JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1481 of 2198

on transmission. Tighten pan bolts to 17 Nzm (150 in.

lbs.) torque.

(7) Lower vehicle.

(8) Refill transmission with Mopar ATF Plus.

VALVE BODY REMOVAL

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Disconnect gearshift and throttle linkage at

transmission levers.

(4) Loosen clamp bolts and remove throttle and

manual valve levers from manual valve shaft.

(5) Disconnect park/neutral position switch wires

and remove switch and switch seal.

(6) Remove valve body oil filter.

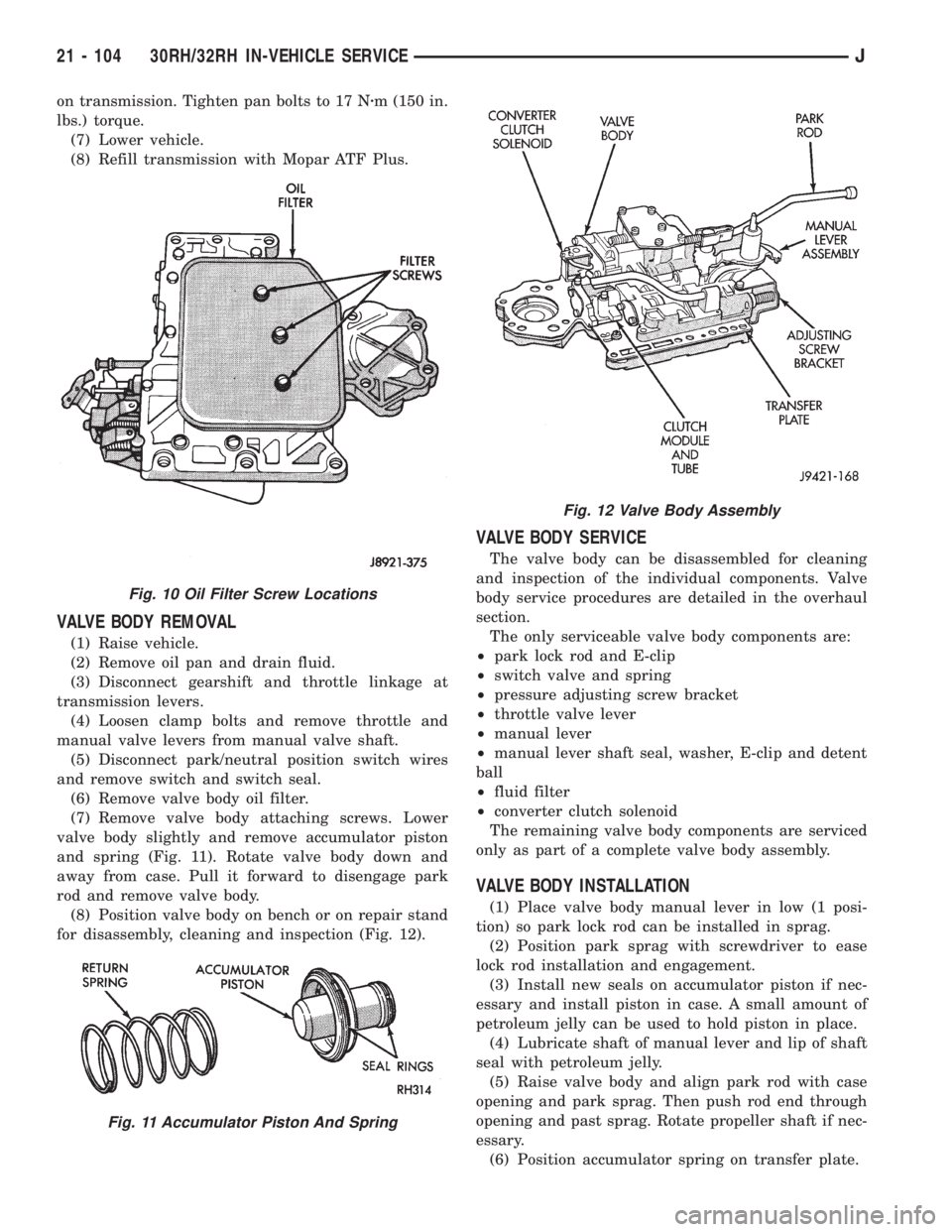

(7) Remove valve body attaching screws. Lower

valve body slightly and remove accumulator piston

and spring (Fig. 11). Rotate valve body down and

away from case. Pull it forward to disengage park

rod and remove valve body.

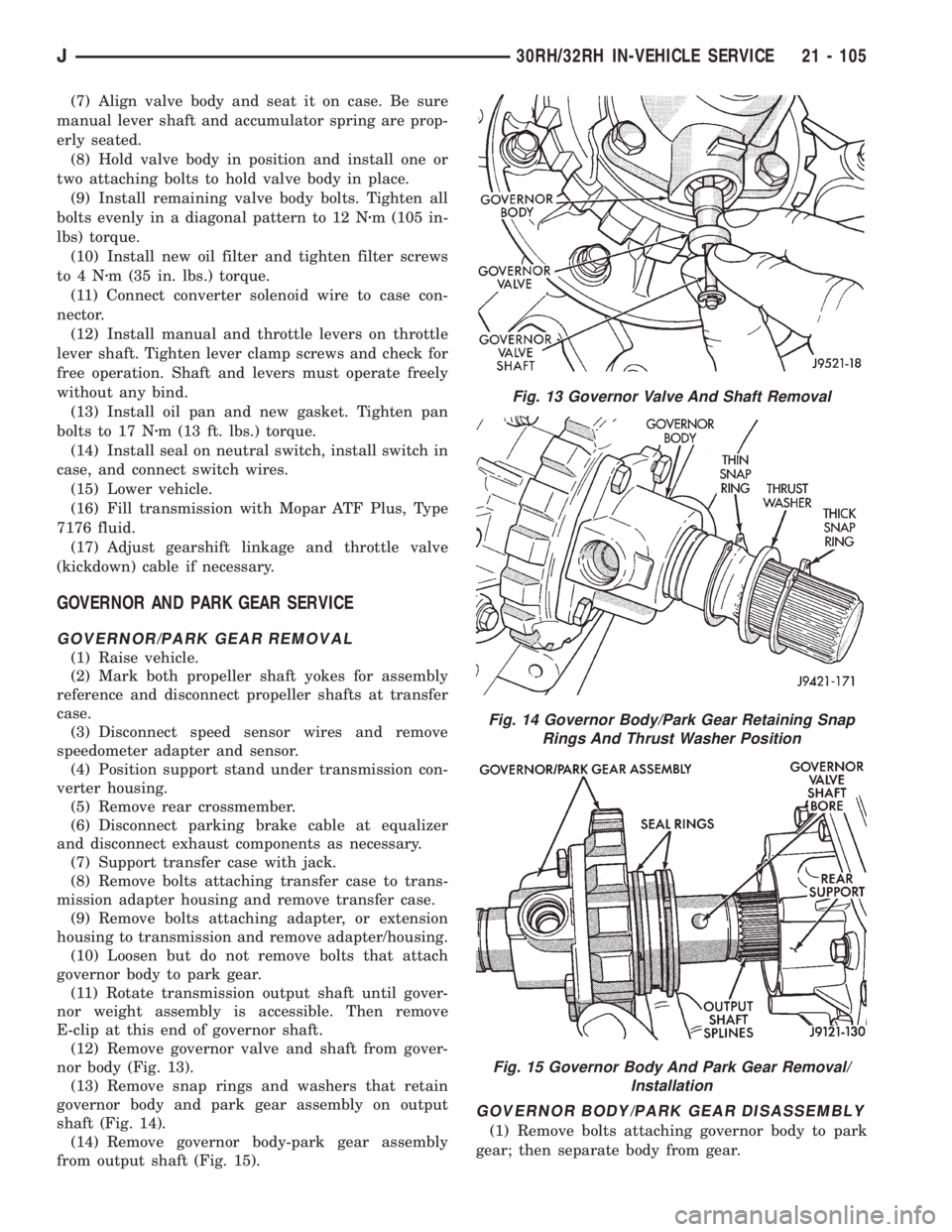

(8) Position valve body on bench or on repair stand

for disassembly, cleaning and inspection (Fig. 12).

VALVE BODY SERVICE

The valve body can be disassembled for cleaning

and inspection of the individual components. Valve

body service procedures are detailed in the overhaul

section.

The only serviceable valve body components are:

²park lock rod and E-clip

²switch valve and spring

²pressure adjusting screw bracket

²throttle valve lever

²manual lever

²manual lever shaft seal, washer, E-clip and detent

ball

²fluid filter

²converter clutch solenoid

The remaining valve body components are serviced

only as part of a complete valve body assembly.

VALVE BODY INSTALLATION

(1) Place valve body manual lever in low (1 posi-

tion) so park lock rod can be installed in sprag.

(2) Position park sprag with screwdriver to ease

lock rod installation and engagement.

(3) Install new seals on accumulator piston if nec-

essary and install piston in case. A small amount of

petroleum jelly can be used to hold piston in place.

(4) Lubricate shaft of manual lever and lip of shaft

seal with petroleum jelly.

(5) Raise valve body and align park rod with case

opening and park sprag. Then push rod end through

opening and past sprag. Rotate propeller shaft if nec-

essary.

(6) Position accumulator spring on transfer plate.

Fig. 10 Oil Filter Screw Locations

Fig. 11 Accumulator Piston And Spring

Fig. 12 Valve Body Assembly

21 - 104 30RH/32RH IN-VEHICLE SERVICEJ

Page 1482 of 2198

(7) Align valve body and seat it on case. Be sure

manual lever shaft and accumulator spring are prop-

erly seated.

(8) Hold valve body in position and install one or

two attaching bolts to hold valve body in place.

(9) Install remaining valve body bolts. Tighten all

bolts evenly in a diagonal pattern to 12 Nzm (105 in-

lbs) torque.

(10) Install new oil filter and tighten filter screws

to4Nzm (35 in. lbs.) torque.

(11) Connect converter solenoid wire to case con-

nector.

(12) Install manual and throttle levers on throttle

lever shaft. Tighten lever clamp screws and check for

free operation. Shaft and levers must operate freely

without any bind.

(13) Install oil pan and new gasket. Tighten pan

bolts to 17 Nzm (13 ft. lbs.) torque.

(14) Install seal on neutral switch, install switch in

case, and connect switch wires.

(15) Lower vehicle.

(16) Fill transmission with Mopar ATF Plus, Type

7176 fluid.

(17) Adjust gearshift linkage and throttle valve

(kickdown) cable if necessary.

GOVERNOR AND PARK GEAR SERVICE

GOVERNOR/PARK GEAR REMOVAL

(1) Raise vehicle.

(2) Mark both propeller shaft yokes for assembly

reference and disconnect propeller shafts at transfer

case.

(3) Disconnect speed sensor wires and remove

speedometer adapter and sensor.

(4) Position support stand under transmission con-

verter housing.

(5) Remove rear crossmember.

(6) Disconnect parking brake cable at equalizer

and disconnect exhaust components as necessary.

(7) Support transfer case with jack.

(8) Remove bolts attaching transfer case to trans-

mission adapter housing and remove transfer case.

(9) Remove bolts attaching adapter, or extension

housing to transmission and remove adapter/housing.

(10) Loosen but do not remove bolts that attach

governor body to park gear.

(11) Rotate transmission output shaft until gover-

nor weight assembly is accessible. Then remove

E-clip at this end of governor shaft.

(12) Remove governor valve and shaft from gover-

nor body (Fig. 13).

(13) Remove snap rings and washers that retain

governor body and park gear assembly on output

shaft (Fig. 14).

(14) Remove governor body-park gear assembly

from output shaft (Fig. 15).

GOVERNOR BODY/PARK GEAR DISASSEMBLY

(1) Remove bolts attaching governor body to park

gear; then separate body from gear.

Fig. 13 Governor Valve And Shaft Removal

Fig. 14 Governor Body/Park Gear Retaining Snap

Rings And Thrust Washer Position

Fig. 15 Governor Body And Park Gear Removal/

Installation

J30RH/32RH IN-VEHICLE SERVICE 21 - 105

Page 1483 of 2198

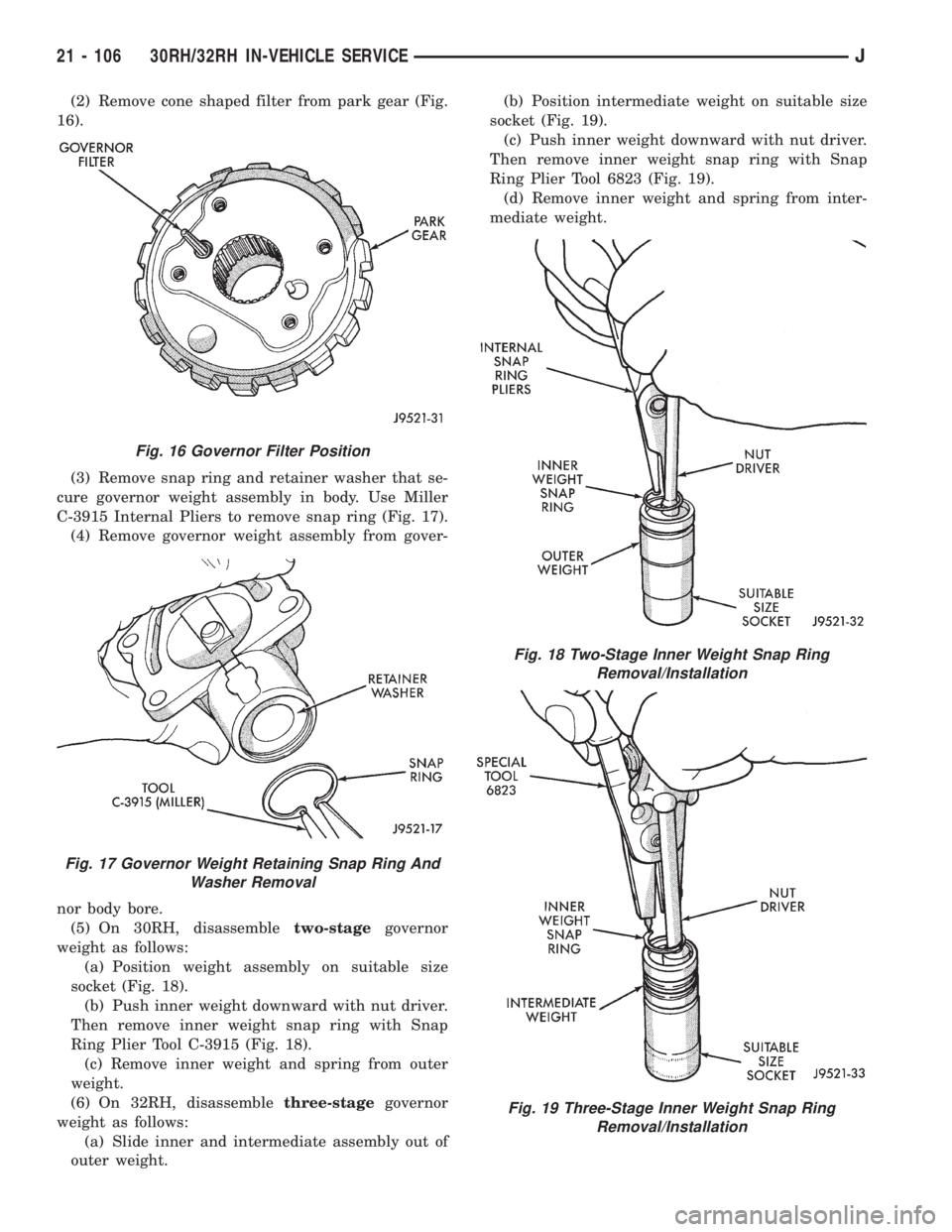

(2) Remove cone shaped filter from park gear (Fig.

16).

(3) Remove snap ring and retainer washer that se-

cure governor weight assembly in body. Use Miller

C-3915 Internal Pliers to remove snap ring (Fig. 17).

(4) Remove governor weight assembly from gover-

nor body bore.

(5) On 30RH, disassembletwo-stagegovernor

weight as follows:

(a) Position weight assembly on suitable size

socket (Fig. 18).

(b) Push inner weight downward with nut driver.

Then remove inner weight snap ring with Snap

Ring Plier Tool C-3915 (Fig. 18).

(c) Remove inner weight and spring from outer

weight.

(6) On 32RH, disassemblethree-stagegovernor

weight as follows:

(a) Slide inner and intermediate assembly out of

outer weight.(b) Position intermediate weight on suitable size

socket (Fig. 19).

(c) Push inner weight downward with nut driver.

Then remove inner weight snap ring with Snap

Ring Plier Tool 6823 (Fig. 19).

(d) Remove inner weight and spring from inter-

mediate weight.

Fig. 16 Governor Filter Position

Fig. 17 Governor Weight Retaining Snap Ring And

Washer Removal

Fig. 18 Two-Stage Inner Weight Snap Ring

Removal/Installation

Fig. 19 Three-Stage Inner Weight Snap Ring

Removal/Installation

21 - 106 30RH/32RH IN-VEHICLE SERVICEJ

Page 1484 of 2198

Governor/Park Gear Cleaning and Inspection

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

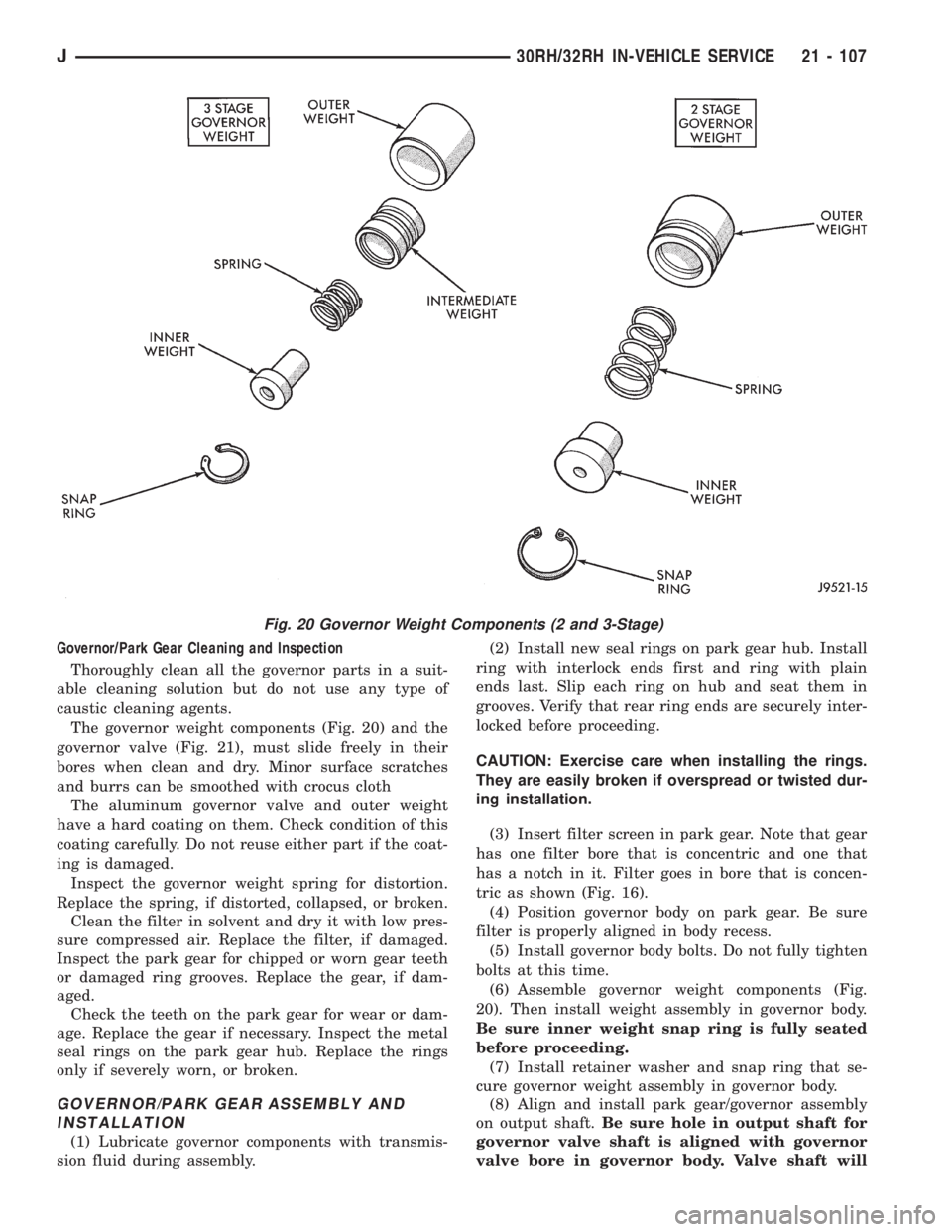

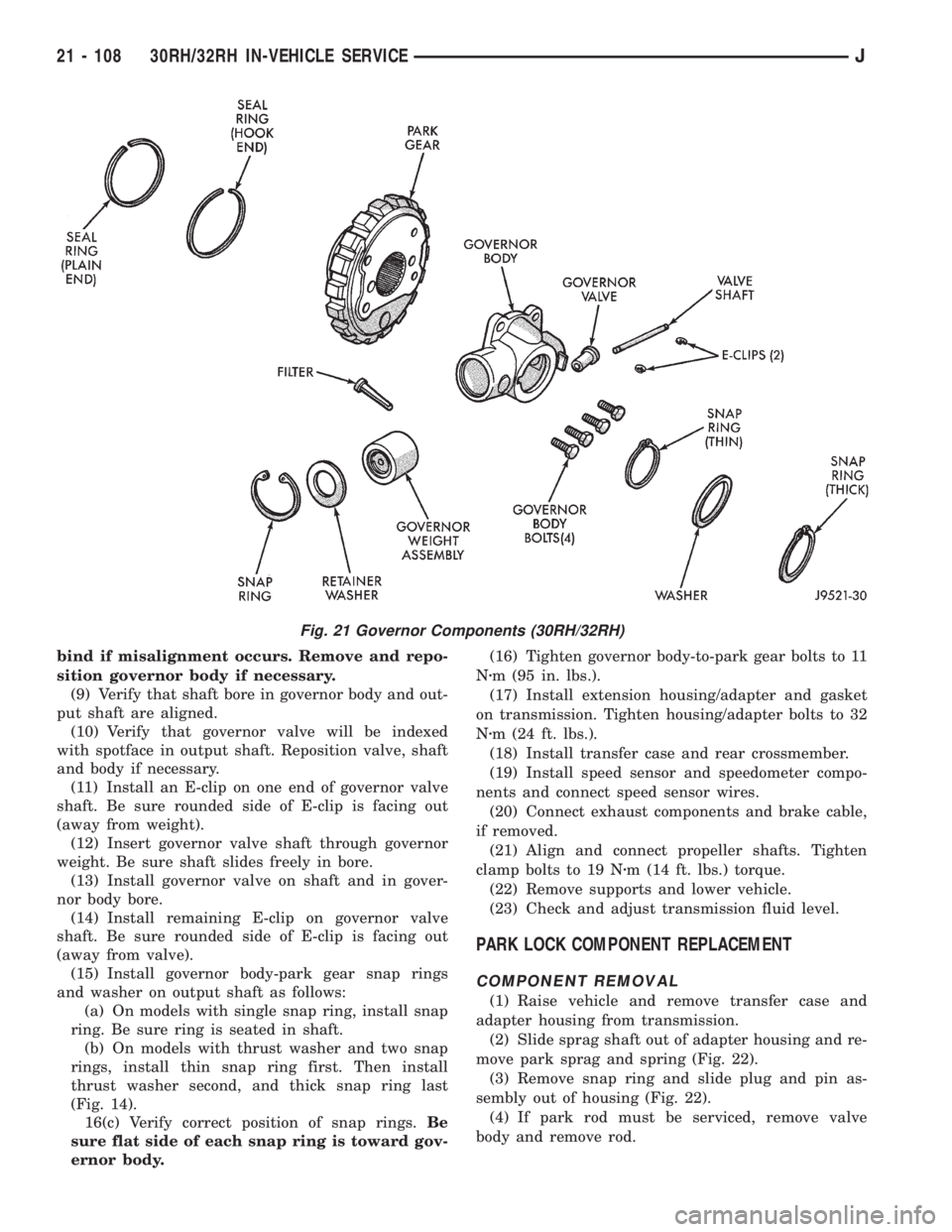

The governor weight components (Fig. 20) and the

governor valve (Fig. 21), must slide freely in their

bores when clean and dry. Minor surface scratches

and burrs can be smoothed with crocus cloth

The aluminum governor valve and outer weight

have a hard coating on them. Check condition of this

coating carefully. Do not reuse either part if the coat-

ing is damaged.

Inspect the governor weight spring for distortion.

Replace the spring, if distorted, collapsed, or broken.

Clean the filter in solvent and dry it with low pres-

sure compressed air. Replace the filter, if damaged.

Inspect the park gear for chipped or worn gear teeth

or damaged ring grooves. Replace the gear, if dam-

aged.

Check the teeth on the park gear for wear or dam-

age. Replace the gear if necessary. Inspect the metal

seal rings on the park gear hub. Replace the rings

only if severely worn, or broken.

GOVERNOR/PARK GEAR ASSEMBLY AND

INSTALLATION

(1) Lubricate governor components with transmis-

sion fluid during assembly.(2) Install new seal rings on park gear hub. Install

ring with interlock ends first and ring with plain

ends last. Slip each ring on hub and seat them in

grooves. Verify that rear ring ends are securely inter-

locked before proceeding.

CAUTION: Exercise care when installing the rings.

They are easily broken if overspread or twisted dur-

ing installation.

(3) Insert filter screen in park gear. Note that gear

has one filter bore that is concentric and one that

has a notch in it. Filter goes in bore that is concen-

tric as shown (Fig. 16).

(4) Position governor body on park gear. Be sure

filter is properly aligned in body recess.

(5) Install governor body bolts. Do not fully tighten

bolts at this time.

(6) Assemble governor weight components (Fig.

20). Then install weight assembly in governor body.

Be sure inner weight snap ring is fully seated

before proceeding.

(7) Install retainer washer and snap ring that se-

cure governor weight assembly in governor body.

(8) Align and install park gear/governor assembly

on output shaft.Be sure hole in output shaft for

governor valve shaft is aligned with governor

valve bore in governor body. Valve shaft will

Fig. 20 Governor Weight Components (2 and 3-Stage)

J30RH/32RH IN-VEHICLE SERVICE 21 - 107

Page 1485 of 2198

bind if misalignment occurs. Remove and repo-

sition governor body if necessary.

(9) Verify that shaft bore in governor body and out-

put shaft are aligned.

(10) Verify that governor valve will be indexed

with spotface in output shaft. Reposition valve, shaft

and body if necessary.

(11) Install an E-clip on one end of governor valve

shaft. Be sure rounded side of E-clip is facing out

(away from weight).

(12) Insert governor valve shaft through governor

weight. Be sure shaft slides freely in bore.

(13) Install governor valve on shaft and in gover-

nor body bore.

(14) Install remaining E-clip on governor valve

shaft. Be sure rounded side of E-clip is facing out

(away from valve).

(15) Install governor body-park gear snap rings

and washer on output shaft as follows:

(a) On models with single snap ring, install snap

ring. Be sure ring is seated in shaft.

(b) On models with thrust washer and two snap

rings, install thin snap ring first. Then install

thrust washer second, and thick snap ring last

(Fig. 14).

16(c) Verify correct position of snap rings.Be

sure flat side of each snap ring is toward gov-

ernor body.(16) Tighten governor body-to-park gear bolts to 11

Nzm (95 in. lbs.).

(17) Install extension housing/adapter and gasket

on transmission. Tighten housing/adapter bolts to 32

Nzm (24 ft. lbs.).

(18) Install transfer case and rear crossmember.

(19) Install speed sensor and speedometer compo-

nents and connect speed sensor wires.

(20) Connect exhaust components and brake cable,

if removed.

(21) Align and connect propeller shafts. Tighten

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(22) Remove supports and lower vehicle.

(23) Check and adjust transmission fluid level.

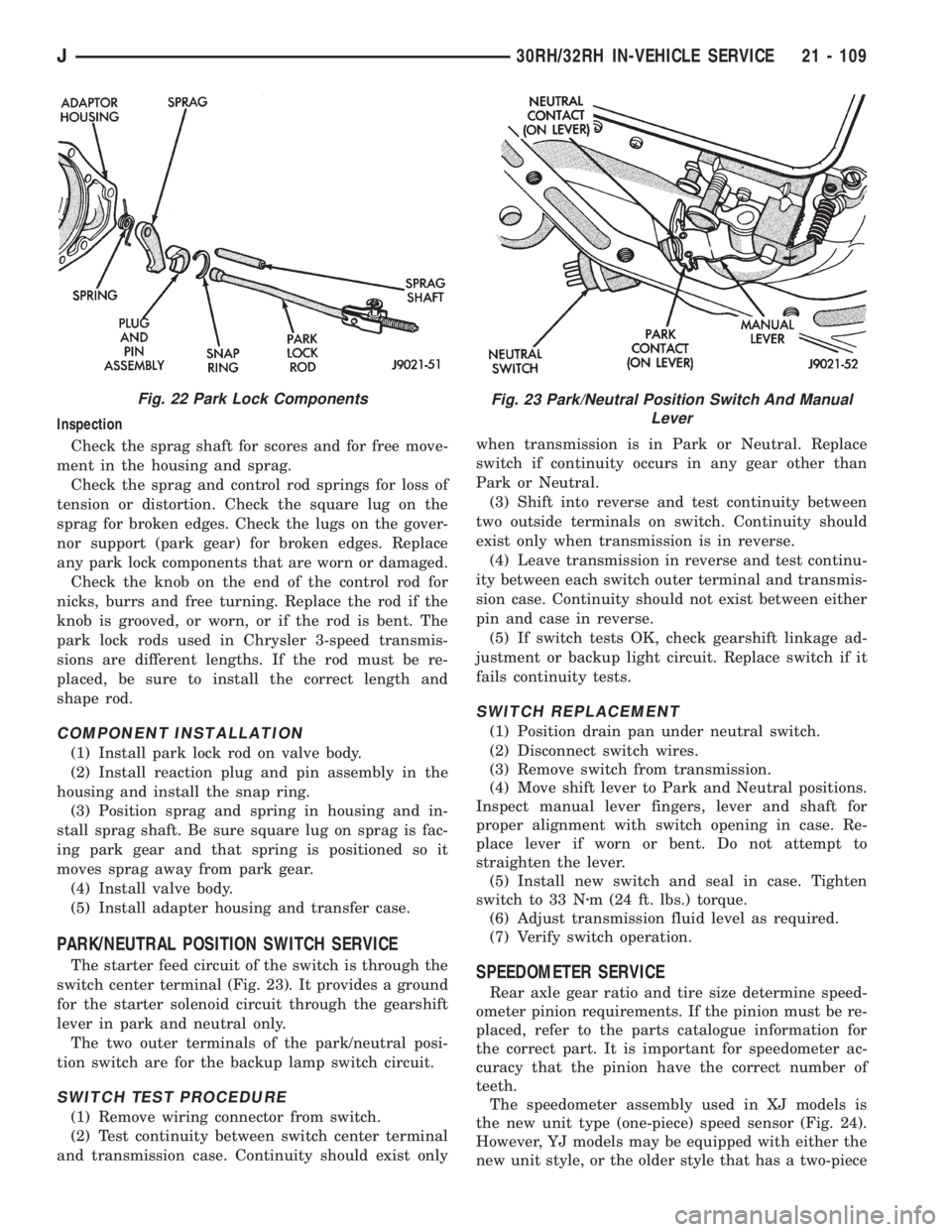

PARK LOCK COMPONENT REPLACEMENT

COMPONENT REMOVAL

(1) Raise vehicle and remove transfer case and

adapter housing from transmission.

(2) Slide sprag shaft out of adapter housing and re-

move park sprag and spring (Fig. 22).

(3) Remove snap ring and slide plug and pin as-

sembly out of housing (Fig. 22).

(4) If park rod must be serviced, remove valve

body and remove rod.

Fig. 21 Governor Components (30RH/32RH)

21 - 108 30RH/32RH IN-VEHICLE SERVICEJ

Page 1486 of 2198

Inspection

Check the sprag shaft for scores and for free move-

ment in the housing and sprag.

Check the sprag and control rod springs for loss of

tension or distortion. Check the square lug on the

sprag for broken edges. Check the lugs on the gover-

nor support (park gear) for broken edges. Replace

any park lock components that are worn or damaged.

Check the knob on the end of the control rod for

nicks, burrs and free turning. Replace the rod if the

knob is grooved, or worn, or if the rod is bent. The

park lock rods used in Chrysler 3-speed transmis-

sions are different lengths. If the rod must be re-

placed, be sure to install the correct length and

shape rod.

COMPONENT INSTALLATION

(1) Install park lock rod on valve body.

(2) Install reaction plug and pin assembly in the

housing and install the snap ring.

(3) Position sprag and spring in housing and in-

stall sprag shaft. Be sure square lug on sprag is fac-

ing park gear and that spring is positioned so it

moves sprag away from park gear.

(4) Install valve body.

(5) Install adapter housing and transfer case.

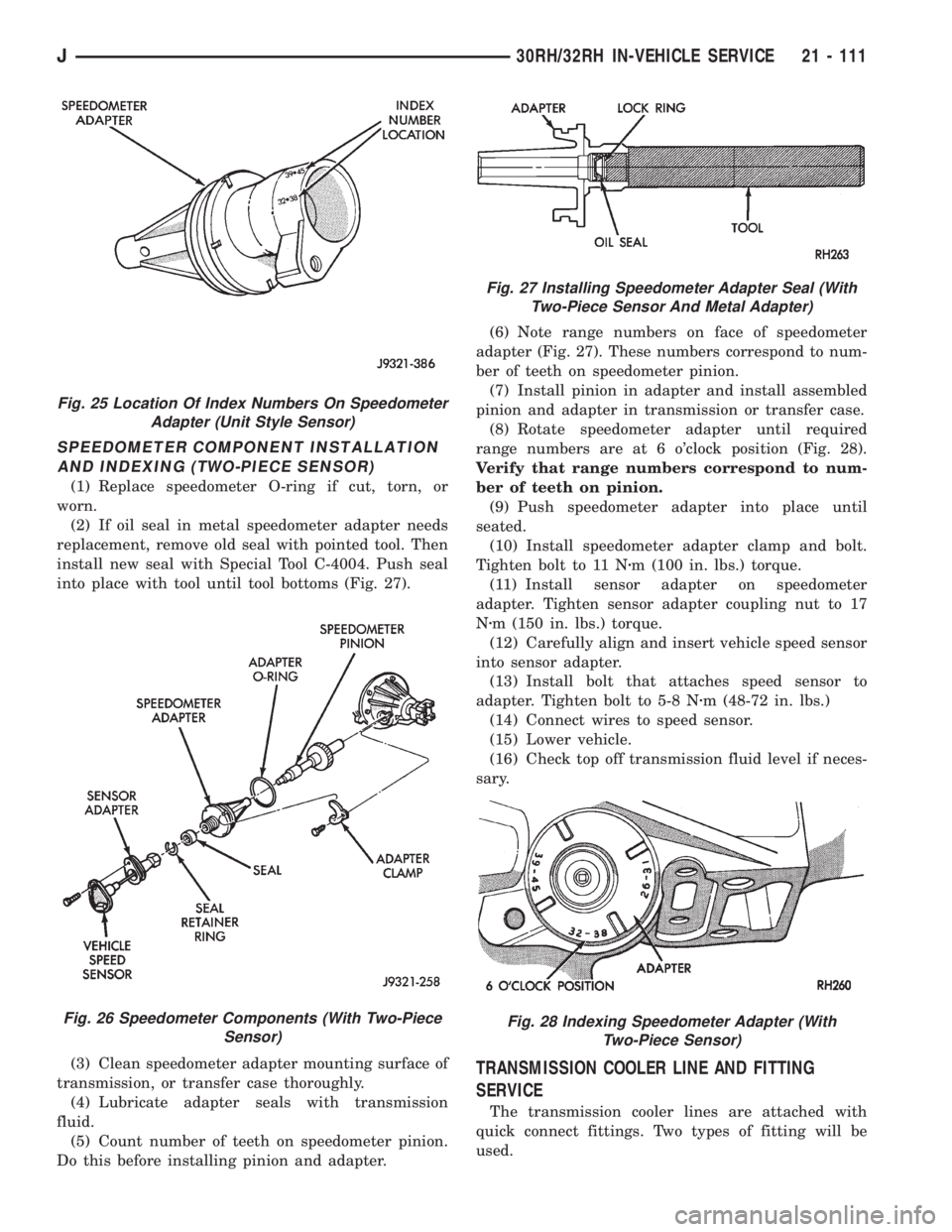

PARK/NEUTRAL POSITION SWITCH SERVICE

The starter feed circuit of the switch is through the

switch center terminal (Fig. 23). It provides a ground

for the starter solenoid circuit through the gearshift

lever in park and neutral only.

The two outer terminals of the park/neutral posi-

tion switch are for the backup lamp switch circuit.

SWITCH TEST PROCEDURE

(1) Remove wiring connector from switch.

(2) Test continuity between switch center terminal

and transmission case. Continuity should exist onlywhen transmission is in Park or Neutral. Replace

switch if continuity occurs in any gear other than

Park or Neutral.

(3) Shift into reverse and test continuity between

two outside terminals on switch. Continuity should

exist only when transmission is in reverse.

(4) Leave transmission in reverse and test continu-

ity between each switch outer terminal and transmis-

sion case. Continuity should not exist between either

pin and case in reverse.

(5) If switch tests OK, check gearshift linkage ad-

justment or backup light circuit. Replace switch if it

fails continuity tests.

SWITCH REPLACEMENT

(1) Position drain pan under neutral switch.

(2) Disconnect switch wires.

(3) Remove switch from transmission.

(4) Move shift lever to Park and Neutral positions.

Inspect manual lever fingers, lever and shaft for

proper alignment with switch opening in case. Re-

place lever if worn or bent. Do not attempt to

straighten the lever.

(5) Install new switch and seal in case. Tighten

switch to 33 Nzm (24 ft. lbs.) torque.

(6) Adjust transmission fluid level as required.

(7) Verify switch operation.

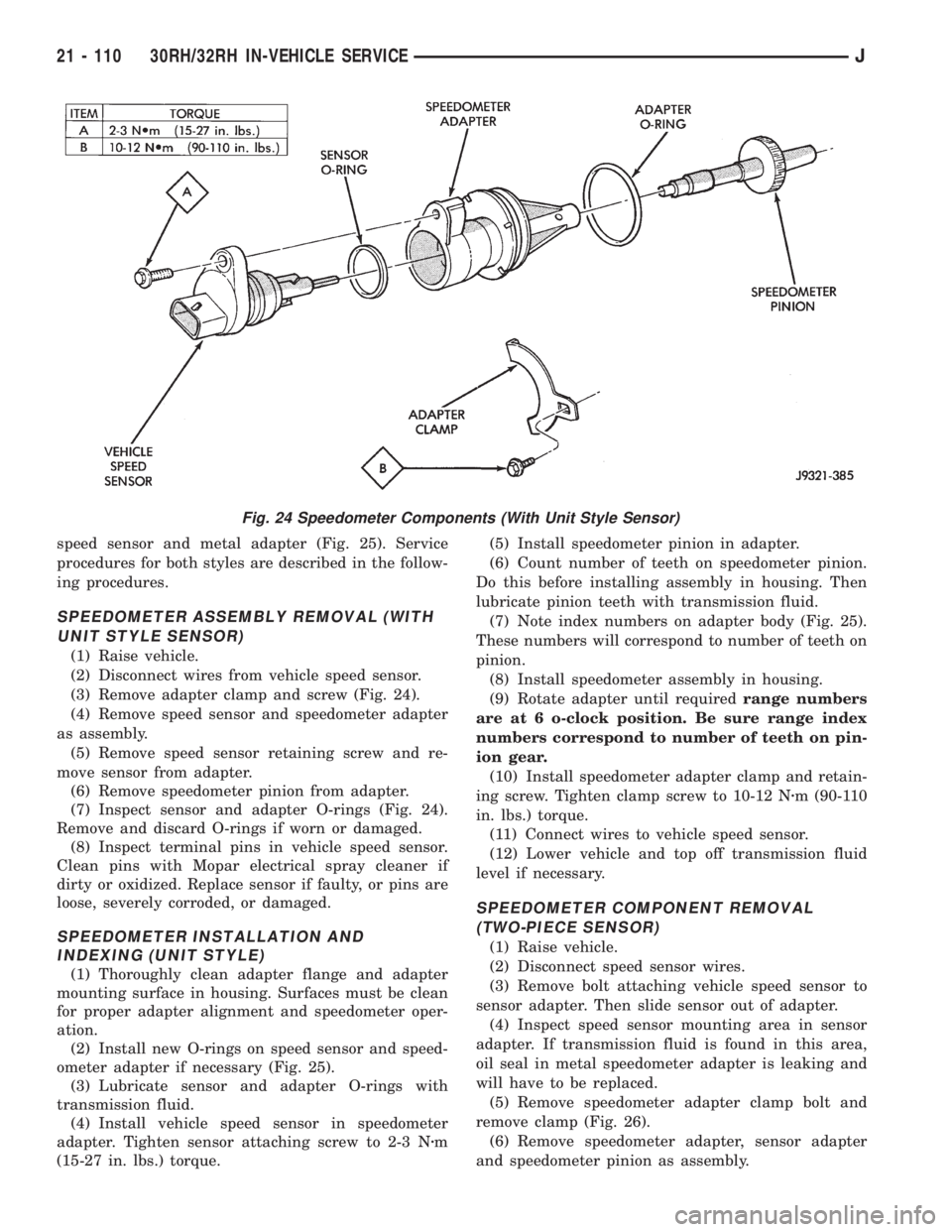

SPEEDOMETER SERVICE

Rear axle gear ratio and tire size determine speed-

ometer pinion requirements. If the pinion must be re-

placed, refer to the parts catalogue information for

the correct part. It is important for speedometer ac-

curacy that the pinion have the correct number of

teeth.

The speedometer assembly used in XJ models is

the new unit type (one-piece) speed sensor (Fig. 24).

However, YJ models may be equipped with either the

new unit style, or the older style that has a two-piece

Fig. 22 Park Lock ComponentsFig. 23 Park/Neutral Position Switch And Manual

Lever

J30RH/32RH IN-VEHICLE SERVICE 21 - 109

Page 1487 of 2198

speed sensor and metal adapter (Fig. 25). Service

procedures for both styles are described in the follow-

ing procedures.

SPEEDOMETER ASSEMBLY REMOVAL (WITH

UNIT STYLE SENSOR)

(1) Raise vehicle.

(2) Disconnect wires from vehicle speed sensor.

(3) Remove adapter clamp and screw (Fig. 24).

(4) Remove speed sensor and speedometer adapter

as assembly.

(5) Remove speed sensor retaining screw and re-

move sensor from adapter.

(6) Remove speedometer pinion from adapter.

(7) Inspect sensor and adapter O-rings (Fig. 24).

Remove and discard O-rings if worn or damaged.

(8) Inspect terminal pins in vehicle speed sensor.

Clean pins with Mopar electrical spray cleaner if

dirty or oxidized. Replace sensor if faulty, or pins are

loose, severely corroded, or damaged.

SPEEDOMETER INSTALLATION AND

INDEXING (UNIT STYLE)

(1) Thoroughly clean adapter flange and adapter

mounting surface in housing. Surfaces must be clean

for proper adapter alignment and speedometer oper-

ation.

(2) Install new O-rings on speed sensor and speed-

ometer adapter if necessary (Fig. 25).

(3) Lubricate sensor and adapter O-rings with

transmission fluid.

(4) Install vehicle speed sensor in speedometer

adapter. Tighten sensor attaching screw to 2-3 Nzm

(15-27 in. lbs.) torque.(5) Install speedometer pinion in adapter.

(6) Count number of teeth on speedometer pinion.

Do this before installing assembly in housing. Then

lubricate pinion teeth with transmission fluid.

(7) Note index numbers on adapter body (Fig. 25).

These numbers will correspond to number of teeth on

pinion.

(8) Install speedometer assembly in housing.

(9) Rotate adapter until requiredrange numbers

are at 6 o-clock position. Be sure range index

numbers correspond to number of teeth on pin-

ion gear.

(10) Install speedometer adapter clamp and retain-

ing screw. Tighten clamp screw to 10-12 Nzm (90-110

in. lbs.) torque.

(11) Connect wires to vehicle speed sensor.

(12) Lower vehicle and top off transmission fluid

level if necessary.

SPEEDOMETER COMPONENT REMOVAL

(TWO-PIECE SENSOR)

(1) Raise vehicle.

(2) Disconnect speed sensor wires.

(3) Remove bolt attaching vehicle speed sensor to

sensor adapter. Then slide sensor out of adapter.

(4) Inspect speed sensor mounting area in sensor

adapter. If transmission fluid is found in this area,

oil seal in metal speedometer adapter is leaking and

will have to be replaced.

(5) Remove speedometer adapter clamp bolt and

remove clamp (Fig. 26).

(6) Remove speedometer adapter, sensor adapter

and speedometer pinion as assembly.

Fig. 24 Speedometer Components (With Unit Style Sensor)

21 - 110 30RH/32RH IN-VEHICLE SERVICEJ

Page 1488 of 2198

SPEEDOMETER COMPONENT INSTALLATION

AND INDEXING (TWO-PIECE SENSOR)

(1) Replace speedometer O-ring if cut, torn, or

worn.

(2) If oil seal in metal speedometer adapter needs

replacement, remove old seal with pointed tool. Then

install new seal with Special Tool C-4004. Push seal

into place with tool until tool bottoms (Fig. 27).

(3) Clean speedometer adapter mounting surface of

transmission, or transfer case thoroughly.

(4) Lubricate adapter seals with transmission

fluid.

(5) Count number of teeth on speedometer pinion.

Do this before installing pinion and adapter.(6) Note range numbers on face of speedometer

adapter (Fig. 27). These numbers correspond to num-

ber of teeth on speedometer pinion.

(7) Install pinion in adapter and install assembled

pinion and adapter in transmission or transfer case.

(8) Rotate speedometer adapter until required

range numbers are at 6 o'clock position (Fig. 28).

Verify that range numbers correspond to num-

ber of teeth on pinion.

(9) Push speedometer adapter into place until

seated.

(10) Install speedometer adapter clamp and bolt.

Tighten bolt to 11 Nzm (100 in. lbs.) torque.

(11) Install sensor adapter on speedometer

adapter. Tighten sensor adapter coupling nut to 17

Nzm (150 in. lbs.) torque.

(12) Carefully align and insert vehicle speed sensor

into sensor adapter.

(13) Install bolt that attaches speed sensor to

adapter. Tighten bolt to 5-8 Nzm (48-72 in. lbs.)

(14) Connect wires to speed sensor.

(15) Lower vehicle.

(16) Check top off transmission fluid level if neces-

sary.

TRANSMISSION COOLER LINE AND FITTING

SERVICE

The transmission cooler lines are attached with

quick connect fittings. Two types of fitting will be

used.

Fig. 25 Location Of Index Numbers On Speedometer

Adapter (Unit Style Sensor)

Fig. 26 Speedometer Components (With Two-Piece

Sensor)

Fig. 27 Installing Speedometer Adapter Seal (With

Two-Piece Sensor And Metal Adapter)

Fig. 28 Indexing Speedometer Adapter (With

Two-Piece Sensor)

J30RH/32RH IN-VEHICLE SERVICE 21 - 111

Page 1489 of 2198

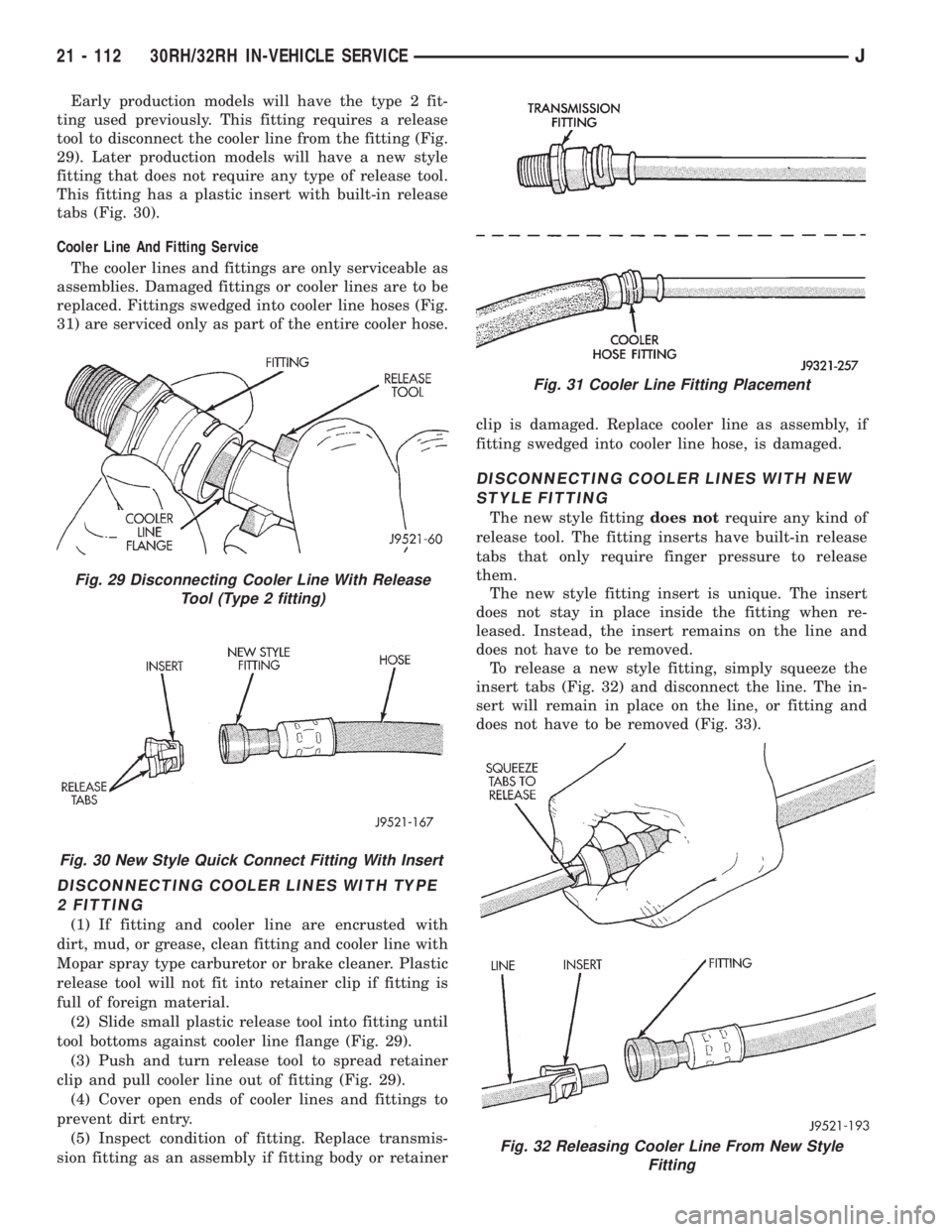

Early production models will have the type 2 fit-

ting used previously. This fitting requires a release

tool to disconnect the cooler line from the fitting (Fig.

29). Later production models will have a new style

fitting that does not require any type of release tool.

This fitting has a plastic insert with built-in release

tabs (Fig. 30).

Cooler Line And Fitting Service

The cooler lines and fittings are only serviceable as

assemblies. Damaged fittings or cooler lines are to be

replaced. Fittings swedged into cooler line hoses (Fig.

31) are serviced only as part of the entire cooler hose.

DISCONNECTING COOLER LINES WITH TYPE

2 FITTING

(1) If fitting and cooler line are encrusted with

dirt, mud, or grease, clean fitting and cooler line with

Mopar spray type carburetor or brake cleaner. Plastic

release tool will not fit into retainer clip if fitting is

full of foreign material.

(2) Slide small plastic release tool into fitting until

tool bottoms against cooler line flange (Fig. 29).

(3) Push and turn release tool to spread retainer

clip and pull cooler line out of fitting (Fig. 29).

(4) Cover open ends of cooler lines and fittings to

prevent dirt entry.

(5) Inspect condition of fitting. Replace transmis-

sion fitting as an assembly if fitting body or retainerclip is damaged. Replace cooler line as assembly, if

fitting swedged into cooler line hose, is damaged.

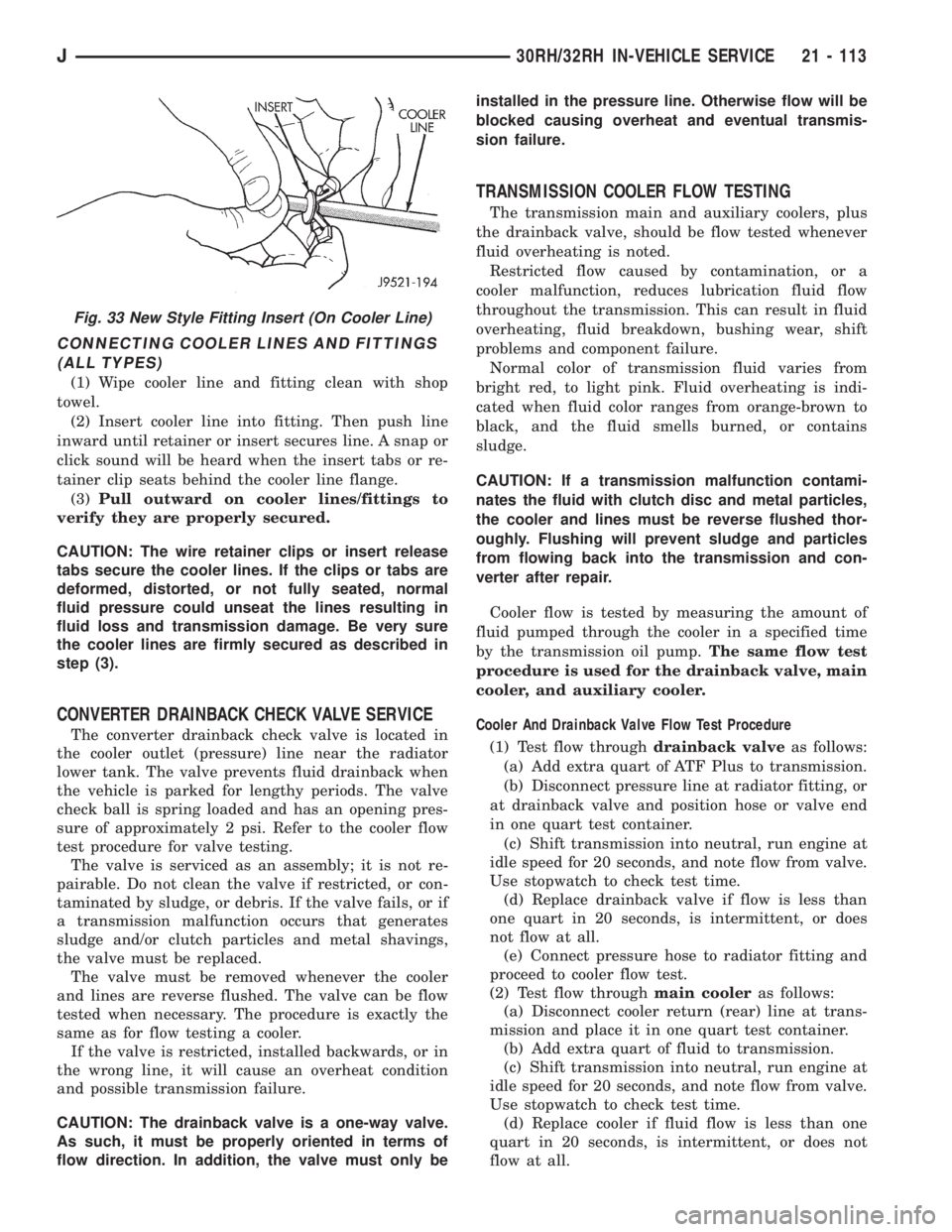

DISCONNECTING COOLER LINES WITH NEW

STYLE FITTING

The new style fittingdoes notrequire any kind of

release tool. The fitting inserts have built-in release

tabs that only require finger pressure to release

them.

The new style fitting insert is unique. The insert

does not stay in place inside the fitting when re-

leased. Instead, the insert remains on the line and

does not have to be removed.

To release a new style fitting, simply squeeze the

insert tabs (Fig. 32) and disconnect the line. The in-

sert will remain in place on the line, or fitting and

does not have to be removed (Fig. 33).

Fig. 30 New Style Quick Connect Fitting With Insert

Fig. 29 Disconnecting Cooler Line With Release

Tool (Type 2 fitting)

Fig. 31 Cooler Line Fitting Placement

Fig. 32 Releasing Cooler Line From New Style

Fitting

21 - 112 30RH/32RH IN-VEHICLE SERVICEJ

Page 1490 of 2198

CONNECTING COOLER LINES AND FITTINGS

(ALL TYPES)

(1) Wipe cooler line and fitting clean with shop

towel.

(2) Insert cooler line into fitting. Then push line

inward until retainer or insert secures line. A snap or

click sound will be heard when the insert tabs or re-

tainer clip seats behind the cooler line flange.

(3)Pull outward on cooler lines/fittings to

verify they are properly secured.

CAUTION: The wire retainer clips or insert release

tabs secure the cooler lines. If the clips or tabs are

deformed, distorted, or not fully seated, normal

fluid pressure could unseat the lines resulting in

fluid loss and transmission damage. Be very sure

the cooler lines are firmly secured as described in

step (3).

CONVERTER DRAINBACK CHECK VALVE SERVICE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

lower tank. The valve prevents fluid drainback when

the vehicle is parked for lengthy periods. The valve

check ball is spring loaded and has an opening pres-

sure of approximately 2 psi. Refer to the cooler flow

test procedure for valve testing.

The valve is serviced as an assembly; it is not re-

pairable. Do not clean the valve if restricted, or con-

taminated by sludge, or debris. If the valve fails, or if

a transmission malfunction occurs that generates

sludge and/or clutch particles and metal shavings,

the valve must be replaced.

The valve must be removed whenever the cooler

and lines are reverse flushed. The valve can be flow

tested when necessary. The procedure is exactly the

same as for flow testing a cooler.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheat condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way valve.

As such, it must be properly oriented in terms of

flow direction. In addition, the valve must only beinstalled in the pressure line. Otherwise flow will be

blocked causing overheat and eventual transmis-

sion failure.

TRANSMISSION COOLER FLOW TESTING

The transmission main and auxiliary coolers, plus

the drainback valve, should be flow tested whenever

fluid overheating is noted.

Restricted flow caused by contamination, or a

cooler malfunction, reduces lubrication fluid flow

throughout the transmission. This can result in fluid

overheating, fluid breakdown, bushing wear, shift

problems and component failure.

Normal color of transmission fluid varies from

bright red, to light pink. Fluid overheating is indi-

cated when fluid color ranges from orange-brown to

black, and the fluid smells burned, or contains

sludge.

CAUTION: If a transmission malfunction contami-

nates the fluid with clutch disc and metal particles,

the cooler and lines must be reverse flushed thor-

oughly. Flushing will prevent sludge and particles

from flowing back into the transmission and con-

verter after repair.

Cooler flow is tested by measuring the amount of

fluid pumped through the cooler in a specified time

by the transmission oil pump.The same flow test

procedure is used for the drainback valve, main

cooler, and auxiliary cooler.

Cooler And Drainback Valve Flow Test Procedure

(1) Test flow throughdrainback valveas follows:

(a) Add extra quart of ATF Plus to transmission.

(b) Disconnect pressure line at radiator fitting, or

at drainback valve and position hose or valve end

in one quart test container.

(c) Shift transmission into neutral, run engine at

idle speed for 20 seconds, and note flow from valve.

Use stopwatch to check test time.

(d) Replace drainback valve if flow is less than

one quart in 20 seconds, is intermittent, or does

not flow at all.

(e) Connect pressure hose to radiator fitting and

proceed to cooler flow test.

(2) Test flow throughmain cooleras follows:

(a) Disconnect cooler return (rear) line at trans-

mission and place it in one quart test container.

(b) Add extra quart of fluid to transmission.

(c) Shift transmission into neutral, run engine at

idle speed for 20 seconds, and note flow from valve.

Use stopwatch to check test time.

(d) Replace cooler if fluid flow is less than one

quart in 20 seconds, is intermittent, or does not

flow at all.

Fig. 33 New Style Fitting Insert (On Cooler Line)

J30RH/32RH IN-VEHICLE SERVICE 21 - 113