JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1491 of 2198

(3) If vehicle is equipped withauxiliary cooler,

test cooler flow as described in step (2).

TRANSMISSION COOLER REVERSE FLUSHING

The flushing procedure applies to standard and

auxiliary coolers alike. Although pressure equipment

is preferred, reverse flushing can be performed with

hand operated equipment as follows.

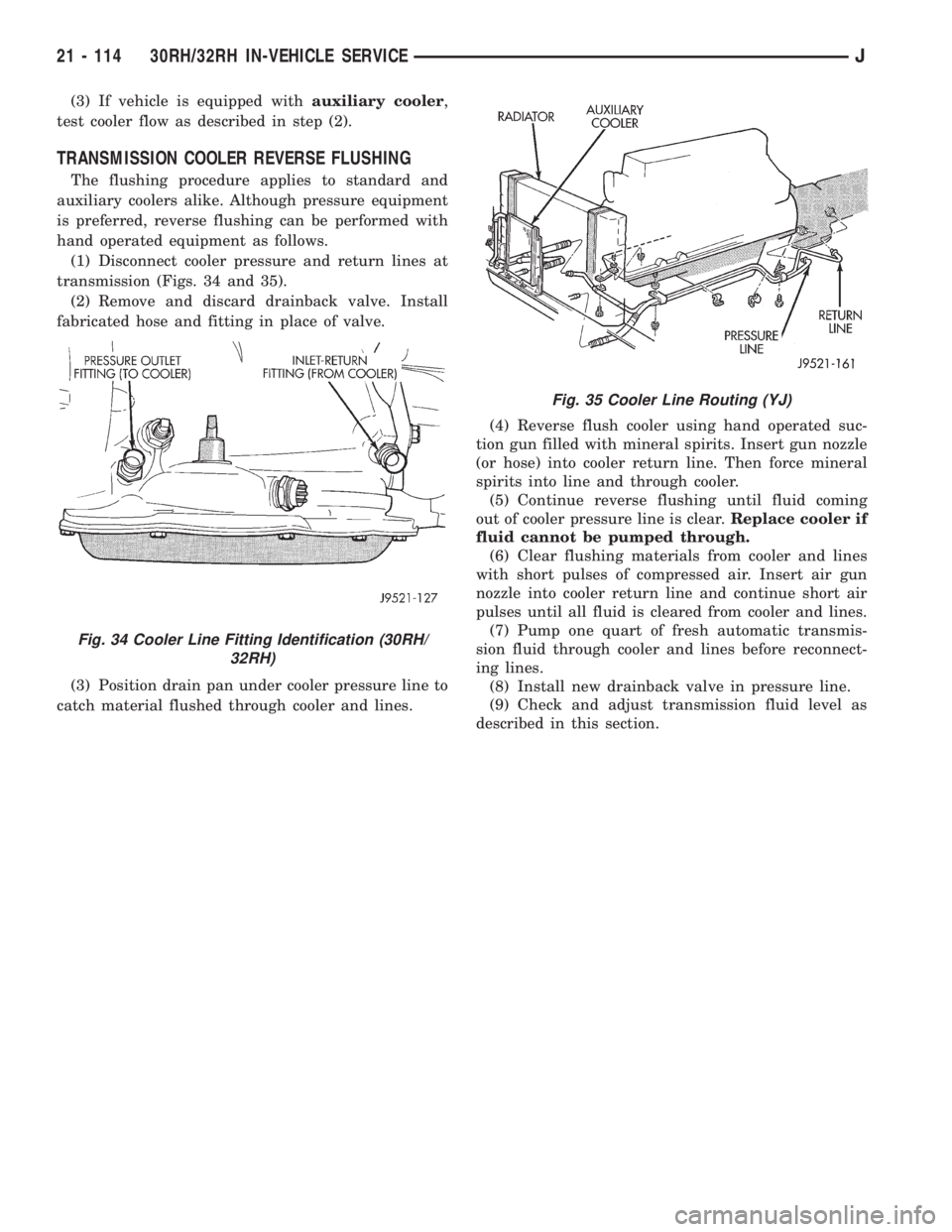

(1) Disconnect cooler pressure and return lines at

transmission (Figs. 34 and 35).

(2) Remove and discard drainback valve. Install

fabricated hose and fitting in place of valve.

(3) Position drain pan under cooler pressure line to

catch material flushed through cooler and lines.(4) Reverse flush cooler using hand operated suc-

tion gun filled with mineral spirits. Insert gun nozzle

(or hose) into cooler return line. Then force mineral

spirits into line and through cooler.

(5) Continue reverse flushing until fluid coming

out of cooler pressure line is clear.Replace cooler if

fluid cannot be pumped through.

(6) Clear flushing materials from cooler and lines

with short pulses of compressed air. Insert air gun

nozzle into cooler return line and continue short air

pulses until all fluid is cleared from cooler and lines.

(7) Pump one quart of fresh automatic transmis-

sion fluid through cooler and lines before reconnect-

ing lines.

(8) Install new drainback valve in pressure line.

(9) Check and adjust transmission fluid level as

described in this section.

Fig. 34 Cooler Line Fitting Identification (30RH/

32RH)

Fig. 35 Cooler Line Routing (YJ)

21 - 114 30RH/32RH IN-VEHICLE SERVICEJ

Page 1492 of 2198

30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

ConverterÐPump SealÐDrive Plate Service.... 116

Transmission and Converter Installation........ 117Transmission and Converter Removal......... 115

TRANSMISSION AND CONVERTER REMOVAL

(1) Remove fan shroud attaching bolts.

(2) Disconnect transmission fill tube at upper

bracket.

(3) Raise vehicle.

(4) Remove inspection cover from converter hous-

ing and remove skid plate for access, if necessary.

(5) Remove transmission fill tube and fill tube O-

ring.

(6) Remove starter motor.

(7) Mark propeller shafts and axle yokes for align-

ment reference.

(8) Disconnect propeller shafts at yokes. Secure

shafts to frame rails with wire.

(9) Disconnect exhaust pipes at exhaust manifolds,

if necessary.

(10) Drain transfer case lubricant, if transfer case

will also be serviced.

(11) Disconnect vehicle speed sensor wires.

(12) Disconnect transfer case shift linkage.

(13) Disconnect gearshift cable/linkage and throttle

valve cable at transmission levers.

(14) Disconnect transfer case vent hose. Then dis-

connect indicator switch wires on XJ, or vacuum

switch harness on YJ.

(15) Remove wire harness from clips on transfer

case.

(16) Remove transfer case attaching nuts and re-

move transfer case. Use transmission jack or helper

to support and remove transfer case.

(17) Disconnect park/neutral position switch wires.

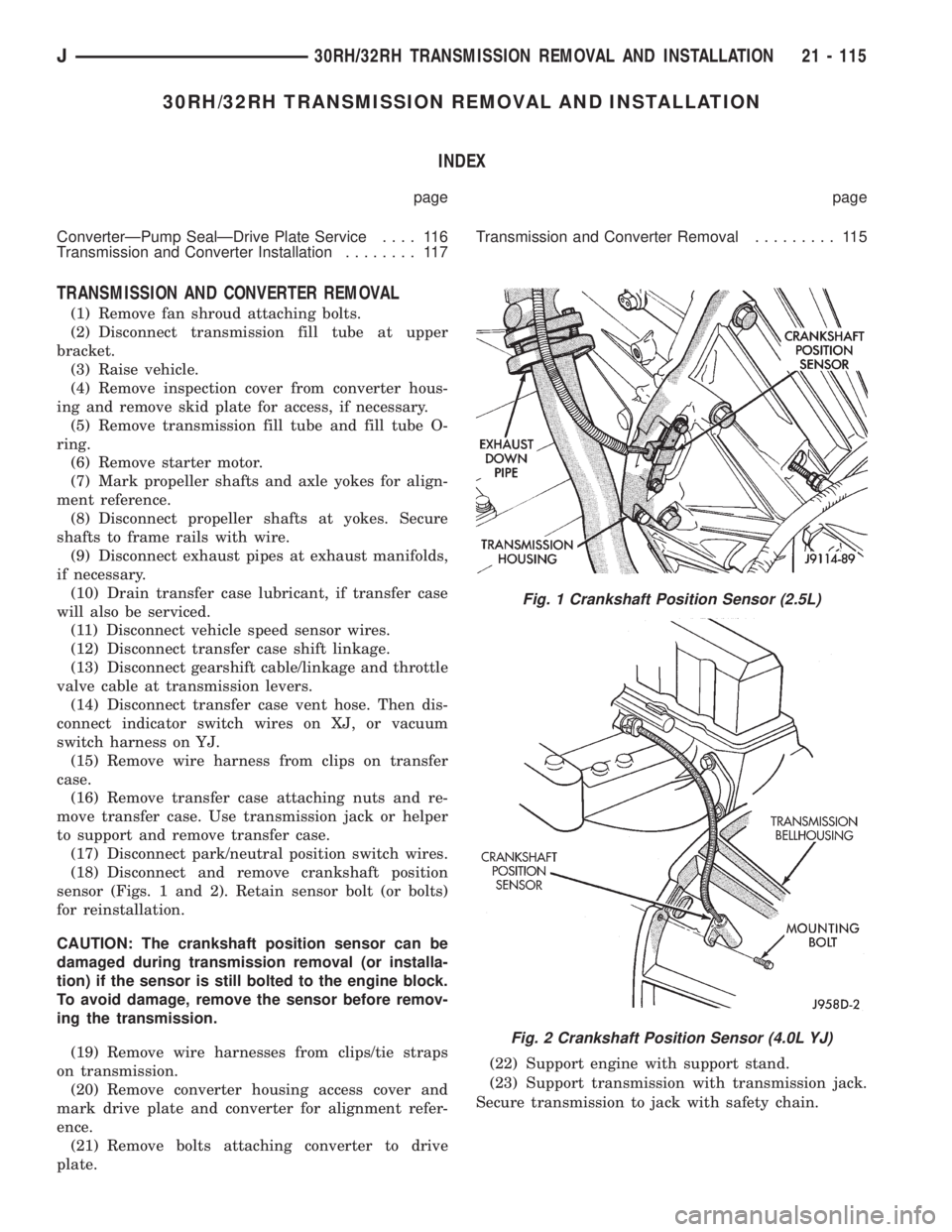

(18) Disconnect and remove crankshaft position

sensor (Figs. 1 and 2). Retain sensor bolt (or bolts)

for reinstallation.

CAUTION: The crankshaft position sensor can be

damaged during transmission removal (or installa-

tion) if the sensor is still bolted to the engine block.

To avoid damage, remove the sensor before remov-

ing the transmission.

(19) Remove wire harnesses from clips/tie straps

on transmission.

(20) Remove converter housing access cover and

mark drive plate and converter for alignment refer-

ence.

(21) Remove bolts attaching converter to drive

plate.(22) Support engine with support stand.

(23) Support transmission with transmission jack.

Secure transmission to jack with safety chain.

Fig. 1 Crankshaft Position Sensor (2.5L)

Fig. 2 Crankshaft Position Sensor (4.0L YJ)

J30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION 21 - 115

Page 1493 of 2198

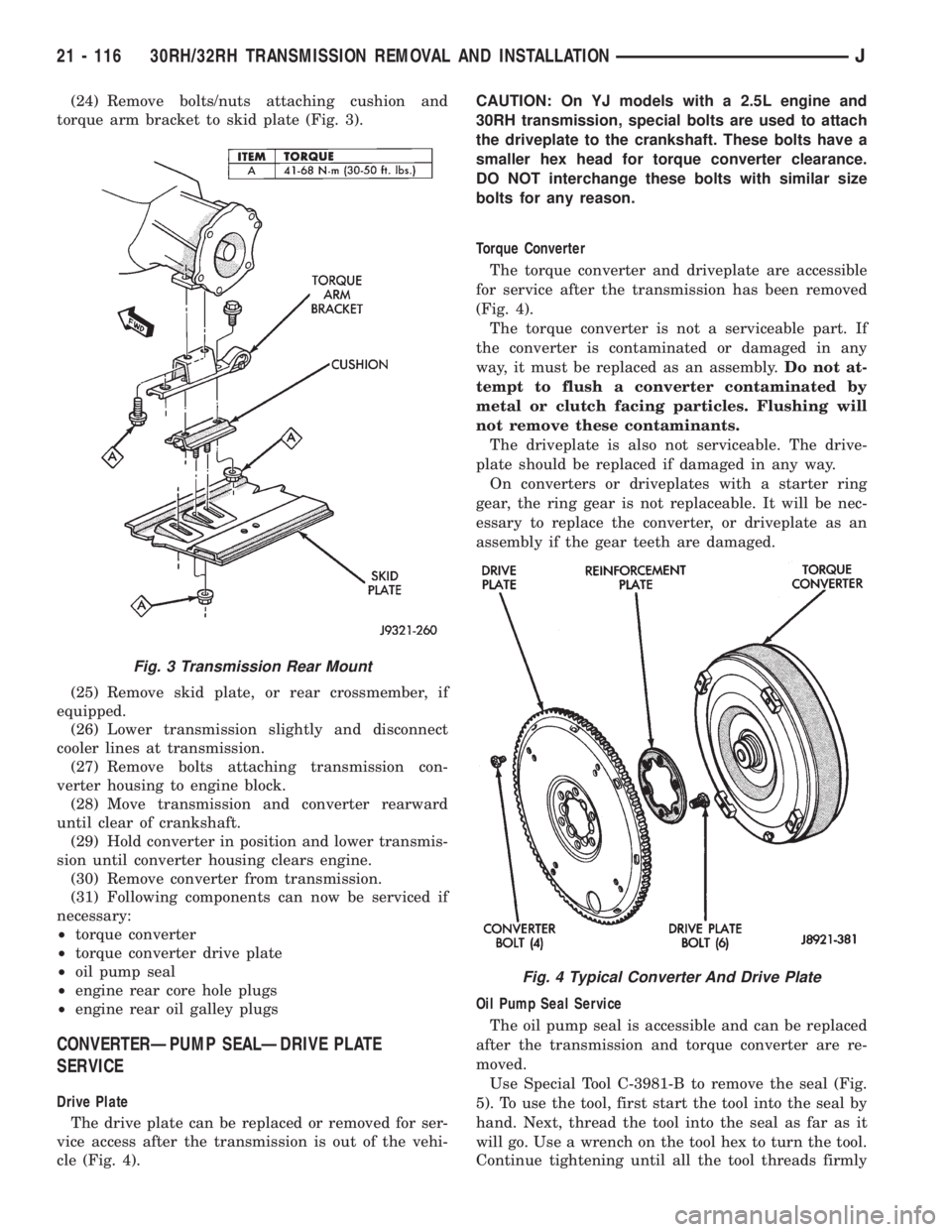

(24) Remove bolts/nuts attaching cushion and

torque arm bracket to skid plate (Fig. 3).

(25) Remove skid plate, or rear crossmember, if

equipped.

(26) Lower transmission slightly and disconnect

cooler lines at transmission.

(27) Remove bolts attaching transmission con-

verter housing to engine block.

(28) Move transmission and converter rearward

until clear of crankshaft.

(29) Hold converter in position and lower transmis-

sion until converter housing clears engine.

(30) Remove converter from transmission.

(31) Following components can now be serviced if

necessary:

²torque converter

²torque converter drive plate

²oil pump seal

²engine rear core hole plugs

²engine rear oil galley plugs

CONVERTERÐPUMP SEALÐDRIVE PLATE

SERVICE

Drive Plate

The drive plate can be replaced or removed for ser-

vice access after the transmission is out of the vehi-

cle (Fig. 4).CAUTION: On YJ models with a 2.5L engine and

30RH transmission, special bolts are used to attach

the driveplate to the crankshaft. These bolts have a

smaller hex head for torque converter clearance.

DO NOT interchange these bolts with similar size

bolts for any reason.

Torque Converter

The torque converter and driveplate are accessible

for service after the transmission has been removed

(Fig. 4).

The torque converter is not a serviceable part. If

the converter is contaminated or damaged in any

way, it must be replaced as an assembly.Do not at-

tempt to flush a converter contaminated by

metal or clutch facing particles. Flushing will

not remove these contaminants.

The driveplate is also not serviceable. The drive-

plate should be replaced if damaged in any way.

On converters or driveplates with a starter ring

gear, the ring gear is not replaceable. It will be nec-

essary to replace the converter, or driveplate as an

assembly if the gear teeth are damaged.

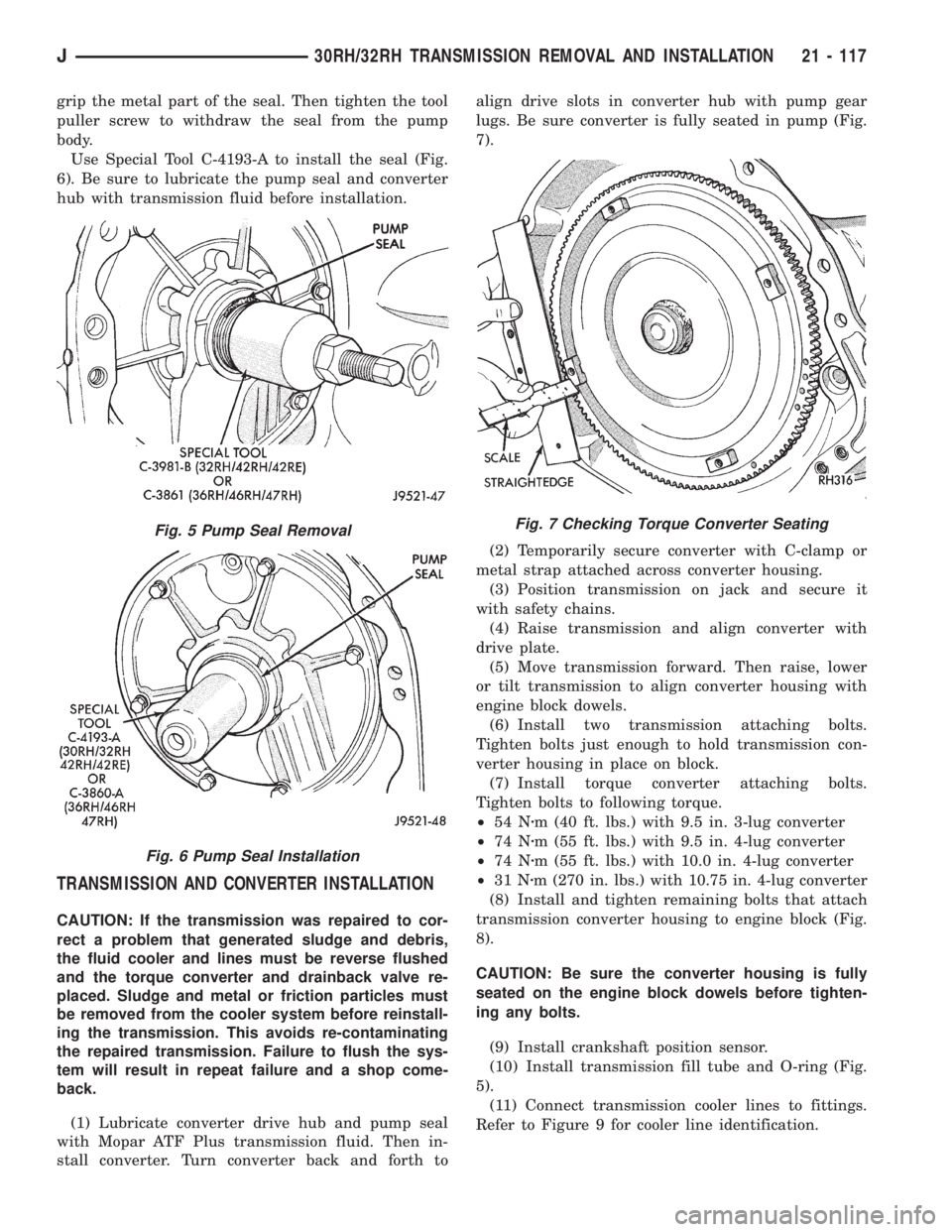

Oil Pump Seal Service

The oil pump seal is accessible and can be replaced

after the transmission and torque converter are re-

moved.

Use Special Tool C-3981-B to remove the seal (Fig.

5). To use the tool, first start the tool into the seal by

hand. Next, thread the tool into the seal as far as it

will go. Use a wrench on the tool hex to turn the tool.

Continue tightening until all the tool threads firmly

Fig. 3 Transmission Rear Mount

Fig. 4 Typical Converter And Drive Plate

21 - 116 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1494 of 2198

grip the metal part of the seal. Then tighten the tool

puller screw to withdraw the seal from the pump

body.

Use Special Tool C-4193-A to install the seal (Fig.

6). Be sure to lubricate the pump seal and converter

hub with transmission fluid before installation.

TRANSMISSION AND CONVERTER INSTALLATION

CAUTION: If the transmission was repaired to cor-

rect a problem that generated sludge and debris,

the fluid cooler and lines must be reverse flushed

and the torque converter and drainback valve re-

placed. Sludge and metal or friction particles must

be removed from the cooler system before reinstall-

ing the transmission. This avoids re-contaminating

the repaired transmission. Failure to flush the sys-

tem will result in repeat failure and a shop come-

back.

(1) Lubricate converter drive hub and pump seal

with Mopar ATF Plus transmission fluid. Then in-

stall converter. Turn converter back and forth toalign drive slots in converter hub with pump gear

lugs. Be sure converter is fully seated in pump (Fig.

7).

(2) Temporarily secure converter with C-clamp or

metal strap attached across converter housing.

(3) Position transmission on jack and secure it

with safety chains.

(4) Raise transmission and align converter with

drive plate.

(5) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(6) Install two transmission attaching bolts.

Tighten bolts just enough to hold transmission con-

verter housing in place on block.

(7) Install torque converter attaching bolts.

Tighten bolts to following torque.

²54 Nzm (40 ft. lbs.) with 9.5 in. 3-lug converter

²74 Nzm (55 ft. lbs.) with 9.5 in. 4-lug converter

²74 Nzm (55 ft. lbs.) with 10.0 in. 4-lug converter

²31 Nzm (270 in. lbs.) with 10.75 in. 4-lug converter

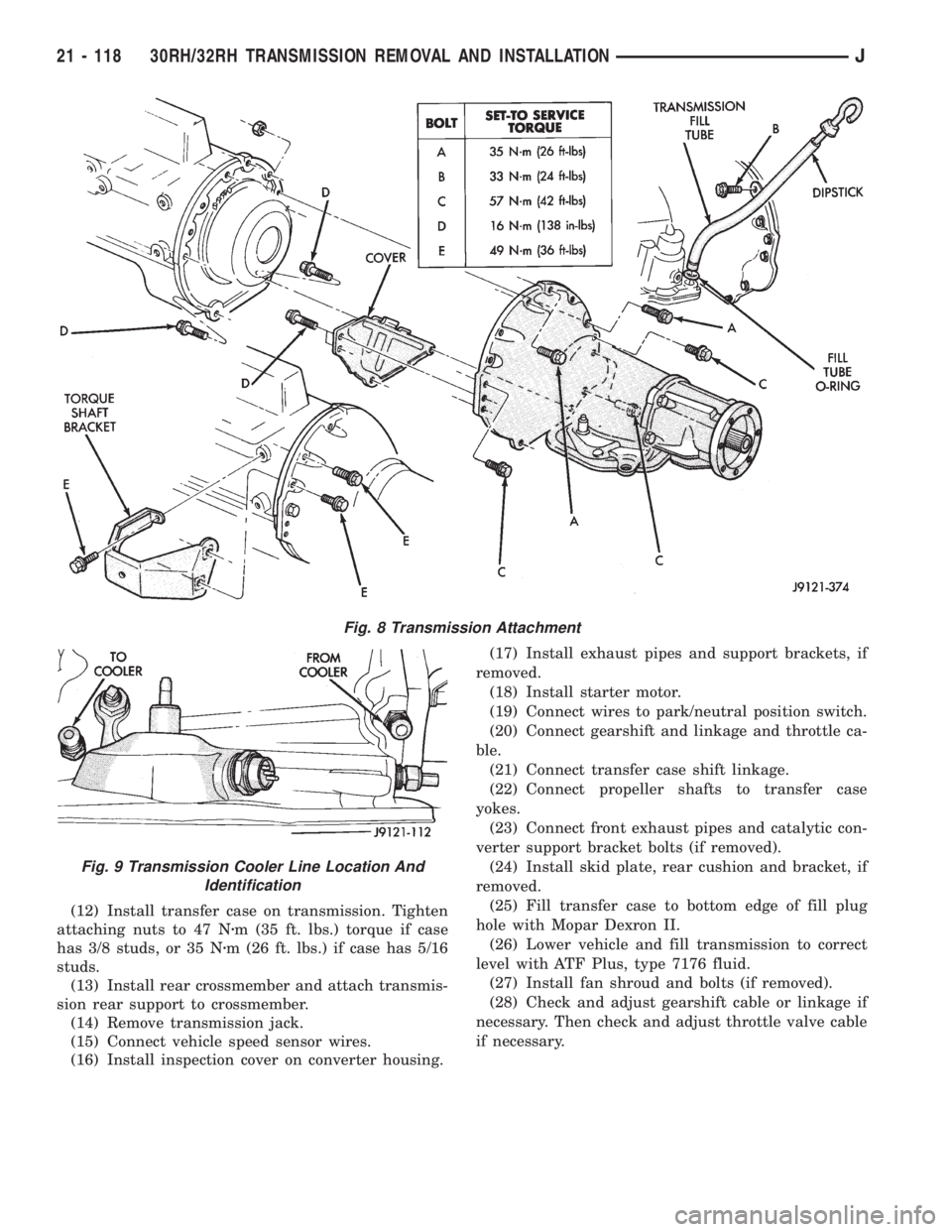

(8) Install and tighten remaining bolts that attach

transmission converter housing to engine block (Fig.

8).

CAUTION: Be sure the converter housing is fully

seated on the engine block dowels before tighten-

ing any bolts.

(9) Install crankshaft position sensor.

(10) Install transmission fill tube and O-ring (Fig.

5).

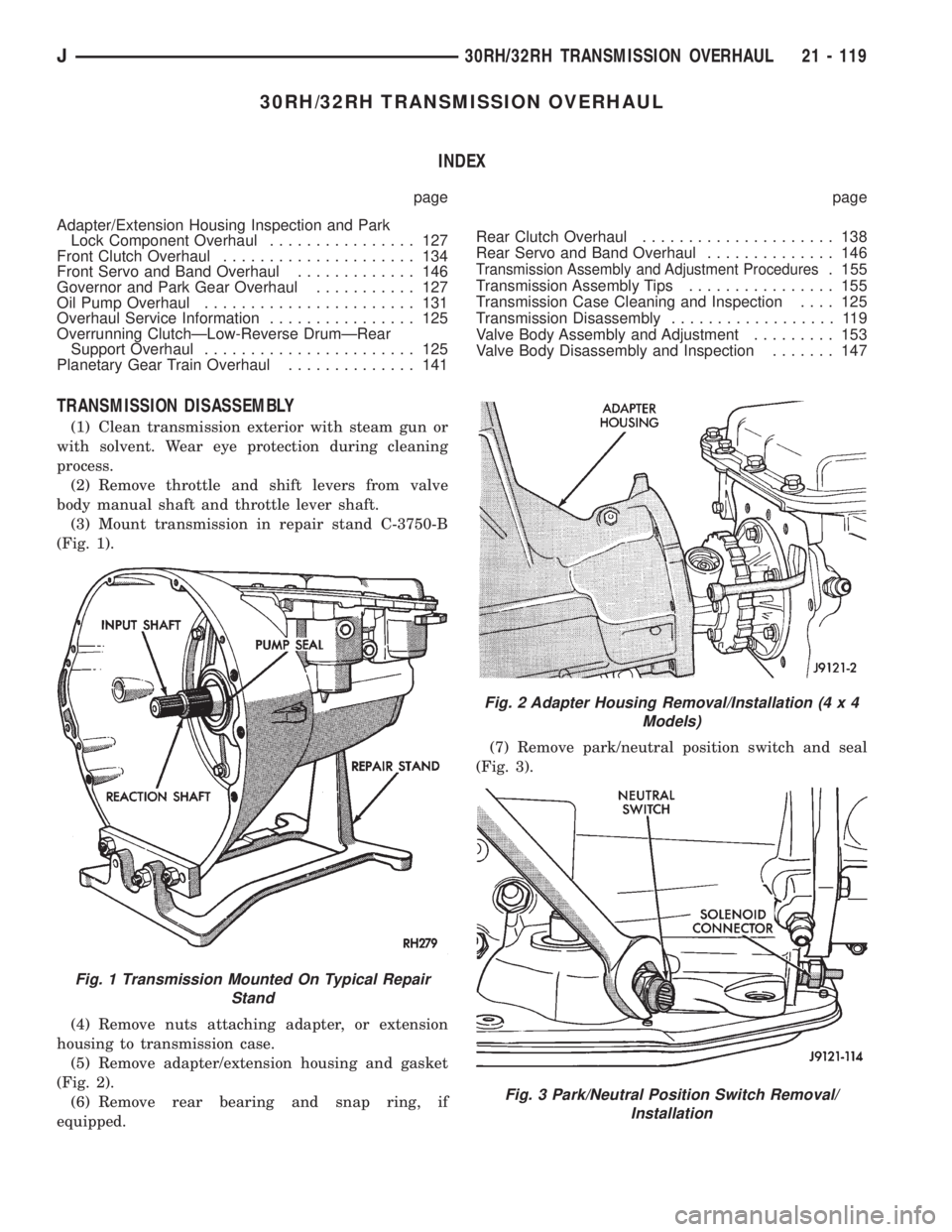

(11) Connect transmission cooler lines to fittings.

Refer to Figure 9 for cooler line identification.

Fig. 5 Pump Seal Removal

Fig. 6 Pump Seal Installation

Fig. 7 Checking Torque Converter Seating

J30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION 21 - 117

Page 1495 of 2198

(12) Install transfer case on transmission. Tighten

attaching nuts to 47 Nzm (35 ft. lbs.) torque if case

has 3/8 studs, or 35 Nzm (26 ft. lbs.) if case has 5/16

studs.

(13) Install rear crossmember and attach transmis-

sion rear support to crossmember.

(14) Remove transmission jack.

(15) Connect vehicle speed sensor wires.

(16) Install inspection cover on converter housing.(17) Install exhaust pipes and support brackets, if

removed.

(18) Install starter motor.

(19) Connect wires to park/neutral position switch.

(20) Connect gearshift and linkage and throttle ca-

ble.

(21) Connect transfer case shift linkage.

(22) Connect propeller shafts to transfer case

yokes.

(23) Connect front exhaust pipes and catalytic con-

verter support bracket bolts (if removed).

(24) Install skid plate, rear cushion and bracket, if

removed.

(25) Fill transfer case to bottom edge of fill plug

hole with Mopar Dexron II.

(26) Lower vehicle and fill transmission to correct

level with ATF Plus, type 7176 fluid.

(27) Install fan shroud and bolts (if removed).

(28) Check and adjust gearshift cable or linkage if

necessary. Then check and adjust throttle valve cable

if necessary.

Fig. 8 Transmission Attachment

Fig. 9 Transmission Cooler Line Location And

Identification

21 - 118 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1496 of 2198

30RH/32RH TRANSMISSION OVERHAUL

INDEX

page page

Adapter/Extension Housing Inspection and Park

Lock Component Overhaul................ 127

Front Clutch Overhaul..................... 134

Front Servo and Band Overhaul............. 146

Governor and Park Gear Overhaul........... 127

Oil Pump Overhaul....................... 131

Overhaul Service Information................ 125

Overrunning ClutchÐLow-Reverse DrumÐRear

Support Overhaul....................... 125

Planetary Gear Train Overhaul.............. 141Rear Clutch Overhaul..................... 138

Rear Servo and Band Overhaul.............. 146

Transmission Assembly and Adjustment Procedures. 155

Transmission Assembly Tips................ 155

Transmission Case Cleaning and Inspection.... 125

Transmission Disassembly.................. 119

Valve Body Assembly and Adjustment......... 153

Valve Body Disassembly and Inspection....... 147

TRANSMISSION DISASSEMBLY

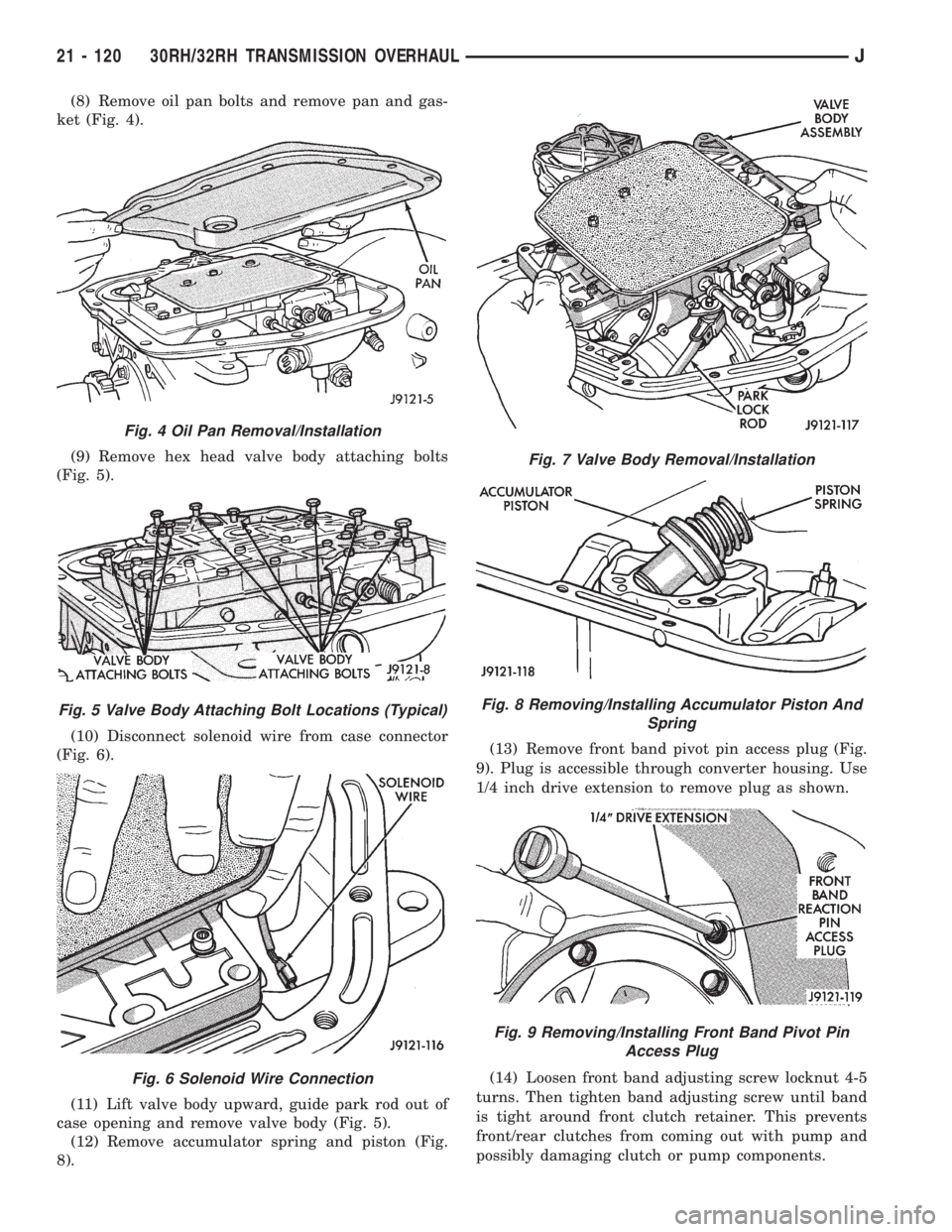

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

process.

(2) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

(3) Mount transmission in repair stand C-3750-B

(Fig. 1).

(4) Remove nuts attaching adapter, or extension

housing to transmission case.

(5) Remove adapter/extension housing and gasket

(Fig. 2).

(6) Remove rear bearing and snap ring, if

equipped.(7) Remove park/neutral position switch and seal

(Fig. 3).

Fig. 1 Transmission Mounted On Typical Repair

Stand

Fig. 2 Adapter Housing Removal/Installation (4 x 4

Models)

Fig. 3 Park/Neutral Position Switch Removal/

Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 119

Page 1497 of 2198

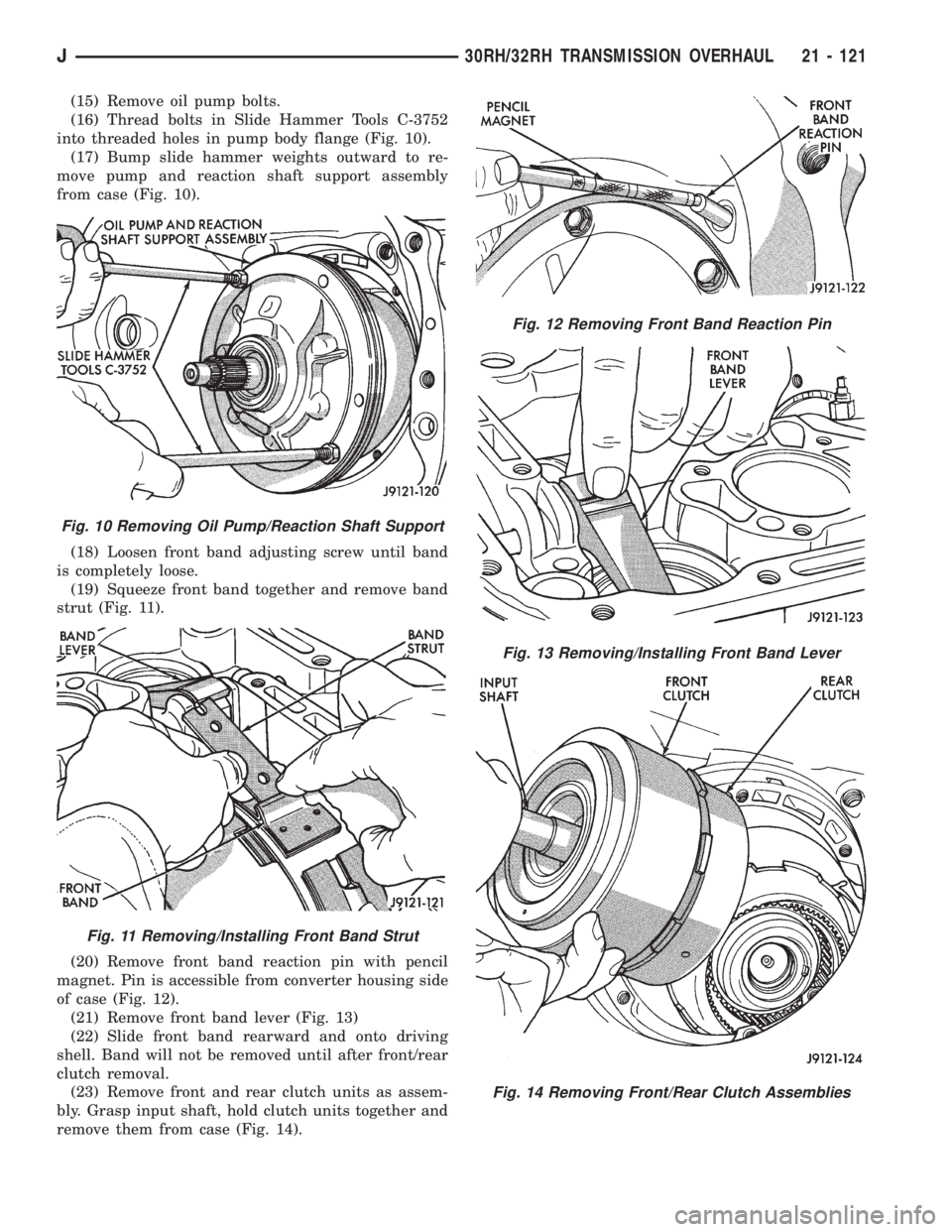

(8) Remove oil pan bolts and remove pan and gas-

ket (Fig. 4).

(9) Remove hex head valve body attaching bolts

(Fig. 5).

(10) Disconnect solenoid wire from case connector

(Fig. 6).

(11) Lift valve body upward, guide park rod out of

case opening and remove valve body (Fig. 5).

(12) Remove accumulator spring and piston (Fig.

8).(13) Remove front band pivot pin access plug (Fig.

9). Plug is accessible through converter housing. Use

1/4 inch drive extension to remove plug as shown.

(14) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

Fig. 4 Oil Pan Removal/Installation

Fig. 5 Valve Body Attaching Bolt Locations (Typical)

Fig. 6 Solenoid Wire Connection

Fig. 7 Valve Body Removal/Installation

Fig. 8 Removing/Installing Accumulator Piston And

Spring

Fig. 9 Removing/Installing Front Band Pivot Pin

Access Plug

21 - 120 30RH/32RH TRANSMISSION OVERHAULJ

Page 1498 of 2198

(15) Remove oil pump bolts.

(16) Thread bolts in Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 10).

(17) Bump slide hammer weights outward to re-

move pump and reaction shaft support assembly

from case (Fig. 10).

(18) Loosen front band adjusting screw until band

is completely loose.

(19) Squeeze front band together and remove band

strut (Fig. 11).

(20) Remove front band reaction pin with pencil

magnet. Pin is accessible from converter housing side

of case (Fig. 12).

(21) Remove front band lever (Fig. 13)

(22) Slide front band rearward and onto driving

shell. Band will not be removed until after front/rear

clutch removal.

(23) Remove front and rear clutch units as assem-

bly. Grasp input shaft, hold clutch units together and

remove them from case (Fig. 14).

Fig. 10 Removing Oil Pump/Reaction Shaft Support

Fig. 11 Removing/Installing Front Band Strut

Fig. 12 Removing Front Band Reaction Pin

Fig. 13 Removing/Installing Front Band Lever

Fig. 14 Removing Front/Rear Clutch Assemblies

J30RH/32RH TRANSMISSION OVERHAUL 21 - 121

Page 1499 of 2198

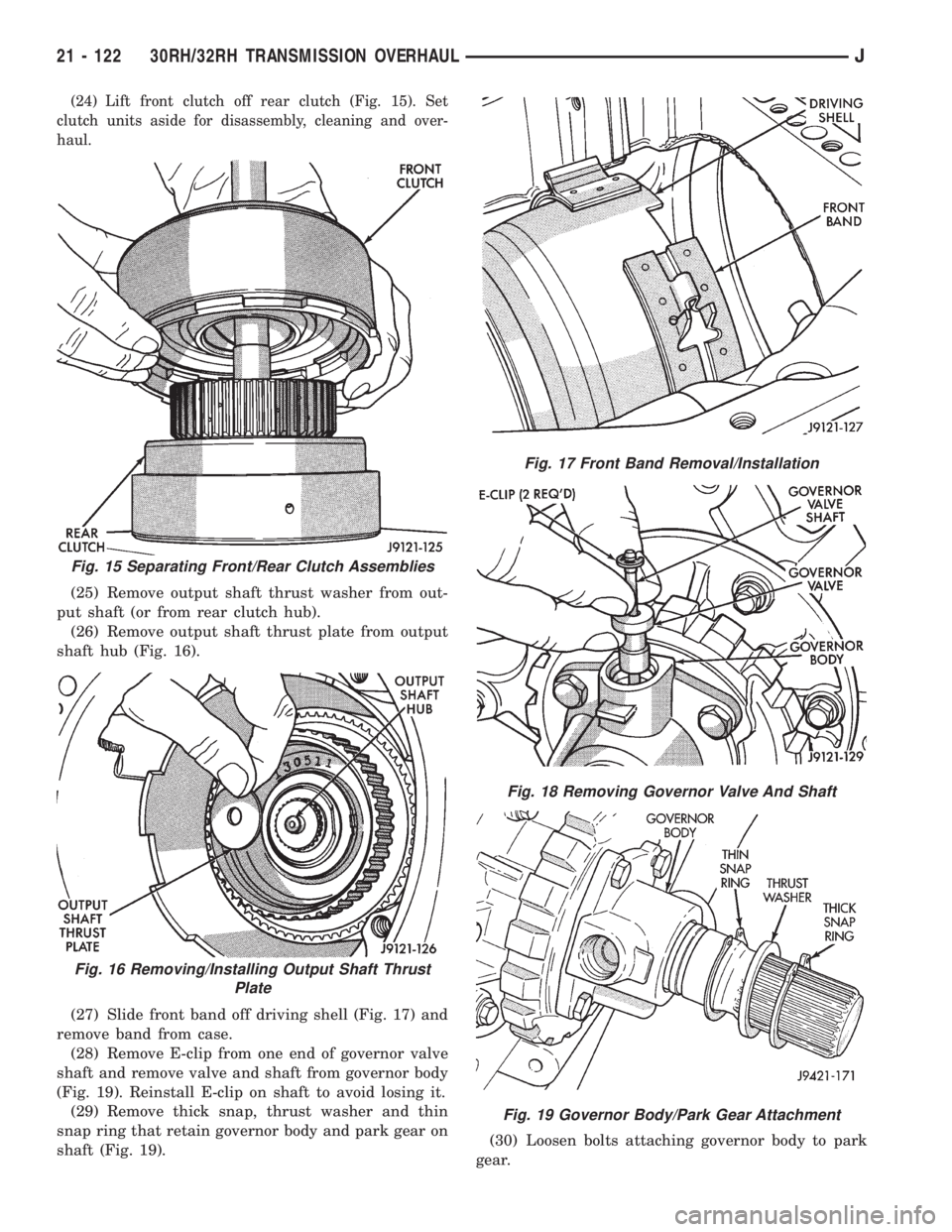

(24) Lift front clutch off rear clutch (Fig. 15). Set

clutch units aside for disassembly, cleaning and over-

haul.

(25) Remove output shaft thrust washer from out-

put shaft (or from rear clutch hub).

(26) Remove output shaft thrust plate from output

shaft hub (Fig. 16).

(27) Slide front band off driving shell (Fig. 17) and

remove band from case.

(28) Remove E-clip from one end of governor valve

shaft and remove valve and shaft from governor body

(Fig. 19). Reinstall E-clip on shaft to avoid losing it.

(29) Remove thick snap, thrust washer and thin

snap ring that retain governor body and park gear on

shaft (Fig. 19).(30) Loosen bolts attaching governor body to park

gear.

Fig. 15 Separating Front/Rear Clutch Assemblies

Fig. 16 Removing/Installing Output Shaft Thrust

Plate

Fig. 17 Front Band Removal/Installation

Fig. 18 Removing Governor Valve And Shaft

Fig. 19 Governor Body/Park Gear Attachment

21 - 122 30RH/32RH TRANSMISSION OVERHAULJ

Page 1500 of 2198

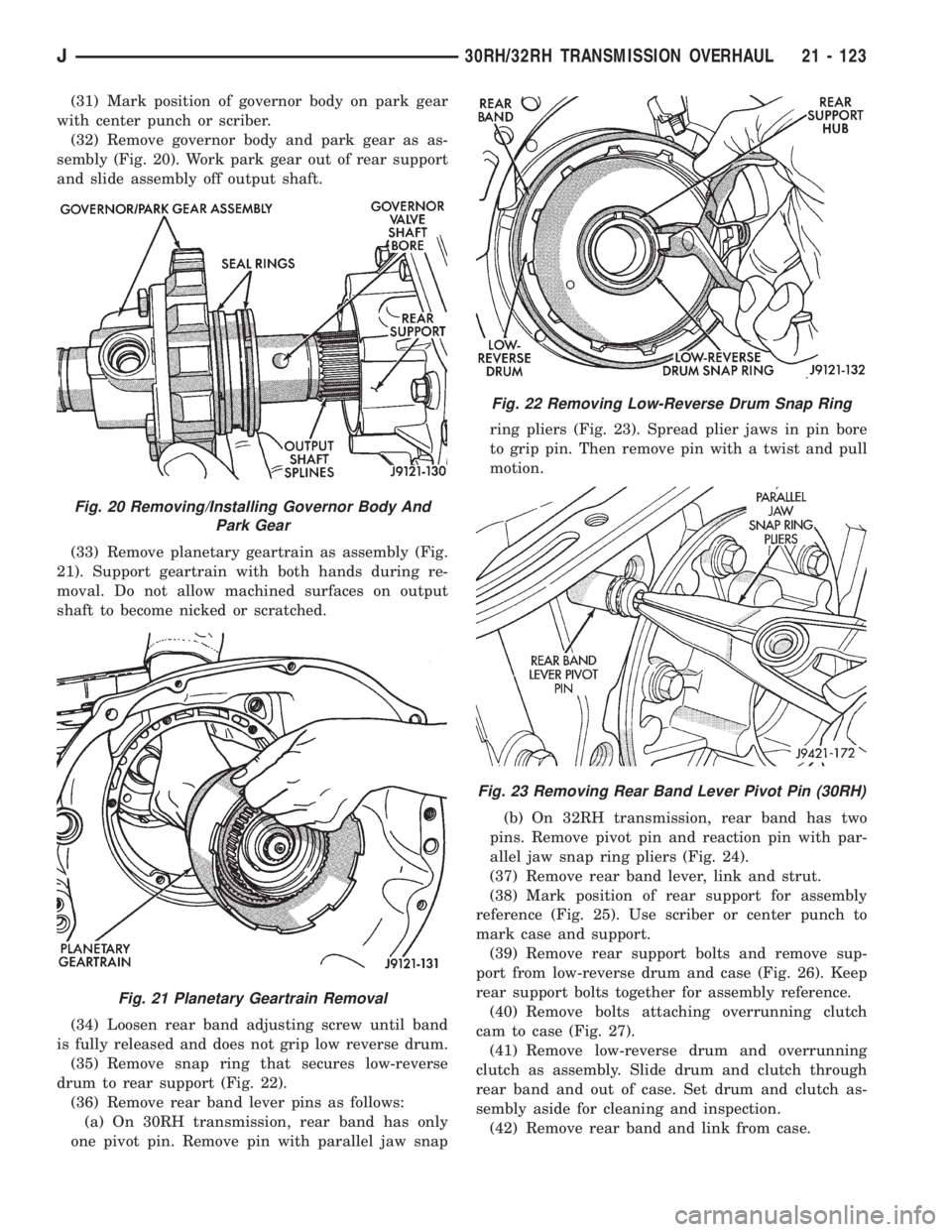

(31) Mark position of governor body on park gear

with center punch or scriber.

(32) Remove governor body and park gear as as-

sembly (Fig. 20). Work park gear out of rear support

and slide assembly off output shaft.

(33) Remove planetary geartrain as assembly (Fig.

21). Support geartrain with both hands during re-

moval. Do not allow machined surfaces on output

shaft to become nicked or scratched.

(34) Loosen rear band adjusting screw until band

is fully released and does not grip low reverse drum.

(35) Remove snap ring that secures low-reverse

drum to rear support (Fig. 22).

(36) Remove rear band lever pins as follows:

(a) On 30RH transmission, rear band has only

one pivot pin. Remove pin with parallel jaw snapring pliers (Fig. 23). Spread plier jaws in pin bore

to grip pin. Then remove pin with a twist and pull

motion.

(b) On 32RH transmission, rear band has two

pins. Remove pivot pin and reaction pin with par-

allel jaw snap ring pliers (Fig. 24).

(37) Remove rear band lever, link and strut.

(38) Mark position of rear support for assembly

reference (Fig. 25). Use scriber or center punch to

mark case and support.

(39) Remove rear support bolts and remove sup-

port from low-reverse drum and case (Fig. 26). Keep

rear support bolts together for assembly reference.

(40) Remove bolts attaching overrunning clutch

cam to case (Fig. 27).

(41) Remove low-reverse drum and overrunning

clutch as assembly. Slide drum and clutch through

rear band and out of case. Set drum and clutch as-

sembly aside for cleaning and inspection.

(42) Remove rear band and link from case.

Fig. 20 Removing/Installing Governor Body And

Park Gear

Fig. 21 Planetary Geartrain Removal

Fig. 22 Removing Low-Reverse Drum Snap Ring

Fig. 23 Removing Rear Band Lever Pivot Pin (30RH)

J30RH/32RH TRANSMISSION OVERHAUL 21 - 123