warning JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1158 of 2198

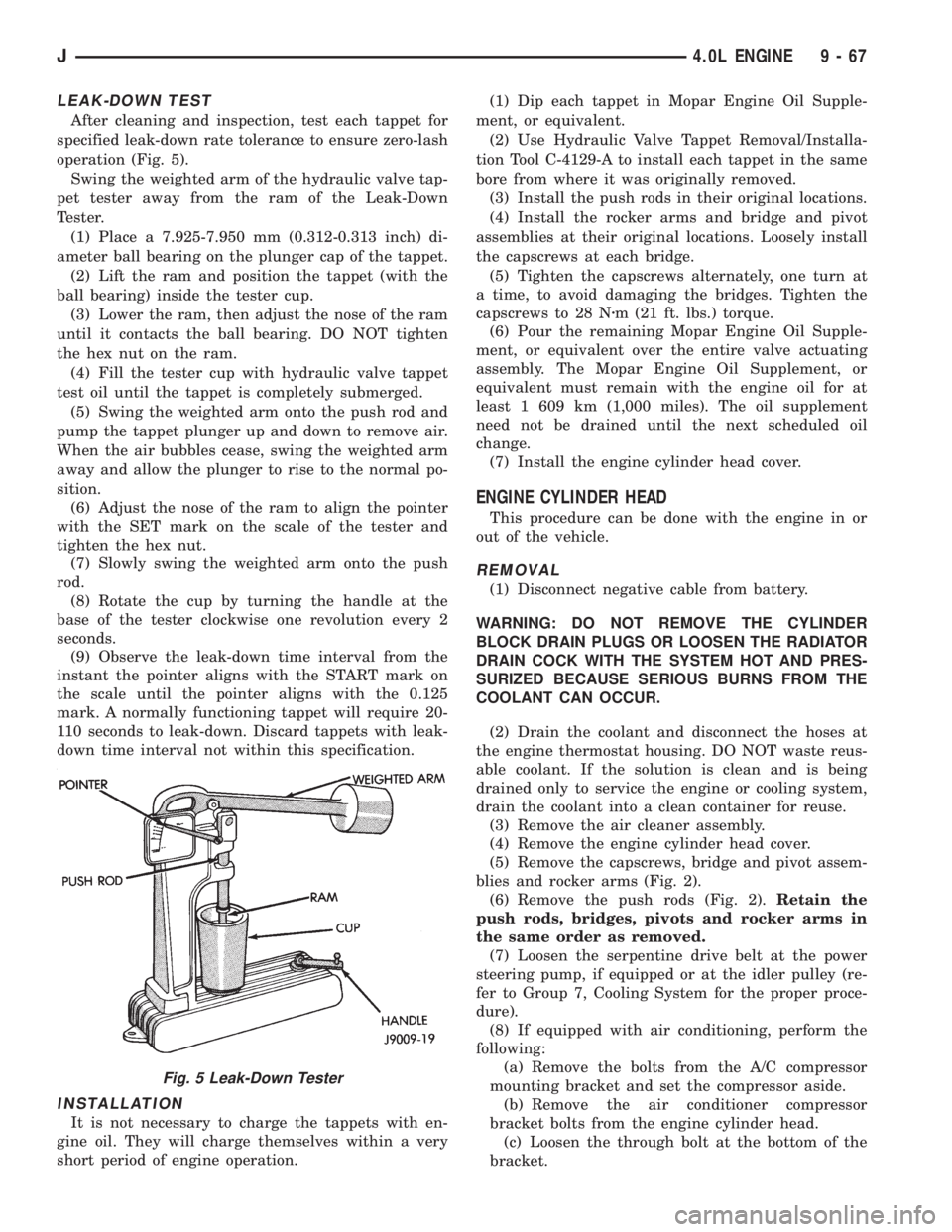

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 5).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Leak-Down

Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the push rods in their original locations.

(4) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(5) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(6) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

Fig. 5 Leak-Down Tester

J4.0L ENGINE 9 - 67

Page 1160 of 2198

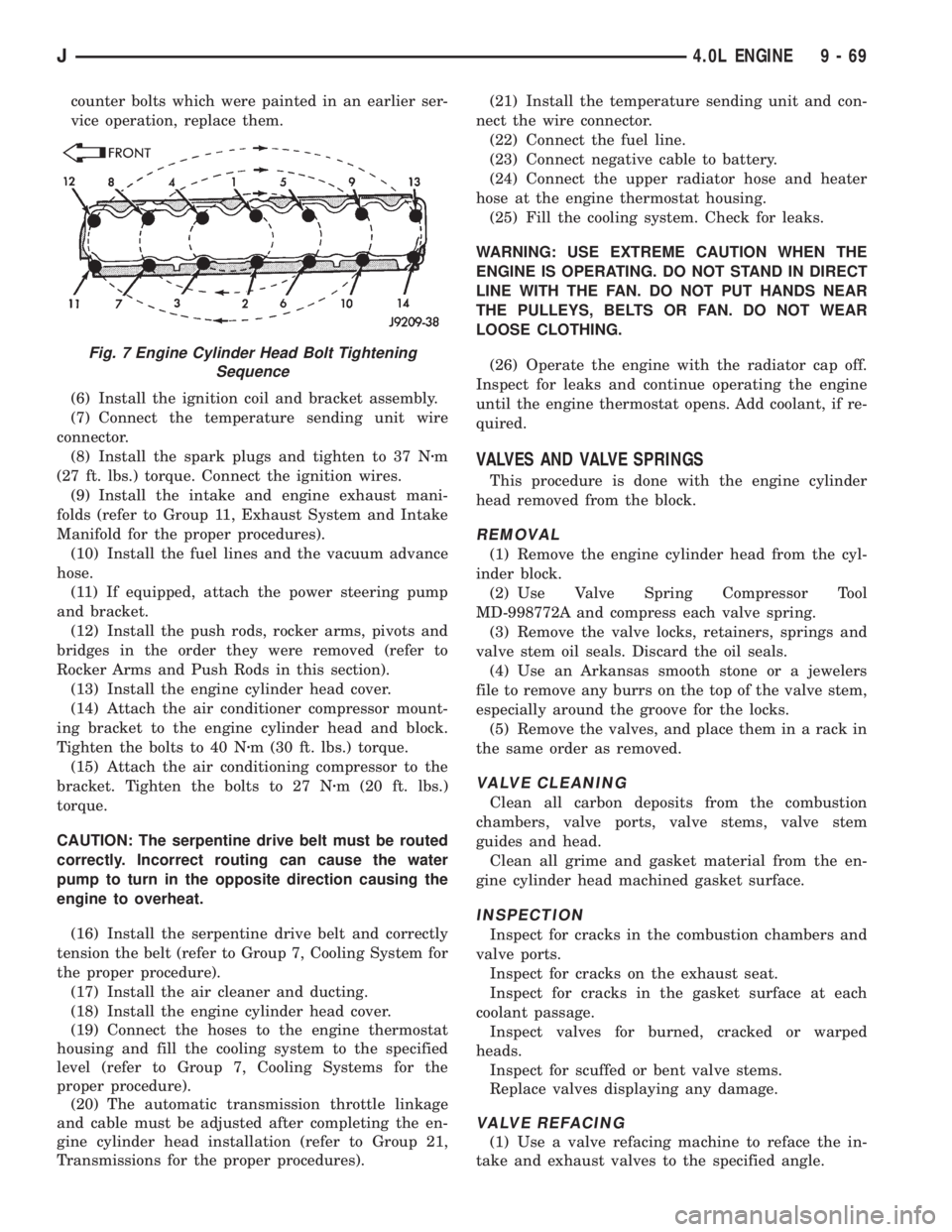

counter bolts which were painted in an earlier ser-

vice operation, replace them.

(6) Install the ignition coil and bracket assembly.

(7) Connect the temperature sending unit wire

connector.

(8) Install the spark plugs and tighten to 37 Nzm

(27 ft. lbs.) torque. Connect the ignition wires.

(9) Install the intake and engine exhaust mani-

folds (refer to Group 11, Exhaust System and Intake

Manifold for the proper procedures).

(10) Install the fuel lines and the vacuum advance

hose.

(11) If equipped, attach the power steering pump

and bracket.

(12) Install the push rods, rocker arms, pivots and

bridges in the order they were removed (refer to

Rocker Arms and Push Rods in this section).

(13) Install the engine cylinder head cover.

(14) Attach the air conditioner compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 Nzm (30 ft. lbs.) torque.

(15) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 Nzm (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(16) Install the serpentine drive belt and correctly

tension the belt (refer to Group 7, Cooling System for

the proper procedure).

(17) Install the air cleaner and ducting.

(18) Install the engine cylinder head cover.

(19) Connect the hoses to the engine thermostat

housing and fill the cooling system to the specified

level (refer to Group 7, Cooling Systems for the

proper procedure).

(20) The automatic transmission throttle linkage

and cable must be adjusted after completing the en-

gine cylinder head installation (refer to Group 21,

Transmissions for the proper procedures).(21) Install the temperature sending unit and con-

nect the wire connector.

(22) Connect the fuel line.

(23) Connect negative cable to battery.

(24) Connect the upper radiator hose and heater

hose at the engine thermostat housing.

(25) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(26) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the engine thermostat opens. Add coolant, if re-

quired.

VALVES AND VALVE SPRINGS

This procedure is done with the engine cylinder

head removed from the block.

REMOVAL

(1) Remove the engine cylinder head from the cyl-

inder block.

(2) Use Valve Spring Compressor Tool

MD-998772A and compress each valve spring.

(3) Remove the valve locks, retainers, springs and

valve stem oil seals. Discard the oil seals.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Clean all grime and gasket material from the en-

gine cylinder head machined gasket surface.

INSPECTION

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped

heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage.

VALVE REFACING

(1) Use a valve refacing machine to reface the in-

take and exhaust valves to the specified angle.

Fig. 7 Engine Cylinder Head Bolt Tightening

Sequence

J4.0L ENGINE 9 - 69

Page 1165 of 2198

properly aligned ensures correct valve timing. A worn

or stretched timing chain will adversely affect valve

timing. If the timing chain deflects more than 12.7

mm (1/2 inch) replace it. The correct timing chain

has 48 pins. A chain with more than 48 pins will

cause excessive slack.

INSTALLATION

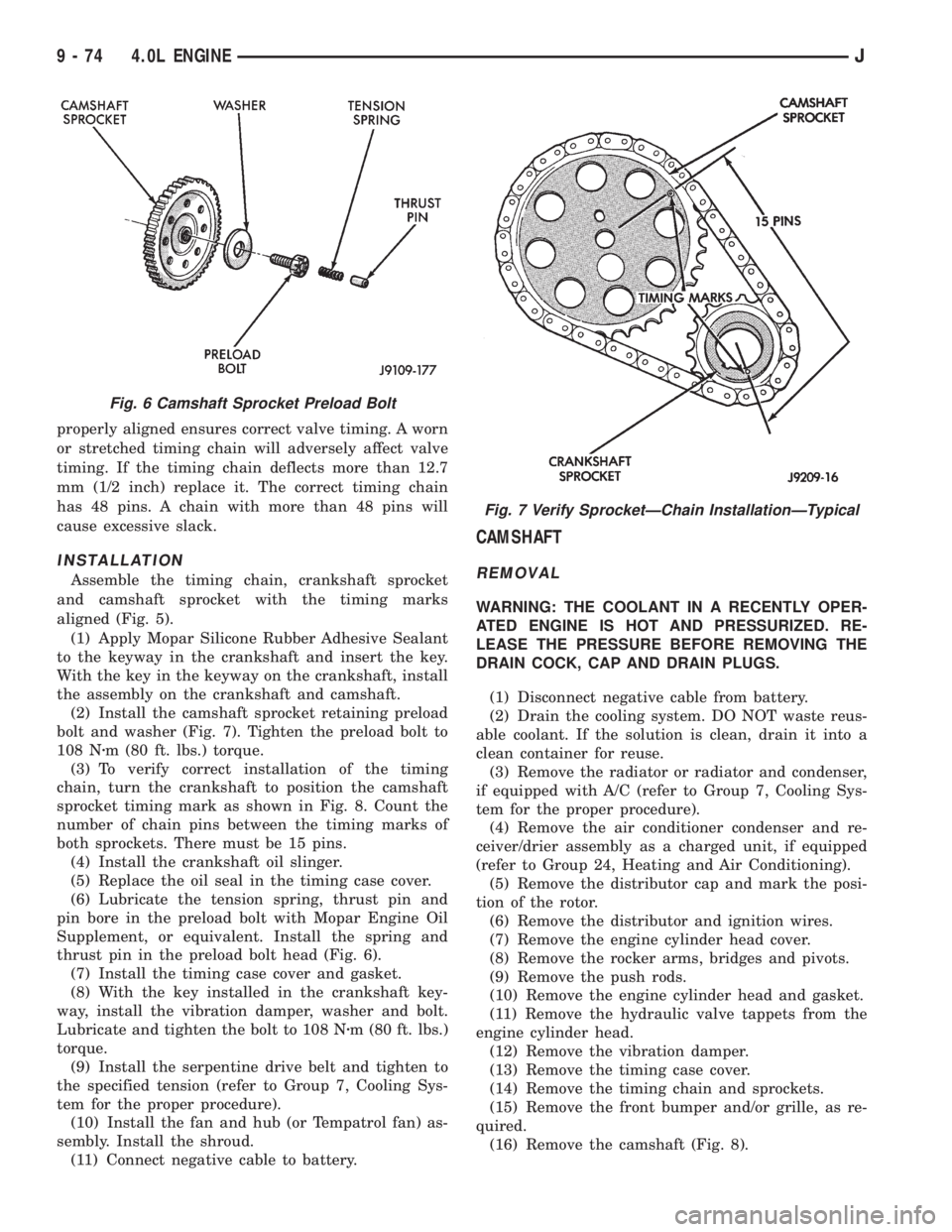

Assemble the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned (Fig. 5).

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in the keyway on the crankshaft, install

the assembly on the crankshaft and camshaft.

(2) Install the camshaft sprocket retaining preload

bolt and washer (Fig. 7). Tighten the preload bolt to

108 Nzm (80 ft. lbs.) torque.

(3) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 8. Count the

number of chain pins between the timing marks of

both sprockets. There must be 15 pins.

(4) Install the crankshaft oil slinger.

(5) Replace the oil seal in the timing case cover.

(6) Lubricate the tension spring, thrust pin and

pin bore in the preload bolt with Mopar Engine Oil

Supplement, or equivalent. Install the spring and

thrust pin in the preload bolt head (Fig. 6).

(7) Install the timing case cover and gasket.

(8) With the key installed in the crankshaft key-

way, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(9) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(10) Install the fan and hub (or Tempatrol fan) as-

sembly. Install the shroud.

(11) Connect negative cable to battery.

CAMSHAFT

REMOVAL

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. RE-

LEASE THE PRESSURE BEFORE REMOVING THE

DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system. DO NOT waste reus-

able coolant. If the solution is clean, drain it into a

clean container for reuse.

(3) Remove the radiator or radiator and condenser,

if equipped with A/C (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(4) Remove the air conditioner condenser and re-

ceiver/drier assembly as a charged unit, if equipped

(refer to Group 24, Heating and Air Conditioning).

(5) Remove the distributor cap and mark the posi-

tion of the rotor.

(6) Remove the distributor and ignition wires.

(7) Remove the engine cylinder head cover.

(8) Remove the rocker arms, bridges and pivots.

(9) Remove the push rods.

(10) Remove the engine cylinder head and gasket.

(11) Remove the hydraulic valve tappets from the

engine cylinder head.

(12) Remove the vibration damper.

(13) Remove the timing case cover.

(14) Remove the timing chain and sprockets.

(15) Remove the front bumper and/or grille, as re-

quired.

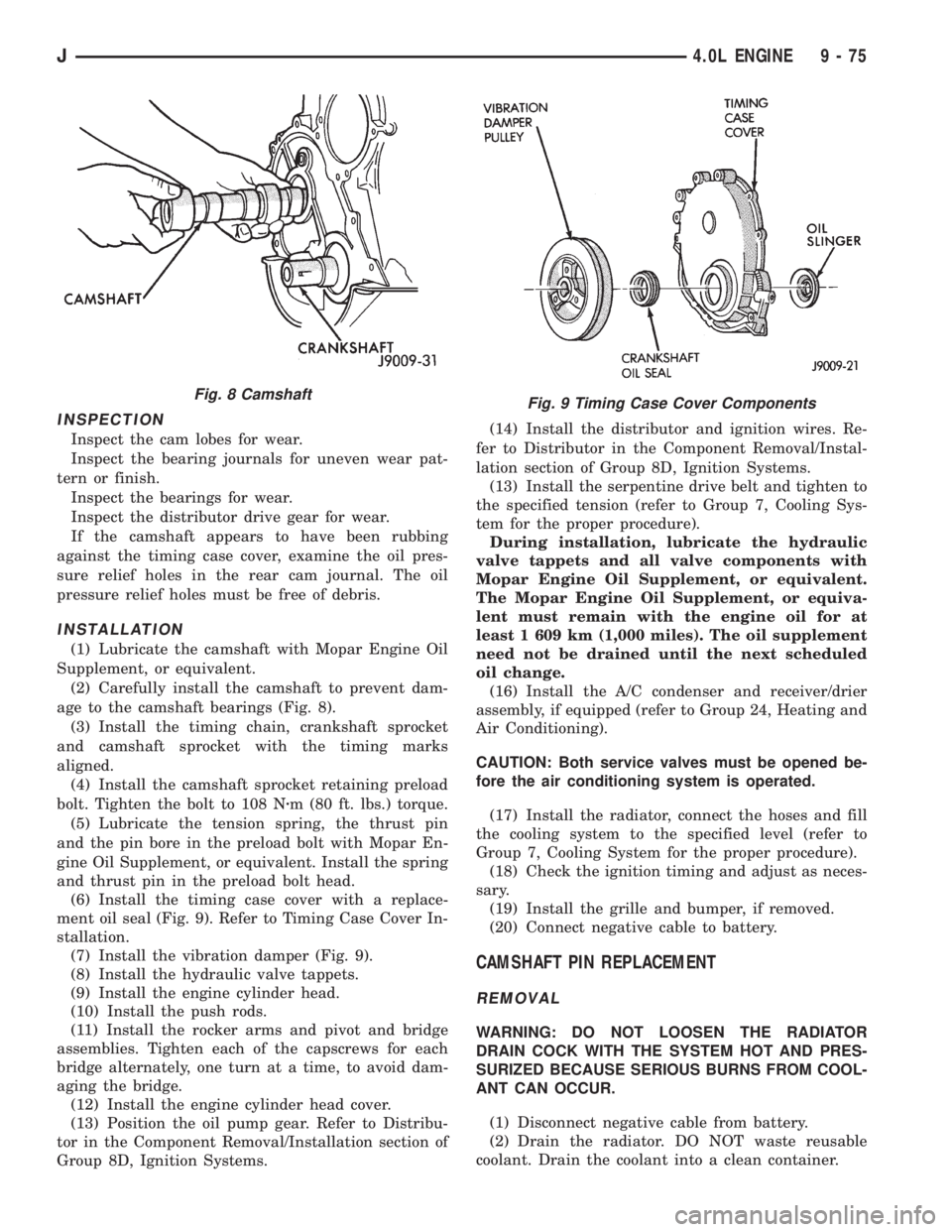

(16) Remove the camshaft (Fig. 8).

Fig. 6 Camshaft Sprocket Preload Bolt

Fig. 7 Verify SprocketÐChain InstallationÐTypical

9 - 74 4.0L ENGINEJ

Page 1166 of 2198

INSPECTION

Inspect the cam lobes for wear.

Inspect the bearing journals for uneven wear pat-

tern or finish.

Inspect the bearings for wear.

Inspect the distributor drive gear for wear.

If the camshaft appears to have been rubbing

against the timing case cover, examine the oil pres-

sure relief holes in the rear cam journal. The oil

pressure relief holes must be free of debris.

INSTALLATION

(1) Lubricate the camshaft with Mopar Engine Oil

Supplement, or equivalent.

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings (Fig. 8).

(3) Install the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned.

(4) Install the camshaft sprocket retaining preload

bolt. Tighten the bolt to 108 Nzm (80 ft. lbs.) torque.

(5) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

(6) Install the timing case cover with a replace-

ment oil seal (Fig. 9). Refer to Timing Case Cover In-

stallation.

(7) Install the vibration damper (Fig. 9).

(8) Install the hydraulic valve tappets.

(9) Install the engine cylinder head.

(10) Install the push rods.

(11) Install the rocker arms and pivot and bridge

assemblies. Tighten each of the capscrews for each

bridge alternately, one turn at a time, to avoid dam-

aging the bridge.

(12) Install the engine cylinder head cover.

(13) Position the oil pump gear. Refer to Distribu-

tor in the Component Removal/Installation section of

Group 8D, Ignition Systems.(14) Install the distributor and ignition wires. Re-

fer to Distributor in the Component Removal/Instal-

lation section of Group 8D, Ignition Systems.

(13) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

During installation, lubricate the hydraulic

valve tappets and all valve components with

Mopar Engine Oil Supplement, or equivalent.

The Mopar Engine Oil Supplement, or equiva-

lent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled

oil change.

(16) Install the A/C condenser and receiver/drier

assembly, if equipped (refer to Group 24, Heating and

Air Conditioning).

CAUTION: Both service valves must be opened be-

fore the air conditioning system is operated.

(17) Install the radiator, connect the hoses and fill

the cooling system to the specified level (refer to

Group 7, Cooling System for the proper procedure).

(18) Check the ignition timing and adjust as neces-

sary.

(19) Install the grille and bumper, if removed.

(20) Connect negative cable to battery.

CAMSHAFT PIN REPLACEMENT

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM COOL-

ANT CAN OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain the radiator. DO NOT waste reusable

coolant. Drain the coolant into a clean container.

Fig. 9 Timing Case Cover ComponentsFig. 8 Camshaft

J4.0L ENGINE 9 - 75

Page 1169 of 2198

(3) Slide the one-piece gasket over the dowels and

onto the block and timing case cover.

(4) Position the oil pan over the dowels and onto

the gasket. If equipped with an oil level sensor, take

care not to damage the sensor.

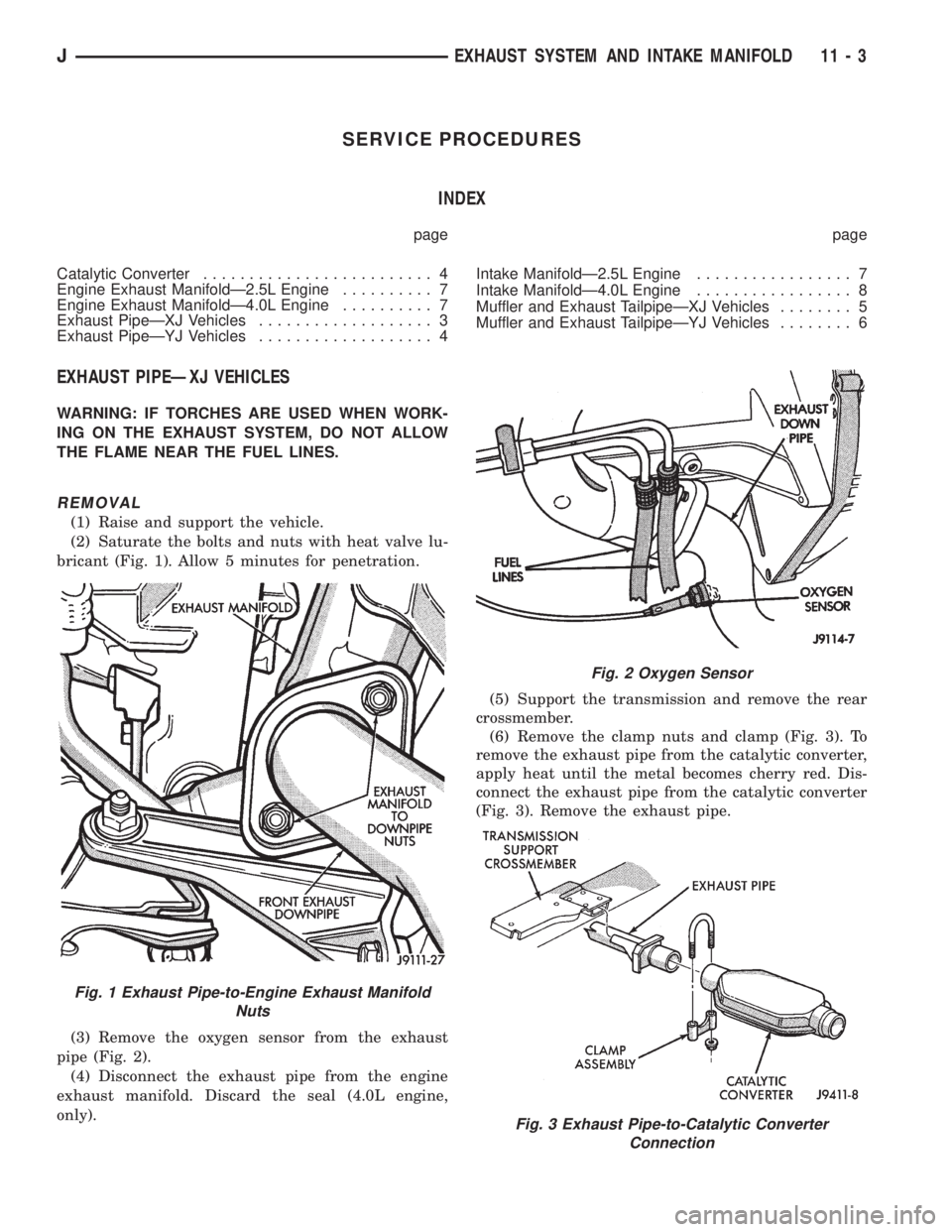

(5) Install the 1/4 inch oil pan bolts. Tighten these

bolts to 14 Nzm (120 in. lbs.) torque. Install the 5/16

inch oil pan bolts (Fig. 3). Tighten these bolts to 18

Nzm (156 in. lbs.) torque.

(6) Remove the dowels. Install the remaining 1/4

inch oil pan bolts. Tighten these bolts to 14 Nzm (120

in. lbs.) torque.(7) Lower the engine until it is properly located on

the engine mounts.

(8) Install the through bolts and tighten the nuts.

(9) Lower the jack stand and remove the piece of

wood.

(10) Install the engine flywheel and transmission

torque converter housing access cover.

(11) Install the engine starter motor.

(12) Connect the exhaust pipe to the hanger and to

the gine exhaust manifold.

(13) Install the oil pan drain plug (Fig. 3). Tighten

the plug to 34 Nzm (25 ft. lbs.) torque.

(14) Lower the vehicle.

(15) Connect negative cable to battery.

(16) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(18) Start the engine and inspect for leaks.

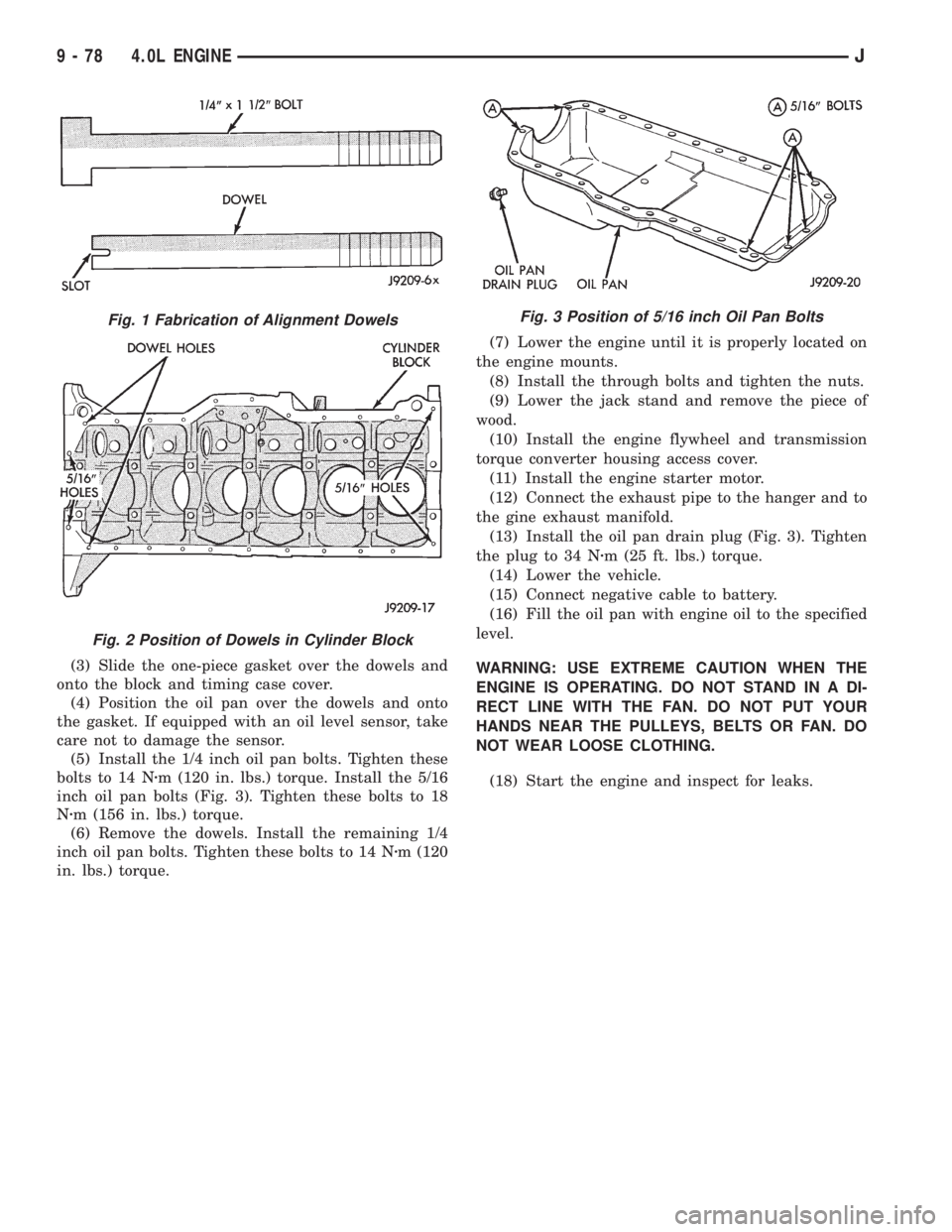

Fig. 1 Fabrication of Alignment Dowels

Fig. 2 Position of Dowels in Cylinder Block

Fig. 3 Position of 5/16 inch Oil Pan Bolts

9 - 78 4.0L ENGINEJ

Page 1190 of 2198

SERVICE PROCEDURES

INDEX

page page

Catalytic Converter......................... 4

Engine Exhaust ManifoldÐ2.5L Engine.......... 7

Engine Exhaust ManifoldÐ4.0L Engine.......... 7

Exhaust PipeÐXJ Vehicles................... 3

Exhaust PipeÐYJ Vehicles................... 4Intake ManifoldÐ2.5L Engine................. 7

Intake ManifoldÐ4.0L Engine................. 8

Muffler and Exhaust TailpipeÐXJ Vehicles........ 5

Muffler and Exhaust TailpipeÐYJ Vehicles........ 6

EXHAUST PIPEÐXJ VEHICLES

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

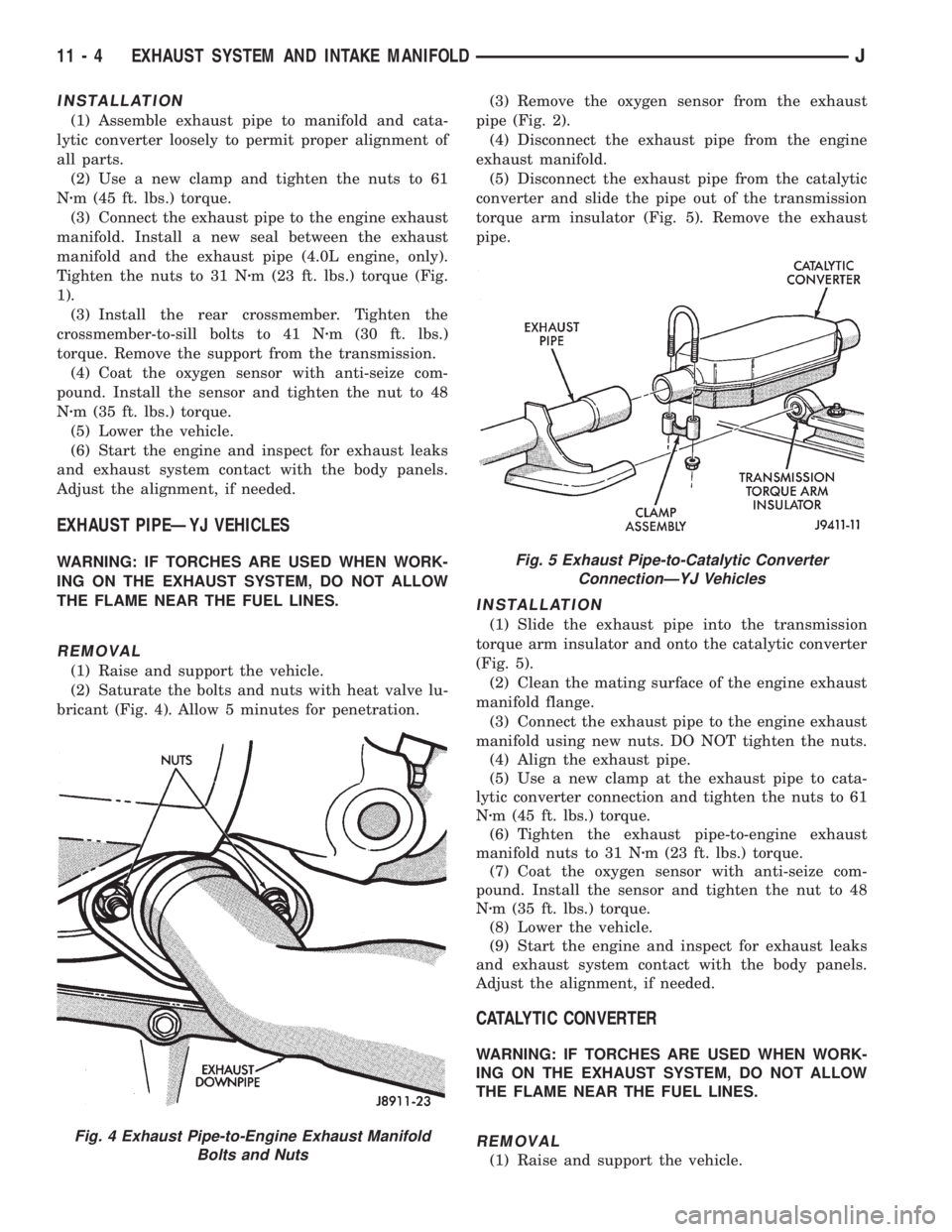

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve lu-

bricant (Fig. 1). Allow 5 minutes for penetration.

(3) Remove the oxygen sensor from the exhaust

pipe (Fig. 2).

(4) Disconnect the exhaust pipe from the engine

exhaust manifold. Discard the seal (4.0L engine,

only).(5) Support the transmission and remove the rear

crossmember.

(6) Remove the clamp nuts and clamp (Fig. 3). To

remove the exhaust pipe from the catalytic converter,

apply heat until the metal becomes cherry red. Dis-

connect the exhaust pipe from the catalytic converter

(Fig. 3). Remove the exhaust pipe.

Fig. 1 Exhaust Pipe-to-Engine Exhaust Manifold

Nuts

Fig. 2 Oxygen Sensor

Fig. 3 Exhaust Pipe-to-Catalytic Converter

Connection

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

Page 1191 of 2198

INSTALLATION

(1) Assemble exhaust pipe to manifold and cata-

lytic converter loosely to permit proper alignment of

all parts.

(2) Use a new clamp and tighten the nuts to 61

Nzm (45 ft. lbs.) torque.

(3) Connect the exhaust pipe to the engine exhaust

manifold. Install a new seal between the exhaust

manifold and the exhaust pipe (4.0L engine, only).

Tighten the nuts to 31 Nzm (23 ft. lbs.) torque (Fig.

1).

(3) Install the rear crossmember. Tighten the

crossmember-to-sill bolts to 41 Nzm (30 ft. lbs.)

torque. Remove the support from the transmission.

(4) Coat the oxygen sensor with anti-seize com-

pound. Install the sensor and tighten the nut to 48

Nzm (35 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

EXHAUST PIPEÐYJ VEHICLES

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve lu-

bricant (Fig. 4). Allow 5 minutes for penetration.(3) Remove the oxygen sensor from the exhaust

pipe (Fig. 2).

(4) Disconnect the exhaust pipe from the engine

exhaust manifold.

(5) Disconnect the exhaust pipe from the catalytic

converter and slide the pipe out of the transmission

torque arm insulator (Fig. 5). Remove the exhaust

pipe.

INSTALLATION

(1) Slide the exhaust pipe into the transmission

torque arm insulator and onto the catalytic converter

(Fig. 5).

(2) Clean the mating surface of the engine exhaust

manifold flange.

(3) Connect the exhaust pipe to the engine exhaust

manifold using new nuts. DO NOT tighten the nuts.

(4) Align the exhaust pipe.

(5) Use a new clamp at the exhaust pipe to cata-

lytic converter connection and tighten the nuts to 61

Nzm (45 ft. lbs.) torque.

(6) Tighten the exhaust pipe-to-engine exhaust

manifold nuts to 31 Nzm (23 ft. lbs.) torque.

(7) Coat the oxygen sensor with anti-seize com-

pound. Install the sensor and tighten the nut to 48

Nzm (35 ft. lbs.) torque.

(8) Lower the vehicle.

(9) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

CATALYTIC CONVERTER

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

Fig. 4 Exhaust Pipe-to-Engine Exhaust Manifold

Bolts and Nuts

Fig. 5 Exhaust Pipe-to-Catalytic Converter

ConnectionÐYJ Vehicles

11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 1192 of 2198

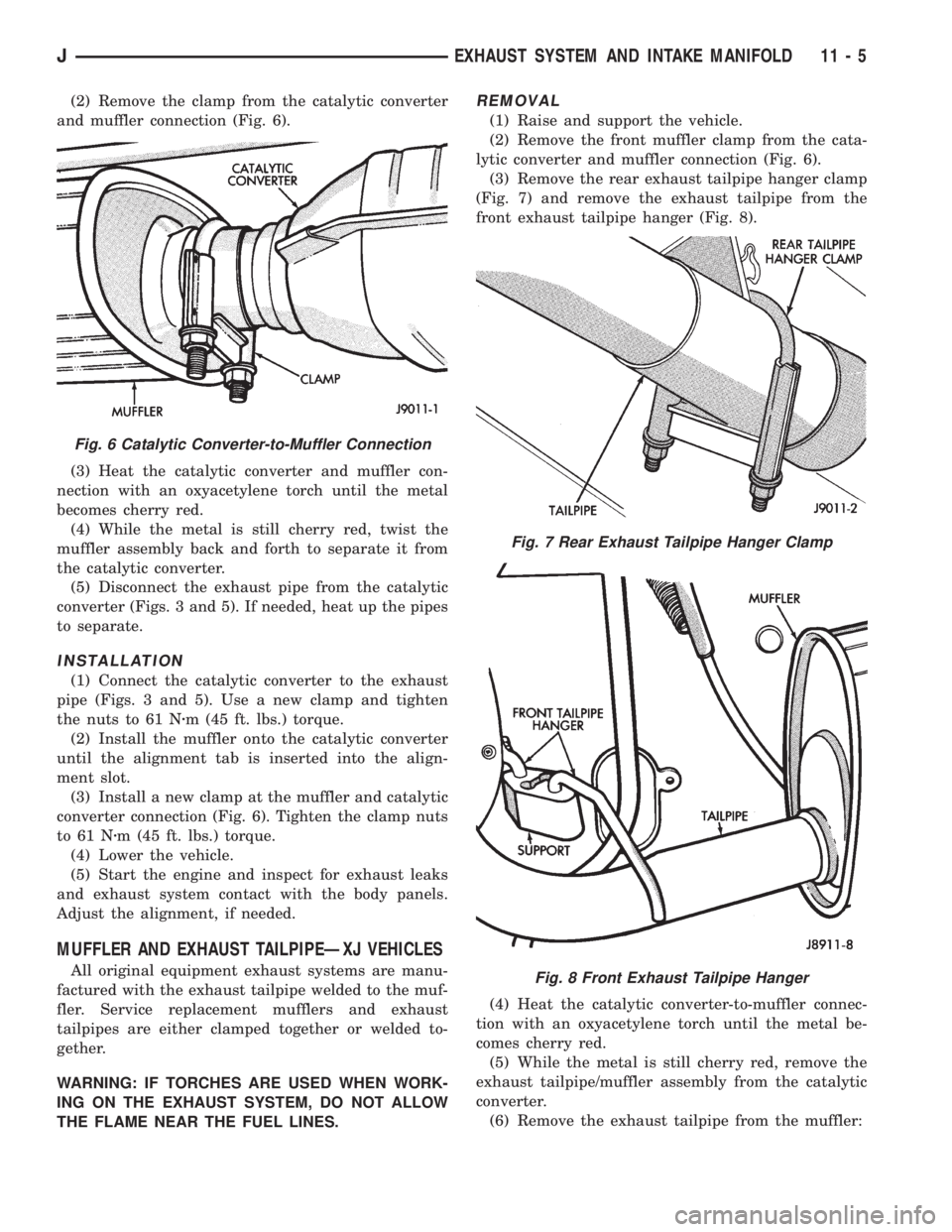

(2) Remove the clamp from the catalytic converter

and muffler connection (Fig. 6).

(3) Heat the catalytic converter and muffler con-

nection with an oxyacetylene torch until the metal

becomes cherry red.

(4) While the metal is still cherry red, twist the

muffler assembly back and forth to separate it from

the catalytic converter.

(5) Disconnect the exhaust pipe from the catalytic

converter (Figs. 3 and 5). If needed, heat up the pipes

to separate.

INSTALLATION

(1) Connect the catalytic converter to the exhaust

pipe (Figs. 3 and 5). Use a new clamp and tighten

the nuts to 61 Nzm (45 ft. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install a new clamp at the muffler and catalytic

converter connection (Fig. 6). Tighten the clamp nuts

to 61 Nzm (45 ft. lbs.) torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

MUFFLER AND EXHAUST TAILPIPEÐXJ VEHICLES

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are either clamped together or welded to-

gether.

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front muffler clamp from the cata-

lytic converter and muffler connection (Fig. 6).

(3) Remove the rear exhaust tailpipe hanger clamp

(Fig. 7) and remove the exhaust tailpipe from the

front exhaust tailpipe hanger (Fig. 8).

(4) Heat the catalytic converter-to-muffler connec-

tion with an oxyacetylene torch until the metal be-

comes cherry red.

(5) While the metal is still cherry red, remove the

exhaust tailpipe/muffler assembly from the catalytic

converter.

(6) Remove the exhaust tailpipe from the muffler:

Fig. 6 Catalytic Converter-to-Muffler Connection

Fig. 7 Rear Exhaust Tailpipe Hanger Clamp

Fig. 8 Front Exhaust Tailpipe Hanger

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 5

Page 1193 of 2198

²To remove an original equipment exhaust tailpipe/

muffler combination, cut the exhaust tailpipe close to

the muffler. Collapse the part remaining in the muf-

fler and remove.

²To remove a service exhaust tailpipe/muffler com-

bination, apply heat until the metal becomes cherry

red. Remove the exhaust tailpipe/muffler clamp and

twist the exhaust tailpipe out of the muffler.

INSTALLATION

(1) Install the muffler onto the catalytic converter.

Install the clamp and tighten the nuts finger tight.

(2) Install the exhaust tailpipe into the rear of the

muffler.

(3) Install the exhaust tailpipe/muffler assembly on

the rear exhaust tailpipe hanger. Make sure that the

exhaust tailpipe has sufficient clearance from the

floor pan.

(4) Install the remaining clamps and the front ex-

haust tailpipe hanger.

(5) Tighten the nuts on the muffler-to-catalytic

converter clamp to 61 Nzm (45 ft. lbs.) torque (Fig. 6).

Tighten the nuts on the rear exhaust tailpipe clamp

to 14 Nzm (10 ft. lbs.) torque (Fig. 7).

(6) Lower the vehicle.

(7) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

MUFFLER AND EXHAUST TAILPIPEÐYJ VEHICLES

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are clamped together.

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise the vehicle and support the rear of the

vehicle by the side rails and allow the axle to hang

free.

(2) Remove the front muffler clamp from the cata-

lytic converter and muffler connection (Fig. 6).

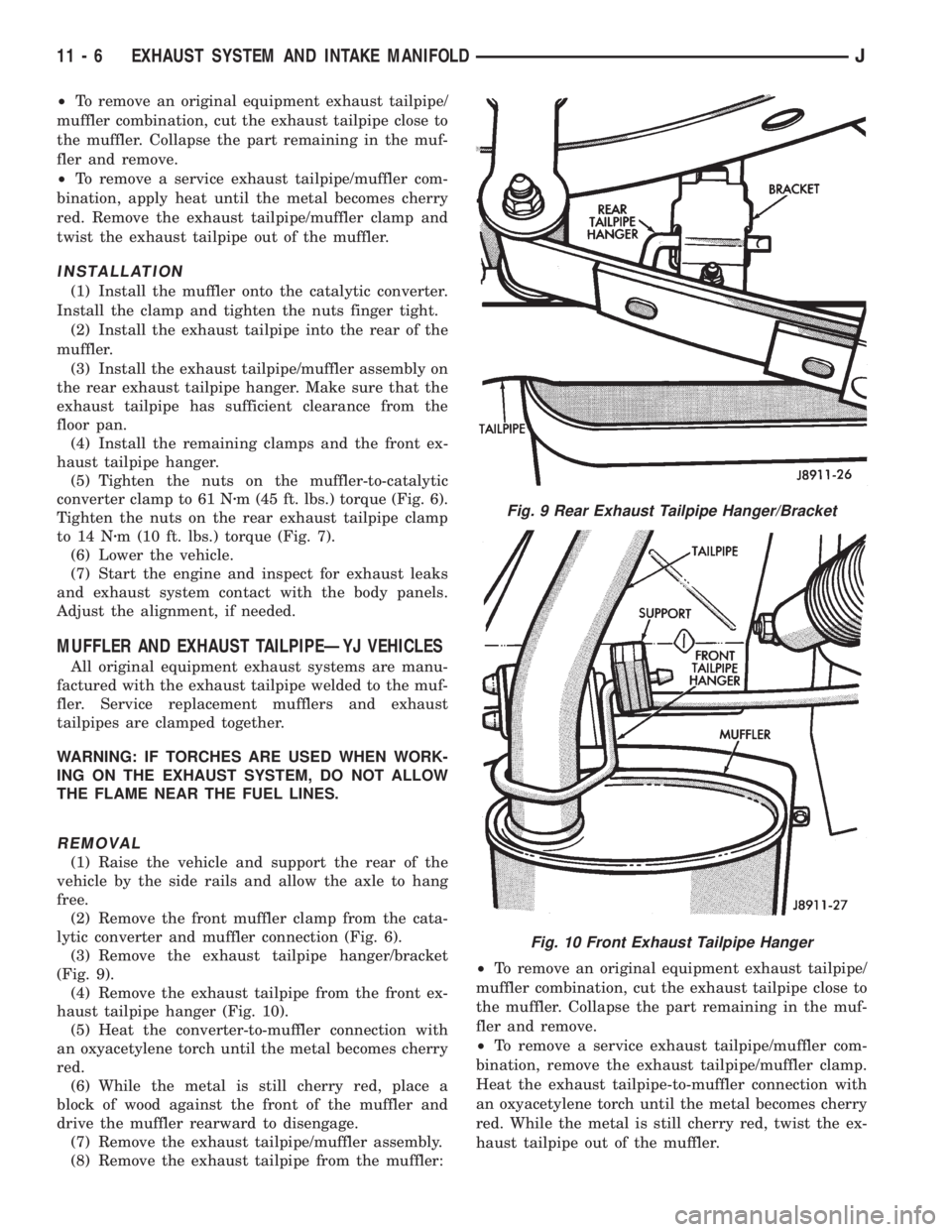

(3) Remove the exhaust tailpipe hanger/bracket

(Fig. 9).

(4) Remove the exhaust tailpipe from the front ex-

haust tailpipe hanger (Fig. 10).

(5) Heat the converter-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red.

(6) While the metal is still cherry red, place a

block of wood against the front of the muffler and

drive the muffler rearward to disengage.

(7) Remove the exhaust tailpipe/muffler assembly.

(8) Remove the exhaust tailpipe from the muffler:²To remove an original equipment exhaust tailpipe/

muffler combination, cut the exhaust tailpipe close to

the muffler. Collapse the part remaining in the muf-

fler and remove.

²To remove a service exhaust tailpipe/muffler com-

bination, remove the exhaust tailpipe/muffler clamp.

Heat the exhaust tailpipe-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red. While the metal is still cherry red, twist the ex-

haust tailpipe out of the muffler.

Fig. 9 Rear Exhaust Tailpipe Hanger/Bracket

Fig. 10 Front Exhaust Tailpipe Hanger

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 1207 of 2198

FRAME

INDEX

page page

Frame Dimensions........................ 13

Frame Repairs........................... 13

Frame Straightening....................... 13

Fuel Tank Skid Plate....................... 15

General Information....................... 10Generator Splash Shield.................... 13

Safety Precautions and Warnings............. 10

Tow Hooks.............................. 13

Transfer Case Skid Plate.................... 15

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

BEFORE PROCEEDING WITH FRAME REPAIR IN-

VOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

DO NOT ALLOW OPEN FLAME TO CONTACT

PLASTIC BODY PANELS. FIRE OR EXPLOSION CAN

RESULT.

WHEN WELDED FRAME COMPONENTS ARE RE-

PLACED, 100% PENETRATION WELD MUST BE

ACHIEVED DURING INSTALLATION. IF NOT, DAN-

GEROUS OPERATING CONDITIONS CAN RESULT.

STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN RE-

SULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT SUPPORTED ON SAFETY STANDS,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect.

Do not drill holes in top or bottom frame rail

flanges, frame rail failure can result.

Do Not use softer than Grade 3 bolts to replace

production fasteners, loosening or failure can re-

sult.When using heat to straighten frame components

do not exceed 566ÉC (1050ÉF), metal fatigue can re-

sult.

Welding the joints around riveted cross members

and frame side rails can weaken frame

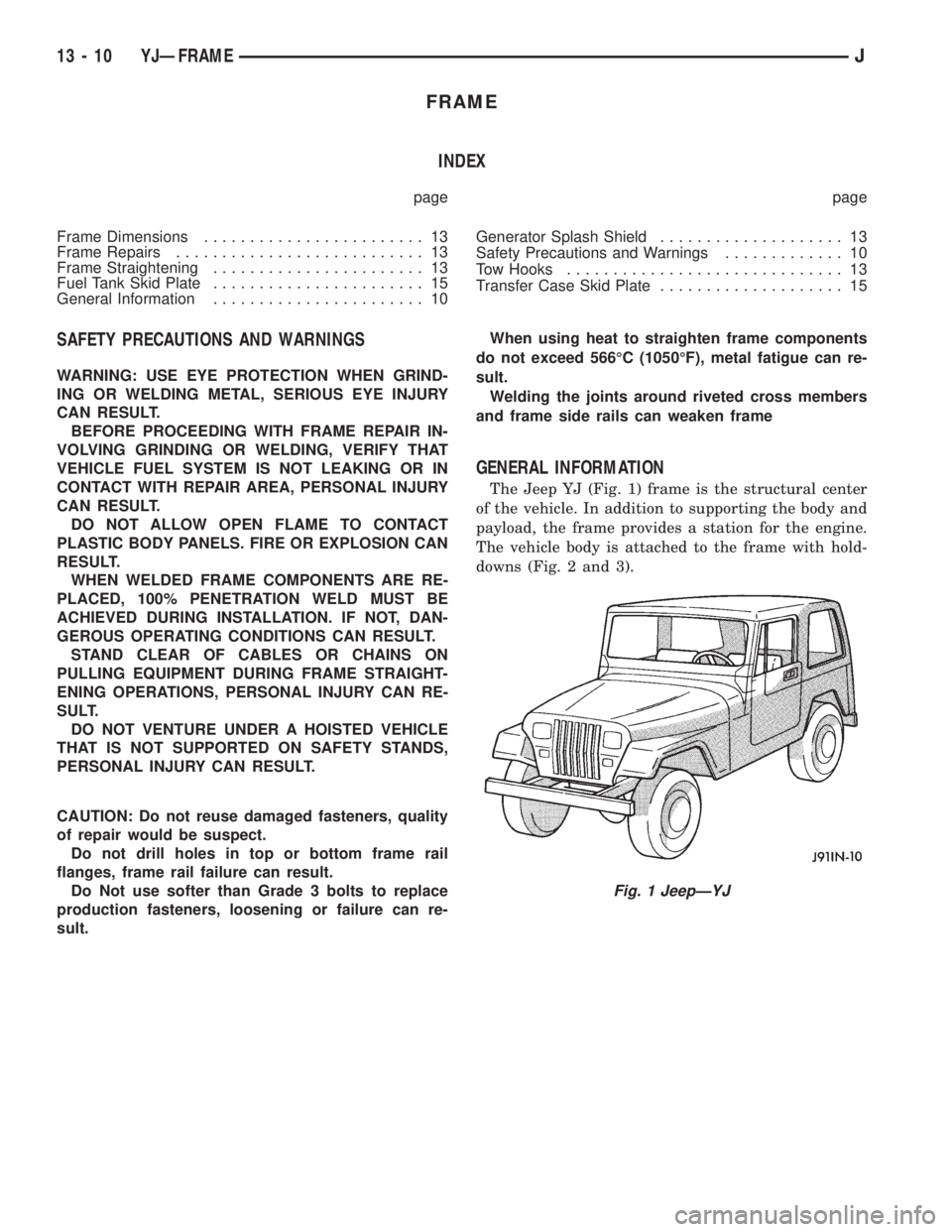

GENERAL INFORMATION

The Jeep YJ (Fig. 1) frame is the structural center

of the vehicle. In addition to supporting the body and

payload, the frame provides a station for the engine.

The vehicle body is attached to the frame with hold-

downs (Fig. 2 and 3).

Fig. 1 JeepÐYJ

13 - 10 YJÐFRAMEJ