warning JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1230 of 2198

(1) Disconnect negative battery cable.

(2) Remove the fuel filler cap. Using an approved

portable gasoline siphon/storage tank, drain fuel

tank.

(3) Raise and support vehicle.

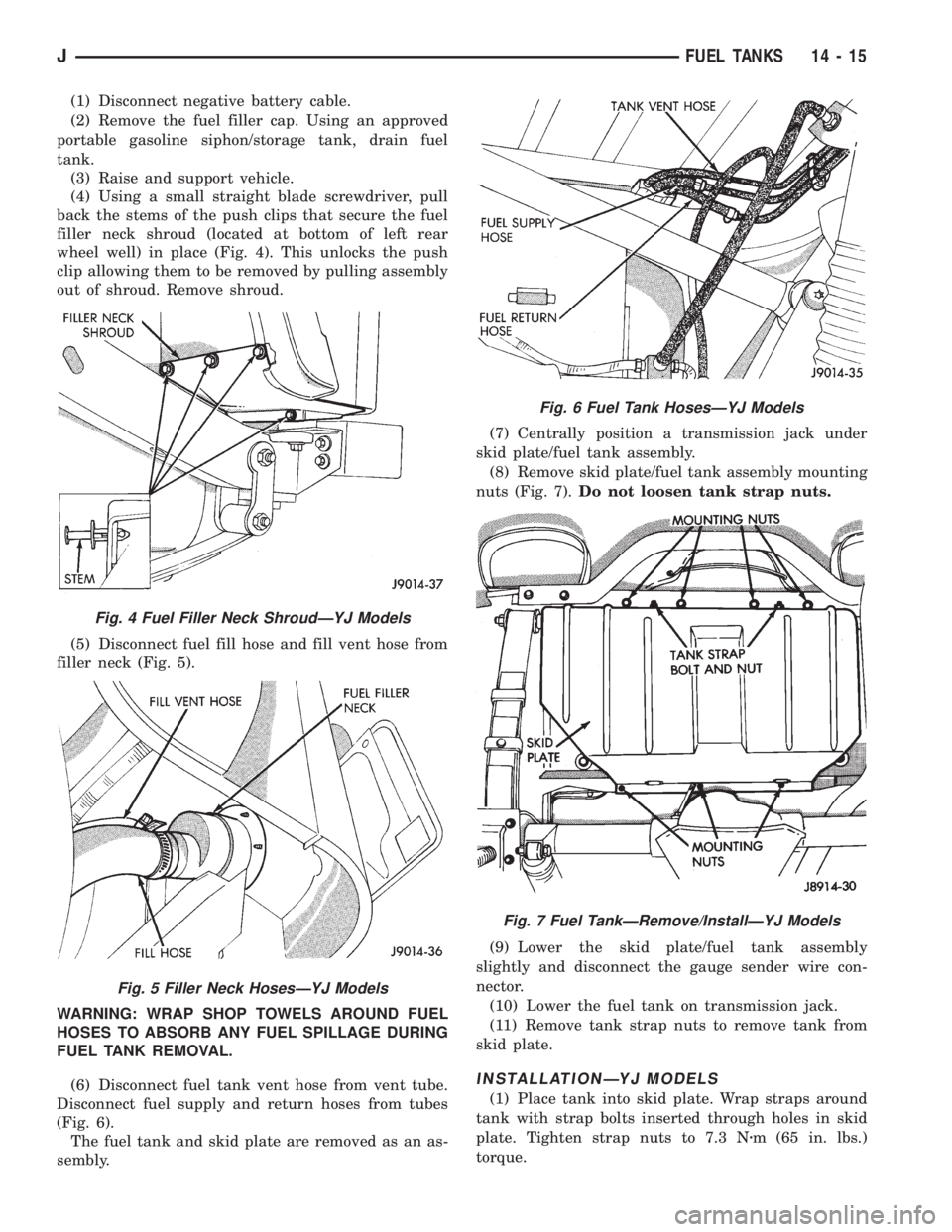

(4) Using a small straight blade screwdriver, pull

back the stems of the push clips that secure the fuel

filler neck shroud (located at bottom of left rear

wheel well) in place (Fig. 4). This unlocks the push

clip allowing them to be removed by pulling assembly

out of shroud. Remove shroud.

(5) Disconnect fuel fill hose and fill vent hose from

filler neck (Fig. 5).

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

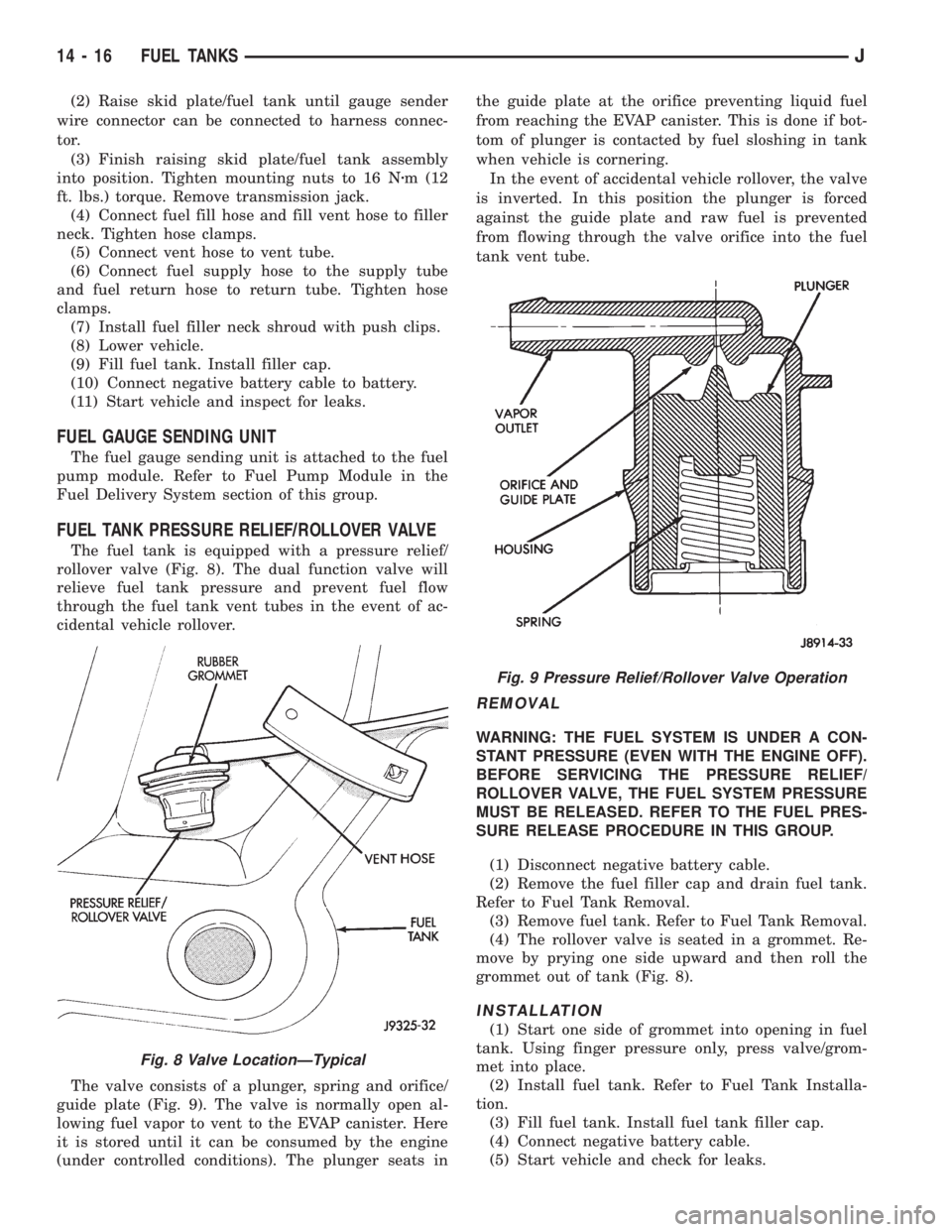

(6) Disconnect fuel tank vent hose from vent tube.

Disconnect fuel supply and return hoses from tubes

(Fig. 6).

The fuel tank and skid plate are removed as an as-

sembly.(7) Centrally position a transmission jack under

skid plate/fuel tank assembly.

(8) Remove skid plate/fuel tank assembly mounting

nuts (Fig. 7).Do not loosen tank strap nuts.

(9) Lower the skid plate/fuel tank assembly

slightly and disconnect the gauge sender wire con-

nector.

(10) Lower the fuel tank on transmission jack.

(11) Remove tank strap nuts to remove tank from

skid plate.

INSTALLATIONÐYJ MODELS

(1) Place tank into skid plate. Wrap straps around

tank with strap bolts inserted through holes in skid

plate. Tighten strap nuts to 7.3 Nzm (65 in. lbs.)

torque.

Fig. 4 Fuel Filler Neck ShroudÐYJ Models

Fig. 5 Filler Neck HosesÐYJ Models

Fig. 6 Fuel Tank HosesÐYJ Models

Fig. 7 Fuel TankÐRemove/InstallÐYJ Models

JFUEL TANKS 14 - 15

Page 1231 of 2198

(2) Raise skid plate/fuel tank until gauge sender

wire connector can be connected to harness connec-

tor.

(3) Finish raising skid plate/fuel tank assembly

into position. Tighten mounting nuts to 16 Nzm (12

ft. lbs.) torque. Remove transmission jack.

(4) Connect fuel fill hose and fill vent hose to filler

neck. Tighten hose clamps.

(5) Connect vent hose to vent tube.

(6) Connect fuel supply hose to the supply tube

and fuel return hose to return tube. Tighten hose

clamps.

(7) Install fuel filler neck shroud with push clips.

(8) Lower vehicle.

(9) Fill fuel tank. Install filler cap.

(10) Connect negative battery cable to battery.

(11) Start vehicle and inspect for leaks.

FUEL GAUGE SENDING UNIT

The fuel gauge sending unit is attached to the fuel

pump module. Refer to Fuel Pump Module in the

Fuel Delivery System section of this group.

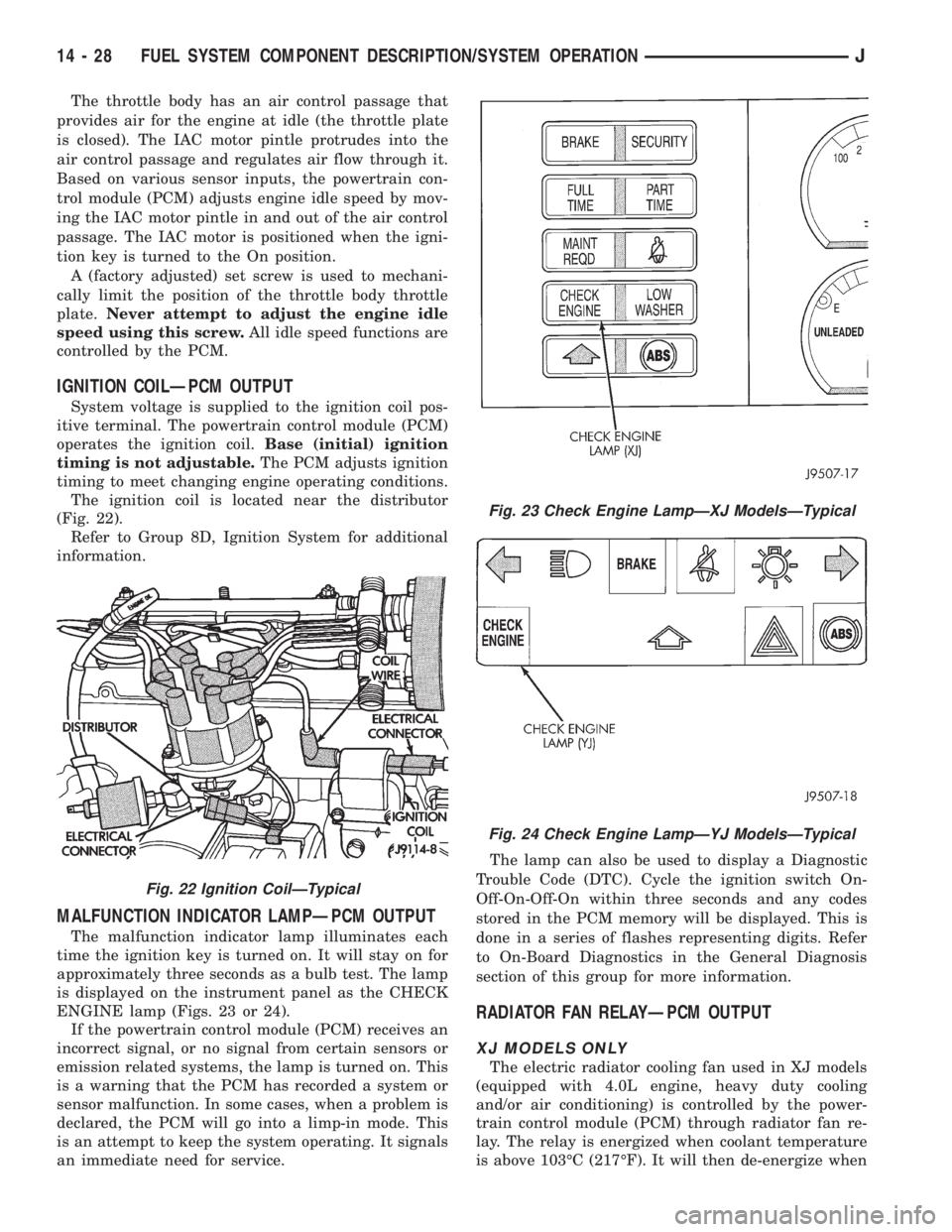

FUEL TANK PRESSURE RELIEF/ROLLOVER VALVE

The fuel tank is equipped with a pressure relief/

rollover valve (Fig. 8). The dual function valve will

relieve fuel tank pressure and prevent fuel flow

through the fuel tank vent tubes in the event of ac-

cidental vehicle rollover.

The valve consists of a plunger, spring and orifice/

guide plate (Fig. 9). The valve is normally open al-

lowing fuel vapor to vent to the EVAP canister. Here

it is stored until it can be consumed by the engine

(under controlled conditions). The plunger seats inthe guide plate at the orifice preventing liquid fuel

from reaching the EVAP canister. This is done if bot-

tom of plunger is contacted by fuel sloshing in tank

when vehicle is cornering.

In the event of accidental vehicle rollover, the valve

is inverted. In this position the plunger is forced

against the guide plate and raw fuel is prevented

from flowing through the valve orifice into the fuel

tank vent tube.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE PRESSURE RELIEF/

ROLLOVER VALVE, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

(1) Disconnect negative battery cable.

(2) Remove the fuel filler cap and drain fuel tank.

Refer to Fuel Tank Removal.

(3) Remove fuel tank. Refer to Fuel Tank Removal.

(4) The rollover valve is seated in a grommet. Re-

move by prying one side upward and then roll the

grommet out of tank (Fig. 8).

INSTALLATION

(1) Start one side of grommet into opening in fuel

tank. Using finger pressure only, press valve/grom-

met into place.

(2) Install fuel tank. Refer to Fuel Tank Installa-

tion.

(3) Fill fuel tank. Install fuel tank filler cap.

(4) Connect negative battery cable.

(5) Start vehicle and check for leaks.

Fig. 8 Valve LocationÐTypical

Fig. 9 Pressure Relief/Rollover Valve Operation

14 - 16 FUEL TANKSJ

Page 1243 of 2198

The throttle body has an air control passage that

provides air for the engine at idle (the throttle plate

is closed). The IAC motor pintle protrudes into the

air control passage and regulates air flow through it.

Based on various sensor inputs, the powertrain con-

trol module (PCM) adjusts engine idle speed by mov-

ing the IAC motor pintle in and out of the air control

passage. The IAC motor is positioned when the igni-

tion key is turned to the On position.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

IGNITION COILÐPCM OUTPUT

System voltage is supplied to the ignition coil pos-

itive terminal. The powertrain control module (PCM)

operates the ignition coil.Base (initial) ignition

timing is not adjustable.The PCM adjusts ignition

timing to meet changing engine operating conditions.

The ignition coil is located near the distributor

(Fig. 22).

Refer to Group 8D, Ignition System for additional

information.

MALFUNCTION INDICATOR LAMPÐPCM OUTPUT

The malfunction indicator lamp illuminates each

time the ignition key is turned on. It will stay on for

approximately three seconds as a bulb test. The lamp

is displayed on the instrument panel as the CHECK

ENGINE lamp (Figs. 23 or 24).

If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals

an immediate need for service.The lamp can also be used to display a Diagnostic

Trouble Code (DTC). Cycle the ignition switch On-

Off-On-Off-On within three seconds and any codes

stored in the PCM memory will be displayed. This is

done in a series of flashes representing digits. Refer

to On-Board Diagnostics in the General Diagnosis

section of this group for more information.

RADIATOR FAN RELAYÐPCM OUTPUT

XJ MODELS ONLY

The electric radiator cooling fan used in XJ models

(equipped with 4.0L engine, heavy duty cooling

and/or air conditioning) is controlled by the power-

train control module (PCM) through radiator fan re-

lay. The relay is energized when coolant temperature

is above 103ÉC (217ÉF). It will then de-energize when

Fig. 22 Ignition CoilÐTypical

Fig. 23 Check Engine LampÐXJ ModelsÐTypical

Fig. 24 Check Engine LampÐYJ ModelsÐTypical

14 - 28 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 1275 of 2198

CAMSHAFT POSITION SENSOR

For removal/installation procedures, refer to Group

8D, Ignition System. See Camshaft Position Sensor.

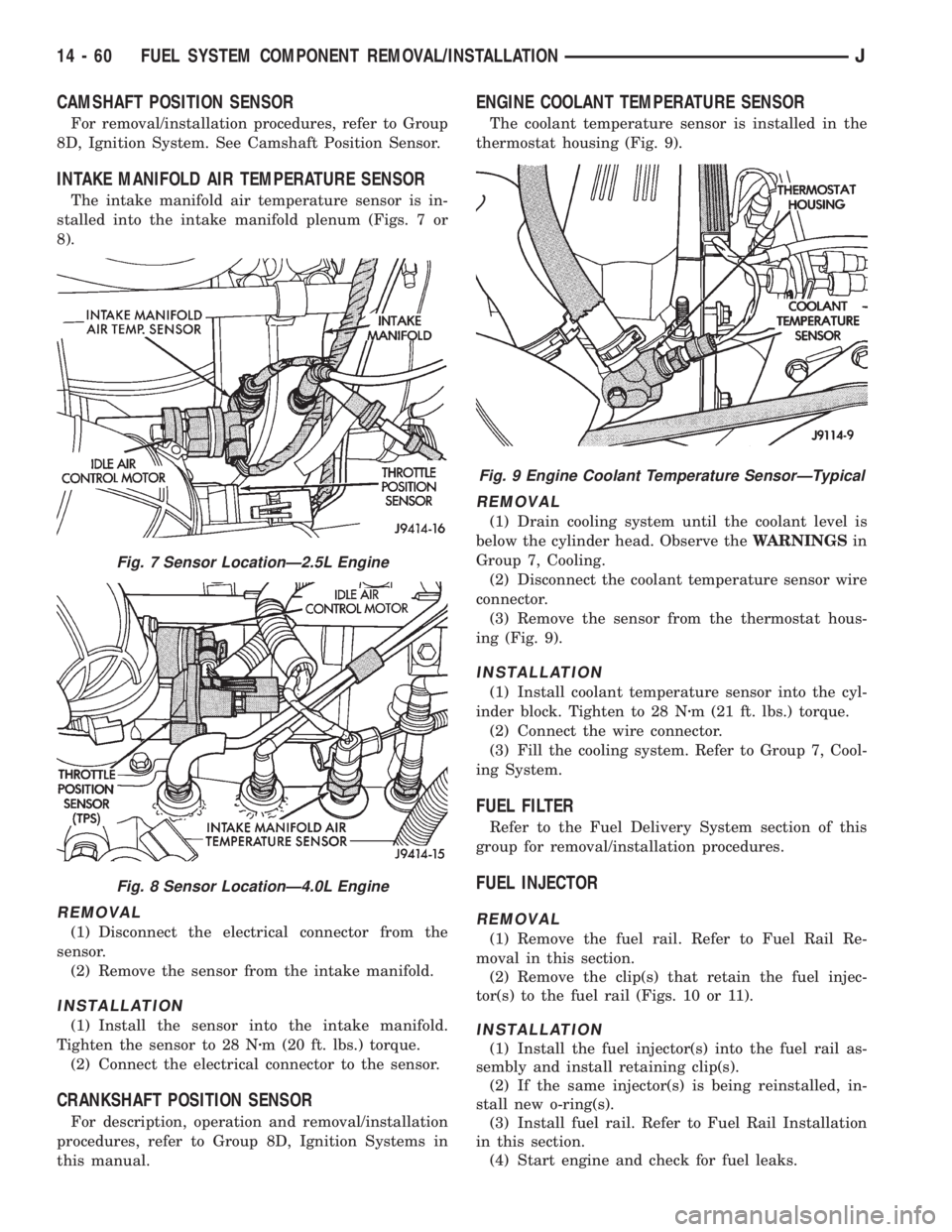

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

The intake manifold air temperature sensor is in-

stalled into the intake manifold plenum (Figs. 7 or

8).

REMOVAL

(1) Disconnect the electrical connector from the

sensor.

(2) Remove the sensor from the intake manifold.

INSTALLATION

(1) Install the sensor into the intake manifold.

Tighten the sensor to 28 Nzm (20 ft. lbs.) torque.

(2) Connect the electrical connector to the sensor.

CRANKSHAFT POSITION SENSOR

For description, operation and removal/installation

procedures, refer to Group 8D, Ignition Systems in

this manual.

ENGINE COOLANT TEMPERATURE SENSOR

The coolant temperature sensor is installed in the

thermostat housing (Fig. 9).

REMOVAL

(1) Drain cooling system until the coolant level is

below the cylinder head. Observe theWARNINGSin

Group 7, Cooling.

(2) Disconnect the coolant temperature sensor wire

connector.

(3) Remove the sensor from the thermostat hous-

ing (Fig. 9).

INSTALLATION

(1) Install coolant temperature sensor into the cyl-

inder block. Tighten to 28 Nzm (21 ft. lbs.) torque.

(2) Connect the wire connector.

(3) Fill the cooling system. Refer to Group 7, Cool-

ing System.

FUEL FILTER

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

FUEL INJECTOR

REMOVAL

(1) Remove the fuel rail. Refer to Fuel Rail Re-

moval in this section.

(2) Remove the clip(s) that retain the fuel injec-

tor(s) to the fuel rail (Figs. 10 or 11).

INSTALLATION

(1) Install the fuel injector(s) into the fuel rail as-

sembly and install retaining clip(s).

(2) If the same injector(s) is being reinstalled, in-

stall new o-ring(s).

(3) Install fuel rail. Refer to Fuel Rail Installation

in this section.

(4) Start engine and check for fuel leaks.

Fig. 7 Sensor LocationÐ2.5L Engine

Fig. 8 Sensor LocationÐ4.0L Engine

Fig. 9 Engine Coolant Temperature SensorÐTypical

14 - 60 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1276 of 2198

FUEL PUMP MODULE

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

FUEL PUMP RELAY

The fuel pump relay is located in the power distri-

bution center (PDC) (Figs. 1 or 2). For location of this

relay within the PDC, refer to label on PDC cover.

FUEL PRESSURE REGULATOR

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE

TURNED OFF). BEFORE SERVICING THE FUEL

PRESSURE REGULATOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.To release fuel pressure, refer to the Fuel Delivery

System section of this group. See Fuel System Pres-

sure Release.

REMOVAL

The fuel pressure regulator is located at the front

of the fuel rail (Fig 12). It is held to the fuel rail

(mounted vertically) with a clamp and bolt (Fig. 13).

(1) Perform the fuel pressure release procedure.

(2) Remove the vacuum line from the pressure reg-

ulator.

(3) Remove the clamp mounting bolt and regulator

mounting clamp from the fuel rail (Fig. 13).

(4) Remove pressure regulator from fuel rail.

(5) Remove and discard the o-ring seals.

INSTALLATION

(1) Install new o-ring seals to pressure regulator.

(2) Install pressure regulator to fuel rail.

(3) Install retaining clamp and clamp bolt.

(4) Install vacuum line to pressure regulator.

(5) Start engine and check for leaks.

Fig. 10 Injector Mounting

Fig. 11 Injector Retaining ClipsÐTypical Injector

Fig. 12 Fuel Injector HarnessÐTypical

Fig. 13 Fuel Rail AssemblyÐTypical

JFUEL SYSTEM COMPONENT REMOVAL/INSTALLATION 14 - 61

Page 1277 of 2198

FUEL RAIL ASSEMBLY

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39 PSI).

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING THE FUEL RAIL.

(1) Remove fuel tank filler tube cap.

(2) Disconnect the negative battery cable from bat-

tery.

(3) Perform the Fuel System Pressure Release Pro-

cedure as described in the Fuel Delivery System sec-

tion of this Group.

(4) Remove and numerically attach a tag (if fuel

injector is not already tagged), the injector harness

connectors. Do this at each injector (Fig. 12).

(5) Disconnect vacuum line from fuel pressure reg-

ulator (Fig. 12).

(6) Disconnect fuel supply line from fuel rail and

the fuel return line from fuel pressure regulator (Fig.

12). Refer to Fuel Tubes/Lines/Hoses and Clamps, or

Quick-Connect Fittings. These can both be found in

the Fuel Delivery section of this group.

(7) Remove fuel rail mounting bolts.

On models with automatic transmissions, it may be

necessary to remove automatic transmission throttle

line pressure cable and bracket. This will aid in fuel

rail assembly removal.

(8) Remove fuel rail by gently rocking until all the

fuel injectors are out of the intake manifold.

INSTALLATION

(1) Position tips of all fuel injectors into the corre-

sponding injector bore in the intake manifold. Seat

injectors into manifold.

(2) Tighten fuel rail mounting bolts to 27 Nzm (20

ft. lbs.) torque.

(3) Connect injector harness connectors to appro-

priate (tagged) injector.

(4) Connect both fuel lines to fuel rail. Refer to the

Fuel Delivery section of this group for procedures.

(5) Connect vacuum supply line to fuel pressure

regulator.

(6) Install protective cap to pressure test port fit-

ting.

(7) Install fuel tank cap.

(8) Connect negative battery cable to battery.

(9) Start engine and check for fuel leaks.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF)

OF APPROXIMATELY 100 KPA (14.5 PSI). BEFORE

SERVICING THE FUEL PUMP, FUEL RAIL, FUELLINES, FUEL FILTER OR FUEL INJECTOR, THE

FUEL SYSTEM PRESSURE MUST BE RELEASED.

Refer to the Fuel Delivery System section of this

group. See Fuel Pressure Release procedure.

FUEL TANKS

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TANK PRESSURE RELIEF/ROLLOVER VALVE

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TUBES/LINES/HOSES AND CLAMPS

Refer to the Fuel Delivery System section of this

group for removal/installation procedures. Also refer

to Quick-Connect Fittings in the Fuel Delivery sec-

tion of this group.

IDLE AIR CONTROL (IAC) MOTOR

The IAC motor is mounted to the throttle body ad-

jacent to the throttle position sensor (Fig. 14).

REMOVAL

(1) Disconnect the electrical connector from the

IAC motor.

(2) Remove IAC motor torx head mounting bolts.

(3) Remove IAC motor.

INSTALLATION

(1) Install IAC motor into throttle body and

tighten retaining bolts.

(2) Connect electrical connector to IAC motor.

IGNITION COIL

Refer to Group 8D, Ignition Systems for removal/

installation procedures.

Fig. 14 Idle Air Control MotorÐRemoval/

InstallationÐTypical

14 - 62 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1278 of 2198

INTAKE MANIFOLD

Refer to Group 11, Exhaust System and Intake

Manifold for removal/installation procedures.

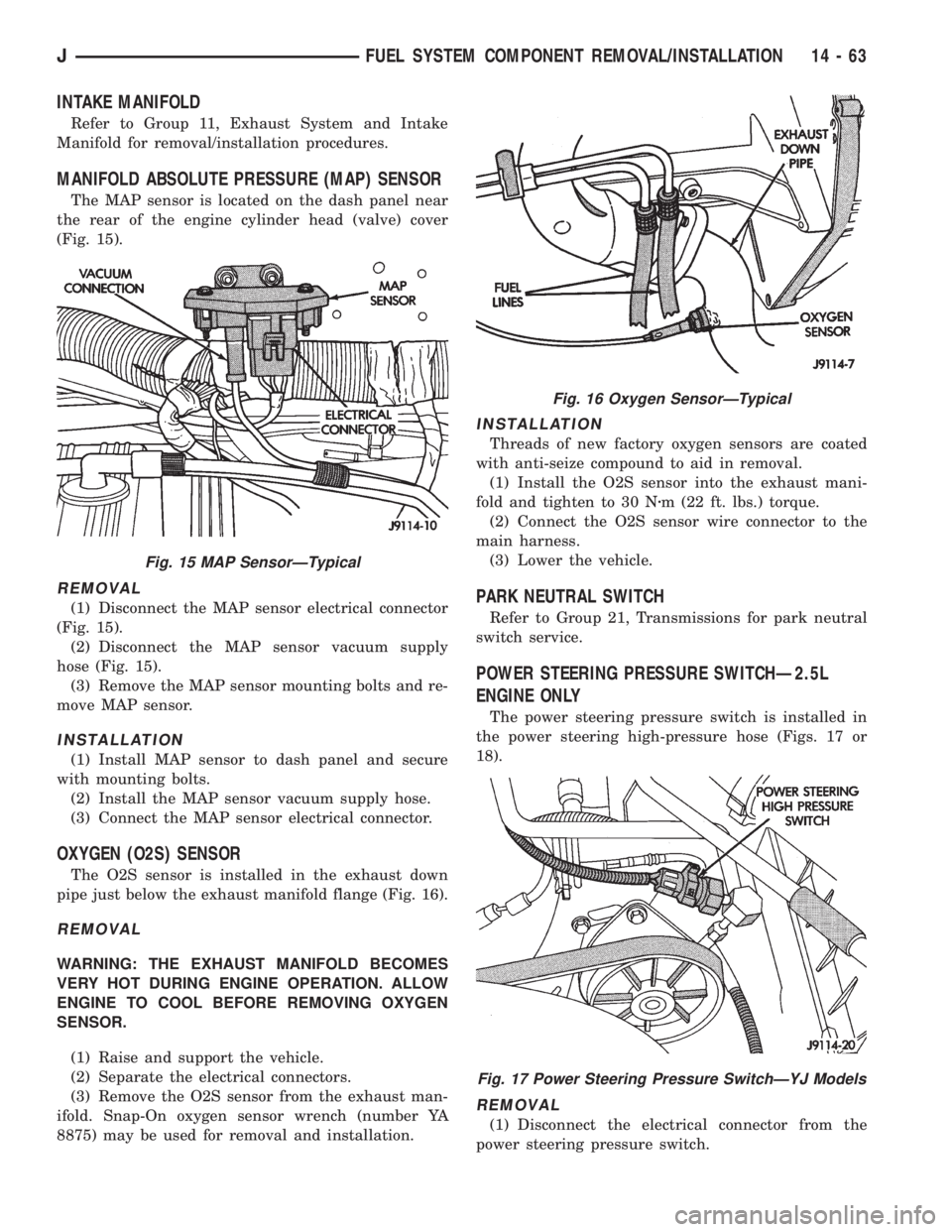

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor is located on the dash panel near

the rear of the engine cylinder head (valve) cover

(Fig. 15).

REMOVAL

(1) Disconnect the MAP sensor electrical connector

(Fig. 15).

(2) Disconnect the MAP sensor vacuum supply

hose (Fig. 15).

(3) Remove the MAP sensor mounting bolts and re-

move MAP sensor.

INSTALLATION

(1) Install MAP sensor to dash panel and secure

with mounting bolts.

(2) Install the MAP sensor vacuum supply hose.

(3) Connect the MAP sensor electrical connector.

OXYGEN (O2S) SENSOR

The O2S sensor is installed in the exhaust down

pipe just below the exhaust manifold flange (Fig. 16).

REMOVAL

WARNING: THE EXHAUST MANIFOLD BECOMES

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support the vehicle.

(2) Separate the electrical connectors.

(3) Remove the O2S sensor from the exhaust man-

ifold. Snap-On oxygen sensor wrench (number YA

8875) may be used for removal and installation.

INSTALLATION

Threads of new factory oxygen sensors are coated

with anti-seize compound to aid in removal.

(1) Install the O2S sensor into the exhaust mani-

fold and tighten to 30 Nzm (22 ft. lbs.) torque.

(2) Connect the O2S sensor wire connector to the

main harness.

(3) Lower the vehicle.

PARK NEUTRAL SWITCH

Refer to Group 21, Transmissions for park neutral

switch service.

POWER STEERING PRESSURE SWITCHÐ2.5L

ENGINE ONLY

The power steering pressure switch is installed in

the power steering high-pressure hose (Figs. 17 or

18).

REMOVAL

(1) Disconnect the electrical connector from the

power steering pressure switch.

Fig. 15 MAP SensorÐTypical

Fig. 16 Oxygen SensorÐTypical

Fig. 17 Power Steering Pressure SwitchÐYJ Models

JFUEL SYSTEM COMPONENT REMOVAL/INSTALLATION 14 - 63

Page 1310 of 2198

POWER STEERING PUMP

INDEX

page page

Drive Pulley Replacement................... 13

Flow Control Valve Fitting O-Ring Seal......... 14

Power Steering PumpÐInitial Operation........ 15

Pressure and Return Hose Replacement........ 11Pump Replacement........................ 12

Reservoir Replacement..................... 14

Service Information........................ 11

SERVICE INFORMATION

The power steering pump internal components are

not serviced or adjusted. If a malfunction or an inter-

nal fluid leak occurs, the complete unit must be re-

placed. A reservoir, cap, and O-ring seal kit are the

only service components available.

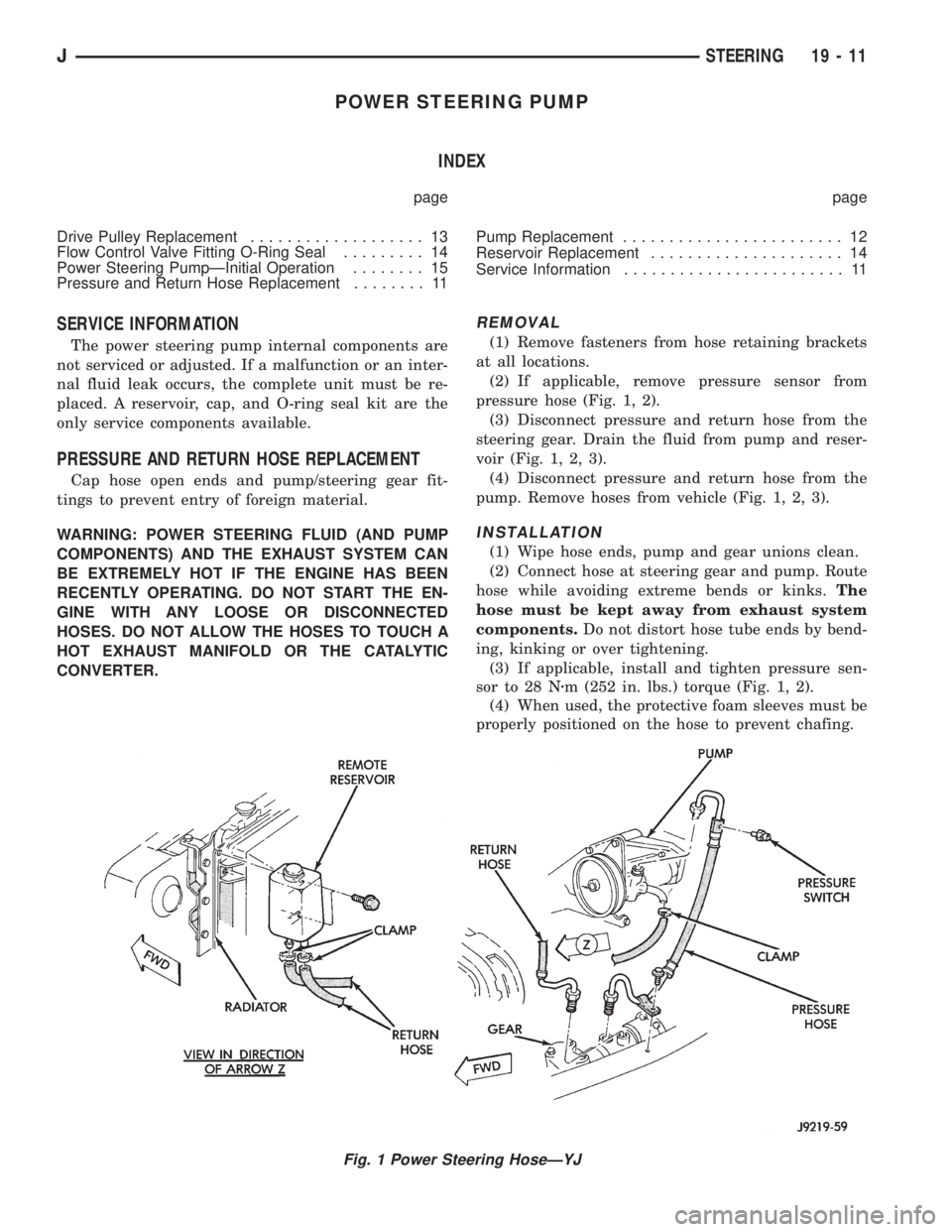

PRESSURE AND RETURN HOSE REPLACEMENT

Cap hose open ends and pump/steering gear fit-

tings to prevent entry of foreign material.

WARNING: POWER STEERING FLUID (AND PUMP

COMPONENTS) AND THE EXHAUST SYSTEM CAN

BE EXTREMELY HOT IF THE ENGINE HAS BEEN

RECENTLY OPERATING. DO NOT START THE EN-

GINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW THE HOSES TO TOUCH A

HOT EXHAUST MANIFOLD OR THE CATALYTIC

CONVERTER.

REMOVAL

(1) Remove fasteners from hose retaining brackets

at all locations.

(2) If applicable, remove pressure sensor from

pressure hose (Fig. 1, 2).

(3) Disconnect pressure and return hose from the

steering gear. Drain the fluid from pump and reser-

voir (Fig. 1, 2, 3).

(4) Disconnect pressure and return hose from the

pump. Remove hoses from vehicle (Fig. 1, 2, 3).

INSTALLATION

(1) Wipe hose ends, pump and gear unions clean.

(2) Connect hose at steering gear and pump. Route

hose while avoiding extreme bends or kinks.The

hose must be kept away from exhaust system

components.Do not distort hose tube ends by bend-

ing, kinking or over tightening.

(3) If applicable, install and tighten pressure sen-

sor to 28 Nzm (252 in. lbs.) torque (Fig. 1, 2).

(4) When used, the protective foam sleeves must be

properly positioned on the hose to prevent chafing.

Fig. 1 Power Steering HoseÐYJ

JSTEERING 19 - 11

Page 1332 of 2198

CLEAN AND INSPECTION

(1) Wash all components in clean solvent and dry

with compressed air.

(2) Check for scores, nicks or burrs on the rack pis-

ton finished surface. Slight wear is normal on the

worm gear surfaces.

ASSEMBLE

(1) Install O-ring seal and teflon ring and lubricate

with power steering fluid.

(2) Install worm shaft to rack piston outside of

housing. Fully seat worm shaft to rack piston and

align worm shaft spiral groove with rack piston ball

guide hole (Fig. 33).

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.There are 24 balls in the rack piston circuit,

12 are black and 12 are silver (Chrome). The

black rack piston balls are smaller than the sil-

ver balls. THE BLACK AND SILVER BALLS

MUST BE INSTALLED ALTERNATELY INTO

THE RACK PISTON AND BALL GUIDE. This

procedure will maintain worm shaft preload.

(3) Lubricate and install rack piston balls through

return guide hole while turning wormshaft COUN-

TERCLOCKWISE.

(4) Install remaining balls to guide using grease or

petroleum jelly at each end to hold in place (Fig. 34).

(5) Install guide onto rack piston and return with

clamp and screws. Tighten screws to 58 Nzm (43 in.

lbs.) torque.

(6) Insert Arbor C-4175 into bore of rack piston.

Hold tool tightly against worm shaft while turning

Fig. 31 Remove and Install Rack Piston

Fig. 32 Remove and Install Seal on Rack Piston

Fig. 33 Installing Balls in Rack Piston

Fig. 34 Balls in the Return Guide

JSTEERING 19 - 33

Page 1333 of 2198

the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

(7) Install the races and thrust bearing to worm

shaft (Fig. 35).

(8) Install worm shaft to housing.

(9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals.

²Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

Nzm (111 ft. lbs.) torque.

(12) Install housing end plug. Refer to Housing

End Plug Replacement in this section.

(13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

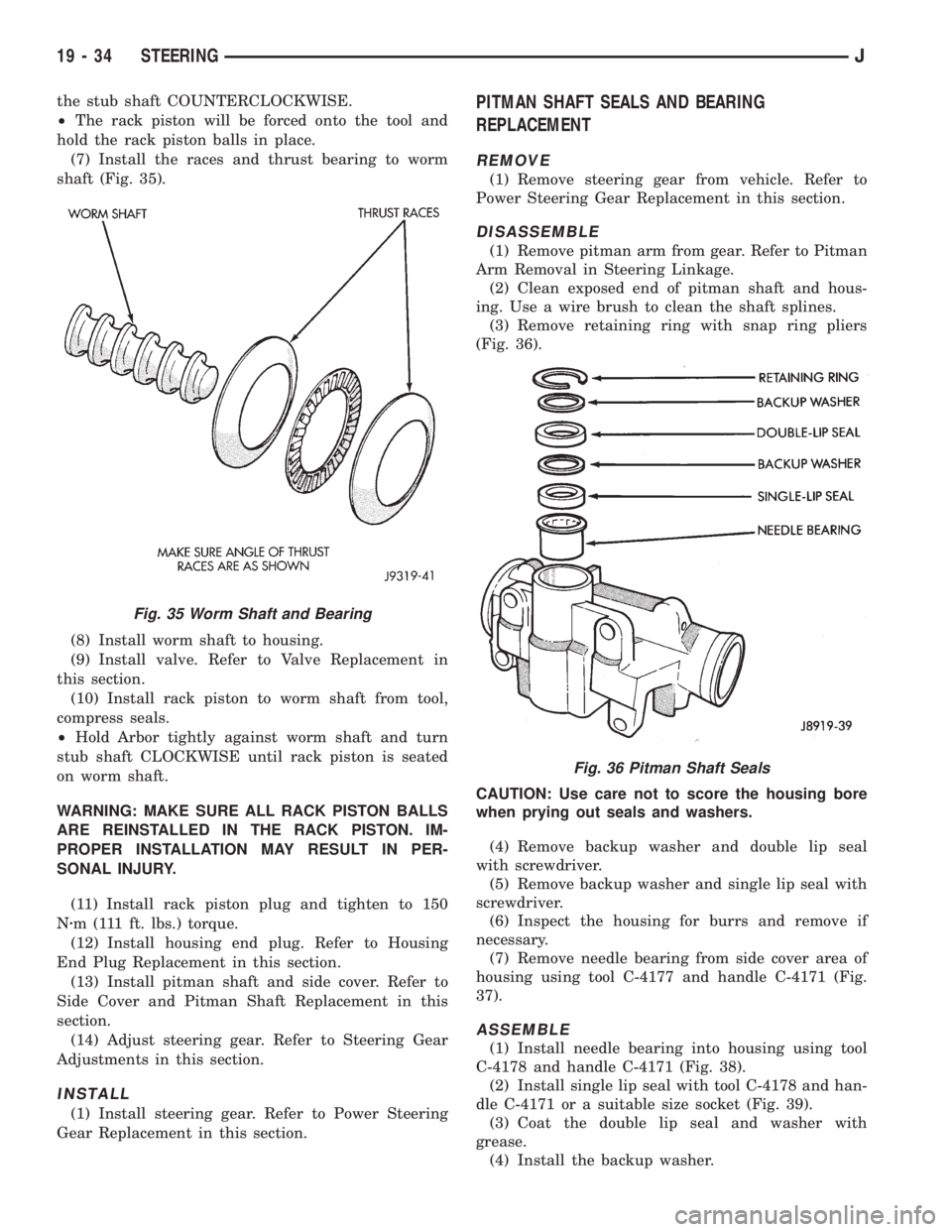

PITMAN SHAFT SEALS AND BEARING

REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman arm from gear. Refer to Pitman

Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and hous-

ing. Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 36).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing using tool C-4177 and handle C-4171 (Fig.

37).

ASSEMBLE

(1) Install needle bearing into housing using tool

C-4178 and handle C-4171 (Fig. 38).

(2) Install single lip seal with tool C-4178 and han-

dle C-4171 or a suitable size socket (Fig. 39).

(3) Coat the double lip seal and washer with

grease.

(4) Install the backup washer.

Fig. 35 Worm Shaft and Bearing

Fig. 36 Pitman Shaft Seals

19 - 34 STEERINGJ