JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1651 of 1784

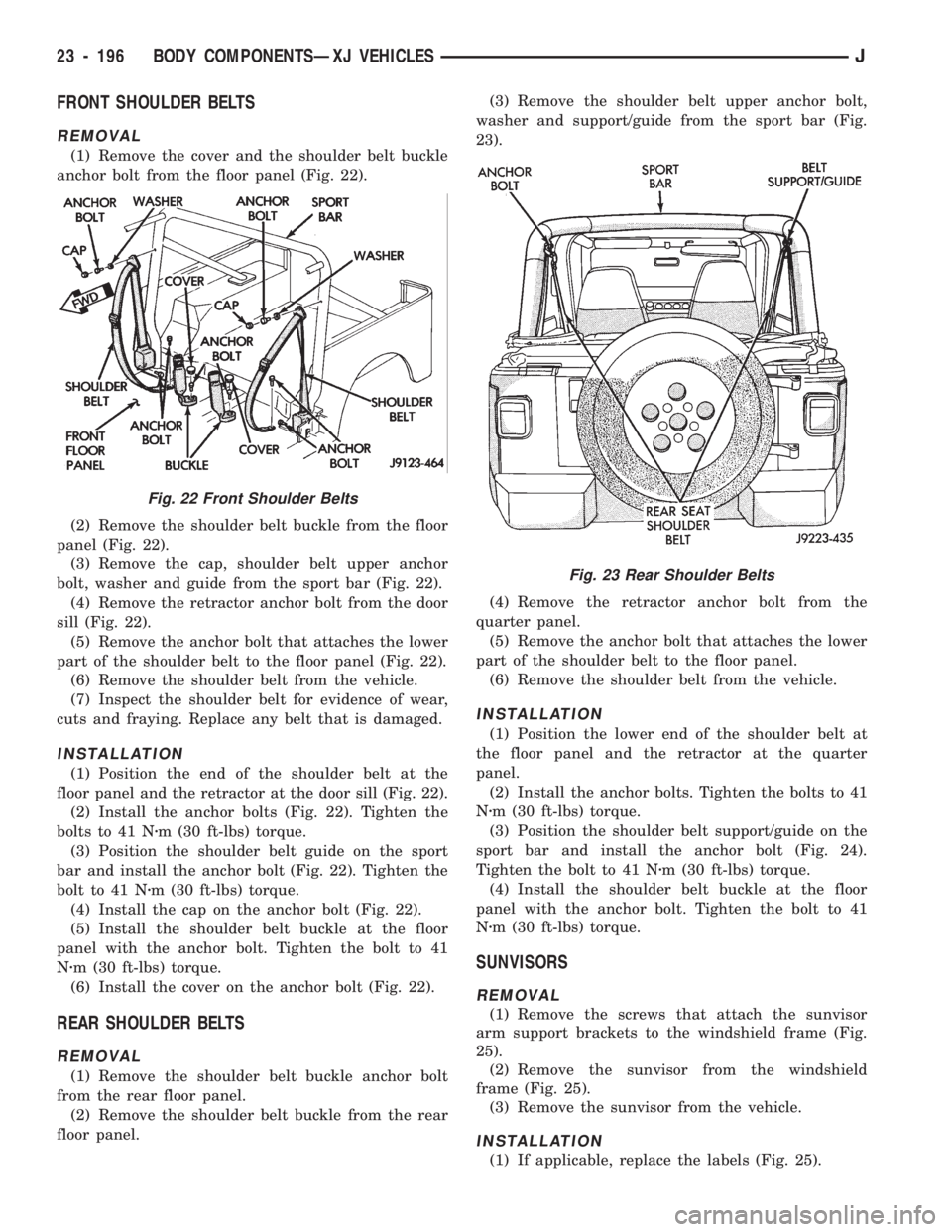

FRONT SHOULDER BELTS

REMOVAL

(1) Remove the cover and the shoulder belt buckle

anchor bolt from the floor panel (Fig. 22).

(2) Remove the shoulder belt buckle from the floor

panel (Fig. 22).

(3) Remove the cap, shoulder belt upper anchor

bolt, washer and guide from the sport bar (Fig. 22).

(4) Remove the retractor anchor bolt from the door

sill (Fig. 22).

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel (Fig. 22).

(6) Remove the shoulder belt from the vehicle.

(7) Inspect the shoulder belt for evidence of wear,

cuts and fraying. Replace any belt that is damaged.

INSTALLATION

(1) Position the end of the shoulder belt at the

floor panel and the retractor at the door sill (Fig. 22).

(2) Install the anchor bolts (Fig. 22). Tighten the

bolts to 41 Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt guide on the sport

bar and install the anchor bolt (Fig. 22). Tighten the

bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the cap on the anchor bolt (Fig. 22).

(5) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

(6) Install the cover on the anchor bolt (Fig. 22).

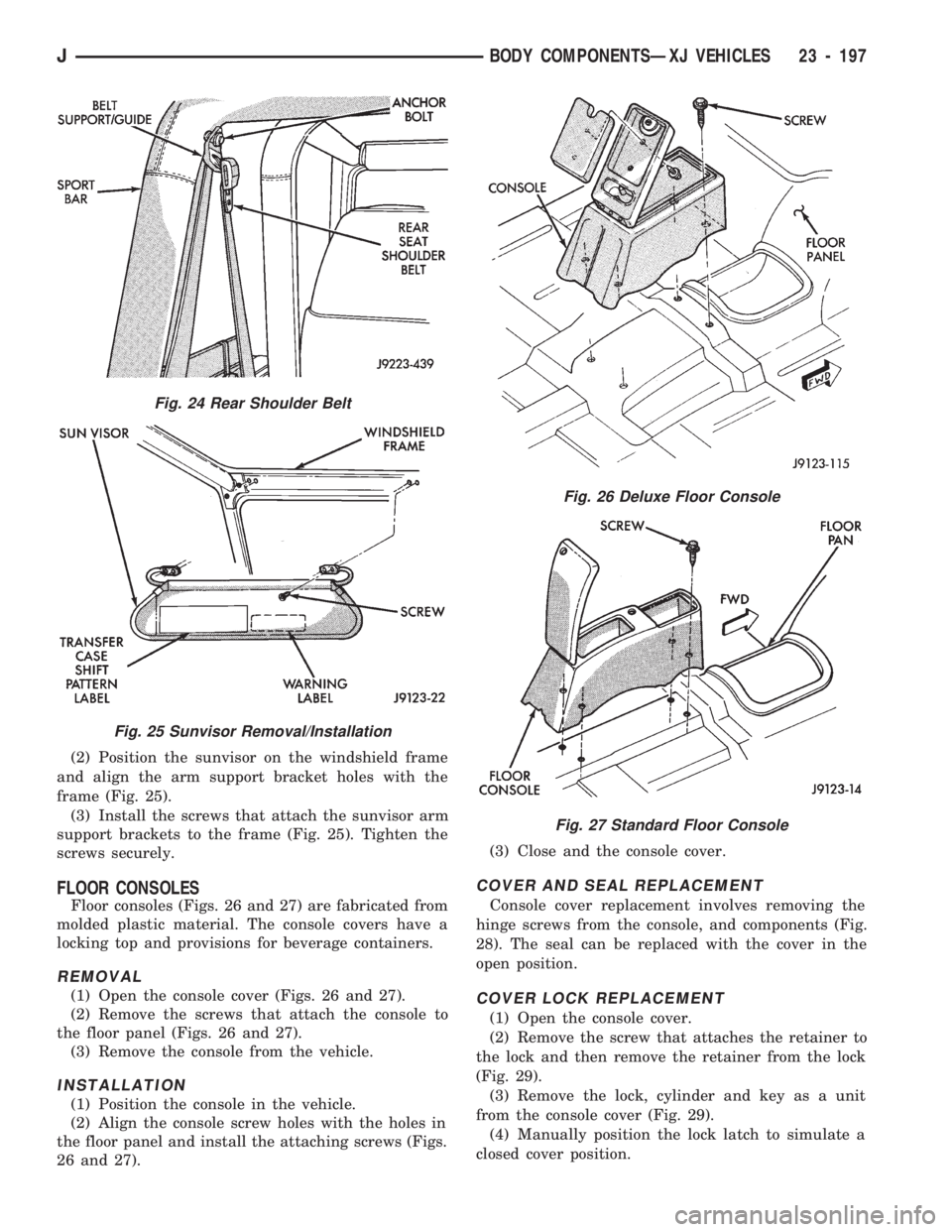

REAR SHOULDER BELTS

REMOVAL

(1) Remove the shoulder belt buckle anchor bolt

from the rear floor panel.

(2) Remove the shoulder belt buckle from the rear

floor panel.(3) Remove the shoulder belt upper anchor bolt,

washer and support/guide from the sport bar (Fig.

23).

(4) Remove the retractor anchor bolt from the

quarter panel.

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel.

(6) Remove the shoulder belt from the vehicle.

INSTALLATION

(1) Position the lower end of the shoulder belt at

the floor panel and the retractor at the quarter

panel.

(2) Install the anchor bolts. Tighten the bolts to 41

Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt support/guide on the

sport bar and install the anchor bolt (Fig. 24).

Tighten the bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

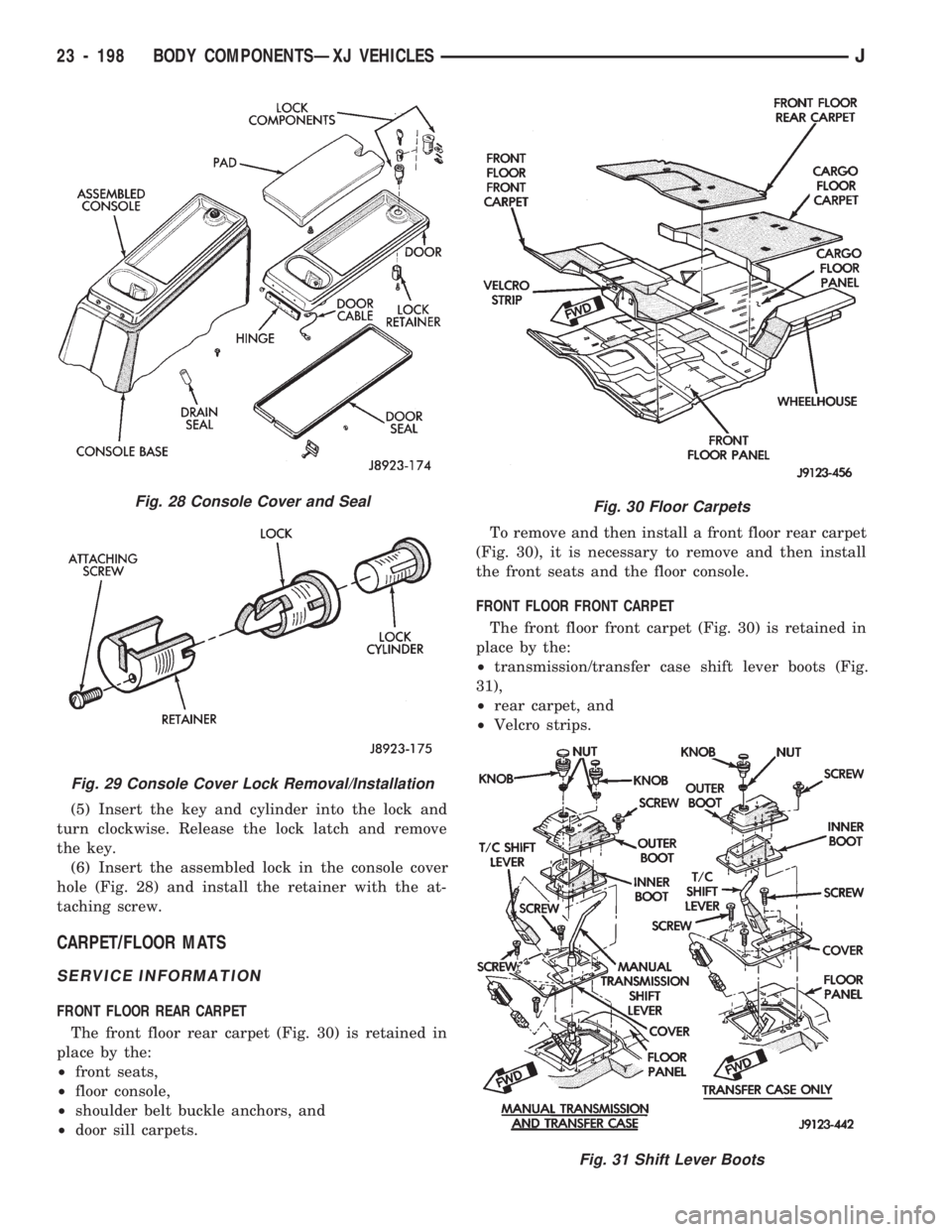

SUNVISORS

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support brackets to the windshield frame (Fig.

25).

(2) Remove the sunvisor from the windshield

frame (Fig. 25).

(3) Remove the sunvisor from the vehicle.

INSTALLATION

(1) If applicable, replace the labels (Fig. 25).

Fig. 22 Front Shoulder Belts

Fig. 23 Rear Shoulder Belts

23 - 196 BODY COMPONENTSÐXJ VEHICLESJ

Page 1652 of 1784

(2) Position the sunvisor on the windshield frame

and align the arm support bracket holes with the

frame (Fig. 25).

(3) Install the screws that attach the sunvisor arm

support brackets to the frame (Fig. 25). Tighten the

screws securely.

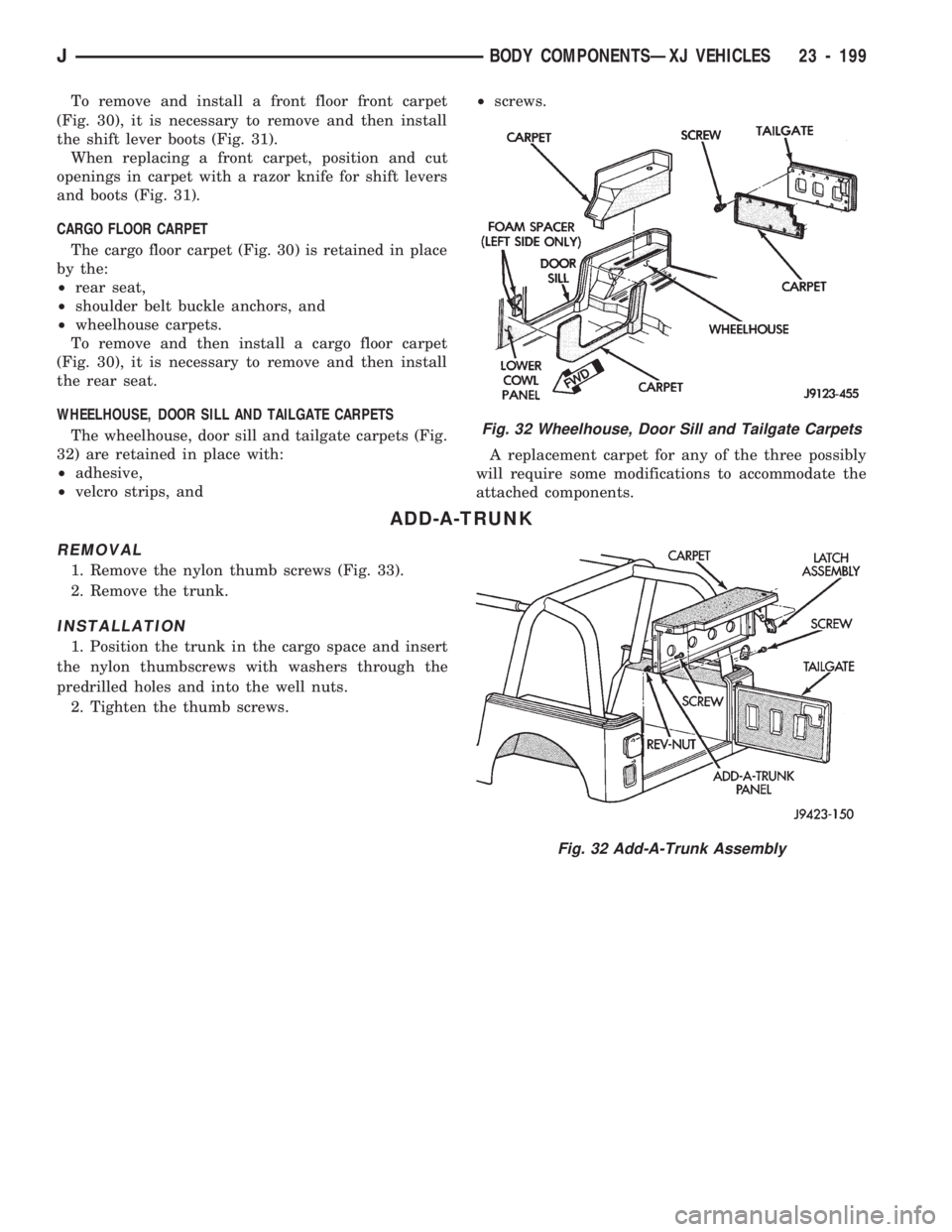

FLOOR CONSOLES

Floor consoles (Figs. 26 and 27) are fabricated from

molded plastic material. The console covers have a

locking top and provisions for beverage containers.

REMOVAL

(1) Open the console cover (Figs. 26 and 27).

(2) Remove the screws that attach the console to

the floor panel (Figs. 26 and 27).

(3) Remove the console from the vehicle.

INSTALLATION

(1) Position the console in the vehicle.

(2) Align the console screw holes with the holes in

the floor panel and install the attaching screws (Figs.

26 and 27).(3) Close and the console cover.

COVER AND SEAL REPLACEMENT

Console cover replacement involves removing the

hinge screws from the console, and components (Fig.

28). The seal can be replaced with the cover in the

open position.

COVER LOCK REPLACEMENT

(1) Open the console cover.

(2) Remove the screw that attaches the retainer to

the lock and then remove the retainer from the lock

(Fig. 29).

(3) Remove the lock, cylinder and key as a unit

from the console cover (Fig. 29).

(4) Manually position the lock latch to simulate a

closed cover position.

Fig. 24 Rear Shoulder Belt

Fig. 25 Sunvisor Removal/Installation

Fig. 26 Deluxe Floor Console

Fig. 27 Standard Floor Console

JBODY COMPONENTSÐXJ VEHICLES 23 - 197

Page 1653 of 1784

(5) Insert the key and cylinder into the lock and

turn clockwise. Release the lock latch and remove

the key.

(6) Insert the assembled lock in the console cover

hole (Fig. 28) and install the retainer with the at-

taching screw.

CARPET/FLOOR MATS

SERVICE INFORMATION

FRONT FLOOR REAR CARPET

The front floor rear carpet (Fig. 30) is retained in

place by the:

²front seats,

²floor console,

²shoulder belt buckle anchors, and

²door sill carpets.To remove and then install a front floor rear carpet

(Fig. 30), it is necessary to remove and then install

the front seats and the floor console.

FRONT FLOOR FRONT CARPET

The front floor front carpet (Fig. 30) is retained in

place by the:

²transmission/transfer case shift lever boots (Fig.

31),

²rear carpet, and

²Velcro strips.

Fig. 28 Console Cover and Seal

Fig. 29 Console Cover Lock Removal/Installation

Fig. 30 Floor Carpets

Fig. 31 Shift Lever Boots

23 - 198 BODY COMPONENTSÐXJ VEHICLESJ

Page 1654 of 1784

To remove and install a front floor front carpet

(Fig. 30), it is necessary to remove and then install

the shift lever boots (Fig. 31).

When replacing a front carpet, position and cut

openings in carpet with a razor knife for shift levers

and boots (Fig. 31).

CARGO FLOOR CARPET

The cargo floor carpet (Fig. 30) is retained in place

by the:

²rear seat,

²shoulder belt buckle anchors, and

²wheelhouse carpets.

To remove and then install a cargo floor carpet

(Fig. 30), it is necessary to remove and then install

the rear seat.

WHEELHOUSE, DOOR SILL AND TAILGATE CARPETS

The wheelhouse, door sill and tailgate carpets (Fig.

32) are retained in place with:

²adhesive,

²velcro strips, and²screws.

A replacement carpet for any of the three possibly

will require some modifications to accommodate the

attached components.

ADD-A-TRUNK

REMOVAL

1. Remove the nylon thumb screws (Fig. 33).

2. Remove the trunk.

INSTALLATION

1. Position the trunk in the cargo space and insert

the nylon thumbscrews with washers through the

predrilled holes and into the well nuts.

2. Tighten the thumb screws.

Fig. 32 Wheelhouse, Door Sill and Tailgate Carpets

Fig. 32 Add-A-Trunk Assembly

JBODY COMPONENTSÐXJ VEHICLES 23 - 199

Page 1655 of 1784

BODY COMPONENTSÐREFINISHING

CONTENTS

page page

PAINT APPLICATION................... 201SERVICE INFORMATION................ 200

SERVICE INFORMATION

SAFETY PRECAUTIONS

Protective eye shields, masks, respirators, should

be used.

For maximum protection from paint solvent vapor,

use a fresh-air type, compressor-powered respirator.

PREPARATION

Do not allow any type of open flame or other source

of vapor ignition in the painting area. Paint vapor is

highly flammable when it is concentrated.

²Paint only in a well ventilated area.

²Use a good quality, high capacity respirator.

²Use protective goggles and clothing.

²Use rubber or latex gloves when mixing paint and

other, similar liquid products.

²When not in use, keep paint containers in a pro-

tective cabinet or locker.

²Keep the paint storage area well ventilated.

TECHNICAL TERMS

SINGLE COAT

A single-coat spray pattern is applied from left-to-

right. Then, the returning right-to-left spray pattern is

applied so that it overlaps the lower one-half of the ini-

tial spray pattern. This process is repeated until a com-

plete, single-coat coverage of a body panel is obtained.

DOUBLE COAT

A double-coat spray pattern is applied from left-to-

right. Then, the returning right-to-left spray pattern

is applied.

DRYING

Drying and hardening of paint film involves three

stages of evaporation.

The first stage is referred to as dust-free stage.

The second stage is referred to as tack-free stage.

The third and final stage is referred to as hard-dry0

stage.

DE-GREASE/DE-WAX

De-greasing/de-waxing involves cleaning a panel sur-

face with either 3M All purpose cleaner, or a similar

product. This removes the surface grease, or wax.

FEATHEREDGING

Tapering and blending the edges of repaired areas

is referred to as featheredging.

FERROUS AND NON-FERROUS METAL

Iron and steel are ferrous metals. Non-ferrous

metal includes aluminum, brass, copper, magnesium

and several types of alloy metal.

FLASH TIME

The time required for most of the solvent to evap-

orate from an applied primer/paint coat.

MIST COAT

A mist coat is frequently used as the final color

coat. Mist coats are over-thinned paint that is

sprayed wet.

SURFACE PRIMER COAT

A surface primer coat must be applied over re-

paired as well as bare metal substrate. The primer

provides a bond between the metal and the color

(base) coat. Various types of surface primers and

primer/sealants are available. Surface primers are

available in either sandable or non-sandable form.

Glazing or spot putty can be applied to primer cov-

ered surfaces. The putty is used to fill the small im-

perfections that a standard primer will not to cover.

REDUCERS/THINNERS

Enamel reducers and lacquer thinners are mix-

tures of volatile liquids and are used to reduce sur-

face primers and color-coat paints. Use only the type

of reducer/thinner that is specified by the paint man-

ufacturer.Do not intermix different types of re-

ducer/thinner.

TACK RAG

Tack rags are used to wipe dust from a body panel

surface prior to primer/paint application. Dust parti-

cles will adhere to the tacky surface of the rag when

it is moved over a panel surface.

23 - 200 BODY COMPONENTSÐXJ VEHICLESJ

Page 1656 of 1784

PAINT APPLICATION

INDEX

page page

Accent Paint........................... 202

Base/Color Coat........................ 201

Basecoat/Clearcoat...................... 202

Body Undercoat......................... 203

Buffing and Polishing..................... 203

Exterior Body Colors..................... 204Paint Repair on Galvanized Metals.......... 202

Plastic Components...................... 203

Primer................................ 201

Stone Chip Protection.................... 201

Surface Preparation...................... 201

SURFACE PREPARATION

Proper surface preparation is the key to top-quality

body panel refinishing. The bare metal must be

cleaned, de-greased, de-waxed and treated with phos-

phate.

Always clean the panel surface with a wax and

grease removal solution, and then wipe the surface

with a tack rag before applying primer or paint.

Cleaning will also remove any residual silicone from

the painted surface.

Body putty that is procured from a major supplier

is highly recommended. If a synthetic body filler is to

be used, it should also be a quality product.

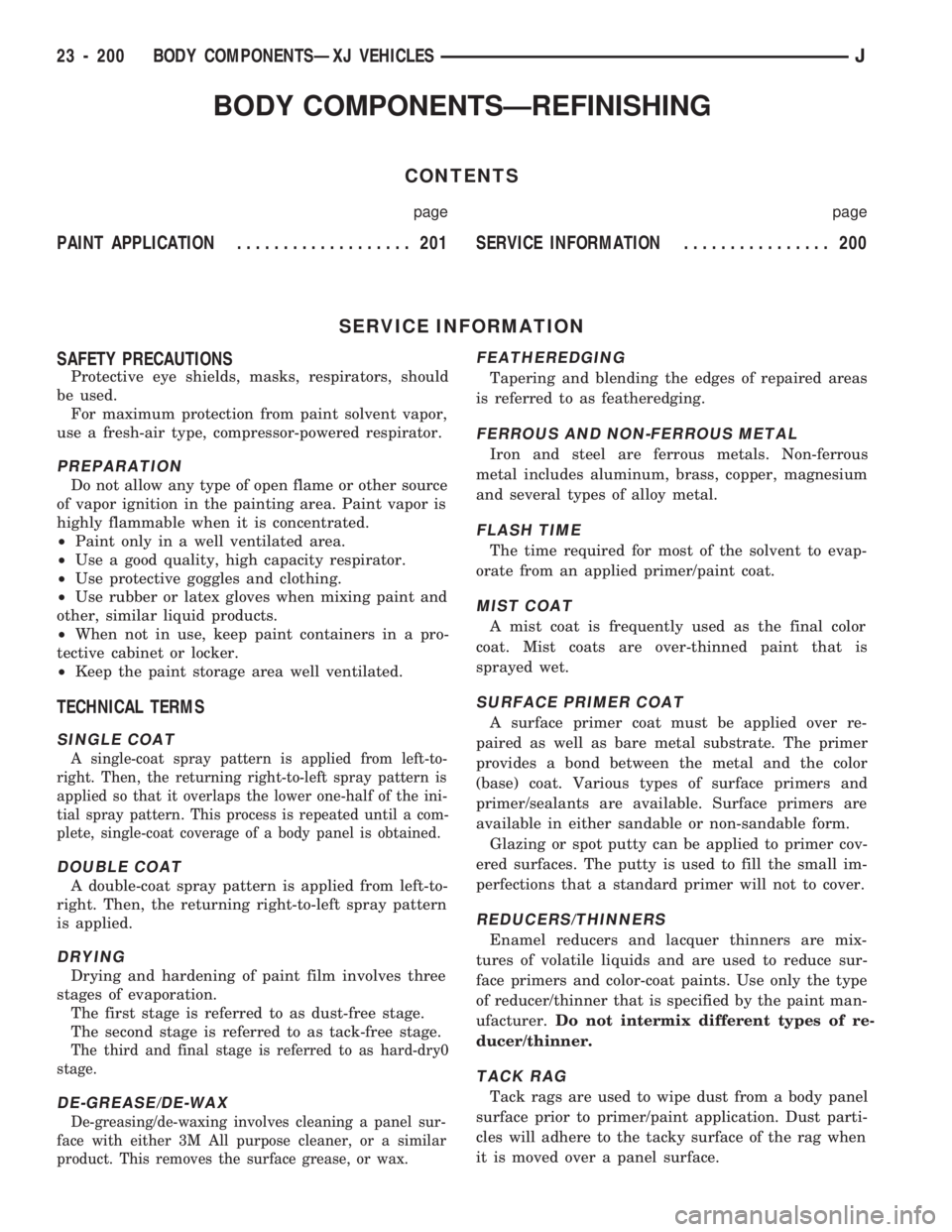

STONE CHIP PROTECTION

When applicable, the stone chip protection coat

(Fig. 1) must be applied before the primer coat. The

coating extends downward from the character line to

the bottom flanges. Then horizontally to the wheel-

house opening flanges.

PRIMER

The type of primer to be used is dependent on the

condition of the panel surface. Bare metal should be

primed with an epoxy-base. A sealant is recom-

mended when applying a second color coat over an

existing color coat. With certain colors, sealants are

also important in preventing color bleed-through.

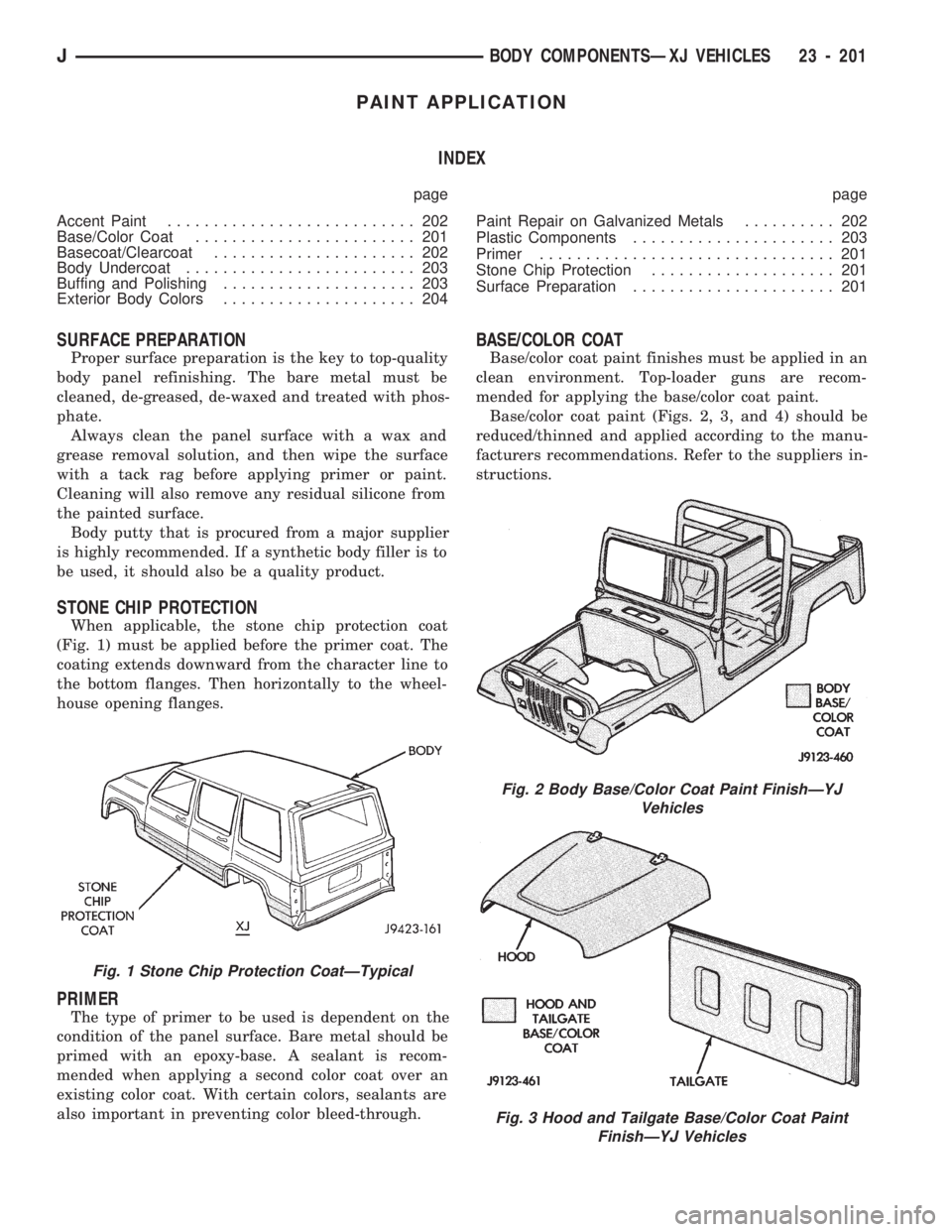

BASE/COLOR COAT

Base/color coat paint finishes must be applied in an

clean environment. Top-loader guns are recom-

mended for applying the base/color coat paint.

Base/color coat paint (Figs. 2, 3, and 4) should be

reduced/thinned and applied according to the manu-

facturers recommendations. Refer to the suppliers in-

structions.

Fig. 2 Body Base/Color Coat Paint FinishÐYJ

Vehicles

Fig. 3 Hood and Tailgate Base/Color Coat Paint

FinishÐYJ Vehicles

Fig. 1 Stone Chip Protection CoatÐTypical

JBODY COMPONENTSÐXJ VEHICLES 23 - 201

Page 1657 of 1784

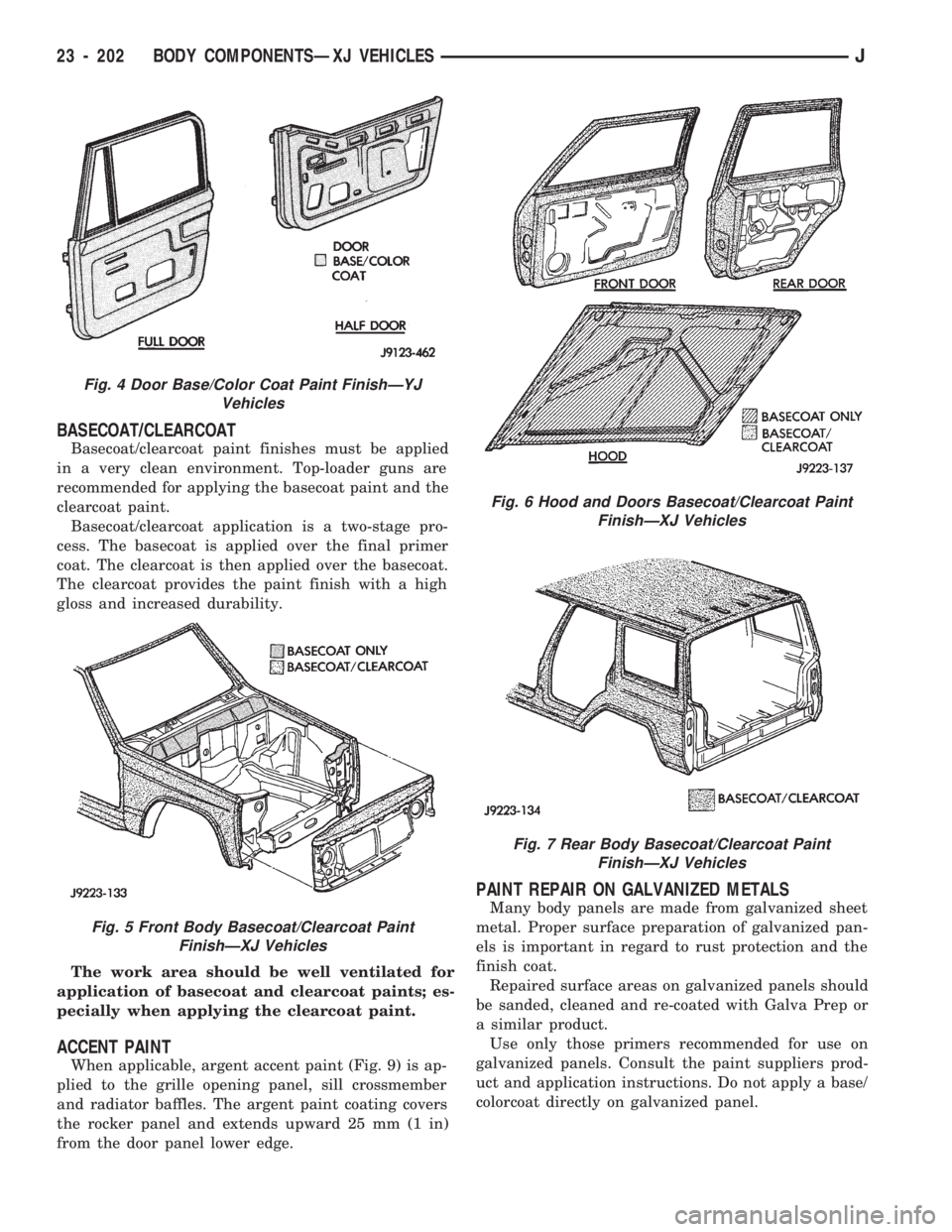

BASECOAT/CLEARCOAT

Basecoat/clearcoat paint finishes must be applied

in a very clean environment. Top-loader guns are

recommended for applying the basecoat paint and the

clearcoat paint.

Basecoat/clearcoat application is a two-stage pro-

cess. The basecoat is applied over the final primer

coat. The clearcoat is then applied over the basecoat.

The clearcoat provides the paint finish with a high

gloss and increased durability.

The work area should be well ventilated for

application of basecoat and clearcoat paints; es-

pecially when applying the clearcoat paint.

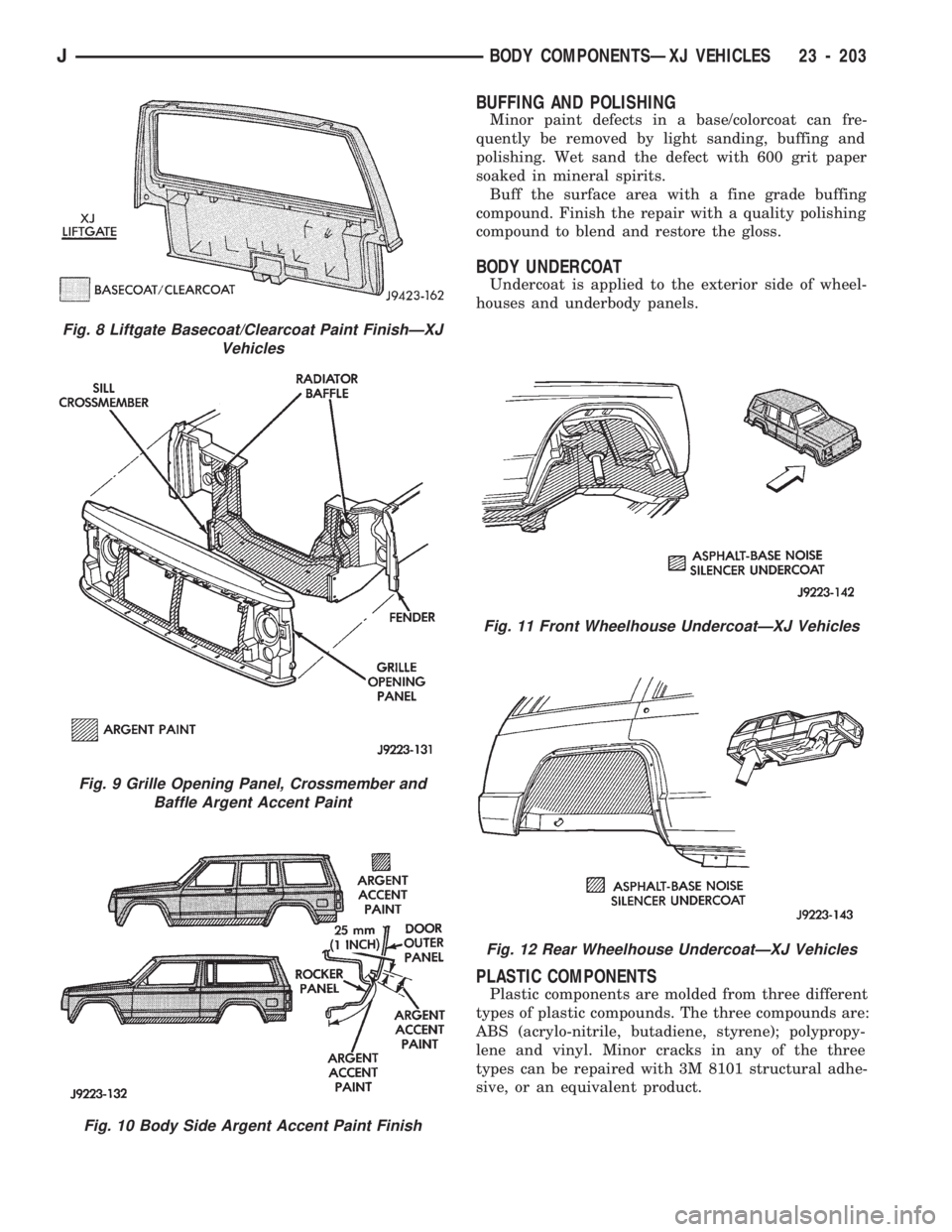

ACCENT PAINT

When applicable, argent accent paint (Fig. 9) is ap-

plied to the grille opening panel, sill crossmember

and radiator baffles. The argent paint coating covers

the rocker panel and extends upward 25 mm (1 in)

from the door panel lower edge.

PAINT REPAIR ON GALVANIZED METALS

Many body panels are made from galvanized sheet

metal. Proper surface preparation of galvanized pan-

els is important in regard to rust protection and the

finish coat.

Repaired surface areas on galvanized panels should

be sanded, cleaned and re-coated with Galva Prep or

a similar product.

Use only those primers recommended for use on

galvanized panels. Consult the paint suppliers prod-

uct and application instructions. Do not apply a base/

colorcoat directly on galvanized panel.

Fig. 4 Door Base/Color Coat Paint FinishÐYJ

Vehicles

Fig. 5 Front Body Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

Fig. 6 Hood and Doors Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

Fig. 7 Rear Body Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

23 - 202 BODY COMPONENTSÐXJ VEHICLESJ

Page 1658 of 1784

BUFFING AND POLISHING

Minor paint defects in a base/colorcoat can fre-

quently be removed by light sanding, buffing and

polishing. Wet sand the defect with 600 grit paper

soaked in mineral spirits.

Buff the surface area with a fine grade buffing

compound. Finish the repair with a quality polishing

compound to blend and restore the gloss.

BODY UNDERCOAT

Undercoat is applied to the exterior side of wheel-

houses and underbody panels.

PLASTIC COMPONENTS

Plastic components are molded from three different

types of plastic compounds. The three compounds are:

ABS (acrylo-nitrile, butadiene, styrene); polypropy-

lene and vinyl. Minor cracks in any of the three

types can be repaired with 3M 8101 structural adhe-

sive, or an equivalent product.

Fig. 8 Liftgate Basecoat/Clearcoat Paint FinishÐXJ

Vehicles

Fig. 9 Grille Opening Panel, Crossmember and

Baffle Argent Accent Paint

Fig. 10 Body Side Argent Accent Paint Finish

Fig. 11 Front Wheelhouse UndercoatÐXJ Vehicles

Fig. 12 Rear Wheelhouse UndercoatÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 203

Page 1659 of 1784

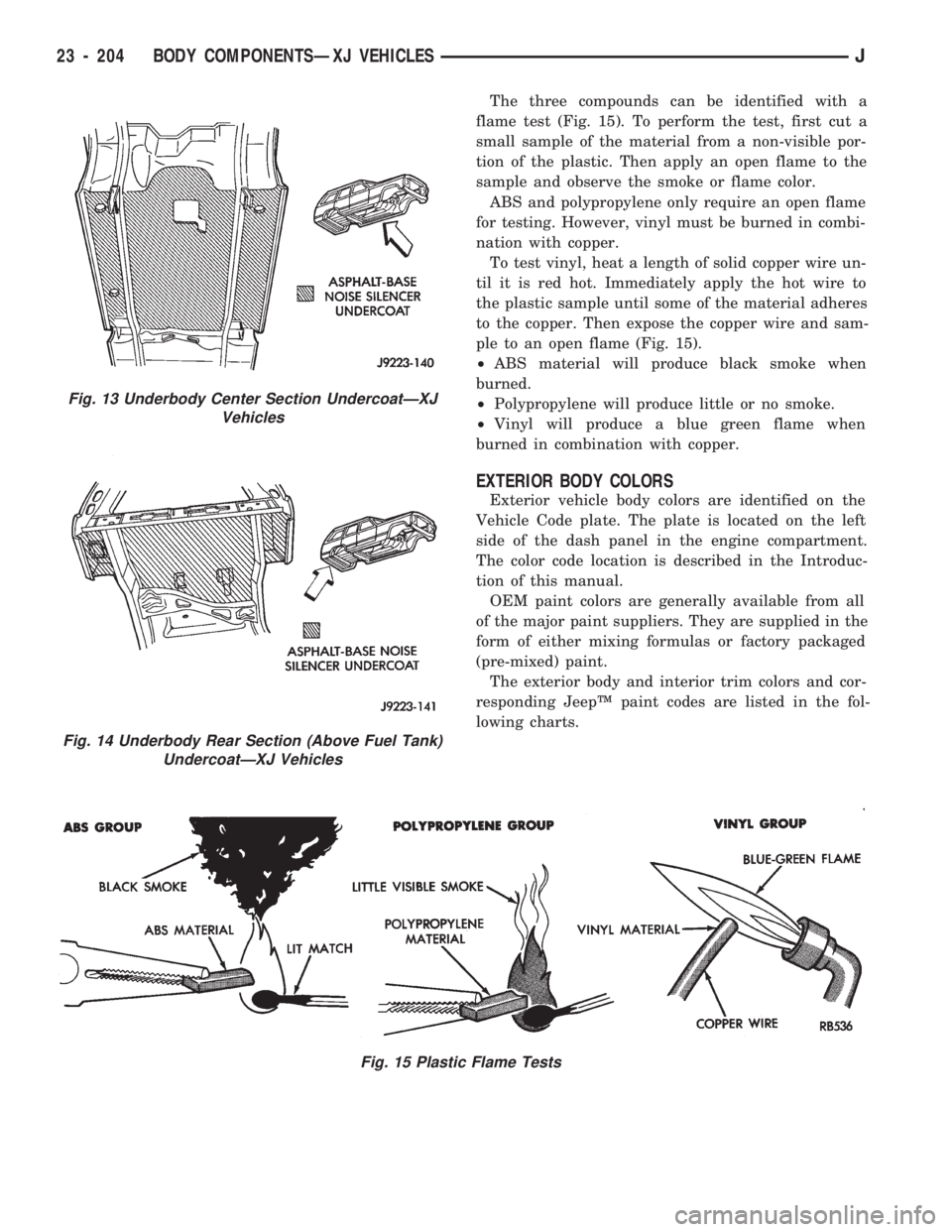

The three compounds can be identified with a

flame test (Fig. 15). To perform the test, first cut a

small sample of the material from a non-visible por-

tion of the plastic. Then apply an open flame to the

sample and observe the smoke or flame color.

ABS and polypropylene only require an open flame

for testing. However, vinyl must be burned in combi-

nation with copper.

To test vinyl, heat a length of solid copper wire un-

til it is red hot. Immediately apply the hot wire to

the plastic sample until some of the material adheres

to the copper. Then expose the copper wire and sam-

ple to an open flame (Fig. 15).

²ABS material will produce black smoke when

burned.

²Polypropylene will produce little or no smoke.

²Vinyl will produce a blue green flame when

burned in combination with copper.

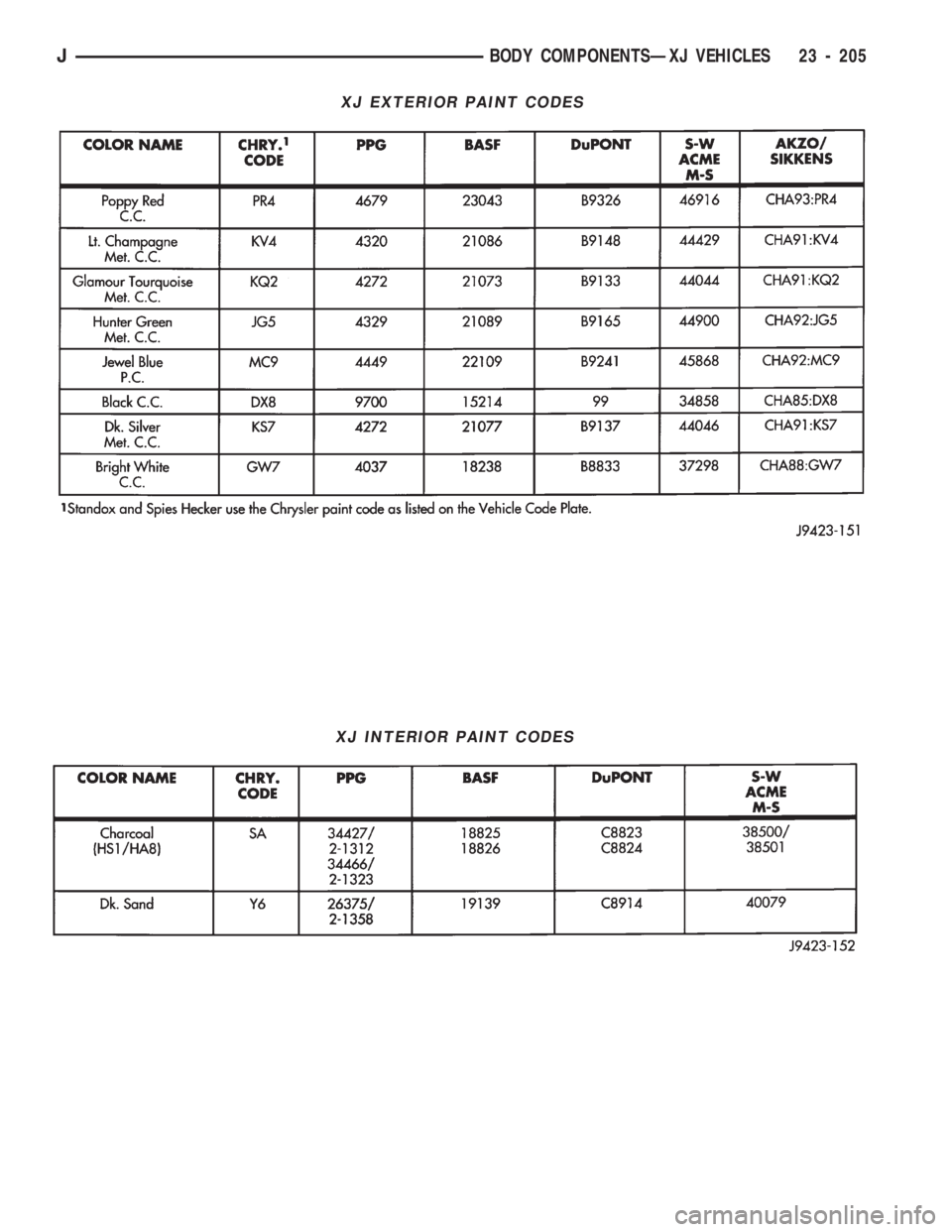

EXTERIOR BODY COLORS

Exterior vehicle body colors are identified on the

Vehicle Code plate. The plate is located on the left

side of the dash panel in the engine compartment.

The color code location is described in the Introduc-

tion of this manual.

OEM paint colors are generally available from all

of the major paint suppliers. They are supplied in the

form of either mixing formulas or factory packaged

(pre-mixed) paint.

The exterior body and interior trim colors and cor-

responding JeepŸ paint codes are listed in the fol-

lowing charts.

Fig. 15 Plastic Flame Tests

Fig. 13 Underbody Center Section UndercoatÐXJ

Vehicles

Fig. 14 Underbody Rear Section (Above Fuel Tank)

UndercoatÐXJ Vehicles

23 - 204 BODY COMPONENTSÐXJ VEHICLESJ

Page 1660 of 1784

XJ EXTERIOR PAINT CODES

XJ INTERIOR PAINT CODES

JBODY COMPONENTSÐXJ VEHICLES 23 - 205