warning JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1346 of 2198

STEERING COLUMN GENERAL SERVICEÐXJ

INDEX

page

Airbag System........................... 47

AIRBAG SYSTEM

WARNING: THE MECHANICAL AIRBAG SYSTEM IS

A SENSITIVE, COMPLEX MECHANICAL UNIT. BE-

FORE ATTEMPTING TO REMOVE OR INSTALL THE

AIRBAG SYSTEM OR RELATED STEERING WHEEL

AND STEERING COLUMN COMPONENTS YOU

MUST FIRST DISARM THE AIRBAG FIRING MECHA-

NISM. FAILURE TO DO SO COULD RESULT IN AC-

CIDENTAL DEPLOYMENT AND POSSIBLE INJURY.

WARNING: THE AIRBAG MODULE INFLATOR/SEN-

SOR ASSEMBLY CONTAINS SODIUM AZIDE AND

POTASSIUM NITRATE. THESE MATERIALS ARE

POISONOUS AND EXTREMELY FLAMMABLE. CON-

TACT WITH ACID, WATER OR HEAVY METALS MAY

PRODUCE HARMFUL AND IRRITATING GASES (SO-

DIUM HYDROXIDE IS FORMED IN THE PRESENCE

OF MOISTURE) OR COMBUSTIBLE COMPOUNDS.

DO NOT ATTEMPT TO DISMANTLE THE MODULE

OR TAMPER WITH ITS ARMING LEVER. DO NOT

PUNCTURE, INCINERATE, OR BRING INTO CON-

TACT WITH ELECTRICITY. DO NOT STORE AT TEM-

PERATURES EXCEEDING 200ÉF.WARNING: REPLACE AIRBAG SYSTEM COMPO-

NENTS WITH PARTS SPECIFIED IN THE CHRYSLER

MOPAR PARTS CATALOG ONLY. IT IS OF PARTICU-

LAR IMPORTANCE THAT ANY COMPONENTS USED

IN THIS MECHANICALLY-FIRED AIRBAG SYSTEM

NOT BE MIXED WITH COMPONENTS FROM AN

ELECTRICALLY-FIRED AIRBAG SYSTEM. SUBSTI-

TUTE PARTS MAY APPEAR THE SAME, BUT INTER-

NAL DIFFERENCES MAY RESULT IN INFERIOR

OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS, ORIGINALLY USED FOR THE AIRBAG COM-

PONENTS, HAVE SPECIAL COATINGS AND ARE

SPECIFICALLY DESIGNED FOR THE AIRBAG SYS-

TEM. THEY MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

SPECIFIED IN THE CHRYSLER MOPAR PARTS CAT-

ALOG.

JSTEERING 19 - 47

Page 1348 of 2198

AIRBAG MODULE REMOVEÐINSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-

ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

(1) Disconnect battery negative cable and isolate.

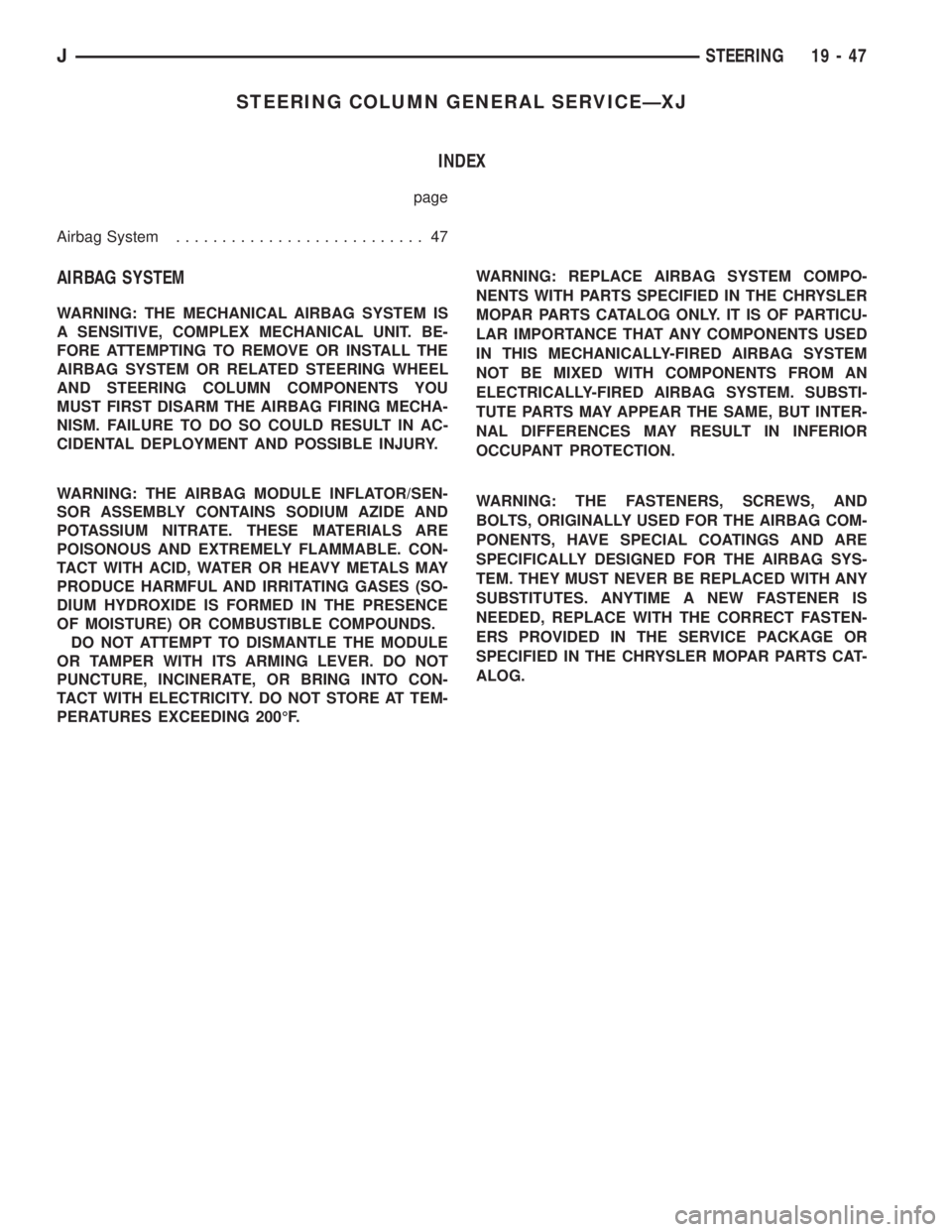

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

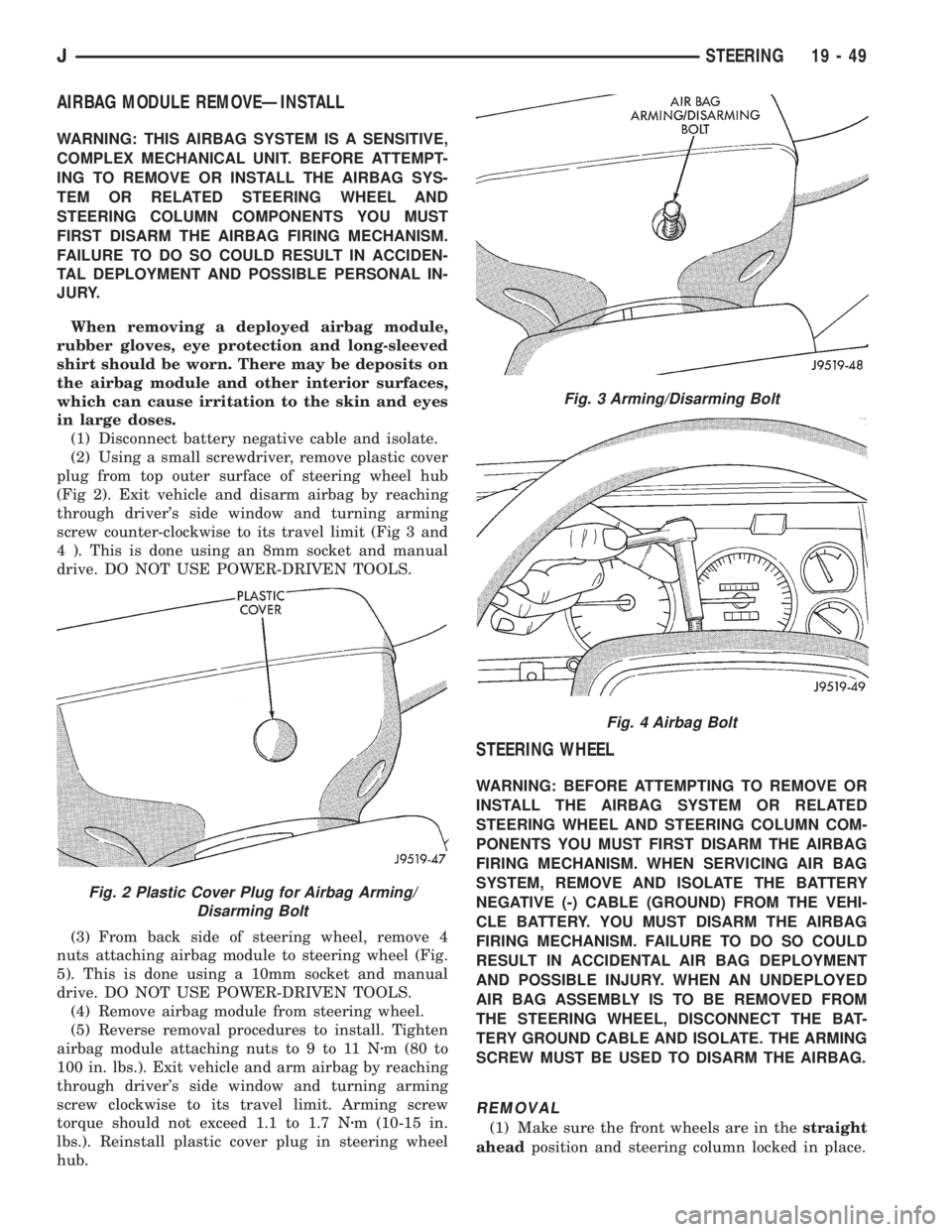

(Fig 2). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit (Fig 3 and

4 ). This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

5). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

STEERING WHEEL

WARNING: BEFORE ATTEMPTING TO REMOVE OR

INSTALL THE AIRBAG SYSTEM OR RELATED

STEERING WHEEL AND STEERING COLUMN COM-

PONENTS YOU MUST FIRST DISARM THE AIRBAG

FIRING MECHANISM. WHEN SERVICING AIR BAG

SYSTEM, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. YOU MUST DISARM THE AIRBAG

FIRING MECHANISM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIR BAG DEPLOYMENT

AND POSSIBLE INJURY. WHEN AN UNDEPLOYED

AIR BAG ASSEMBLY IS TO BE REMOVED FROM

THE STEERING WHEEL, DISCONNECT THE BAT-

TERY GROUND CABLE AND ISOLATE. THE ARMING

SCREW MUST BE USED TO DISARM THE AIRBAG.

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition and steering column locked in place.

Fig. 2 Plastic Cover Plug for Airbag Arming/

Disarming Bolt

Fig. 3 Arming/Disarming Bolt

Fig. 4 Airbag Bolt

JSTEERING 19 - 49

Page 1350 of 2198

CLOCKSPRING

WARNING: BEFORE SERVICING AIR BAG SYSTEM,

REMOVE AND ISOLATE BATTERY NEGATIVE (-) CA-

BLE (GROUND) FROM VEHICLE BATTERY. WHEN

AN UNDEPLOYED AIR BAG ASSEMBLY IS TO BE

REMOVED FROM THE STEERING WHEEL, DISCON-

NECT THE BATTERY GROUND CABLE AND ISO-

LATE.

REMOVAL

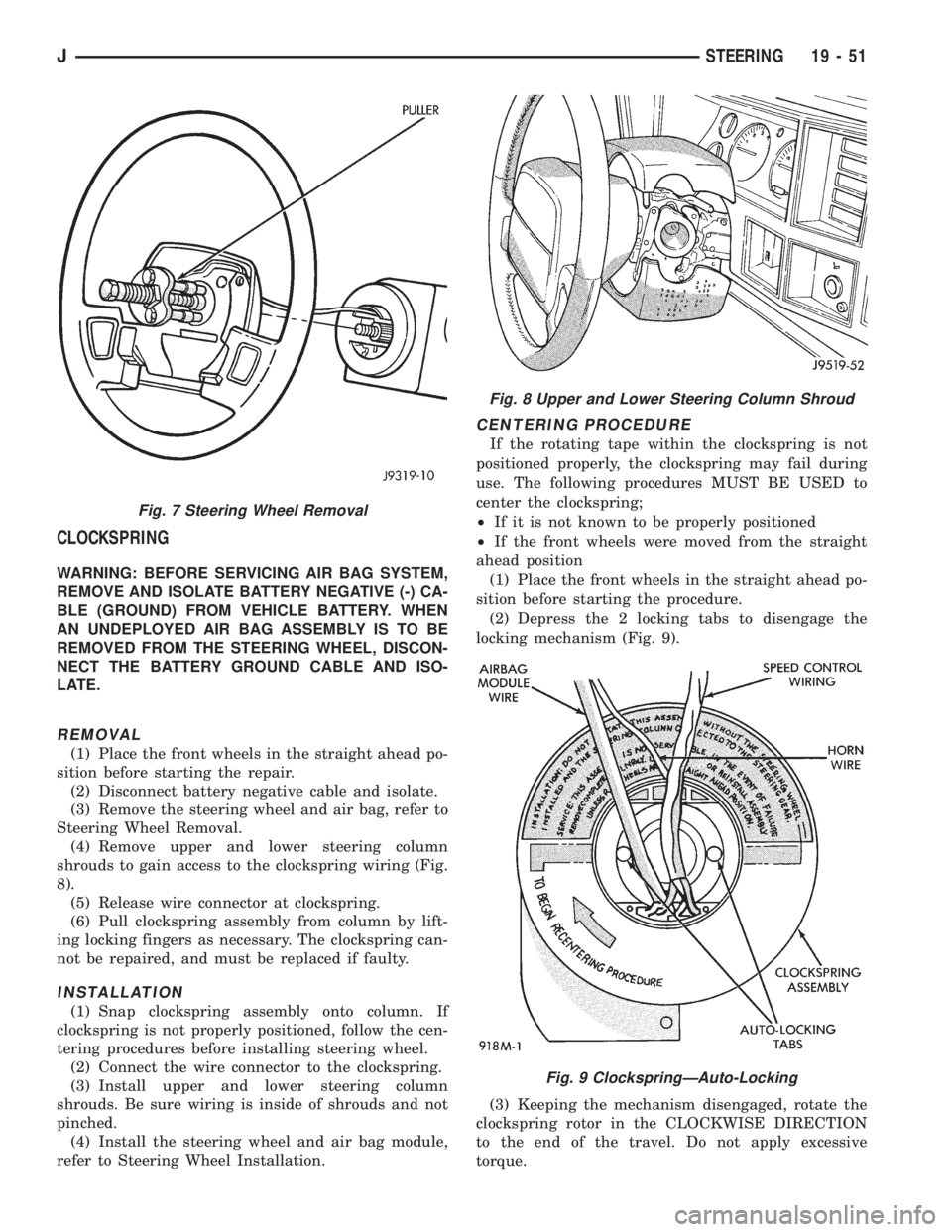

(1) Place the front wheels in the straight ahead po-

sition before starting the repair.

(2) Disconnect battery negative cable and isolate.

(3) Remove the steering wheel and air bag, refer to

Steering Wheel Removal.

(4) Remove upper and lower steering column

shrouds to gain access to the clockspring wiring (Fig.

8).

(5) Release wire connector at clockspring.

(6) Pull clockspring assembly from column by lift-

ing locking fingers as necessary. The clockspring can-

not be repaired, and must be replaced if faulty.

INSTALLATION

(1) Snap clockspring assembly onto column. If

clockspring is not properly positioned, follow the cen-

tering procedures before installing steering wheel.

(2) Connect the wire connector to the clockspring.

(3) Install upper and lower steering column

shrouds. Be sure wiring is inside of shrouds and not

pinched.

(4) Install the steering wheel and air bag module,

refer to Steering Wheel Installation.

CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly, the clockspring may fail during

use. The following procedures MUST BE USED to

center the clockspring;

²If it is not known to be properly positioned

²If the front wheels were moved from the straight

ahead position

(1) Place the front wheels in the straight ahead po-

sition before starting the procedure.

(2) Depress the 2 locking tabs to disengage the

locking mechanism (Fig. 9).

(3) Keeping the mechanism disengaged, rotate the

clockspring rotor in the CLOCKWISE DIRECTION

to the end of the travel. Do not apply excessive

torque.

Fig. 7 Steering Wheel Removal

Fig. 8 Upper and Lower Steering Column Shroud

Fig. 9 ClockspringÐAuto-Locking

JSTEERING 19 - 51

Page 1351 of 2198

(4) From the end of travel, rotate the rotor 2 1/2

full turns in the COUNTER CLOCKWISE direction.

The horn wire should end up at the top and the

squib wire at the bottom (Fig. 9).

(5) Install the steering wheel and air bag module,

refer to Steering Wheel Installation.

COLUMN ASSEMBLY REPLACEMENT

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Observe Cautions and disconnect the negative

(ground) cable from the battery.

(3) Disarm airbag, refer to Arming/Disarming Air-

bag in this section.

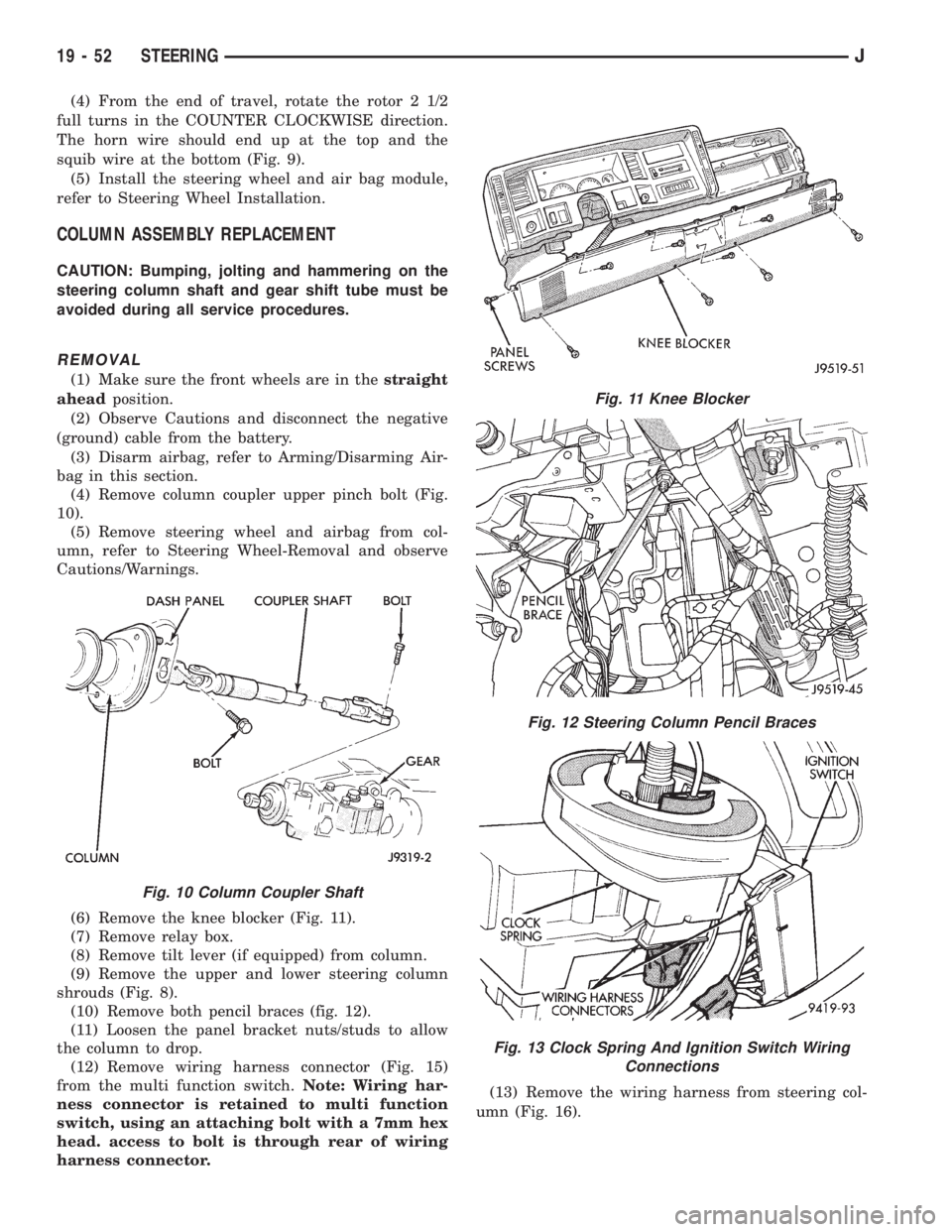

(4) Remove column coupler upper pinch bolt (Fig.

10).

(5) Remove steering wheel and airbag from col-

umn, refer to Steering Wheel-Removal and observe

Cautions/Warnings.

(6) Remove the knee blocker (Fig. 11).

(7) Remove relay box.

(8) Remove tilt lever (if equipped) from column.

(9) Remove the upper and lower steering column

shrouds (Fig. 8).

(10) Remove both pencil braces (fig. 12).

(11) Loosen the panel bracket nuts/studs to allow

the column to drop.

(12) Remove wiring harness connector (Fig. 15)

from the multi function switch.Note: Wiring har-

ness connector is retained to multi function

switch, using an attaching bolt with a 7mm hex

head. access to bolt is through rear of wiring

harness connector.(13) Remove the wiring harness from steering col-

umn (Fig. 16).

Fig. 10 Column Coupler Shaft

Fig. 11 Knee Blocker

Fig. 12 Steering Column Pencil Braces

Fig. 13 Clock Spring And Ignition Switch Wiring

Connections

19 - 52 STEERINGJ

Page 1359 of 2198

(6) Column shift vehicles, install the shift cable

grommet on the shift lever.

(7) Install and tighten the toe plate to floor pan

bolts/nuts to 21.5 Nzm (192 in. lbs.) torque (Fig. 5).

(8) Install the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(9) Install steering wheel on column, refer to Steer-

ing Wheel-Installation.

(10) Connect the negative (ground) cable to the

battery.

NON-TILT STEERING COLUMN

DISASSEMBLYÐCOLUMN OR CONSOLE SHIFT

Steering column removal from the vehicle is not

necessary for;

²Lockplate cover

²Lockplate

²Steering shaft retaining ring

²Canceling cam

²Turn signal switch

²Upper bearing preload spring

²Ignition key/lock cylinder service

The steering column must be removed from

the vehicle to service any other component.

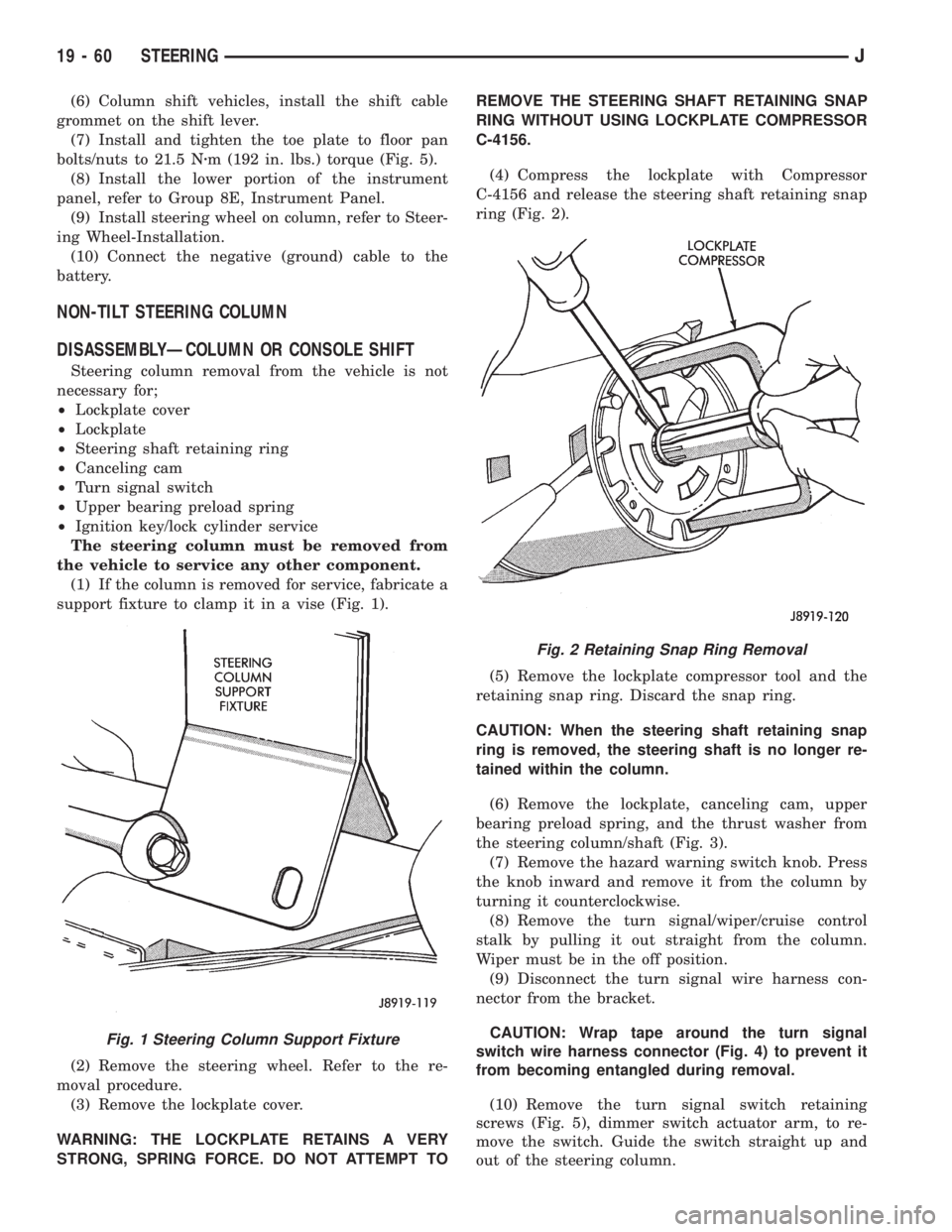

(1) If the column is removed for service, fabricate a

support fixture to clamp it in a vise (Fig. 1).

(2) Remove the steering wheel. Refer to the re-

moval procedure.

(3) Remove the lockplate cover.

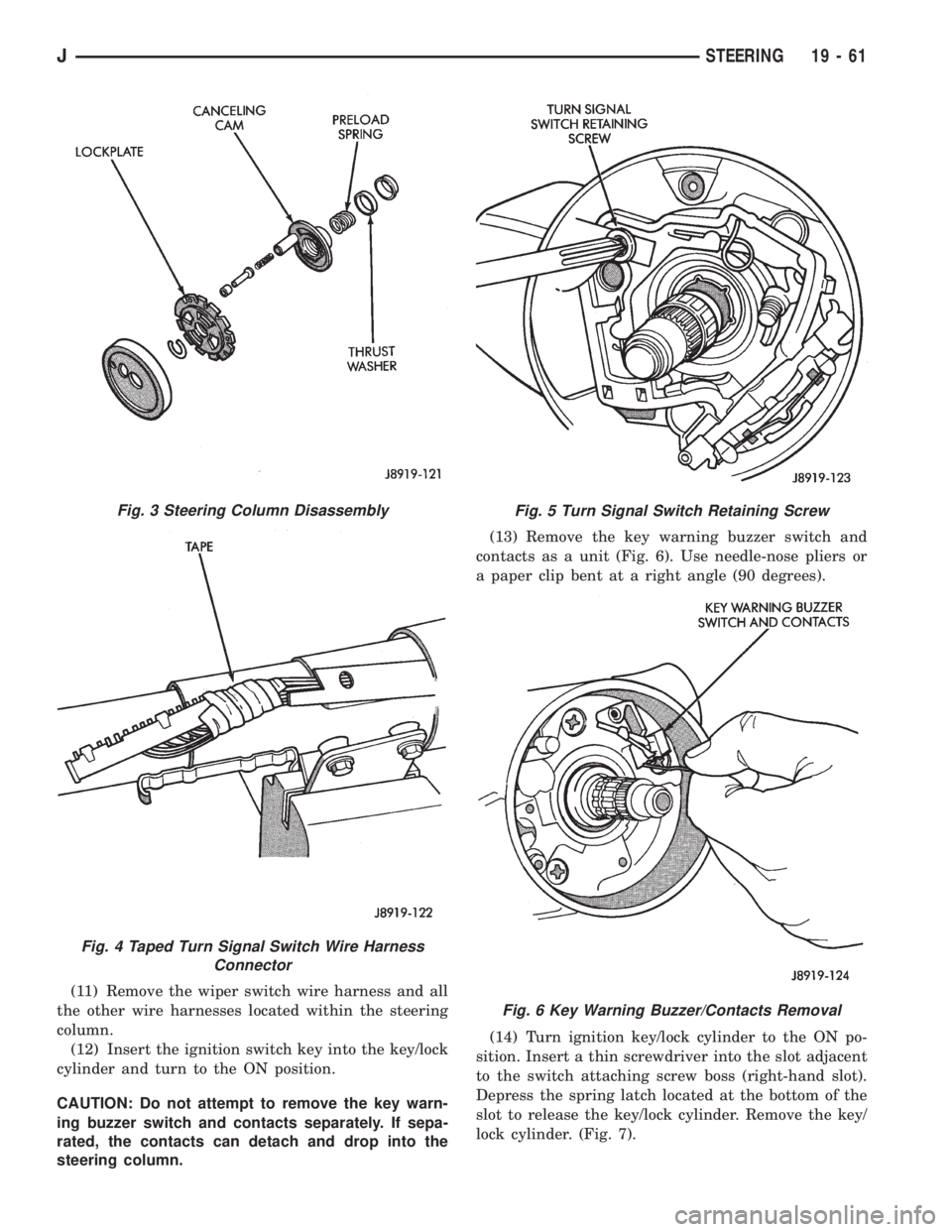

WARNING: THE LOCKPLATE RETAINS A VERY

STRONG, SPRING FORCE. DO NOT ATTEMPT TOREMOVE THE STEERING SHAFT RETAINING SNAP

RING WITHOUT USING LOCKPLATE COMPRESSOR

C-4156.

(4) Compress the lockplate with Compressor

C-4156 and release the steering shaft retaining snap

ring (Fig. 2).

(5) Remove the lockplate compressor tool and the

retaining snap ring. Discard the snap ring.

CAUTION: When the steering shaft retaining snap

ring is removed, the steering shaft is no longer re-

tained within the column.

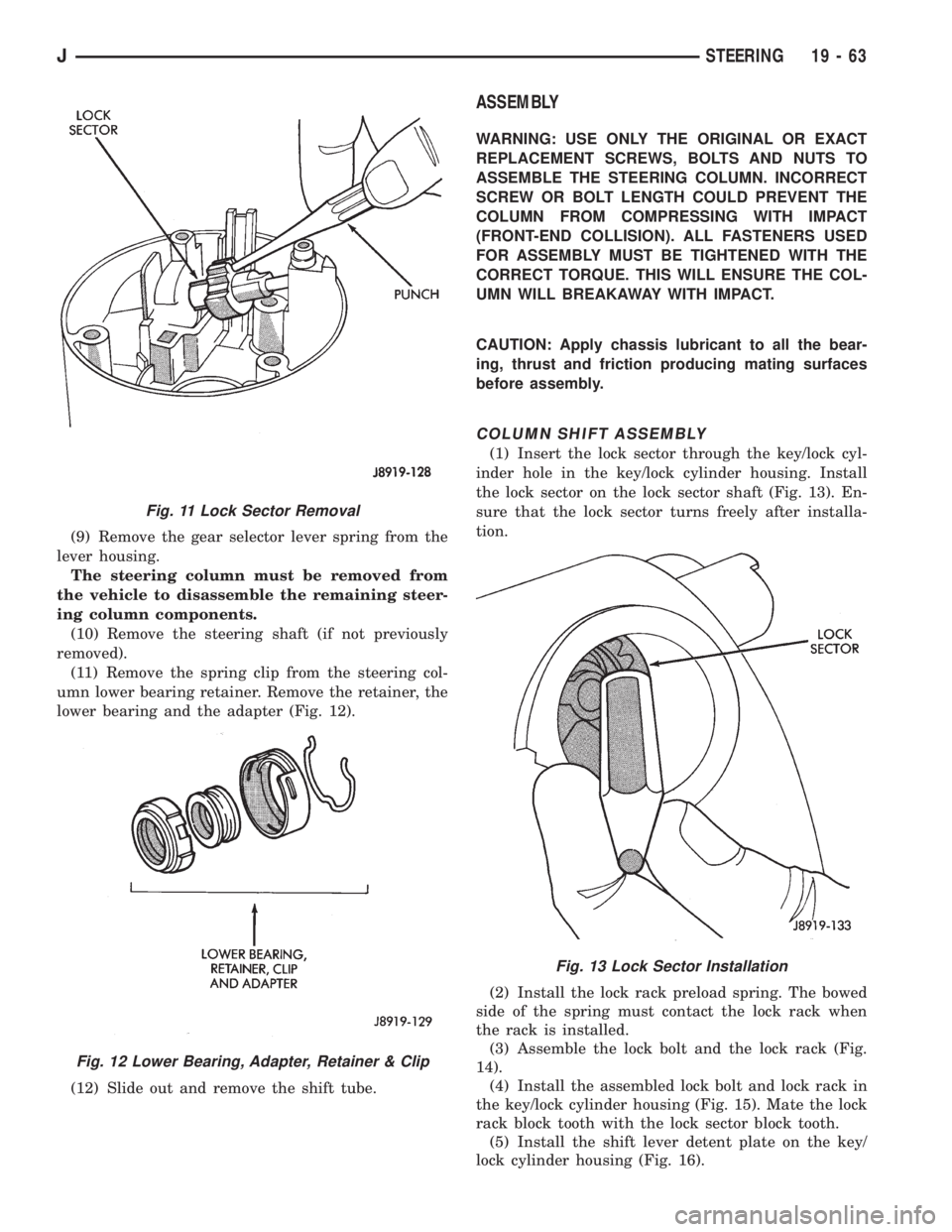

(6) Remove the lockplate, canceling cam, upper

bearing preload spring, and the thrust washer from

the steering column/shaft (Fig. 3).

(7) Remove the hazard warning switch knob. Press

the knob inward and remove it from the column by

turning it counterclockwise.

(8) Remove the turn signal/wiper/cruise control

stalk by pulling it out straight from the column.

Wiper must be in the off position.

(9) Disconnect the turn signal wire harness con-

nector from the bracket.

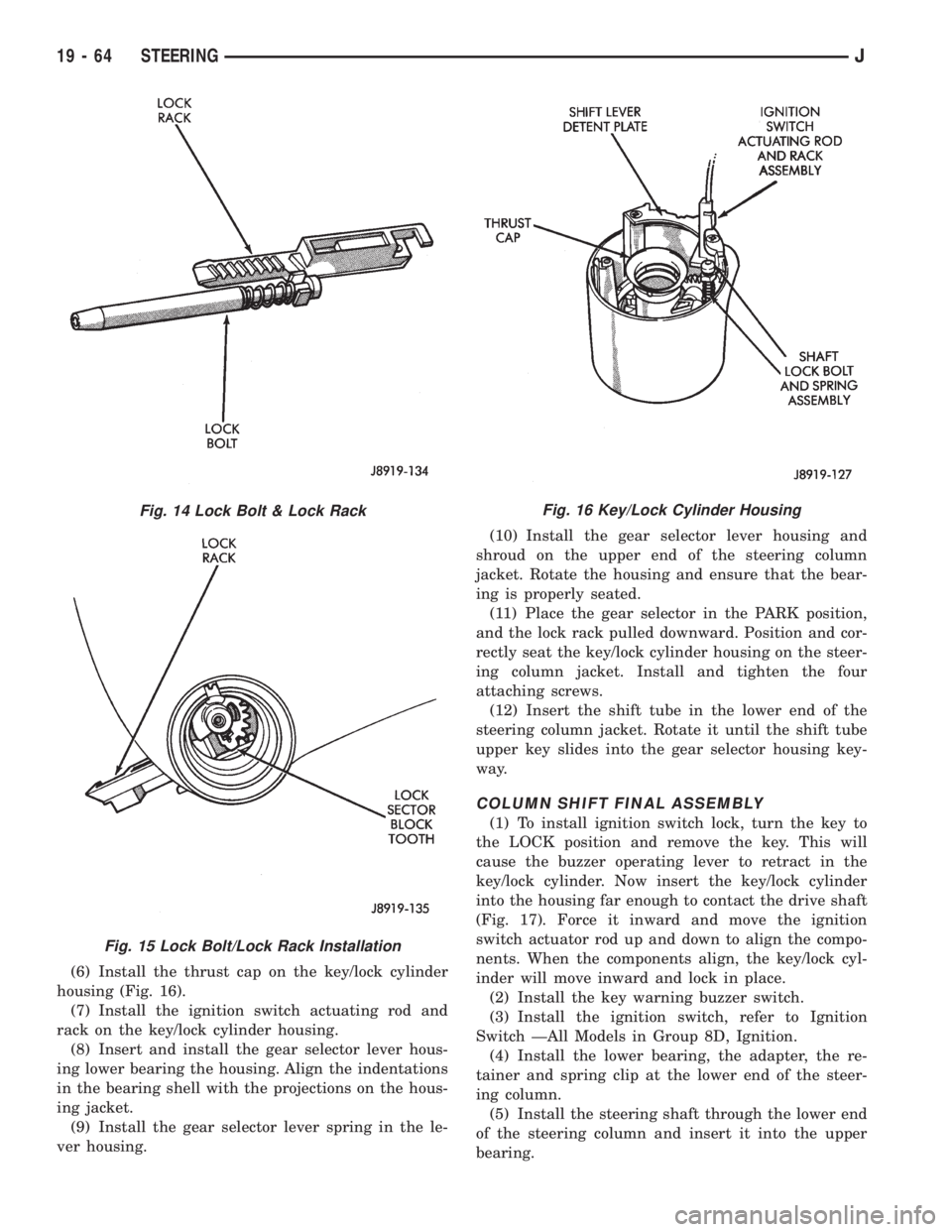

CAUTION: Wrap tape around the turn signal

switch wire harness connector (Fig. 4) to prevent it

from becoming entangled during removal.

(10) Remove the turn signal switch retaining

screws (Fig. 5), dimmer switch actuator arm, to re-

move the switch. Guide the switch straight up and

out of the steering column.

Fig. 1 Steering Column Support Fixture

Fig. 2 Retaining Snap Ring Removal

19 - 60 STEERINGJ

Page 1360 of 2198

(11) Remove the wiper switch wire harness and all

the other wire harnesses located within the steering

column.

(12) Insert the ignition switch key into the key/lock

cylinder and turn to the ON position.

CAUTION: Do not attempt to remove the key warn-

ing buzzer switch and contacts separately. If sepa-

rated, the contacts can detach and drop into the

steering column.(13) Remove the key warning buzzer switch and

contacts as a unit (Fig. 6). Use needle-nose pliers or

a paper clip bent at a right angle (90 degrees).

(14) Turn ignition key/lock cylinder to the ON po-

sition. Insert a thin screwdriver into the slot adjacent

to the switch attaching screw boss (right-hand slot).

Depress the spring latch located at the bottom of the

slot to release the key/lock cylinder. Remove the key/

lock cylinder. (Fig. 7).

Fig. 3 Steering Column Disassembly

Fig. 4 Taped Turn Signal Switch Wire Harness

Connector

Fig. 5 Turn Signal Switch Retaining Screw

Fig. 6 Key Warning Buzzer/Contacts Removal

JSTEERING 19 - 61

Page 1362 of 2198

(9) Remove the gear selector lever spring from the

lever housing.

The steering column must be removed from

the vehicle to disassemble the remaining steer-

ing column components.

(10) Remove the steering shaft (if not previously

removed).

(11) Remove the spring clip from the steering col-

umn lower bearing retainer. Remove the retainer, the

lower bearing and the adapter (Fig. 12).

(12) Slide out and remove the shift tube.

ASSEMBLY

WARNING: USE ONLY THE ORIGINAL OR EXACT

REPLACEMENT SCREWS, BOLTS AND NUTS TO

ASSEMBLE THE STEERING COLUMN. INCORRECT

SCREW OR BOLT LENGTH COULD PREVENT THE

COLUMN FROM COMPRESSING WITH IMPACT

(FRONT-END COLLISION). ALL FASTENERS USED

FOR ASSEMBLY MUST BE TIGHTENED WITH THE

CORRECT TORQUE. THIS WILL ENSURE THE COL-

UMN WILL BREAKAWAY WITH IMPACT.

CAUTION: Apply chassis lubricant to all the bear-

ing, thrust and friction producing mating surfaces

before assembly.

COLUMN SHIFT ASSEMBLY

(1) Insert the lock sector through the key/lock cyl-

inder hole in the key/lock cylinder housing. Install

the lock sector on the lock sector shaft (Fig. 13). En-

sure that the lock sector turns freely after installa-

tion.

(2) Install the lock rack preload spring. The bowed

side of the spring must contact the lock rack when

the rack is installed.

(3) Assemble the lock bolt and the lock rack (Fig.

14).

(4) Install the assembled lock bolt and lock rack in

the key/lock cylinder housing (Fig. 15). Mate the lock

rack block tooth with the lock sector block tooth.

(5) Install the shift lever detent plate on the key/

lock cylinder housing (Fig. 16).

Fig. 11 Lock Sector Removal

Fig. 12 Lower Bearing, Adapter, Retainer & Clip

Fig. 13 Lock Sector Installation

JSTEERING 19 - 63

Page 1363 of 2198

(6) Install the thrust cap on the key/lock cylinder

housing (Fig. 16).

(7) Install the ignition switch actuating rod and

rack on the key/lock cylinder housing.

(8) Insert and install the gear selector lever hous-

ing lower bearing the housing. Align the indentations

in the bearing shell with the projections on the hous-

ing jacket.

(9) Install the gear selector lever spring in the le-

ver housing.(10) Install the gear selector lever housing and

shroud on the upper end of the steering column

jacket. Rotate the housing and ensure that the bear-

ing is properly seated.

(11) Place the gear selector in the PARK position,

and the lock rack pulled downward. Position and cor-

rectly seat the key/lock cylinder housing on the steer-

ing column jacket. Install and tighten the four

attaching screws.

(12) Insert the shift tube in the lower end of the

steering column jacket. Rotate it until the shift tube

upper key slides into the gear selector housing key-

way.

COLUMN SHIFT FINAL ASSEMBLY

(1) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive shaft

(Fig. 17). Force it inward and move the ignition

switch actuator rod up and down to align the compo-

nents. When the components align, the key/lock cyl-

inder will move inward and lock in place.

(2) Install the key warning buzzer switch.

(3) Install the ignition switch, refer to Ignition

Switch ÐAll Models in Group 8D, Ignition.

(4) Install the lower bearing, the adapter, the re-

tainer and spring clip at the lower end of the steer-

ing column.

(5) Install the steering shaft through the lower end

of the steering column and insert it into the upper

bearing.

Fig. 14 Lock Bolt & Lock Rack

Fig. 15 Lock Bolt/Lock Rack Installation

Fig. 16 Key/Lock Cylinder Housing

19 - 64 STEERINGJ

Page 1364 of 2198

(6) Position the turn signal switch and wire har-

ness in the cylinder housing. Fold the wires against

the connector. Route the connector down through the

steering column jacket.

(7) Install the windshield wiper wire harness and

switch. Route the wire harness down through steer-

ing column jacket.

(8) Align the turn signal switch in the housing and

secure the switch with the attaching screws. Tighten

the screws to 4 Nzm (35 in. lbs.) torque.

(9) Install the dimmer switch actuator arm.

Tighten the attaching screws to 4 Nzm (35 in. lbs.)

torque.

(10) If equipped, install the cruise control wire har-

ness. Install the turn signal stalk by pushing it

straight into the column.

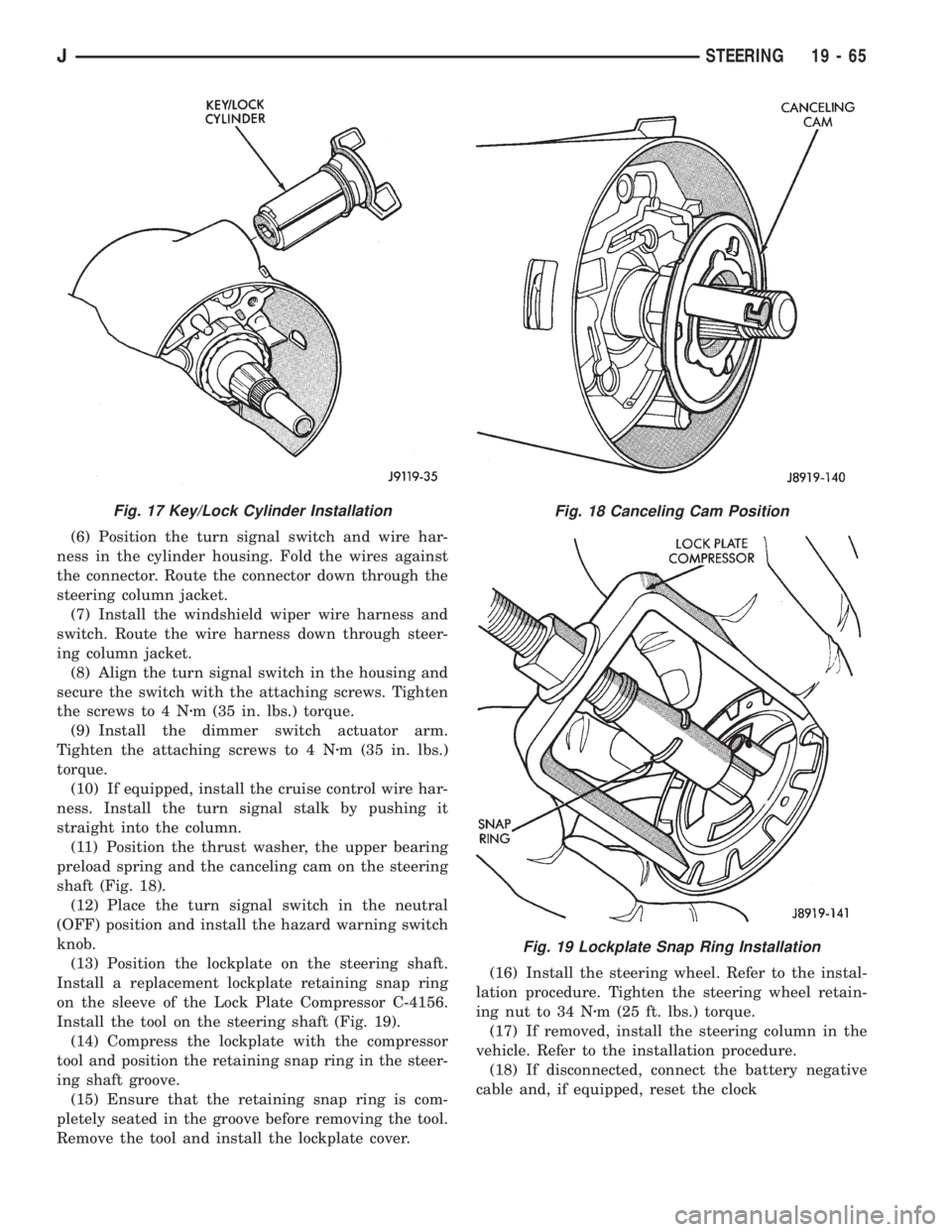

(11) Position the thrust washer, the upper bearing

preload spring and the canceling cam on the steering

shaft (Fig. 18).

(12) Place the turn signal switch in the neutral

(OFF) position and install the hazard warning switch

knob.

(13) Position the lockplate on the steering shaft.

Install a replacement lockplate retaining snap ring

on the sleeve of the Lock Plate Compressor C-4156.

Install the tool on the steering shaft (Fig. 19).

(14) Compress the lockplate with the compressor

tool and position the retaining snap ring in the steer-

ing shaft groove.

(15) Ensure that the retaining snap ring is com-

pletely seated in the groove before removing the tool.

Remove the tool and install the lockplate cover.(16) Install the steering wheel. Refer to the instal-

lation procedure. Tighten the steering wheel retain-

ing nut to 34 Nzm (25 ft. lbs.) torque.

(17) If removed, install the steering column in the

vehicle. Refer to the installation procedure.

(18) If disconnected, connect the battery negative

cable and, if equipped, reset the clock

Fig. 17 Key/Lock Cylinder InstallationFig. 18 Canceling Cam Position

Fig. 19 Lockplate Snap Ring Installation

JSTEERING 19 - 65

Page 1365 of 2198

TILT STEERING COLUMN

DISASSEMBLY

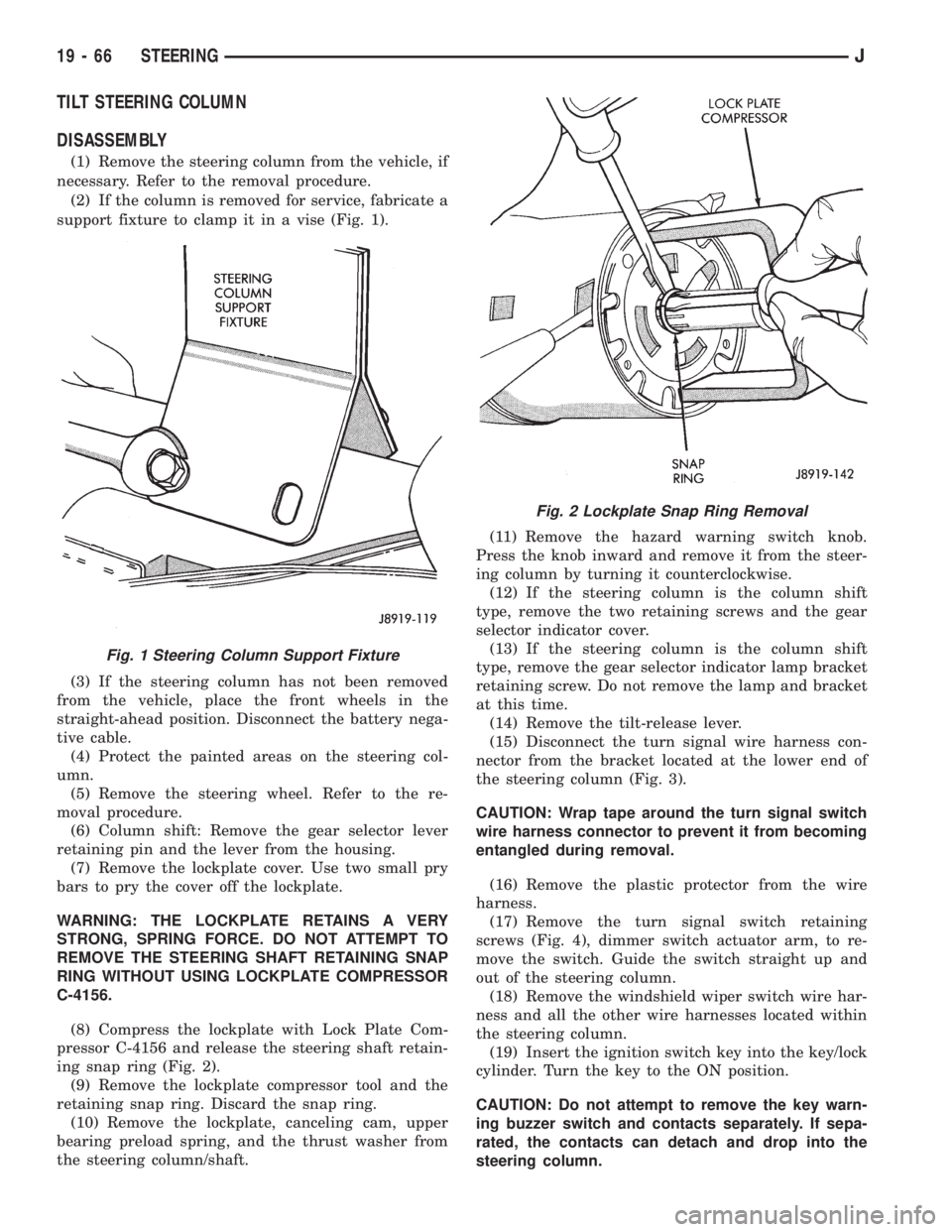

(1) Remove the steering column from the vehicle, if

necessary. Refer to the removal procedure.

(2) If the column is removed for service, fabricate a

support fixture to clamp it in a vise (Fig. 1).

(3) If the steering column has not been removed

from the vehicle, place the front wheels in the

straight-ahead position. Disconnect the battery nega-

tive cable.

(4) Protect the painted areas on the steering col-

umn.

(5) Remove the steering wheel. Refer to the re-

moval procedure.

(6) Column shift: Remove the gear selector lever

retaining pin and the lever from the housing.

(7) Remove the lockplate cover. Use two small pry

bars to pry the cover off the lockplate.

WARNING: THE LOCKPLATE RETAINS A VERY

STRONG, SPRING FORCE. DO NOT ATTEMPT TO

REMOVE THE STEERING SHAFT RETAINING SNAP

RING WITHOUT USING LOCKPLATE COMPRESSOR

C-4156.

(8) Compress the lockplate with Lock Plate Com-

pressor C-4156 and release the steering shaft retain-

ing snap ring (Fig. 2).

(9) Remove the lockplate compressor tool and the

retaining snap ring. Discard the snap ring.

(10) Remove the lockplate, canceling cam, upper

bearing preload spring, and the thrust washer from

the steering column/shaft.(11) Remove the hazard warning switch knob.

Press the knob inward and remove it from the steer-

ing column by turning it counterclockwise.

(12) If the steering column is the column shift

type, remove the two retaining screws and the gear

selector indicator cover.

(13) If the steering column is the column shift

type, remove the gear selector indicator lamp bracket

retaining screw. Do not remove the lamp and bracket

at this time.

(14) Remove the tilt-release lever.

(15) Disconnect the turn signal wire harness con-

nector from the bracket located at the lower end of

the steering column (Fig. 3).

CAUTION: Wrap tape around the turn signal switch

wire harness connector to prevent it from becoming

entangled during removal.

(16) Remove the plastic protector from the wire

harness.

(17) Remove the turn signal switch retaining

screws (Fig. 4), dimmer switch actuator arm, to re-

move the switch. Guide the switch straight up and

out of the steering column.

(18) Remove the windshield wiper switch wire har-

ness and all the other wire harnesses located within

the steering column.

(19) Insert the ignition switch key into the key/lock

cylinder. Turn the key to the ON position.

CAUTION: Do not attempt to remove the key warn-

ing buzzer switch and contacts separately. If sepa-

rated, the contacts can detach and drop into the

steering column.

Fig. 1 Steering Column Support Fixture

Fig. 2 Lockplate Snap Ring Removal

19 - 66 STEERINGJ