JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 331 of 1784

Check the high-tension cable connections for good

contact at the ignition coil, distributor cap towers

and spark plugs. Terminals should be fully seated.

The terminals and spark plug covers should be in

good condition. Terminals should fit tightly to the ig-

nition coil, distributor cap and spark plugs. The

spark plug cover (boot) of the cable should fit tight

around the spark plug insulator. Loose cable connec-

tions can cause corrosion and increase resistance, re-

sulting in shorter cable service life.

Clean the high tension cables with a cloth moist-

ened with a nonflammable solvent and wipe dry.

Check for brittle or cracked insulation.

When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer.

If an oscilloscope is not available, spark plug cables

may be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.

Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. Remove the dis-

tributor cap from the distributor.Do not remove

cables from cap.Remove cable from spark plug.

Connect ohmmeter to spark plug terminal end of ca-

ble and to corresponding electrode in distributor cap.

Resistance should be 250 to 1000 Ohms per inch of

cable. If not, remove cable from distributor cap tower

and connect ohmmeter to the terminal ends of cable.

If resistance is not within specifications as found in

the Spark Plug Cable Resistance chart, replace the

cable. Test all spark plug cables in this manner.To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

For removal and installation of spark plug cables,

refer to Spark Plug Secondary Cables in the Compo-

nent Removal/Installation section.

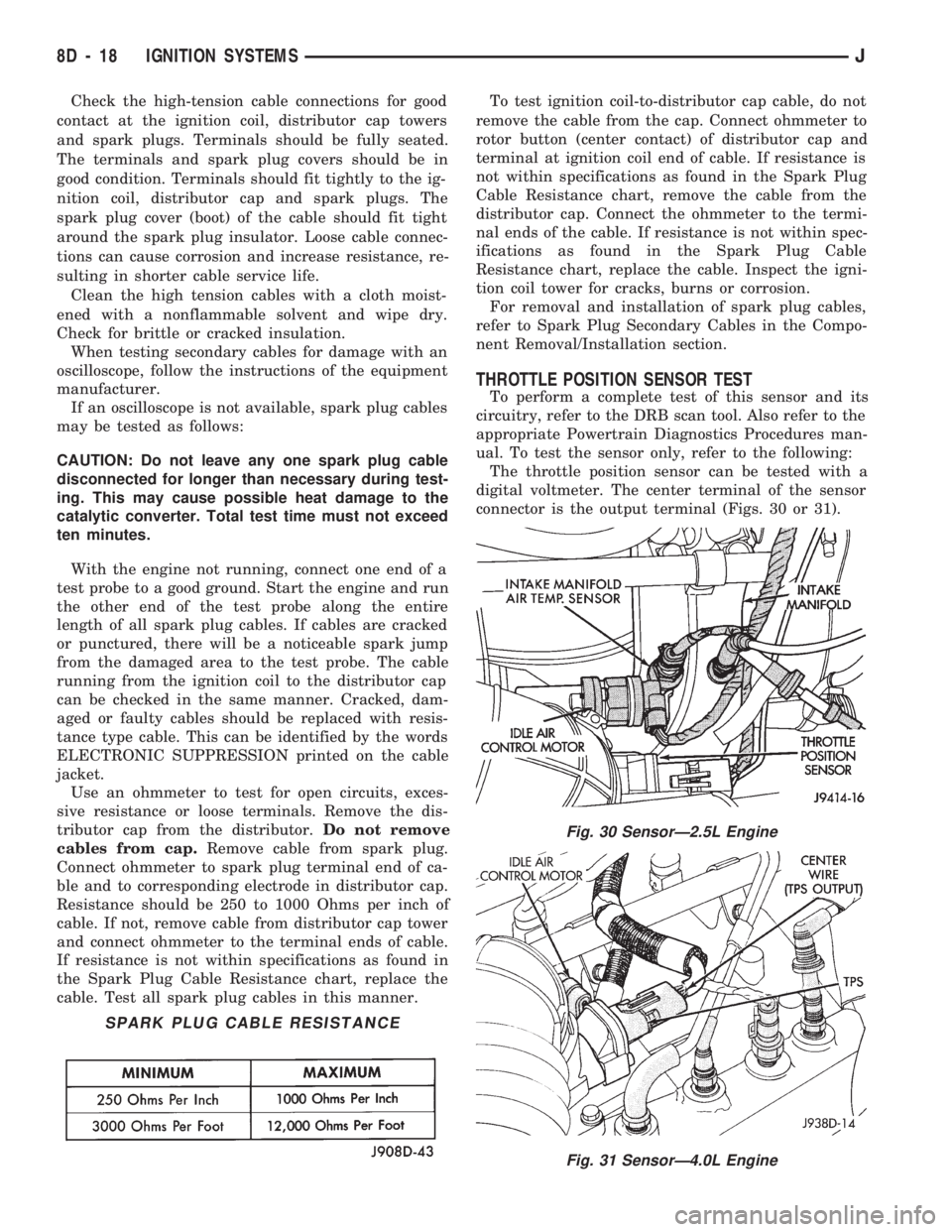

THROTTLE POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The throttle position sensor can be tested with a

digital voltmeter. The center terminal of the sensor

connector is the output terminal (Figs. 30 or 31).

SPARK PLUG CABLE RESISTANCE

Fig. 30 SensorÐ2.5L Engine

Fig. 31 SensorÐ4.0L Engine

8D - 18 IGNITION SYSTEMSJ

Page 332 of 1784

With the ignition key in the ON position and en-

gine not running, check the sensor output voltage at

the center terminal wire of the connector. Check this

at idle (throttle plate closed) and at wide open throt-

tle (WOT). At idle, sensor output voltage should be

greater than 200 millivolts. At wide open throttle,

sensor output voltage must be less than 4.8 volts.

The output voltage should increase gradually as the

throttle plate is slowly opened from idle to WOT.

OXYGEN SENSOR TESTS

For diagnosis, removal or installation, refer to

Group 14, Fuel Systems in this manual.

ON-BOARD DIAGNOSTICS (OBD)

FOR IGNITION SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor certain ignition system cir-

cuits:

EXAMPLE:

If a reference signal is not being detected during

engine cranking from the crankshaft position sensor,

a Diagnostic Trouble Code (DTC) number 11 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

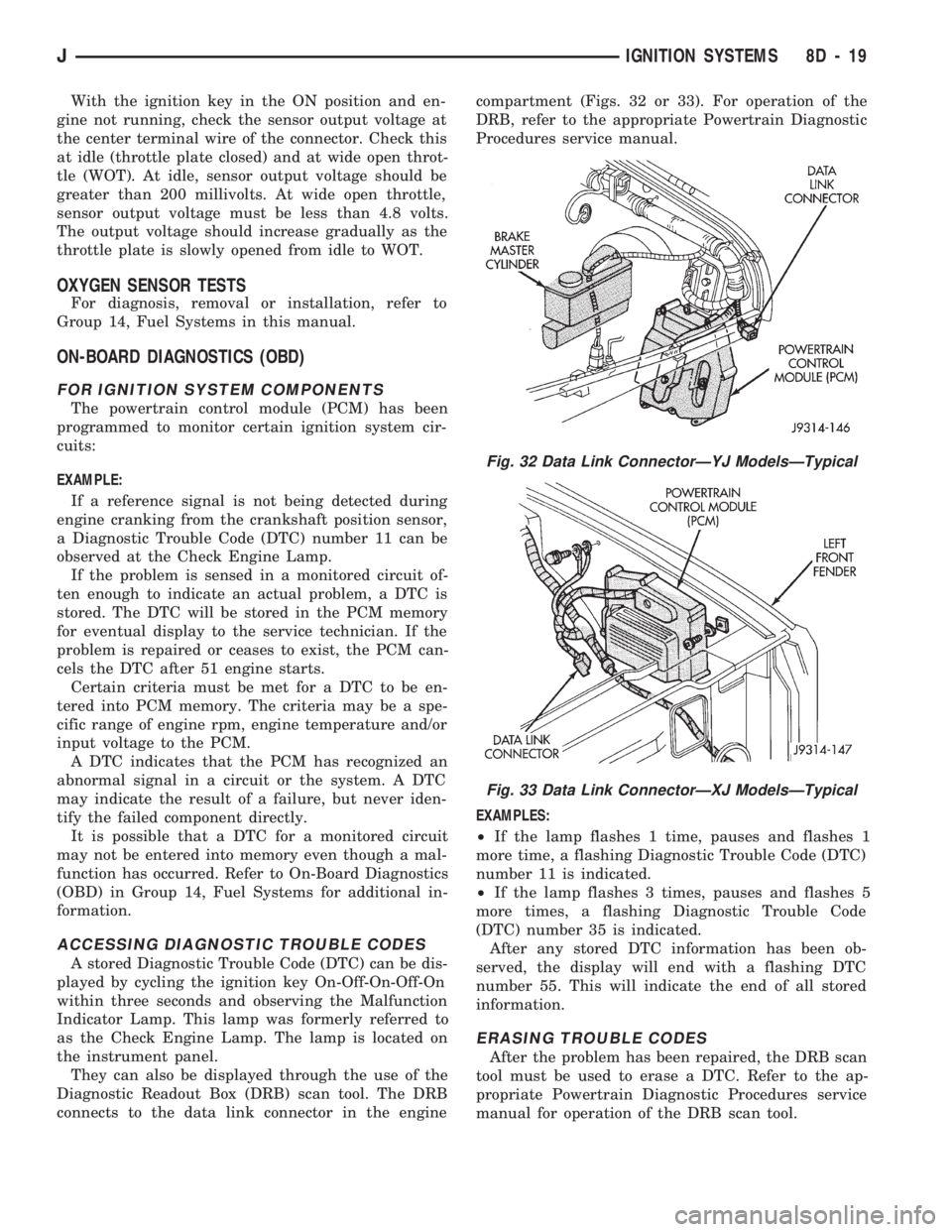

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

connects to the data link connector in the enginecompartment (Figs. 32 or 33). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.

EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 11 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

ERASING TROUBLE CODES

After the problem has been repaired, the DRB scan

tool must be used to erase a DTC. Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool.

Fig. 32 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 33 Data Link ConnectorÐXJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 19

Page 333 of 1784

COMPONENT REMOVAL/INSTALLATION

INDEX

page page

Automatic Shut Down (ASD) Relay........... 20

Camshaft Position Sensor.................. 20

Crankshaft Position Sensor................. 21

Distributor.............................. 23

Engine Coolant Temperature Sensor.......... 22

General Information....................... 20

Ignition Coil............................. 26Intake Manifold Air Temperature Sensor....... 27

Manifold Absolute Pressure (MAP) Sensor..... 27

Oxygen (O2S) Sensor..................... 28

Powertrain Control Module (PCM)............ 28

Spark Plug Secondary Cables............... 29

Spark Plugs............................ 28

Throttle Position Sensor (TPS).............. 29

GENERAL INFORMATION

This section of the group, Component Removal/In-

stallation, will discuss the removal and installation

of ignition system components.

For basic ignition system diagnostics and service

adjustments, refer to the Diagnostics/Service Proce-

dures section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

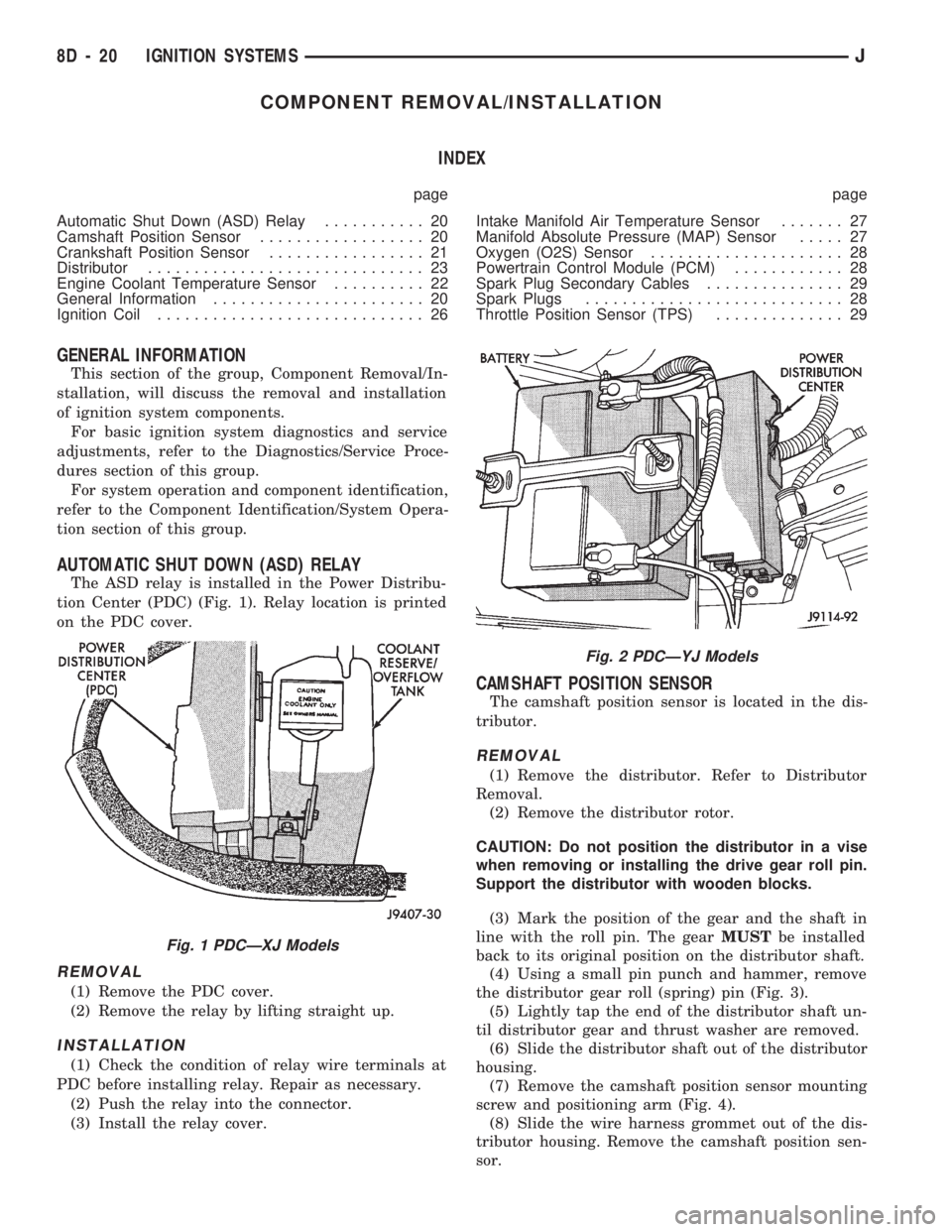

AUTOMATIC SHUT DOWN (ASD) RELAY

The ASD relay is installed in the Power Distribu-

tion Center (PDC) (Fig. 1). Relay location is printed

on the PDC cover.

REMOVAL

(1) Remove the PDC cover.

(2) Remove the relay by lifting straight up.

INSTALLATION

(1) Check the condition of relay wire terminals at

PDC before installing relay. Repair as necessary.

(2) Push the relay into the connector.

(3) Install the relay cover.

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the dis-

tributor.

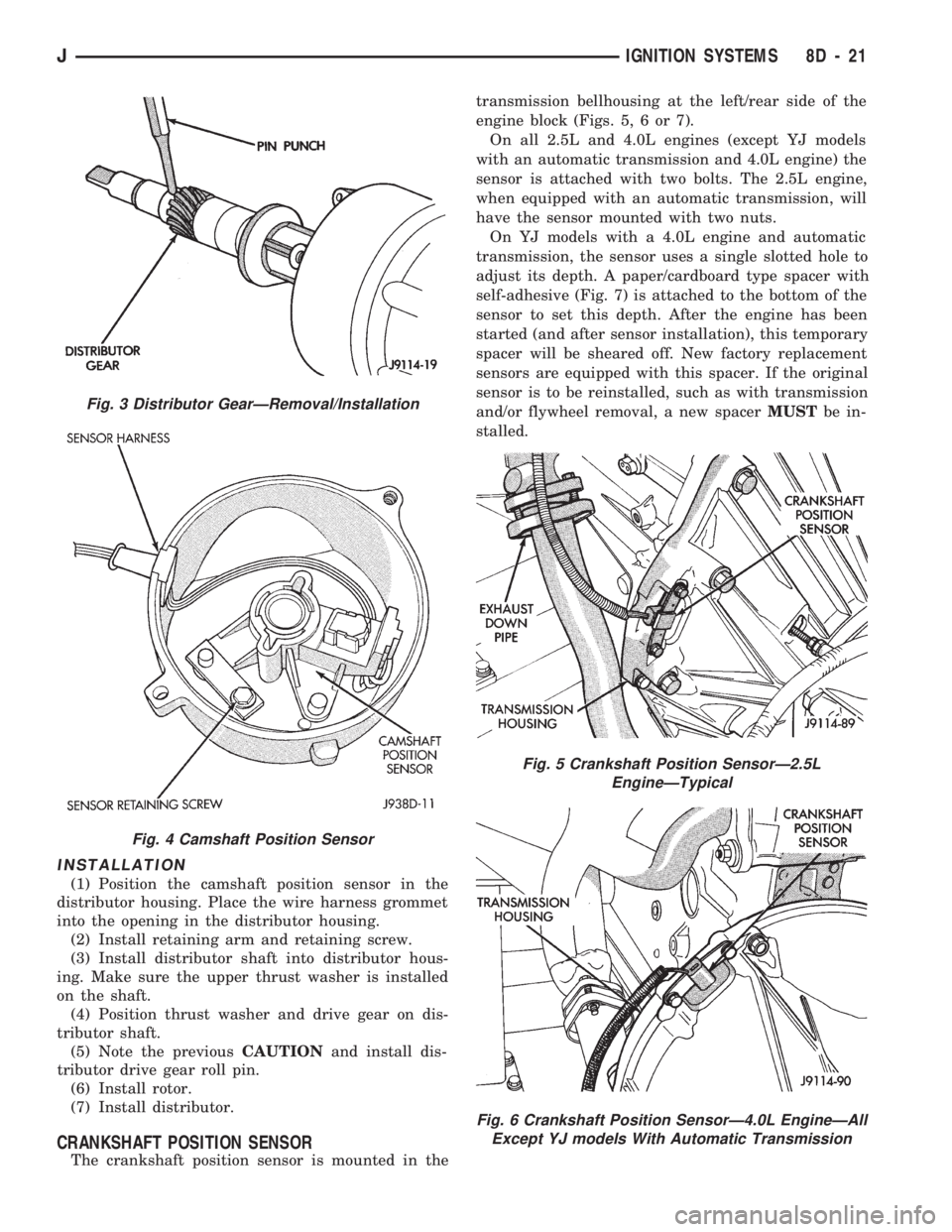

REMOVAL

(1) Remove the distributor. Refer to Distributor

Removal.

(2) Remove the distributor rotor.

CAUTION: Do not position the distributor in a vise

when removing or installing the drive gear roll pin.

Support the distributor with wooden blocks.

(3) Mark the position of the gear and the shaft in

line with the roll pin. The gearMUSTbe installed

back to its original position on the distributor shaft.

(4) Using a small pin punch and hammer, remove

the distributor gear roll (spring) pin (Fig. 3).

(5) Lightly tap the end of the distributor shaft un-

til distributor gear and thrust washer are removed.

(6) Slide the distributor shaft out of the distributor

housing.

(7) Remove the camshaft position sensor mounting

screw and positioning arm (Fig. 4).

(8) Slide the wire harness grommet out of the dis-

tributor housing. Remove the camshaft position sen-

sor.

Fig. 1 PDCÐXJ Models

Fig. 2 PDCÐYJ Models

8D - 20 IGNITION SYSTEMSJ

Page 334 of 1784

INSTALLATION

(1) Position the camshaft position sensor in the

distributor housing. Place the wire harness grommet

into the opening in the distributor housing.

(2) Install retaining arm and retaining screw.

(3) Install distributor shaft into distributor hous-

ing. Make sure the upper thrust washer is installed

on the shaft.

(4) Position thrust washer and drive gear on dis-

tributor shaft.

(5) Note the previousCAUTIONand install dis-

tributor drive gear roll pin.

(6) Install rotor.

(7) Install distributor.

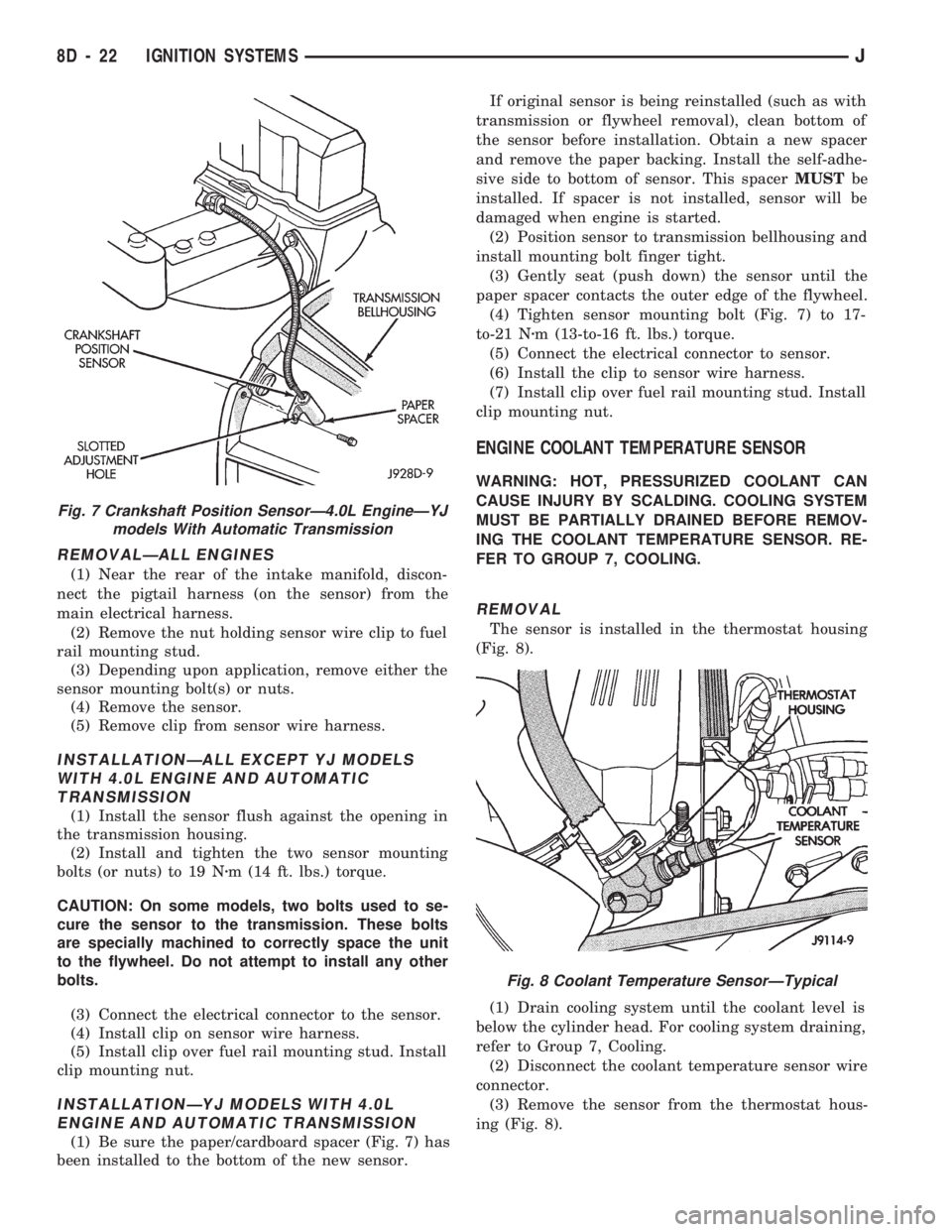

CRANKSHAFT POSITION SENSOR

The crankshaft position sensor is mounted in thetransmission bellhousing at the left/rear side of the

engine block (Figs. 5, 6 or 7).

On all 2.5L and 4.0L engines (except YJ models

with an automatic transmission and 4.0L engine) the

sensor is attached with two bolts. The 2.5L engine,

when equipped with an automatic transmission, will

have the sensor mounted with two nuts.

On YJ models with a 4.0L engine and automatic

transmission, the sensor uses a single slotted hole to

adjust its depth. A paper/cardboard type spacer with

self-adhesive (Fig. 7) is attached to the bottom of the

sensor to set this depth. After the engine has been

started (and after sensor installation), this temporary

spacer will be sheared off. New factory replacement

sensors are equipped with this spacer. If the original

sensor is to be reinstalled, such as with transmission

and/or flywheel removal, a new spacerMUSTbe in-

stalled.

Fig. 3 Distributor GearÐRemoval/Installation

Fig. 4 Camshaft Position Sensor

Fig. 5 Crankshaft Position SensorÐ2.5L

EngineÐTypical

Fig. 6 Crankshaft Position SensorÐ4.0L EngineÐAll

Except YJ models With Automatic Transmission

JIGNITION SYSTEMS 8D - 21

Page 335 of 1784

REMOVALÐALL ENGINES

(1) Near the rear of the intake manifold, discon-

nect the pigtail harness (on the sensor) from the

main electrical harness.

(2) Remove the nut holding sensor wire clip to fuel

rail mounting stud.

(3) Depending upon application, remove either the

sensor mounting bolt(s) or nuts.

(4) Remove the sensor.

(5) Remove clip from sensor wire harness.

INSTALLATIONÐALL EXCEPT YJ MODELS

WITH 4.0L ENGINE AND AUTOMATIC

TRANSMISSION

(1) Install the sensor flush against the opening in

the transmission housing.

(2) Install and tighten the two sensor mounting

bolts (or nuts) to 19 Nzm (14 ft. lbs.) torque.

CAUTION: On some models, two bolts used to se-

cure the sensor to the transmission. These bolts

are specially machined to correctly space the unit

to the flywheel. Do not attempt to install any other

bolts.

(3) Connect the electrical connector to the sensor.

(4) Install clip on sensor wire harness.

(5) Install clip over fuel rail mounting stud. Install

clip mounting nut.

INSTALLATIONÐYJ MODELS WITH 4.0L

ENGINE AND AUTOMATIC TRANSMISSION

(1) Be sure the paper/cardboard spacer (Fig. 7) has

been installed to the bottom of the new sensor.If original sensor is being reinstalled (such as with

transmission or flywheel removal), clean bottom of

the sensor before installation. Obtain a new spacer

and remove the paper backing. Install the self-adhe-

sive side to bottom of sensor. This spacerMUSTbe

installed. If spacer is not installed, sensor will be

damaged when engine is started.

(2) Position sensor to transmission bellhousing and

install mounting bolt finger tight.

(3) Gently seat (push down) the sensor until the

paper spacer contacts the outer edge of the flywheel.

(4) Tighten sensor mounting bolt (Fig. 7) to 17-

to-21 Nzm (13-to-16 ft. lbs.) torque.

(5) Connect the electrical connector to sensor.

(6) Install the clip to sensor wire harness.

(7) Install clip over fuel rail mounting stud. Install

clip mounting nut.

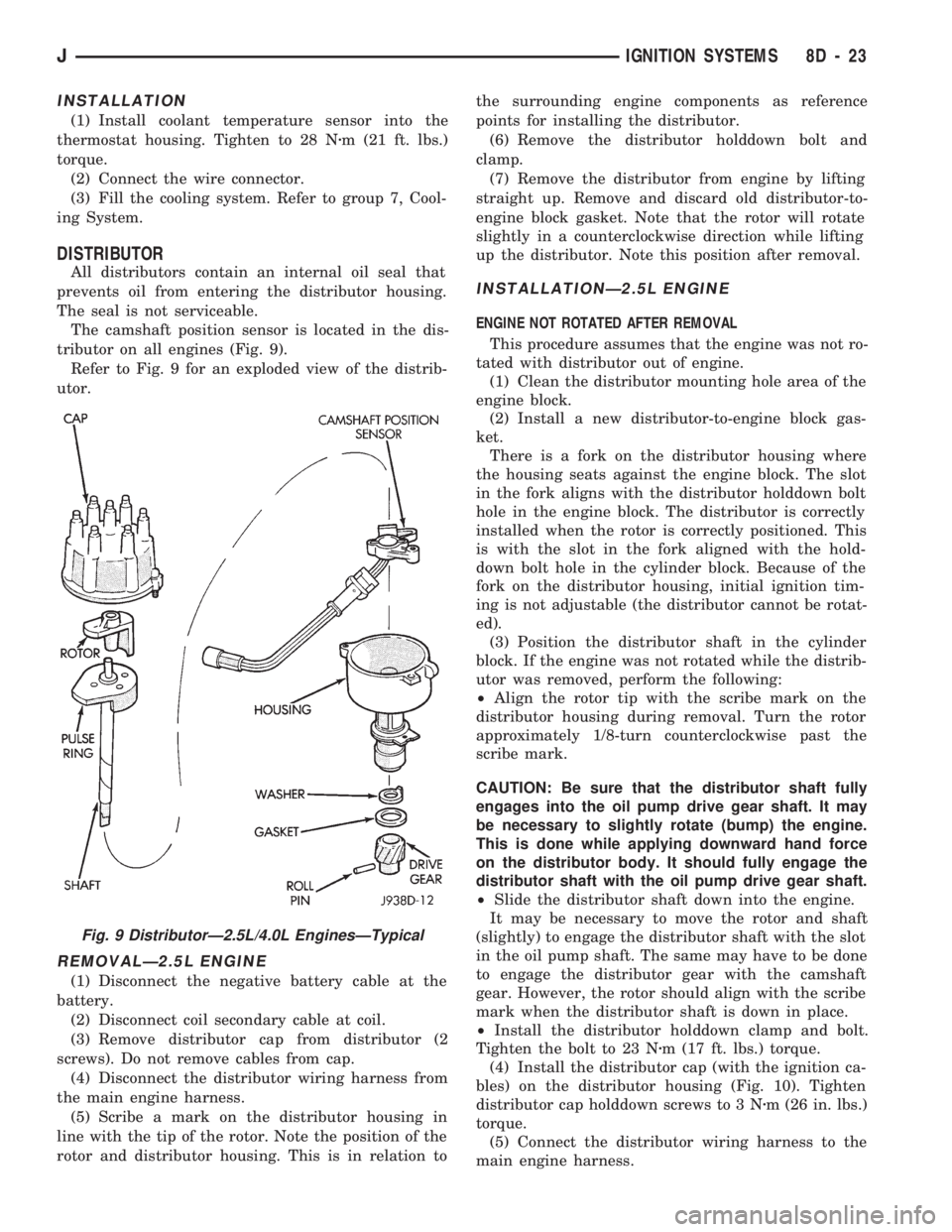

ENGINE COOLANT TEMPERATURE SENSOR

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR. RE-

FER TO GROUP 7, COOLING.

REMOVAL

The sensor is installed in the thermostat housing

(Fig. 8).

(1) Drain cooling system until the coolant level is

below the cylinder head. For cooling system draining,

refer to Group 7, Cooling.

(2) Disconnect the coolant temperature sensor wire

connector.

(3) Remove the sensor from the thermostat hous-

ing (Fig. 8).

Fig. 7 Crankshaft Position SensorÐ4.0L EngineÐYJ

models With Automatic Transmission

Fig. 8 Coolant Temperature SensorÐTypical

8D - 22 IGNITION SYSTEMSJ

Page 336 of 1784

INSTALLATION

(1) Install coolant temperature sensor into the

thermostat housing. Tighten to 28 Nzm (21 ft. lbs.)

torque.

(2) Connect the wire connector.

(3) Fill the cooling system. Refer to group 7, Cool-

ing System.

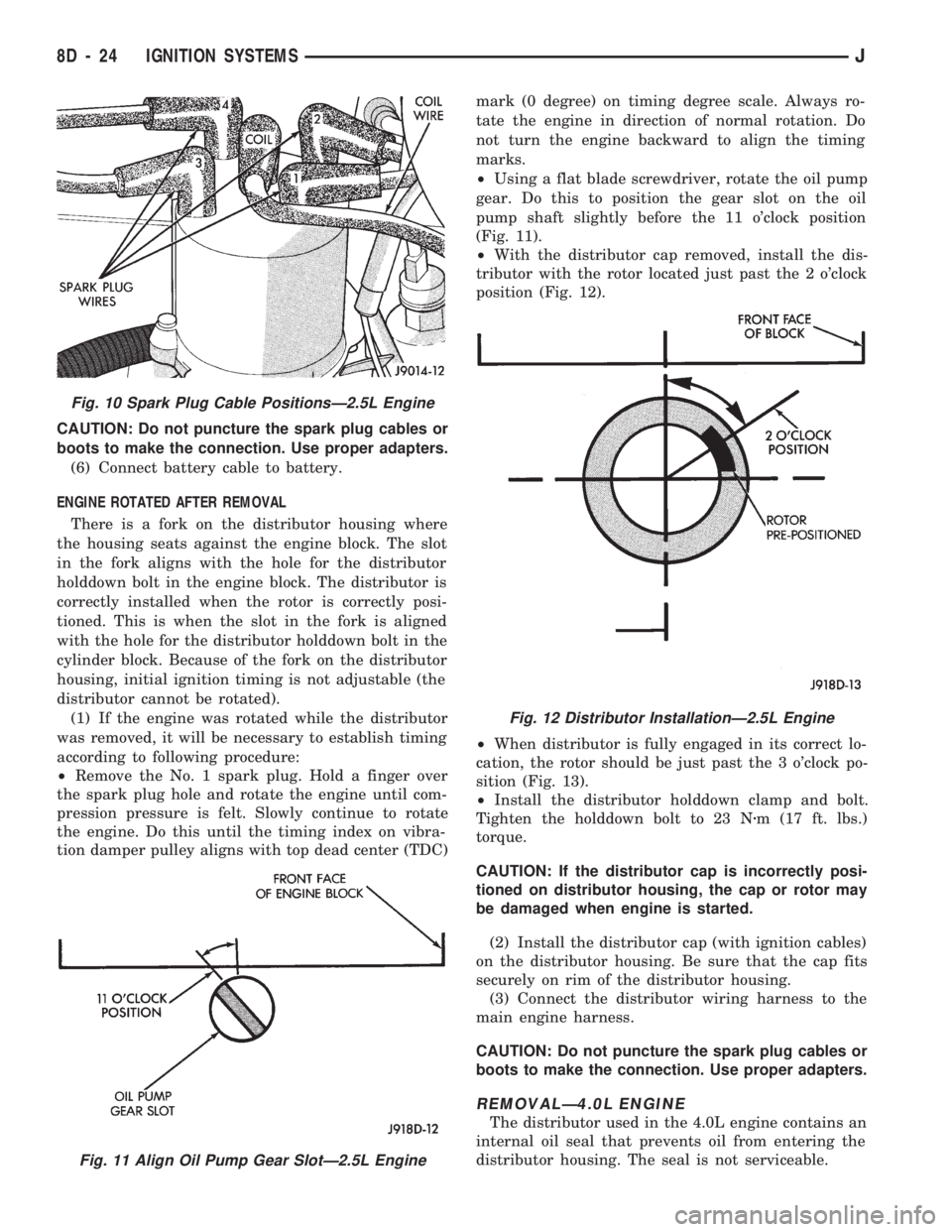

DISTRIBUTOR

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

The camshaft position sensor is located in the dis-

tributor on all engines (Fig. 9).

Refer to Fig. 9 for an exploded view of the distrib-

utor.

REMOVALÐ2.5L ENGINE

(1) Disconnect the negative battery cable at the

battery.

(2) Disconnect coil secondary cable at coil.

(3) Remove distributor cap from distributor (2

screws). Do not remove cables from cap.

(4) Disconnect the distributor wiring harness from

the main engine harness.

(5) Scribe a mark on the distributor housing in

line with the tip of the rotor. Note the position of the

rotor and distributor housing. This is in relation tothe surrounding engine components as reference

points for installing the distributor.

(6) Remove the distributor holddown bolt and

clamp.

(7) Remove the distributor from engine by lifting

straight up. Remove and discard old distributor-to-

engine block gasket. Note that the rotor will rotate

slightly in a counterclockwise direction while lifting

up the distributor. Note this position after removal.

INSTALLATIONÐ2.5L ENGINE

ENGINE NOT ROTATED AFTER REMOVAL

This procedure assumes that the engine was not ro-

tated with distributor out of engine.

(1) Clean the distributor mounting hole area of the

engine block.

(2) Install a new distributor-to-engine block gas-

ket.

There is a fork on the distributor housing where

the housing seats against the engine block. The slot

in the fork aligns with the distributor holddown bolt

hole in the engine block. The distributor is correctly

installed when the rotor is correctly positioned. This

is with the slot in the fork aligned with the hold-

down bolt hole in the cylinder block. Because of the

fork on the distributor housing, initial ignition tim-

ing is not adjustable (the distributor cannot be rotat-

ed).

(3) Position the distributor shaft in the cylinder

block. If the engine was not rotated while the distrib-

utor was removed, perform the following:

²Align the rotor tip with the scribe mark on the

distributor housing during removal. Turn the rotor

approximately 1/8-turn counterclockwise past the

scribe mark.

CAUTION: Be sure that the distributor shaft fully

engages into the oil pump drive gear shaft. It may

be necessary to slightly rotate (bump) the engine.

This is done while applying downward hand force

on the distributor body. It should fully engage the

distributor shaft with the oil pump drive gear shaft.

²Slide the distributor shaft down into the engine.

It may be necessary to move the rotor and shaft

(slightly) to engage the distributor shaft with the slot

in the oil pump shaft. The same may have to be done

to engage the distributor gear with the camshaft

gear. However, the rotor should align with the scribe

mark when the distributor shaft is down in place.

²Install the distributor holddown clamp and bolt.

Tighten the bolt to 23 Nzm (17 ft. lbs.) torque.

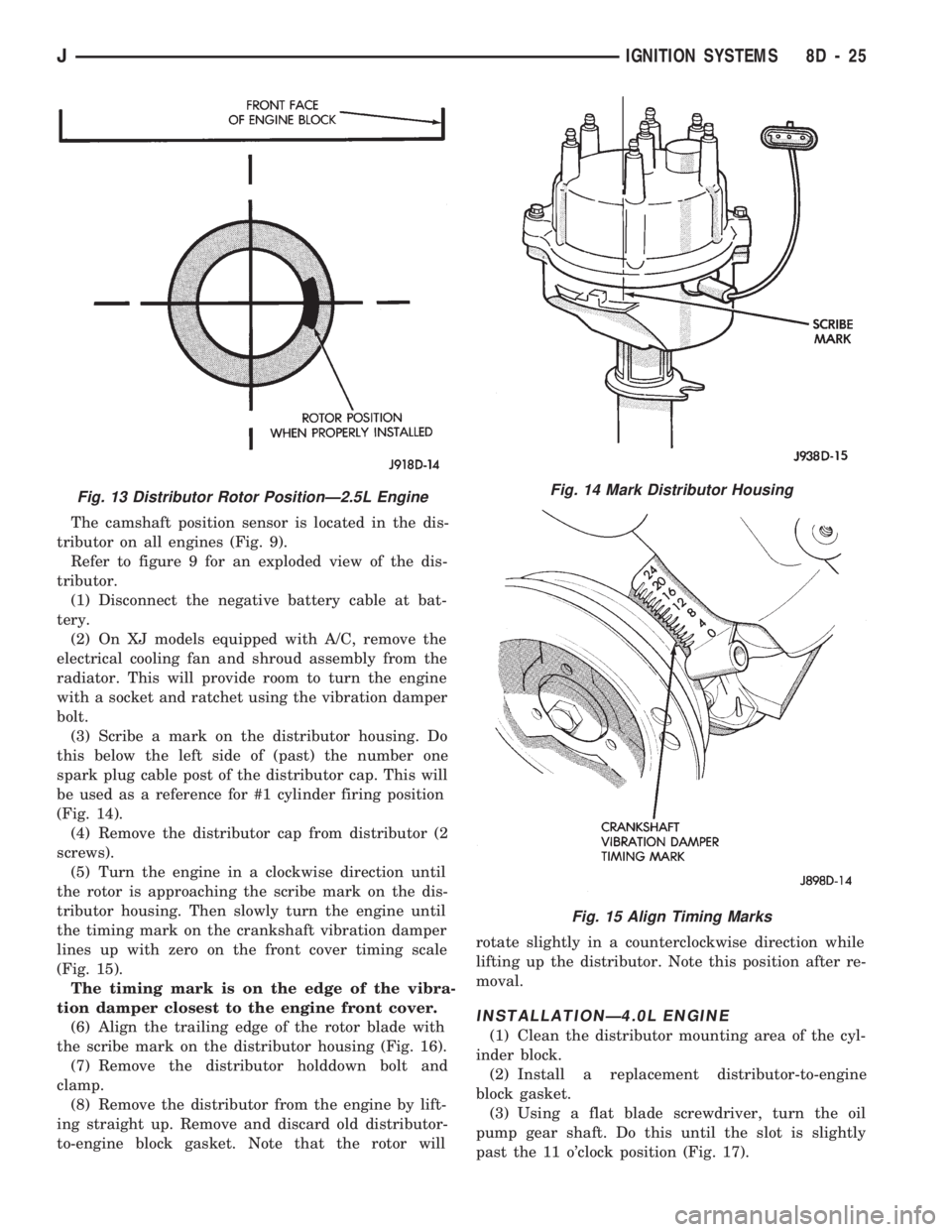

(4) Install the distributor cap (with the ignition ca-

bles) on the distributor housing (Fig. 10). Tighten

distributor cap holddown screws to 3 Nzm (26 in. lbs.)

torque.

(5) Connect the distributor wiring harness to the

main engine harness.

Fig. 9 DistributorÐ2.5L/4.0L EnginesÐTypical

JIGNITION SYSTEMS 8D - 23

Page 337 of 1784

CAUTION: Do not puncture the spark plug cables or

boots to make the connection. Use proper adapters.

(6) Connect battery cable to battery.

ENGINE ROTATED AFTER REMOVAL

There is a fork on the distributor housing where

the housing seats against the engine block. The slot

in the fork aligns with the hole for the distributor

holddown bolt in the engine block. The distributor is

correctly installed when the rotor is correctly posi-

tioned. This is when the slot in the fork is aligned

with the hole for the distributor holddown bolt in the

cylinder block. Because of the fork on the distributor

housing, initial ignition timing is not adjustable (the

distributor cannot be rotated).

(1) If the engine was rotated while the distributor

was removed, it will be necessary to establish timing

according to following procedure:

²Remove the No. 1 spark plug. Hold a finger over

the spark plug hole and rotate the engine until com-

pression pressure is felt. Slowly continue to rotate

the engine. Do this until the timing index on vibra-

tion damper pulley aligns with top dead center (TDC)mark (0 degree) on timing degree scale. Always ro-

tate the engine in direction of normal rotation. Do

not turn the engine backward to align the timing

marks.

²Using a flat blade screwdriver, rotate the oil pump

gear. Do this to position the gear slot on the oil

pump shaft slightly before the 11 o'clock position

(Fig. 11).

²With the distributor cap removed, install the dis-

tributor with the rotor located just past the 2 o'clock

position (Fig. 12).

²When distributor is fully engaged in its correct lo-

cation, the rotor should be just past the 3 o'clock po-

sition (Fig. 13).

²Install the distributor holddown clamp and bolt.

Tighten the holddown bolt to 23 Nzm (17 ft. lbs.)

torque.

CAUTION: If the distributor cap is incorrectly posi-

tioned on distributor housing, the cap or rotor may

be damaged when engine is started.

(2) Install the distributor cap (with ignition cables)

on the distributor housing. Be sure that the cap fits

securely on rim of the distributor housing.

(3) Connect the distributor wiring harness to the

main engine harness.

CAUTION: Do not puncture the spark plug cables or

boots to make the connection. Use proper adapters.

REMOVALÐ4.0L ENGINE

The distributor used in the 4.0L engine contains an

internal oil seal that prevents oil from entering the

distributor housing. The seal is not serviceable.

Fig. 11 Align Oil Pump Gear SlotÐ2.5L Engine

Fig. 10 Spark Plug Cable PositionsÐ2.5L Engine

Fig. 12 Distributor InstallationÐ2.5L Engine

8D - 24 IGNITION SYSTEMSJ

Page 338 of 1784

The camshaft position sensor is located in the dis-

tributor on all engines (Fig. 9).

Refer to figure 9 for an exploded view of the dis-

tributor.

(1) Disconnect the negative battery cable at bat-

tery.

(2) On XJ models equipped with A/C, remove the

electrical cooling fan and shroud assembly from the

radiator. This will provide room to turn the engine

with a socket and ratchet using the vibration damper

bolt.

(3) Scribe a mark on the distributor housing. Do

this below the left side of (past) the number one

spark plug cable post of the distributor cap. This will

be used as a reference for #1 cylinder firing position

(Fig. 14).

(4) Remove the distributor cap from distributor (2

screws).

(5) Turn the engine in a clockwise direction until

the rotor is approaching the scribe mark on the dis-

tributor housing. Then slowly turn the engine until

the timing mark on the crankshaft vibration damper

lines up with zero on the front cover timing scale

(Fig. 15).

The timing mark is on the edge of the vibra-

tion damper closest to the engine front cover.

(6) Align the trailing edge of the rotor blade with

the scribe mark on the distributor housing (Fig. 16).

(7) Remove the distributor holddown bolt and

clamp.

(8) Remove the distributor from the engine by lift-

ing straight up. Remove and discard old distributor-

to-engine block gasket. Note that the rotor willrotate slightly in a counterclockwise direction while

lifting up the distributor. Note this position after re-

moval.

INSTALLATIONÐ4.0L ENGINE

(1) Clean the distributor mounting area of the cyl-

inder block.

(2) Install a replacement distributor-to-engine

block gasket.

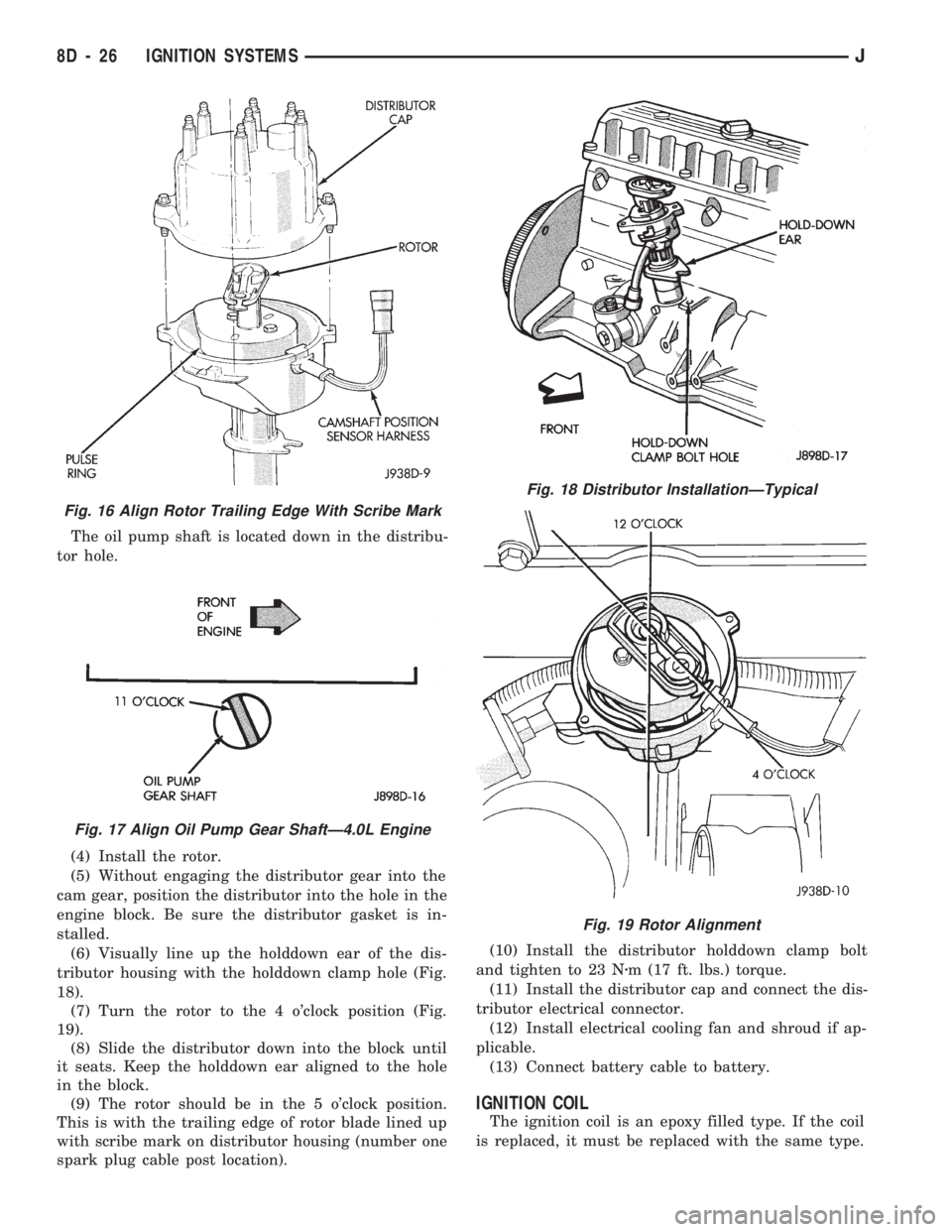

(3) Using a flat blade screwdriver, turn the oil

pump gear shaft. Do this until the slot is slightly

past the 11 o'clock position (Fig. 17).

Fig. 13 Distributor Rotor PositionÐ2.5L EngineFig. 14 Mark Distributor Housing

Fig. 15 Align Timing Marks

JIGNITION SYSTEMS 8D - 25

Page 339 of 1784

The oil pump shaft is located down in the distribu-

tor hole.

(4) Install the rotor.

(5) Without engaging the distributor gear into the

cam gear, position the distributor into the hole in the

engine block. Be sure the distributor gasket is in-

stalled.

(6) Visually line up the holddown ear of the dis-

tributor housing with the holddown clamp hole (Fig.

18).

(7) Turn the rotor to the 4 o'clock position (Fig.

19).

(8) Slide the distributor down into the block until

it seats. Keep the holddown ear aligned to the hole

in the block.

(9) The rotor should be in the 5 o'clock position.

This is with the trailing edge of rotor blade lined up

with scribe mark on distributor housing (number one

spark plug cable post location).(10) Install the distributor holddown clamp bolt

and tighten to 23 Nzm (17 ft. lbs.) torque.

(11) Install the distributor cap and connect the dis-

tributor electrical connector.

(12) Install electrical cooling fan and shroud if ap-

plicable.

(13) Connect battery cable to battery.

IGNITION COIL

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

Fig. 16 Align Rotor Trailing Edge With Scribe Mark

Fig. 17 Align Oil Pump Gear ShaftÐ4.0L Engine

Fig. 18 Distributor InstallationÐTypical

Fig. 19 Rotor Alignment

8D - 26 IGNITION SYSTEMSJ

Page 340 of 1784

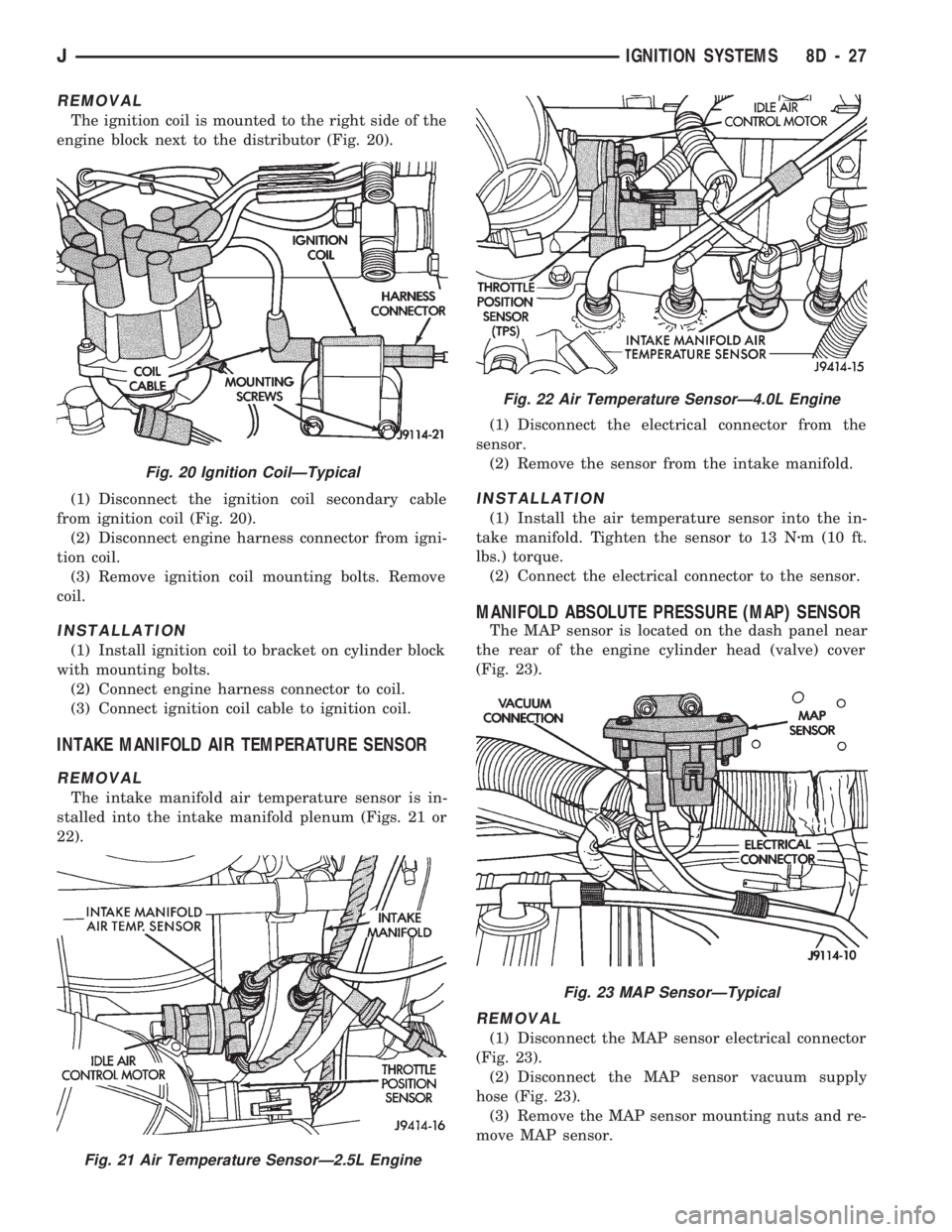

REMOVAL

The ignition coil is mounted to the right side of the

engine block next to the distributor (Fig. 20).

(1) Disconnect the ignition coil secondary cable

from ignition coil (Fig. 20).

(2) Disconnect engine harness connector from igni-

tion coil.

(3) Remove ignition coil mounting bolts. Remove

coil.

INSTALLATION

(1) Install ignition coil to bracket on cylinder block

with mounting bolts.

(2) Connect engine harness connector to coil.

(3) Connect ignition coil cable to ignition coil.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

REMOVAL

The intake manifold air temperature sensor is in-

stalled into the intake manifold plenum (Figs. 21 or

22).(1) Disconnect the electrical connector from the

sensor.

(2) Remove the sensor from the intake manifold.

INSTALLATION

(1) Install the air temperature sensor into the in-

take manifold. Tighten the sensor to 13 Nzm (10 ft.

lbs.) torque.

(2) Connect the electrical connector to the sensor.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor is located on the dash panel near

the rear of the engine cylinder head (valve) cover

(Fig. 23).

REMOVAL

(1) Disconnect the MAP sensor electrical connector

(Fig. 23).

(2) Disconnect the MAP sensor vacuum supply

hose (Fig. 23).

(3) Remove the MAP sensor mounting nuts and re-

move MAP sensor.

Fig. 20 Ignition CoilÐTypical

Fig. 21 Air Temperature SensorÐ2.5L Engine

Fig. 22 Air Temperature SensorÐ4.0L Engine

Fig. 23 MAP SensorÐTypical

JIGNITION SYSTEMS 8D - 27