front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1416 of 1784

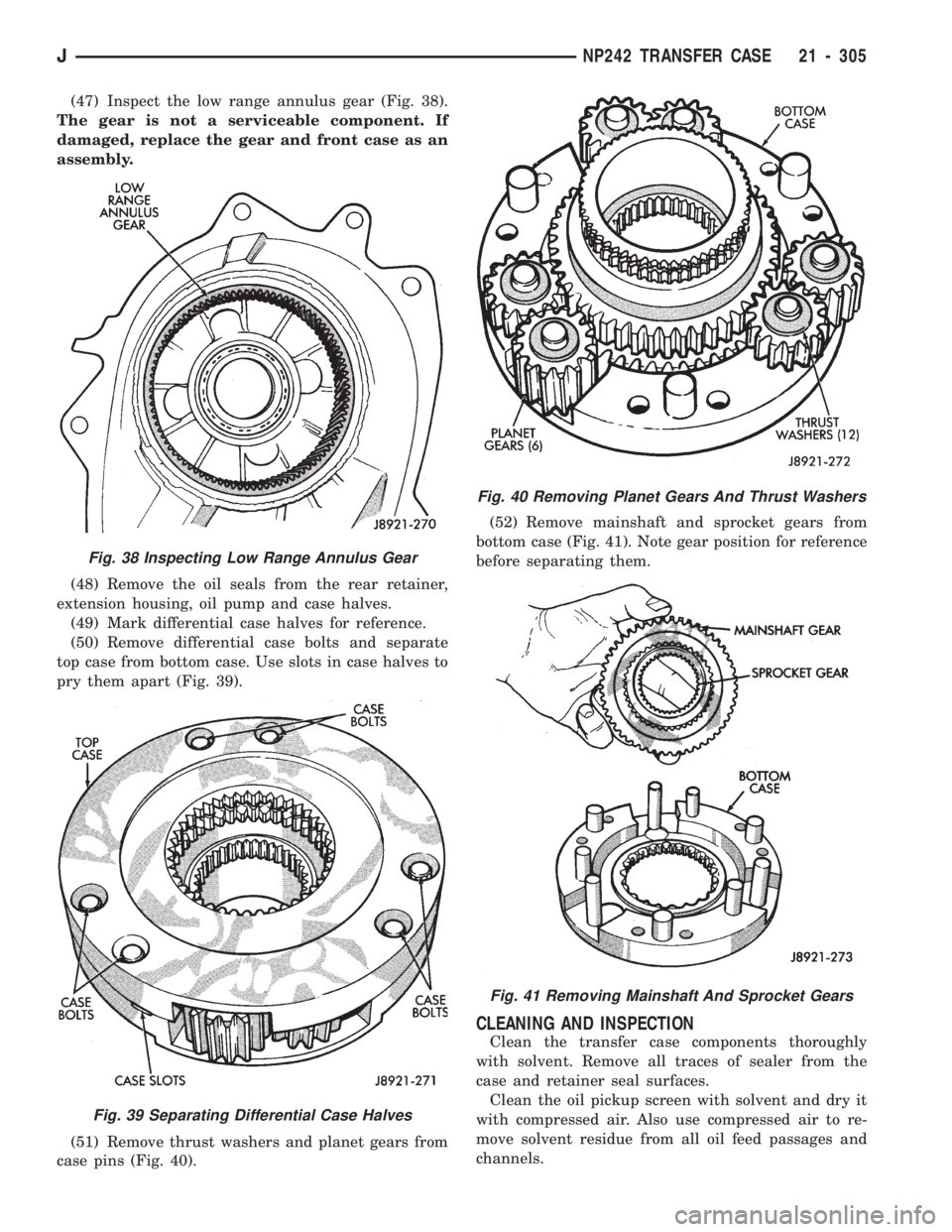

(47) Inspect the low range annulus gear (Fig. 38).

The gear is not a serviceable component. If

damaged, replace the gear and front case as an

assembly.

(48) Remove the oil seals from the rear retainer,

extension housing, oil pump and case halves.

(49) Mark differential case halves for reference.

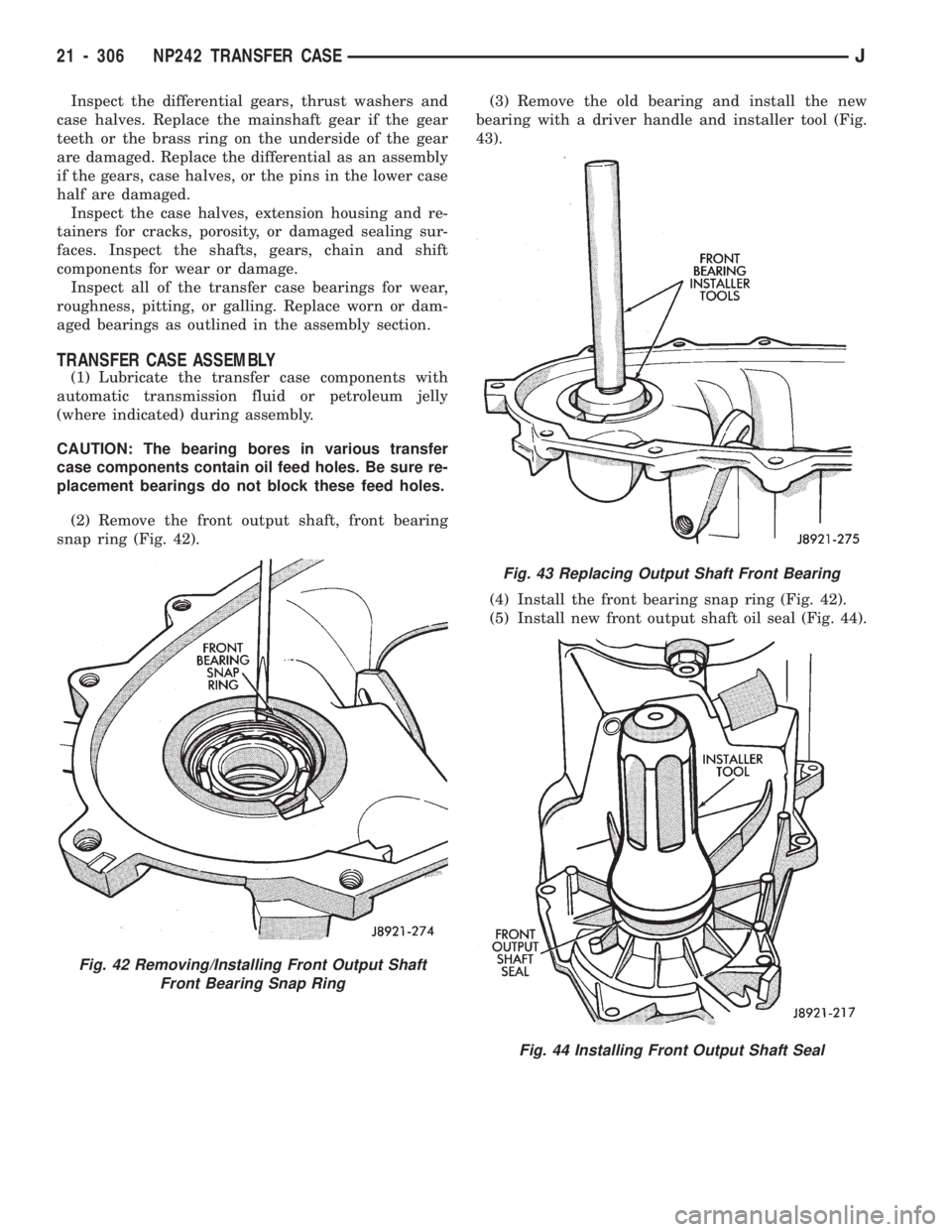

(50) Remove differential case bolts and separate

top case from bottom case. Use slots in case halves to

pry them apart (Fig. 39).

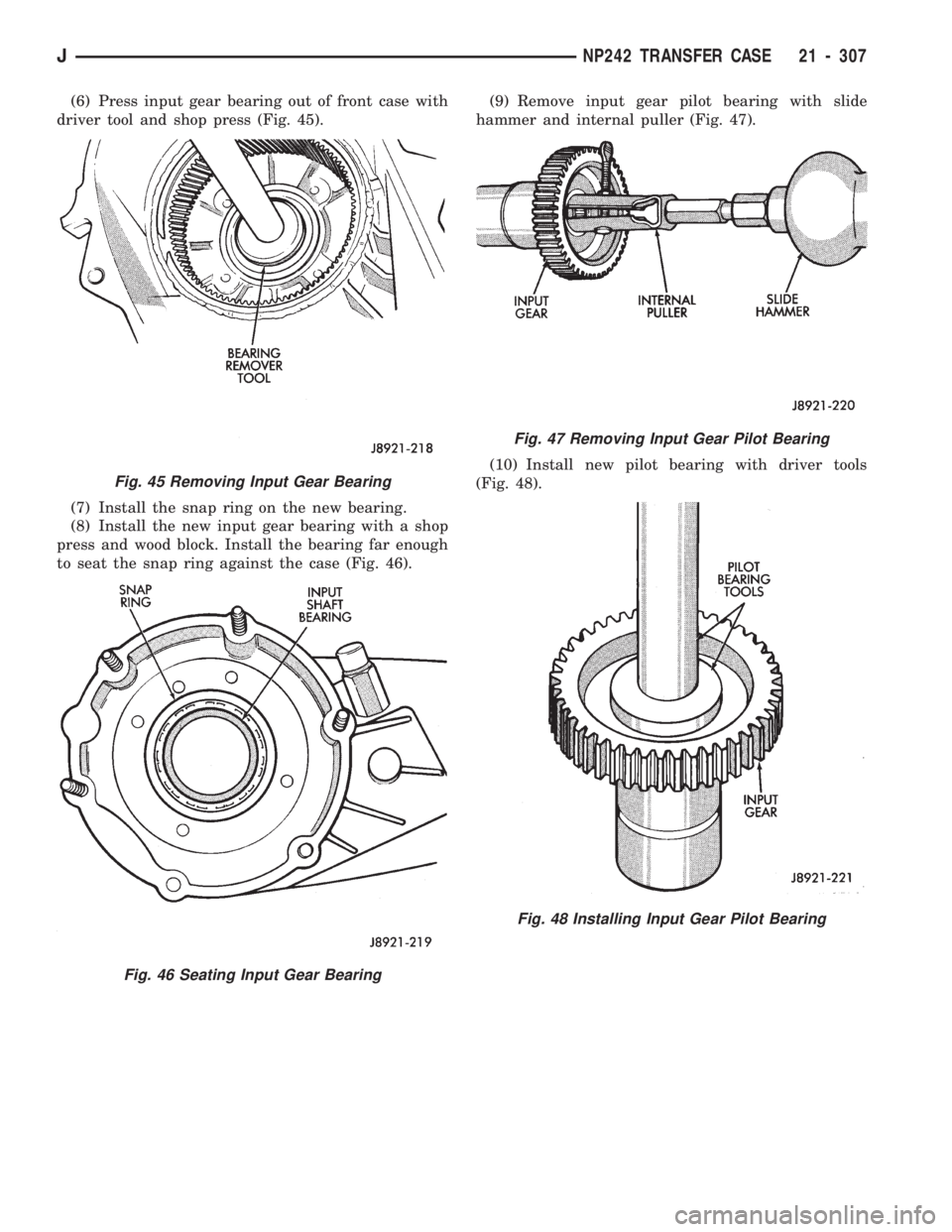

(51) Remove thrust washers and planet gears from

case pins (Fig. 40).(52) Remove mainshaft and sprocket gears from

bottom case (Fig. 41). Note gear position for reference

before separating them.

CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent and dry it

with compressed air. Also use compressed air to re-

move solvent residue from all oil feed passages and

channels.

Fig. 38 Inspecting Low Range Annulus Gear

Fig. 39 Separating Differential Case Halves

Fig. 40 Removing Planet Gears And Thrust Washers

Fig. 41 Removing Mainshaft And Sprocket Gears

JNP242 TRANSFER CASE 21 - 305

Page 1417 of 1784

Inspect the differential gears, thrust washers and

case halves. Replace the mainshaft gear if the gear

teeth or the brass ring on the underside of the gear

are damaged. Replace the differential as an assembly

if the gears, case halves, or the pins in the lower case

half are damaged.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces. Inspect the shafts, gears, chain and shift

components for wear or damage.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the assembly section.

TRANSFER CASE ASSEMBLY

(1) Lubricate the transfer case components with

automatic transmission fluid or petroleum jelly

(where indicated) during assembly.

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

(2) Remove the front output shaft, front bearing

snap ring (Fig. 42).(3) Remove the old bearing and install the new

bearing with a driver handle and installer tool (Fig.

43).

(4) Install the front bearing snap ring (Fig. 42).

(5) Install new front output shaft oil seal (Fig. 44).

Fig. 42 Removing/Installing Front Output Shaft

Front Bearing Snap Ring

Fig. 43 Replacing Output Shaft Front Bearing

Fig. 44 Installing Front Output Shaft Seal

21 - 306 NP242 TRANSFER CASEJ

Page 1418 of 1784

(6) Press input gear bearing out of front case with

driver tool and shop press (Fig. 45).

(7) Install the snap ring on the new bearing.

(8) Install the new input gear bearing with a shop

press and wood block. Install the bearing far enough

to seat the snap ring against the case (Fig. 46).(9) Remove input gear pilot bearing with slide

hammer and internal puller (Fig. 47).

(10) Install new pilot bearing with driver tools

(Fig. 48).

Fig. 45 Removing Input Gear Bearing

Fig. 46 Seating Input Gear Bearing

Fig. 47 Removing Input Gear Pilot Bearing

Fig. 48 Installing Input Gear Pilot Bearing

JNP242 TRANSFER CASE 21 - 307

Page 1419 of 1784

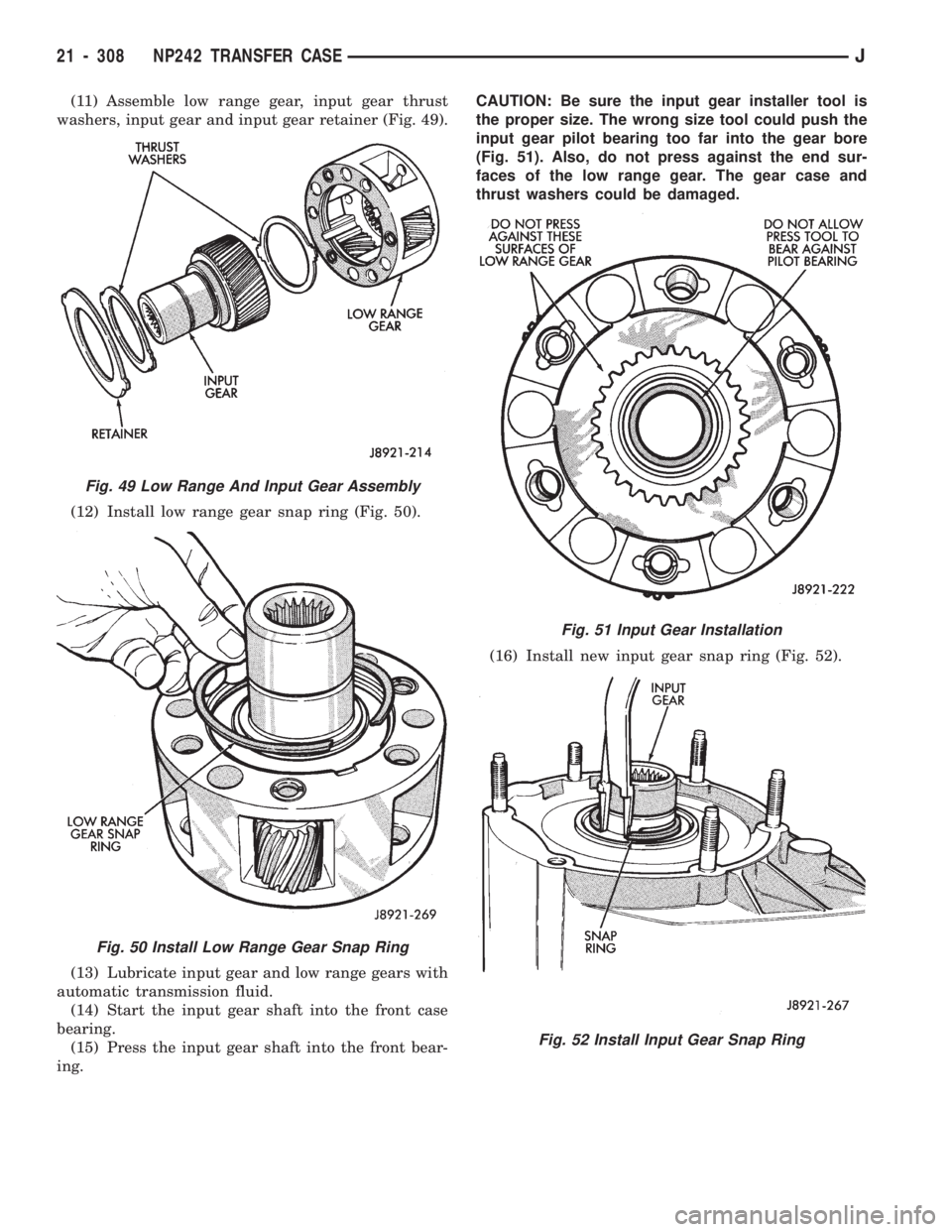

(11) Assemble low range gear, input gear thrust

washers, input gear and input gear retainer (Fig. 49).

(12) Install low range gear snap ring (Fig. 50).

(13) Lubricate input gear and low range gears with

automatic transmission fluid.

(14) Start the input gear shaft into the front case

bearing.

(15) Press the input gear shaft into the front bear-

ing.CAUTION: Be sure the input gear installer tool is

the proper size. The wrong size tool could push the

input gear pilot bearing too far into the gear bore

(Fig. 51). Also, do not press against the end sur-

faces of the low range gear. The gear case and

thrust washers could be damaged.

(16) Install new input gear snap ring (Fig. 52).

Fig. 49 Low Range And Input Gear Assembly

Fig. 50 Install Low Range Gear Snap Ring

Fig. 51 Input Gear Installation

Fig. 52 Install Input Gear Snap Ring

21 - 308 NP242 TRANSFER CASEJ

Page 1420 of 1784

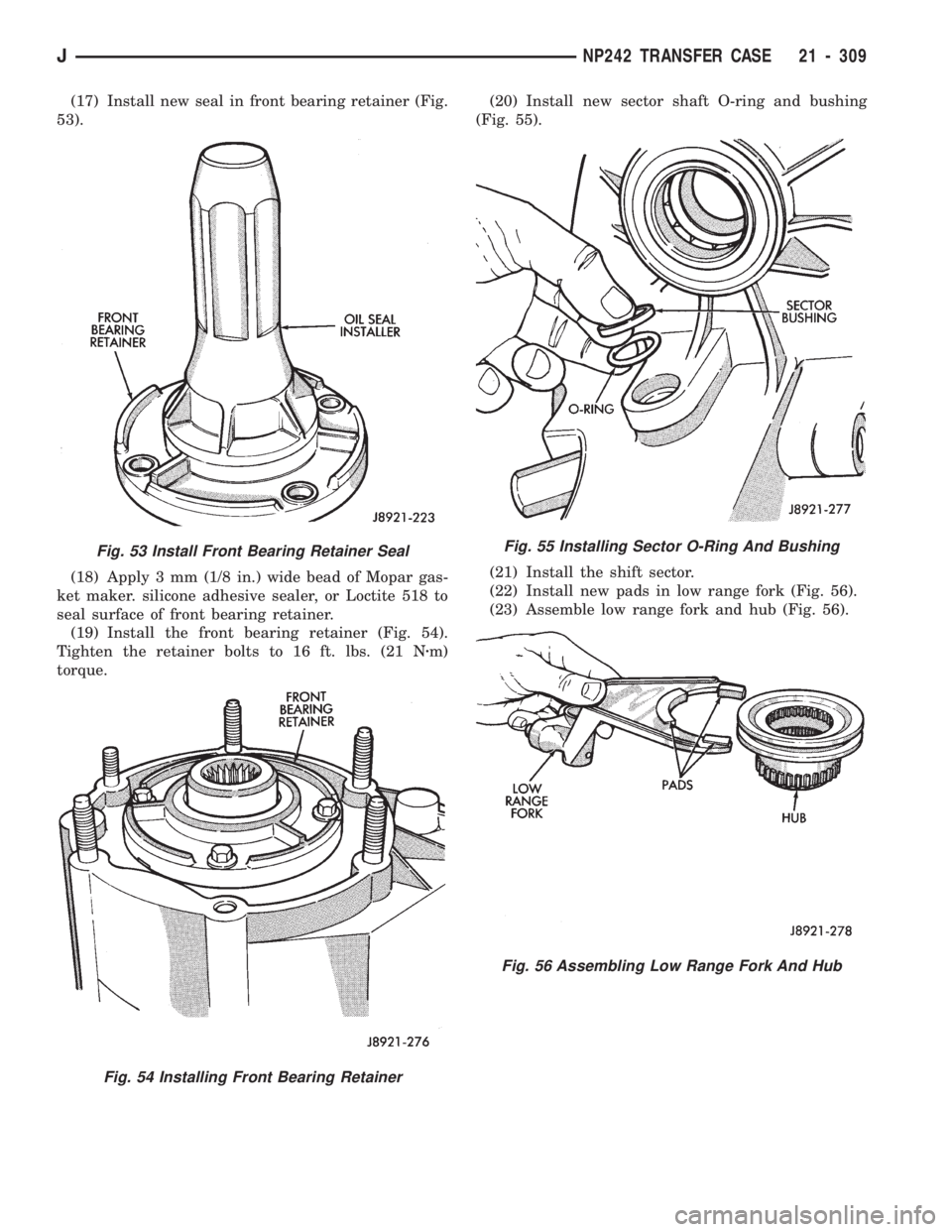

(17) Install new seal in front bearing retainer (Fig.

53).

(18) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker. silicone adhesive sealer, or Loctite 518 to

seal surface of front bearing retainer.

(19) Install the front bearing retainer (Fig. 54).

Tighten the retainer bolts to 16 ft. lbs. (21 Nzm)

torque.(20) Install new sector shaft O-ring and bushing

(Fig. 55).

(21) Install the shift sector.

(22) Install new pads in low range fork (Fig. 56).

(23) Assemble low range fork and hub (Fig. 56).

Fig. 55 Installing Sector O-Ring And Bushing

Fig. 56 Assembling Low Range Fork And Hub

Fig. 53 Install Front Bearing Retainer Seal

Fig. 54 Installing Front Bearing Retainer

JNP242 TRANSFER CASE 21 - 309

Page 1425 of 1784

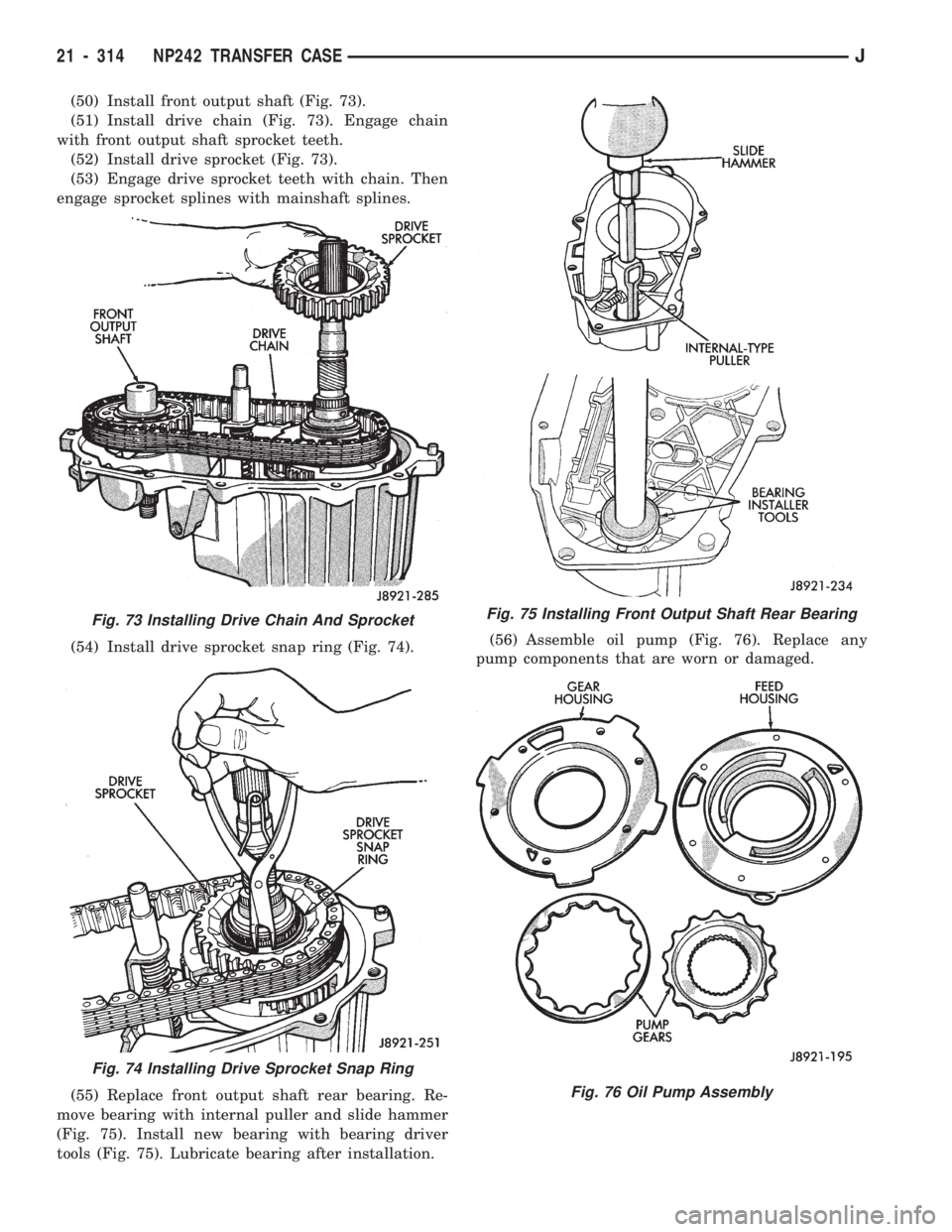

(50) Install front output shaft (Fig. 73).

(51) Install drive chain (Fig. 73). Engage chain

with front output shaft sprocket teeth.

(52) Install drive sprocket (Fig. 73).

(53) Engage drive sprocket teeth with chain. Then

engage sprocket splines with mainshaft splines.

(54) Install drive sprocket snap ring (Fig. 74).

(55) Replace front output shaft rear bearing. Re-

move bearing with internal puller and slide hammer

(Fig. 75). Install new bearing with bearing driver

tools (Fig. 75). Lubricate bearing after installation.(56) Assemble oil pump (Fig. 76). Replace any

pump components that are worn or damaged.

Fig. 73 Installing Drive Chain And Sprocket

Fig. 74 Installing Drive Sprocket Snap Ring

Fig. 75 Installing Front Output Shaft Rear Bearing

Fig. 76 Oil Pump Assembly

21 - 314 NP242 TRANSFER CASEJ

Page 1426 of 1784

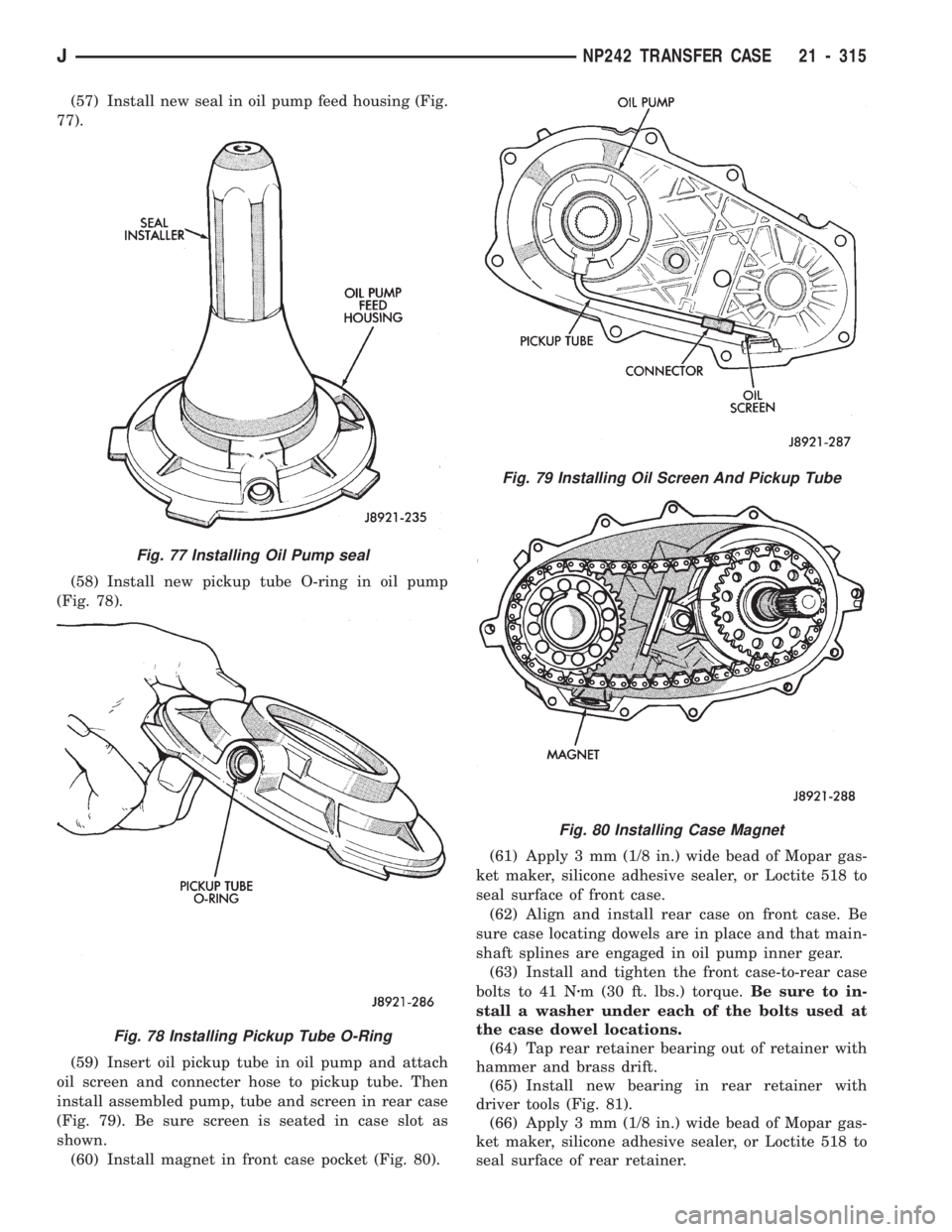

(57) Install new seal in oil pump feed housing (Fig.

77).

(58) Install new pickup tube O-ring in oil pump

(Fig. 78).

(59) Insert oil pickup tube in oil pump and attach

oil screen and connecter hose to pickup tube. Then

install assembled pump, tube and screen in rear case

(Fig. 79). Be sure screen is seated in case slot as

shown.

(60) Install magnet in front case pocket (Fig. 80).(61) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of front case.

(62) Align and install rear case on front case. Be

sure case locating dowels are in place and that main-

shaft splines are engaged in oil pump inner gear.

(63) Install and tighten the front case-to-rear case

bolts to 41 Nzm (30 ft. lbs.) torque.Be sure to in-

stall a washer under each of the bolts used at

the case dowel locations.

(64) Tap rear retainer bearing out of retainer with

hammer and brass drift.

(65) Install new bearing in rear retainer with

driver tools (Fig. 81).

(66) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of rear retainer.

Fig. 77 Installing Oil Pump seal

Fig. 78 Installing Pickup Tube O-Ring

Fig. 79 Installing Oil Screen And Pickup Tube

Fig. 80 Installing Case Magnet

JNP242 TRANSFER CASE 21 - 315

Page 1428 of 1784

(72) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of extension housing.

(73) Install extension housing on case. Tighten

housing bolts to 41 Nzm (30 ft. lbs.) torque.

(74) Install front yoke. Secure yoke with new seal

washer and nut. Tighten nut to 149 Nzm (110 ft. lbs.)

torque.

(75) Install new gasket on vacuum switch and in-

stall switch in the case. Tighten switch to 27 Nzm (20

ft. lbs.) torque.

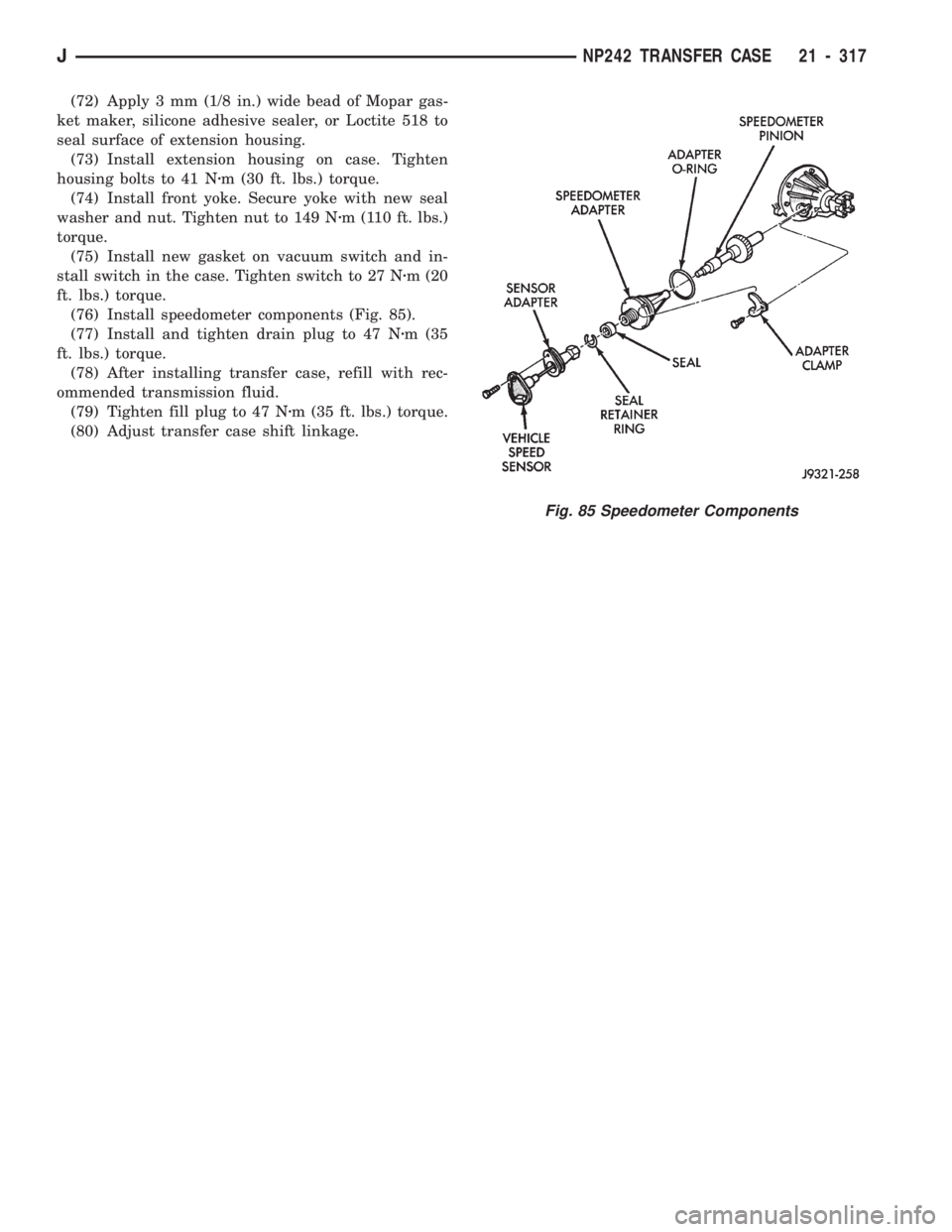

(76) Install speedometer components (Fig. 85).

(77) Install and tighten drain plug to 47 Nzm (35

ft. lbs.) torque.

(78) After installing transfer case, refill with rec-

ommended transmission fluid.

(79) Tighten fill plug to 47 Nzm (35 ft. lbs.) torque.

(80) Adjust transfer case shift linkage.

Fig. 85 Speedometer Components

JNP242 TRANSFER CASE 21 - 317

Page 1444 of 1784

WHEELS AND TIRES

CONTENTS

page page

SPECIFICATIONS....................... 11

TIRES................................. 1VEHICLE VIBRATION..................... 9

WHEELS............................... 6

TIRES

INDEX

page page

Cleaning of Tires.......................... 2

General Information........................ 1

Pressure Gauges......................... 2

Repairing Leaks.......................... 3

Replacement Tires........................ 2Rotation................................ 3

Tire Inflation Pressures..................... 2

Tire Noise or Vibration..................... 4

Tire Wear Patterns........................ 4

Tread Wear Indicators...................... 3

GENERAL INFORMATION

Tires are designed for each specific vehicle. They

provide the best overall performance for normal op-

eration. The ride and handling characteristics match

the vehicle's requirements. With proper care they

will give excellent reliability, traction, skid resis-

tance, and tread life. These tires have specific load

carrying capacities. When correctly inflated, they

will operate properly.

Tires used in cool climates, and with light loads

will have a longer life than tires used in hot climates

with heavy loads. Abrasive road surfaces will accel-

erate tire wear.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain much

greater mileage than careless drivers.

Driving habits that shorten the life of any tire;

²Rapid acceleration and deceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

It is very important to follow the tire rotation in-

terval

IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).

Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating isnot always printed on the tire sidewall. The letterS

indicates that the tire is speed rated up to 112 mph.

²Qup to 100 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manufac-

turer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorMÐS(indicating mud and snow traction) im-

printed on the side wall.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary, but reduced speeds are

recommended.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They use

the same recommended inflation pressures.

SPARE TIRE (TEMPORARY)

The compact spare tire is designed for emergency

use only. The original tire should be repaired and re-

installed at the first opportunity. Refer to Owner's

Manual for complete details.

JWHEELS AND TIRES 22 - 1

Page 1446 of 1784

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

Original equipment tires should be used when re-

placement is needed.

Refer to the placard on the vehicle or the

Owner's Manual for the correct replacement

tire.

Failure to use original or equivalent replacement

tires may adversely affect the handling of the vehi-

cle.

The use of oversize tiresis not recommended.

They may cause interference with vehicle suspension

and steering travel. This can cause tire damage or

failure.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE LOAD CAPABILITY CAN

RESULT IN SUDDEN TIRE FAILURE.

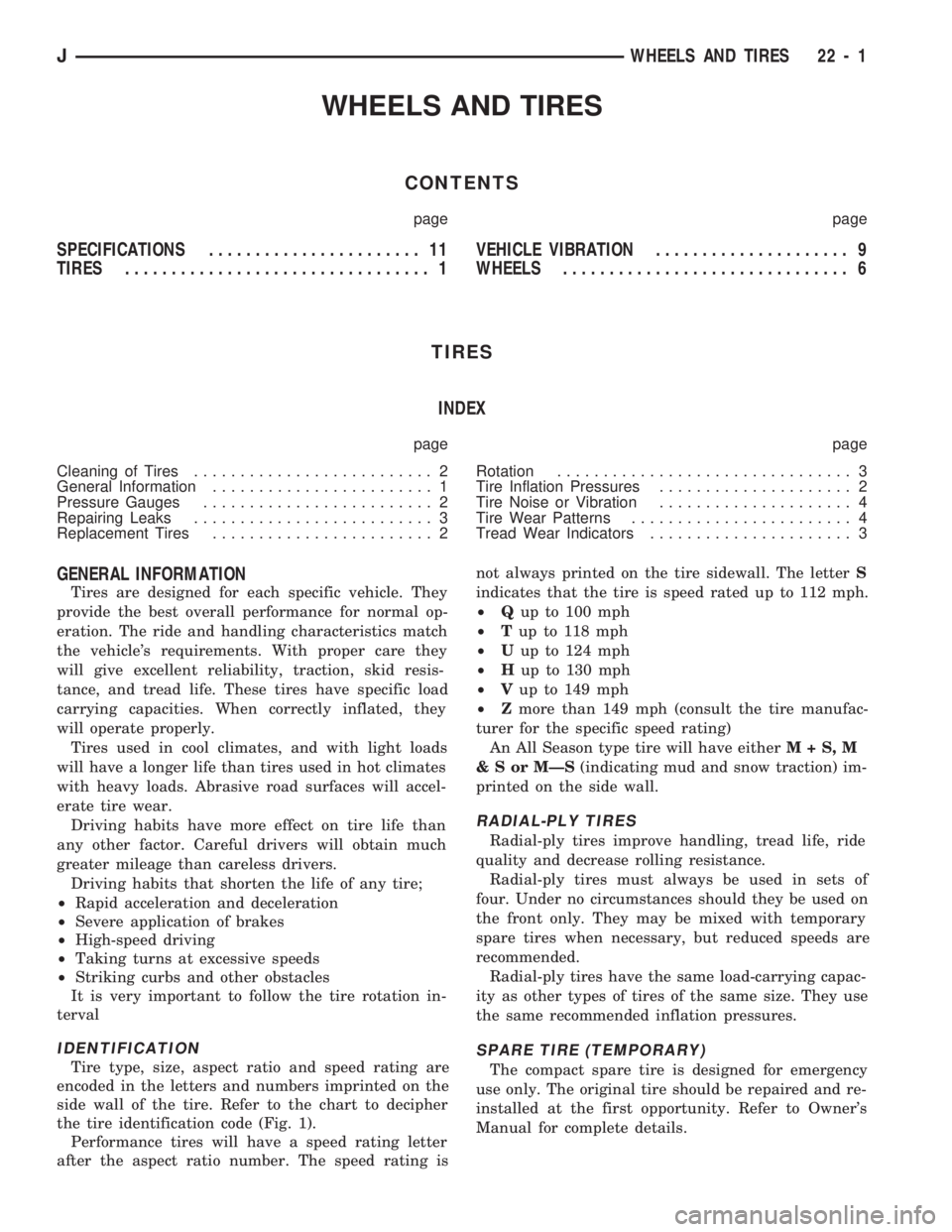

ROTATION

Tires on the front and rear axles operate at differ-

ent loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotat-

ing the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The suggested method of tire rotation is thesame

side front to rearpattern (Fig. 4). Other rotation

methods can be used, but may not provide the same

tire longevity benefits.

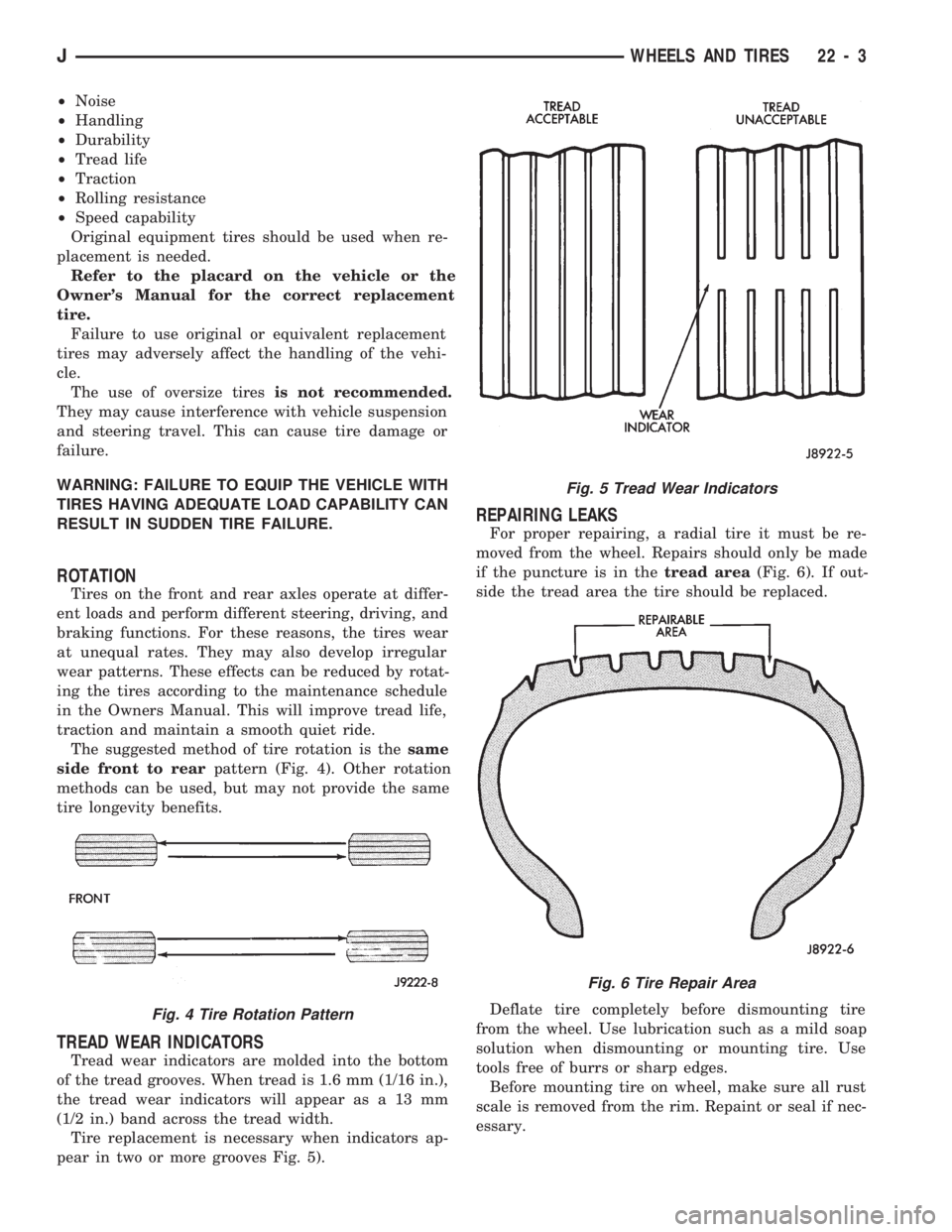

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread is 1.6 mm (1/16 in.),

the tread wear indicators will appear as a 13 mm

(1/2 in.) band across the tread width.

Tire replacement is necessary when indicators ap-

pear in two or more grooves Fig. 5).

REPAIRING LEAKS

For proper repairing, a radial tire it must be re-

moved from the wheel. Repairs should only be made

if the puncture is in thetread area(Fig. 6). If out-

side the tread area the tire should be replaced.

Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges.

Before mounting tire on wheel, make sure all rust

scale is removed from the rim. Repaint or seal if nec-

essary.

Fig. 4 Tire Rotation Pattern

Fig. 5 Tread Wear Indicators

Fig. 6 Tire Repair Area

JWHEELS AND TIRES 22 - 3