JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 311 of 1784

(6) Should any segment in any of the digit positions

fail to light, the unit is defective and should be re-

placed.

THERMOMETER AND SENSOR SYSTEM REPAIR

PROCEDURES

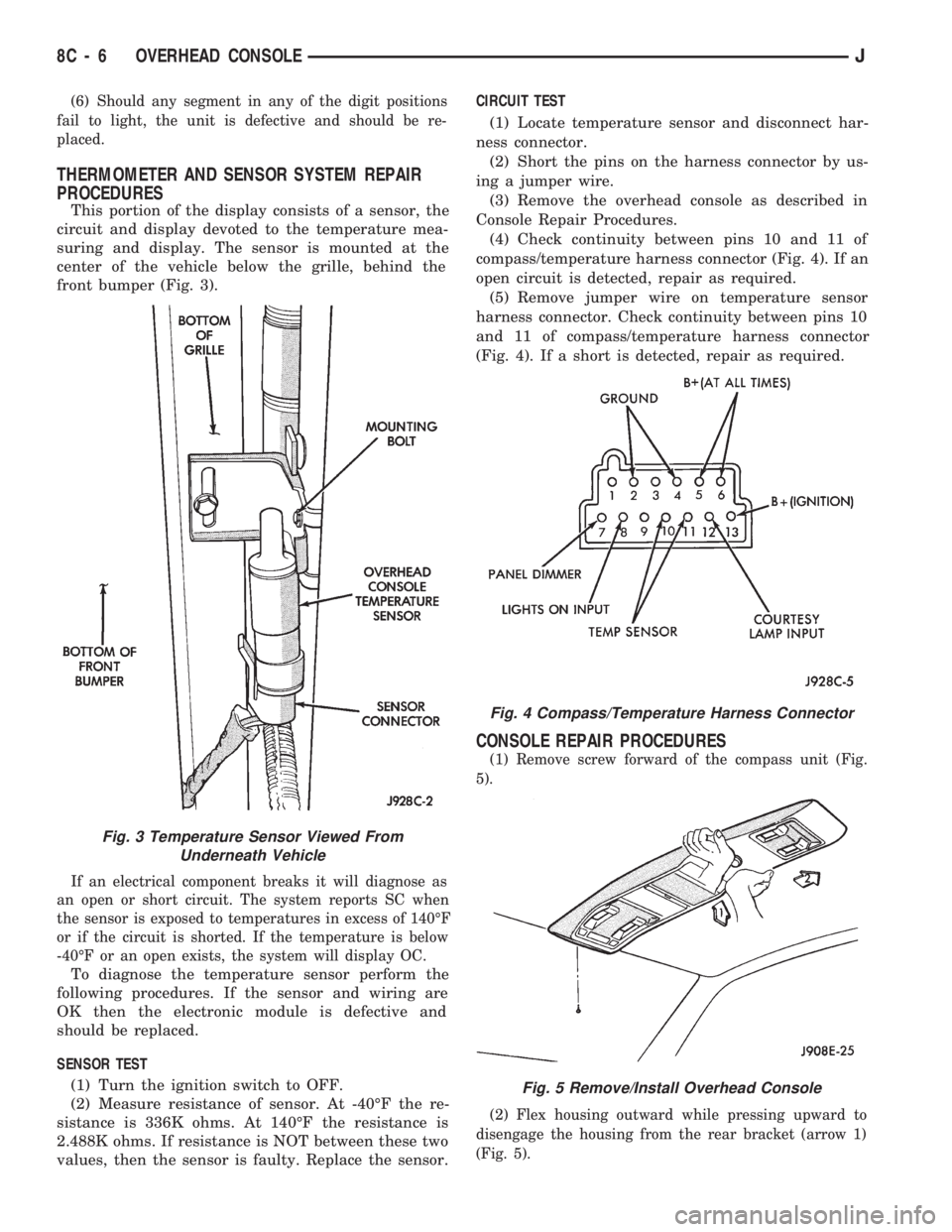

This portion of the display consists of a sensor, the

circuit and display devoted to the temperature mea-

suring and display. The sensor is mounted at the

center of the vehicle below the grille, behind the

front bumper (Fig. 3).

If an electrical component breaks it will diagnose as

an open or short circuit. The system reports SC when

the sensor is exposed to temperatures in excess of 140ÉF

or if the circuit is shorted. If the temperature is below

-40ÉF or an open exists, the system will display OC.

To diagnose the temperature sensor perform the

following procedures. If the sensor and wiring are

OK then the electronic module is defective and

should be replaced.

SENSOR TEST

(1) Turn the ignition switch to OFF.

(2) Measure resistance of sensor. At -40ÉF the re-

sistance is 336K ohms. At 140ÉF the resistance is

2.488K ohms. If resistance is NOT between these two

values, then the sensor is faulty. Replace the sensor.CIRCUIT TEST

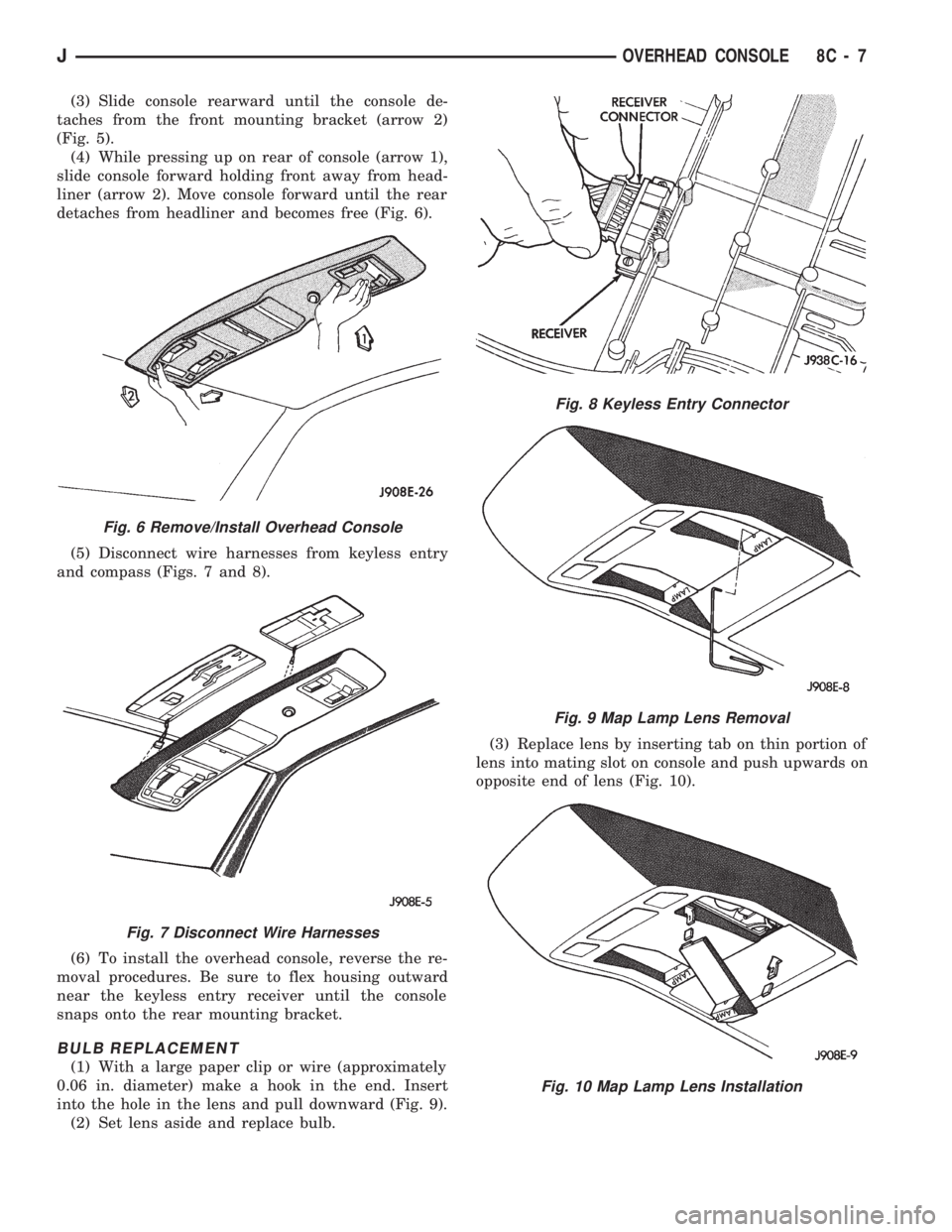

(1) Locate temperature sensor and disconnect har-

ness connector.

(2) Short the pins on the harness connector by us-

ing a jumper wire.

(3) Remove the overhead console as described in

Console Repair Procedures.

(4) Check continuity between pins 10 and 11 of

compass/temperature harness connector (Fig. 4). If an

open circuit is detected, repair as required.

(5) Remove jumper wire on temperature sensor

harness connector. Check continuity between pins 10

and 11 of compass/temperature harness connector

(Fig. 4). If a short is detected, repair as required.

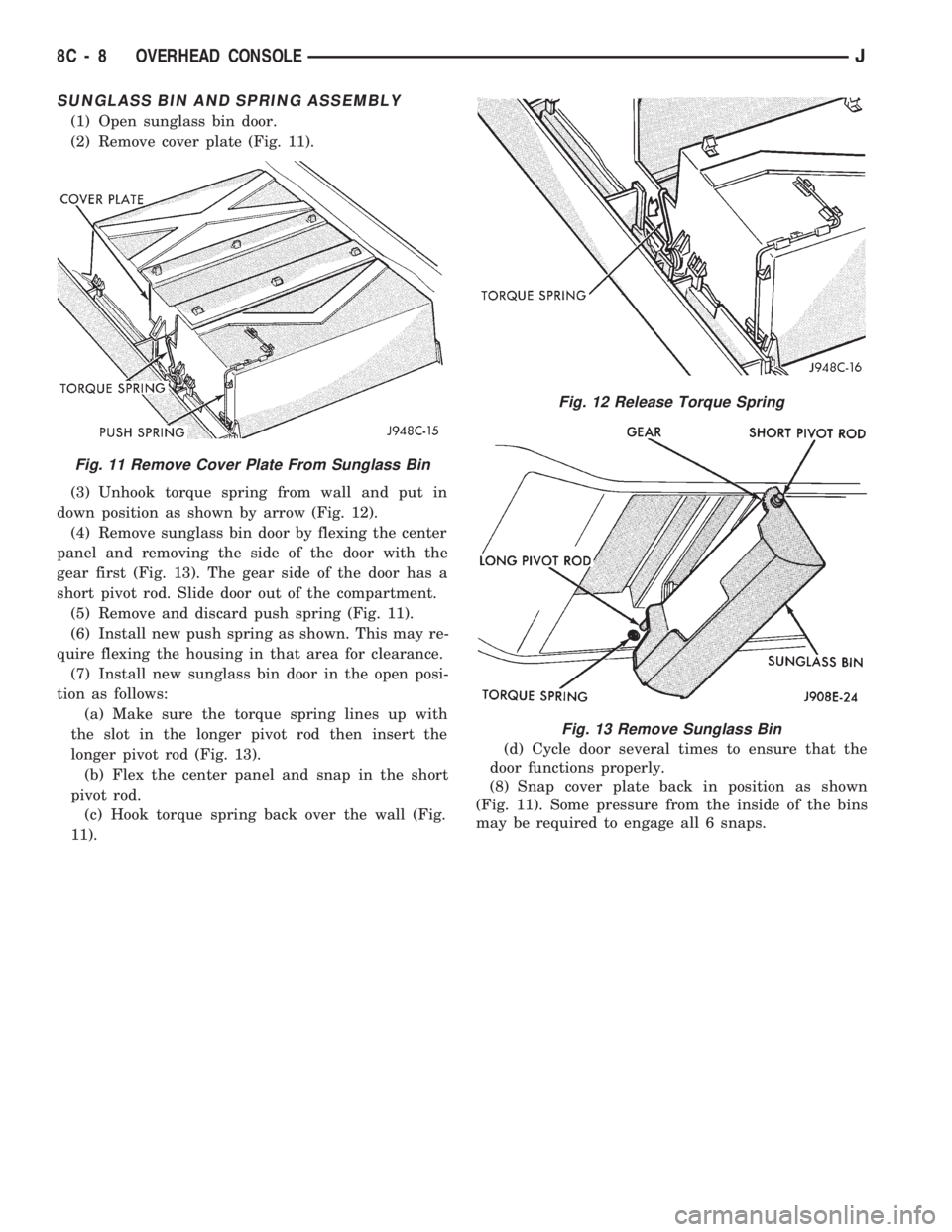

CONSOLE REPAIR PROCEDURES

(1) Remove screw forward of the compass unit (Fig.

5).

(2) Flex housing outward while pressing upward to

disengage the housing from the rear bracket (arrow 1)

(Fig. 5).

Fig. 4 Compass/Temperature Harness Connector

Fig. 5 Remove/Install Overhead Console

Fig. 3 Temperature Sensor Viewed From

Underneath Vehicle

8C - 6 OVERHEAD CONSOLEJ

Page 312 of 1784

(3) Slide console rearward until the console de-

taches from the front mounting bracket (arrow 2)

(Fig. 5).

(4) While pressing up on rear of console (arrow 1),

slide console forward holding front away from head-

liner (arrow 2). Move console forward until the rear

detaches from headliner and becomes free (Fig. 6).

(5) Disconnect wire harnesses from keyless entry

and compass (Figs. 7 and 8).

(6) To install the overhead console, reverse the re-

moval procedures. Be sure to flex housing outward

near the keyless entry receiver until the console

snaps onto the rear mounting bracket.

BULB REPLACEMENT

(1) With a large paper clip or wire (approximately

0.06 in. diameter) make a hook in the end. Insert

into the hole in the lens and pull downward (Fig. 9).

(2) Set lens aside and replace bulb.(3) Replace lens by inserting tab on thin portion of

lens into mating slot on console and push upwards on

opposite end of lens (Fig. 10).

Fig. 6 Remove/Install Overhead Console

Fig. 7 Disconnect Wire Harnesses

Fig. 8 Keyless Entry Connector

Fig. 9 Map Lamp Lens Removal

Fig. 10 Map Lamp Lens Installation

JOVERHEAD CONSOLE 8C - 7

Page 313 of 1784

SUNGLASS BIN AND SPRING ASSEMBLY

(1) Open sunglass bin door.

(2) Remove cover plate (Fig. 11).

(3) Unhook torque spring from wall and put in

down position as shown by arrow (Fig. 12).

(4) Remove sunglass bin door by flexing the center

panel and removing the side of the door with the

gear first (Fig. 13). The gear side of the door has a

short pivot rod. Slide door out of the compartment.

(5) Remove and discard push spring (Fig. 11).

(6) Install new push spring as shown. This may re-

quire flexing the housing in that area for clearance.

(7) Install new sunglass bin door in the open posi-

tion as follows:

(a) Make sure the torque spring lines up with

the slot in the longer pivot rod then insert the

longer pivot rod (Fig. 13).

(b) Flex the center panel and snap in the short

pivot rod.

(c) Hook torque spring back over the wall (Fig.

11).(d) Cycle door several times to ensure that the

door functions properly.

(8) Snap cover plate back in position as shown

(Fig. 11). Some pressure from the inside of the bins

may be required to engage all 6 snaps.

Fig. 11 Remove Cover Plate From Sunglass Bin

Fig. 12 Release Torque Spring

Fig. 13 Remove Sunglass Bin

8C - 8 OVERHEAD CONSOLEJ

Page 314 of 1784

IGNITION SYSTEMS

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM

OPERATION.......................... 1

COMPONENT REMOVAL/INSTALLATION..... 20DIAGNOSTICS/SERVICE PROCEDURES....... 8

IGNITION SWITCH...................... 30

SPECIFICATIONS....................... 33

COMPONENT IDENTIFICATION/SYSTEM OPERATION

INDEX

page page

Automatic Shut Down (ASD) Relay............ 1

Camshaft Position Sensor................... 1

Crankshaft Position Sensor.................. 2

Distributors.............................. 3

Engine Coolant Temperature Sensor........... 4

General Information........................ 1Ignition Coil.............................. 4

Intake Manifold Air Temperature Sensor........ 5

Manifold Absolute Pressure (MAP) Sensor...... 5

Powertrain Control Module (PCM)............. 6

Throttle Position Sensor.................... 6

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction group at the be-

ginning of this manual.

This section of the group, Component Identifica-

tion/System Operation, will discuss ignition system

operation and will identify ignition system compo-

nents.

For diagnostic procedures and adjustments, refer to

the Diagnostics/Service Procedures section of this

group.

For removal and installation of ignition system

components, refer to the Component Removal/Instal-

lation section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

An Ignition specifications section is included at the

end of this group. A general Maintenance Schedule

(mileage intervals) for ignition related items can be

found in Group 0, Lubrication and Maintenance. This

schedule can also be found in the Owners Manual.

IGNITION SYSTEMS

A multi-port, fuel injected engine is used on all

models. The ignition system is controlled by the Pow-

ertrain Control Module (PCM) on all engines. The

PCM was formerly referred to as the SBEC or engine

controller.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Ignition distributor (contains rotor and camshaft

position sensor)

²Powertrain Control Module (PCM)

²Crankshaft Position Sensor

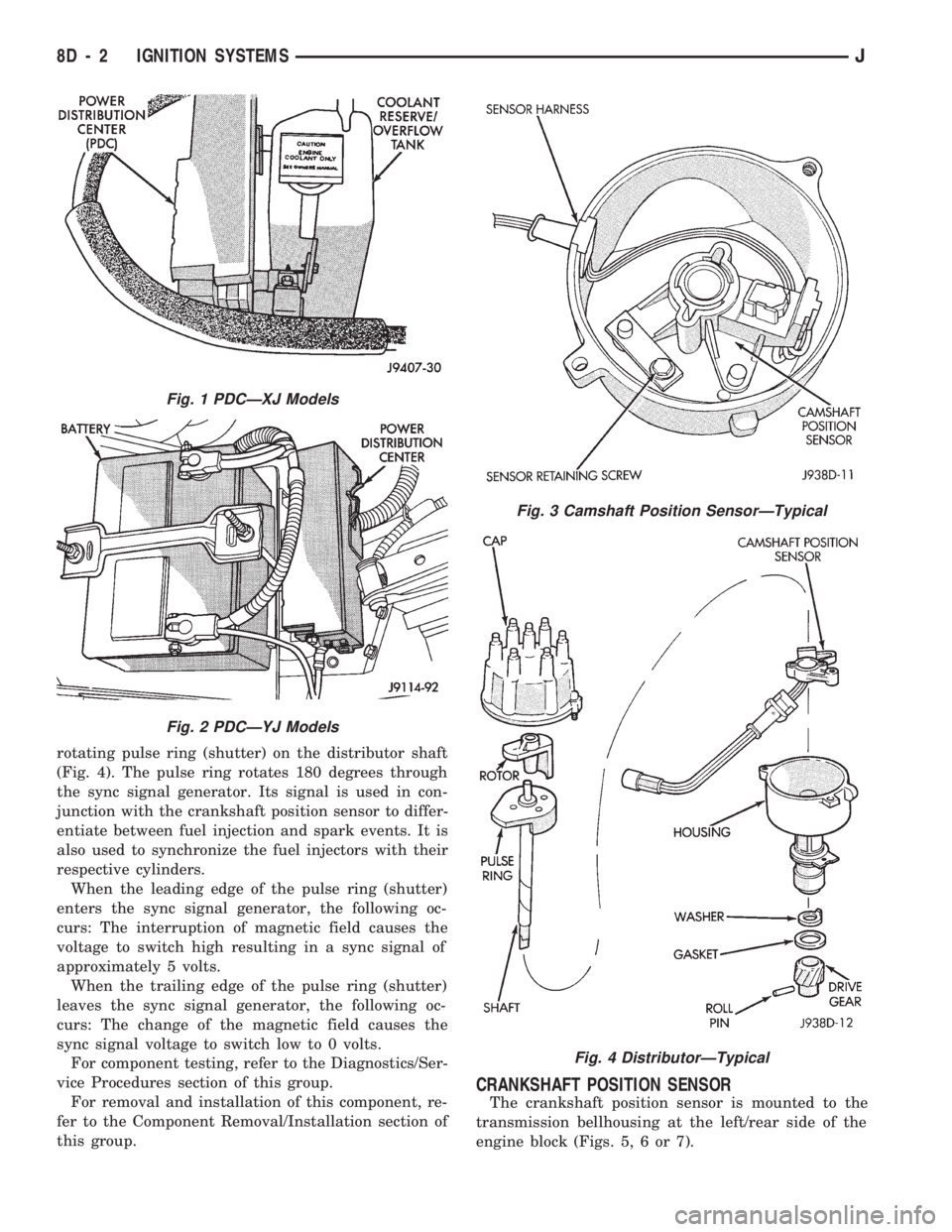

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay is located in

the Power Distribution Center (PDC) near the bat-

tery (Fig. 1 or 2). As one of its functions, it will sup-

ply battery voltage to the ignition coil. The ground

circuit for the ASD relay is controlled by the Power-

train Control Module (PCM). The PCM regulates

ASD relay operation by switching the ground circuit

on-and-off.

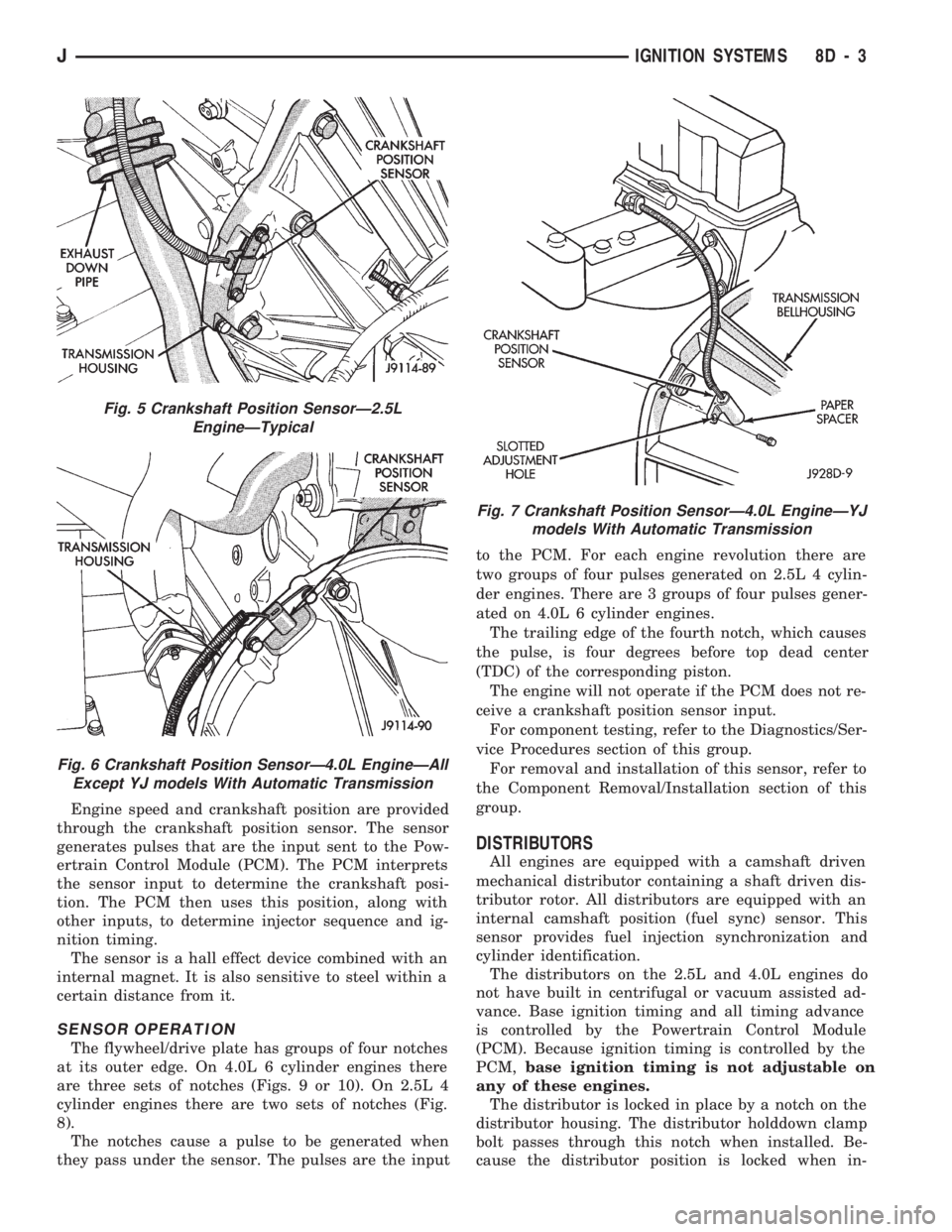

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the igni-

tion distributor (Figs. 3 or 4) on all engines.

The camshaft position sensor contains a hall effect

device called a sync signal generator to generate a

fuel sync signal. This sync signal generator detects a

JIGNITION SYSTEMS 8D - 1

Page 315 of 1784

rotating pulse ring (shutter) on the distributor shaft

(Fig. 4). The pulse ring rotates 180 degrees through

the sync signal generator. Its signal is used in con-

junction with the crankshaft position sensor to differ-

entiate between fuel injection and spark events. It is

also used to synchronize the fuel injectors with their

respective cylinders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following oc-

curs: The interruption of magnetic field causes the

voltage to switch high resulting in a sync signal of

approximately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following oc-

curs: The change of the magnetic field causes the

sync signal voltage to switch low to 0 volts.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

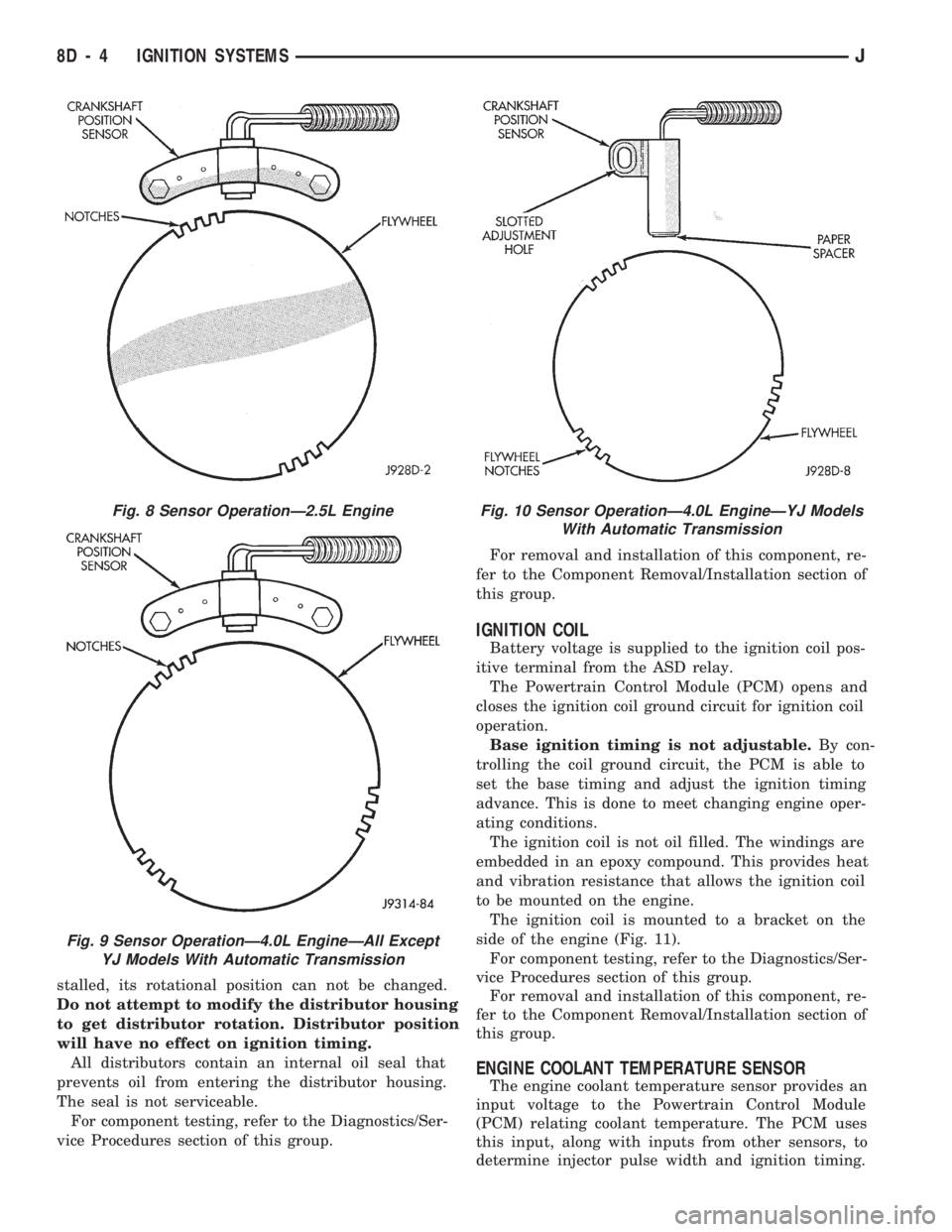

CRANKSHAFT POSITION SENSOR

The crankshaft position sensor is mounted to the

transmission bellhousing at the left/rear side of the

engine block (Figs. 5, 6 or 7).

Fig. 1 PDCÐXJ Models

Fig. 2 PDCÐYJ Models

Fig. 3 Camshaft Position SensorÐTypical

Fig. 4 DistributorÐTypical

8D - 2 IGNITION SYSTEMSJ

Page 316 of 1784

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the Pow-

ertrain Control Module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and ig-

nition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

SENSOR OPERATION

The flywheel/drive plate has groups of four notches

at its outer edge. On 4.0L 6 cylinder engines there

are three sets of notches (Figs. 9 or 10). On 2.5L 4

cylinder engines there are two sets of notches (Fig.

8).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the inputto the PCM. For each engine revolution there are

two groups of four pulses generated on 2.5L 4 cylin-

der engines. There are 3 groups of four pulses gener-

ated on 4.0L 6 cylinder engines.

The trailing edge of the fourth notch, which causes

the pulse, is four degrees before top dead center

(TDC) of the corresponding piston.

The engine will not operate if the PCM does not re-

ceive a crankshaft position sensor input.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this sensor, refer to

the Component Removal/Installation section of this

group.

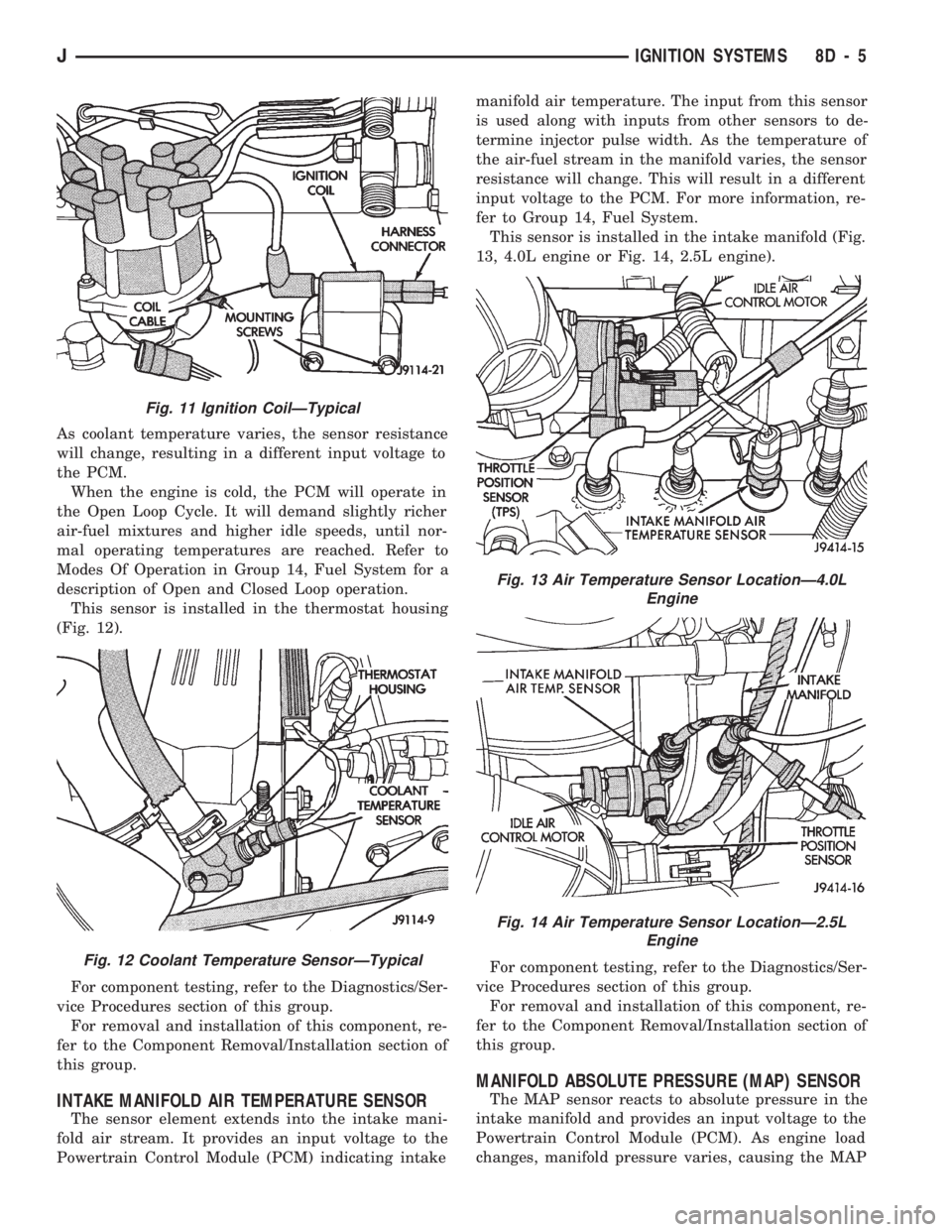

DISTRIBUTORS

All engines are equipped with a camshaft driven

mechanical distributor containing a shaft driven dis-

tributor rotor. All distributors are equipped with an

internal camshaft position (fuel sync) sensor. This

sensor provides fuel injection synchronization and

cylinder identification.

The distributors on the 2.5L and 4.0L engines do

not have built in centrifugal or vacuum assisted ad-

vance. Base ignition timing and all timing advance

is controlled by the Powertrain Control Module

(PCM). Because ignition timing is controlled by the

PCM,base ignition timing is not adjustable on

any of these engines.

The distributor is locked in place by a notch on the

distributor housing. The distributor holddown clamp

bolt passes through this notch when installed. Be-

cause the distributor position is locked when in-

Fig. 5 Crankshaft Position SensorÐ2.5L

EngineÐTypical

Fig. 6 Crankshaft Position SensorÐ4.0L EngineÐAll

Except YJ models With Automatic Transmission

Fig. 7 Crankshaft Position SensorÐ4.0L EngineÐYJ

models With Automatic Transmission

JIGNITION SYSTEMS 8D - 3

Page 317 of 1784

stalled, its rotational position can not be changed.

Do not attempt to modify the distributor housing

to get distributor rotation. Distributor position

will have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

IGNITION COIL

Battery voltage is supplied to the ignition coil pos-

itive terminal from the ASD relay.

The Powertrain Control Module (PCM) opens and

closes the ignition coil ground circuit for ignition coil

operation.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to

set the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

The ignition coil is mounted to a bracket on the

side of the engine (Fig. 11).

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor provides an

input voltage to the Powertrain Control Module

(PCM) relating coolant temperature. The PCM uses

this input, along with inputs from other sensors, to

determine injector pulse width and ignition timing.

Fig. 8 Sensor OperationÐ2.5L Engine

Fig. 9 Sensor OperationÐ4.0L EngineÐAll Except

YJ Models With Automatic Transmission

Fig. 10 Sensor OperationÐ4.0L EngineÐYJ Models

With Automatic Transmission

8D - 4 IGNITION SYSTEMSJ

Page 318 of 1784

As coolant temperature varies, the sensor resistance

will change, resulting in a different input voltage to

the PCM.

When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer

air-fuel mixtures and higher idle speeds, until nor-

mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

This sensor is installed in the thermostat housing

(Fig. 12).

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

The sensor element extends into the intake mani-

fold air stream. It provides an input voltage to the

Powertrain Control Module (PCM) indicating intakemanifold air temperature. The input from this sensor

is used along with inputs from other sensors to de-

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different

input voltage to the PCM. For more information, re-

fer to Group 14, Fuel System.

This sensor is installed in the intake manifold (Fig.

13, 4.0L engine or Fig. 14, 2.5L engine).

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

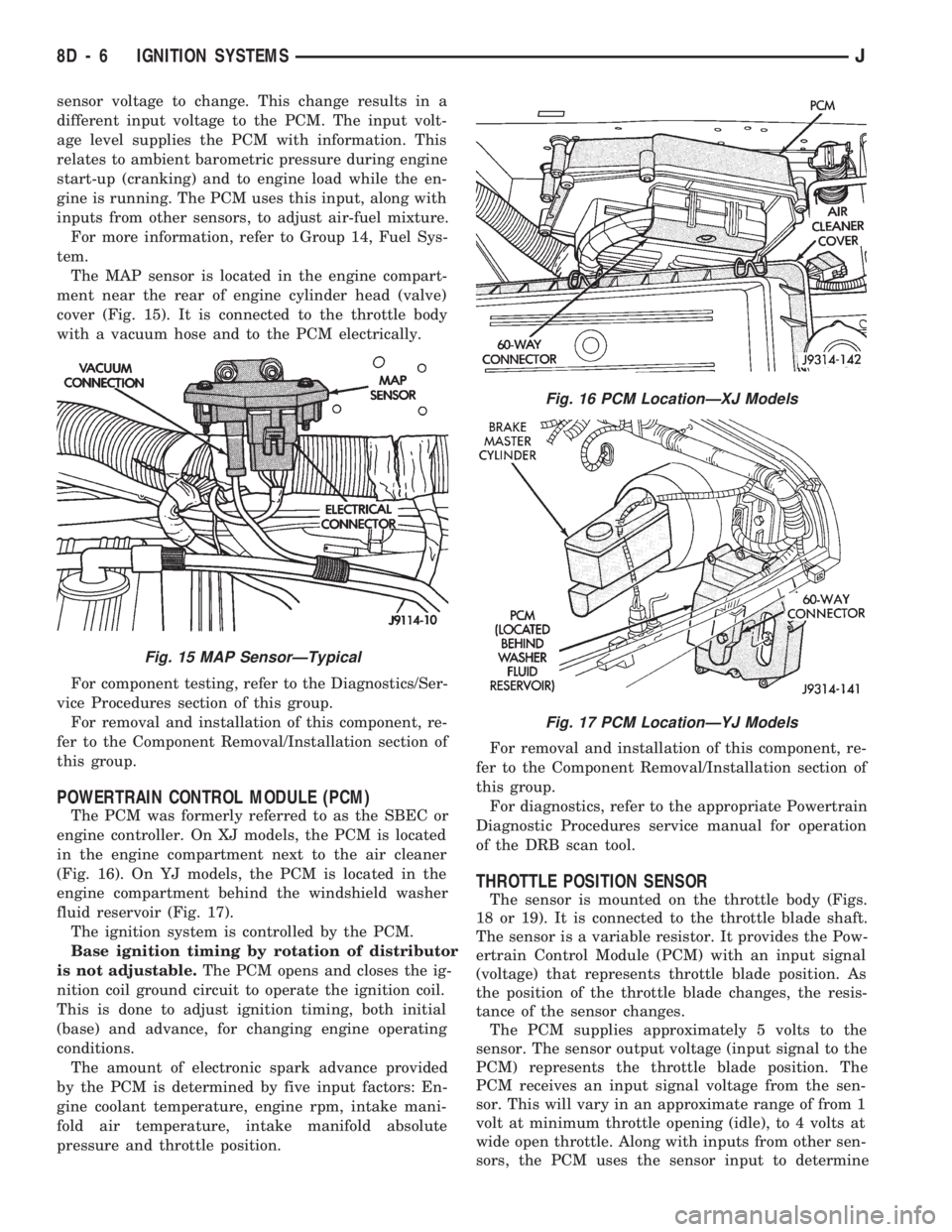

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

Powertrain Control Module (PCM). As engine load

changes, manifold pressure varies, causing the MAP

Fig. 11 Ignition CoilÐTypical

Fig. 12 Coolant Temperature SensorÐTypical

Fig. 13 Air Temperature Sensor LocationÐ4.0L

Engine

Fig. 14 Air Temperature Sensor LocationÐ2.5L

Engine

JIGNITION SYSTEMS 8D - 5

Page 319 of 1784

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt-

age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

start-up (cranking) and to engine load while the en-

gine is running. The PCM uses this input, along with

inputs from other sensors, to adjust air-fuel mixture.

For more information, refer to Group 14, Fuel Sys-

tem.

The MAP sensor is located in the engine compart-

ment near the rear of engine cylinder head (valve)

cover (Fig. 15). It is connected to the throttle body

with a vacuum hose and to the PCM electrically.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller. On XJ models, the PCM is located

in the engine compartment next to the air cleaner

(Fig. 16). On YJ models, the PCM is located in the

engine compartment behind the windshield washer

fluid reservoir (Fig. 17).

The ignition system is controlled by the PCM.

Base ignition timing by rotation of distributor

is not adjustable.The PCM opens and closes the ig-

nition coil ground circuit to operate the ignition coil.

This is done to adjust ignition timing, both initial

(base) and advance, for changing engine operating

conditions.

The amount of electronic spark advance provided

by the PCM is determined by five input factors: En-

gine coolant temperature, engine rpm, intake mani-

fold air temperature, intake manifold absolute

pressure and throttle position.For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB scan tool.

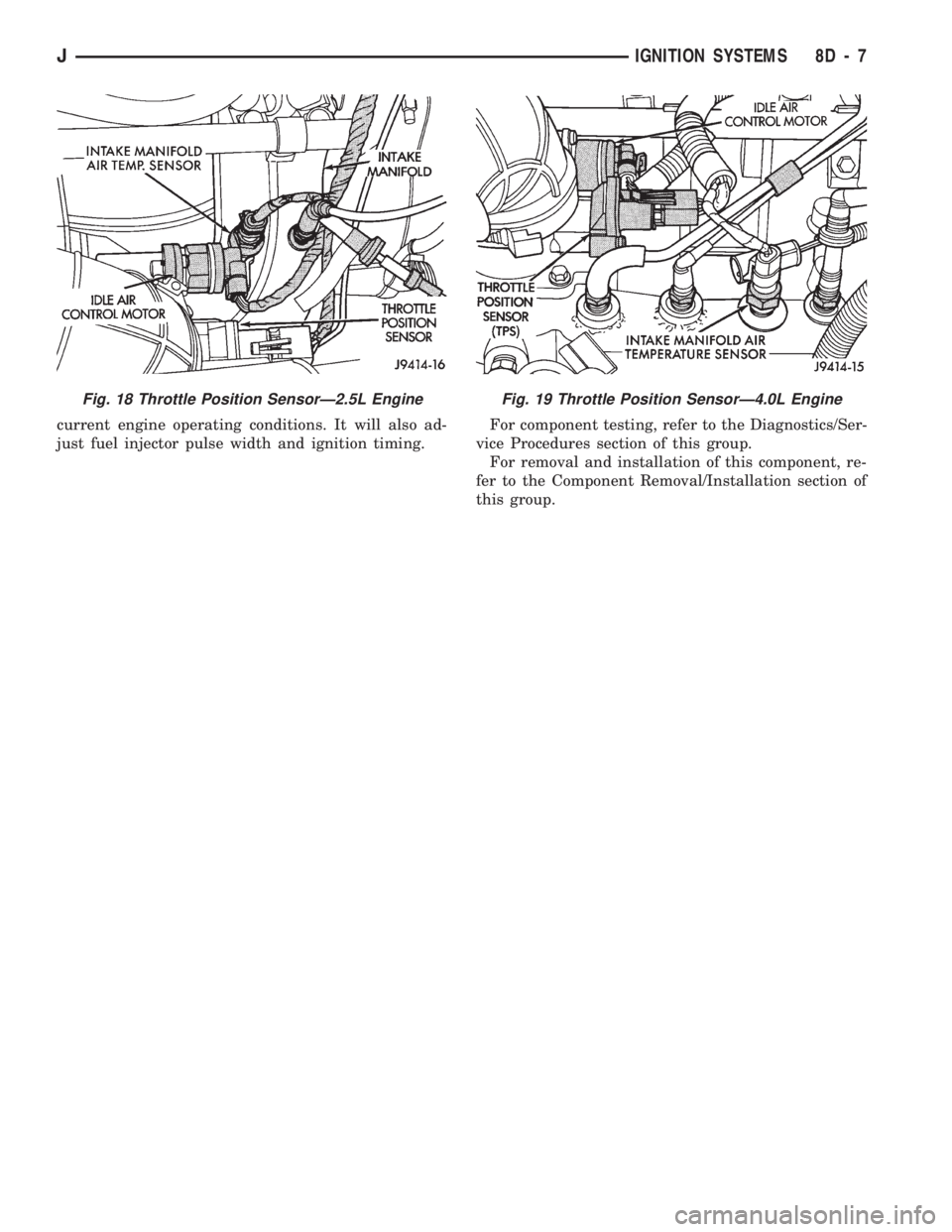

THROTTLE POSITION SENSOR

The sensor is mounted on the throttle body (Figs.

18 or 19). It is connected to the throttle blade shaft.

The sensor is a variable resistor. It provides the Pow-

ertrain Control Module (PCM) with an input signal

(voltage) that represents throttle blade position. As

the position of the throttle blade changes, the resis-

tance of the sensor changes.

The PCM supplies approximately 5 volts to the

sensor. The sensor output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the sen-

sor. This will vary in an approximate range of from 1

volt at minimum throttle opening (idle), to 4 volts at

wide open throttle. Along with inputs from other sen-

sors, the PCM uses the sensor input to determine

Fig. 15 MAP SensorÐTypical

Fig. 16 PCM LocationÐXJ Models

Fig. 17 PCM LocationÐYJ Models

8D - 6 IGNITION SYSTEMSJ

Page 320 of 1784

current engine operating conditions. It will also ad-

just fuel injector pulse width and ignition timing.For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 18 Throttle Position SensorÐ2.5L EngineFig. 19 Throttle Position SensorÐ4.0L Engine

JIGNITION SYSTEMS 8D - 7