JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1511 of 2198

CAUTION: The pump inner gear is a one way fit.

The bore on one side of the gear inside diameter

(I.D.) is chamfered. Be sure the chamfered side

faces forward (to front of pump).

(6) Install new thrust washer on hub of reaction

shaft support. Lubricate washer with transmission

fluid or petroleum jelly.

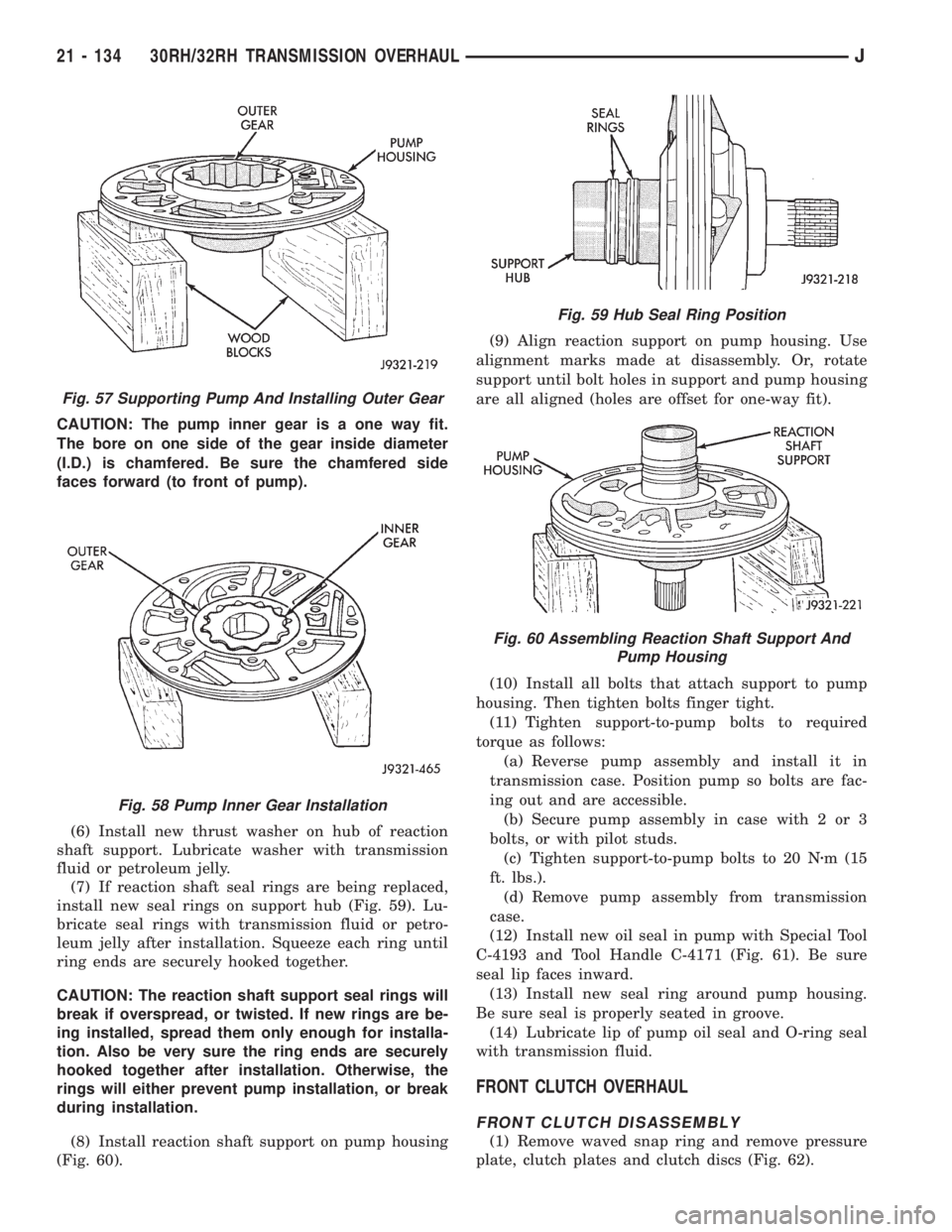

(7) If reaction shaft seal rings are being replaced,

install new seal rings on support hub (Fig. 59). Lu-

bricate seal rings with transmission fluid or petro-

leum jelly after installation. Squeeze each ring until

ring ends are securely hooked together.

CAUTION: The reaction shaft support seal rings will

break if overspread, or twisted. If new rings are be-

ing installed, spread them only enough for installa-

tion. Also be very sure the ring ends are securely

hooked together after installation. Otherwise, the

rings will either prevent pump installation, or break

during installation.

(8) Install reaction shaft support on pump housing

(Fig. 60).(9) Align reaction support on pump housing. Use

alignment marks made at disassembly. Or, rotate

support until bolt holes in support and pump housing

are all aligned (holes are offset for one-way fit).

(10) Install all bolts that attach support to pump

housing. Then tighten bolts finger tight.

(11) Tighten support-to-pump bolts to required

torque as follows:

(a) Reverse pump assembly and install it in

transmission case. Position pump so bolts are fac-

ing out and are accessible.

(b) Secure pump assembly in case with 2 or 3

bolts, or with pilot studs.

(c) Tighten support-to-pump bolts to 20 Nzm (15

ft. lbs.).

(d) Remove pump assembly from transmission

case.

(12) Install new oil seal in pump with Special Tool

C-4193 and Tool Handle C-4171 (Fig. 61). Be sure

seal lip faces inward.

(13) Install new seal ring around pump housing.

Be sure seal is properly seated in groove.

(14) Lubricate lip of pump oil seal and O-ring seal

with transmission fluid.

FRONT CLUTCH OVERHAUL

FRONT CLUTCH DISASSEMBLY

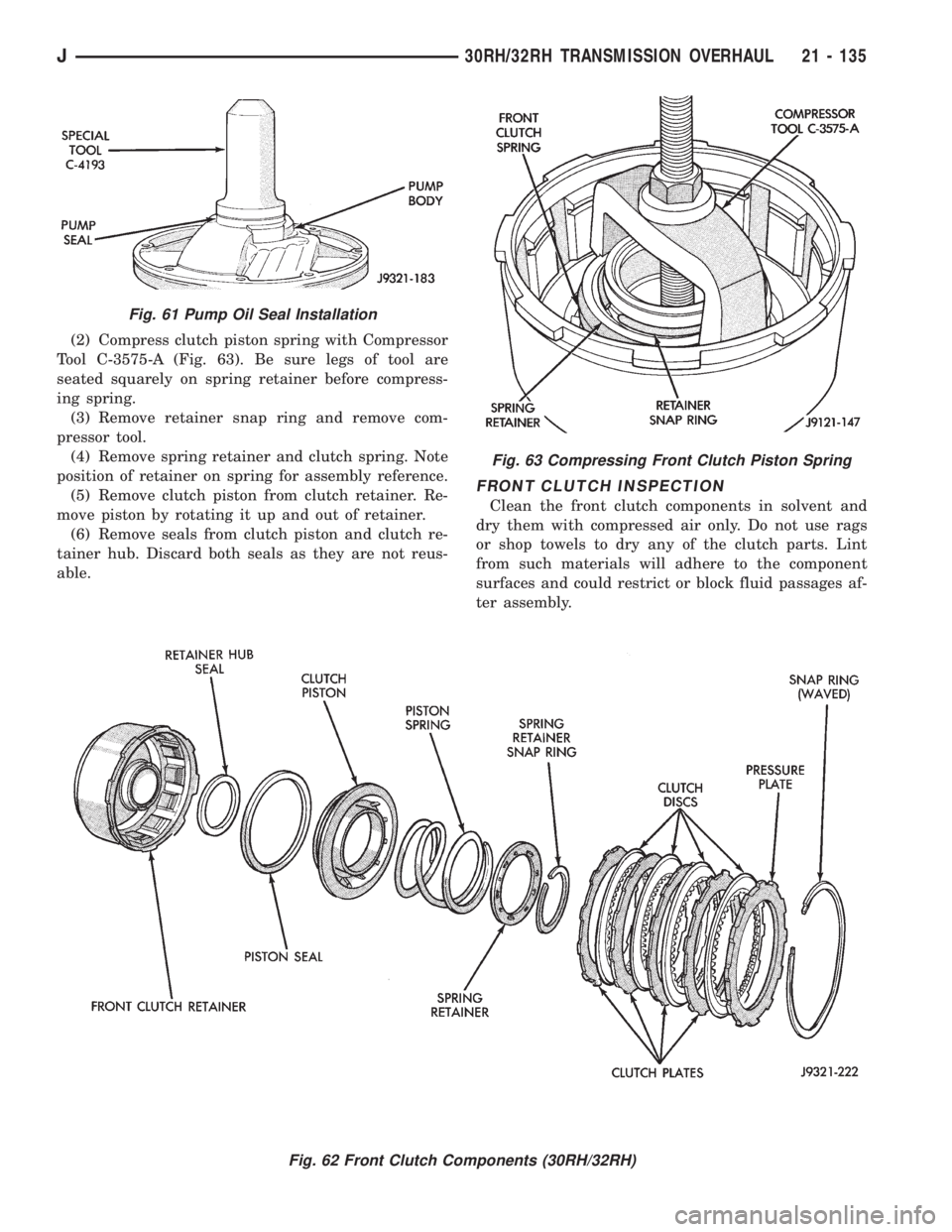

(1) Remove waved snap ring and remove pressure

plate, clutch plates and clutch discs (Fig. 62).

Fig. 57 Supporting Pump And Installing Outer Gear

Fig. 58 Pump Inner Gear Installation

Fig. 59 Hub Seal Ring Position

Fig. 60 Assembling Reaction Shaft Support And

Pump Housing

21 - 134 30RH/32RH TRANSMISSION OVERHAULJ

Page 1512 of 2198

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 63). Be sure legs of tool are

seated squarely on spring retainer before compress-

ing spring.

(3) Remove retainer snap ring and remove com-

pressor tool.

(4) Remove spring retainer and clutch spring. Note

position of retainer on spring for assembly reference.

(5) Remove clutch piston from clutch retainer. Re-

move piston by rotating it up and out of retainer.

(6) Remove seals from clutch piston and clutch re-

tainer hub. Discard both seals as they are not reus-

able.

FRONT CLUTCH INSPECTION

Clean the front clutch components in solvent and

dry them with compressed air only. Do not use rags

or shop towels to dry any of the clutch parts. Lint

from such materials will adhere to the component

surfaces and could restrict or block fluid passages af-

ter assembly.

Fig. 63 Compressing Front Clutch Piston Spring

Fig. 62 Front Clutch Components (30RH/32RH)

Fig. 61 Pump Oil Seal Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 135

Page 1513 of 2198

Replace the clutch discs if warped, worn, scored,

burned or charred, or if the facing is flaking off. Re-

place the steel plates if heavily scored, warped, or

broken. Be sure the driving lugs on the plates are in

good condition. The lugs must not be bent, cracked or

damaged in any way.

Replace the clutch spring and spring retainer if ei-

ther is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

steel plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged.

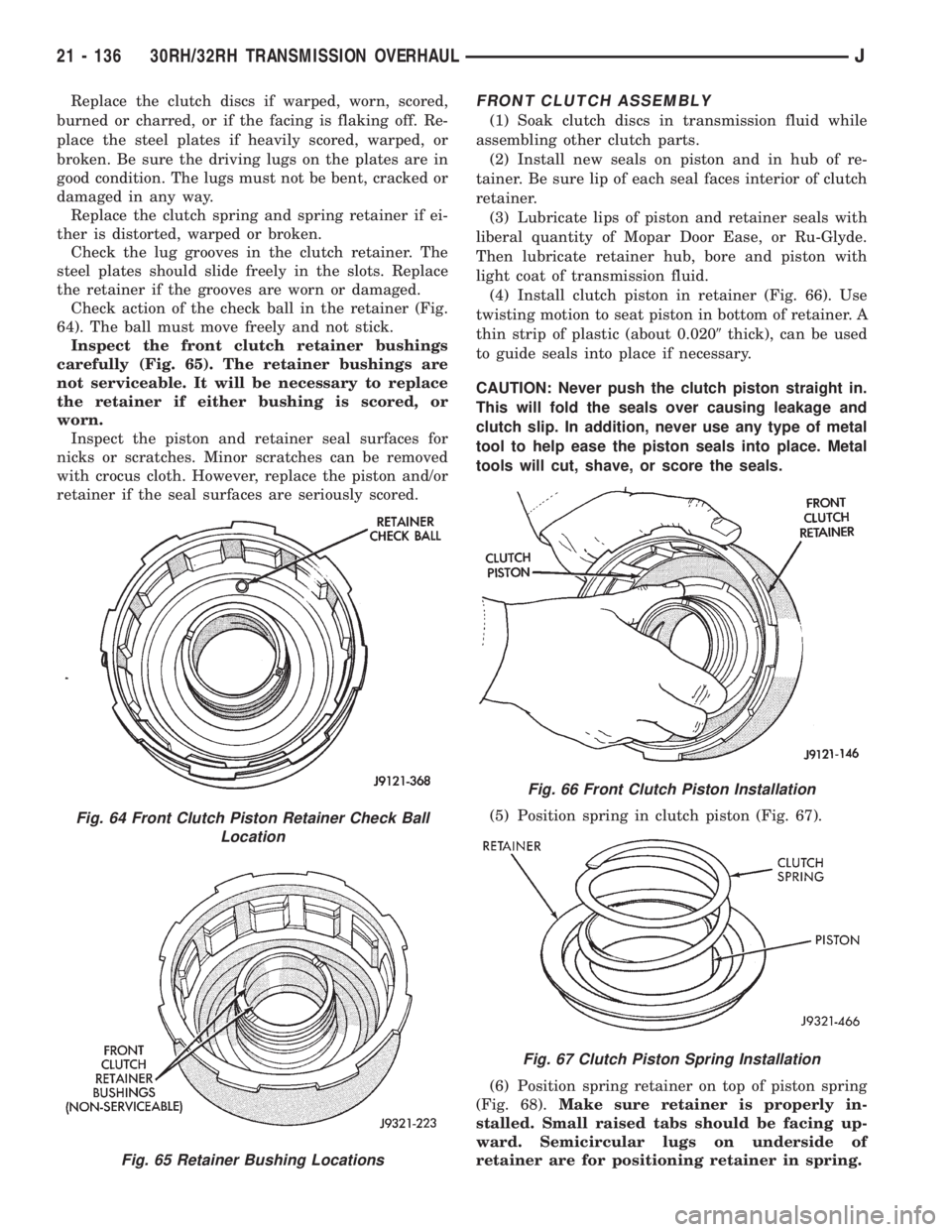

Check action of the check ball in the retainer (Fig.

64). The ball must move freely and not stick.

Inspect the front clutch retainer bushings

carefully (Fig. 65). The retainer bushings are

not serviceable. It will be necessary to replace

the retainer if either bushing is scored, or

worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.FRONT CLUTCH ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals on piston and in hub of re-

tainer. Be sure lip of each seal faces interior of clutch

retainer.

(3) Lubricate lips of piston and retainer seals with

liberal quantity of Mopar Door Ease, or Ru-Glyde.

Then lubricate retainer hub, bore and piston with

light coat of transmission fluid.

(4) Install clutch piston in retainer (Fig. 66). Use

twisting motion to seat piston in bottom of retainer. A

thin strip of plastic (about 0.0209thick), can be used

to guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(5) Position spring in clutch piston (Fig. 67).

(6) Position spring retainer on top of piston spring

(Fig. 68).Make sure retainer is properly in-

stalled. Small raised tabs should be facing up-

ward. Semicircular lugs on underside of

retainer are for positioning retainer in spring.

Fig. 64 Front Clutch Piston Retainer Check Ball

Location

Fig. 65 Retainer Bushing Locations

Fig. 66 Front Clutch Piston Installation

Fig. 67 Clutch Piston Spring Installation

21 - 136 30RH/32RH TRANSMISSION OVERHAULJ

Page 1514 of 2198

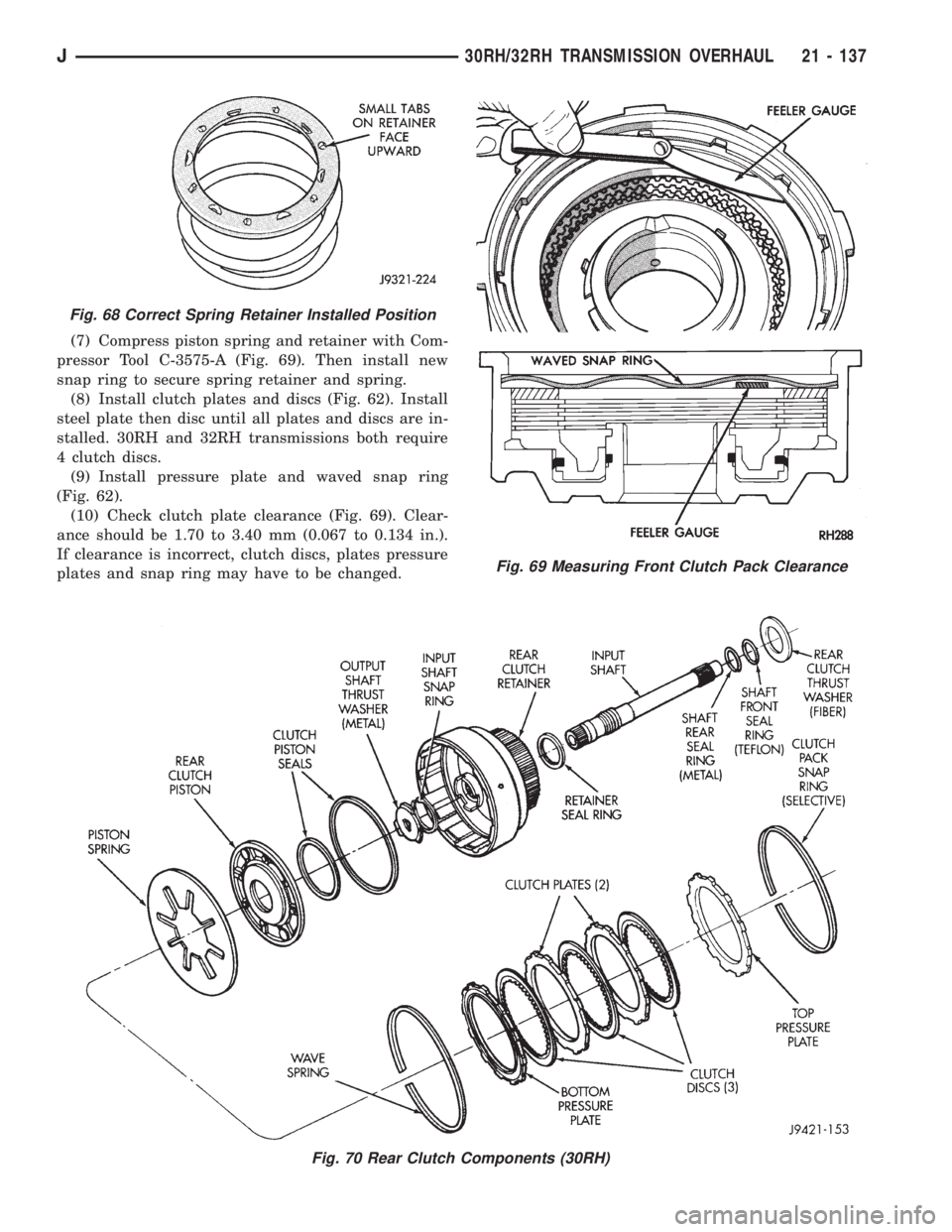

(7) Compress piston spring and retainer with Com-

pressor Tool C-3575-A (Fig. 69). Then install new

snap ring to secure spring retainer and spring.

(8) Install clutch plates and discs (Fig. 62). Install

steel plate then disc until all plates and discs are in-

stalled. 30RH and 32RH transmissions both require

4 clutch discs.

(9) Install pressure plate and waved snap ring

(Fig. 62).

(10) Check clutch plate clearance (Fig. 69). Clear-

ance should be 1.70 to 3.40 mm (0.067 to 0.134 in.).

If clearance is incorrect, clutch discs, plates pressure

plates and snap ring may have to be changed.

Fig. 70 Rear Clutch Components (30RH)

Fig. 68 Correct Spring Retainer Installed Position

Fig. 69 Measuring Front Clutch Pack Clearance

J30RH/32RH TRANSMISSION OVERHAUL 21 - 137

Page 1515 of 2198

REAR CLUTCH OVERHAUL

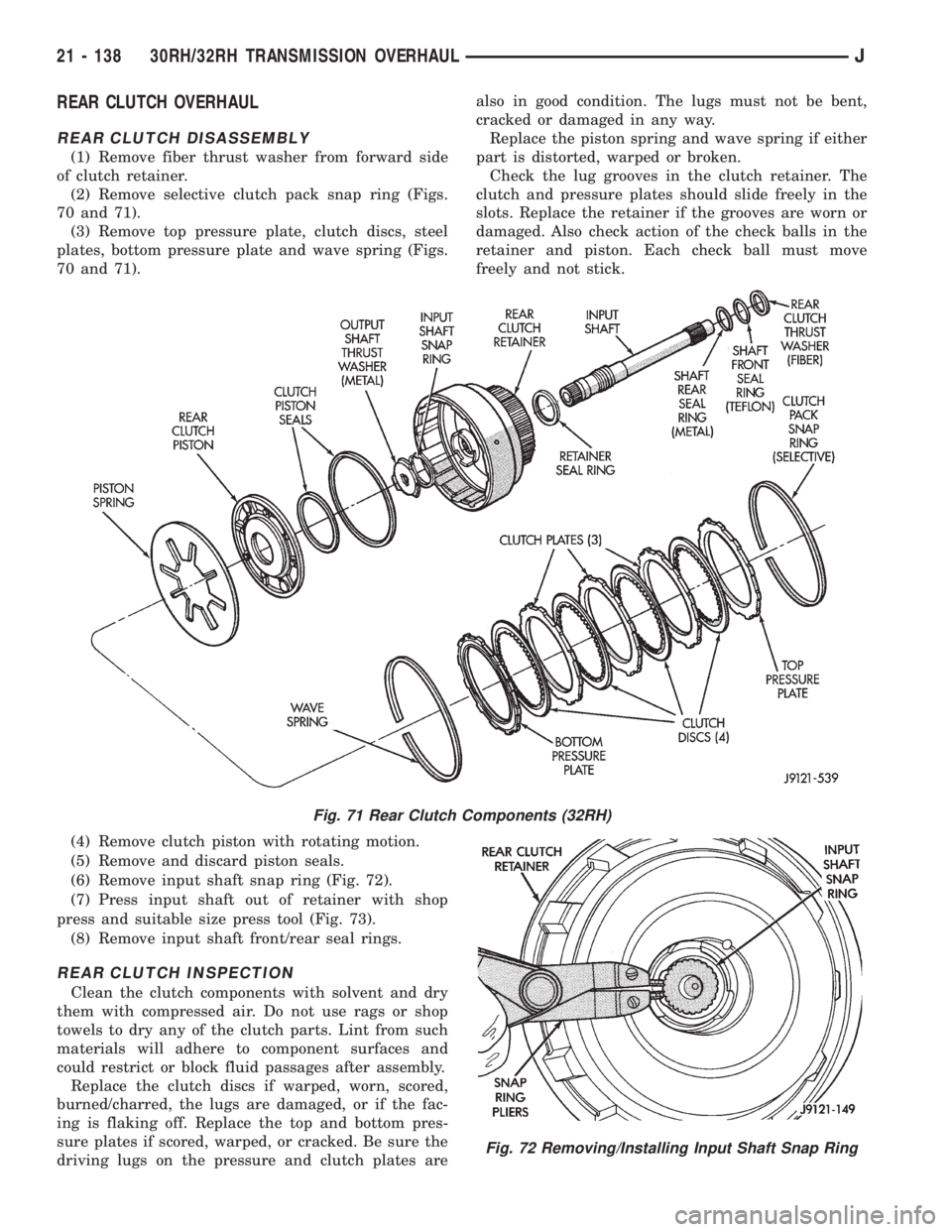

REAR CLUTCH DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove selective clutch pack snap ring (Figs.

70 and 71).

(3) Remove top pressure plate, clutch discs, steel

plates, bottom pressure plate and wave spring (Figs.

70 and 71).

(4) Remove clutch piston with rotating motion.

(5) Remove and discard piston seals.

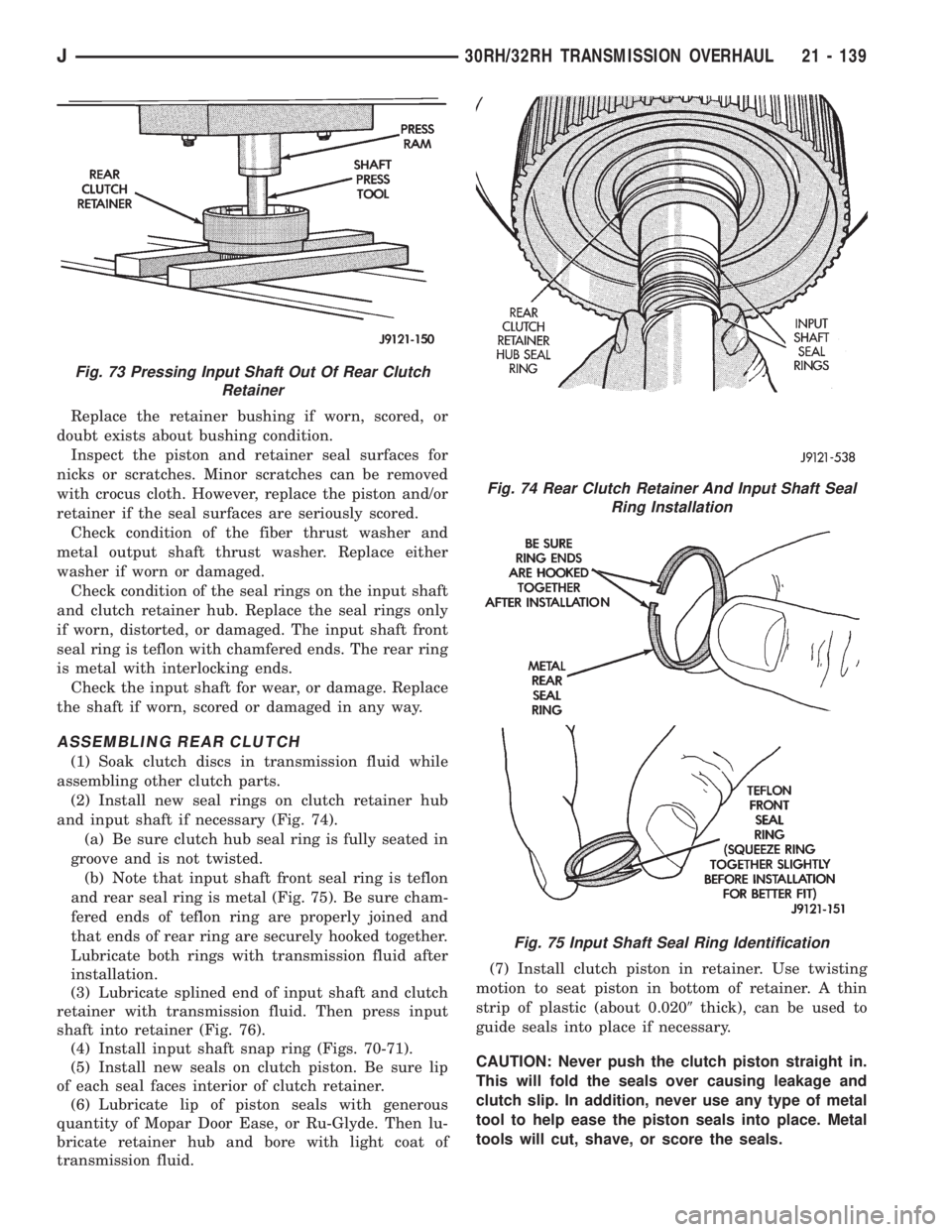

(6) Remove input shaft snap ring (Fig. 72).

(7) Press input shaft out of retainer with shop

press and suitable size press tool (Fig. 73).

(8) Remove input shaft front/rear seal rings.

REAR CLUTCH INSPECTION

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates arealso in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Fig. 71 Rear Clutch Components (32RH)

Fig. 72 Removing/Installing Input Shaft Snap Ring

21 - 138 30RH/32RH TRANSMISSION OVERHAULJ

Page 1516 of 2198

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLING REAR CLUTCH

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary (Fig. 74).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(b) Note that input shaft front seal ring is teflon

and rear seal ring is metal (Fig. 75). Be sure cham-

fered ends of teflon ring are properly joined and

that ends of rear ring are securely hooked together.

Lubricate both rings with transmission fluid after

installation.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 76).

(4) Install input shaft snap ring (Figs. 70-71).

(5) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(6) Lubricate lip of piston seals with generous

quantity of Mopar Door Ease, or Ru-Glyde. Then lu-

bricate retainer hub and bore with light coat of

transmission fluid.(7) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

Fig. 73 Pressing Input Shaft Out Of Rear Clutch

Retainer

Fig. 74 Rear Clutch Retainer And Input Shaft Seal

Ring Installation

Fig. 75 Input Shaft Seal Ring Identification

J30RH/32RH TRANSMISSION OVERHAUL 21 - 139

Page 1517 of 2198

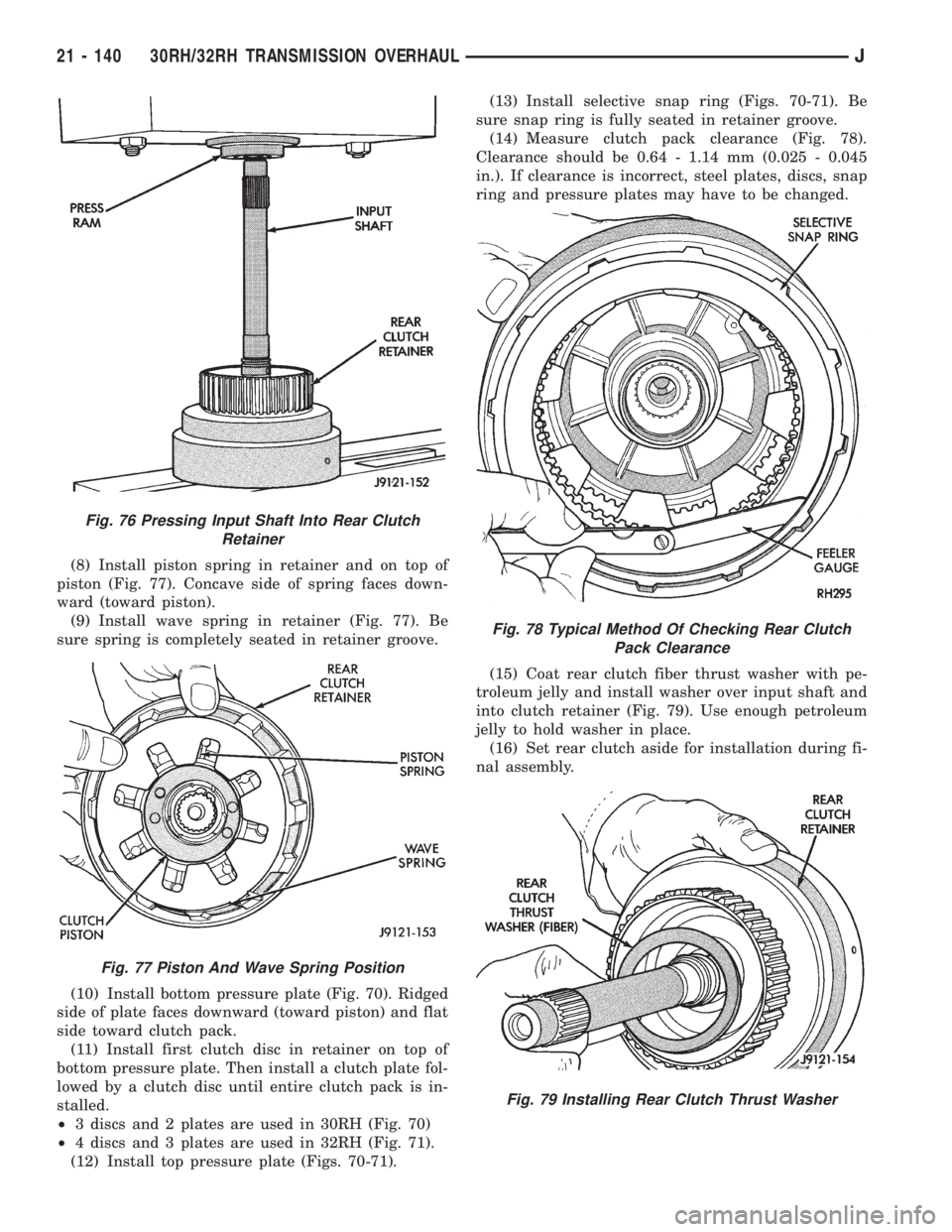

(8) Install piston spring in retainer and on top of

piston (Fig. 77). Concave side of spring faces down-

ward (toward piston).

(9) Install wave spring in retainer (Fig. 77). Be

sure spring is completely seated in retainer groove.

(10) Install bottom pressure plate (Fig. 70). Ridged

side of plate faces downward (toward piston) and flat

side toward clutch pack.

(11) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is in-

stalled.

²3 discs and 2 plates are used in 30RH (Fig. 70)

²4 discs and 3 plates are used in 32RH (Fig. 71).

(12) Install top pressure plate (Figs. 70-71).(13) Install selective snap ring (Figs. 70-71). Be

sure snap ring is fully seated in retainer groove.

(14) Measure clutch pack clearance (Fig. 78).

Clearance should be 0.64 - 1.14 mm (0.025 - 0.045

in.). If clearance is incorrect, steel plates, discs, snap

ring and pressure plates may have to be changed.

(15) Coat rear clutch fiber thrust washer with pe-

troleum jelly and install washer over input shaft and

into clutch retainer (Fig. 79). Use enough petroleum

jelly to hold washer in place.

(16) Set rear clutch aside for installation during fi-

nal assembly.

Fig. 76 Pressing Input Shaft Into Rear Clutch

Retainer

Fig. 77 Piston And Wave Spring Position

Fig. 78 Typical Method Of Checking Rear Clutch

Pack Clearance

Fig. 79 Installing Rear Clutch Thrust Washer

21 - 140 30RH/32RH TRANSMISSION OVERHAULJ

Page 1518 of 2198

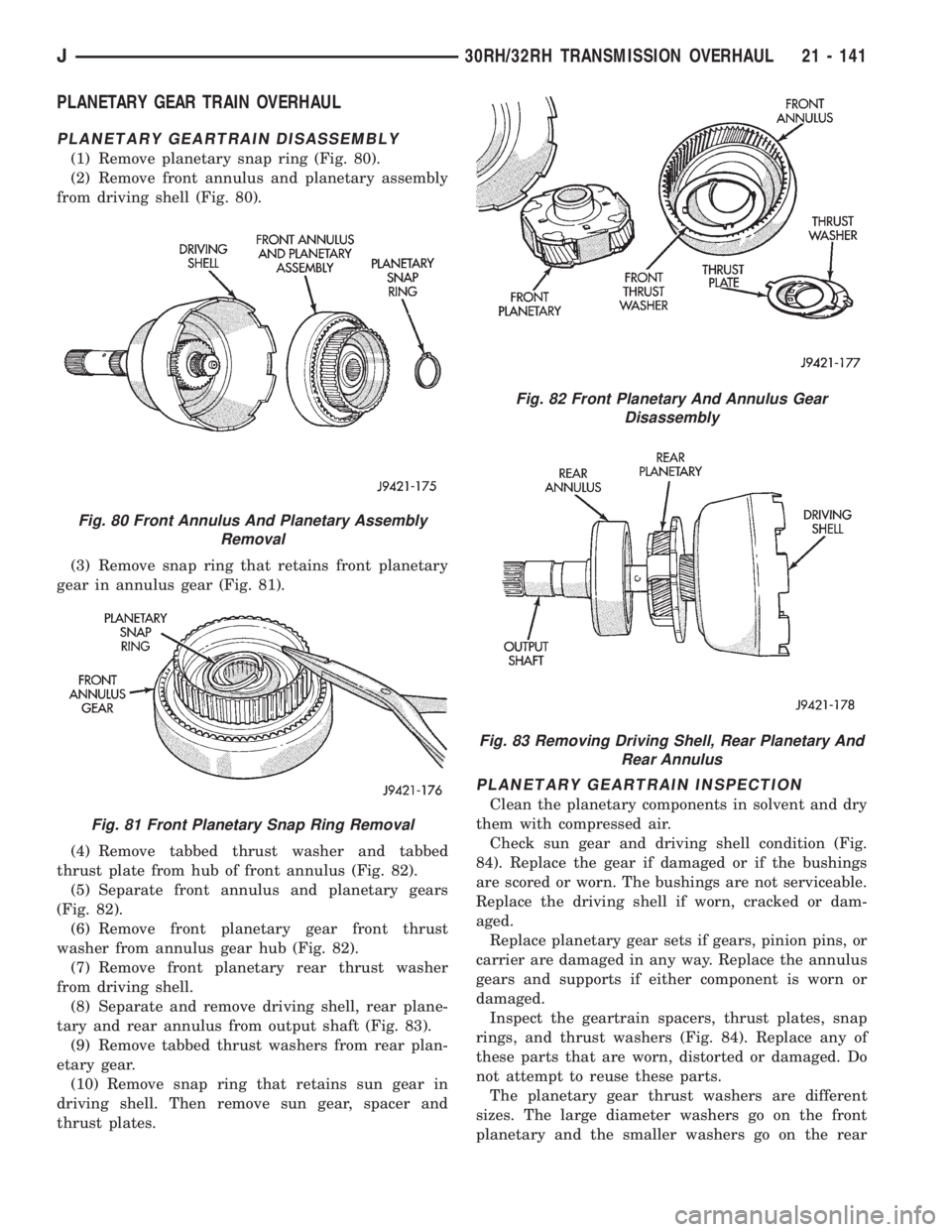

PLANETARY GEAR TRAIN OVERHAUL

PLANETARY GEARTRAIN DISASSEMBLY

(1) Remove planetary snap ring (Fig. 80).

(2) Remove front annulus and planetary assembly

from driving shell (Fig. 80).

(3) Remove snap ring that retains front planetary

gear in annulus gear (Fig. 81).

(4) Remove tabbed thrust washer and tabbed

thrust plate from hub of front annulus (Fig. 82).

(5) Separate front annulus and planetary gears

(Fig. 82).

(6) Remove front planetary gear front thrust

washer from annulus gear hub (Fig. 82).

(7) Remove front planetary rear thrust washer

from driving shell.

(8) Separate and remove driving shell, rear plane-

tary and rear annulus from output shaft (Fig. 83).

(9) Remove tabbed thrust washers from rear plan-

etary gear.

(10) Remove snap ring that retains sun gear in

driving shell. Then remove sun gear, spacer and

thrust plates.

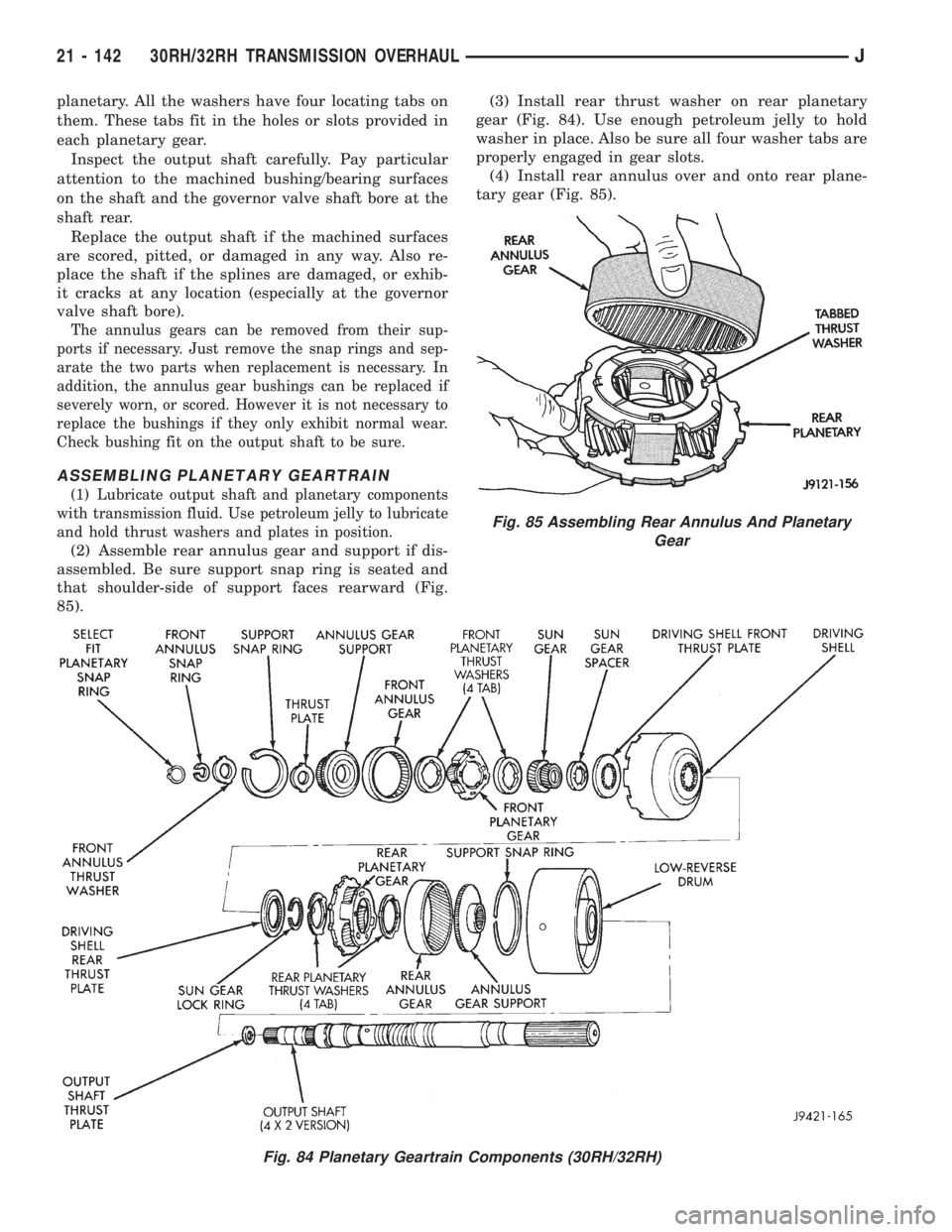

PLANETARY GEARTRAIN INSPECTION

Clean the planetary components in solvent and dry

them with compressed air.

Check sun gear and driving shell condition (Fig.

84). Replace the gear if damaged or if the bushings

are scored or worn. The bushings are not serviceable.

Replace the driving shell if worn, cracked or dam-

aged.

Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annulus

gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap

rings, and thrust washers (Fig. 84). Replace any of

these parts that are worn, distorted or damaged. Do

not attempt to reuse these parts.

The planetary gear thrust washers are different

sizes. The large diameter washers go on the front

planetary and the smaller washers go on the rear

Fig. 80 Front Annulus And Planetary Assembly

Removal

Fig. 81 Front Planetary Snap Ring Removal

Fig. 82 Front Planetary And Annulus Gear

Disassembly

Fig. 83 Removing Driving Shell, Rear Planetary And

Rear Annulus

J30RH/32RH TRANSMISSION OVERHAUL 21 - 141

Page 1519 of 2198

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also re-

place the shaft if the splines are damaged, or exhib-

it cracks at any location (especially at the governor

valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap rings and sep-

arate the two parts when replacement is necessary. In

addition, the annulus gear bushings can be replaced if

severely worn, or scored. However it is not necessary to

replace the bushings if they only exhibit normal wear.

Check bushing fit on the output shaft to be sure.

ASSEMBLING PLANETARY GEARTRAIN

(1) Lubricate output shaft and planetary components

with transmission fluid. Use petroleum jelly to lubricate

and hold thrust washers and plates in position.

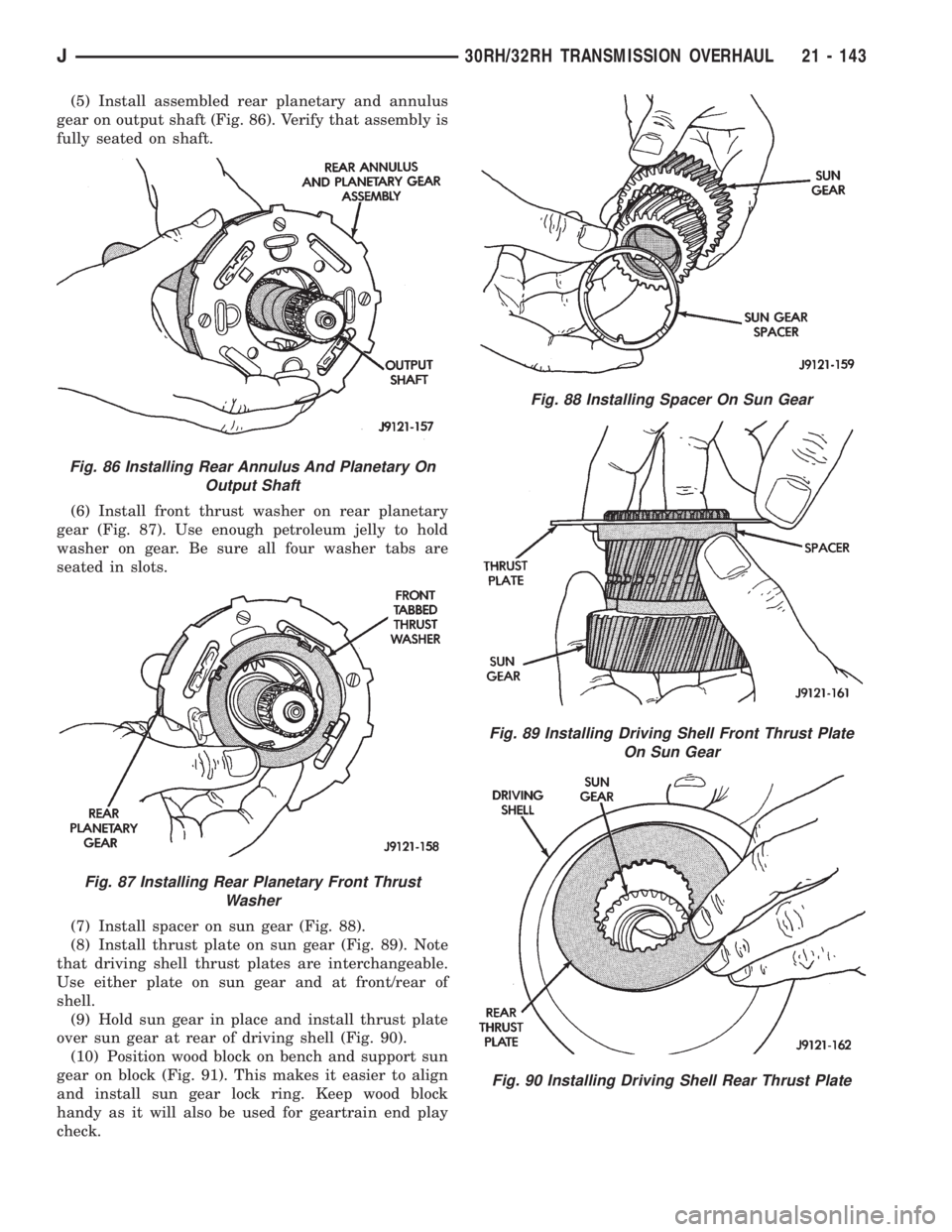

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap ring is seated and

that shoulder-side of support faces rearward (Fig.

85).(3) Install rear thrust washer on rear planetary

gear (Fig. 84). Use enough petroleum jelly to hold

washer in place. Also be sure all four washer tabs are

properly engaged in gear slots.

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 85).

Fig. 84 Planetary Geartrain Components (30RH/32RH)

Fig. 85 Assembling Rear Annulus And Planetary

Gear

21 - 142 30RH/32RH TRANSMISSION OVERHAULJ

Page 1520 of 2198

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 86). Verify that assembly is

fully seated on shaft.

(6) Install front thrust washer on rear planetary

gear (Fig. 87). Use enough petroleum jelly to hold

washer on gear. Be sure all four washer tabs are

seated in slots.

(7) Install spacer on sun gear (Fig. 88).

(8) Install thrust plate on sun gear (Fig. 89). Note

that driving shell thrust plates are interchangeable.

Use either plate on sun gear and at front/rear of

shell.

(9) Hold sun gear in place and install thrust plate

over sun gear at rear of driving shell (Fig. 90).

(10) Position wood block on bench and support sun

gear on block (Fig. 91). This makes it easier to align

and install sun gear lock ring. Keep wood block

handy as it will also be used for geartrain end play

check.

Fig. 86 Installing Rear Annulus And Planetary On

Output Shaft

Fig. 87 Installing Rear Planetary Front Thrust

Washer

Fig. 88 Installing Spacer On Sun Gear

Fig. 89 Installing Driving Shell Front Thrust Plate

On Sun Gear

Fig. 90 Installing Driving Shell Rear Thrust Plate

J30RH/32RH TRANSMISSION OVERHAUL 21 - 143