after replacing a system

component.

In cases where rapid loss of refrigerant and oil

occurred, the system must be evacuated and

purged. Then the compressor must be filled with

the necessary amount of oil to fill the entire sys-

tem.

PROCEDURE A

(1) Remove the oil filler plug, discharge cap and

suction port caps from the original and replacement

compressor.

(2) Use a clean container to drain the oil from the

replacement compressor. Drain the oil through the

oil filler plug hole, the discharge and suction. Then

rotate clutch front plate several times to push the oil

on cylinder out to discharge chamber of cylinder

head and drain the oil from discharge port.

(3) Drain the oil from the original compressor into

a measuring cup or graduated beaker in the same

way as Step 2. Note the amount of oil drained.

(4) Fill the replacement compressor with the same

amount of oil drained from the original compressor

plus 30 ml (1 fluid oz.).

FOR EXAMPLE:ÐIf the old compressor contained

103.5 ml (3.5 fluid oz.) of oil, fill the replacement

compressor with a total of 133 ml (4.5 fluid oz.) of oil.

PROCEDURE B

(1) Start the engine and operate the engine at idle.

(2) Operate the air conditioning system for 10 min-

utes to return the maximum amount of oil in the sys-

tem to the compressor.(3) Stop the engine and disconnect the magnetic

clutch feed wire.

(4) Front-seat the discharge and suction service

valves.

(5) Determine the mounting angle.

(a) Position an Angle Gauge across the flat sur-

faces of the front mounting ears.

(b) Center the bubble.

(c) Read the mounting angle to the closest de-

gree.

(d) These vehicles should have 0É mounting an-

gle.

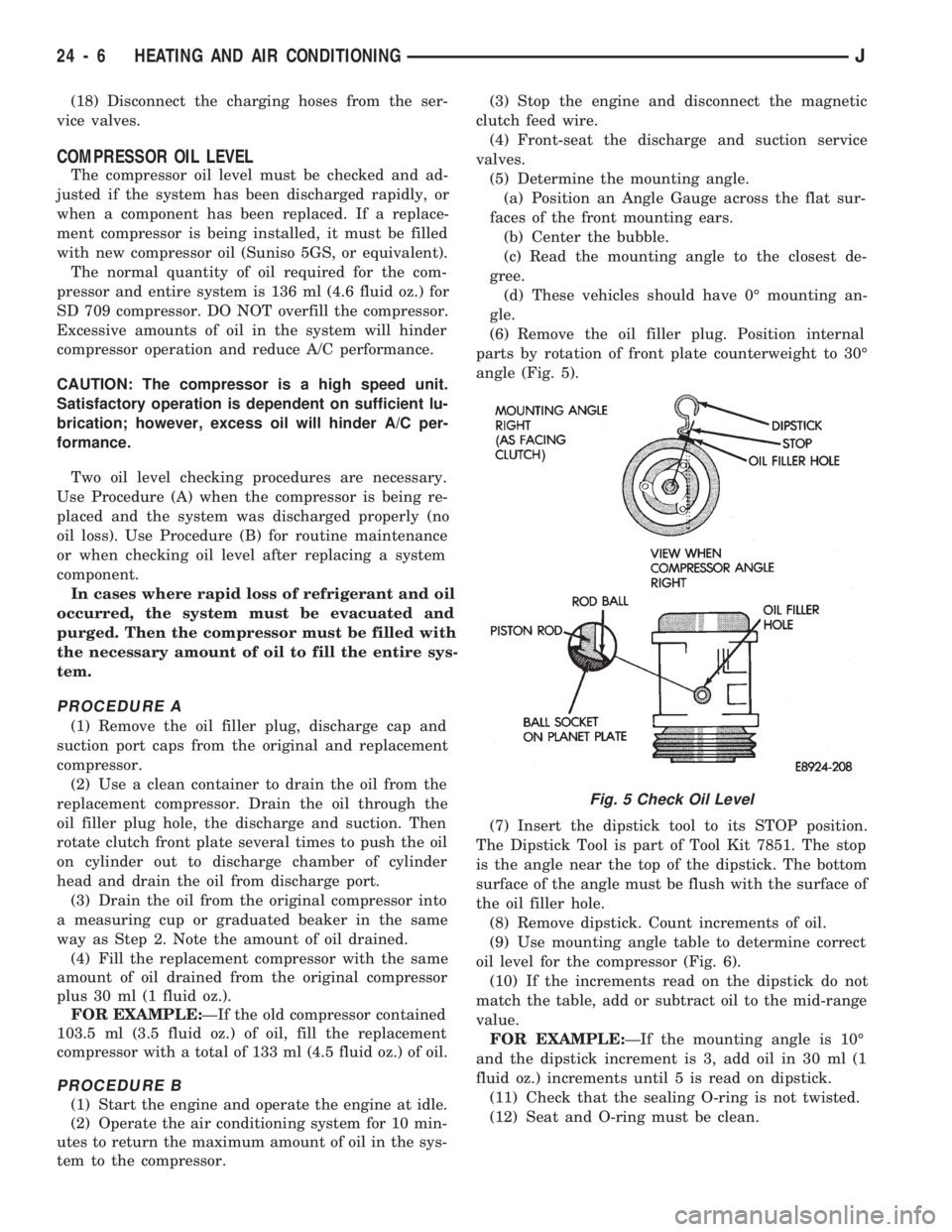

(6) Remove the oil filler plug. Position internal

parts by rotation of front plate counterweight to 30É

angle (Fig. 5).

(7) Insert the dipstick tool to its STOP position.

The Dipstick Tool is part of Tool Kit 7851. The stop

is the angle near the top of the dipstick. The bottom

surface of the angle must be flush with the surface of

the oil filler hole.

(8) Remove dipstick. Count increments of oil.

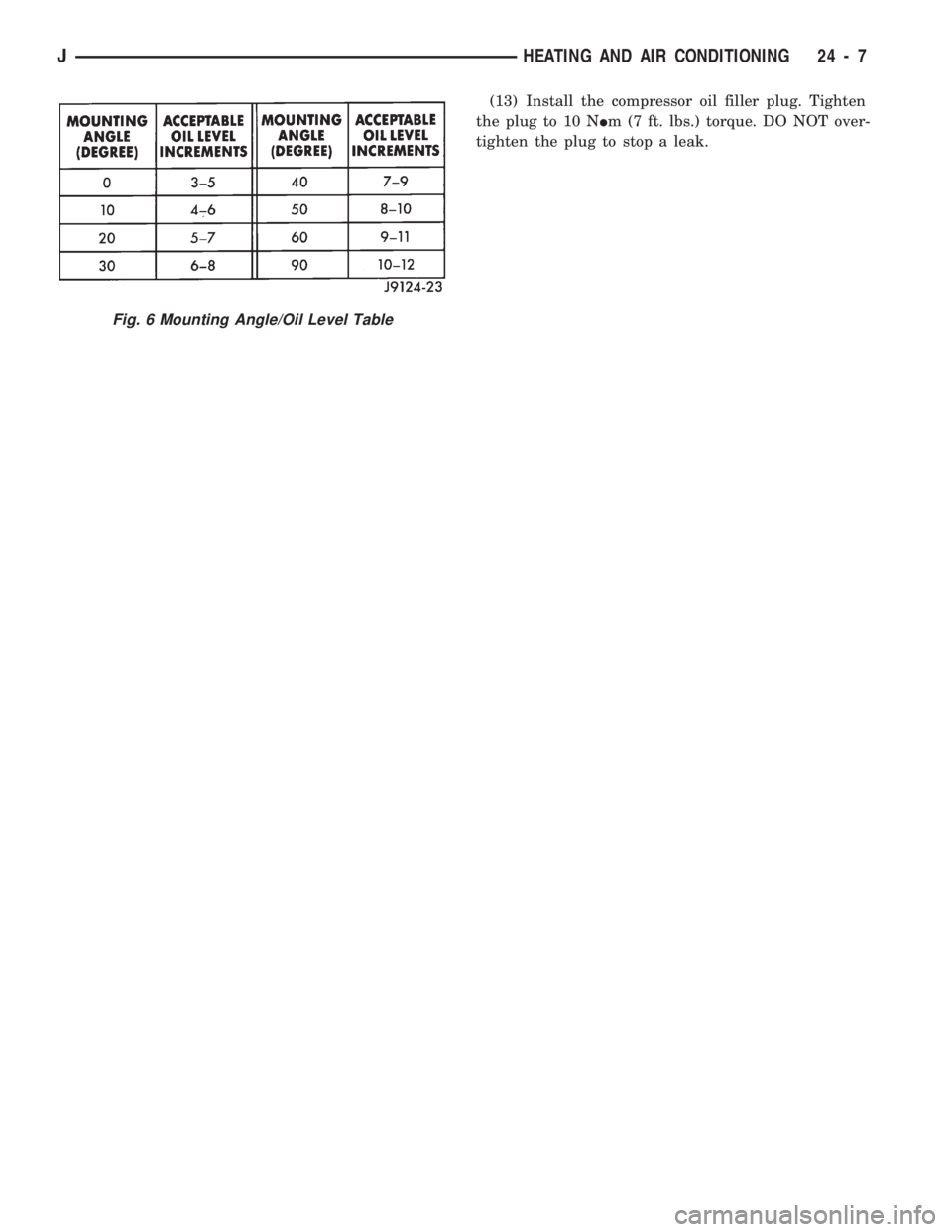

(9) Use mounting angle table to determine correct

oil level for the compressor (Fig. 6).

(10) If the increments read on the dipstick do not

match the table, add or subtract oil to the mid-range

value.

FOR EXAMPLE:ÐIf the mounting angle is 10É

and the dipstick increment is 3, add oil in 30 ml (1

fluid oz.) increments until 5 is read on dipstick.

(11) Check that the sealing O-ring is not twisted.

(12) Seat and O-ring must be clean.

Fig. 5 Check Oil Level

24 - 6 HEATING AND AIR CONDITIONINGJ

Page 1670 of 1784

(13) Install the compressor oil filler plug. Tighten

the plug to 10 NIm (7 ft. lbs.) torque. DO NOT over-

tighten the plug to stop a leak.

Fig. 6 Mounting Angle/Oil Level Table

JHEATING AND AIR CONDITIONING 24 - 7