JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 281 of 1784

SPECIFICATIONS

IGNITION OFF DRAW (IOD) DIAGNOSIS

GENERAL INFORMATION

Ignition off draw refers to power being drained

from the battery with the ignition switch turned off.

A normal vehicle electrical system will draw from 5

to 20 milliamps. This is with the ignition switch in

the OFF position, and all non-ignition controlled cir-

cuits in proper working order. A vehicle that has not

been operated for approximately 20 days, may dis-

charge the battery to an inadequate level. Battery

drain should not exceed approximately 20 MA (20

milliamps = 0.020 amps).

The 20 MA are needed to supply PCM memory,

digital clock memory, and ETR (electronically tuned

radio) memory.

Excessive battery drain is caused by items left

turned on, internally shorted generator, or intermit-

tent short in wiring.

If the IOD is over 20 milliamperes, the defect must

be found and corrected before replacing a battery. In

most cases the battery can be charged and returned

to service.

When a vehicle will not be used for 20 days or

more (stored), remove IOD fuse in the Power Distri-

bution Center to reduce battery discharging.

TEST PROCEDURE

Testing for higher amperage IOD must be per-

formed first to prevent damage to most milliamp

meters.

(1) Verify that all electrical accessories are OFF.

Turn off all lamps, remove ignition key, and close all

doors. If the vehicle is equipped with electronic acces-

sories (illuminated entry, high line radio), allow the

systems to automatically shut off (time out), up to 3

minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect or remove bulb.

(3) Disconnect negative cable from battery.

(4) Connect a typical 12-volt test lamp (low watt-

age bulb) between the negative cable clamp and the

battery negative terminal. If equipped with security

alarm, cycle the key in the door to turn off the flash-ing lights. Make sure that the doors remain closed so

that illuminated entry is not activated.

The test lamp may light brightly for up to 3 min-

utes or may not light at all (depending on the elec-

trical equipment). The term brightly being used

throughout the following tests, implies the bright-

ness of the test lamp will be the same as if it were

connected across the battery.

The test lamp must be securely clamped to the neg-

ative cable and battery terminal. If the test lamp be-

comes disconnected during any part of the IOD test,

the electronic timer function will be activated and all

tests must be repeated.

If the ammeter circuit is broken the Security

Alarm Module will turn on parking lamps.

(5) After 3 minutes, the test lamp should turn OFF

or be DIMLY lit (depending on the electrical equip-

ment). If the test lamp remains brightly lit do not

disconnect it. Remove each fuse or circuit breaker

(refer to Group 8 - Wiring Diagrams) until test lamp

is either OFF or DIMLY lit. This will eliminate the

higher amperage draw.

If test lamp is still bright after disconnecting each

fuse and circuit breaker, disconnect the wiring har-

ness from the generator. Refer to Generator Test Pro-

cedures in this group. Do not disconnect the test

lamp.

After higher amperage IOD has been corrected, low

amperage IOD may be checked.

It is now safe to install milliamp meter to check for

low amperage IOD.

(6) With test lamp still connected securely, clamp

an ammeter between battery negative terminal and

negative battery cable.

Do not open any doors or turn on any electri-

cal accessories with the test lamp disconnected

or the meter may be damaged.

(7) Disconnect test lamp. The current draw should

not exceed 0.020 amp. If it exceeds 0.020 milliamps,

isolate each circuit by removing circuit breakers and

fuses. The meter reading drops once the high current

problem is found. Repair this section of the circuit,

whether it is a wiring short or component failure.

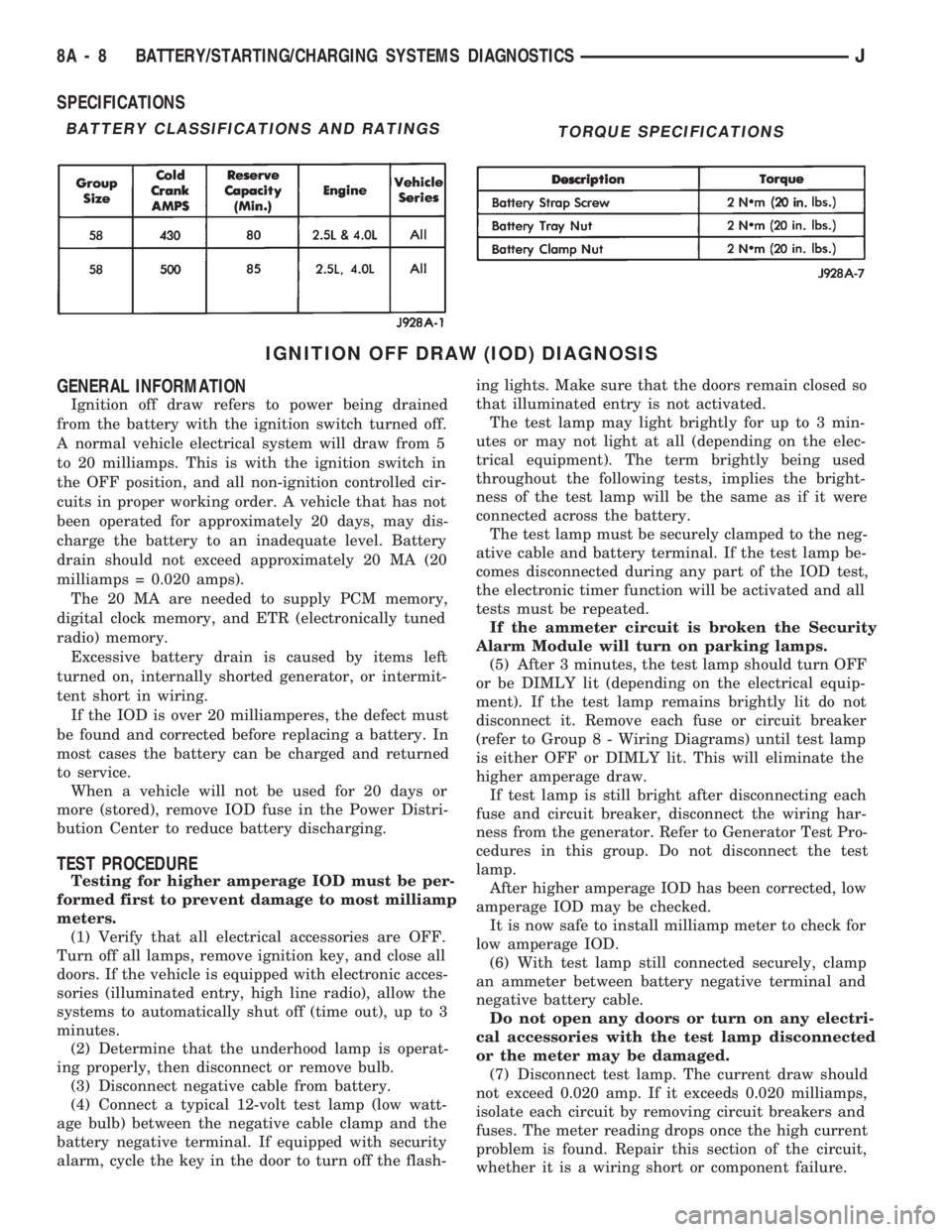

BATTERY CLASSIFICATIONS AND RATINGSTORQUE SPECIFICATIONS

8A - 8 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 282 of 1784

ENGINE STARTER MOTOR TEST PROCEDURES ON VEHICLE

INDEX

page page

2.5L Starter Motor Noise Diagnosis........... 13

General Information........................ 9

Starter Control Circuit Tests................ 11

Starter Feed Circuit Tests - (Voltage Drop Method).9

Starter System Diagnostic Inspections.......... 9

Starting System Cold Cranking Test........... 9

GENERAL INFORMATION

The starting system consists of an:

²ignition switch

²starter relay

²park/neutral position switch (automatic transmis-

sion)

²wiring harness

²battery

²starter motor with an integral solenoid.

These components form 2 separate circuits. A high

amperage circuit that feeds the starter motor up to

300+ amps, and a control circuit that operates on

less than 20 amps.

STARTER SYSTEM DIAGNOSTIC INSPECTIONS

Before removing any unit from the starter motor

system for repair, perform the following inspections:

BATTERY INSPECTION

To determine condition of the battery, perform the

testing procedure outlined in Battery Test Proce-

dures.

WIRING INSPECTION

Inspect wiring for damage. Inspect all connections

at the starter motor solenoid, park/neutral position

switch (if equipped), back-up lamp switch connector,

ignition switch, starter relay, and battery (including

all ground connections). Clean and tighten all con-

nections as required.

SOLENOID, RELAY AND IGNITION SWITCH

INSPECTION

Inspect the solenoid, relay and switch to determine

their condition. Also, if equipped with automatic

transmission, inspect condition of the park/neutral

position switch. Testing information can be found in

the following pages.

STARTING SYSTEM COLD CRANKING TEST

(1) Battery must first pass load and voltage drop

tests and be fully charged before proceeding. Refer to

Battery Test Procedures.(2) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). Refer to the operating in-

structions provided with the tester being used.

(3) Fully engage parking brake, place manual

transmission in NEUTRAL, automatic transmission

in PARK.

(4) Verify that all lamps and accessories are OFF.

(5) Remove coil secondary cable from distributor

and connect to ground.

(6) Rotate and hold the ignition switch in the

START position. Note cranking voltage and amper-

age.

(a) If voltage reads above 9.6 volts and amperage

draw reads above specifications, go to Starter Feed

Circuit Tests.

(b) If voltage reads 12.5 volts or greater and am-

perage reads below specifications, go to Starter

Control Circuit Tests.

A cold engine will increase starter motor cur-

rent and reduce battery voltage.

STARTER FEED CIRCUIT TESTS - (VOLTAGE DROP

METHOD)

The voltage drop tests will determine if there is ex-

cessive resistance in the high current circuit. When

performing these tests, it is important that the volt-

meter be connected to the terminals that the cables

are connected to, instead of to the cables themselves.

For example, when testing between the battery and

solenoid, touch the voltmeter test probes to the bat-

tery post and the solenoid threaded stud. The follow-

ing operation will require a voltmeter, accurate to

1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

²remove coil secondary cable from distributor and

connect to ground

²transmission in NEUTRAL (manual transmission)

or PARK (automatic transmission)

²parking brake applied

²battery is fully charged (refer to Battery Test Pro-

cedures).

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 9

Page 283 of 1784

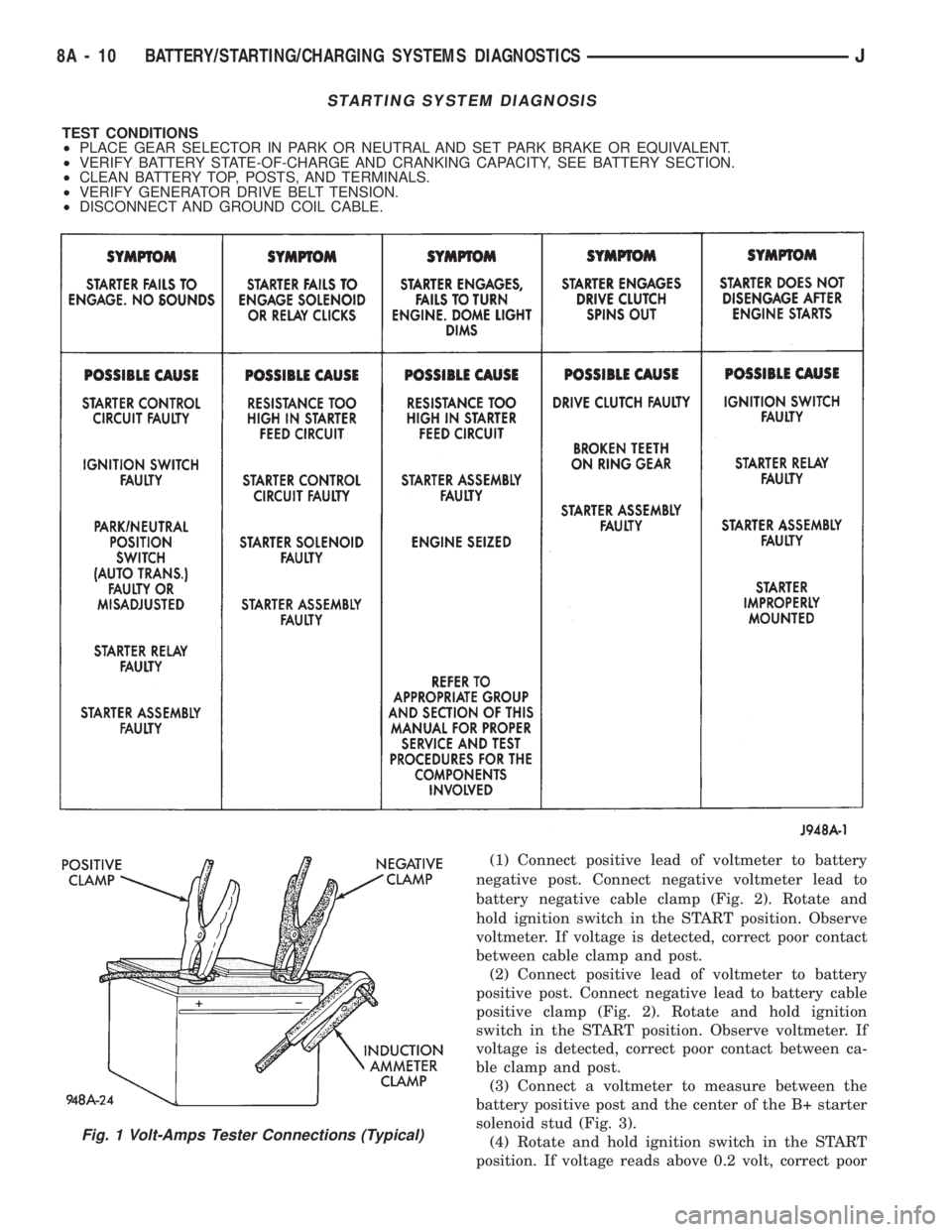

(1) Connect positive lead of voltmeter to battery

negative post. Connect negative voltmeter lead to

battery negative cable clamp (Fig. 2). Rotate and

hold ignition switch in the START position. Observe

voltmeter. If voltage is detected, correct poor contact

between cable clamp and post.

(2) Connect positive lead of voltmeter to battery

positive post. Connect negative lead to battery cable

positive clamp (Fig. 2). Rotate and hold ignition

switch in the START position. Observe voltmeter. If

voltage is detected, correct poor contact between ca-

ble clamp and post.

(3) Connect a voltmeter to measure between the

battery positive post and the center of the B+ starter

solenoid stud (Fig. 3).

(4) Rotate and hold ignition switch in the START

position. If voltage reads above 0.2 volt, correct poor

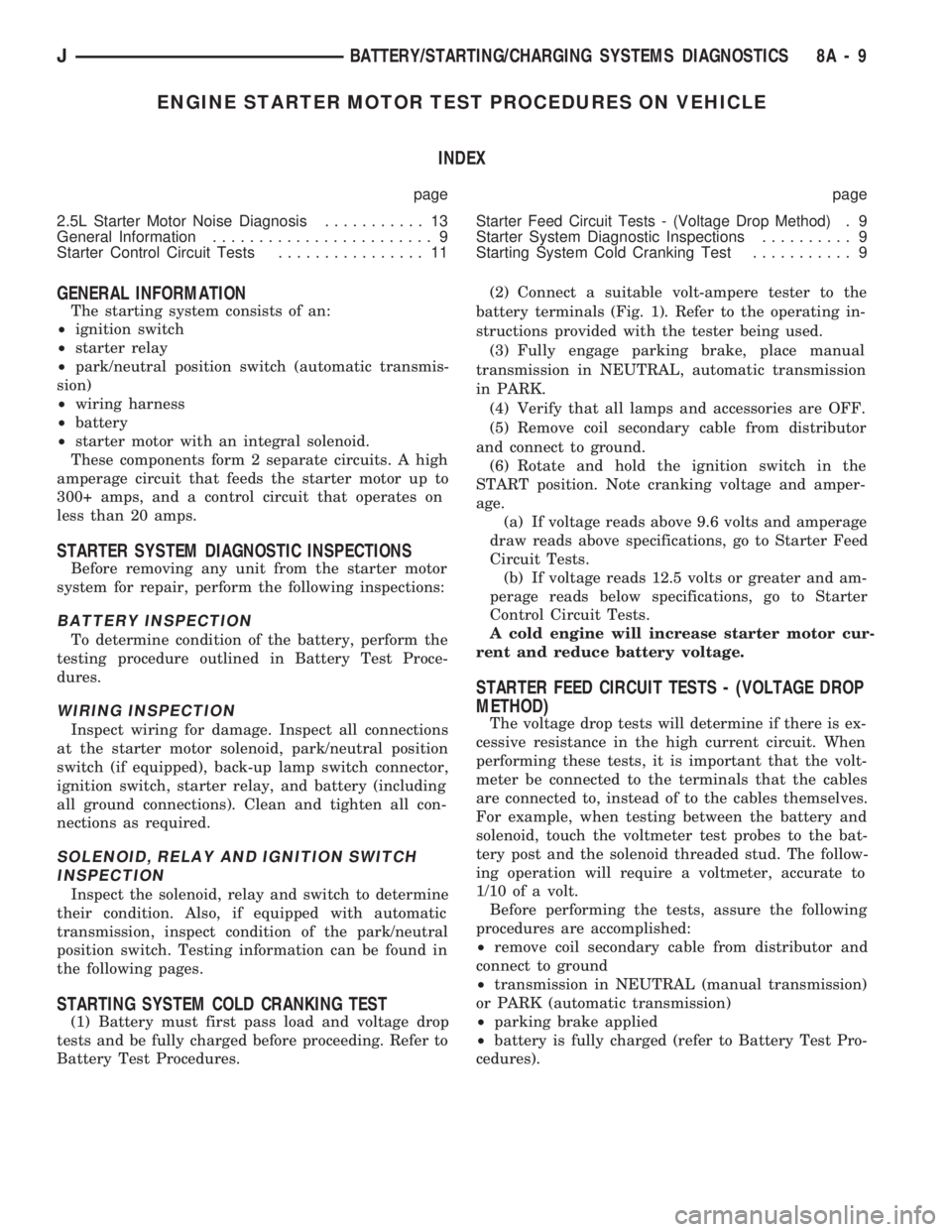

STARTING SYSTEM DIAGNOSIS

TEST CONDITIONS

²PLACE GEAR SELECTOR IN PARK OR NEUTRAL AND SET PARK BRAKE OR EQUIVALENT.

²VERIFY BATTERY STATE-OF-CHARGE AND CRANKING CAPACITY, SEE BATTERY SECTION.

²CLEAN BATTERY TOP, POSTS, AND TERMINALS.

²VERIFY GENERATOR DRIVE BELT TENSION.

²DISCONNECT AND GROUND COIL CABLE.

Fig. 1 Volt-Amps Tester Connections (Typical)

8A - 10 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 284 of 1784

contact at battery cable to solenoid connection. If

reading is still above 0.2 volt, replace positive bat-

tery cable.

(5) Connect voltmeter to measure between the bat-

tery negative post and the engine block (Fig. 4).

(6) Rotate and hold ignition switch in the START po-

sition. If voltage reads above 0.2 volt, correct poor con-tact at ground cable attaching point. Voltage reading

still above 0.2 volt, replace ground cable.

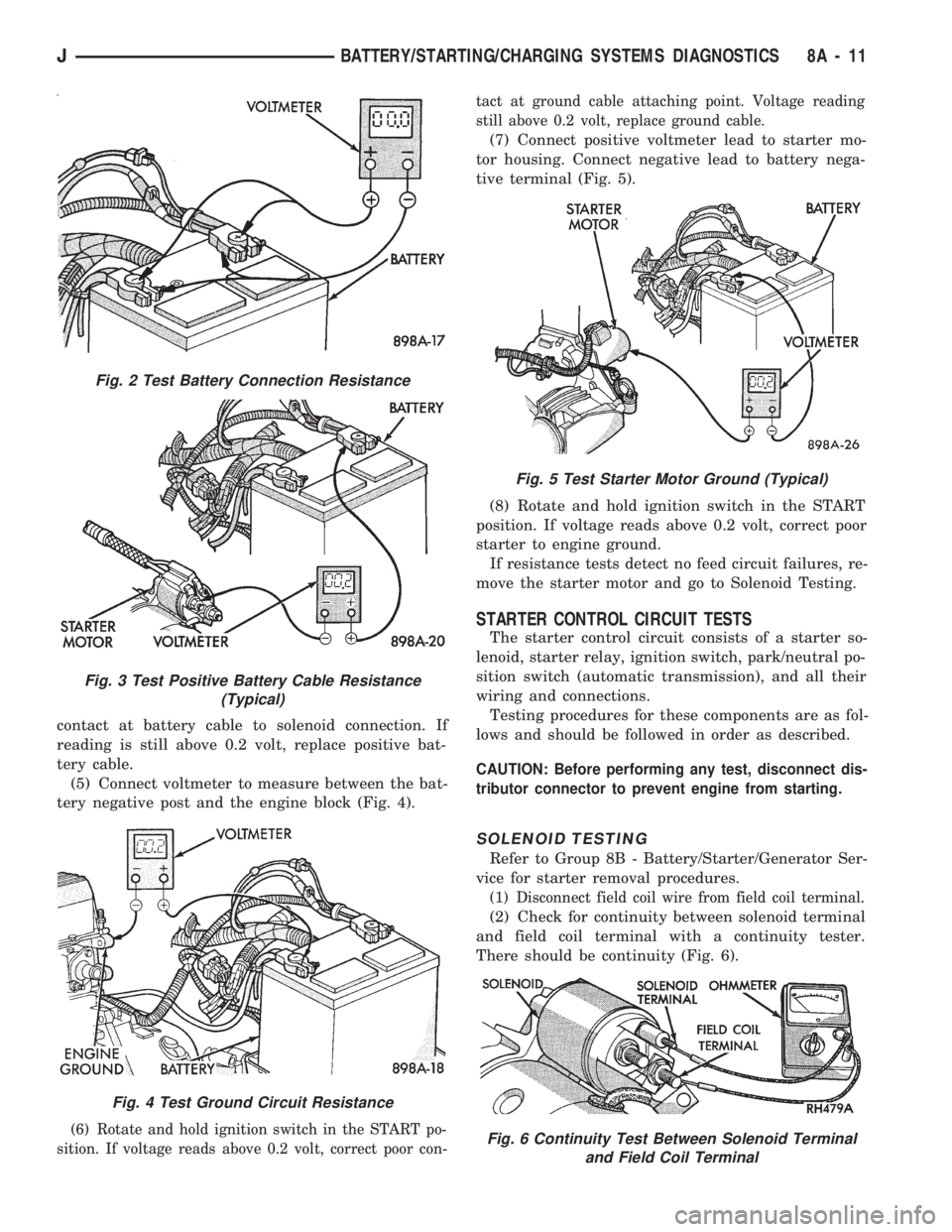

(7) Connect positive voltmeter lead to starter mo-

tor housing. Connect negative lead to battery nega-

tive terminal (Fig. 5).

(8) Rotate and hold ignition switch in the START

position. If voltage reads above 0.2 volt, correct poor

starter to engine ground.

If resistance tests detect no feed circuit failures, re-

move the starter motor and go to Solenoid Testing.

STARTER CONTROL CIRCUIT TESTS

The starter control circuit consists of a starter so-

lenoid, starter relay, ignition switch, park/neutral po-

sition switch (automatic transmission), and all their

wiring and connections.

Testing procedures for these components are as fol-

lows and should be followed in order as described.

CAUTION: Before performing any test, disconnect dis-

tributor connector to prevent engine from starting.

SOLENOID TESTING

Refer to Group 8B - Battery/Starter/Generator Ser-

vice for starter removal procedures.

(1) Disconnect field coil wire from field coil terminal.

(2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester.

There should be continuity (Fig. 6).

Fig. 2 Test Battery Connection Resistance

Fig. 3 Test Positive Battery Cable Resistance

(Typical)

Fig. 4 Test Ground Circuit Resistance

Fig. 5 Test Starter Motor Ground (Typical)

Fig. 6 Continuity Test Between Solenoid Terminal

and Field Coil Terminal

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 11

Page 285 of 1784

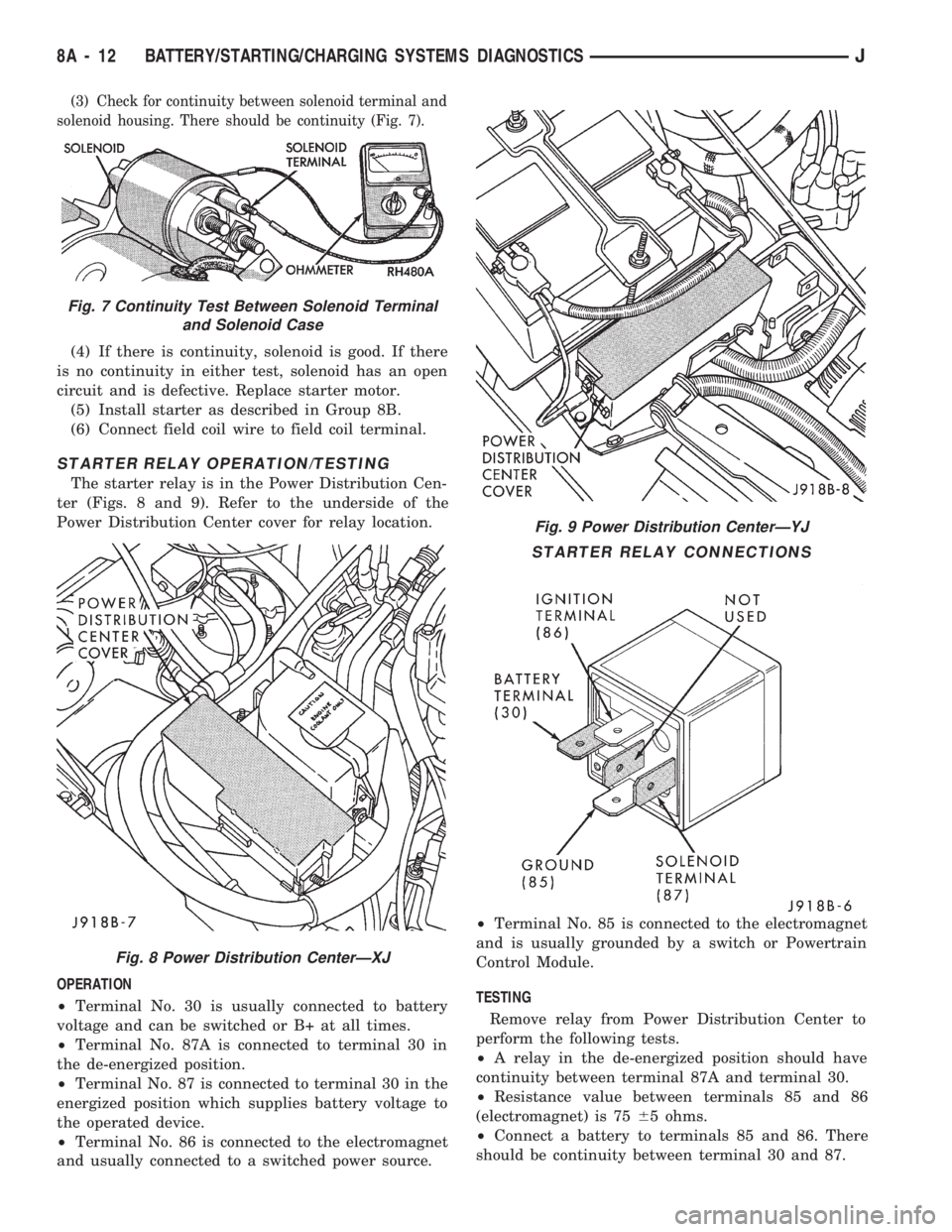

(3) Check for continuity between solenoid terminal and

solenoid housing. There should be continuity (Fig. 7).

(4) If there is continuity, solenoid is good. If there

is no continuity in either test, solenoid has an open

circuit and is defective. Replace starter motor.

(5) Install starter as described in Group 8B.

(6) Connect field coil wire to field coil terminal.

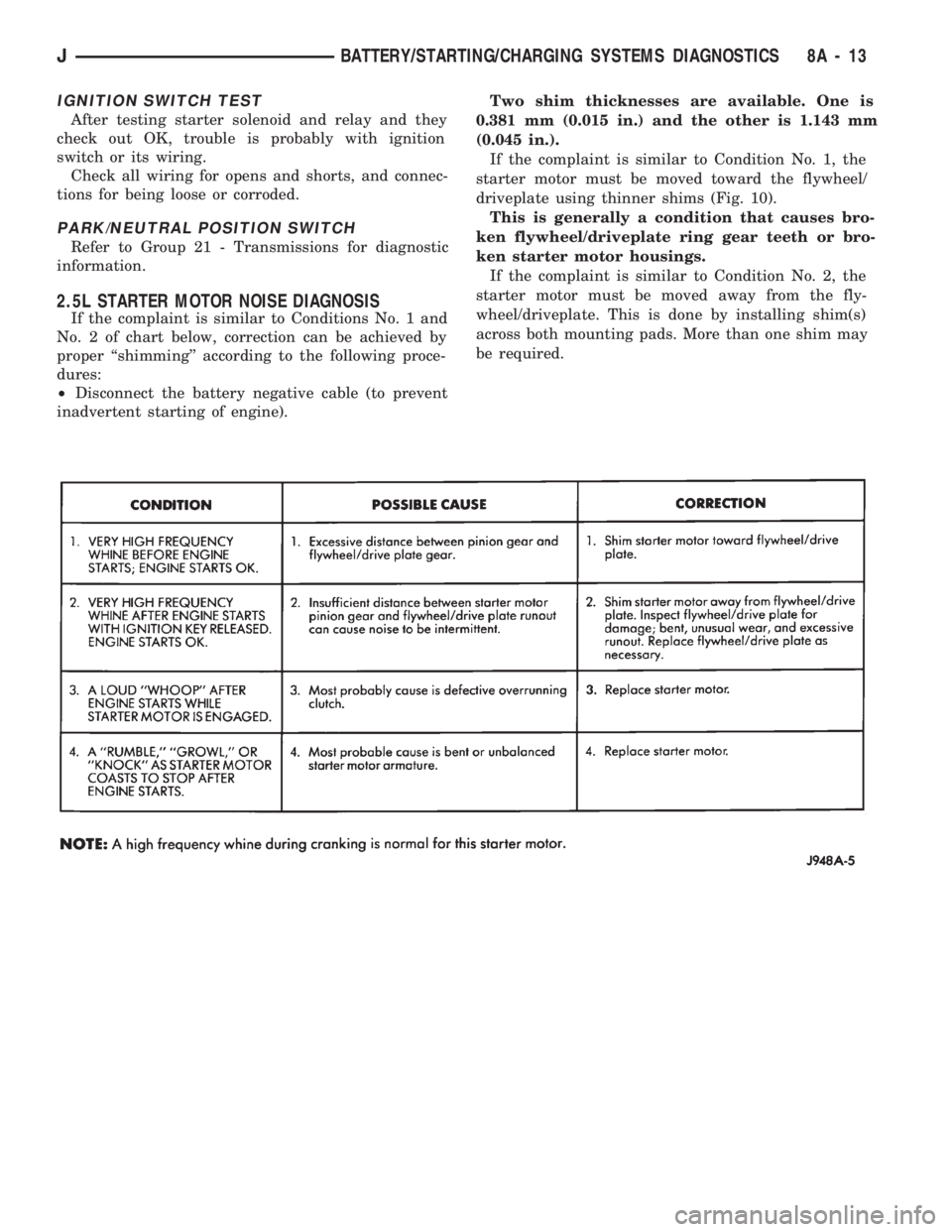

STARTER RELAY OPERATION/TESTING

The starter relay is in the Power Distribution Cen-

ter (Figs. 8 and 9). Refer to the underside of the

Power Distribution Center cover for relay location.

OPERATION

²Terminal No. 30 is usually connected to battery

voltage and can be switched or B+ at all times.

²Terminal No. 87A is connected to terminal 30 in

the de-energized position.

²Terminal No. 87 is connected to terminal 30 in the

energized position which supplies battery voltage to

the operated device.

²Terminal No. 86 is connected to the electromagnet

and usually connected to a switched power source.²Terminal No. 85 is connected to the electromagnet

and is usually grounded by a switch or Powertrain

Control Module.

TESTING

Remove relay from Power Distribution Center to

perform the following tests.

²A relay in the de-energized position should have

continuity between terminal 87A and terminal 30.

²Resistance value between terminals 85 and 86

(electromagnet) is 7565 ohms.

²Connect a battery to terminals 85 and 86. There

should be continuity between terminal 30 and 87.

Fig. 9 Power Distribution CenterÐYJ

STARTER RELAY CONNECTIONS

Fig. 7 Continuity Test Between Solenoid Terminal

and Solenoid Case

Fig. 8 Power Distribution CenterÐXJ

8A - 12 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 286 of 1784

IGNITION SWITCH TEST

After testing starter solenoid and relay and they

check out OK, trouble is probably with ignition

switch or its wiring.

Check all wiring for opens and shorts, and connec-

tions for being loose or corroded.

PARK/NEUTRAL POSITION SWITCH

Refer to Group 21 - Transmissions for diagnostic

information.

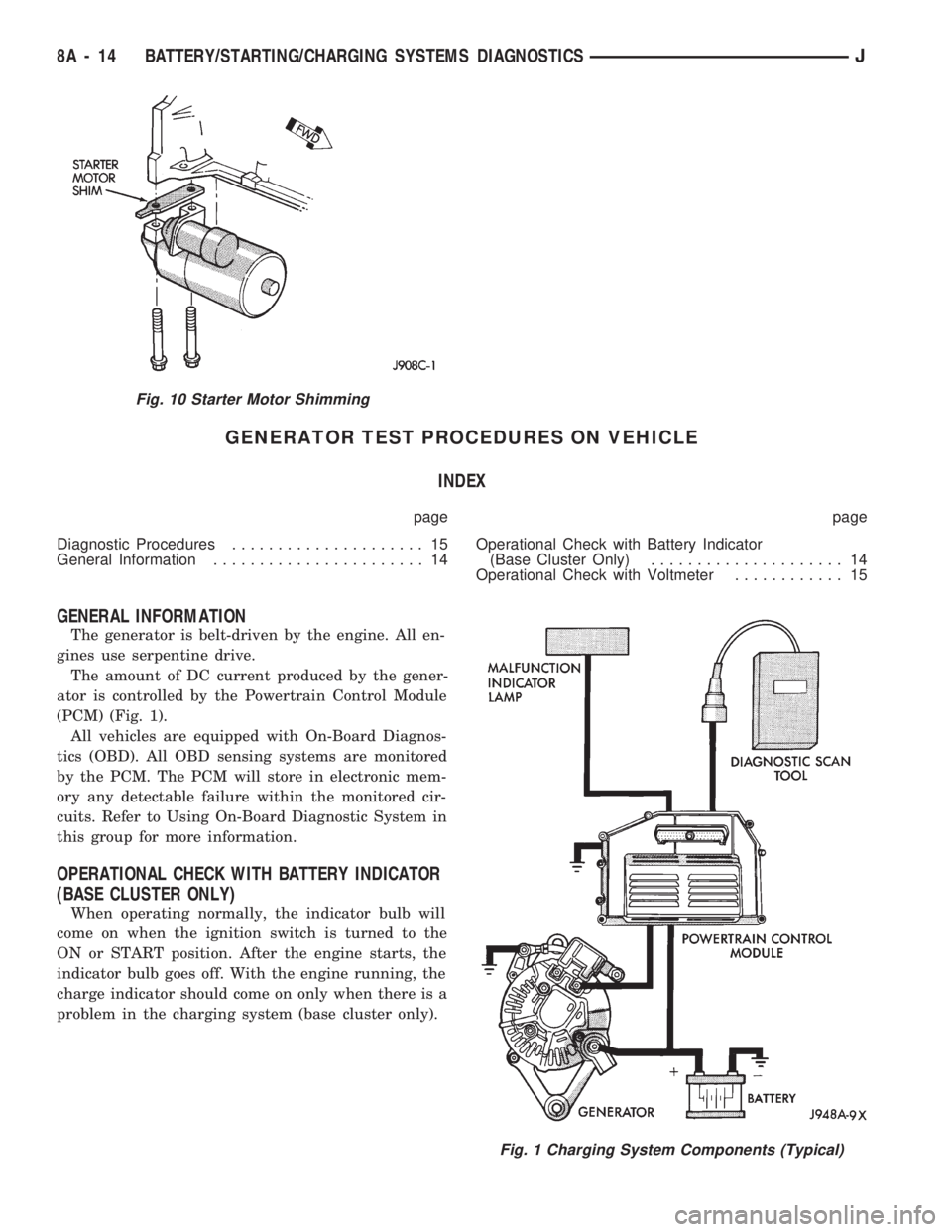

2.5L STARTER MOTOR NOISE DIAGNOSIS

If the complaint is similar to Conditions No. 1 and

No. 2 of chart below, correction can be achieved by

proper ``shimming'' according to the following proce-

dures:

²Disconnect the battery negative cable (to prevent

inadvertent starting of engine).Two shim thicknesses are available. One is

0.381 mm (0.015 in.) and the other is 1.143 mm

(0.045 in.).

If the complaint is similar to Condition No. 1, the

starter motor must be moved toward the flywheel/

driveplate using thinner shims (Fig. 10).

This is generally a condition that causes bro-

ken flywheel/driveplate ring gear teeth or bro-

ken starter motor housings.

If the complaint is similar to Condition No. 2, the

starter motor must be moved away from the fly-

wheel/driveplate. This is done by installing shim(s)

across both mounting pads. More than one shim may

be required.

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 13

Page 287 of 1784

GENERATOR TEST PROCEDURES ON VEHICLE

INDEX

page page

Diagnostic Procedures..................... 15

General Information....................... 14Operational Check with Battery Indicator

(Base Cluster Only)..................... 14

Operational Check with Voltmeter............ 15

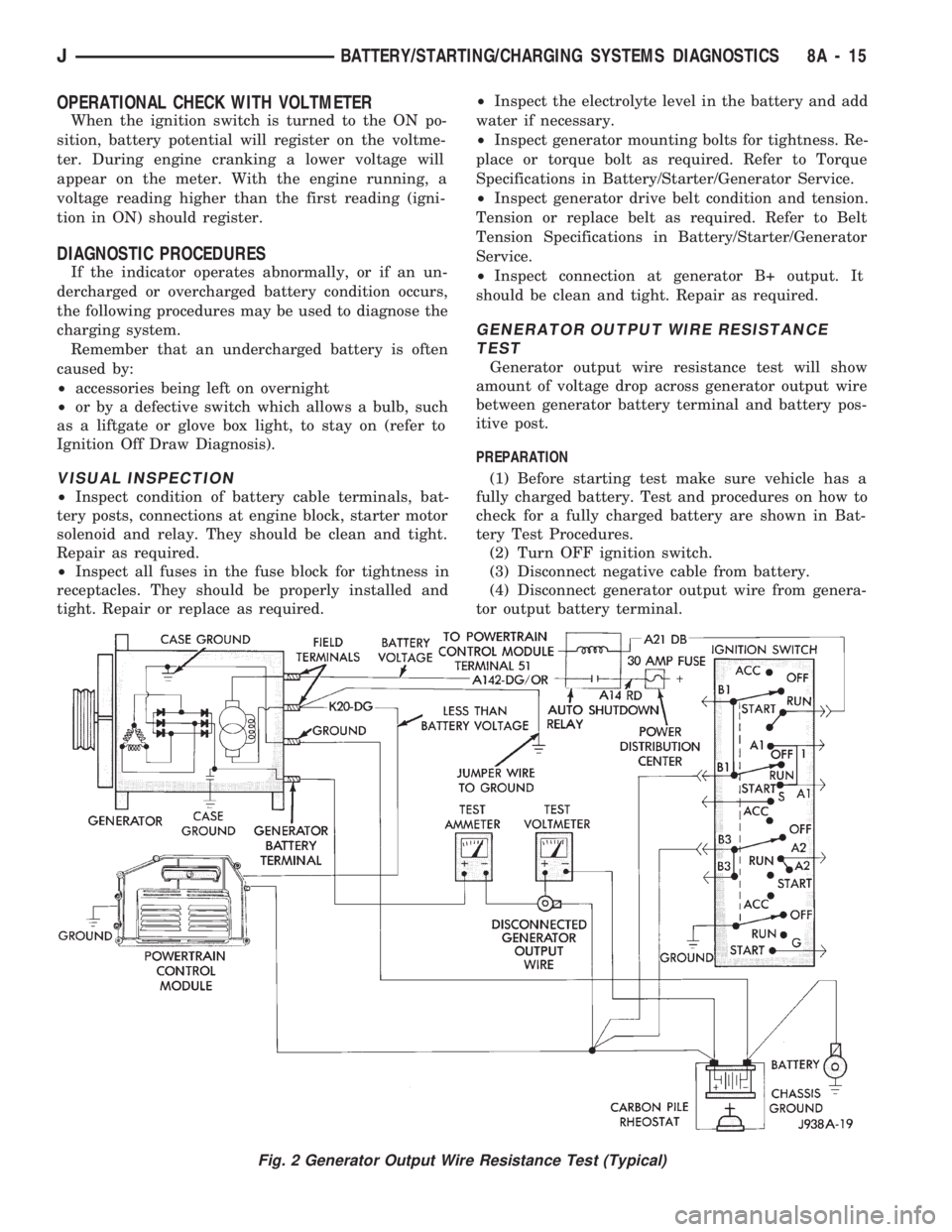

GENERAL INFORMATION

The generator is belt-driven by the engine. All en-

gines use serpentine drive.

The amount of DC current produced by the gener-

ator is controlled by the Powertrain Control Module

(PCM) (Fig. 1).

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD sensing systems are monitored

by the PCM. The PCM will store in electronic mem-

ory any detectable failure within the monitored cir-

cuits. Refer to Using On-Board Diagnostic System in

this group for more information.

OPERATIONAL CHECK WITH BATTERY INDICATOR

(BASE CLUSTER ONLY)

When operating normally, the indicator bulb will

come on when the ignition switch is turned to the

ON or START position. After the engine starts, the

indicator bulb goes off. With the engine running, the

charge indicator should come on only when there is a

problem in the charging system (base cluster only).

Fig. 10 Starter Motor Shimming

Fig. 1 Charging System Components (Typical)

8A - 14 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 288 of 1784

OPERATIONAL CHECK WITH VOLTMETER

When the ignition switch is turned to the ON po-

sition, battery potential will register on the voltme-

ter. During engine cranking a lower voltage will

appear on the meter. With the engine running, a

voltage reading higher than the first reading (igni-

tion in ON) should register.

DIAGNOSTIC PROCEDURES

If the indicator operates abnormally, or if an un-

dercharged or overcharged battery condition occurs,

the following procedures may be used to diagnose the

charging system.

Remember that an undercharged battery is often

caused by:

²accessories being left on overnight

²or by a defective switch which allows a bulb, such

as a liftgate or glove box light, to stay on (refer to

Ignition Off Draw Diagnosis).

VISUAL INSPECTION

²Inspect condition of battery cable terminals, bat-

tery posts, connections at engine block, starter motor

solenoid and relay. They should be clean and tight.

Repair as required.

²Inspect all fuses in the fuse block for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.²Inspect the electrolyte level in the battery and add

water if necessary.

²Inspect generator mounting bolts for tightness. Re-

place or torque bolt as required. Refer to Torque

Specifications in Battery/Starter/Generator Service.

²Inspect generator drive belt condition and tension.

Tension or replace belt as required. Refer to Belt

Tension Specifications in Battery/Starter/Generator

Service.

²Inspect connection at generator B+ output. It

should be clean and tight. Repair as required.

GENERATOR OUTPUT WIRE RESISTANCE

TEST

Generator output wire resistance test will show

amount of voltage drop across generator output wire

between generator battery terminal and battery pos-

itive post.

PREPARATION

(1) Before starting test make sure vehicle has a

fully charged battery. Test and procedures on how to

check for a fully charged battery are shown in Bat-

tery Test Procedures.

(2) Turn OFF ignition switch.

(3) Disconnect negative cable from battery.

(4) Disconnect generator output wire from genera-

tor output battery terminal.

Fig. 2 Generator Output Wire Resistance Test (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 15

Page 289 of 1784

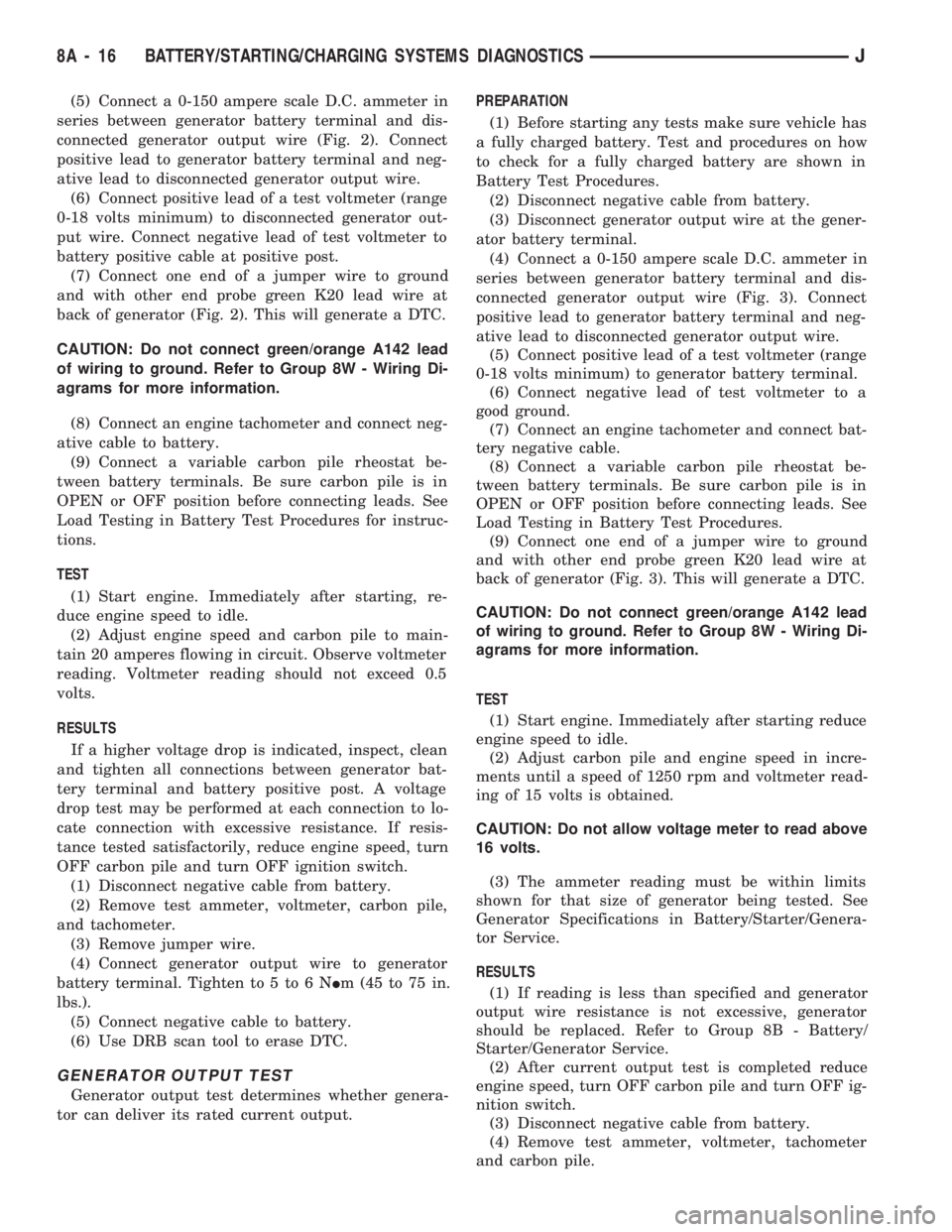

(5) Connect a 0-150 ampere scale D.C. ammeter in

series between generator battery terminal and dis-

connected generator output wire (Fig. 2). Connect

positive lead to generator battery terminal and neg-

ative lead to disconnected generator output wire.

(6) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to disconnected generator out-

put wire. Connect negative lead of test voltmeter to

battery positive cable at positive post.

(7) Connect one end of a jumper wire to ground

and with other end probe green K20 lead wire at

back of generator (Fig. 2). This will generate a DTC.

CAUTION: Do not connect green/orange A142 lead

of wiring to ground. Refer to Group 8W - Wiring Di-

agrams for more information.

(8) Connect an engine tachometer and connect neg-

ative cable to battery.

(9) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Testing in Battery Test Procedures for instruc-

tions.

TEST

(1) Start engine. Immediately after starting, re-

duce engine speed to idle.

(2) Adjust engine speed and carbon pile to main-

tain 20 amperes flowing in circuit. Observe voltmeter

reading. Voltmeter reading should not exceed 0.5

volts.

RESULTS

If a higher voltage drop is indicated, inspect, clean

and tighten all connections between generator bat-

tery terminal and battery positive post. A voltage

drop test may be performed at each connection to lo-

cate connection with excessive resistance. If resis-

tance tested satisfactorily, reduce engine speed, turn

OFF carbon pile and turn OFF ignition switch.

(1) Disconnect negative cable from battery.

(2) Remove test ammeter, voltmeter, carbon pile,

and tachometer.

(3) Remove jumper wire.

(4) Connect generator output wire to generator

battery terminal. Tighten to 5 to 6 NIm (45 to 75 in.

lbs.).

(5) Connect negative cable to battery.

(6) Use DRB scan tool to erase DTC.

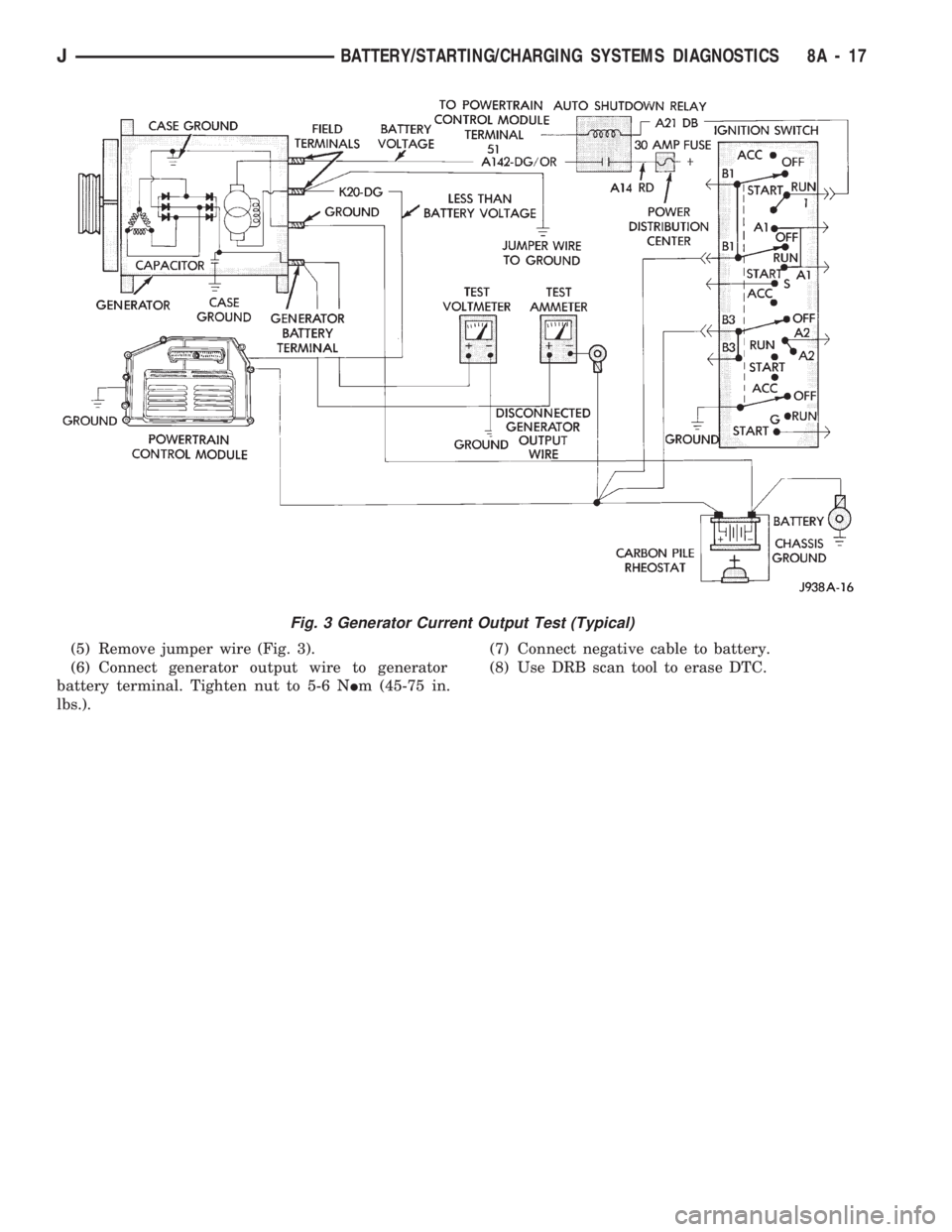

GENERATOR OUTPUT TEST

Generator output test determines whether genera-

tor can deliver its rated current output.PREPARATION

(1) Before starting any tests make sure vehicle has

a fully charged battery. Test and procedures on how

to check for a fully charged battery are shown in

Battery Test Procedures.

(2) Disconnect negative cable from battery.

(3) Disconnect generator output wire at the gener-

ator battery terminal.

(4) Connect a 0-150 ampere scale D.C. ammeter in

series between generator battery terminal and dis-

connected generator output wire (Fig. 3). Connect

positive lead to generator battery terminal and neg-

ative lead to disconnected generator output wire.

(5) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to generator battery terminal.

(6) Connect negative lead of test voltmeter to a

good ground.

(7) Connect an engine tachometer and connect bat-

tery negative cable.

(8) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Testing in Battery Test Procedures.

(9) Connect one end of a jumper wire to ground

and with other end probe green K20 lead wire at

back of generator (Fig. 3). This will generate a DTC.

CAUTION: Do not connect green/orange A142 lead

of wiring to ground. Refer to Group 8W - Wiring Di-

agrams for more information.

TEST

(1) Start engine. Immediately after starting reduce

engine speed to idle.

(2) Adjust carbon pile and engine speed in incre-

ments until a speed of 1250 rpm and voltmeter read-

ing of 15 volts is obtained.

CAUTION: Do not allow voltage meter to read above

16 volts.

(3) The ammeter reading must be within limits

shown for that size of generator being tested. See

Generator Specifications in Battery/Starter/Genera-

tor Service.

RESULTS

(1) If reading is less than specified and generator

output wire resistance is not excessive, generator

should be replaced. Refer to Group 8B - Battery/

Starter/Generator Service.

(2) After current output test is completed reduce

engine speed, turn OFF carbon pile and turn OFF ig-

nition switch.

(3) Disconnect negative cable from battery.

(4) Remove test ammeter, voltmeter, tachometer

and carbon pile.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 290 of 1784

(5) Remove jumper wire (Fig. 3).

(6) Connect generator output wire to generator

battery terminal. Tighten nut to 5-6 NIm (45-75 in.

lbs.).(7) Connect negative cable to battery.

(8) Use DRB scan tool to erase DTC.

Fig. 3 Generator Current Output Test (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 17