JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 321 of 1784

DIAGNOSTICS/SERVICE PROCEDURES

INDEX

page page

Automatic Shut Down (ASD) Relay............ 8

Camshaft Position Sensor Test............... 8

Crankshaft Position Sensor Test.............. 9

Distributor Cap........................... 9

Distributor Rotor......................... 10

DRB Scan Tool.......................... 10

Engine Coolant Temperature Sensor Test...... 12

General Information........................ 8

Ignition Coil............................. 11

Ignition Secondary Circuit Diagnosis.......... 12Ignition Timing........................... 14

Intake Manifold Air Temperature Sensor Test . . . 14

Manifold Absolute Pressure (MAP) Sensor Test . 14

On-Board Diagnostics (OBD)................ 19

Oxygen Sensor Tests..................... 19

Powertrain Control Module (PCM)............ 15

Spark Plug Secondary Cables............... 17

Spark Plugs............................ 16

Throttle Position Sensor Test............... 18

GENERAL INFORMATION

This section of the group, Diagnostics/Service Pro-

cedures, will discuss basic ignition system diagnos-

tics and service adjustments.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

AUTOMATIC SHUT DOWN (ASD) RELAY

Refer to RelaysÐOperation/Testing in the Group

14, Fuel System section of this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor is located in the dis-

tributor on all engines.

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

2.5L OR 4.0L ENGINE

For this test, an analog voltmeter is needed.Do

not remove the distributor connector from the dis-

tributor. Using small paper clips, insert them into

the backside of the distributor wire harness connec-

tor to make contact with the terminals. Be sure that

the connector is not damaged when inserting the pa-

per clips. Attach voltmeter leads to these paper clips.

(1) Connect the positive (+) voltmeter lead into

the sensor output wire. This is at done the distribu-

tor wire harness connector. For wire identification,

refer to Group 8W, Wiring Diagrams.(2) Connect the negative (-) voltmeter lead into the

ground wire. For wire identification, refer to Group

8W, Wiring Diagrams.

(3) Set the voltmeter to the 15 Volt DC scale.

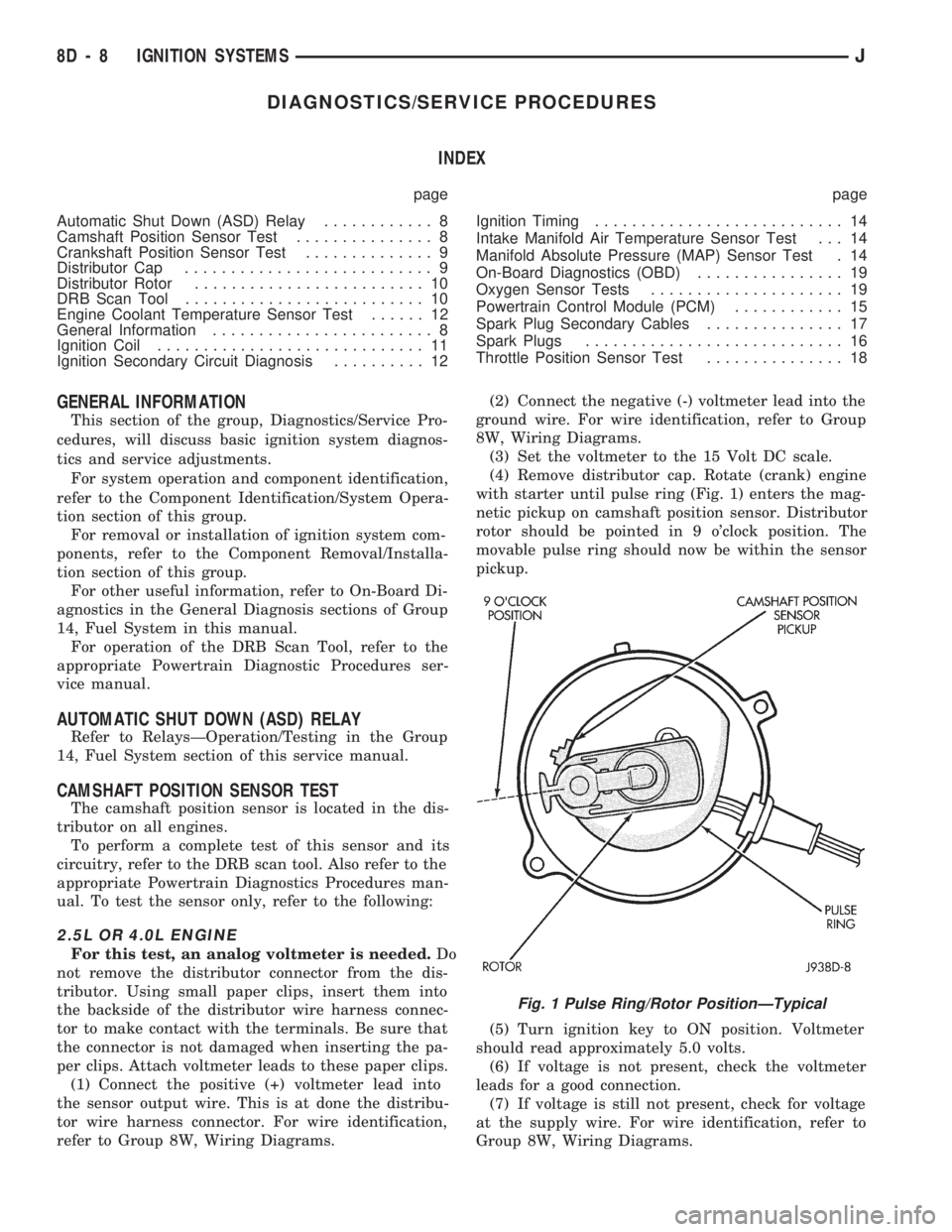

(4) Remove distributor cap. Rotate (crank) engine

with starter until pulse ring (Fig. 1) enters the mag-

netic pickup on camshaft position sensor. Distributor

rotor should be pointed in 9 o'clock position. The

movable pulse ring should now be within the sensor

pickup.

(5) Turn ignition key to ON position. Voltmeter

should read approximately 5.0 volts.

(6) If voltage is not present, check the voltmeter

leads for a good connection.

(7) If voltage is still not present, check for voltage

at the supply wire. For wire identification, refer to

Group 8W, Wiring Diagrams.

Fig. 1 Pulse Ring/Rotor PositionÐTypical

8D - 8 IGNITION SYSTEMSJ

Page 322 of 1784

(8) If voltage is not present at supply wire, check

for voltage at pin 7 of Powertrain Control Module

(PCM) 60-way connector. Leave the PCM connector

connected for this test.

(9) If voltage is still not present, perform vehicle

test using the DRB scan tool.

(10) If voltage is present at pin 7, but not at the

supply wire:

(a) Check continuity between the supply wire.

This is checked between the distributor connector

and pin 7 at the PCM. If continuity is not present,

repair the harness as necessary.

(b) Check for continuity between the camshaft

position sensor output wire and pin 44 at the PCM.

If continuity is not present, repair the harness as

necessary.

(c) Check for continuity between the ground cir-

cuit wire at the distributor connector and ground.

If continuity is not present, repair the harness as

necessary.

(11) While observing the voltmeter, crank the en-

gine with ignition switch. The voltmeter needle

should fluctuate between 0 and 5 volts while the en-

gine is cranking. This verifies that the camshaft po-

sition sensor in the distributor is operating properly

and a sync pulse signal is being generated.

If sync pulse signal is not present, replacement of

the camshaft position sensor is necessary.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

CRANKSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

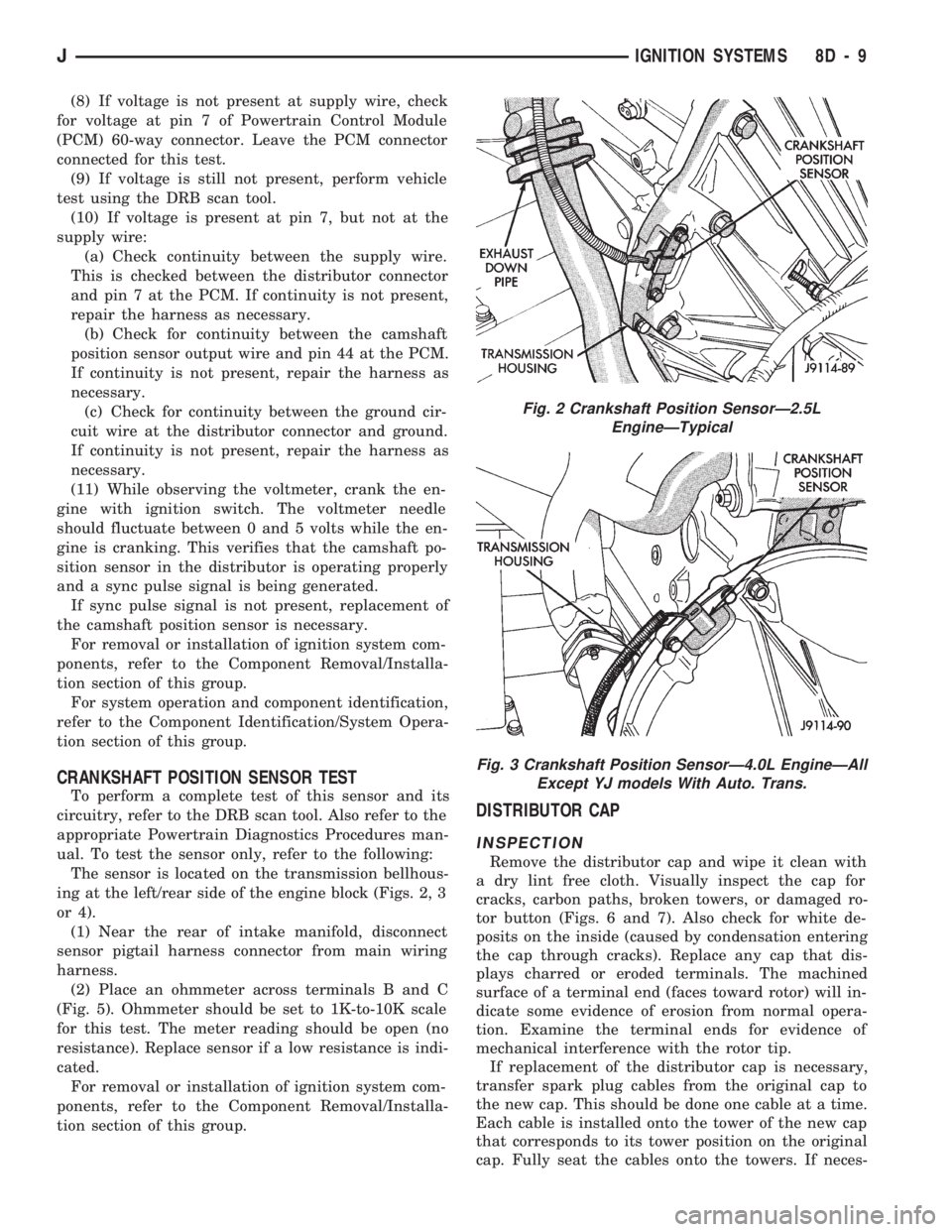

The sensor is located on the transmission bellhous-

ing at the left/rear side of the engine block (Figs. 2, 3

or 4).

(1) Near the rear of intake manifold, disconnect

sensor pigtail harness connector from main wiring

harness.

(2) Place an ohmmeter across terminals B and C

(Fig. 5). Ohmmeter should be set to 1K-to-10K scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi-

cated.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

DISTRIBUTOR CAP

INSPECTION

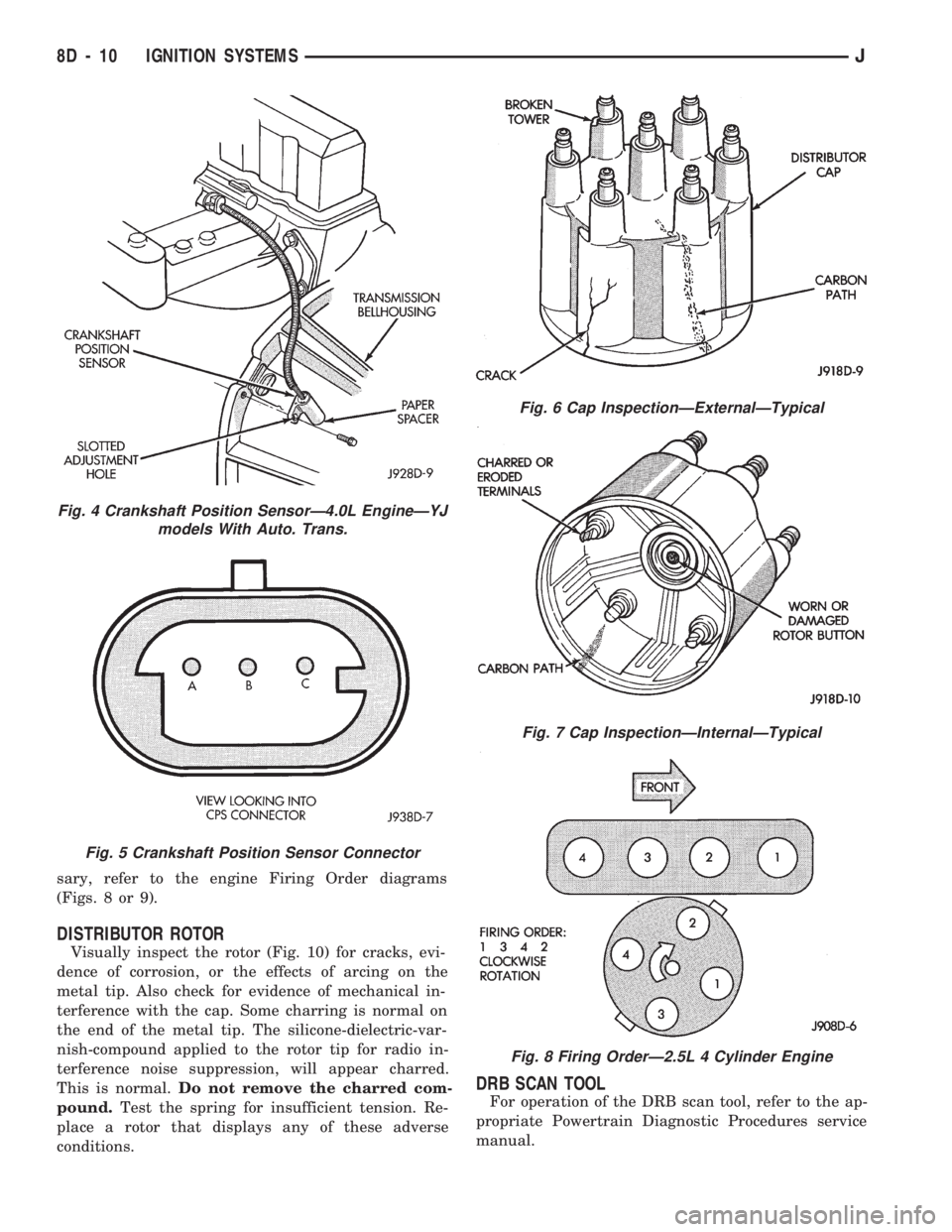

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers, or damaged ro-

tor button (Figs. 6 and 7). Also check for white de-

posits on the inside (caused by condensation entering

the cap through cracks). Replace any cap that dis-

plays charred or eroded terminals. The machined

surface of a terminal end (faces toward rotor) will in-

dicate some evidence of erosion from normal opera-

tion. Examine the terminal ends for evidence of

mechanical interference with the rotor tip.

If replacement of the distributor cap is necessary,

transfer spark plug cables from the original cap to

the new cap. This should be done one cable at a time.

Each cable is installed onto the tower of the new cap

that corresponds to its tower position on the original

cap. Fully seat the cables onto the towers. If neces-

Fig. 2 Crankshaft Position SensorÐ2.5L

EngineÐTypical

Fig. 3 Crankshaft Position SensorÐ4.0L EngineÐAll

Except YJ models With Auto. Trans.

JIGNITION SYSTEMS 8D - 9

Page 323 of 1784

sary, refer to the engine Firing Order diagrams

(Figs. 8 or 9).

DISTRIBUTOR ROTOR

Visually inspect the rotor (Fig. 10) for cracks, evi-

dence of corrosion, or the effects of arcing on the

metal tip. Also check for evidence of mechanical in-

terference with the cap. Some charring is normal on

the end of the metal tip. The silicone-dielectric-var-

nish-compound applied to the rotor tip for radio in-

terference noise suppression, will appear charred.

This is normal.Do not remove the charred com-

pound.Test the spring for insufficient tension. Re-

place a rotor that displays any of these adverse

conditions.

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

Fig. 4 Crankshaft Position SensorÐ4.0L EngineÐYJ

models With Auto. Trans.

Fig. 5 Crankshaft Position Sensor Connector

Fig. 6 Cap InspectionÐExternalÐTypical

Fig. 7 Cap InspectionÐInternalÐTypical

Fig. 8 Firing OrderÐ2.5L 4 Cylinder Engine

8D - 10 IGNITION SYSTEMSJ

Page 324 of 1784

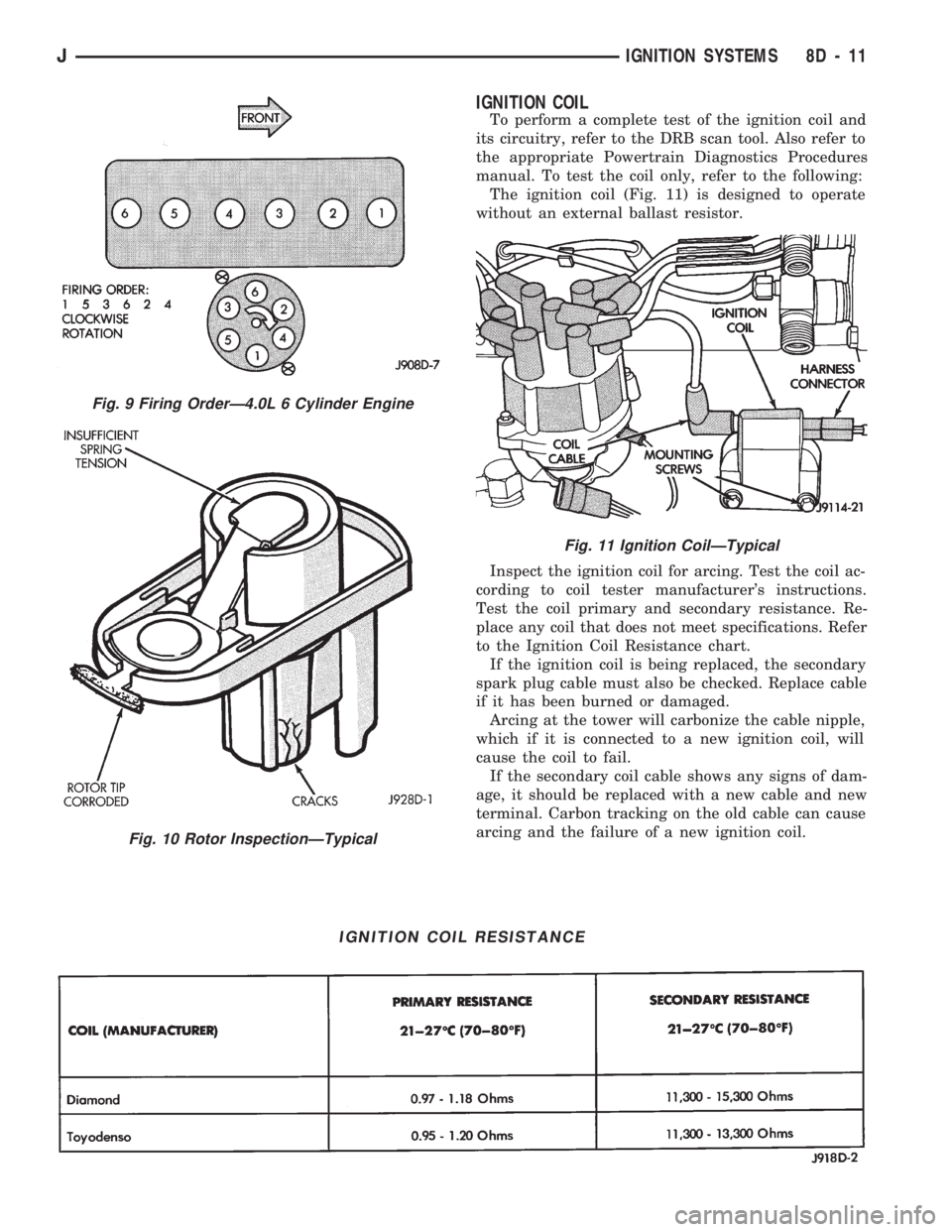

IGNITION COIL

To perform a complete test of the ignition coil and

its circuitry, refer to the DRB scan tool. Also refer to

the appropriate Powertrain Diagnostics Procedures

manual. To test the coil only, refer to the following:

The ignition coil (Fig. 11) is designed to operate

without an external ballast resistor.

Inspect the ignition coil for arcing. Test the coil ac-

cording to coil tester manufacturer's instructions.

Test the coil primary and secondary resistance. Re-

place any coil that does not meet specifications. Refer

to the Ignition Coil Resistance chart.

If the ignition coil is being replaced, the secondary

spark plug cable must also be checked. Replace cable

if it has been burned or damaged.

Arcing at the tower will carbonize the cable nipple,

which if it is connected to a new ignition coil, will

cause the coil to fail.

If the secondary coil cable shows any signs of dam-

age, it should be replaced with a new cable and new

terminal. Carbon tracking on the old cable can cause

arcing and the failure of a new ignition coil.

IGNITION COIL RESISTANCE

Fig. 9 Firing OrderÐ4.0L 6 Cylinder Engine

Fig. 10 Rotor InspectionÐTypical

Fig. 11 Ignition CoilÐTypical

JIGNITION SYSTEMS 8D - 11

Page 325 of 1784

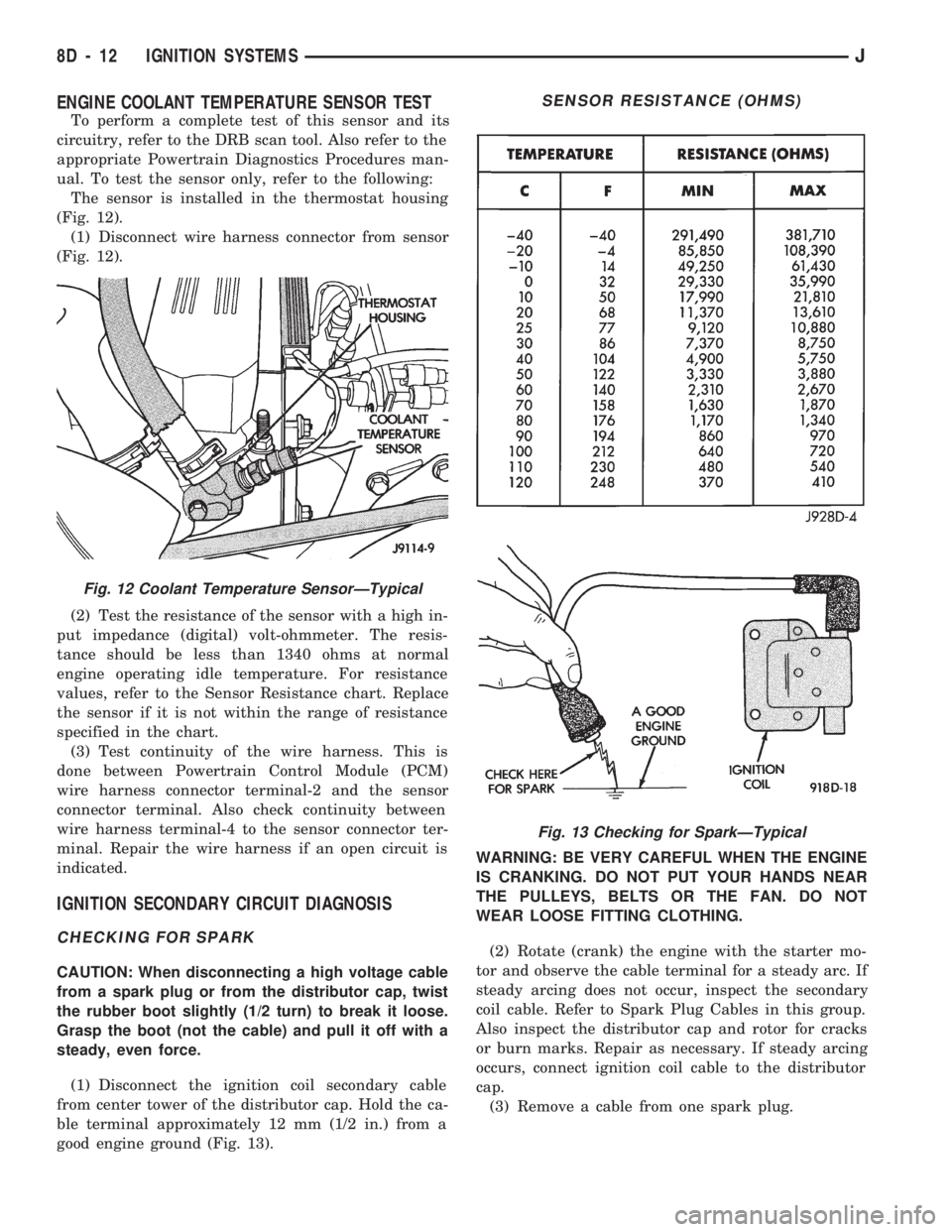

ENGINE COOLANT TEMPERATURE SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The sensor is installed in the thermostat housing

(Fig. 12).

(1) Disconnect wire harness connector from sensor

(Fig. 12).

(2) Test the resistance of the sensor with a high in-

put impedance (digital) volt-ohmmeter. The resis-

tance should be less than 1340 ohms at normal

engine operating idle temperature. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance

specified in the chart.

(3) Test continuity of the wire harness. This is

done between Powertrain Control Module (PCM)

wire harness connector terminal-2 and the sensor

connector terminal. Also check continuity between

wire harness terminal-4 to the sensor connector ter-

minal. Repair the wire harness if an open circuit is

indicated.

IGNITION SECONDARY CIRCUIT DIAGNOSIS

CHECKING FOR SPARK

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose.

Grasp the boot (not the cable) and pull it off with a

steady, even force.

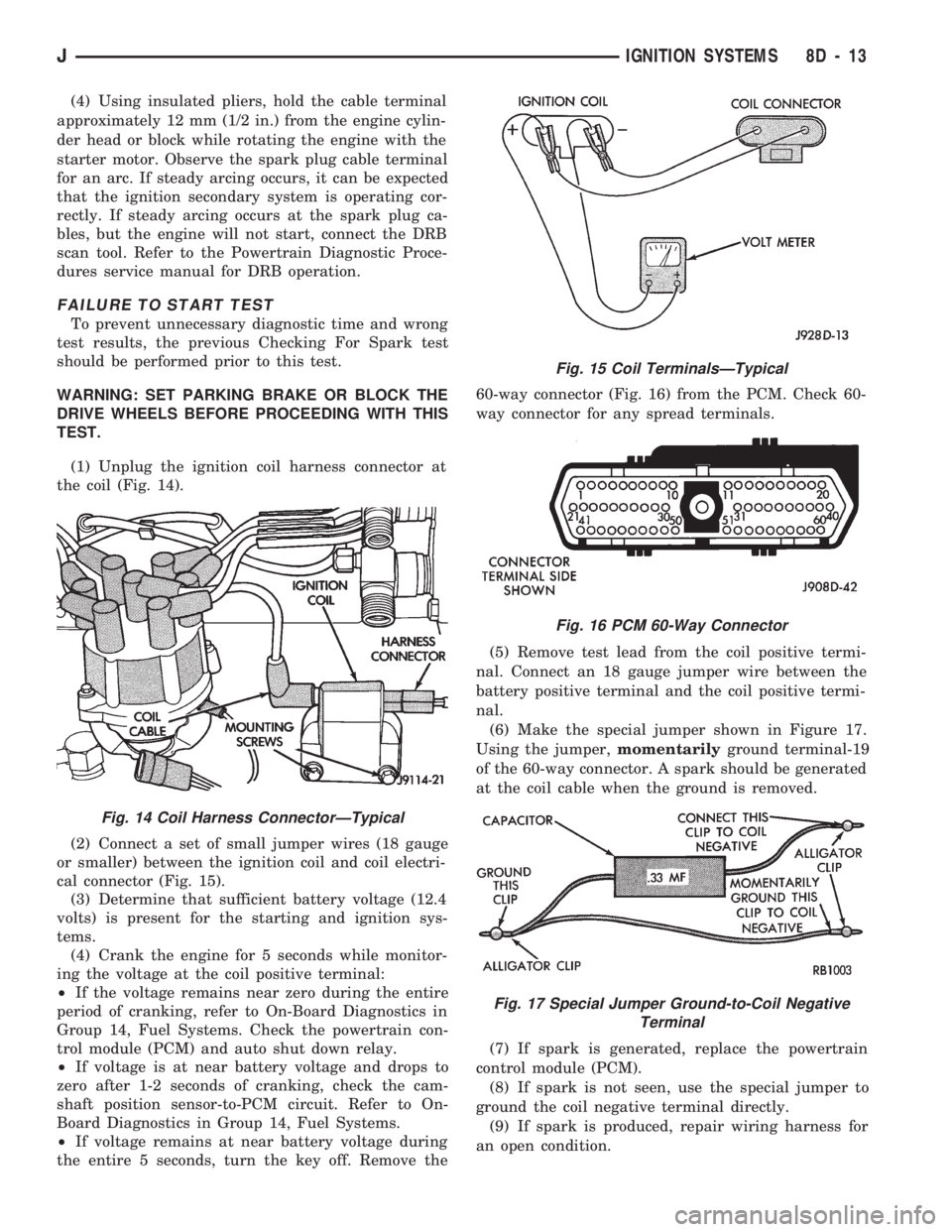

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca-

ble terminal approximately 12 mm (1/2 in.) from a

good engine ground (Fig. 13).WARNING: BE VERY CAREFUL WHEN THE ENGINE

IS CRANKING. DO NOT PUT YOUR HANDS NEAR

THE PULLEYS, BELTS OR THE FAN. DO NOT

WEAR LOOSE FITTING CLOTHING.

(2) Rotate (crank) the engine with the starter mo-

tor and observe the cable terminal for a steady arc. If

steady arcing does not occur, inspect the secondary

coil cable. Refer to Spark Plug Cables in this group.

Also inspect the distributor cap and rotor for cracks

or burn marks. Repair as necessary. If steady arcing

occurs, connect ignition coil cable to the distributor

cap.

(3) Remove a cable from one spark plug.

Fig. 12 Coolant Temperature SensorÐTypical

SENSOR RESISTANCE (OHMS)

Fig. 13 Checking for SparkÐTypical

8D - 12 IGNITION SYSTEMSJ

Page 326 of 1784

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin-

der head or block while rotating the engine with the

starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is operating cor-

rectly. If steady arcing occurs at the spark plug ca-

bles, but the engine will not start, connect the DRB

scan tool. Refer to the Powertrain Diagnostic Proce-

dures service manual for DRB operation.

FAILURE TO START TEST

To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test

should be performed prior to this test.

WARNING: SET PARKING BRAKE OR BLOCK THE

DRIVE WHEELS BEFORE PROCEEDING WITH THIS

TEST.

(1) Unplug the ignition coil harness connector at

the coil (Fig. 14).

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the ignition coil and coil electri-

cal connector (Fig. 15).

(3) Determine that sufficient battery voltage (12.4

volts) is present for the starting and ignition sys-

tems.

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shut down relay.

²If voltage is at near battery voltage and drops to

zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at near battery voltage during

the entire 5 seconds, turn the key off. Remove the60-way connector (Fig. 16) from the PCM. Check 60-

way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in Figure 17.

Using the jumper,momentarilyground terminal-19

of the 60-way connector. A spark should be generated

at the coil cable when the ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

Fig. 14 Coil Harness ConnectorÐTypical

Fig. 15 Coil TerminalsÐTypical

Fig. 16 PCM 60-Way Connector

Fig. 17 Special Jumper Ground-to-Coil Negative

Terminal

JIGNITION SYSTEMS 8D - 13

Page 327 of 1784

(10) If spark is not produced, replace the ignition

coil.

IGNITION TIMING

Base (initial) ignition timing is NOT adjustable

on any of the 2.5L 4 cylinder or 4.0L 6 cylinder

engines. Do not attempt to adjust ignition timing

by rotating the distributor.

Do not attempt to modify the distributor hous-

ing to get distributor rotation. Distributor posi-

tion will have no effect on ignition timing.

All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board

Diagnostics in the Multi-Port Fuel InjectionÐGen-

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow-

ertrain Diagnostics Procedures service manual for

operation of the DRB Scan Tool.

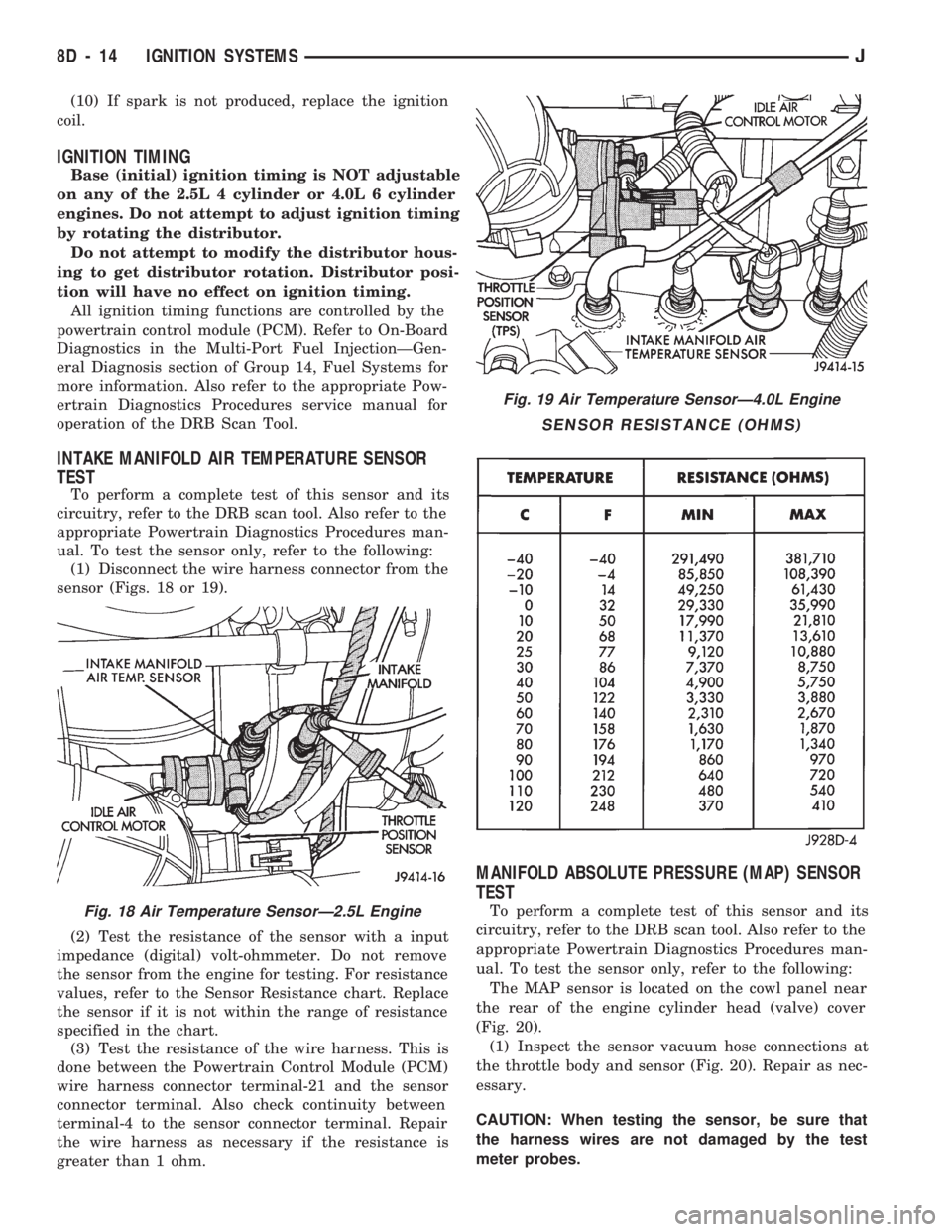

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

(1) Disconnect the wire harness connector from the

sensor (Figs. 18 or 19).

(2) Test the resistance of the sensor with a input

impedance (digital) volt-ohmmeter. Do not remove

the sensor from the engine for testing. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance

specified in the chart.

(3) Test the resistance of the wire harness. This is

done between the Powertrain Control Module (PCM)

wire harness connector terminal-21 and the sensor

connector terminal. Also check continuity between

terminal-4 to the sensor connector terminal. Repair

the wire harness as necessary if the resistance is

greater than 1 ohm.

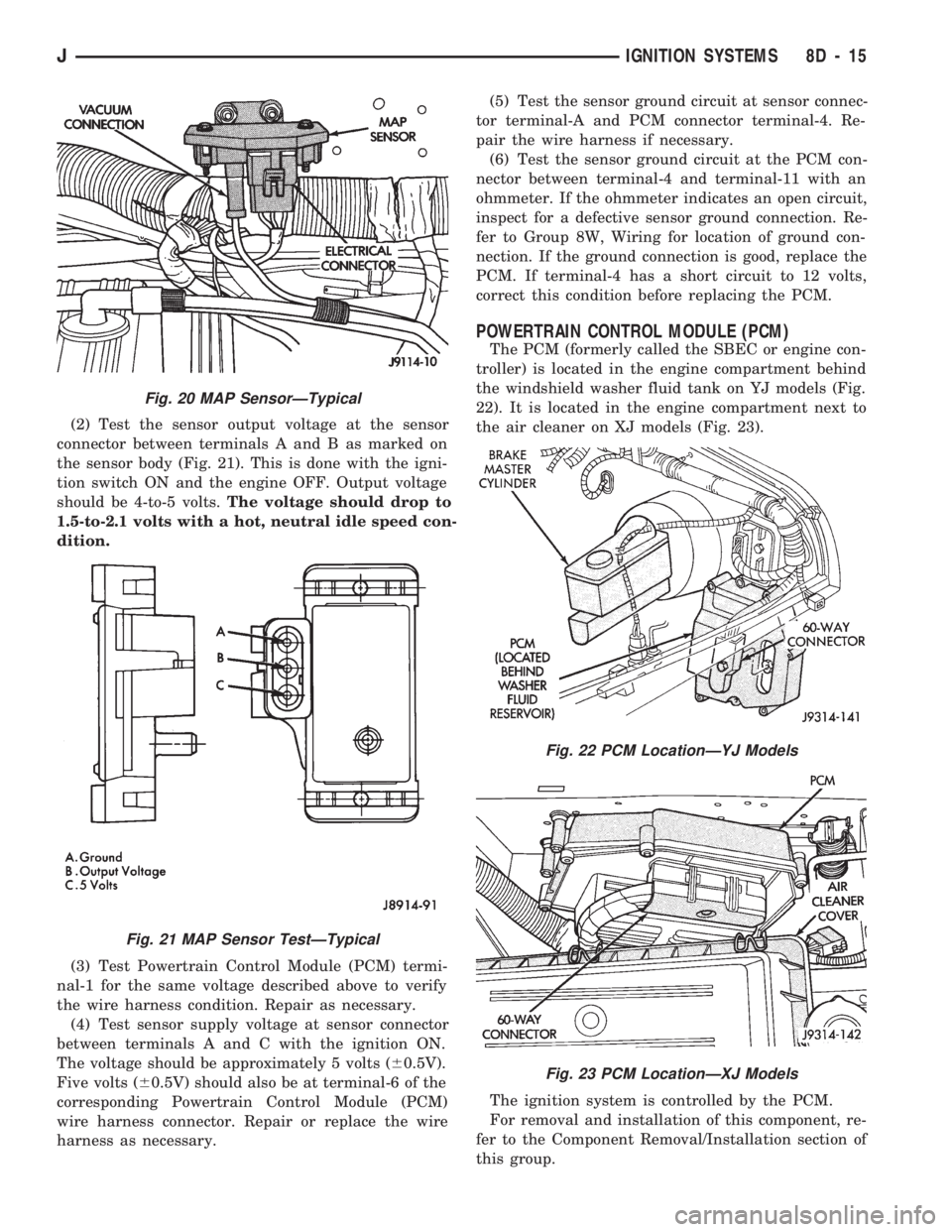

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The MAP sensor is located on the cowl panel near

the rear of the engine cylinder head (valve) cover

(Fig. 20).

(1) Inspect the sensor vacuum hose connections at

the throttle body and sensor (Fig. 20). Repair as nec-

essary.

CAUTION: When testing the sensor, be sure that

the harness wires are not damaged by the test

meter probes.Fig. 18 Air Temperature SensorÐ2.5L Engine

Fig. 19 Air Temperature SensorÐ4.0L Engine

SENSOR RESISTANCE (OHMS)

8D - 14 IGNITION SYSTEMSJ

Page 328 of 1784

(2) Test the sensor output voltage at the sensor

connector between terminals A and B as marked on

the sensor body (Fig. 21). This is done with the igni-

tion switch ON and the engine OFF. Output voltage

should be 4-to-5 volts.The voltage should drop to

1.5-to-2.1 volts with a hot, neutral idle speed con-

dition.

(3) Test Powertrain Control Module (PCM) termi-

nal-1 for the same voltage described above to verify

the wire harness condition. Repair as necessary.

(4) Test sensor supply voltage at sensor connector

between terminals A and C with the ignition ON.

The voltage should be approximately 5 volts (60.5V).

Five volts (60.5V) should also be at terminal-6 of the

corresponding Powertrain Control Module (PCM)

wire harness connector. Repair or replace the wire

harness as necessary.(5) Test the sensor ground circuit at sensor connec-

tor terminal-A and PCM connector terminal-4. Re-

pair the wire harness if necessary.

(6) Test the sensor ground circuit at the PCM con-

nector between terminal-4 and terminal-11 with an

ohmmeter. If the ohmmeter indicates an open circuit,

inspect for a defective sensor ground connection. Re-

fer to Group 8W, Wiring for location of ground con-

nection. If the ground connection is good, replace the

PCM. If terminal-4 has a short circuit to 12 volts,

correct this condition before replacing the PCM.

POWERTRAIN CONTROL MODULE (PCM)

The PCM (formerly called the SBEC or engine con-

troller) is located in the engine compartment behind

the windshield washer fluid tank on YJ models (Fig.

22). It is located in the engine compartment next to

the air cleaner on XJ models (Fig. 23).

The ignition system is controlled by the PCM.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 20 MAP SensorÐTypical

Fig. 21 MAP Sensor TestÐTypical

Fig. 22 PCM LocationÐYJ Models

Fig. 23 PCM LocationÐXJ Models

JIGNITION SYSTEMS 8D - 15

Page 329 of 1784

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB scan tool.

SPARK PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In-

stallation section of this group.

Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

number of ways: poor fuel economy, power loss, de-

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in the maintenance chart in Group 0, Lubri-

cation and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

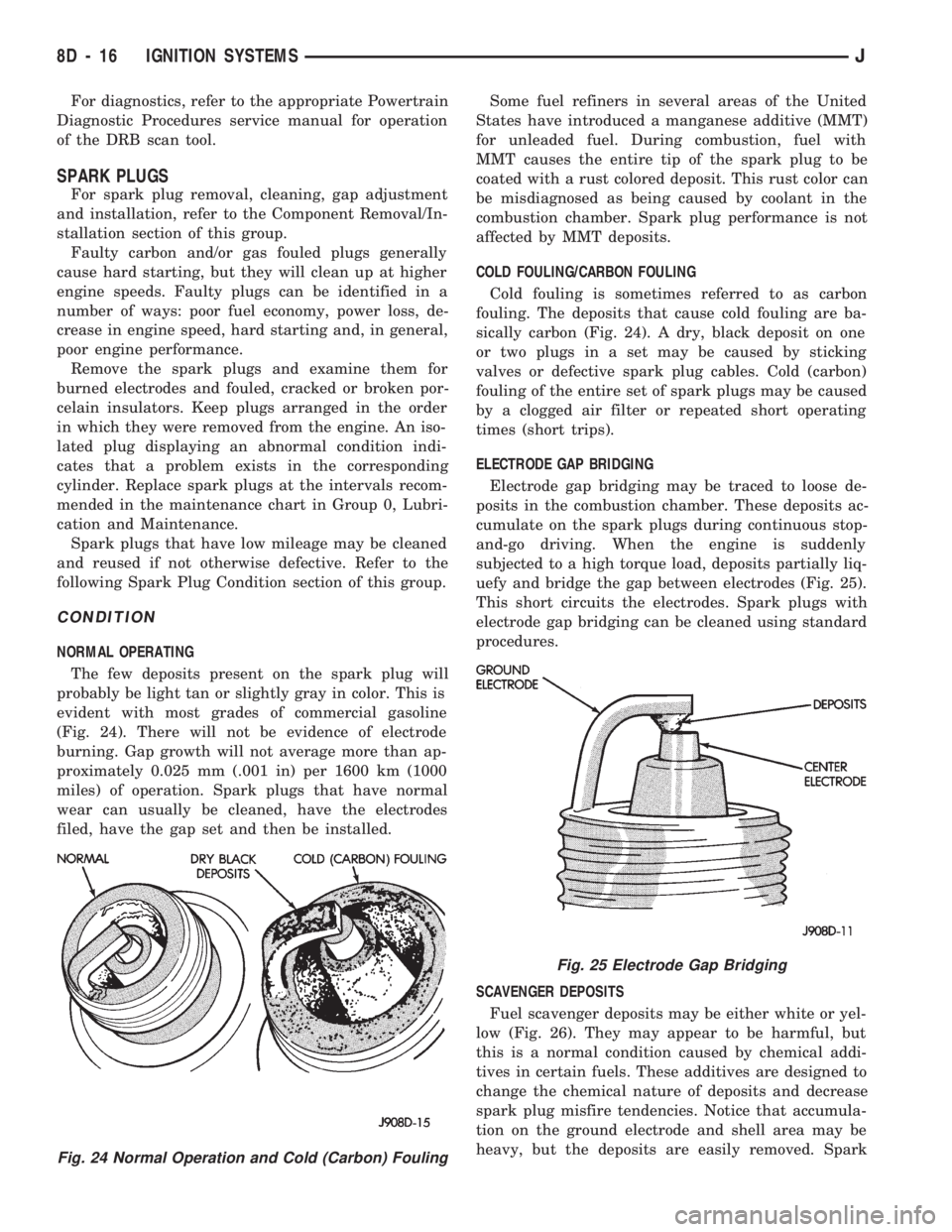

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 24). There will not be evidence of electrode

burning. Gap growth will not average more than ap-

proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with

MMT causes the entire tip of the spark plug to be

coated with a rust colored deposit. This rust color can

be misdiagnosed as being caused by coolant in the

combustion chamber. Spark plug performance is not

affected by MMT deposits.

COLD FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 24). A dry, black deposit on one

or two plugs in a set may be caused by sticking

valves or defective spark plug cables. Cold (carbon)

fouling of the entire set of spark plugs may be caused

by a clogged air filter or repeated short operating

times (short trips).

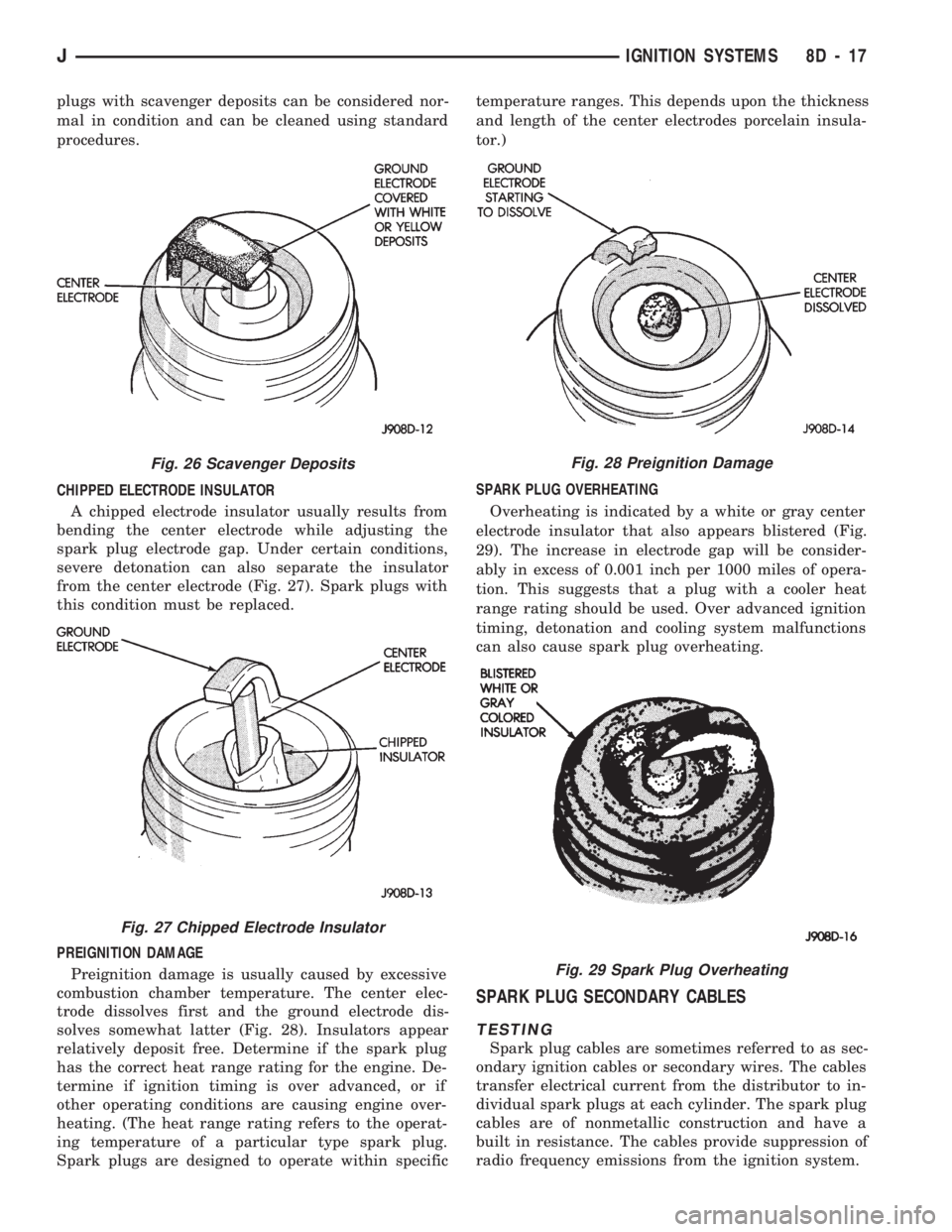

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose de-

posits in the combustion chamber. These deposits ac-

cumulate on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

subjected to a high torque load, deposits partially liq-

uefy and bridge the gap between electrodes (Fig. 25).

This short circuits the electrodes. Spark plugs with

electrode gap bridging can be cleaned using standard

procedures.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 26). They may appear to be harmful, but

this is a normal condition caused by chemical addi-

tives in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy, but the deposits are easily removed. Spark

Fig. 24 Normal Operation and Cold (Carbon) Fouling

Fig. 25 Electrode Gap Bridging

8D - 16 IGNITION SYSTEMSJ

Page 330 of 1784

plugs with scavenger deposits can be considered nor-

mal in condition and can be cleaned using standard

procedures.

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation can also separate the insulator

from the center electrode (Fig. 27). Spark plugs with

this condition must be replaced.

PREIGNITION DAMAGE

Preignition damage is usually caused by excessive

combustion chamber temperature. The center elec-

trode dissolves first and the ground electrode dis-

solves somewhat latter (Fig. 28). Insulators appear

relatively deposit free. Determine if the spark plug

has the correct heat range rating for the engine. De-

termine if ignition timing is over advanced, or if

other operating conditions are causing engine over-

heating. (The heat range rating refers to the operat-

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specifictemperature ranges. This depends upon the thickness

and length of the center electrodes porcelain insula-

tor.)

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

29). The increase in electrode gap will be consider-

ably in excess of 0.001 inch per 1000 miles of opera-

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions

can also cause spark plug overheating.

SPARK PLUG SECONDARY CABLES

TESTING

Spark plug cables are sometimes referred to as sec-

ondary ignition cables or secondary wires. The cables

transfer electrical current from the distributor to in-

dividual spark plugs at each cylinder. The spark plug

cables are of nonmetallic construction and have a

built in resistance. The cables provide suppression of

radio frequency emissions from the ignition system.

Fig. 26 Scavenger Deposits

Fig. 27 Chipped Electrode Insulator

Fig. 28 Preignition Damage

Fig. 29 Spark Plug Overheating

JIGNITION SYSTEMS 8D - 17