JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1501 of 2198

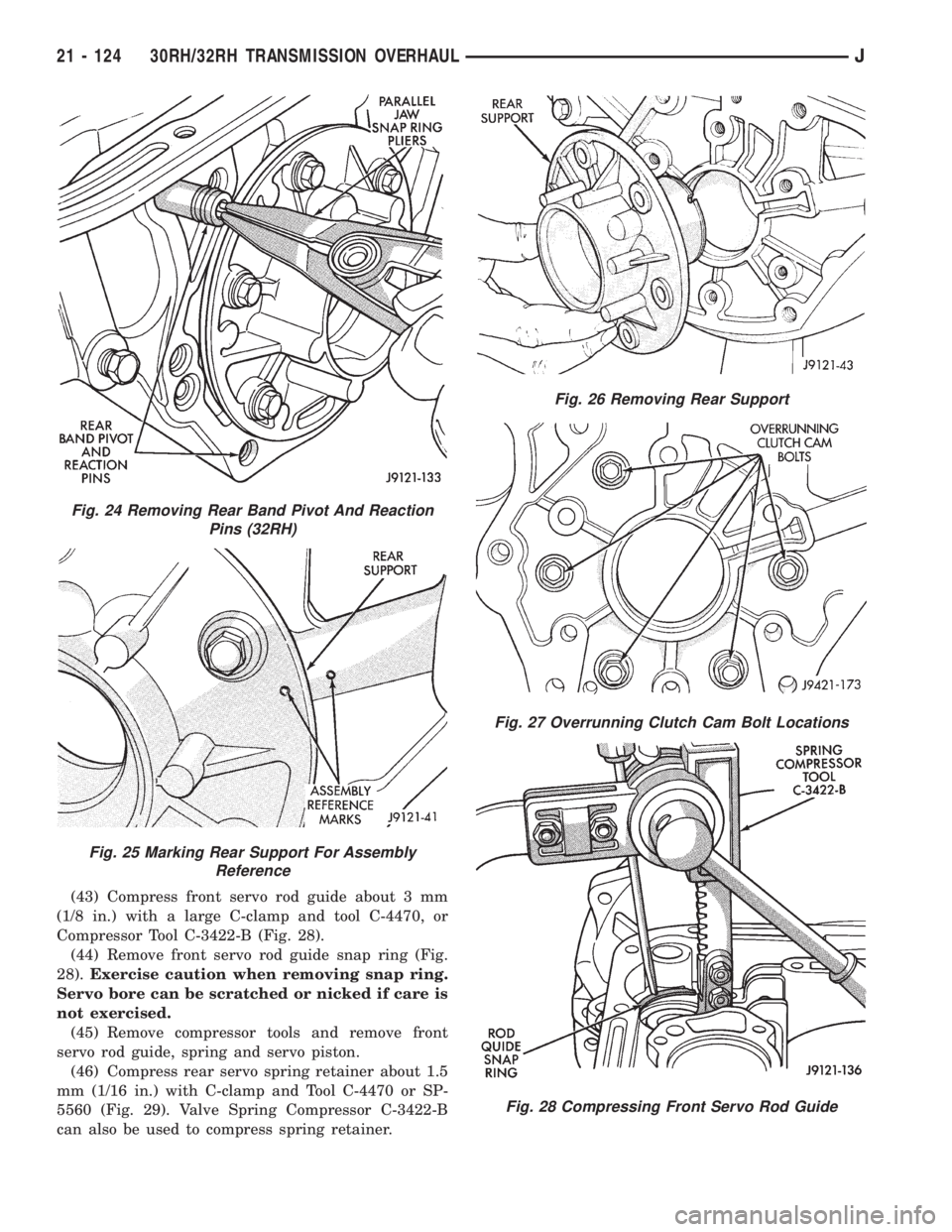

(43) Compress front servo rod guide about 3 mm

(1/8 in.) with a large C-clamp and tool C-4470, or

Compressor Tool C-3422-B (Fig. 28).

(44) Remove front servo rod guide snap ring (Fig.

28).Exercise caution when removing snap ring.

Servo bore can be scratched or nicked if care is

not exercised.

(45) Remove compressor tools and remove front

servo rod guide, spring and servo piston.

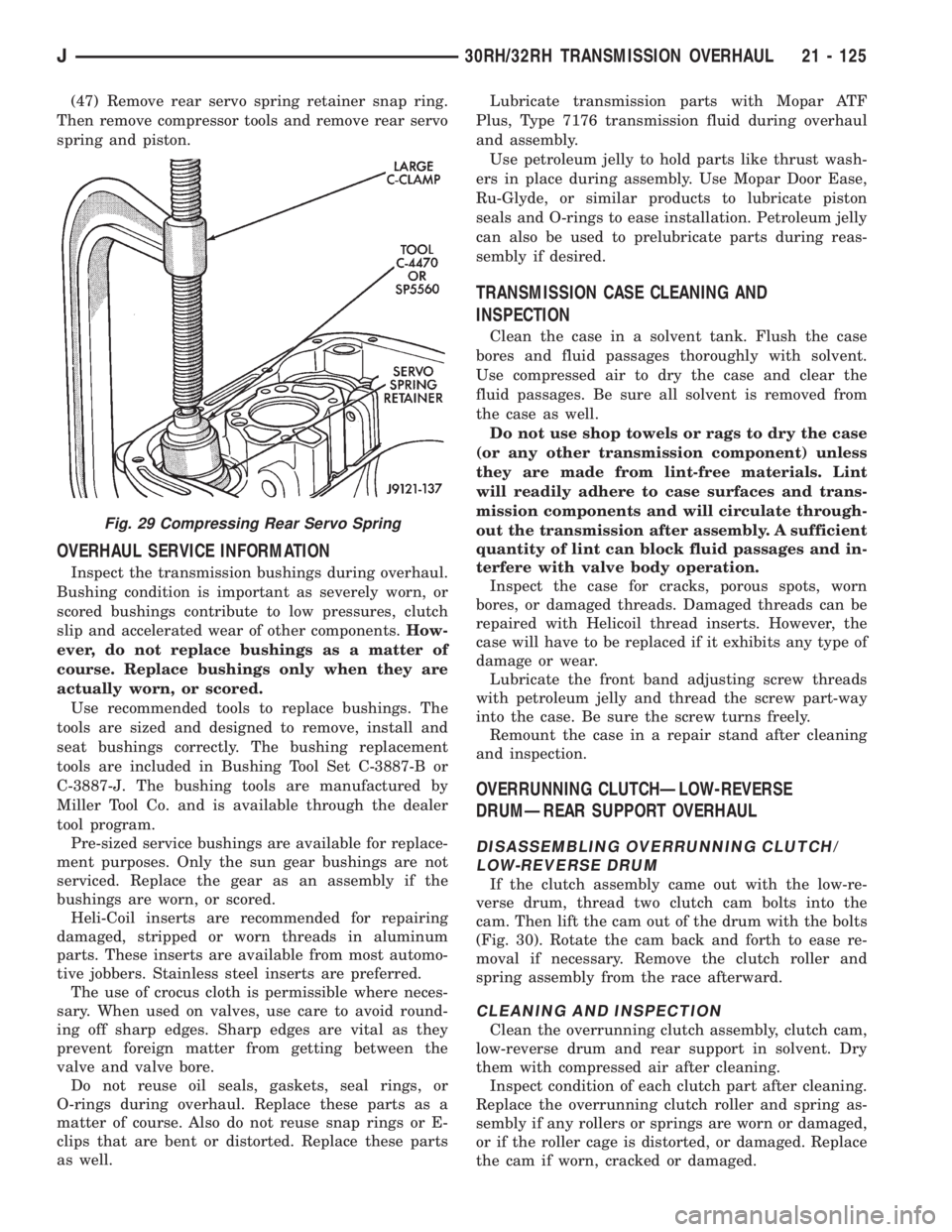

(46) Compress rear servo spring retainer about 1.5

mm (1/16 in.) with C-clamp and Tool C-4470 or SP-

5560 (Fig. 29). Valve Spring Compressor C-3422-B

can also be used to compress spring retainer.

Fig. 24 Removing Rear Band Pivot And Reaction

Pins (32RH)

Fig. 25 Marking Rear Support For Assembly

Reference

Fig. 26 Removing Rear Support

Fig. 27 Overrunning Clutch Cam Bolt Locations

Fig. 28 Compressing Front Servo Rod Guide

21 - 124 30RH/32RH TRANSMISSION OVERHAULJ

Page 1502 of 2198

(47) Remove rear servo spring retainer snap ring.

Then remove compressor tools and remove rear servo

spring and piston.

OVERHAUL SERVICE INFORMATION

Inspect the transmission bushings during overhaul.

Bushing condition is important as severely worn, or

scored bushings contribute to low pressures, clutch

slip and accelerated wear of other components.How-

ever, do not replace bushings as a matter of

course. Replace bushings only when they are

actually worn, or scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B or

C-3887-J. The bushing tools are manufactured by

Miller Tool Co. and is available through the dealer

tool program.

Pre-sized service bushings are available for replace-

ment purposes. Only the sun gear bushings are not

serviced. Replace the gear as an assembly if the

bushings are worn, or scored.

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts. These inserts are available from most automo-

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces-

sary. When used on valves, use care to avoid round-

ing off sharp edges. Sharp edges are vital as they

prevent foreign matter from getting between the

valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or E-

clips that are bent or distorted. Replace these parts

as well.Lubricate transmission parts with Mopar ATF

Plus, Type 7176 transmission fluid during overhaul

and assembly.

Use petroleum jelly to hold parts like thrust wash-

ers in place during assembly. Use Mopar Door Ease,

Ru-Glyde, or similar products to lubricate piston

seals and O-rings to ease installation. Petroleum jelly

can also be used to prelubricate parts during reas-

sembly if desired.

TRANSMISSION CASE CLEANING AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Use compressed air to dry the case and clear the

fluid passages. Be sure all solvent is removed from

the case as well.

Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint

will readily adhere to case surfaces and trans-

mission components and will circulate through-

out the transmission after assembly. A sufficient

quantity of lint can block fluid passages and in-

terfere with valve body operation.

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Remount the case in a repair stand after cleaning

and inspection.

OVERRUNNING CLUTCHÐLOW-REVERSE

DRUMÐREAR SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/

LOW-REVERSE DRUM

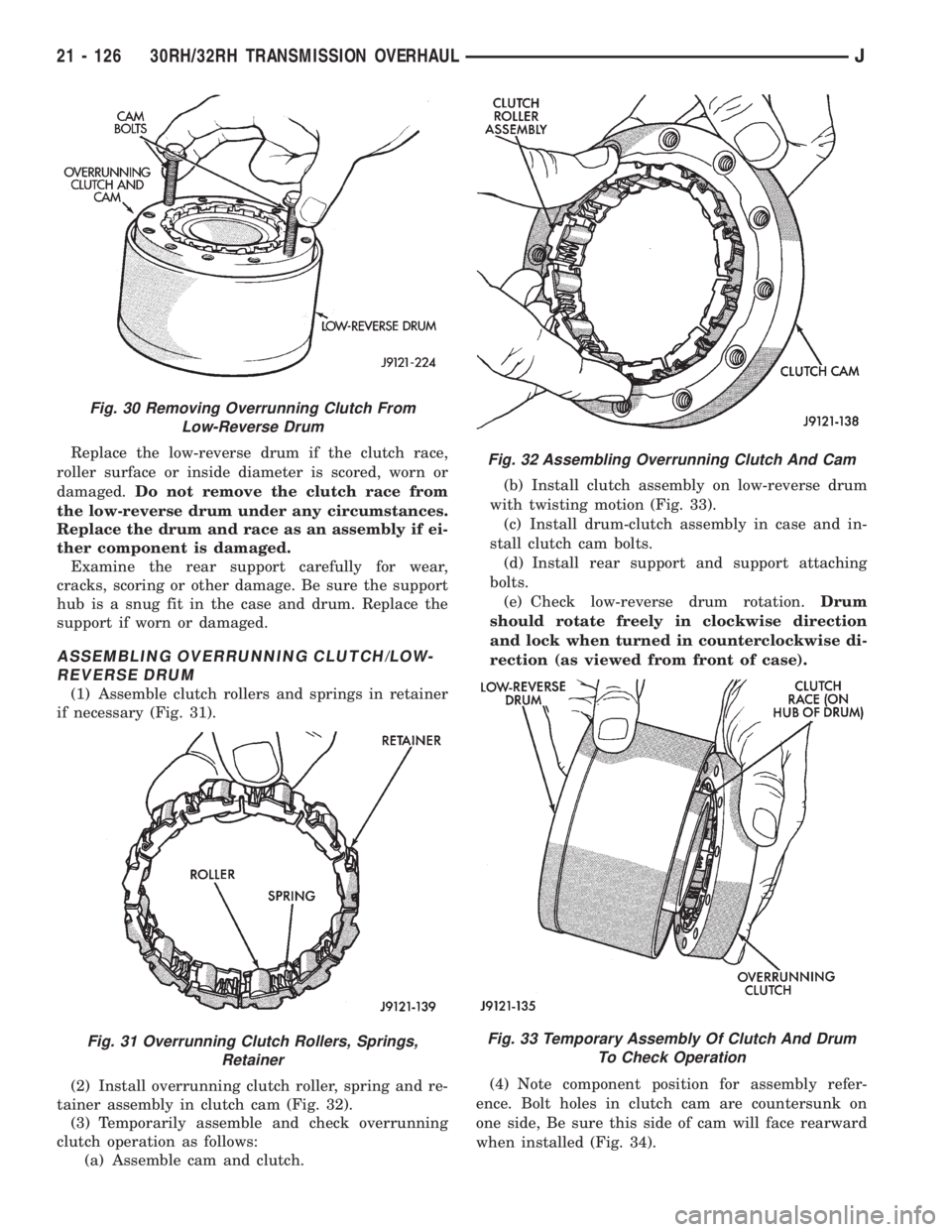

If the clutch assembly came out with the low-re-

verse drum, thread two clutch cam bolts into the

cam. Then lift the cam out of the drum with the bolts

(Fig. 30). Rotate the cam back and forth to ease re-

moval if necessary. Remove the clutch roller and

spring assembly from the race afterward.

CLEANING AND INSPECTION

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum and rear support in solvent. Dry

them with compressed air after cleaning.

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as-

sembly if any rollers or springs are worn or damaged,

or if the roller cage is distorted, or damaged. Replace

the cam if worn, cracked or damaged.

Fig. 29 Compressing Rear Servo Spring

J30RH/32RH TRANSMISSION OVERHAUL 21 - 125

Page 1503 of 2198

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if ei-

ther component is damaged.

Examine the rear support carefully for wear,

cracks, scoring or other damage. Be sure the support

hub is a snug fit in the case and drum. Replace the

support if worn or damaged.

ASSEMBLING OVERRUNNING CLUTCH/LOW-

REVERSE DRUM

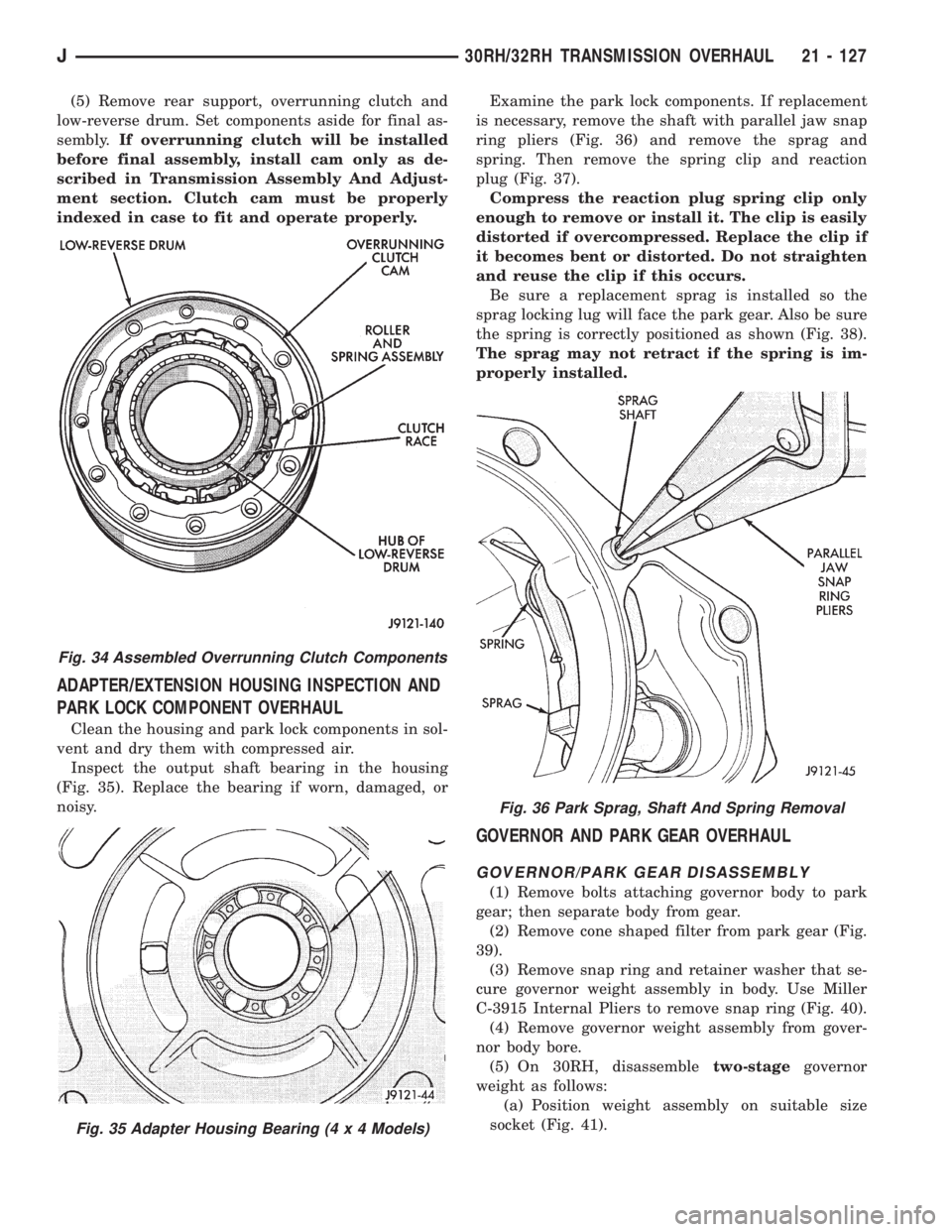

(1) Assemble clutch rollers and springs in retainer

if necessary (Fig. 31).

(2) Install overrunning clutch roller, spring and re-

tainer assembly in clutch cam (Fig. 32).

(3) Temporarily assemble and check overrunning

clutch operation as follows:

(a) Assemble cam and clutch.(b) Install clutch assembly on low-reverse drum

with twisting motion (Fig. 33).

(c) Install drum-clutch assembly in case and in-

stall clutch cam bolts.

(d) Install rear support and support attaching

bolts.

(e) Check low-reverse drum rotation.Drum

should rotate freely in clockwise direction

and lock when turned in counterclockwise di-

rection (as viewed from front of case).

(4) Note component position for assembly refer-

ence. Bolt holes in clutch cam are countersunk on

one side, Be sure this side of cam will face rearward

when installed (Fig. 34).

Fig. 30 Removing Overrunning Clutch From

Low-Reverse Drum

Fig. 31 Overrunning Clutch Rollers, Springs,

Retainer

Fig. 32 Assembling Overrunning Clutch And Cam

Fig. 33 Temporary Assembly Of Clutch And Drum

To Check Operation

21 - 126 30RH/32RH TRANSMISSION OVERHAULJ

Page 1504 of 2198

(5) Remove rear support, overrunning clutch and

low-reverse drum. Set components aside for final as-

sembly.If overrunning clutch will be installed

before final assembly, install cam only as de-

scribed in Transmission Assembly And Adjust-

ment section. Clutch cam must be properly

indexed in case to fit and operate properly.

ADAPTER/EXTENSION HOUSING INSPECTION AND

PARK LOCK COMPONENT OVERHAUL

Clean the housing and park lock components in sol-

vent and dry them with compressed air.

Inspect the output shaft bearing in the housing

(Fig. 35). Replace the bearing if worn, damaged, or

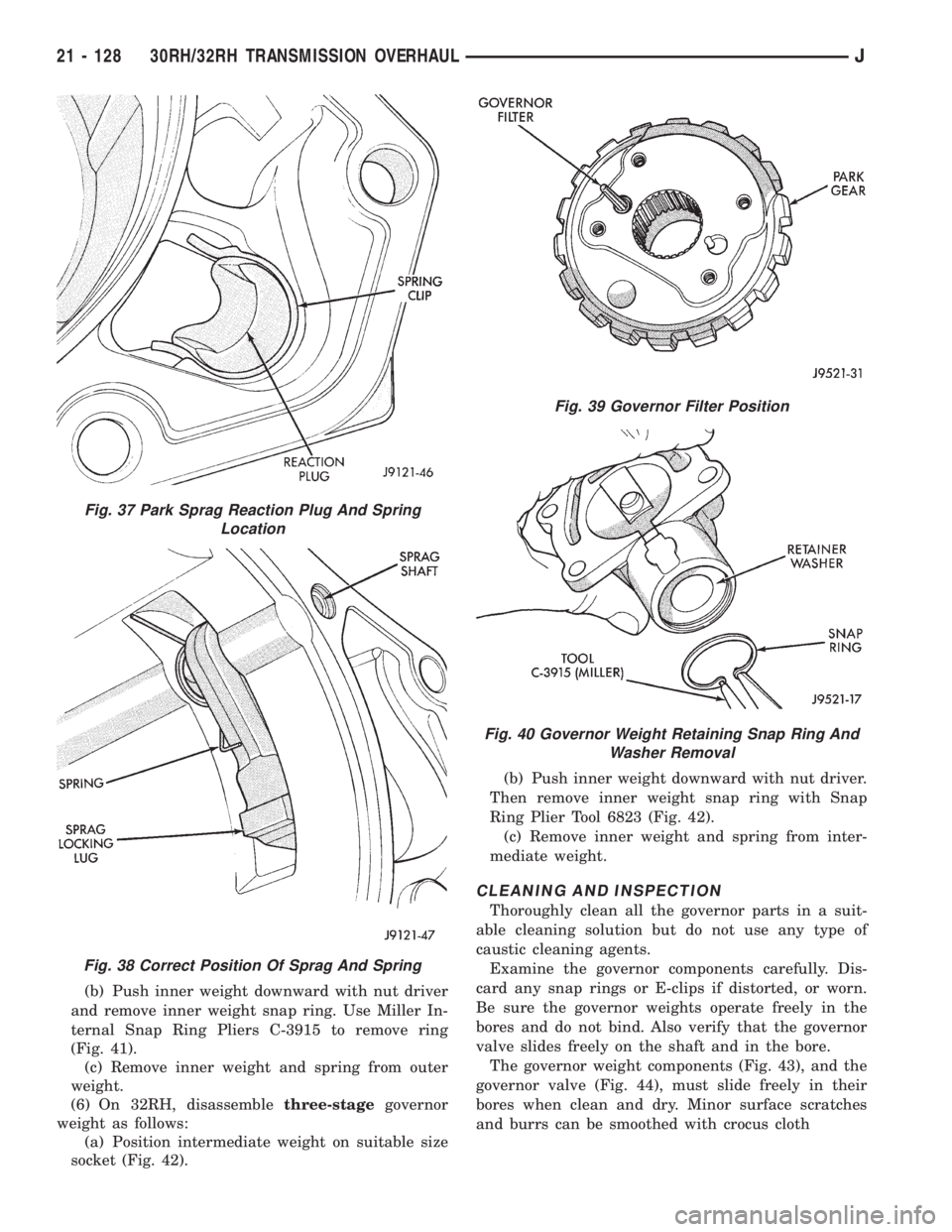

noisy.Examine the park lock components. If replacement

is necessary, remove the shaft with parallel jaw snap

ring pliers (Fig. 36) and remove the sprag and

spring. Then remove the spring clip and reaction

plug (Fig. 37).

Compress the reaction plug spring clip only

enough to remove or install it. The clip is easily

distorted if overcompressed. Replace the clip if

it becomes bent or distorted. Do not straighten

and reuse the clip if this occurs.

Be sure a replacement sprag is installed so the

sprag locking lug will face the park gear. Also be sure

the spring is correctly positioned as shown (Fig. 38).

The sprag may not retract if the spring is im-

properly installed.

GOVERNOR AND PARK GEAR OVERHAUL

GOVERNOR/PARK GEAR DISASSEMBLY

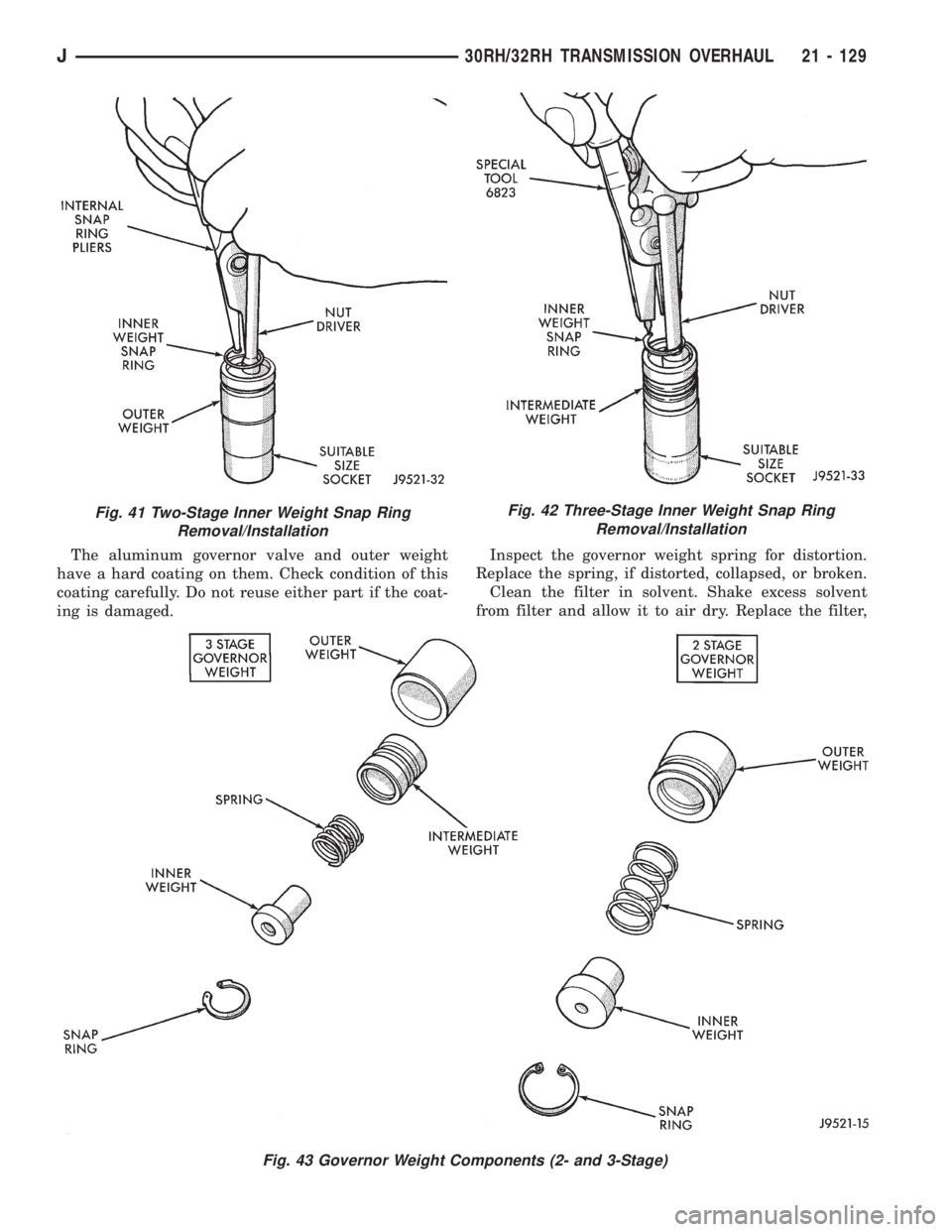

(1) Remove bolts attaching governor body to park

gear; then separate body from gear.

(2) Remove cone shaped filter from park gear (Fig.

39).

(3) Remove snap ring and retainer washer that se-

cure governor weight assembly in body. Use Miller

C-3915 Internal Pliers to remove snap ring (Fig. 40).

(4) Remove governor weight assembly from gover-

nor body bore.

(5) On 30RH, disassembletwo-stagegovernor

weight as follows:

(a) Position weight assembly on suitable size

socket (Fig. 41).

Fig. 34 Assembled Overrunning Clutch Components

Fig. 35 Adapter Housing Bearing (4 x 4 Models)

Fig. 36 Park Sprag, Shaft And Spring Removal

J30RH/32RH TRANSMISSION OVERHAUL 21 - 127

Page 1505 of 2198

(b) Push inner weight downward with nut driver

and remove inner weight snap ring. Use Miller In-

ternal Snap Ring Pliers C-3915 to remove ring

(Fig. 41).

(c) Remove inner weight and spring from outer

weight.

(6) On 32RH, disassemblethree-stagegovernor

weight as follows:

(a) Position intermediate weight on suitable size

socket (Fig. 42).(b) Push inner weight downward with nut driver.

Then remove inner weight snap ring with Snap

Ring Plier Tool 6823 (Fig. 42).

(c) Remove inner weight and spring from inter-

mediate weight.

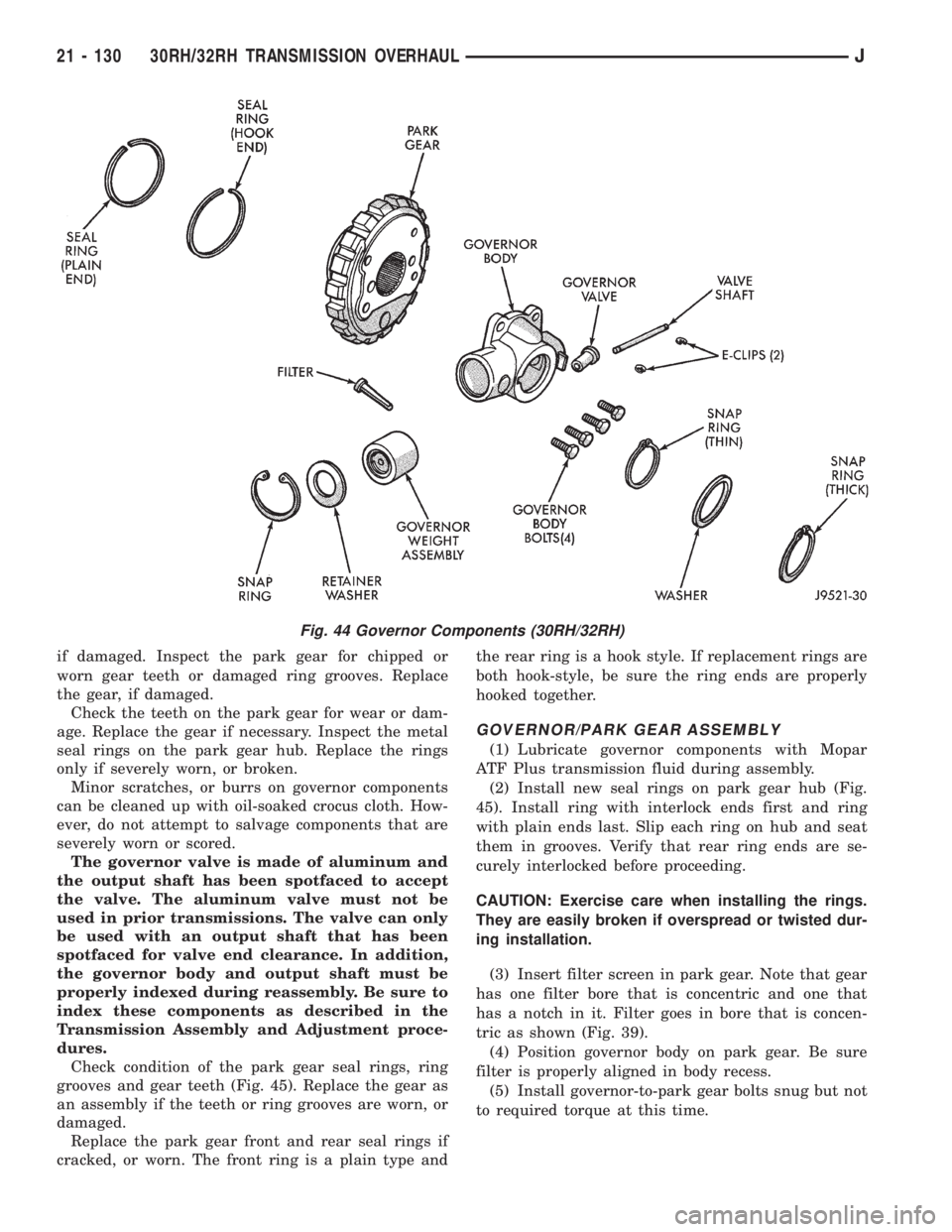

CLEANING AND INSPECTION

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

Examine the governor components carefully. Dis-

card any snap rings or E-clips if distorted, or worn.

Be sure the governor weights operate freely in the

bores and do not bind. Also verify that the governor

valve slides freely on the shaft and in the bore.

The governor weight components (Fig. 43), and the

governor valve (Fig. 44), must slide freely in their

bores when clean and dry. Minor surface scratches

and burrs can be smoothed with crocus cloth

Fig. 37 Park Sprag Reaction Plug And Spring

Location

Fig. 38 Correct Position Of Sprag And Spring

Fig. 39 Governor Filter Position

Fig. 40 Governor Weight Retaining Snap Ring And

Washer Removal

21 - 128 30RH/32RH TRANSMISSION OVERHAULJ

Page 1506 of 2198

The aluminum governor valve and outer weight

have a hard coating on them. Check condition of this

coating carefully. Do not reuse either part if the coat-

ing is damaged.Inspect the governor weight spring for distortion.

Replace the spring, if distorted, collapsed, or broken.

Clean the filter in solvent. Shake excess solvent

from filter and allow it to air dry. Replace the filter,

Fig. 41 Two-Stage Inner Weight Snap Ring

Removal/InstallationFig. 42 Three-Stage Inner Weight Snap Ring

Removal/Installation

Fig. 43 Governor Weight Components (2- and 3-Stage)

J30RH/32RH TRANSMISSION OVERHAUL 21 - 129

Page 1507 of 2198

if damaged. Inspect the park gear for chipped or

worn gear teeth or damaged ring grooves. Replace

the gear, if damaged.

Check the teeth on the park gear for wear or dam-

age. Replace the gear if necessary. Inspect the metal

seal rings on the park gear hub. Replace the rings

only if severely worn, or broken.

Minor scratches, or burrs on governor components

can be cleaned up with oil-soaked crocus cloth. How-

ever, do not attempt to salvage components that are

severely worn or scored.

The governor valve is made of aluminum and

the output shaft has been spotfaced to accept

the valve. The aluminum valve must not be

used in prior transmissions. The valve can only

be used with an output shaft that has been

spotfaced for valve end clearance. In addition,

the governor body and output shaft must be

properly indexed during reassembly. Be sure to

index these components as described in the

Transmission Assembly and Adjustment proce-

dures.

Check condition of the park gear seal rings, ring

grooves and gear teeth (Fig. 45). Replace the gear as

an assembly if the teeth or ring grooves are worn, or

damaged.

Replace the park gear front and rear seal rings if

cracked, or worn. The front ring is a plain type andthe rear ring is a hook style. If replacement rings are

both hook-style, be sure the ring ends are properly

hooked together.

GOVERNOR/PARK GEAR ASSEMBLY

(1) Lubricate governor components with Mopar

ATF Plus transmission fluid during assembly.

(2) Install new seal rings on park gear hub (Fig.

45). Install ring with interlock ends first and ring

with plain ends last. Slip each ring on hub and seat

them in grooves. Verify that rear ring ends are se-

curely interlocked before proceeding.

CAUTION: Exercise care when installing the rings.

They are easily broken if overspread or twisted dur-

ing installation.

(3) Insert filter screen in park gear. Note that gear

has one filter bore that is concentric and one that

has a notch in it. Filter goes in bore that is concen-

tric as shown (Fig. 39).

(4) Position governor body on park gear. Be sure

filter is properly aligned in body recess.

(5) Install governor-to-park gear bolts snug but not

to required torque at this time.

Fig. 44 Governor Components (30RH/32RH)

21 - 130 30RH/32RH TRANSMISSION OVERHAULJ

Page 1508 of 2198

(6) Assemble governor weight components (Fig.

43). Then install weight assembly in governor body.

Be sure inner weight snap ring is fully seated

before proceeding.

(7) Install retainer washer and snap ring that se-

cure governor weight assembly in governor body.

(8) Set assembly aside until final assembly and in-

stallation.

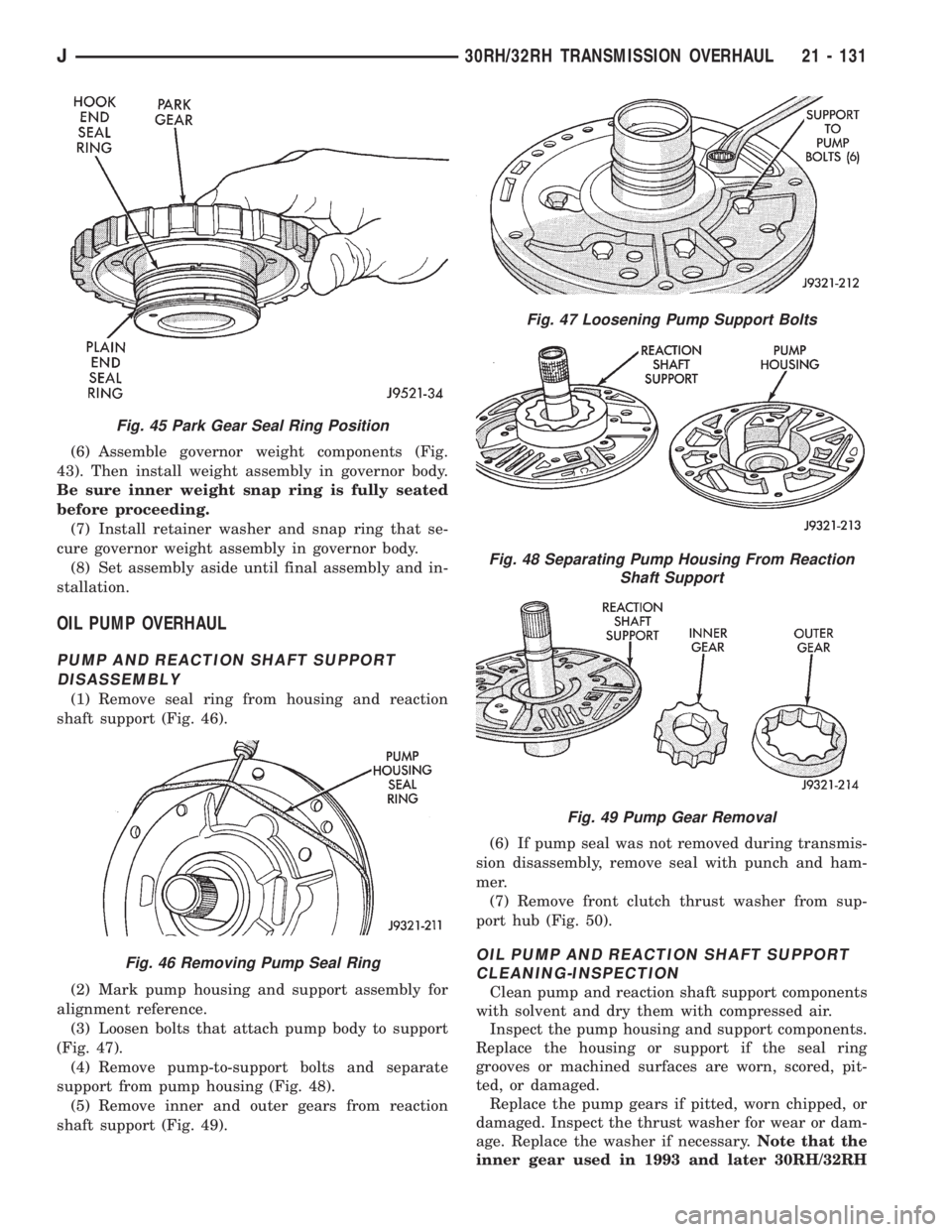

OIL PUMP OVERHAUL

PUMP AND REACTION SHAFT SUPPORT

DISASSEMBLY

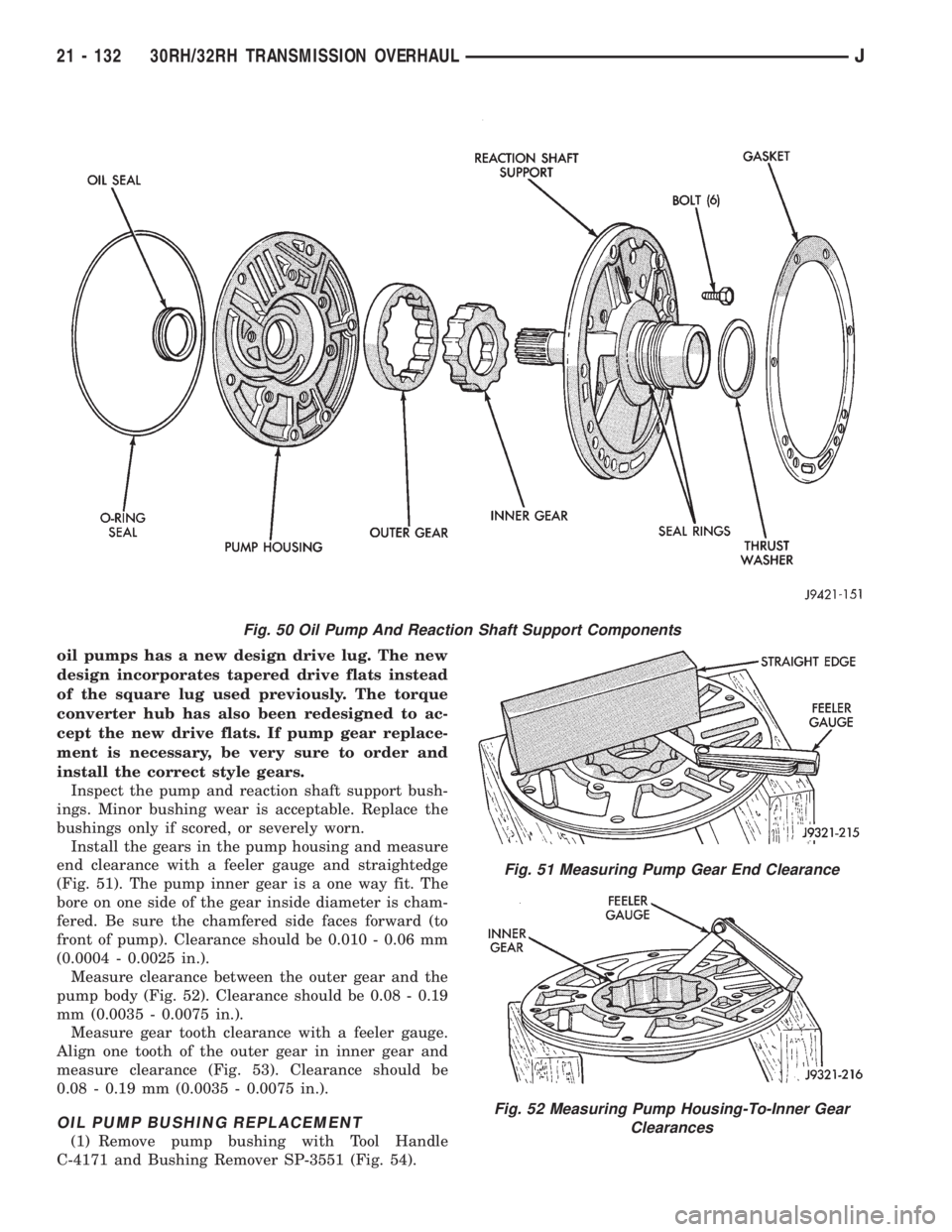

(1) Remove seal ring from housing and reaction

shaft support (Fig. 46).

(2) Mark pump housing and support assembly for

alignment reference.

(3) Loosen bolts that attach pump body to support

(Fig. 47).

(4) Remove pump-to-support bolts and separate

support from pump housing (Fig. 48).

(5) Remove inner and outer gears from reaction

shaft support (Fig. 49).(6) If pump seal was not removed during transmis-

sion disassembly, remove seal with punch and ham-

mer.

(7) Remove front clutch thrust washer from sup-

port hub (Fig. 50).

OIL PUMP AND REACTION SHAFT SUPPORT

CLEANING-INSPECTION

Clean pump and reaction shaft support components

with solvent and dry them with compressed air.

Inspect the pump housing and support components.

Replace the housing or support if the seal ring

grooves or machined surfaces are worn, scored, pit-

ted, or damaged.

Replace the pump gears if pitted, worn chipped, or

damaged. Inspect the thrust washer for wear or dam-

age. Replace the washer if necessary.Note that the

inner gear used in 1993 and later 30RH/32RH

Fig. 45 Park Gear Seal Ring Position

Fig. 46 Removing Pump Seal Ring

Fig. 47 Loosening Pump Support Bolts

Fig. 48 Separating Pump Housing From Reaction

Shaft Support

Fig. 49 Pump Gear Removal

J30RH/32RH TRANSMISSION OVERHAUL 21 - 131

Page 1509 of 2198

oil pumps has a new design drive lug. The new

design incorporates tapered drive flats instead

of the square lug used previously. The torque

converter hub has also been redesigned to ac-

cept the new drive flats. If pump gear replace-

ment is necessary, be very sure to order and

install the correct style gears.

Inspect the pump and reaction shaft support bush-

ings. Minor bushing wear is acceptable. Replace the

bushings only if scored, or severely worn.

Install the gears in the pump housing and measure

end clearance with a feeler gauge and straightedge

(Fig. 51). The pump inner gear is a one way fit. The

bore on one side of the gear inside diameter is cham-

fered. Be sure the chamfered side faces forward (to

front of pump). Clearance should be 0.010 - 0.06 mm

(0.0004 - 0.0025 in.).

Measure clearance between the outer gear and the

pump body (Fig. 52). Clearance should be 0.08 - 0.19

mm (0.0035 - 0.0075 in.).

Measure gear tooth clearance with a feeler gauge.

Align one tooth of the outer gear in inner gear and

measure clearance (Fig. 53). Clearance should be

0.08 - 0.19 mm (0.0035 - 0.0075 in.).

OIL PUMP BUSHING REPLACEMENT

(1) Remove pump bushing with Tool Handle

C-4171 and Bushing Remover SP-3551 (Fig. 54).

Fig. 50 Oil Pump And Reaction Shaft Support Components

Fig. 51 Measuring Pump Gear End Clearance

Fig. 52 Measuring Pump Housing-To-Inner Gear

Clearances

21 - 132 30RH/32RH TRANSMISSION OVERHAULJ

Page 1510 of 2198

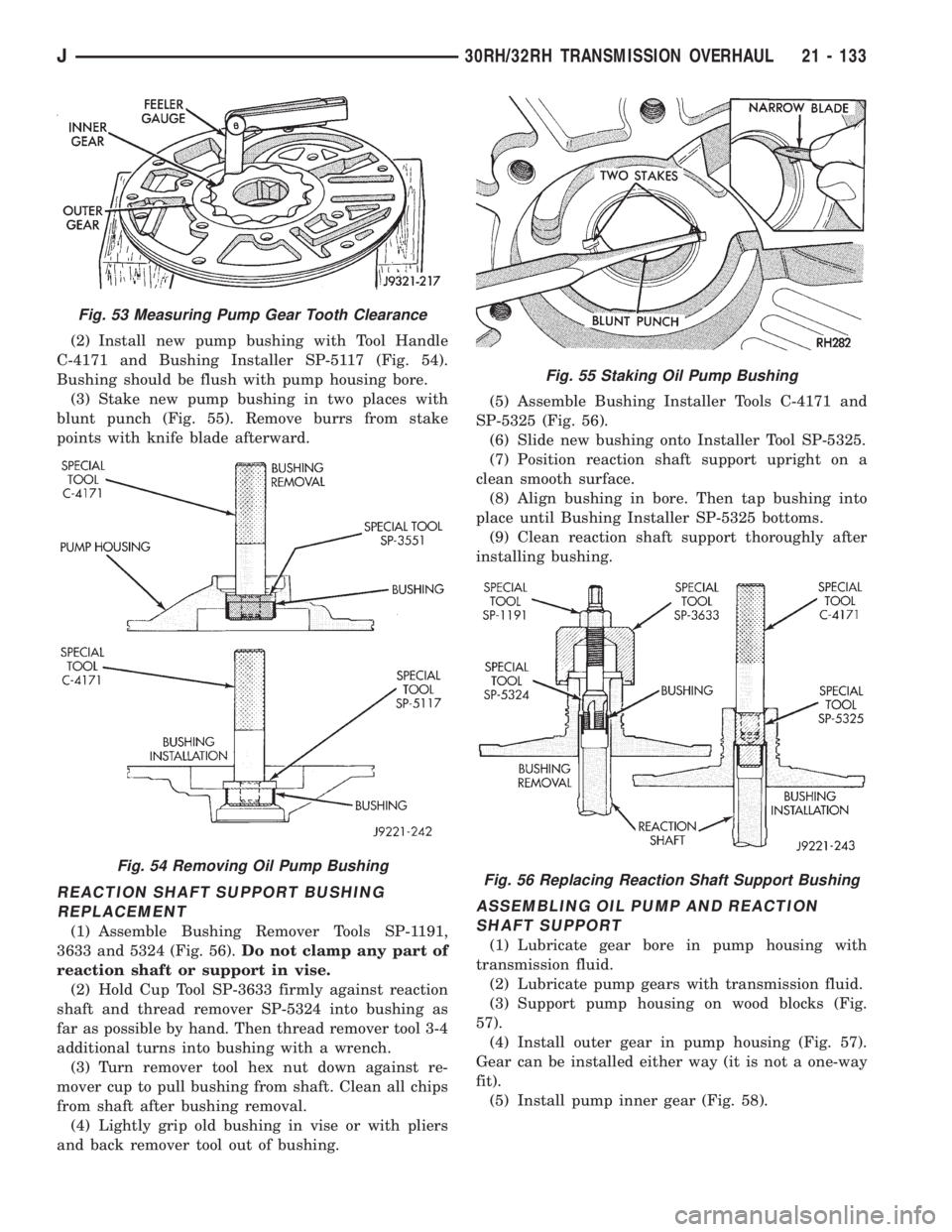

(2) Install new pump bushing with Tool Handle

C-4171 and Bushing Installer SP-5117 (Fig. 54).

Bushing should be flush with pump housing bore.

(3) Stake new pump bushing in two places with

blunt punch (Fig. 55). Remove burrs from stake

points with knife blade afterward.

REACTION SHAFT SUPPORT BUSHING

REPLACEMENT

(1) Assemble Bushing Remover Tools SP-1191,

3633 and 5324 (Fig. 56).Do not clamp any part of

reaction shaft or support in vise.

(2) Hold Cup Tool SP-3633 firmly against reaction

shaft and thread remover SP-5324 into bushing as

far as possible by hand. Then thread remover tool 3-4

additional turns into bushing with a wrench.

(3) Turn remover tool hex nut down against re-

mover cup to pull bushing from shaft. Clean all chips

from shaft after bushing removal.

(4) Lightly grip old bushing in vise or with pliers

and back remover tool out of bushing.(5) Assemble Bushing Installer Tools C-4171 and

SP-5325 (Fig. 56).

(6) Slide new bushing onto Installer Tool SP-5325.

(7) Position reaction shaft support upright on a

clean smooth surface.

(8) Align bushing in bore. Then tap bushing into

place until Bushing Installer SP-5325 bottoms.

(9) Clean reaction shaft support thoroughly after

installing bushing.

ASSEMBLING OIL PUMP AND REACTION

SHAFT SUPPORT

(1) Lubricate gear bore in pump housing with

transmission fluid.

(2) Lubricate pump gears with transmission fluid.

(3) Support pump housing on wood blocks (Fig.

57).

(4) Install outer gear in pump housing (Fig. 57).

Gear can be installed either way (it is not a one-way

fit).

(5) Install pump inner gear (Fig. 58).

Fig. 53 Measuring Pump Gear Tooth Clearance

Fig. 54 Removing Oil Pump Bushing

Fig. 55 Staking Oil Pump Bushing

Fig. 56 Replacing Reaction Shaft Support Bushing

J30RH/32RH TRANSMISSION OVERHAUL 21 - 133