JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1711 of 1784

New service ports are used to ensure that the sys-

tem is not accidentally filled with the wrong refriger-

ant.

Due to the different characteristics of R-134a it re-

quires all new service procedures. Refer to Refriger-

ant Service Procedures in this section before making

any repairs to the air conditioning system.

Chrysler Corporation recommends that a

R-134a refrigerant Recovery/Recycling Station

that meets SAE standard J2210 be used.Refer tothe operating instructions provided with the equip-

ment for proper operation.

REFRIGERANT OIL

R-134a refrigerant requires a special type of com-

pressor oil. The system uses polyalklene glycol syn-

thetic wax-free refrigerant oil SP-20 PAG. No other

oil should be used.

R-12 compressor oil can not be mixed with the

R-134a compressor oil. They ARE NOT compatible.

2 AIR CONDITIONINGJ

Page 1712 of 1784

WARNINGS AND CAUTIONS FOR R134A SYSTEM

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND/OR THROAT. WEAR

EYE PROTECTION WHEN SERVICING THE AIR

CONDITIONING REFRIGERANT SYSTEM. SERIOUS

EYE INJURY CAN RESULT FROM EYE CONTACT

WITH REFRIGERANT. IF EYE CONTACT IS MADE,

SEEK MEDICAL ATTENTION IMMEDIATELY.

WARNING: DO NOT EXPOSE REFRIGERANT TO

OPEN FLAME. POISONOUS GAS IS CREATED

WHEN REFRIGERANT IS BURNED. AN ELEC-

TRONIC LEAK DETECTOR IS RECOMMENDED.

WARNING: IF ACCIDENTAL SYSTEM DISCHARGE

OCCURS, VENTILATE THE WORK AREA BEFORE

RESUMING SERVICE. LARGE AMOUNTS OF RE-

FRIGERANT RELEASED IN A CLOSED WORK AREA

WILL DISPLACE THE OXYGEN AND CAUSE SUFFO-

CATION.

WARNING: THE EVAPORATION RATE OF R-134A

REFRIGERANT AT AVERAGE TEMPERATURE AND

ALTITUDE IS EXTREMELY HIGH. AS A RESULT,

ANYTHING THAT COMES IN CONTACT WITH THE

REFRIGERANT WILL FREEZE. ALWAYS PROTECT

SKIN OR DELICATE OBJECTS FROM DIRECT CON-

TACT WITH REFRIGERANT.WARNING: R-134A SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. SOME MIXTURES OF AIR AND R-134A HAVE

BEEN SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR EX-

PLOSION CAUSING INJURY OR PROPERTY DAM-

AGE.

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

CAUTION: Never add R-12 to a system designed to

use R-134a. Damage to the system will result.

CAUTION: R-12 compressor oil can not be mixed

with the R-134a compressor oil. They ARE NOT

compatible.

CAUTION: DO NOT use R-12 equipment or parts on

the R-134a system. Damage to the system will re-

sult.

SERVICE PRECAUTIONS

Never open or loosen a connection before discharg-

ing the system refrigerant.

The A/C system must always be evacuated before

charging.

DO NOT open a refrigerant system or uncap a re-

placement component unless it is as close as possible

to room temperature. This will prevent condensation

from forming inside of a component which is cooler

than the surrounding air.

Before disconnecting a component from the system,

clean the outside of the fittings thoroughly.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.

Before connecting an open fitting always insall a

new seal/gasket. Coat the fitting and seal with clean

refrigerant oil before connecting.

DO NOT remove the sealing caps from a replace-

ment component until ready to install.When installing a refrigerant line avoid sharp

bends. Position the line away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

aluminum fittings used in the A/C system will not

tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting. This will prevent twisting of the

refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. DO NOT open an oil con-

tainer until ready to use and install the cap

immediately after using. Store the oil only in a clean

moisture-free container.

Keep service tools and the work area clean. Con-

tamination of A/C system through careless work hab-

its must be avoided.

JAIR CONDITIONING3

Page 1713 of 1784

AIR CONDITIONING EQUIPMENT

WARNING: EYE PROTECTION MUST BE USED

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE PROCEEDING WITH THIS OPERATION.

PERSONNEL INJURY CAN RESULT.

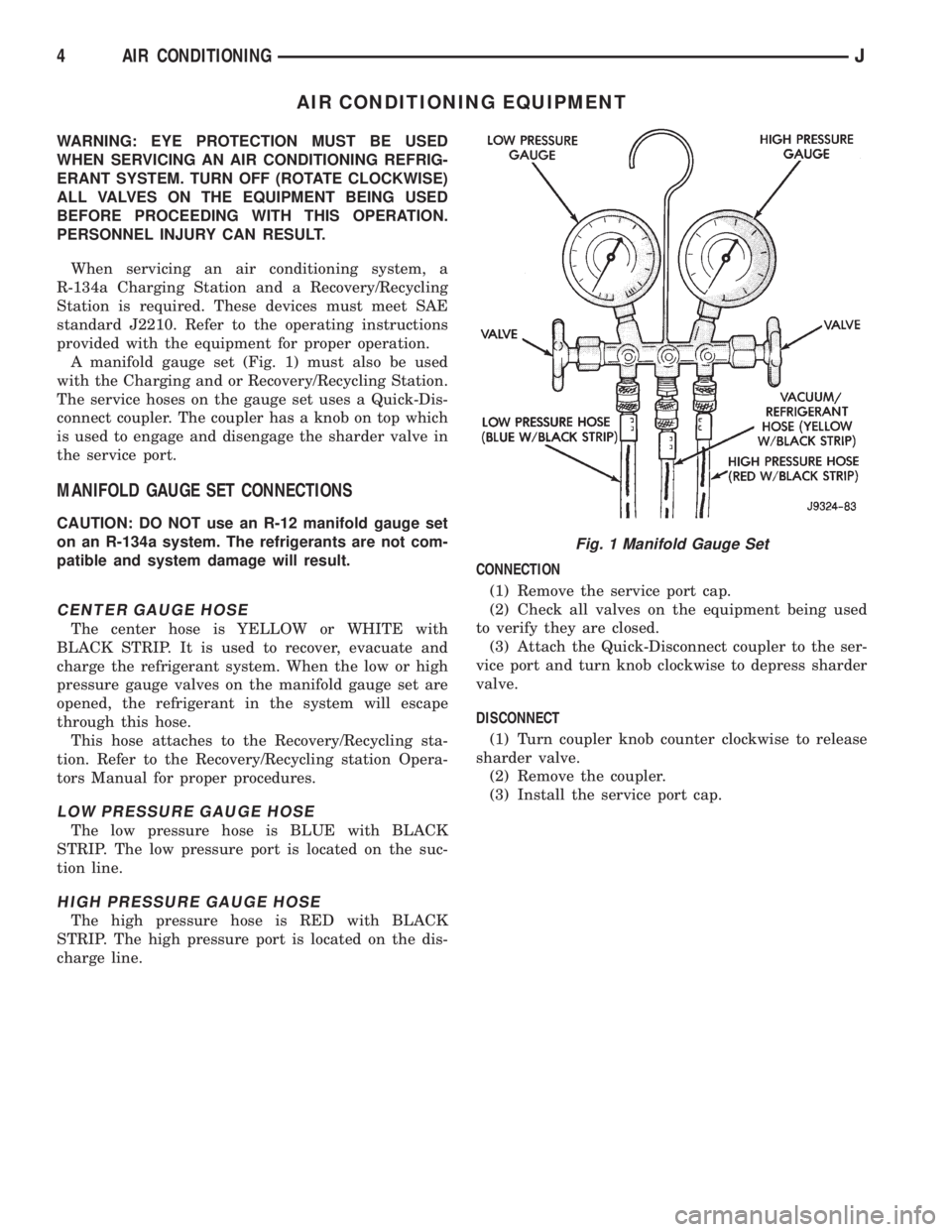

When servicing an air conditioning system, a

R-134a Charging Station and a Recovery/Recycling

Station is required. These devices must meet SAE

standard J2210. Refer to the operating instructions

provided with the equipment for proper operation.

A manifold gauge set (Fig. 1) must also be used

with the Charging and or Recovery/Recycling Station.

The service hoses on the gauge set uses a Quick-Dis-

connect coupler. The coupler has a knob on top which

is used to engage and disengage the sharder valve in

the service port.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: DO NOT use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

CENTER GAUGE HOSE

The center hose is YELLOW or WHITE with

BLACK STRIP. It is used to recover, evacuate and

charge the refrigerant system. When the low or high

pressure gauge valves on the manifold gauge set are

opened, the refrigerant in the system will escape

through this hose.

This hose attaches to the Recovery/Recycling sta-

tion. Refer to the Recovery/Recycling station Opera-

tors Manual for proper procedures.

LOW PRESSURE GAUGE HOSE

The low pressure hose is BLUE with BLACK

STRIP. The low pressure port is located on the suc-

tion line.

HIGH PRESSURE GAUGE HOSE

The high pressure hose is RED with BLACK

STRIP. The high pressure port is located on the dis-

charge line.CONNECTION

(1) Remove the service port cap.

(2) Check all valves on the equipment being used

to verify they are closed.

(3) Attach the Quick-Disconnect coupler to the ser-

vice port and turn knob clockwise to depress sharder

valve.

DISCONNECT

(1) Turn coupler knob counter clockwise to release

sharder valve.

(2) Remove the coupler.

(3) Install the service port cap.

Fig. 1 Manifold Gauge Set

4 AIR CONDITIONINGJ

Page 1714 of 1784

AIR CONDITIONING PERFORMANCE TESTS

Humidity has an improtant bearing on the tempra-

ture of the air delivered to the vehicle's interior. It is

important to understand the effect humidity has on

the performance of the system. When humidity is

high, the evaporator has to perform a double duty. It

must lower the air temperature and the temperature

of the moisture carried in the air. Condensing the

moisture in the air transfers heat energy into the

evaporator fins and tubing. This reduces the amount

of heat the evaporator can absorb from the air. High

humidity greatly reduces the evaporator 's ability to

lower the temperature of the air.

Evaporator capacity used to reduce the amount of

moisture in the air is not wasted. Wringing some of

the moisture out of the air entering the vehicle adds

to the comfort of the passengers. However, an owner

may expect too much from their air conditioning sys-

tem on humid days. A performance test is the best

way to determine whether or not the system is per-

forming up to standard. This test also provides valu-

able clues to the possible cause of trouble.

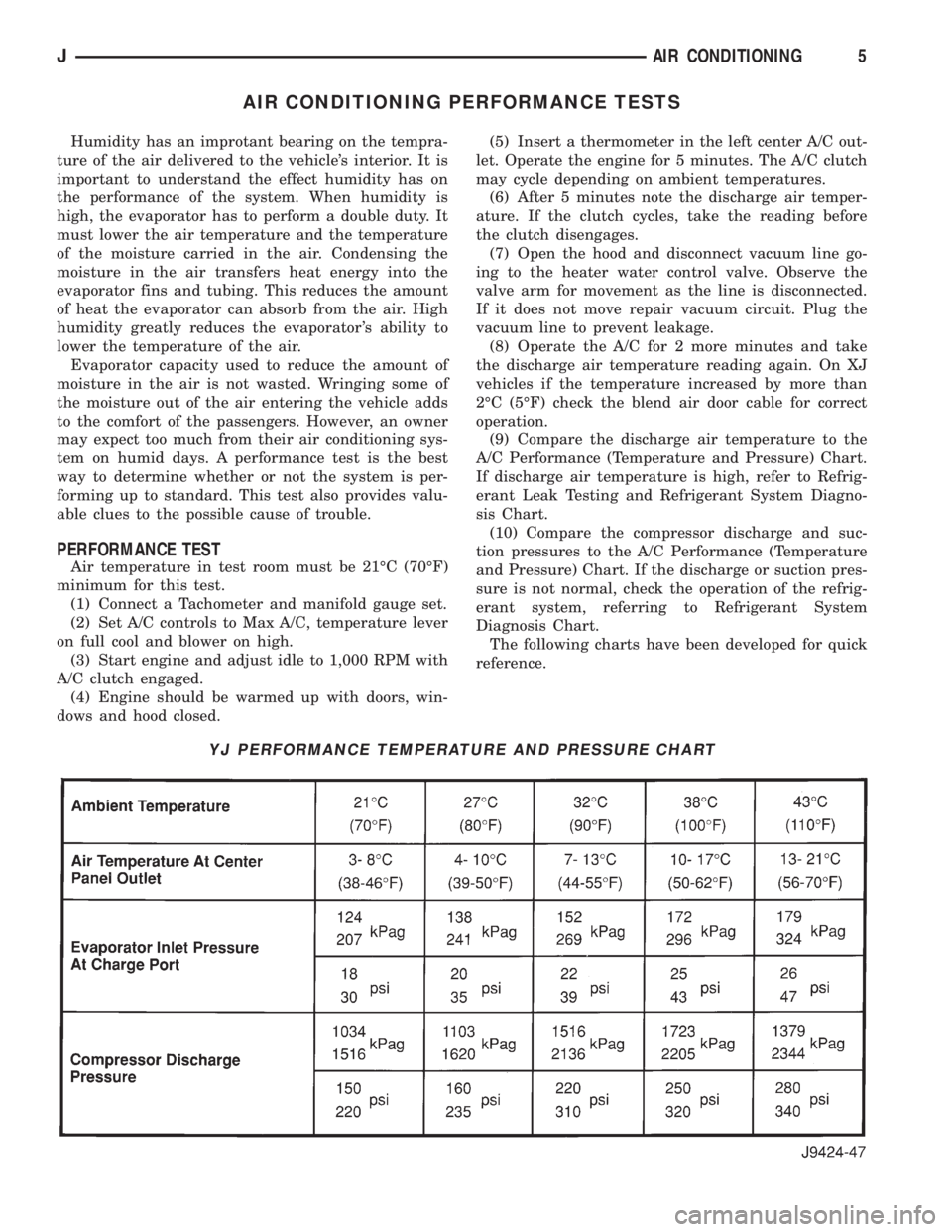

PERFORMANCE TEST

Air temperature in test room must be 21ÉC (70ÉF)

minimum for this test.

(1) Connect a Tachometer and manifold gauge set.

(2) Set A/C controls to Max A/C, temperature lever

on full cool and blower on high.

(3) Start engine and adjust idle to 1,000 RPM with

A/C clutch engaged.

(4) Engine should be warmed up with doors, win-

dows and hood closed.(5) Insert a thermometer in the left center A/C out-

let. Operate the engine for 5 minutes. The A/C clutch

may cycle depending on ambient temperatures.

(6) After 5 minutes note the discharge air temper-

ature. If the clutch cycles, take the reading before

the clutch disengages.

(7) Open the hood and disconnect vacuum line go-

ing to the heater water control valve. Observe the

valve arm for movement as the line is disconnected.

If it does not move repair vacuum circuit. Plug the

vacuum line to prevent leakage.

(8) Operate the A/C for 2 more minutes and take

the discharge air temperature reading again. On XJ

vehicles if the temperature increased by more than

2ÉC (5ÉF) check the blend air door cable for correct

operation.

(9) Compare the discharge air temperature to the

A/C Performance (Temperature and Pressure) Chart.

If discharge air temperature is high, refer to Refrig-

erant Leak Testing and Refrigerant System Diagno-

sis Chart.

(10) Compare the compressor discharge and suc-

tion pressures to the A/C Performance (Temperature

and Pressure) Chart. If the discharge or suction pres-

sure is not normal, check the operation of the refrig-

erant system, referring to Refrigerant System

Diagnosis Chart.

The following charts have been developed for quick

reference.

YJ PERFORMANCE TEMPERATURE AND PRESSURE CHART

JAIR CONDITIONING5

Page 1715 of 1784

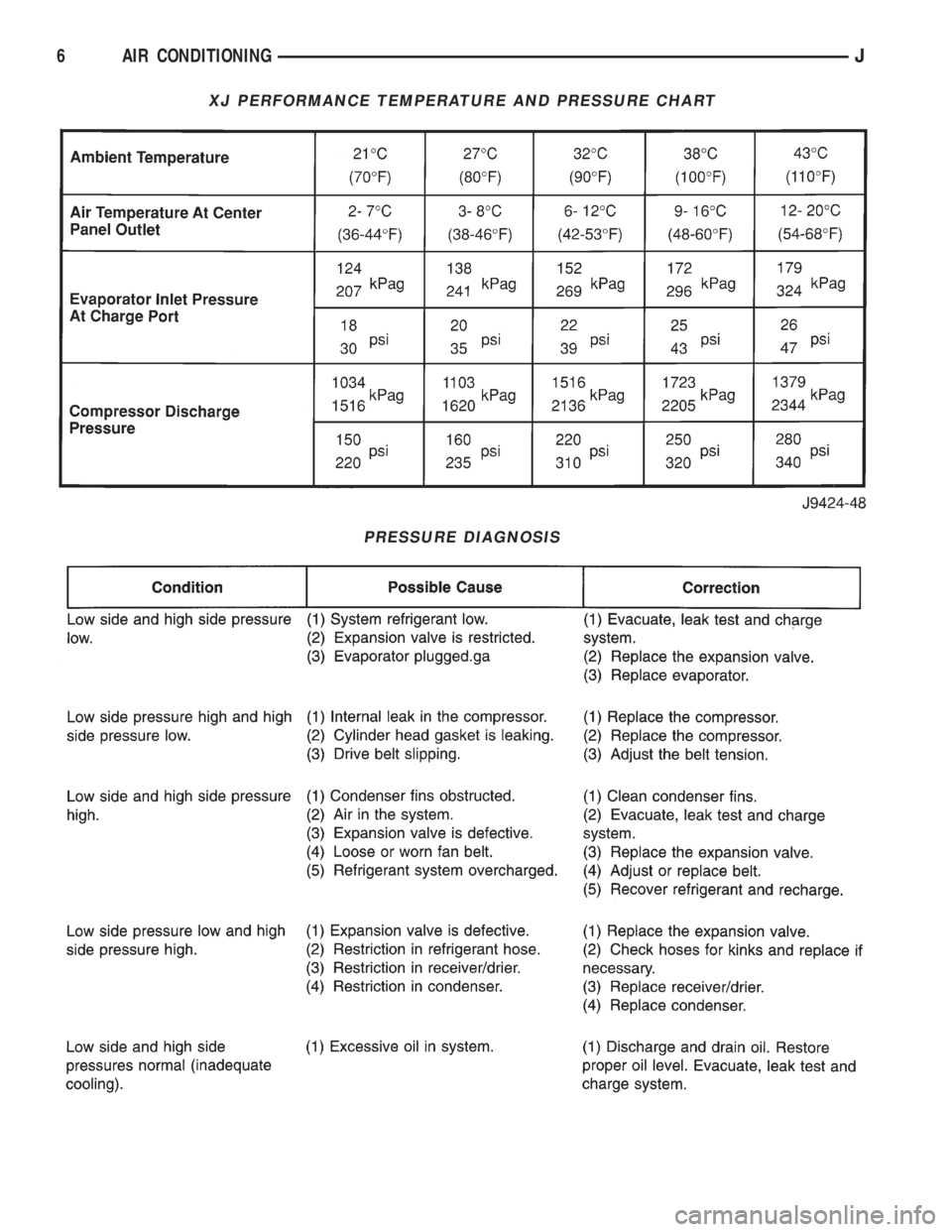

XJ PERFORMANCE TEMPERATURE AND PRESSURE CHART

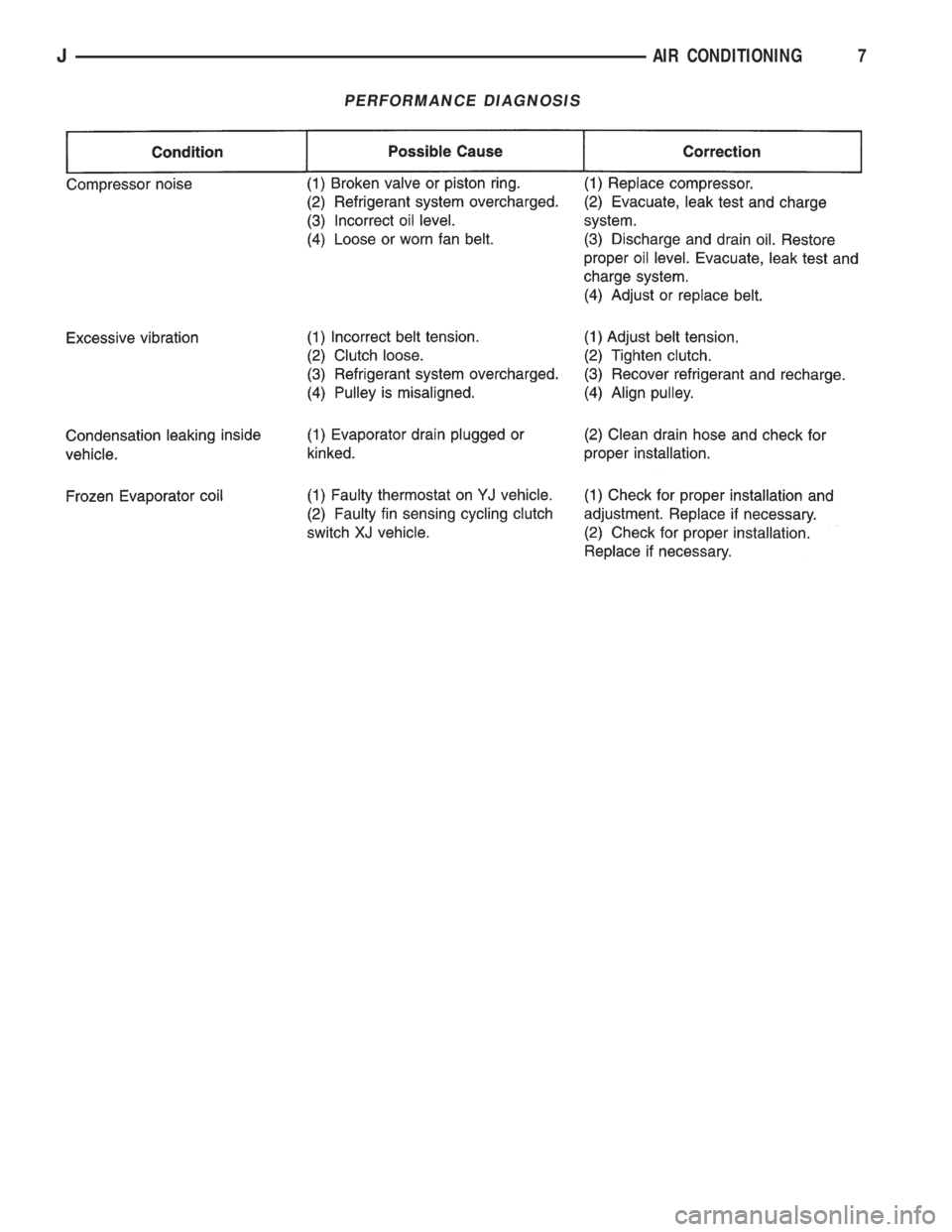

PRESSURE DIAGNOSIS

6 AIR CONDITIONINGJ

Page 1716 of 1784

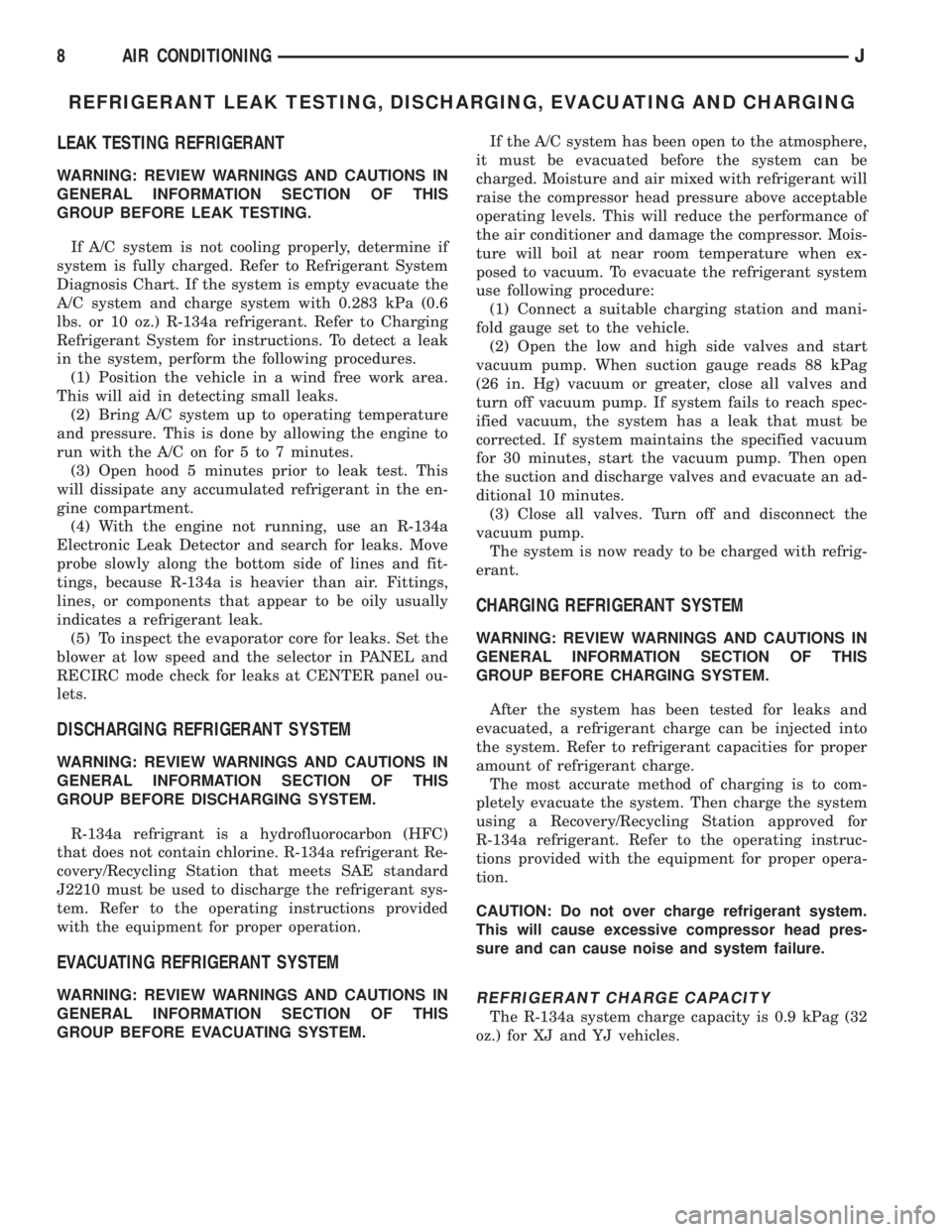

PERFORMANCE DIAGNOSIS

JAIR CONDITIONING7

Page 1717 of 1784

REFRIGERANT LEAK TESTING, DISCHARGING, EVACUATING AND CHARGING

LEAK TESTING REFRIGERANT

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE LEAK TESTING.

If A/C system is not cooling properly, determine if

system is fully charged. Refer to Refrigerant System

Diagnosis Chart. If the system is empty evacuate the

A/C system and charge system with 0.283 kPa (0.6

lbs. or 10 oz.) R-134a refrigerant. Refer to Charging

Refrigerant System for instructions. To detect a leak

in the system, perform the following procedures.

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Bring A/C system up to operating temperature

and pressure. This is done by allowing the engine to

run with the A/C on for 5 to 7 minutes.

(3) Open hood 5 minutes prior to leak test. This

will dissipate any accumulated refrigerant in the en-

gine compartment.

(4) With the engine not running, use an R-134a

Electronic Leak Detector and search for leaks. Move

probe slowly along the bottom side of lines and fit-

tings, because R-134a is heavier than air. Fittings,

lines, or components that appear to be oily usually

indicates a refrigerant leak.

(5) To inspect the evaporator core for leaks. Set the

blower at low speed and the selector in PANEL and

RECIRC mode check for leaks at CENTER panel ou-

lets.

DISCHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE DISCHARGING SYSTEM.

R-134a refrigrant is a hydrofluorocarbon (HFC)

that does not contain chlorine. R-134a refrigerant Re-

covery/Recycling Station that meets SAE standard

J2210 must be used to discharge the refrigerant sys-

tem. Refer to the operating instructions provided

with the equipment for proper operation.

EVACUATING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE EVACUATING SYSTEM.If the A/C system has been open to the atmosphere,

it must be evacuated before the system can be

charged. Moisture and air mixed with refrigerant will

raise the compressor head pressure above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor. Mois-

ture will boil at near room temperature when ex-

posed to vacuum. To evacuate the refrigerant system

use following procedure:

(1) Connect a suitable charging station and mani-

fold gauge set to the vehicle.

(2) Open the low and high side valves and start

vacuum pump. When suction gauge reads 88 kPag

(26 in. Hg) vacuum or greater, close all valves and

turn off vacuum pump. If system fails to reach spec-

ified vacuum, the system has a leak that must be

corrected. If system maintains the specified vacuum

for 30 minutes, start the vacuum pump. Then open

the suction and discharge valves and evacuate an ad-

ditional 10 minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

The system is now ready to be charged with refrig-

erant.

CHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE CHARGING SYSTEM.

After the system has been tested for leaks and

evacuated, a refrigerant charge can be injected into

the system. Refer to refrigerant capacities for proper

amount of refrigerant charge.

The most accurate method of charging is to com-

pletely evacuate the system. Then charge the system

using a Recovery/Recycling Station approved for

R-134a refrigerant. Refer to the operating instruc-

tions provided with the equipment for proper opera-

tion.

CAUTION: Do not over charge refrigerant system.

This will cause excessive compressor head pres-

sure and can cause noise and system failure.

REFRIGERANT CHARGE CAPACITY

The R-134a system charge capacity is 0.9 kPag (32

oz.) for XJ and YJ vehicles.

8 AIR CONDITIONINGJ

Page 1718 of 1784

REFRIGERANT OIL

It is important to have the correct amount of oil in

the A/C system. This will ensure proper lubrication of

the compressor. Too little oil will result in damage to

the compressor. Too much oil will reduce the cooling

capacity of the system.

The oil used in the SD-709 compressor is a poly-

alkylene glycol synthetic oil SP-20 PAG. This is a

wax-free refrigerant oil. Only refrigerant oil of the

same type should be used to service the system. Do

not use any other oil. The oil container should be

kept tightly capped until it is ready for use and then

capped after use to prevent contamination. Refriger-

ant oil will quickly absorb any moisture it comes in

contact with.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. This may be due to a rupture or leak from a

line, shaft seal, evaporator or condenser. Oil loss at a

leak point will be evident by the presence of a wet,

shiny surface around the leak.Add an additional 28 grams (1 fluid oz.) of

compressor oil to the system when a receiver-

drier, condenser or evaporator core is replaced.

OIL LEVEL

When an A/C system is assembled at the factory,

all components (except the compressor) are refriger-

ant oil free. After the system has been charged and

operated, the oil in the compressor is dispersed

through the system. The evaporator, condenser and

compressor will retain a significant amount of oil (re-

fer to the Refrigerant Oil Capacities Chart).

When a component is replaced, the specified

amount of refrigerant oil must be added. When the

compressor is replaced, the oil must be drained from

the replaced compressor and measured. Drain all the

oil from the new compressor. Add back into the new

compressor the amount of oil that was drained out of

the old compressor.

JAIR CONDITIONING9

Page 1719 of 1784

EMISSION CONTROL SYSTEMS

CONTENTS

page page

COMPONENT REMOVAL/INSTALLATION...... 8

EVAPORATIVE EMISSION CONTROLS....... 4EXHAUST EMISSION CONTROLS........... 7

GENERAL INFORMATION.................. 1

GENERAL INFORMATION

INDEX

page page

DRB Scan Tool........................... 2

Service Reminder Indicator (SRI) Lamp......... 1Vacuum Hose Routing Schematics............ 1

Vehicle Emission Control Information (VECI) Label . 1

SERVICE REMINDER INDICATOR (SRI) LAMP

The instrument panel mounted SRI lamp was for-

merly referred to as the emission maintenance re-

minder (EMR) lamp. It isnot usedon any Jeep

model for the 1994 model year.

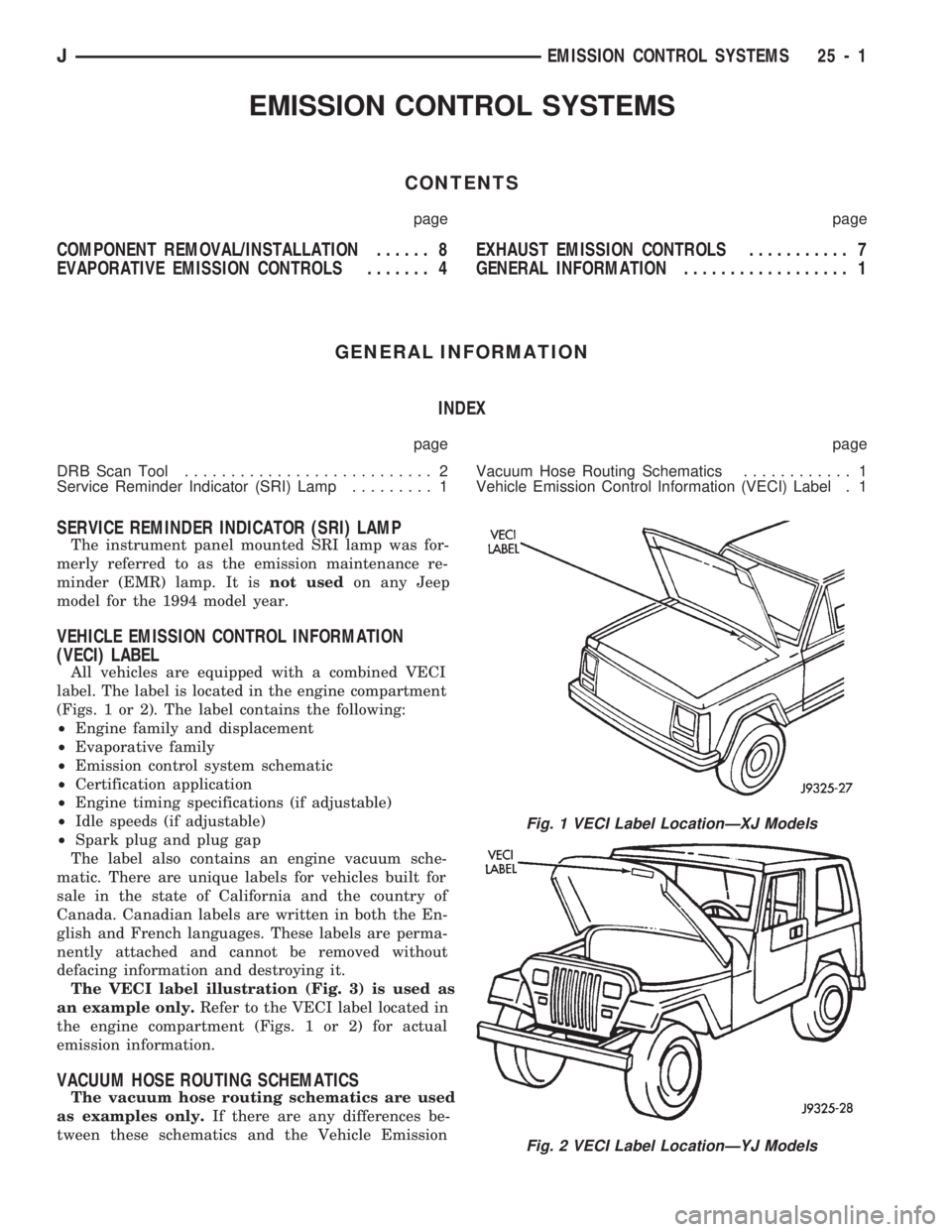

VEHICLE EMISSION CONTROL INFORMATION

(VECI) LABEL

All vehicles are equipped with a combined VECI

label. The label is located in the engine compartment

(Figs. 1 or 2). The label contains the following:

²Engine family and displacement

²Evaporative family

²Emission control system schematic

²Certification application

²Engine timing specifications (if adjustable)

²Idle speeds (if adjustable)

²Spark plug and plug gap

The label also contains an engine vacuum sche-

matic. There are unique labels for vehicles built for

sale in the state of California and the country of

Canada. Canadian labels are written in both the En-

glish and French languages. These labels are perma-

nently attached and cannot be removed without

defacing information and destroying it.

The VECI label illustration (Fig. 3) is used as

an example only.Refer to the VECI label located in

the engine compartment (Figs. 1 or 2) for actual

emission information.

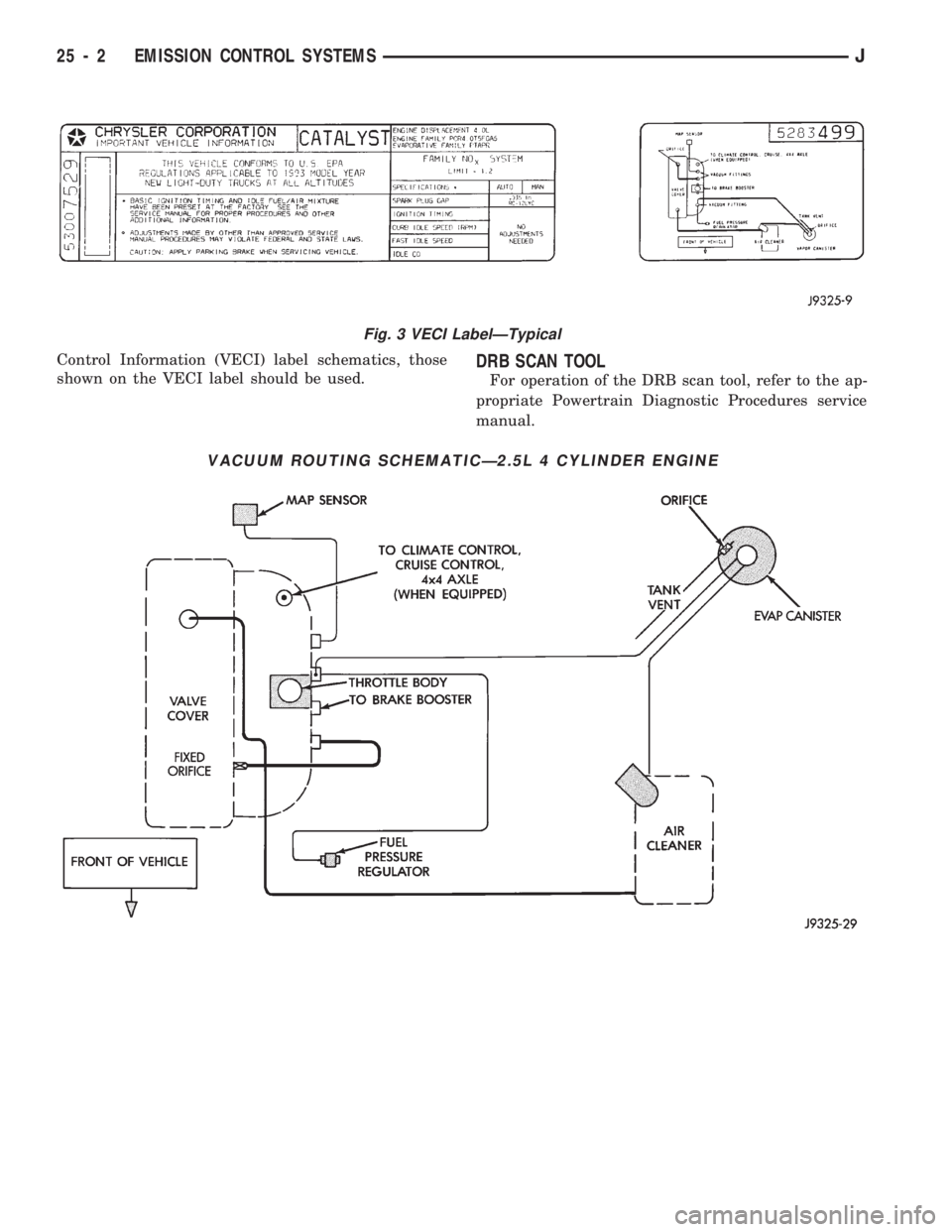

VACUUM HOSE ROUTING SCHEMATICS

The vacuum hose routing schematics are used

as examples only.If there are any differences be-

tween these schematics and the Vehicle Emission

Fig. 1 VECI Label LocationÐXJ Models

Fig. 2 VECI Label LocationÐYJ Models

JEMISSION CONTROL SYSTEMS 25 - 1

Page 1720 of 1784

Control Information (VECI) label schematics, those

shown on the VECI label should be used.DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

VACUUM ROUTING SCHEMATICÐ2.5L 4 CYLINDER ENGINE

Fig. 3 VECI LabelÐTypical

25 - 2 EMISSION CONTROL SYSTEMSJ