front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1453 of 1784

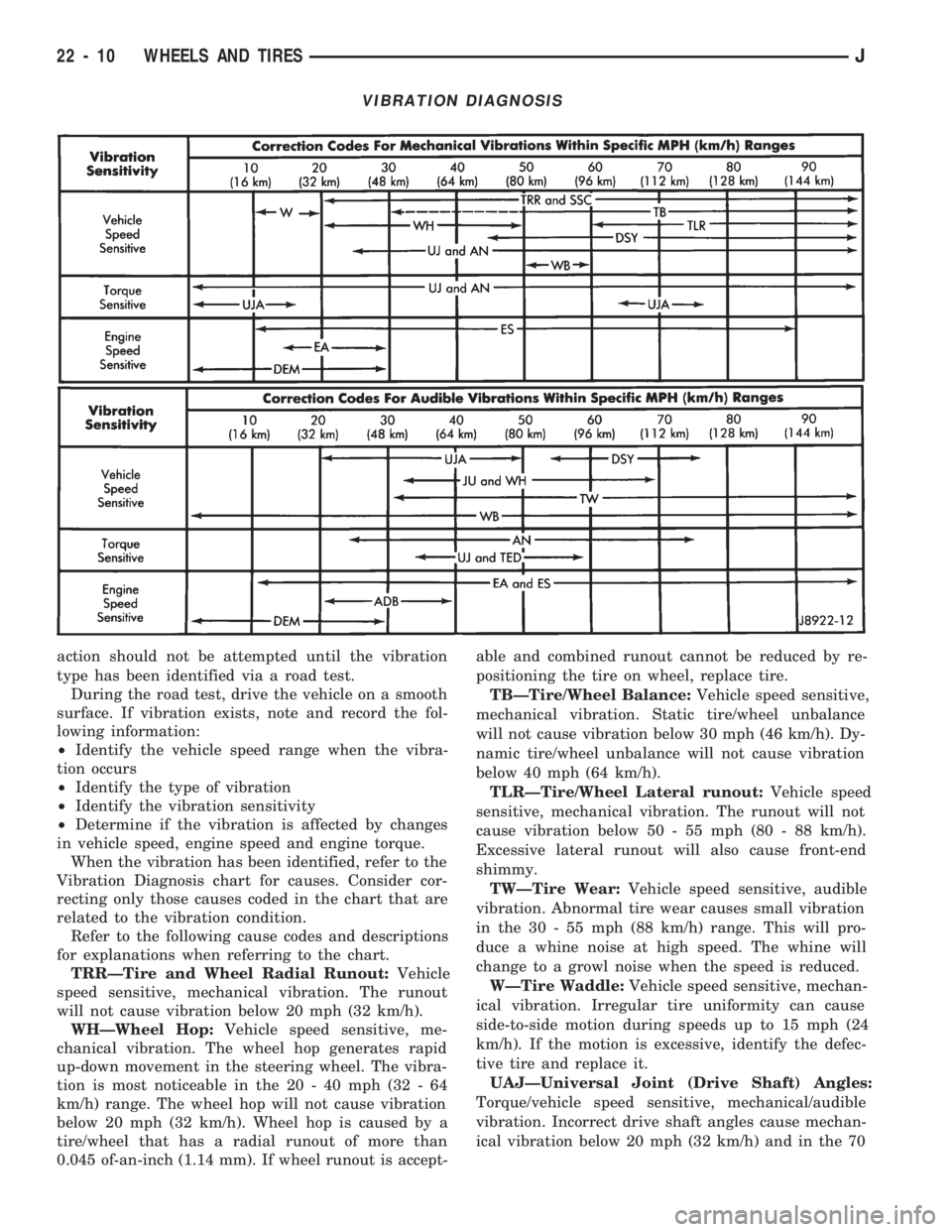

action should not be attempted until the vibration

type has been identified via a road test.

During the road test, drive the vehicle on a smooth

surface. If vibration exists, note and record the fol-

lowing information:

²Identify the vehicle speed range when the vibra-

tion occurs

²Identify the type of vibration

²Identify the vibration sensitivity

²Determine if the vibration is affected by changes

in vehicle speed, engine speed and engine torque.

When the vibration has been identified, refer to the

Vibration Diagnosis chart for causes. Consider cor-

recting only those causes coded in the chart that are

related to the vibration condition.

Refer to the following cause codes and descriptions

for explanations when referring to the chart.

TRRÐTire and Wheel Radial Runout:Vehicle

speed sensitive, mechanical vibration. The runout

will not cause vibration below 20 mph (32 km/h).

WHÐWheel Hop:Vehicle speed sensitive, me-

chanical vibration. The wheel hop generates rapid

up-down movement in the steering wheel. The vibra-

tion is most noticeable in the 20 - 40 mph (32 - 64

km/h) range. The wheel hop will not cause vibration

below 20 mph (32 km/h). Wheel hop is caused by a

tire/wheel that has a radial runout of more than

0.045 of-an-inch (1.14 mm). If wheel runout is accept-able and combined runout cannot be reduced by re-

positioning the tire on wheel, replace tire.

TBÐTire/Wheel Balance:Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy-

namic tire/wheel unbalance will not cause vibration

below 40 mph (64 km/h).

TLRÐTire/Wheel Lateral runout:Vehicle speed

sensitive, mechanical vibration. The runout will not

cause vibration below 50 - 55 mph (80 - 88 km/h).

Excessive lateral runout will also cause front-end

shimmy.

TWÐTire Wear:Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration

in the 30 - 55 mph (88 km/h) range. This will pro-

duce a whine noise at high speed. The whine will

change to a growl noise when the speed is reduced.

WÐTire Waddle:Vehicle speed sensitive, mechan-

ical vibration. Irregular tire uniformity can cause

side-to-side motion during speeds up to 15 mph (24

km/h). If the motion is excessive, identify the defec-

tive tire and replace it.

UAJÐUniversal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible

vibration. Incorrect drive shaft angles cause mechan-

ical vibration below 20 mph (32 km/h) and in the 70

VIBRATION DIAGNOSIS

22 - 10 WHEELS AND TIRESJ

Page 1457 of 1784

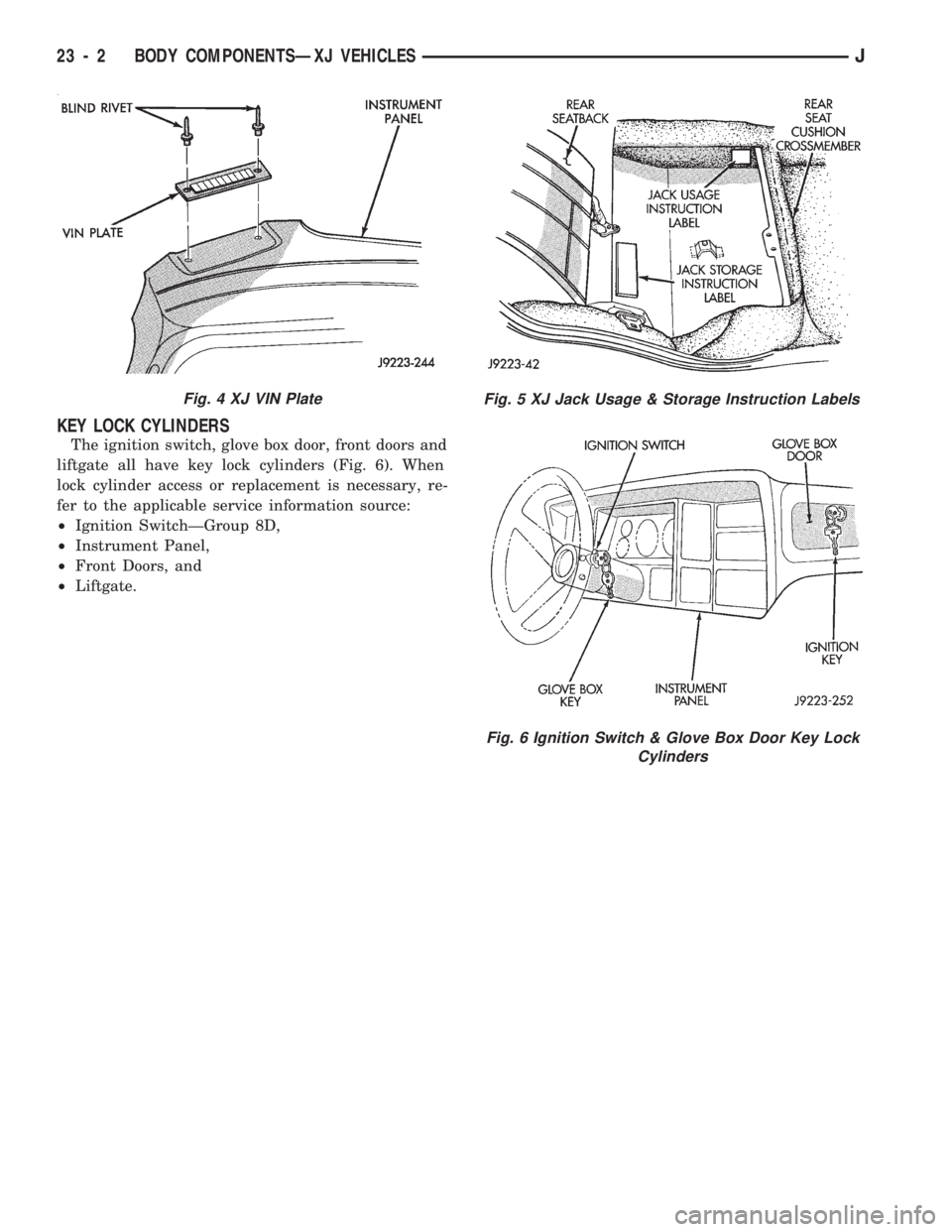

KEY LOCK CYLINDERS

The ignition switch, glove box door, front doors and

liftgate all have key lock cylinders (Fig. 6). When

lock cylinder access or replacement is necessary, re-

fer to the applicable service information source:

²Ignition SwitchÐGroup 8D,

²Instrument Panel,

²Front Doors, and

²Liftgate.

Fig. 4 XJ VIN PlateFig. 5 XJ Jack Usage & Storage Instruction Labels

Fig. 6 Ignition Switch & Glove Box Door Key Lock

Cylinders

23 - 2 BODY COMPONENTSÐXJ VEHICLESJ

Page 1458 of 1784

EXTERIOR COMPONENTS

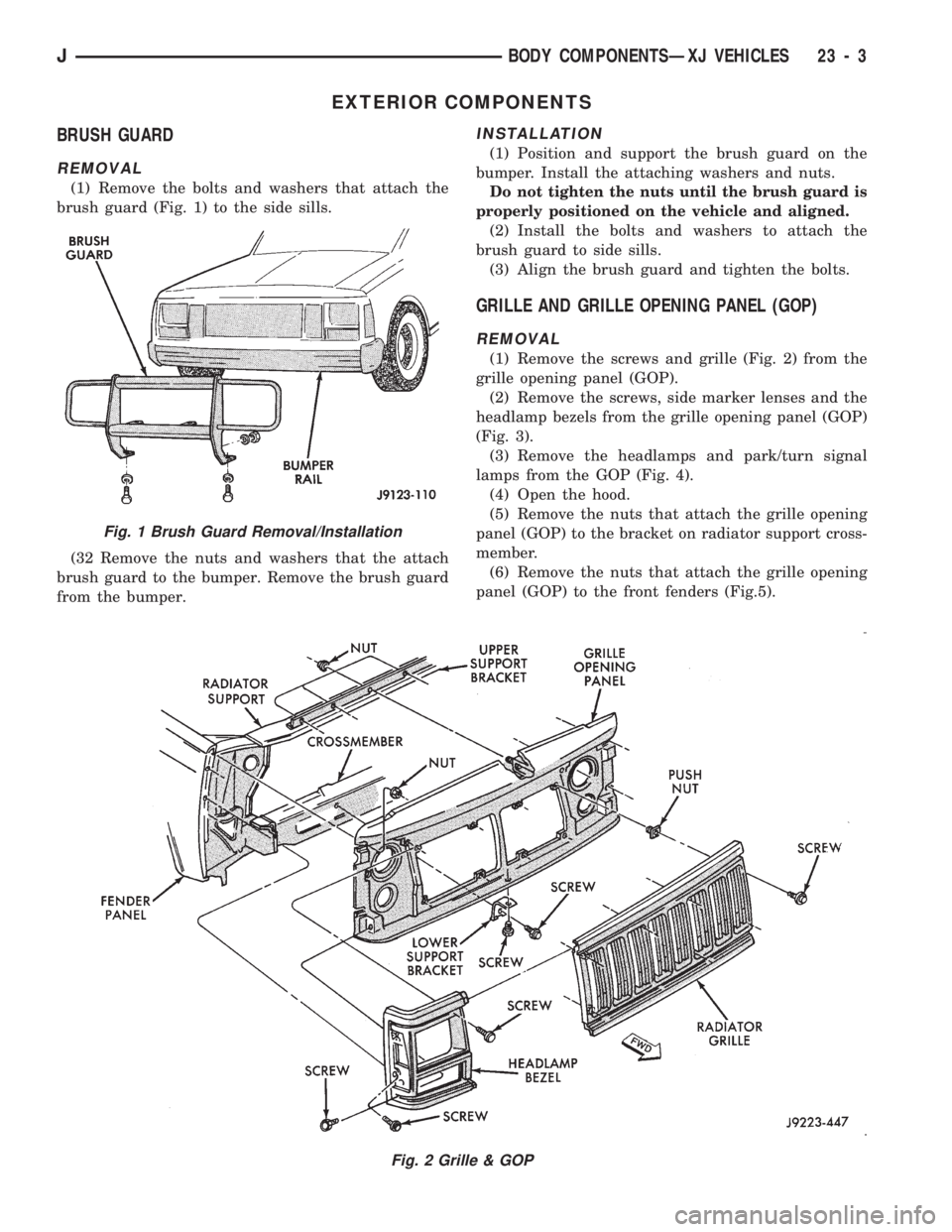

BRUSH GUARD

REMOVAL

(1) Remove the bolts and washers that attach the

brush guard (Fig. 1) to the side sills.

(32 Remove the nuts and washers that the attach

brush guard to the bumper. Remove the brush guard

from the bumper.

INSTALLATION

(1) Position and support the brush guard on the

bumper. Install the attaching washers and nuts.

Do not tighten the nuts until the brush guard is

properly positioned on the vehicle and aligned.

(2) Install the bolts and washers to attach the

brush guard to side sills.

(3) Align the brush guard and tighten the bolts.

GRILLE AND GRILLE OPENING PANEL (GOP)

REMOVAL

(1) Remove the screws and grille (Fig. 2) from the

grille opening panel (GOP).

(2) Remove the screws, side marker lenses and the

headlamp bezels from the grille opening panel (GOP)

(Fig. 3).

(3) Remove the headlamps and park/turn signal

lamps from the GOP (Fig. 4).

(4) Open the hood.

(5) Remove the nuts that attach the grille opening

panel (GOP) to the bracket on radiator support cross-

member.

(6) Remove the nuts that attach the grille opening

panel (GOP) to the front fenders (Fig.5).

Fig. 2 Grille & GOP

Fig. 1 Brush Guard Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 3

Page 1459 of 1784

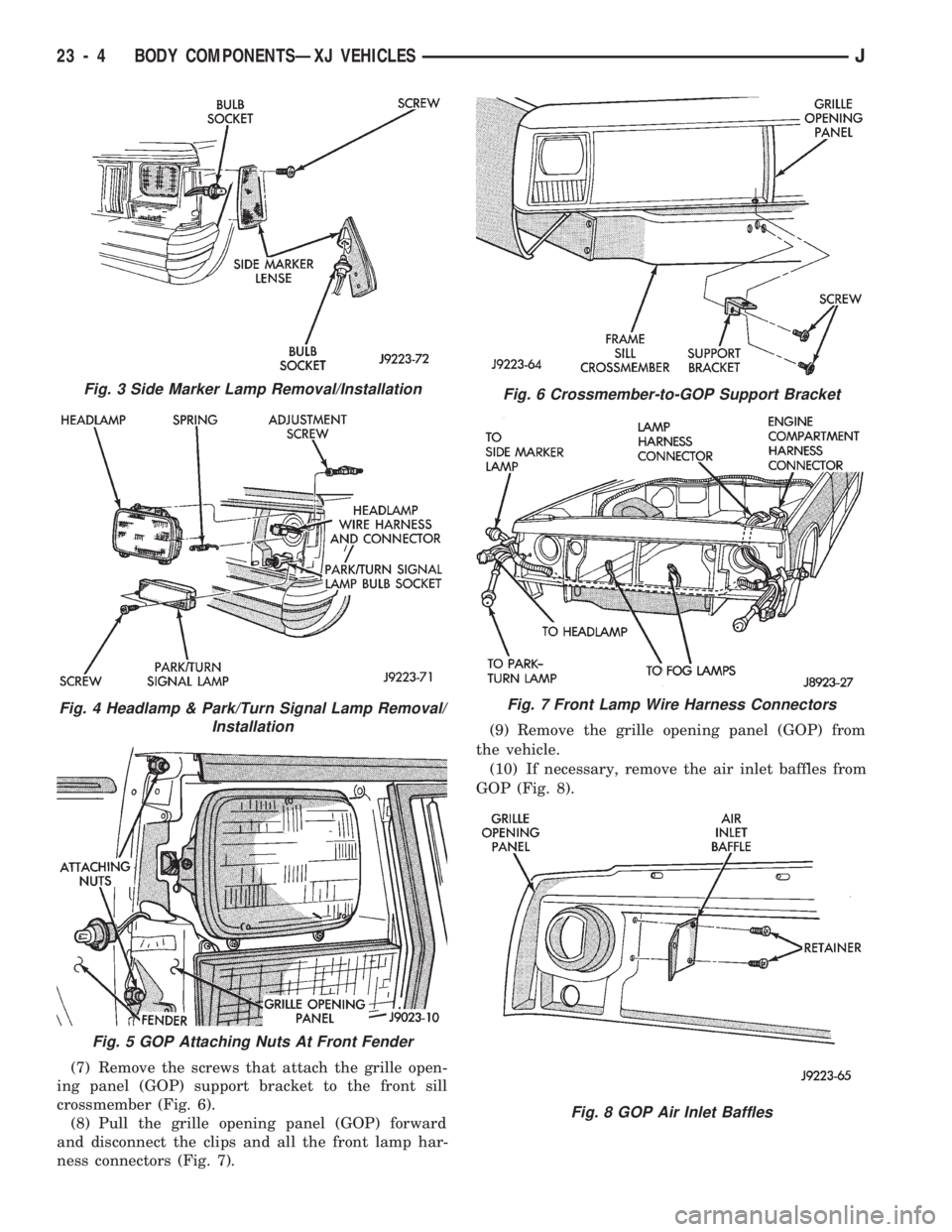

(7) Remove the screws that attach the grille open-

ing panel (GOP) support bracket to the front sill

crossmember (Fig. 6).

(8) Pull the grille opening panel (GOP) forward

and disconnect the clips and all the front lamp har-

ness connectors (Fig. 7).(9) Remove the grille opening panel (GOP) from

the vehicle.

(10) If necessary, remove the air inlet baffles from

GOP (Fig. 8).

Fig. 3 Side Marker Lamp Removal/Installation

Fig. 4 Headlamp & Park/Turn Signal Lamp Removal/

Installation

Fig. 5 GOP Attaching Nuts At Front Fender

Fig. 6 Crossmember-to-GOP Support Bracket

Fig. 7 Front Lamp Wire Harness Connectors

Fig. 8 GOP Air Inlet Baffles

23 - 4 BODY COMPONENTSÐXJ VEHICLESJ

Page 1460 of 1784

INSTALLATION

(1) Place the grille opening panel (GOP) on bumper

and connect all front lamp wire harness connectors.

(2) Position the grille opening panel (GOP) on the

vehicle and install the side and upper nuts. Tighten

nuts to 7 Nzm (58 in-lbs) torque.

(3) Install the screw to attach grille opening panel

(GOP) to the crossmember support bracket. Tighten

the screw to 1 Nzm (11 in-lbs) torque.

(4) Install headlamps and park/turn signal lamps

in GOP.(5) Install the headlamp bezels on the GOP.

Tighten the screws to 1 Nzm (13 in-lbs) torque.

(6) Install the side marker lenses and screws on

the grille opening panel (GOP). Tighten the screws to

1Nzm (13 in-lbs) torque.

(7) Install the grille on the GOP. Tighten screws to

1Nzm (13 in-lbs) torque.

(8) Adjust the headlamp aim, if necessary. Refer to

the headlamp beam adjustment procedure within

Group 8L.

RADIATOR SUPPORT CROSSMEMBER

REMOVAL

(1) Remove the grille opening panel (GOP) (Fig. 2).

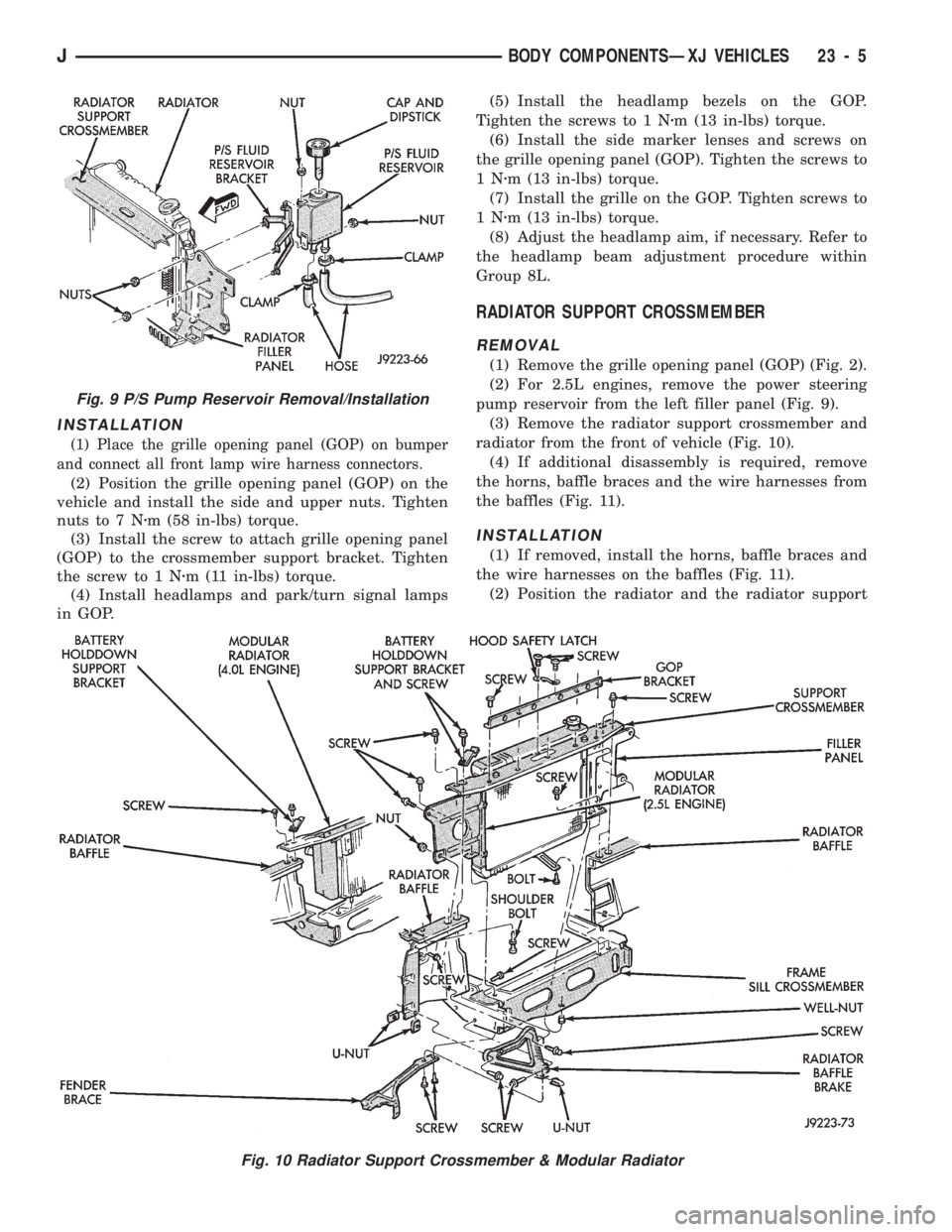

(2) For 2.5L engines, remove the power steering

pump reservoir from the left filler panel (Fig. 9).

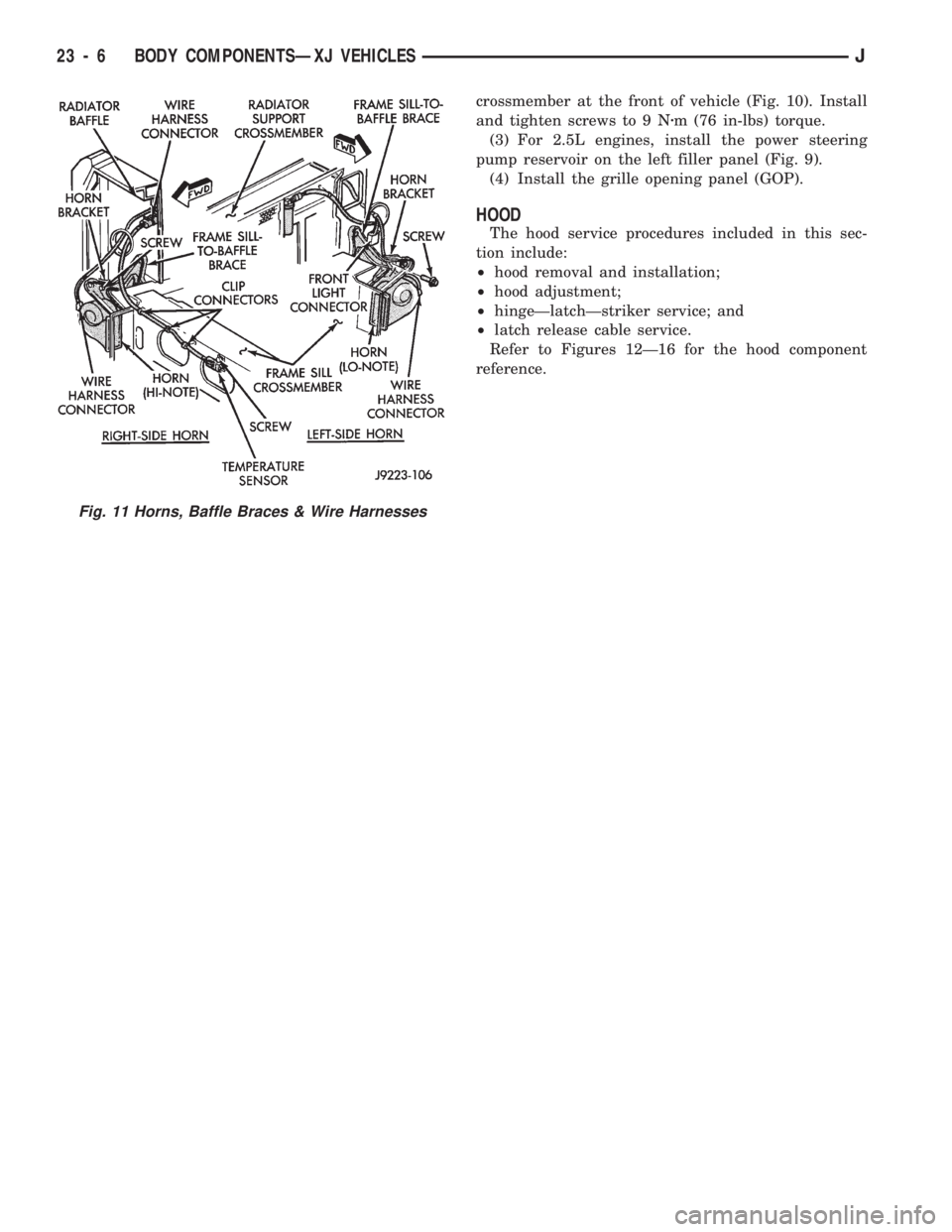

(3) Remove the radiator support crossmember and

radiator from the front of vehicle (Fig. 10).

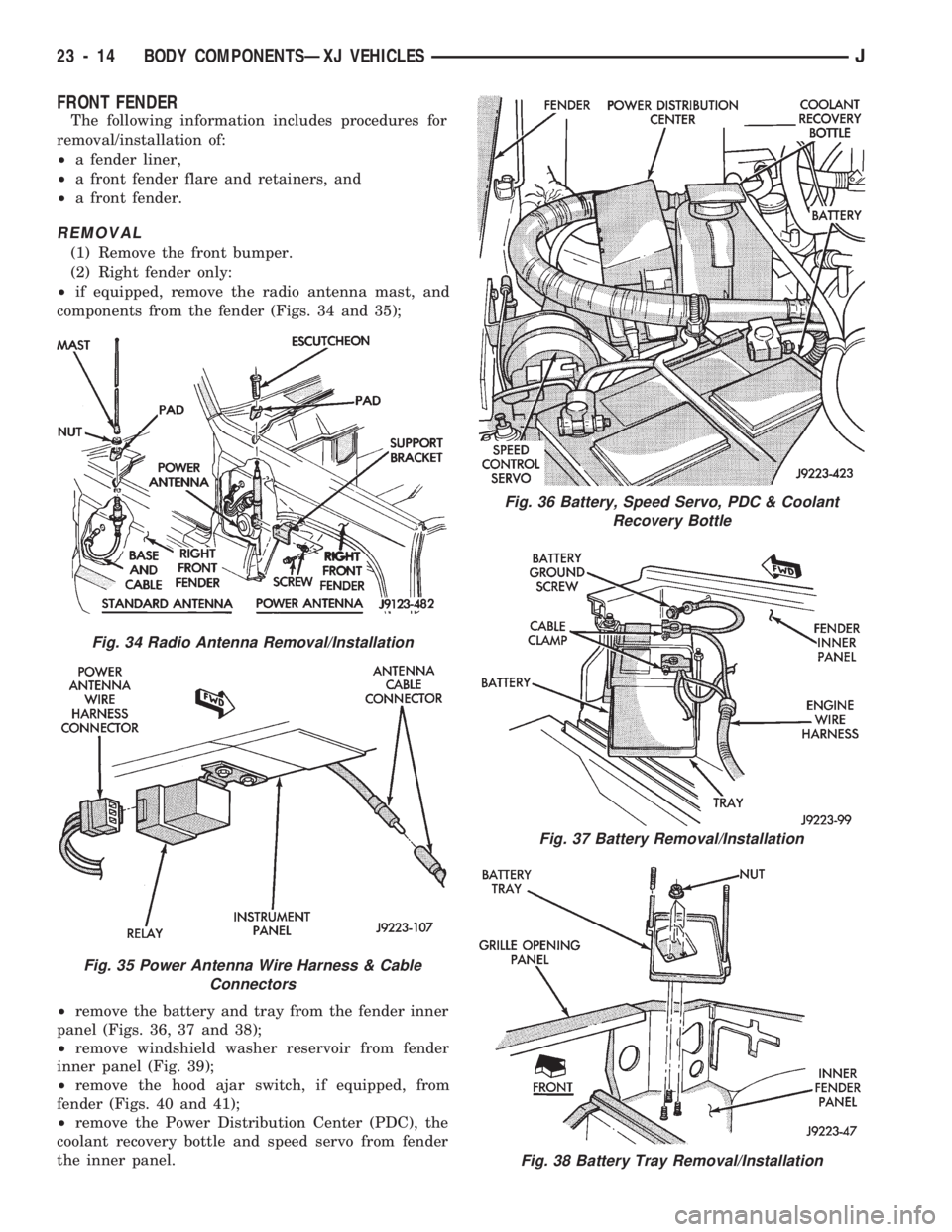

(4) If additional disassembly is required, remove

the horns, baffle braces and the wire harnesses from

the baffles (Fig. 11).

INSTALLATION

(1) If removed, install the horns, baffle braces and

the wire harnesses on the baffles (Fig. 11).

(2) Position the radiator and the radiator support

Fig. 9 P/S Pump Reservoir Removal/Installation

Fig. 10 Radiator Support Crossmember & Modular Radiator

JBODY COMPONENTSÐXJ VEHICLES 23 - 5

Page 1461 of 1784

crossmember at the front of vehicle (Fig. 10). Install

and tighten screws to 9 Nzm (76 in-lbs) torque.

(3) For 2.5L engines, install the power steering

pump reservoir on the left filler panel (Fig. 9).

(4) Install the grille opening panel (GOP).

HOOD

The hood service procedures included in this sec-

tion include:

²hood removal and installation;

²hood adjustment;

²hingeÐlatchÐstriker service; and

²latch release cable service.

Refer to Figures 12Ð16 for the hood component

reference.

Fig. 11 Horns, Baffle Braces & Wire Harnesses

23 - 6 BODY COMPONENTSÐXJ VEHICLESJ

Page 1469 of 1784

FRONT FENDER

The following information includes procedures for

removal/installation of:

²a fender liner,

²a front fender flare and retainers, and

²a front fender.

REMOVAL

(1) Remove the front bumper.

(2) Right fender only:

²if equipped, remove the radio antenna mast, and

components from the fender (Figs. 34 and 35);

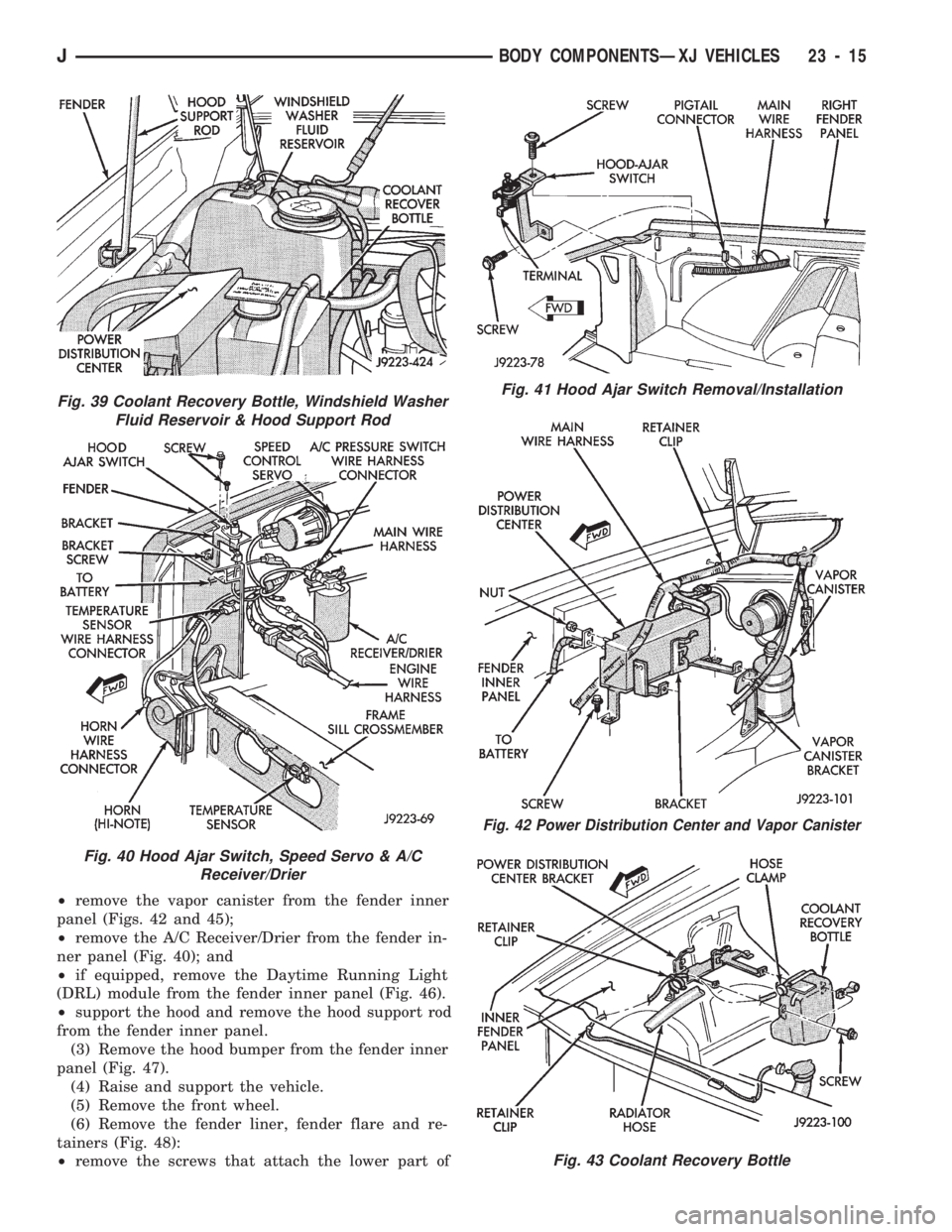

²remove the battery and tray from the fender inner

panel (Figs. 36, 37 and 38);

²remove windshield washer reservoir from fender

inner panel (Fig. 39);

²remove the hood ajar switch, if equipped, from

fender (Figs. 40 and 41);

²remove the Power Distribution Center (PDC), the

coolant recovery bottle and speed servo from fender

the inner panel.

Fig. 36 Battery, Speed Servo, PDC & Coolant

Recovery Bottle

Fig. 37 Battery Removal/Installation

Fig. 38 Battery Tray Removal/Installation

Fig. 34 Radio Antenna Removal/Installation

Fig. 35 Power Antenna Wire Harness & Cable

Connectors

23 - 14 BODY COMPONENTSÐXJ VEHICLESJ

Page 1470 of 1784

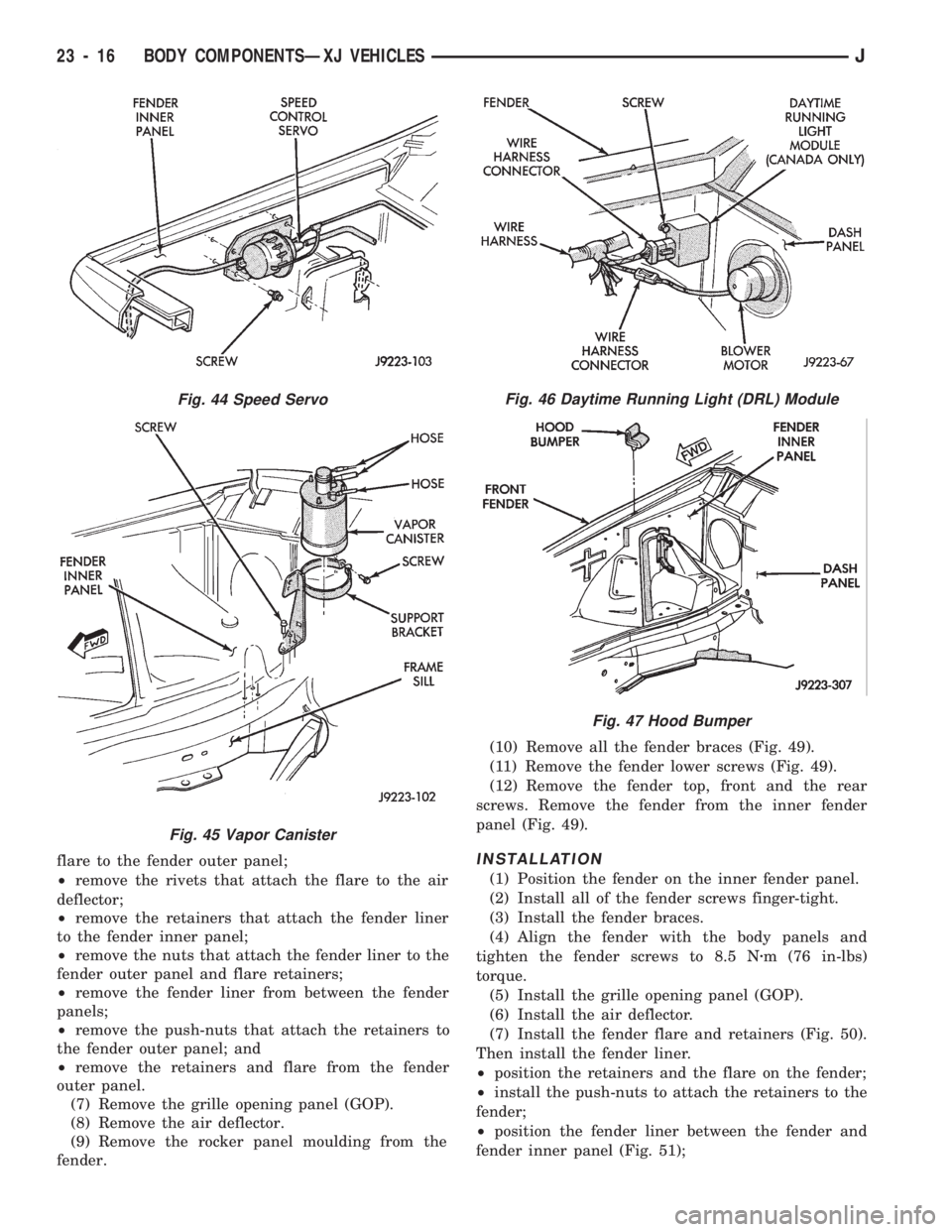

²remove the vapor canister from the fender inner

panel (Figs. 42 and 45);

²remove the A/C Receiver/Drier from the fender in-

ner panel (Fig. 40); and

²if equipped, remove the Daytime Running Light

(DRL) module from the fender inner panel (Fig. 46).

²support the hood and remove the hood support rod

from the fender inner panel.

(3) Remove the hood bumper from the fender inner

panel (Fig. 47).

(4) Raise and support the vehicle.

(5) Remove the front wheel.

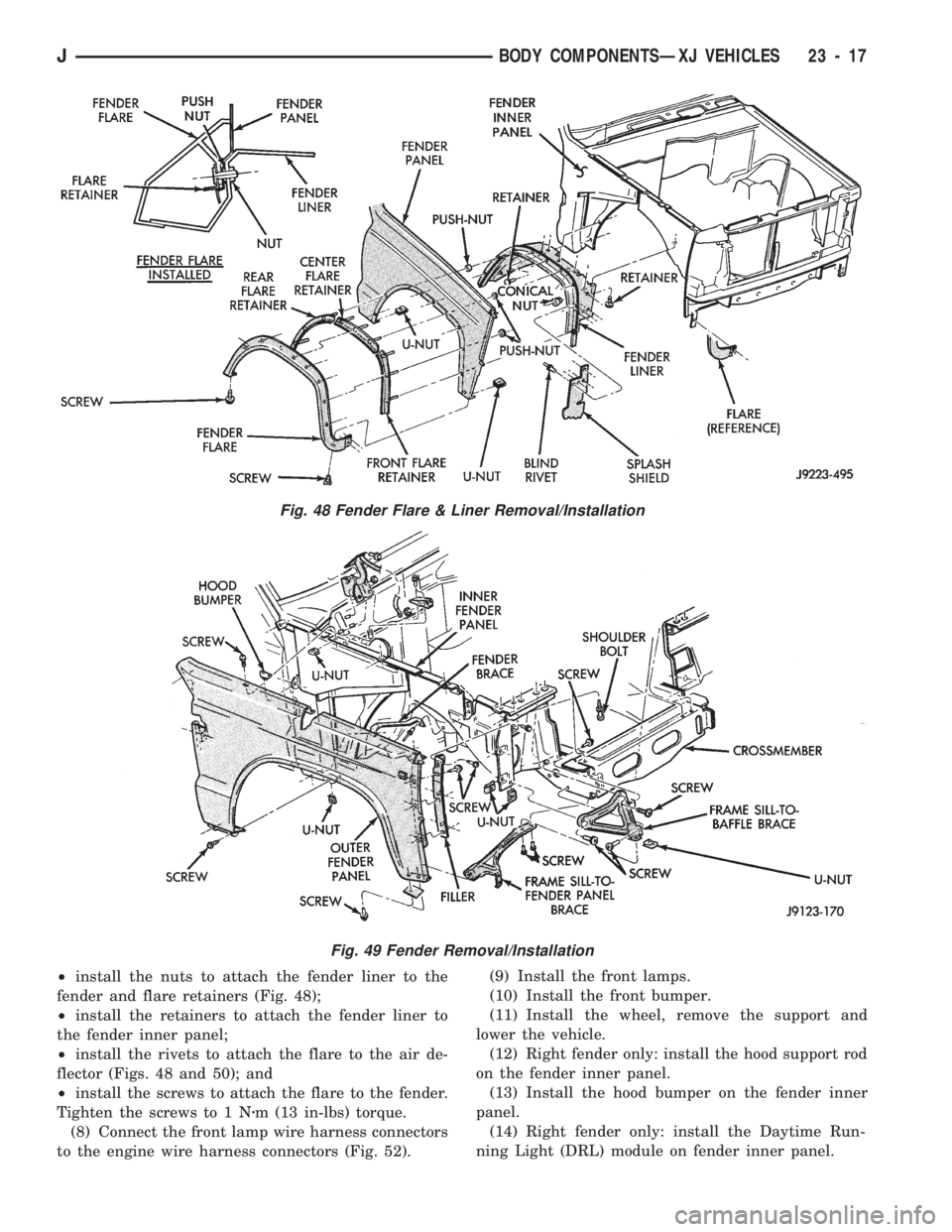

(6) Remove the fender liner, fender flare and re-

tainers (Fig. 48):

²remove the screws that attach the lower part of

Fig. 41 Hood Ajar Switch Removal/Installation

Fig. 42 Power Distribution Center and Vapor Canister

Fig. 43 Coolant Recovery Bottle

Fig. 39 Coolant Recovery Bottle, Windshield Washer

Fluid Reservoir & Hood Support Rod

Fig. 40 Hood Ajar Switch, Speed Servo & A/C

Receiver/Drier

JBODY COMPONENTSÐXJ VEHICLES 23 - 15

Page 1471 of 1784

flare to the fender outer panel;

²remove the rivets that attach the flare to the air

deflector;

²remove the retainers that attach the fender liner

to the fender inner panel;

²remove the nuts that attach the fender liner to the

fender outer panel and flare retainers;

²remove the fender liner from between the fender

panels;

²remove the push-nuts that attach the retainers to

the fender outer panel; and

²remove the retainers and flare from the fender

outer panel.

(7) Remove the grille opening panel (GOP).

(8) Remove the air deflector.

(9) Remove the rocker panel moulding from the

fender.(10) Remove all the fender braces (Fig. 49).

(11) Remove the fender lower screws (Fig. 49).

(12) Remove the fender top, front and the rear

screws. Remove the fender from the inner fender

panel (Fig. 49).INSTALLATION

(1) Position the fender on the inner fender panel.

(2) Install all of the fender screws finger-tight.

(3) Install the fender braces.

(4) Align the fender with the body panels and

tighten the fender screws to 8.5 Nzm (76 in-lbs)

torque.

(5) Install the grille opening panel (GOP).

(6) Install the air deflector.

(7) Install the fender flare and retainers (Fig. 50).

Then install the fender liner.

²position the retainers and the flare on the fender;

²install the push-nuts to attach the retainers to the

fender;

²position the fender liner between the fender and

fender inner panel (Fig. 51);

Fig. 44 Speed Servo

Fig. 45 Vapor Canister

Fig. 46 Daytime Running Light (DRL) Module

Fig. 47 Hood Bumper

23 - 16 BODY COMPONENTSÐXJ VEHICLESJ

Page 1472 of 1784

²install the nuts to attach the fender liner to the

fender and flare retainers (Fig. 48);

²install the retainers to attach the fender liner to

the fender inner panel;

²install the rivets to attach the flare to the air de-

flector (Figs. 48 and 50); and

²install the screws to attach the flare to the fender.

Tighten the screws to 1 Nzm (13 in-lbs) torque.

(8) Connect the front lamp wire harness connectors

to the engine wire harness connectors (Fig. 52).(9) Install the front lamps.

(10) Install the front bumper.

(11) Install the wheel, remove the support and

lower the vehicle.

(12) Right fender only: install the hood support rod

on the fender inner panel.

(13) Install the hood bumper on the fender inner

panel.

(14) Right fender only: install the Daytime Run-

ning Light (DRL) module on fender inner panel.

Fig. 48 Fender Flare & Liner Removal/Installation

Fig. 49 Fender Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 17