JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1681 of 1784

²Used belt tensionÐ623-712 N (140-160 lb-f).

(5) Remove the tape or plastic plugs from all the

suction and discharge openings and install the ser-

vice valves on the compressor.

(6) Connect the clutch lead wire.

(7) Connect negative cable to battery.

(8) Evacuate, charge and test the system for leaks.

MAGNETIC CLUTCH

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly.

The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position.The pulley and plate assembly are mounted on the

compressor shaft.

When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

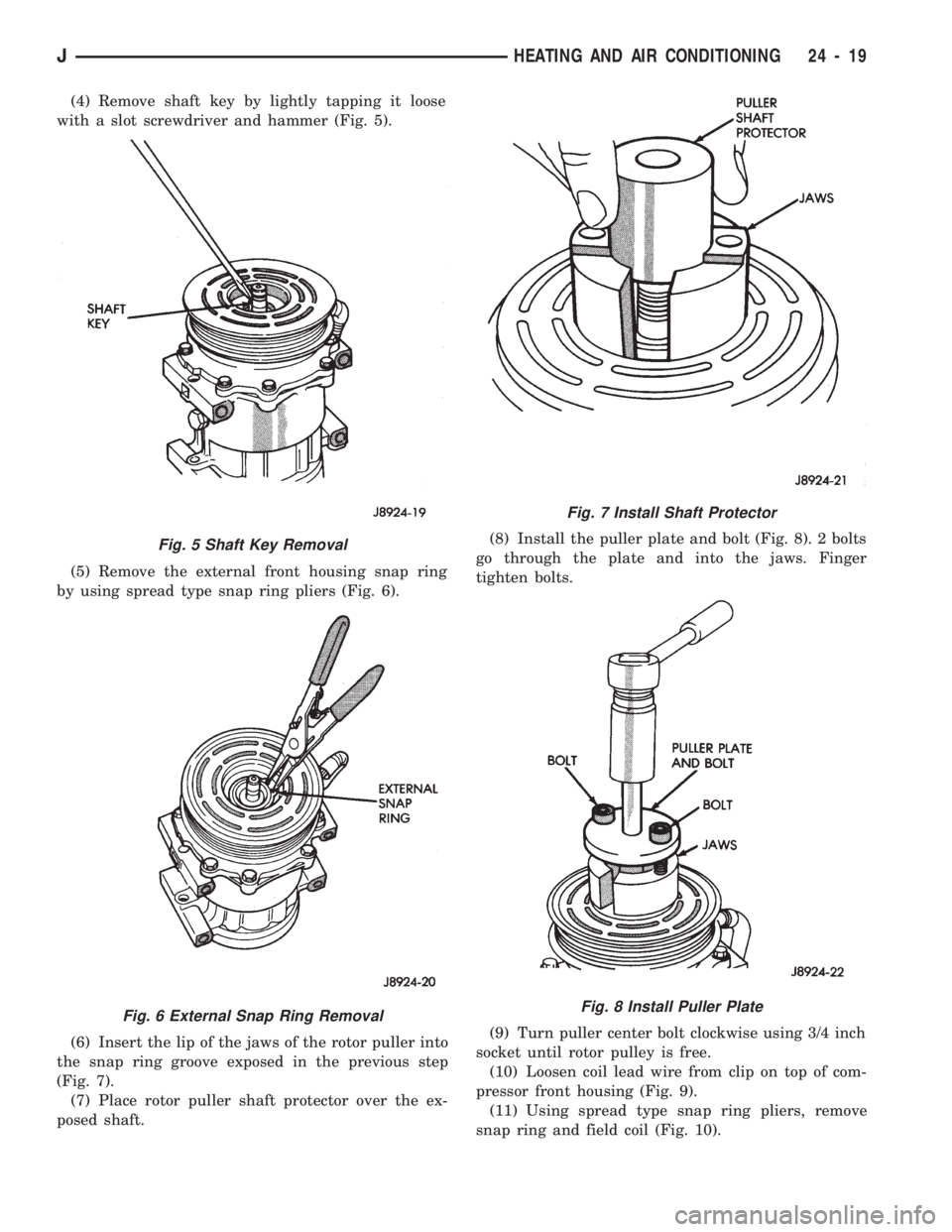

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

3). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket (Fig. 3).

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 4). Thumb

tighten the puller bolts into the threaded holes.

(3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened.

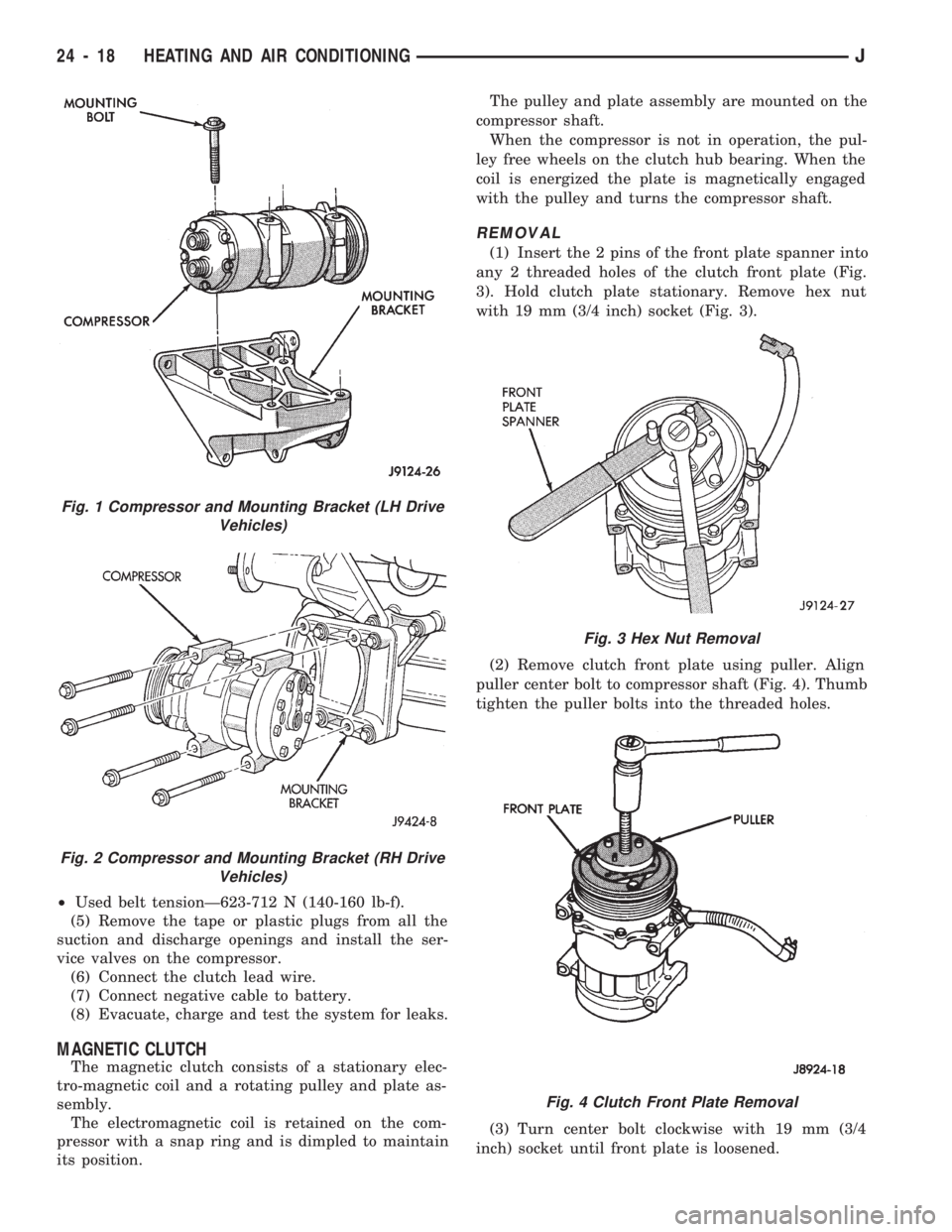

Fig. 1 Compressor and Mounting Bracket (LH Drive

Vehicles)

Fig. 2 Compressor and Mounting Bracket (RH Drive

Vehicles)

Fig. 3 Hex Nut Removal

Fig. 4 Clutch Front Plate Removal

24 - 18 HEATING AND AIR CONDITIONINGJ

Page 1682 of 1784

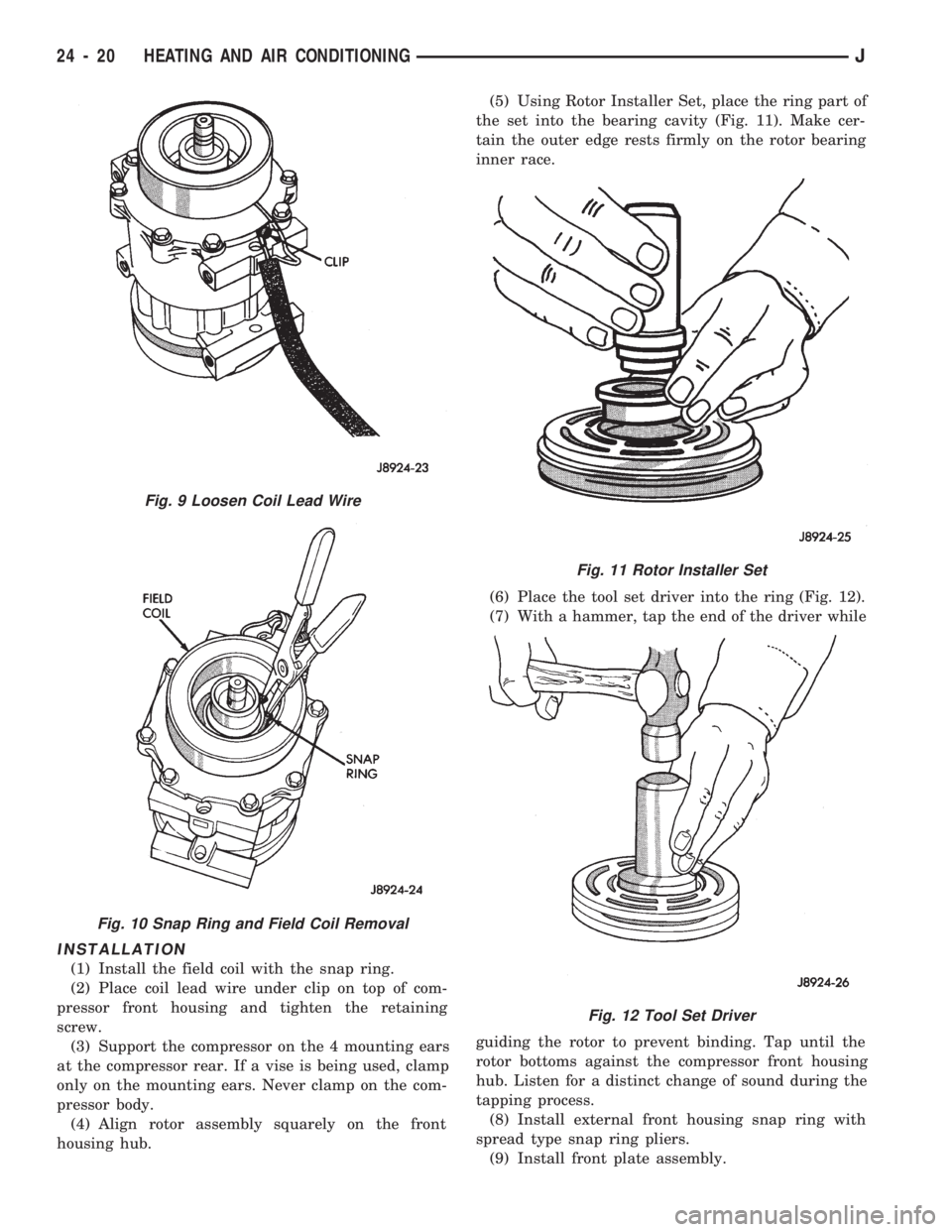

(4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 5).

(5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 6).

(6) Insert the lip of the jaws of the rotor puller into

the snap ring groove exposed in the previous step

(Fig. 7).

(7) Place rotor puller shaft protector over the ex-

posed shaft.(8) Install the puller plate and bolt (Fig. 8). 2 bolts

go through the plate and into the jaws. Finger

tighten bolts.

(9) Turn puller center bolt clockwise using 3/4 inch

socket until rotor pulley is free.

(10) Loosen coil lead wire from clip on top of com-

pressor front housing (Fig. 9).

(11) Using spread type snap ring pliers, remove

snap ring and field coil (Fig. 10).

Fig. 5 Shaft Key Removal

Fig. 6 External Snap Ring Removal

Fig. 7 Install Shaft Protector

Fig. 8 Install Puller Plate

JHEATING AND AIR CONDITIONING 24 - 19

Page 1683 of 1784

INSTALLATION

(1) Install the field coil with the snap ring.

(2) Place coil lead wire under clip on top of com-

pressor front housing and tighten the retaining

screw.

(3) Support the compressor on the 4 mounting ears

at the compressor rear. If a vise is being used, clamp

only on the mounting ears. Never clamp on the com-

pressor body.

(4) Align rotor assembly squarely on the front

housing hub.(5) Using Rotor Installer Set, place the ring part of

the set into the bearing cavity (Fig. 11). Make cer-

tain the outer edge rests firmly on the rotor bearing

inner race.

(6) Place the tool set driver into the ring (Fig. 12).

(7) With a hammer, tap the end of the driver while

guiding the rotor to prevent binding. Tap until the

rotor bottoms against the compressor front housing

hub. Listen for a distinct change of sound during the

tapping process.

(8) Install external front housing snap ring with

spread type snap ring pliers.

(9) Install front plate assembly.

Fig. 9 Loosen Coil Lead Wire

Fig. 10 Snap Ring and Field Coil Removal

Fig. 11 Rotor Installer Set

Fig. 12 Tool Set Driver

24 - 20 HEATING AND AIR CONDITIONINGJ

Page 1684 of 1784

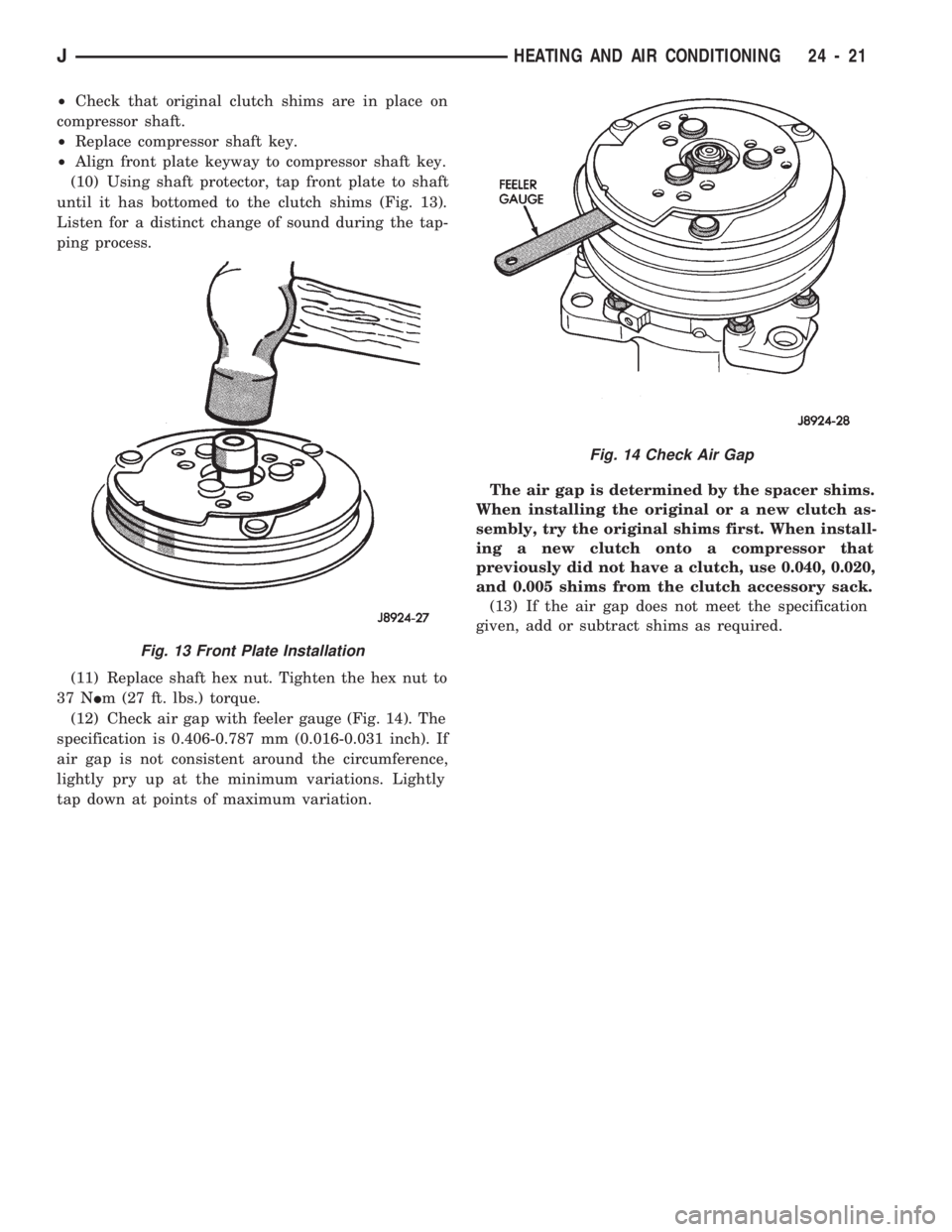

²Check that original clutch shims are in place on

compressor shaft.

²Replace compressor shaft key.

²Align front plate keyway to compressor shaft key.

(10) Using shaft protector, tap front plate to shaft

until it has bottomed to the clutch shims (Fig. 13).

Listen for a distinct change of sound during the tap-

ping process.

(11) Replace shaft hex nut. Tighten the hex nut to

37 NIm (27 ft. lbs.) torque.

(12) Check air gap with feeler gauge (Fig. 14). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

air gap is not consistent around the circumference,

lightly pry up at the minimum variations. Lightly

tap down at points of maximum variation.The air gap is determined by the spacer shims.

When installing the original or a new clutch as-

sembly, try the original shims first. When install-

ing a new clutch onto a compressor that

previously did not have a clutch, use 0.040, 0.020,

and 0.005 shims from the clutch accessory sack.

(13) If the air gap does not meet the specification

given, add or subtract shims as required.

Fig. 13 Front Plate Installation

Fig. 14 Check Air Gap

JHEATING AND AIR CONDITIONING 24 - 21

Page 1685 of 1784

CLIMATE CONTROL SYSTEMÐXJ VEHICLES

INDEX

page page

A/C Recirculating Air Door Vacuum Motor

Replacement.......................... 31

Blower Motor Resistors Replacement......... 35

Blower Motor/Fan Replacement.............. 26

CondenserÐ4.0L Engines.................. 32

Condenser/Receiver DrierÐ2.5L Engines....... 31

Defroster Duct Replacement................ 29

Description............................. 22

Evaporator Coil.......................... 34

Evaporator/Blower Housing................. 33Expansion (H) Valve...................... 35

Heater and A/C Control Panel Replacement.... 26

Heater Control Cable Replacement........... 30

Heater Core............................ 28

Heater Core Housing Replacement........... 29

Heater/Defroster/Instrument Panel Outlet Door

Vacuum Motor Replacement............... 30

Receiver DrierÐ4.0L Engines............... 32

Temperature Control Thermostat............. 35

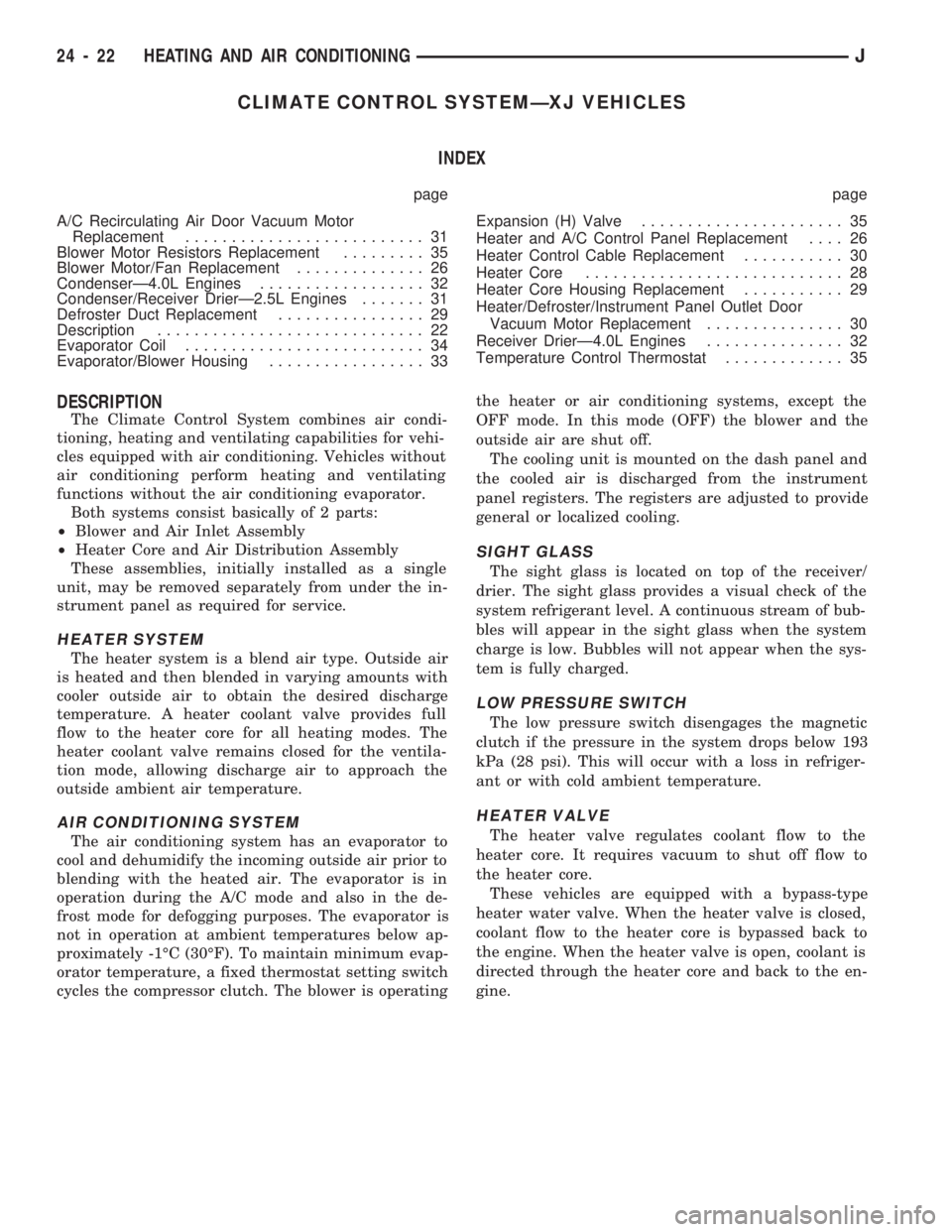

DESCRIPTION

The Climate Control System combines air condi-

tioning, heating and ventilating capabilities for vehi-

cles equipped with air conditioning. Vehicles without

air conditioning perform heating and ventilating

functions without the air conditioning evaporator.

Both systems consist basically of 2 parts:

²Blower and Air Inlet Assembly

²Heater Core and Air Distribution Assembly

These assemblies, initially installed as a single

unit, may be removed separately from under the in-

strument panel as required for service.

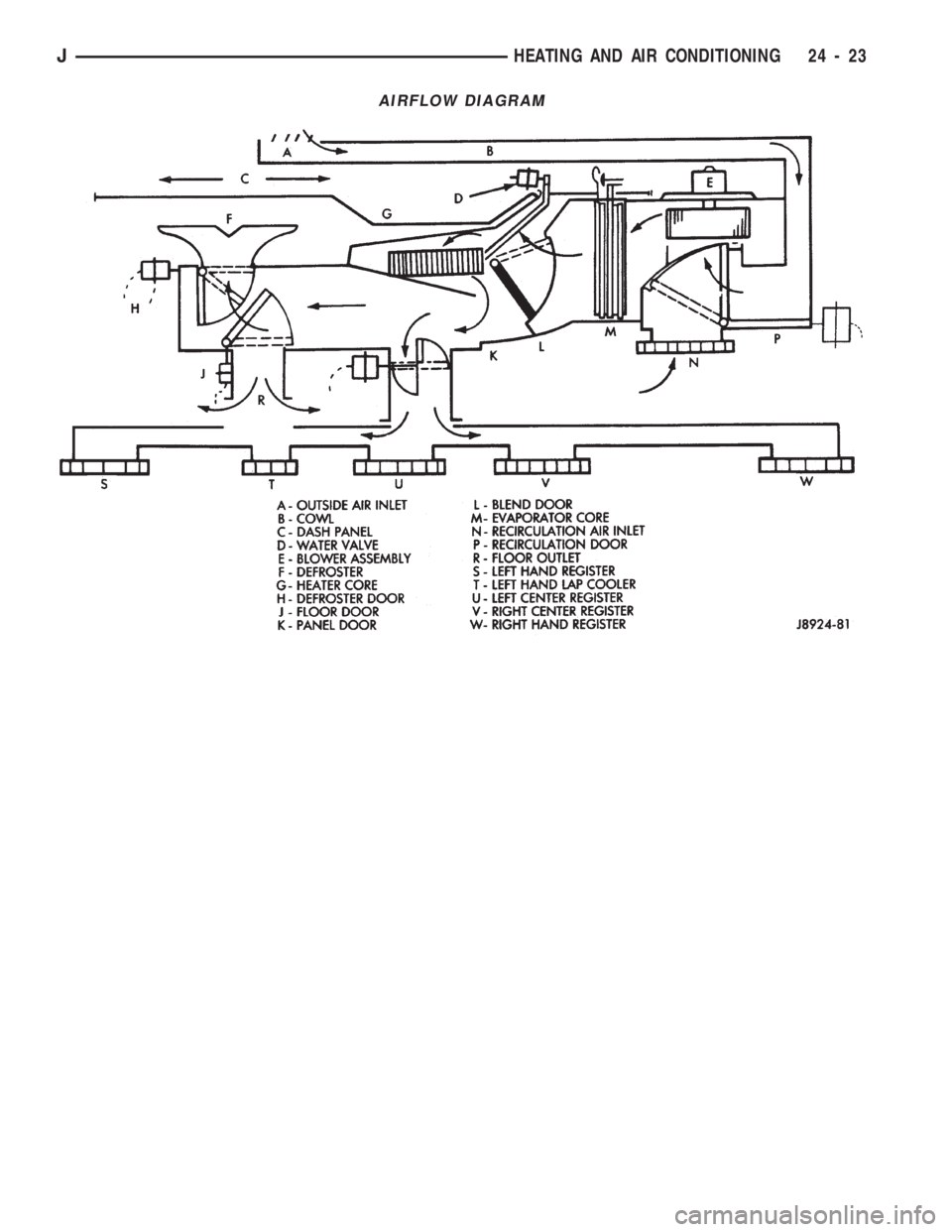

HEATER SYSTEM

The heater system is a blend air type. Outside air

is heated and then blended in varying amounts with

cooler outside air to obtain the desired discharge

temperature. A heater coolant valve provides full

flow to the heater core for all heating modes. The

heater coolant valve remains closed for the ventila-

tion mode, allowing discharge air to approach the

outside ambient air temperature.

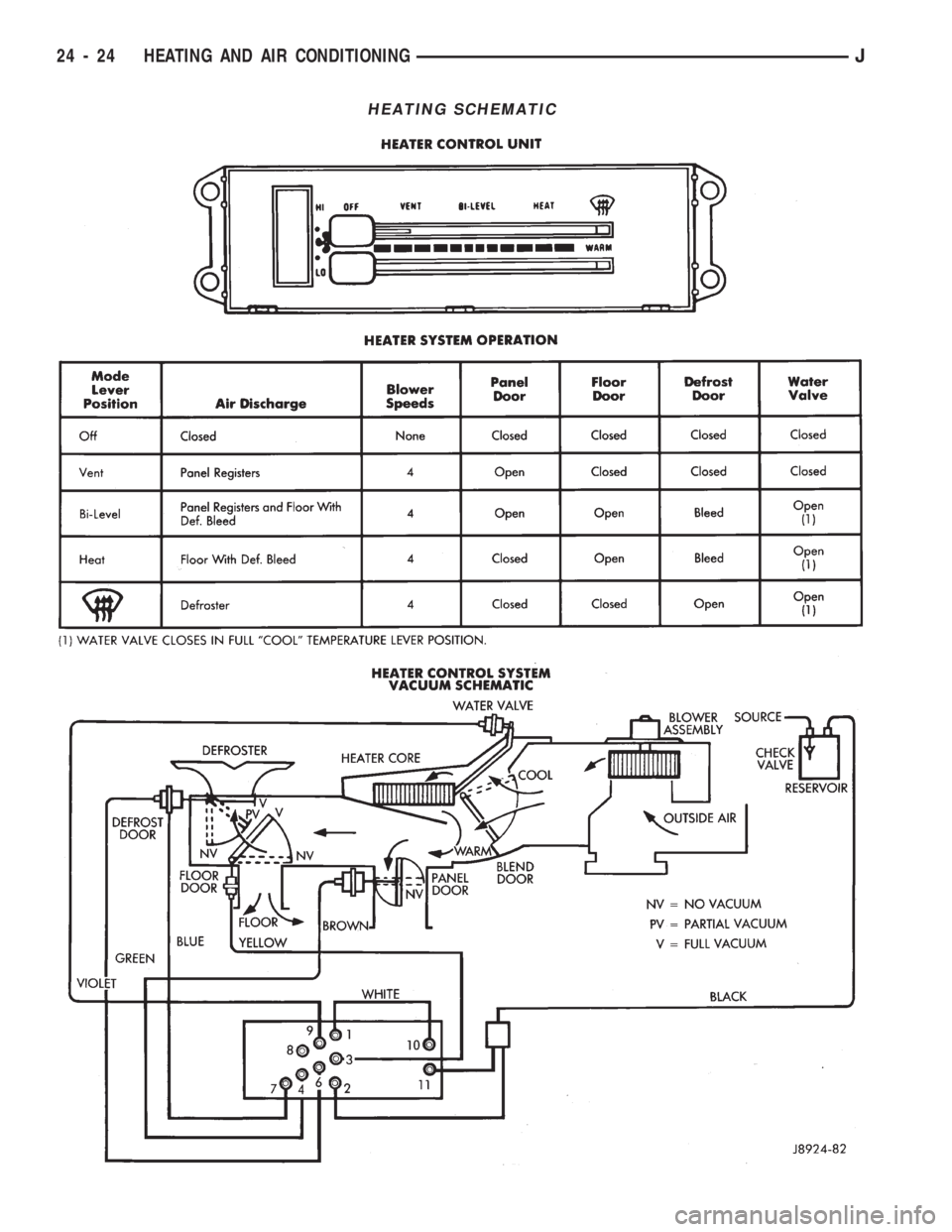

AIR CONDITIONING SYSTEM

The air conditioning system has an evaporator to

cool and dehumidify the incoming outside air prior to

blending with the heated air. The evaporator is in

operation during the A/C mode and also in the de-

frost mode for defogging purposes. The evaporator is

not in operation at ambient temperatures below ap-

proximately -1ÉC (30ÉF). To maintain minimum evap-

orator temperature, a fixed thermostat setting switch

cycles the compressor clutch. The blower is operatingthe heater or air conditioning systems, except the

OFF mode. In this mode (OFF) the blower and the

outside air are shut off.

The cooling unit is mounted on the dash panel and

the cooled air is discharged from the instrument

panel registers. The registers are adjusted to provide

general or localized cooling.

SIGHT GLASS

The sight glass is located on top of the receiver/

drier. The sight glass provides a visual check of the

system refrigerant level. A continuous stream of bub-

bles will appear in the sight glass when the system

charge is low. Bubbles will not appear when the sys-

tem is fully charged.

LOW PRESSURE SWITCH

The low pressure switch disengages the magnetic

clutch if the pressure in the system drops below 193

kPa (28 psi). This will occur with a loss in refriger-

ant or with cold ambient temperature.

HEATER VALVE

The heater valve regulates coolant flow to the

heater core. It requires vacuum to shut off flow to

the heater core.

These vehicles are equipped with a bypass-type

heater water valve. When the heater valve is closed,

coolant flow to the heater core is bypassed back to

the engine. When the heater valve is open, coolant is

directed through the heater core and back to the en-

gine.

24 - 22 HEATING AND AIR CONDITIONINGJ

Page 1686 of 1784

AIRFLOW DIAGRAM

JHEATING AND AIR CONDITIONING 24 - 23

Page 1687 of 1784

HEATING SCHEMATIC

24 - 24 HEATING AND AIR CONDITIONINGJ

Page 1688 of 1784

AIR CONDITIONING SCHEMATIC

JHEATING AND AIR CONDITIONING 24 - 25

Page 1689 of 1784

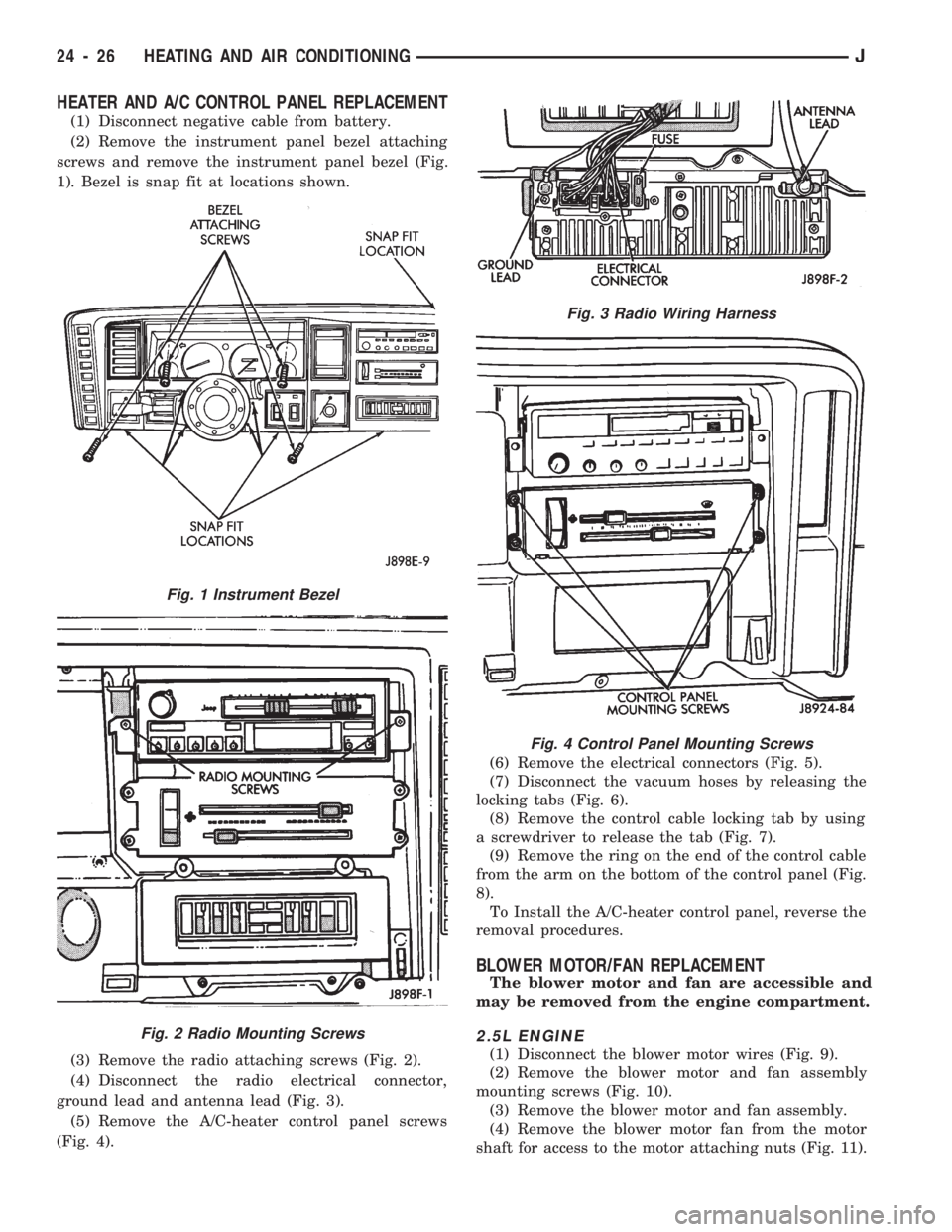

HEATER AND A/C CONTROL PANEL REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove the instrument panel bezel attaching

screws and remove the instrument panel bezel (Fig.

1). Bezel is snap fit at locations shown.

(3) Remove the radio attaching screws (Fig. 2).

(4) Disconnect the radio electrical connector,

ground lead and antenna lead (Fig. 3).

(5) Remove the A/C-heater control panel screws

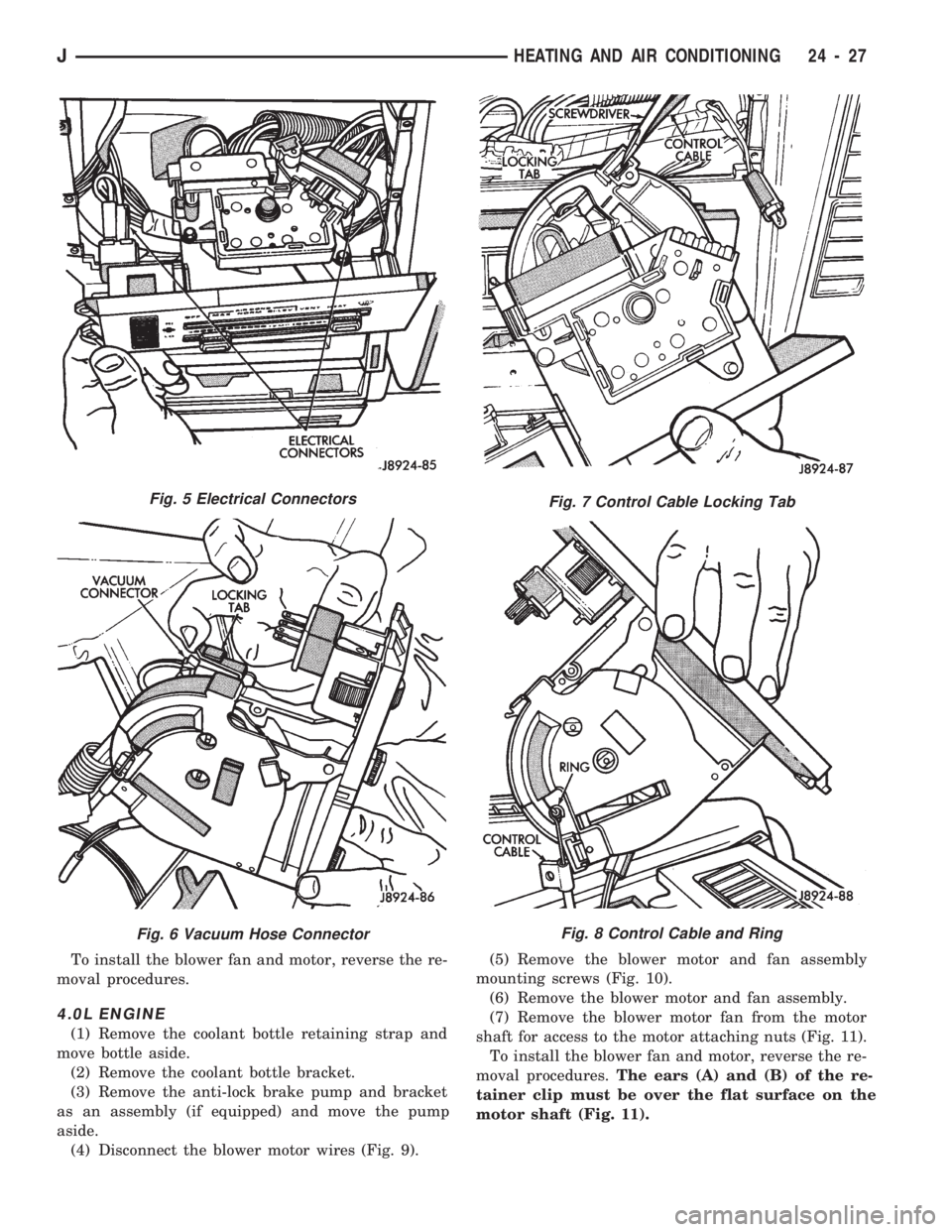

(Fig. 4).(6) Remove the electrical connectors (Fig. 5).

(7) Disconnect the vacuum hoses by releasing the

locking tabs (Fig. 6).

(8) Remove the control cable locking tab by using

a screwdriver to release the tab (Fig. 7).

(9) Remove the ring on the end of the control cable

from the arm on the bottom of the control panel (Fig.

8).

To Install the A/C-heater control panel, reverse the

removal procedures.

BLOWER MOTOR/FAN REPLACEMENT

The blower motor and fan are accessible and

may be removed from the engine compartment.

2.5L ENGINE

(1) Disconnect the blower motor wires (Fig. 9).

(2) Remove the blower motor and fan assembly

mounting screws (Fig. 10).

(3) Remove the blower motor and fan assembly.

(4) Remove the blower motor fan from the motor

shaft for access to the motor attaching nuts (Fig. 11).

Fig. 1 Instrument Bezel

Fig. 2 Radio Mounting Screws

Fig. 3 Radio Wiring Harness

Fig. 4 Control Panel Mounting Screws

24 - 26 HEATING AND AIR CONDITIONINGJ

Page 1690 of 1784

To install the blower fan and motor, reverse the re-

moval procedures.

4.0L ENGINE

(1) Remove the coolant bottle retaining strap and

move bottle aside.

(2) Remove the coolant bottle bracket.

(3) Remove the anti-lock brake pump and bracket

as an assembly (if equipped) and move the pump

aside.

(4) Disconnect the blower motor wires (Fig. 9).(5) Remove the blower motor and fan assembly

mounting screws (Fig. 10).

(6) Remove the blower motor and fan assembly.

(7) Remove the blower motor fan from the motor

shaft for access to the motor attaching nuts (Fig. 11).

To install the blower fan and motor, reverse the re-

moval procedures.The ears (A) and (B) of the re-

tainer clip must be over the flat surface on the

motor shaft (Fig. 11).

Fig. 5 Electrical Connectors

Fig. 6 Vacuum Hose Connector

Fig. 7 Control Cable Locking Tab

Fig. 8 Control Cable and Ring

JHEATING AND AIR CONDITIONING 24 - 27