warning JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1366 of 2198

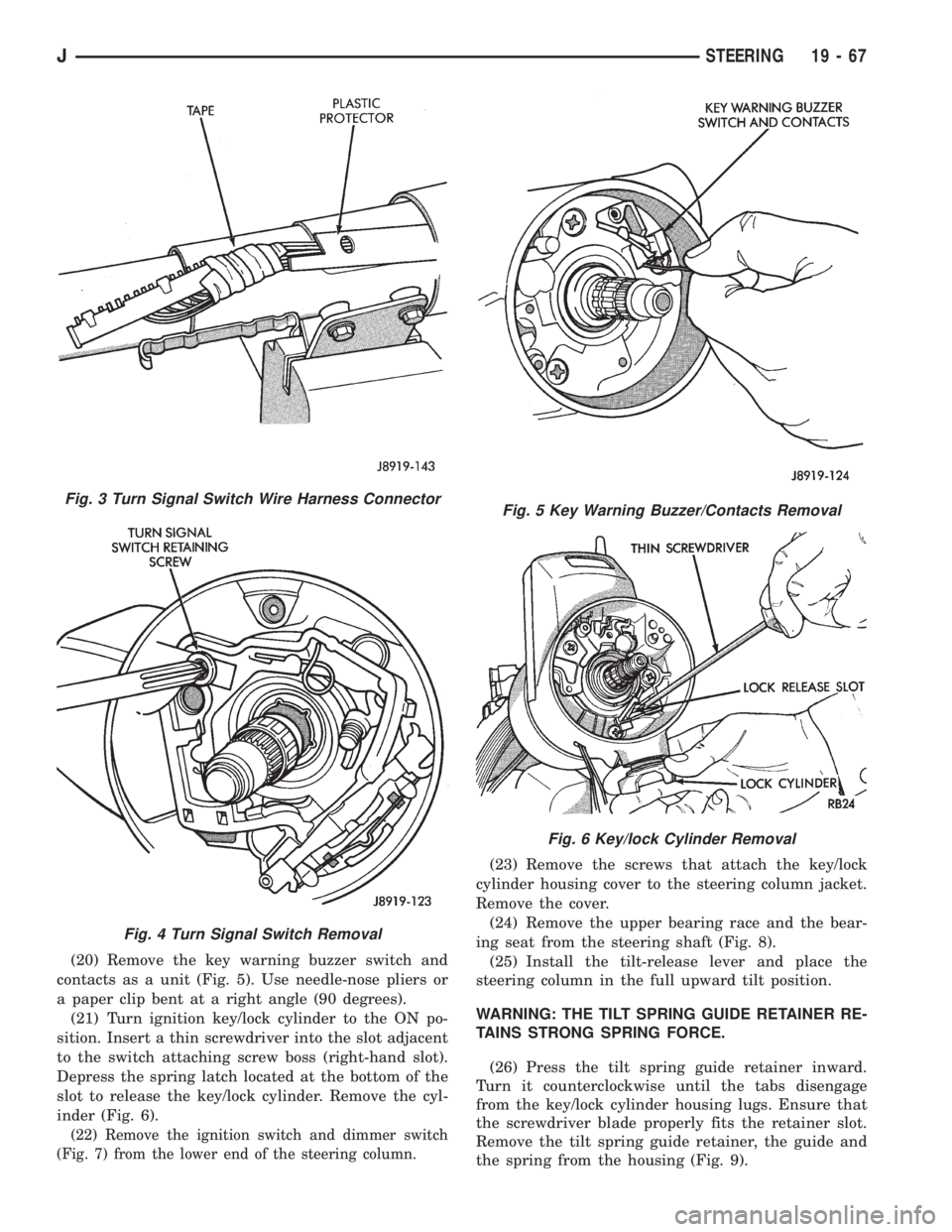

(20) Remove the key warning buzzer switch and

contacts as a unit (Fig. 5). Use needle-nose pliers or

a paper clip bent at a right angle (90 degrees).

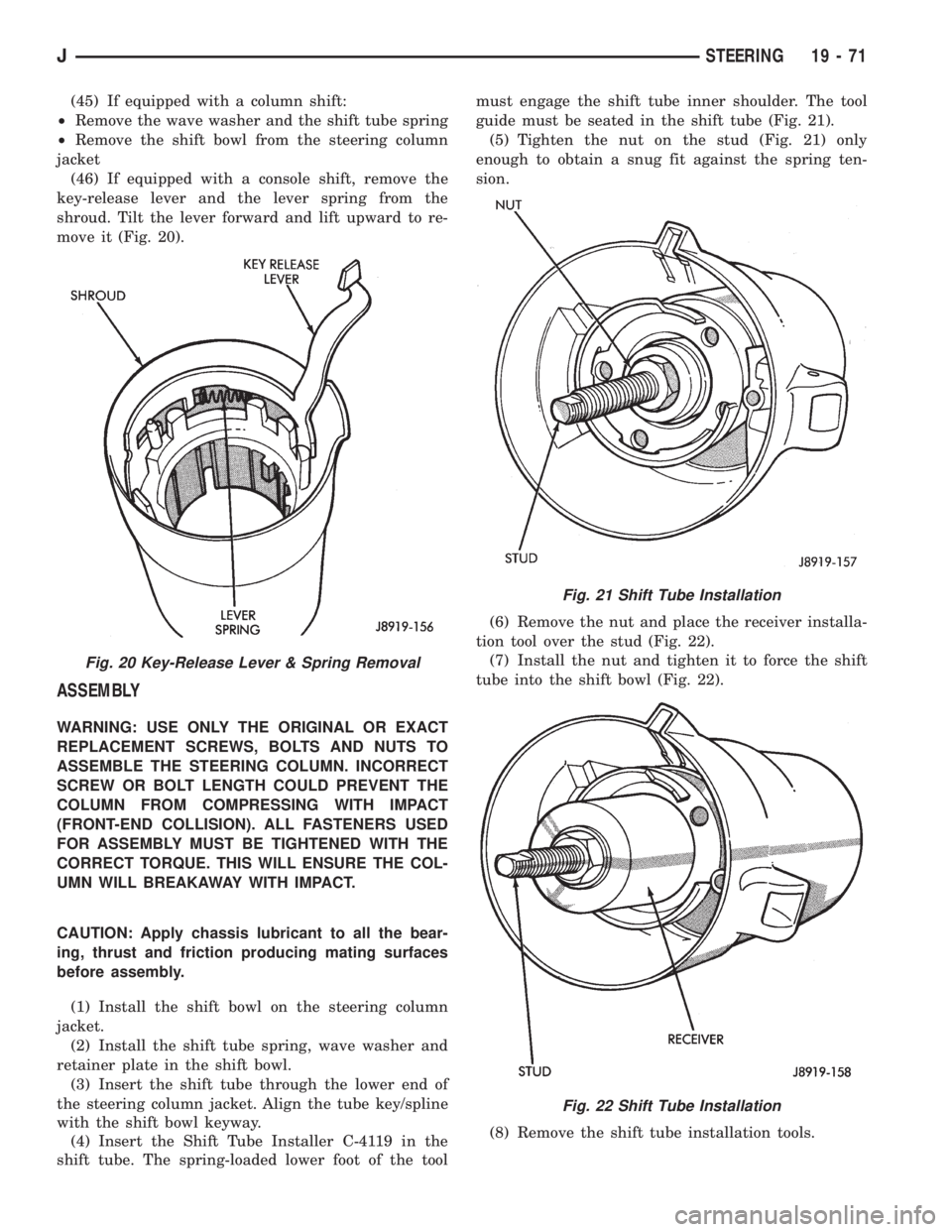

(21) Turn ignition key/lock cylinder to the ON po-

sition. Insert a thin screwdriver into the slot adjacent

to the switch attaching screw boss (right-hand slot).

Depress the spring latch located at the bottom of the

slot to release the key/lock cylinder. Remove the cyl-

inder (Fig. 6).

(22) Remove the ignition switch and dimmer switch

(Fig. 7) from the lower end of the steering column.

(23) Remove the screws that attach the key/lock

cylinder housing cover to the steering column jacket.

Remove the cover.

(24) Remove the upper bearing race and the bear-

ing seat from the steering shaft (Fig. 8).

(25) Install the tilt-release lever and place the

steering column in the full upward tilt position.

WARNING: THE TILT SPRING GUIDE RETAINER RE-

TAINS STRONG SPRING FORCE.

(26) Press the tilt spring guide retainer inward.

Turn it counterclockwise until the tabs disengage

from the key/lock cylinder housing lugs. Ensure that

the screwdriver blade properly fits the retainer slot.

Remove the tilt spring guide retainer, the guide and

the spring from the housing (Fig. 9).

Fig. 3 Turn Signal Switch Wire Harness Connector

Fig. 4 Turn Signal Switch Removal

Fig. 5 Key Warning Buzzer/Contacts Removal

Fig. 6 Key/lock Cylinder Removal

JSTEERING 19 - 67

Page 1370 of 2198

(45) If equipped with a column shift:

²Remove the wave washer and the shift tube spring

²Remove the shift bowl from the steering column

jacket

(46) If equipped with a console shift, remove the

key-release lever and the lever spring from the

shroud. Tilt the lever forward and lift upward to re-

move it (Fig. 20).

ASSEMBLY

WARNING: USE ONLY THE ORIGINAL OR EXACT

REPLACEMENT SCREWS, BOLTS AND NUTS TO

ASSEMBLE THE STEERING COLUMN. INCORRECT

SCREW OR BOLT LENGTH COULD PREVENT THE

COLUMN FROM COMPRESSING WITH IMPACT

(FRONT-END COLLISION). ALL FASTENERS USED

FOR ASSEMBLY MUST BE TIGHTENED WITH THE

CORRECT TORQUE. THIS WILL ENSURE THE COL-

UMN WILL BREAKAWAY WITH IMPACT.

CAUTION: Apply chassis lubricant to all the bear-

ing, thrust and friction producing mating surfaces

before assembly.

(1) Install the shift bowl on the steering column

jacket.

(2) Install the shift tube spring, wave washer and

retainer plate in the shift bowl.

(3) Insert the shift tube through the lower end of

the steering column jacket. Align the tube key/spline

with the shift bowl keyway.

(4) Insert the Shift Tube Installer C-4119 in the

shift tube. The spring-loaded lower foot of the toolmust engage the shift tube inner shoulder. The tool

guide must be seated in the shift tube (Fig. 21).

(5) Tighten the nut on the stud (Fig. 21) only

enough to obtain a snug fit against the spring ten-

sion.

(6) Remove the nut and place the receiver installa-

tion tool over the stud (Fig. 22).

(7) Install the nut and tighten it to force the shift

tube into the shift bowl (Fig. 22).

(8) Remove the shift tube installation tools.

Fig. 20 Key-Release Lever & Spring Removal

Fig. 21 Shift Tube Installation

Fig. 22 Shift Tube Installation

JSTEERING 19 - 71

Page 1371 of 2198

(9) Install the shift tube thrust washer and the re-

tainer plate snap ring.

(10) Install the lower bearing in the steering col-

umn.

(11) Position the shift gate in the steering column

support. Install the attaching screws.

(12) Position the support in the steering column.

(13) Install all support attaching screws finger-

tight. Next, tighten the screws alternately and evenly

to7Nzm (60 in. lbs.) torque.

(14) Install the remote rod in the support. Route

the rod through the upper end of the shroud and in-

sert it into the rod slot located in the support.

(15) Install the dimmer switch and ignition switch.

(16) Install the steering shaft in the steering col-

umn.

(17) Install replacement races and bearings in the

key/lock cylinder, if removed.Ensure that the bear-

ings are lubricated with chassis lubricant be-

fore installation.

(18) Install the lock shoes, the lock shoe springs

and the lock shoe pin the key/lock cylinder housing.

Use a 4.5-mm (0.18-in) diameter rod to align the

shoes and the pin during installation.

(19) Install the tilt-release lever, the lever spring

and the lever pin in the key/lock cylinder housing.

Insert a wedge between the housing and the lever to

relieve the spring tension. This will allow easier re-

lease lever pin installation.

(20) Install the lock bolt in the key/lock cylinder

housing and engage it in the lock sector cam surface.

(21) Install the lock rack, the rack preload spring

and a replacement shim in the key/lock cylinder

housing. Align and mate the square block tooth on

the lock rack and the lock sector.

(22) Install the lock spring and the spring retain-

ing screw. Tighten the screw to 4 Nzm (35 in. lbs.)

torque.

(23) Align and install the assembled key/lock cylin-

der housing on the support. Retain the lock shoes in

the disengaged position for easier housing installa-

tion.

(24) Align the pivot pin holes in the housing with

those in the support. Insert the pivot pins.Press the

housing firmly downward when inserting the

pivot pins. This prevents damaging the holes in

the support.When the pivot pins are within both

the housing and the support holes, seat them fully

with a punch and a hammer.

(25) Insert tilt-release lever in key/lock cylinder

housing and place housing in the full-upward tilt po-

sition.

(26) Lubricate the tilt spring guide and the tilt

spring liberally with chassis lubricant and position

the spring on the guide.

(27) Insert the tilt spring guide and the spring into

the key/lock cylinder housing. Install the guide re-tainer over the spring. Engage the retainer lock tabs

with the housing lugs by pressing the retainer down-

ward and turning clockwise with a screwdriver.

(28) Place the cover on the key/lock cylinder hous-

ing. Align and install the cover retaining screws.

Tighten the screws to 7 Nzm (60 in. lbs.) torque.

(29) Install the gear selector indicator lamp mount-

ing bracket screw.

(30) Install the gear selector indicator cover and

retaining screws.

(31) Route the dimmer switch wire harness and

gear selector indicator down through the steering col-

umn.

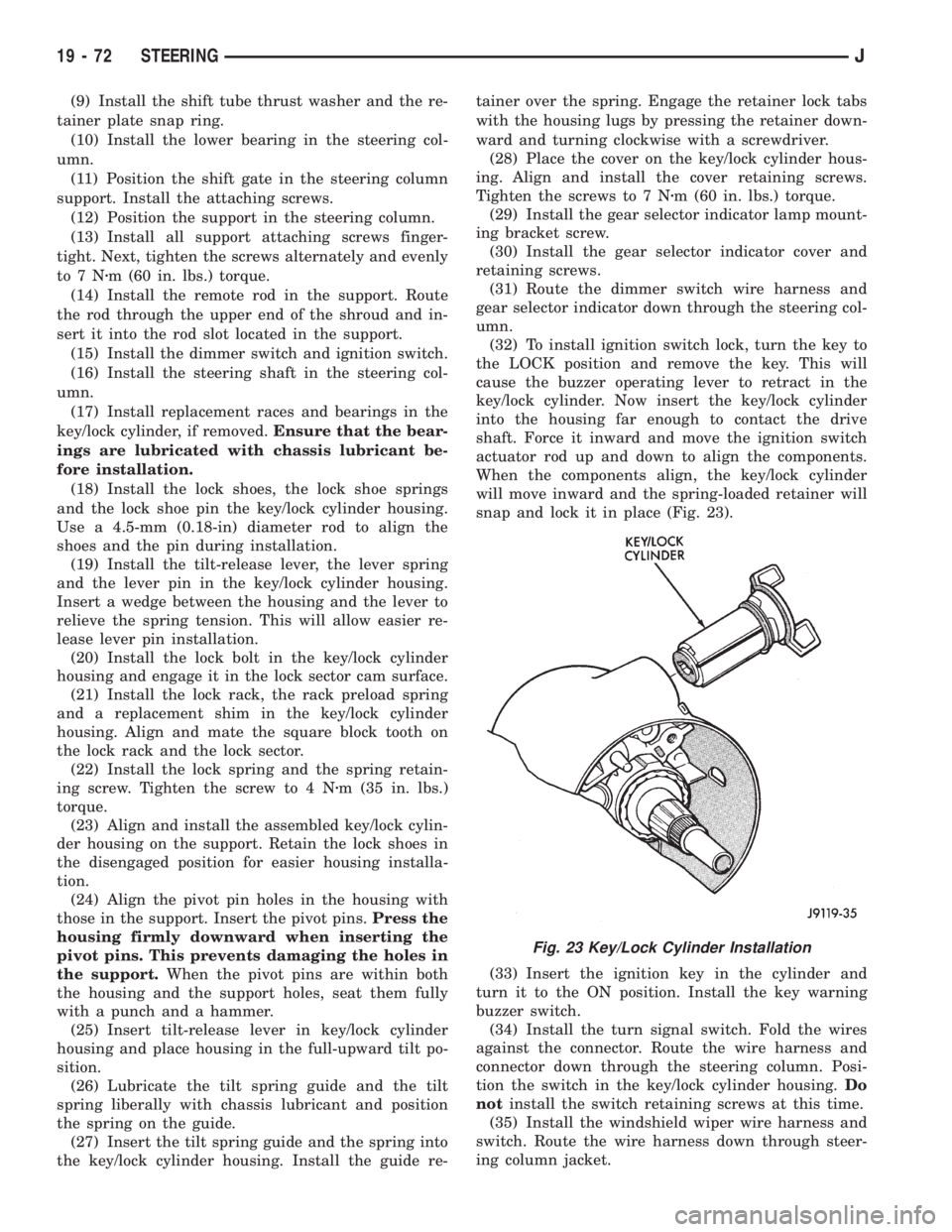

(32) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive

shaft. Force it inward and move the ignition switch

actuator rod up and down to align the components.

When the components align, the key/lock cylinder

will move inward and the spring-loaded retainer will

snap and lock it in place (Fig. 23).

(33) Insert the ignition key in the cylinder and

turn it to the ON position. Install the key warning

buzzer switch.

(34) Install the turn signal switch. Fold the wires

against the connector. Route the wire harness and

connector down through the steering column. Posi-

tion the switch in the key/lock cylinder housing.Do

notinstall the switch retaining screws at this time.

(35) Install the windshield wiper wire harness and

switch. Route the wire harness down through steer-

ing column jacket.

Fig. 23 Key/Lock Cylinder Installation

19 - 72 STEERINGJ

Page 1372 of 2198

(36) If equipped, install the cruise control wire har-

ness. Install the turn signal stalk by pushing it

straight into the column.

(37) Insert the hazard warning knob in the hazard

warning switch and press it inward. Align and install

the turn signal switch retaining screws. Ensure that

the turn signal switch is properly seated before tight-

ening the screws. Tighten the screws to 4 Nzm (33 in.

lbs.) torque. Thread the hazard warning switch knob

into the switch and pull the knob outward.

(38) Install and seat the upper bearing race in the

key/lock cylinder housing.

(39) Install the upper bearing preload spring, the

canceling cam and the lockplate.

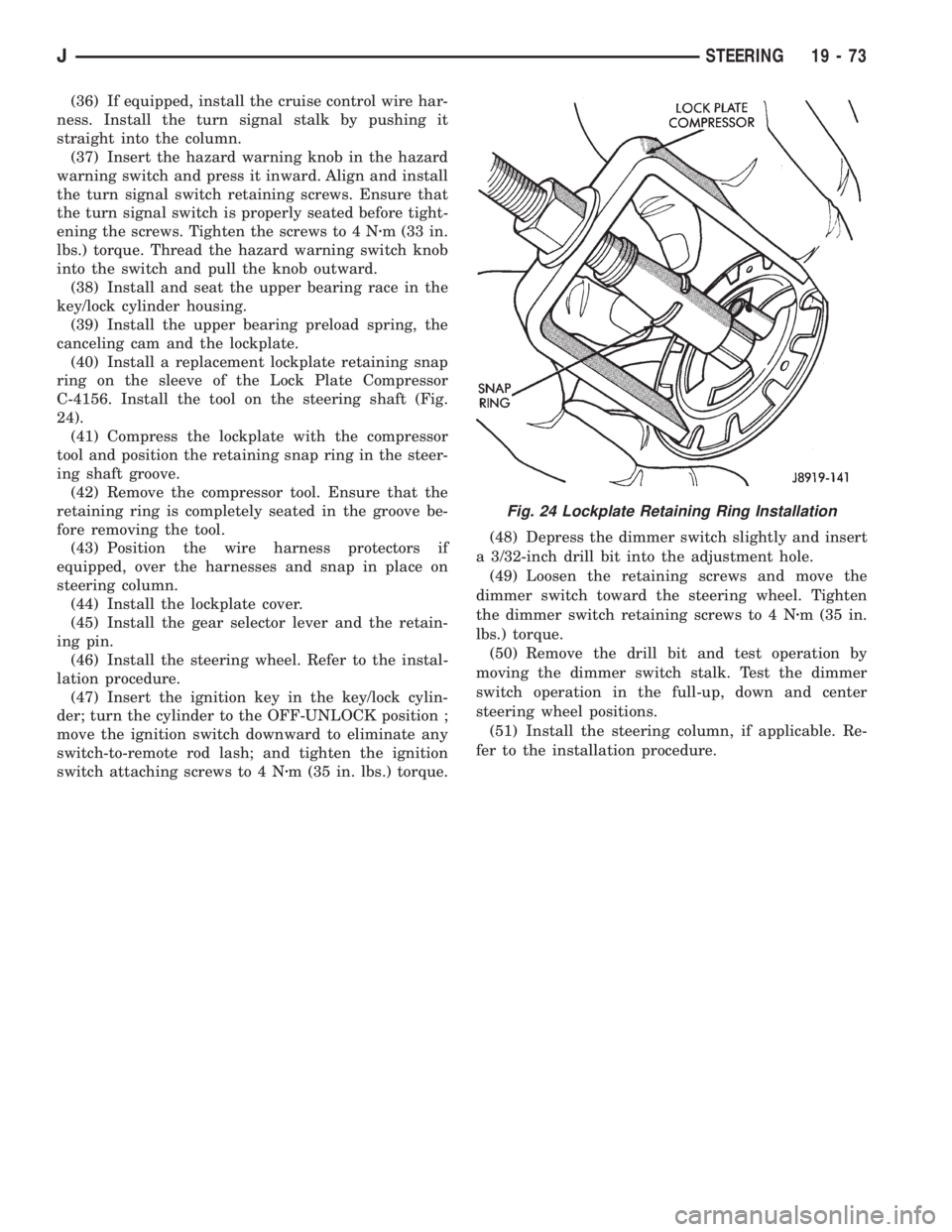

(40) Install a replacement lockplate retaining snap

ring on the sleeve of the Lock Plate Compressor

C-4156. Install the tool on the steering shaft (Fig.

24).

(41) Compress the lockplate with the compressor

tool and position the retaining snap ring in the steer-

ing shaft groove.

(42) Remove the compressor tool. Ensure that the

retaining ring is completely seated in the groove be-

fore removing the tool.

(43) Position the wire harness protectors if

equipped, over the harnesses and snap in place on

steering column.

(44) Install the lockplate cover.

(45) Install the gear selector lever and the retain-

ing pin.

(46) Install the steering wheel. Refer to the instal-

lation procedure.

(47) Insert the ignition key in the key/lock cylin-

der; turn the cylinder to the OFF-UNLOCK position ;

move the ignition switch downward to eliminate any

switch-to-remote rod lash; and tighten the ignition

switch attaching screws to 4 Nzm (35 in. lbs.) torque.(48) Depress the dimmer switch slightly and insert

a 3/32-inch drill bit into the adjustment hole.

(49) Loosen the retaining screws and move the

dimmer switch toward the steering wheel. Tighten

the dimmer switch retaining screws to 4 Nzm (35 in.

lbs.) torque.

(50) Remove the drill bit and test operation by

moving the dimmer switch stalk. Test the dimmer

switch operation in the full-up, down and center

steering wheel positions.

(51) Install the steering column, if applicable. Re-

fer to the installation procedure.

Fig. 24 Lockplate Retaining Ring Installation

JSTEERING 19 - 73

Page 1373 of 2198

STEERING RHD

GENERAL SERVICE PROCEDURE INFORMATION

Right hand drive service procedures and torque

specifications involving steering; linkage, gear and

column are the same as left hand drive vehicles ex-

cept where shown. Refer to appropriate service pro-

cedures regarding each component in the system.

The steering linkage consists of a pitman arm, drag

link, and tie rod. Adjustment sleeves are used on the

tie rod and drag link for toe and steering wheel

alignment (Fig. 1).

RECIRCULATING-BALL POWER STEERING GEARS

The steering gears can be adjusted and internally

serviced. The components CANNOT be interchanged

with those of a left hand drive vehicle.

The steering gear has a 17.5:1 ratio.

POWER STEERING PUMP

PRESSURE AND RETURN LINE

REPLACEMENT

Cap hose open ends and pump/steering gear fit-

tings to prevent entry of foreign material.

WARNING: POWER STEERING FLUID (AND PUMP

COMPONENTS) AND THE EXHAUST SYSTEM CAN

BE EXTREMELY HOT IF THE ENGINE HAS BEEN

RECENTLY OPERATING. DO NOT START THE EN-

GINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW THE LINES TO TOUCH A

HOT EXHAUST MANIFOLD.REMOVAL

(1) Place a drain pan under the pump and gear.

(2) Disconnect the pressure and return line from

the steering gear (Fig. 2, 3).

(3) Disconnect the pressure and return line from

the pump (Fig. 4). Drain the fluid from pump and

reservoir.

Fig. 1 RHD Steering Linkage

Fig. 2 Fluid Lines On Steering Gear

19 - 74 STEERINGJ

Page 1451 of 2198

CONVERTER STALL TEST

Stall testing involves determining maximum engine

rpm obtainable at full throttle with the rear wheels

locked and the transmission in D range. This test

checks the holding ability of the converter overrun-

ning clutch and both of the transmission clutches.

When stall testing is completed, refer to the Stall

Speed Specifications chart and Stall Speed Diagnosis

guides.

WARNING: NEVER ALLOW ANYONE TO STAND IN

FRONT OF THE VEHICLE DURING A STALL TEST.

ALWAYS BLOCK THE FRONT WHEELS AND APPLY

THE SERVICE AND PARKING BRAKES DURING

THE TEST.

STALL TEST PROCEDURE

(1) Connect tachometer to engine.

(2) Check and adjust transmission fluid level.

(3) Start and run engine until transmission fluid

reaches normal operating temperature.

(4) Block front wheels.

(5) Fully apply service and parking brakes.

(6) Open throttle completely and record maximum

engine rpm registered on tachometer. It will take

from 3 to 10 seconds to reach maximum rpm. How-

ever, once maximum rpm has been achieved,do not

hold wide open throttle for more than 5 sec-

onds.

CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 5

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(7) Stall speeds should be in 1700-2150 rpm range.

CAUTION: If engine exceeds 2150 rpm, release ac-

celerator pedal immediately as transmission clutch

slippage is occurring.

(8) Shift transmission into Neutral. Run engine for

20-30 seconds at 1000 rpm to cool fluid. Then stop

engine, shift transmission into Park and release

brakes.

(9) Refer to Stall Test Diagnosis.

STALL TEST DIAGNOSIS

Stall Speed Too Low

Low stall speeds with a properly tuned engine in-

dicate a torque converter overrunning clutch prob-

lem. The condition should be confirmed by road

testing prior to converter replacement.The converter overrunning clutch is slipping when

stall speeds are 250 to 350 rpm below specified min-

imum.

A converter overrunning clutch failure will result

in sluggish acceleration in all speed ranges. It will

also require greater than normal throttle opening to

maintain cruising speeds.

Stall Speed Too High

If stall speed exceeds 2150 rpm, transmission

clutch slippage is occurring.

Stall Speed Normal But Acceleration Is Sluggish

If stall speeds are within specified range but abnor-

mal throttle opening is required for acceleration, or

to maintain cruise speeds, the converter overrunning

clutch is seized. The torque converter will have to be

replaced.

Converter Noise During Test

A whining noise caused by fluid flow is normal dur-

ing a stall test. However, loud metallic noises indi-

cate a damaged converter. To confirm that noise is

originating from the converter, operate the vehicle at

light throttle in Drive and Neutral on a hoist and lis-

ten for noise from the converter housing.

AIR PRESSURE TEST

Air pressure testing can be used to check clutch

and band operation with the transmission either in

the vehicle, or on the work bench as a final check af-

ter overhaul.

Air pressure testing requires that the oil pan and

valve body be removed from the transmission.

The servo and clutch apply passages are shown in

Figure 8.

Air Test Procedure

(1) Place one or two fingers on the clutch housing

and apply air pressure through front clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(2) Place one or two fingers on the clutch housing

and apply air pressure through rear clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(3) Apply air pressure to the front servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

(4) Apply air pressure to the rear servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

21 - 74 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1554 of 2198

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB scan tool.

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

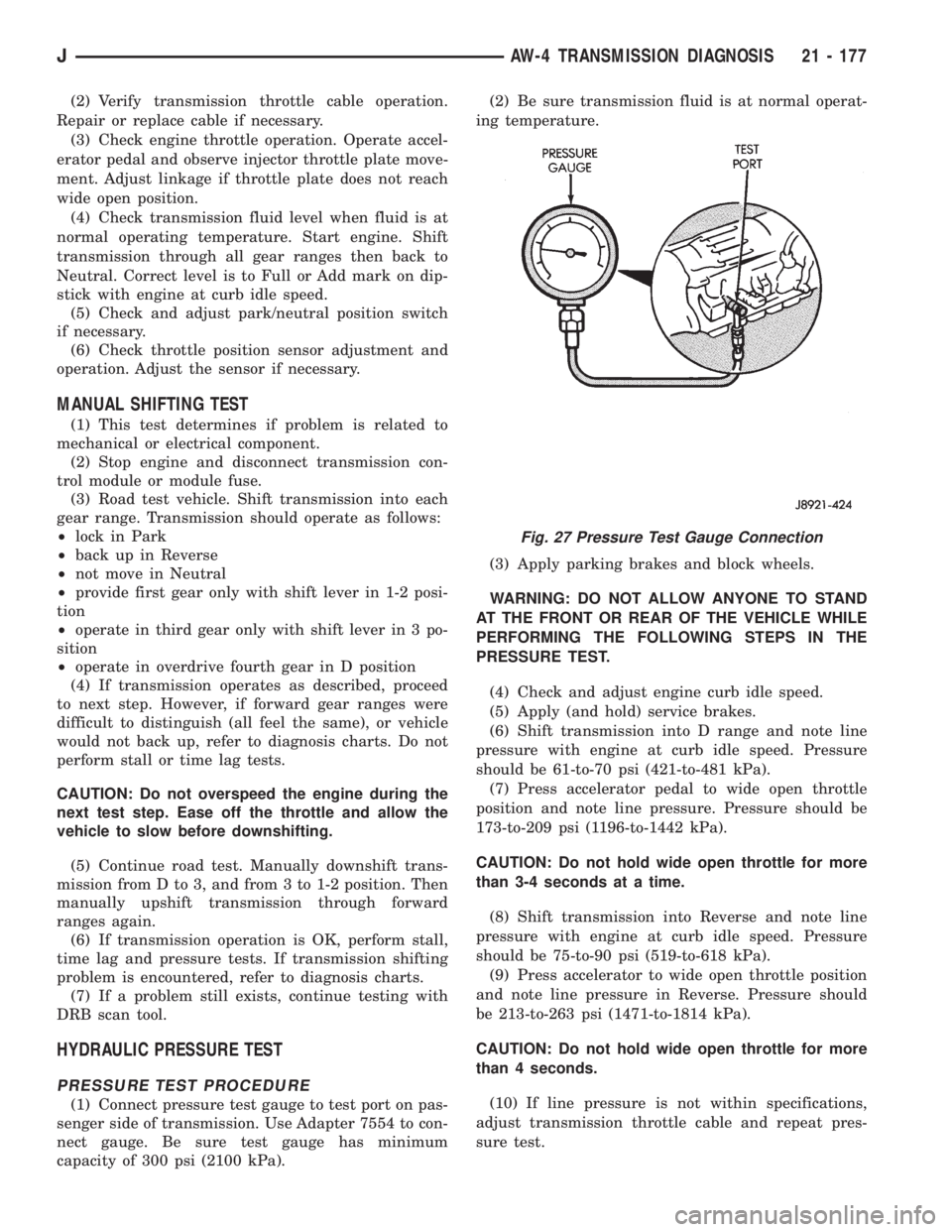

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND

AT THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply (and hold) service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not hold wide open throttle for more

than 3-4 seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not hold wide open throttle for more

than 4 seconds.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

JAW-4 TRANSMISSION DIAGNOSIS 21 - 177

Page 1555 of 2198

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified in test, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified in test, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, or throttle cam

sticking, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn, or damaged

²overdrive clutch worn, or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.Stall speeds are

checked in both Drive and Reverse ranges with

the AW-4 transmission.

(1) Before starting test, be sure fluid level is cor-

rect and fluid is at normal operating temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Open throttle completely and record maximum

engine rpm registered on tachometer. It takes any-

where from 4 to 10 seconds to reach maximum rpm.

However, once maximum rpm has been achieved,do

not hold wide open throttle for more than 3-4

seconds.CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 4

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(9) Stall speed should be in 2100-2400 rpm range

in Drive.

(10) Release throttle, shift transmission into Neu-

tral, and run engine for 20-30 seconds to cool fluid.

(11) Shift transmission into Reverse.

(12) Repeat stall test described in step (8).

(13) Stall speed in Reverse should also be in 2100-

2400 rpm range.

(14) Release accelerator pedal, shift transmission

into Neutral, and run engine for 20-30 seconds to

cool fluid.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

21 - 178 AW-4 TRANSMISSION DIAGNOSISJ

Page 1630 of 2198

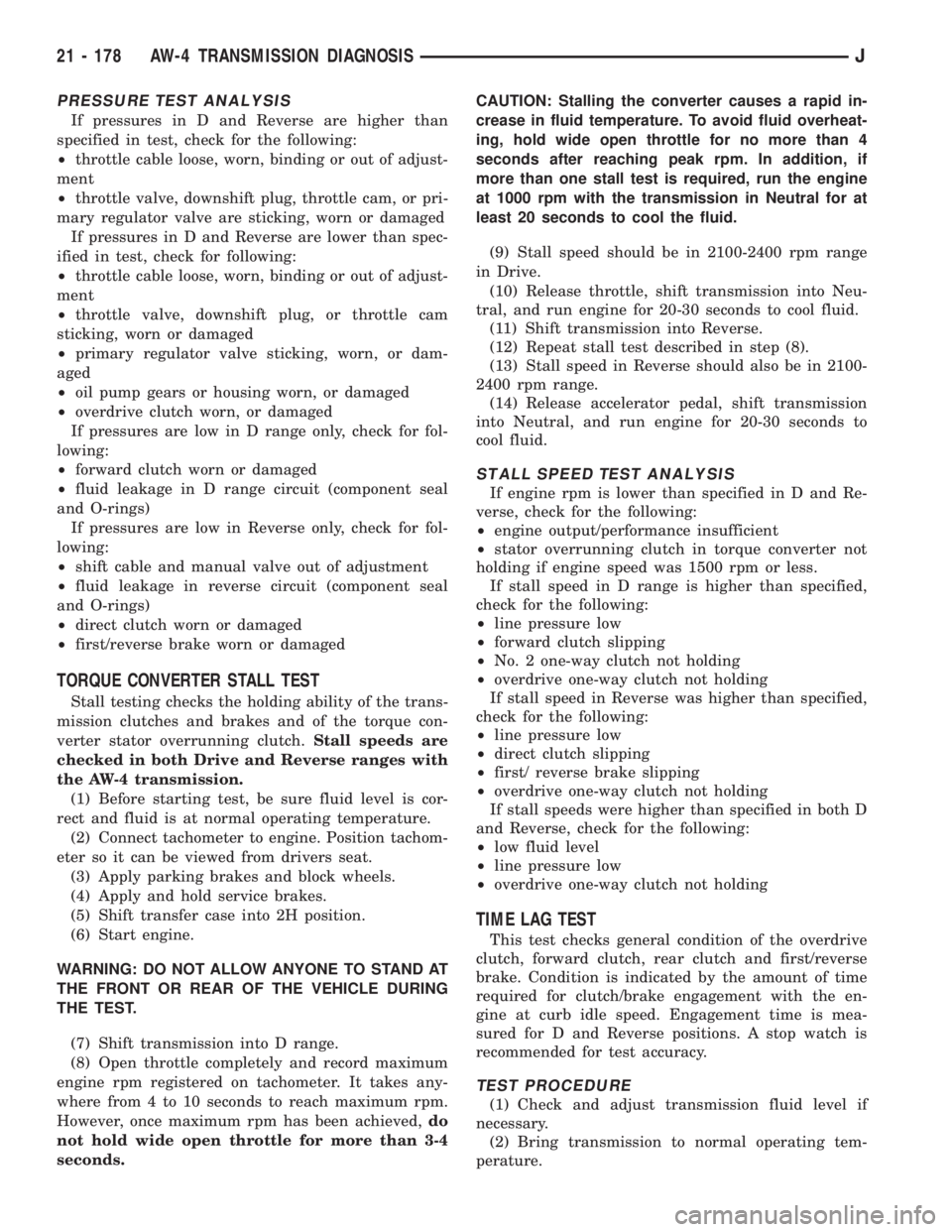

(2) Remove oil strainers (Fig. 2).

(3) Note or mark position of valve retainers and

pressure reducing plug clip for assembly reference

(Fig. 2). Do not remove the retainers at this time.

(4) Remove solenoid No. 1, 2 and 3. Discard sole-

noid O-rings.

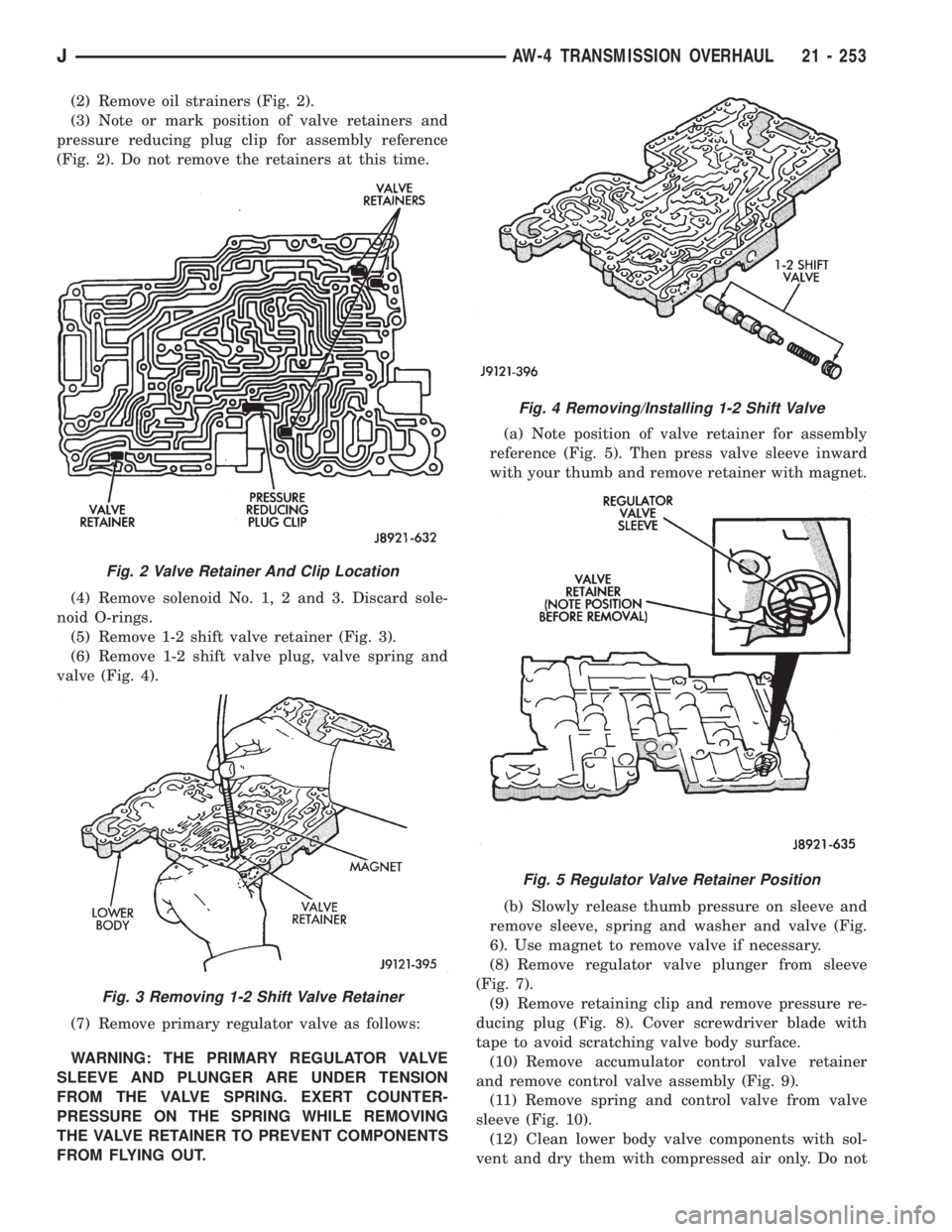

(5) Remove 1-2 shift valve retainer (Fig. 3).

(6) Remove 1-2 shift valve plug, valve spring and

valve (Fig. 4).

(7) Remove primary regulator valve as follows:

WARNING: THE PRIMARY REGULATOR VALVE

SLEEVE AND PLUNGER ARE UNDER TENSION

FROM THE VALVE SPRING. EXERT COUNTER-

PRESSURE ON THE SPRING WHILE REMOVING

THE VALVE RETAINER TO PREVENT COMPONENTS

FROM FLYING OUT.(a) Note position of valve retainer for assembly

reference (Fig. 5). Then press valve sleeve inward

with your thumb and remove retainer with magnet.

(b) Slowly release thumb pressure on sleeve and

remove sleeve, spring and washer and valve (Fig.

6). Use magnet to remove valve if necessary.

(8) Remove regulator valve plunger from sleeve

(Fig. 7).

(9) Remove retaining clip and remove pressure re-

ducing plug (Fig. 8). Cover screwdriver blade with

tape to avoid scratching valve body surface.

(10) Remove accumulator control valve retainer

and remove control valve assembly (Fig. 9).

(11) Remove spring and control valve from valve

sleeve (Fig. 10).

(12) Clean lower body valve components with sol-

vent and dry them with compressed air only. Do not

Fig. 2 Valve Retainer And Clip Location

Fig. 3 Removing 1-2 Shift Valve Retainer

Fig. 4 Removing/Installing 1-2 Shift Valve

Fig. 5 Regulator Valve Retainer Position

JAW-4 TRANSMISSION OVERHAUL 21 - 253

Page 1723 of 2198

TIRE CHAINS

Tire snow chains may be used on certain models.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Steam cleaning may be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

PRESSURE GAUGES

High-quality, dial-type, air-pressure gauges are rec-

ommended. After checking with the gauge, replace

valve cap and finger tight.

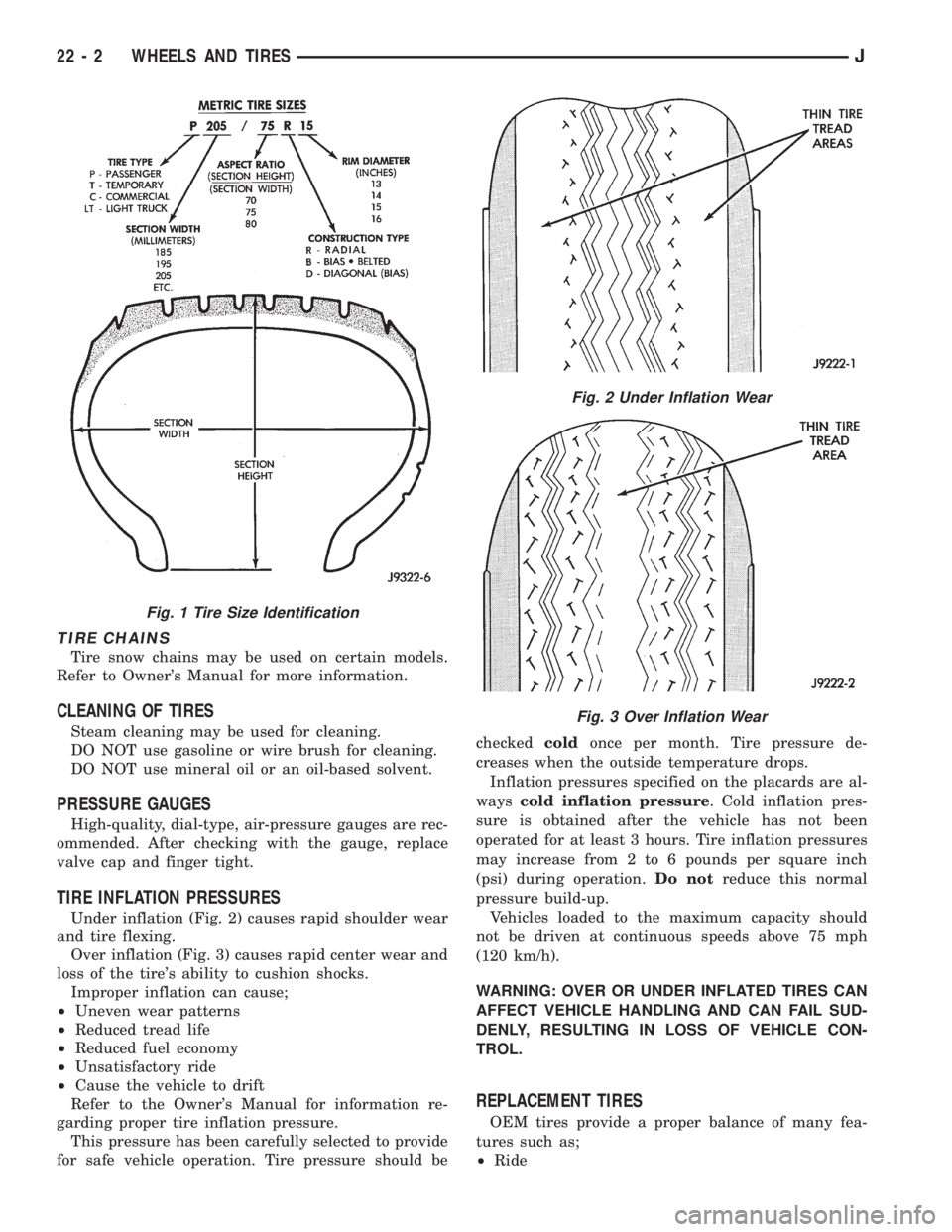

TIRE INFLATION PRESSURES

Under inflation (Fig. 2) causes rapid shoulder wear

and tire flexing.

Over inflation (Fig. 3) causes rapid center wear and

loss of the tire's ability to cushion shocks.

Improper inflation can cause;

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Cause the vehicle to drift

Refer to the Owner's Manual for information re-

garding proper tire inflation pressure.

This pressure has been carefully selected to provide

for safe vehicle operation. Tire pressure should becheckedcoldonce per month. Tire pressure de-

creases when the outside temperature drops.

Inflation pressures specified on the placards are al-

wayscold inflation pressure. Cold inflation pres-

sure is obtained after the vehicle has not been

operated for at least 3 hours. Tire inflation pressures

may increase from 2 to 6 pounds per square inch

(psi) during operation.Do notreduce this normal

pressure build-up.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND CAN FAIL SUD-

DENLY, RESULTING IN LOSS OF VEHICLE CON-

TROL.

REPLACEMENT TIRES

OEM tires provide a proper balance of many fea-

tures such as;

²Ride

Fig. 1 Tire Size Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 WHEELS AND TIRESJ