interior JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 515 of 2198

SERVICE PROCEDURES

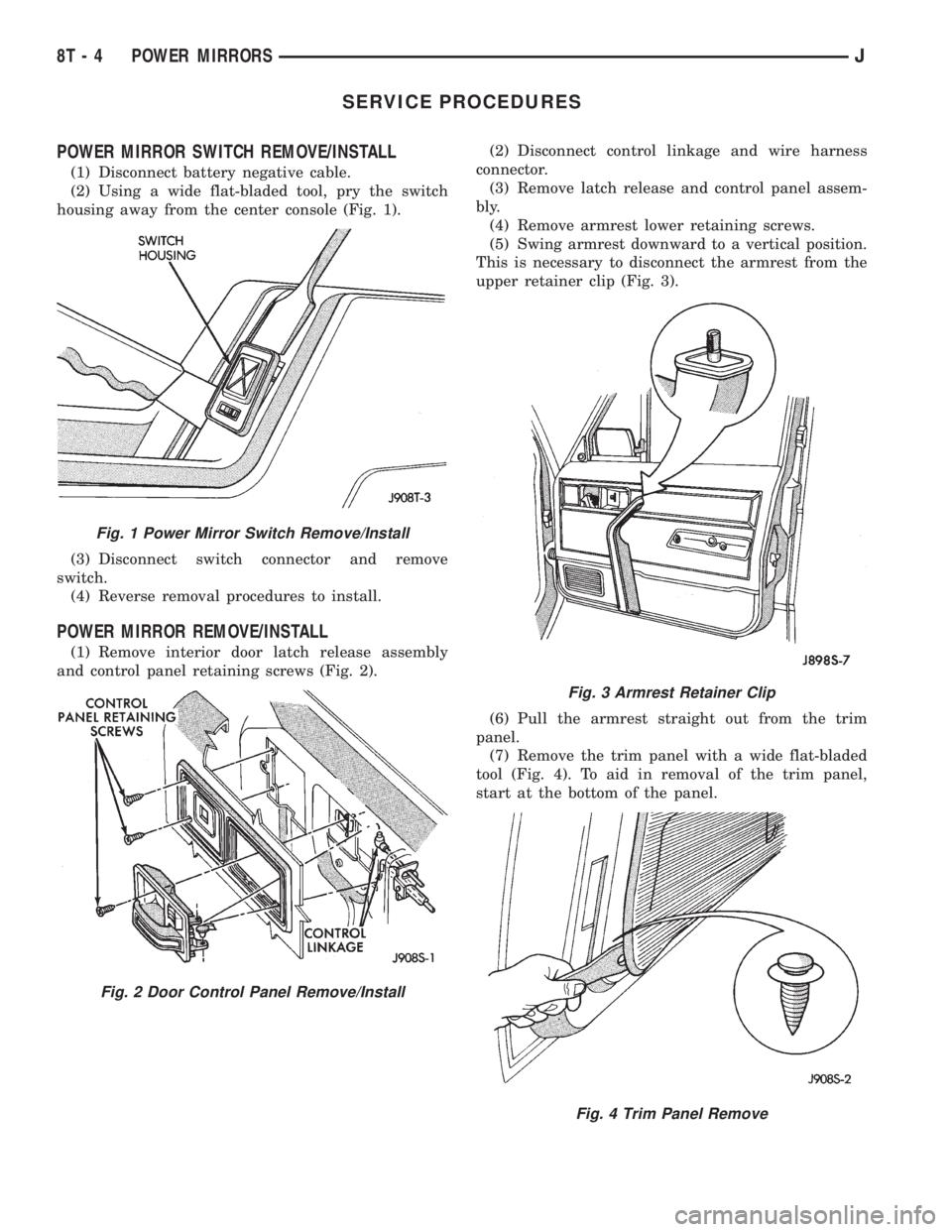

POWER MIRROR SWITCH REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Using a wide flat-bladed tool, pry the switch

housing away from the center console (Fig. 1).

(3) Disconnect switch connector and remove

switch.

(4) Reverse removal procedures to install.

POWER MIRROR REMOVE/INSTALL

(1) Remove interior door latch release assembly

and control panel retaining screws (Fig. 2).(2) Disconnect control linkage and wire harness

connector.

(3) Remove latch release and control panel assem-

bly.

(4) Remove armrest lower retaining screws.

(5) Swing armrest downward to a vertical position.

This is necessary to disconnect the armrest from the

upper retainer clip (Fig. 3).

(6) Pull the armrest straight out from the trim

panel.

(7) Remove the trim panel with a wide flat-bladed

tool (Fig. 4). To aid in removal of the trim panel,

start at the bottom of the panel.

Fig. 1 Power Mirror Switch Remove/Install

Fig. 2 Door Control Panel Remove/Install

Fig. 3 Armrest Retainer Clip

Fig. 4 Trim Panel Remove

8T - 4 POWER MIRRORSJ

Page 519 of 2198

DIAGNOSIS

BUZZER MODULE

(1) Check fuses (15 and 17 - XJ, 3 and 9 - YJ) in

the fuseblock module. If fuses are OK, go to next

step. If not OK, replace fuses as required.

(2) Check for battery voltage at fuse (15 - XJ, 3 -

YJ) in fuseblock module. If OK, go to next step. If not

OK, repair feed circuit from power distribution center

as required.

(3) Turn ignition switch to ON position. Check for

battery voltage at fuse (17 - XJ, 9 - YJ) in the fuse-

block module. If OK, go to next step. If not OK, re-

pair feed from ignition switch as required.

(4) Turn ignition switch to OFF position. Replace

buzzer module with a known good unit and test op-

eration. If not OK, remove buzzer module and go to

next step.

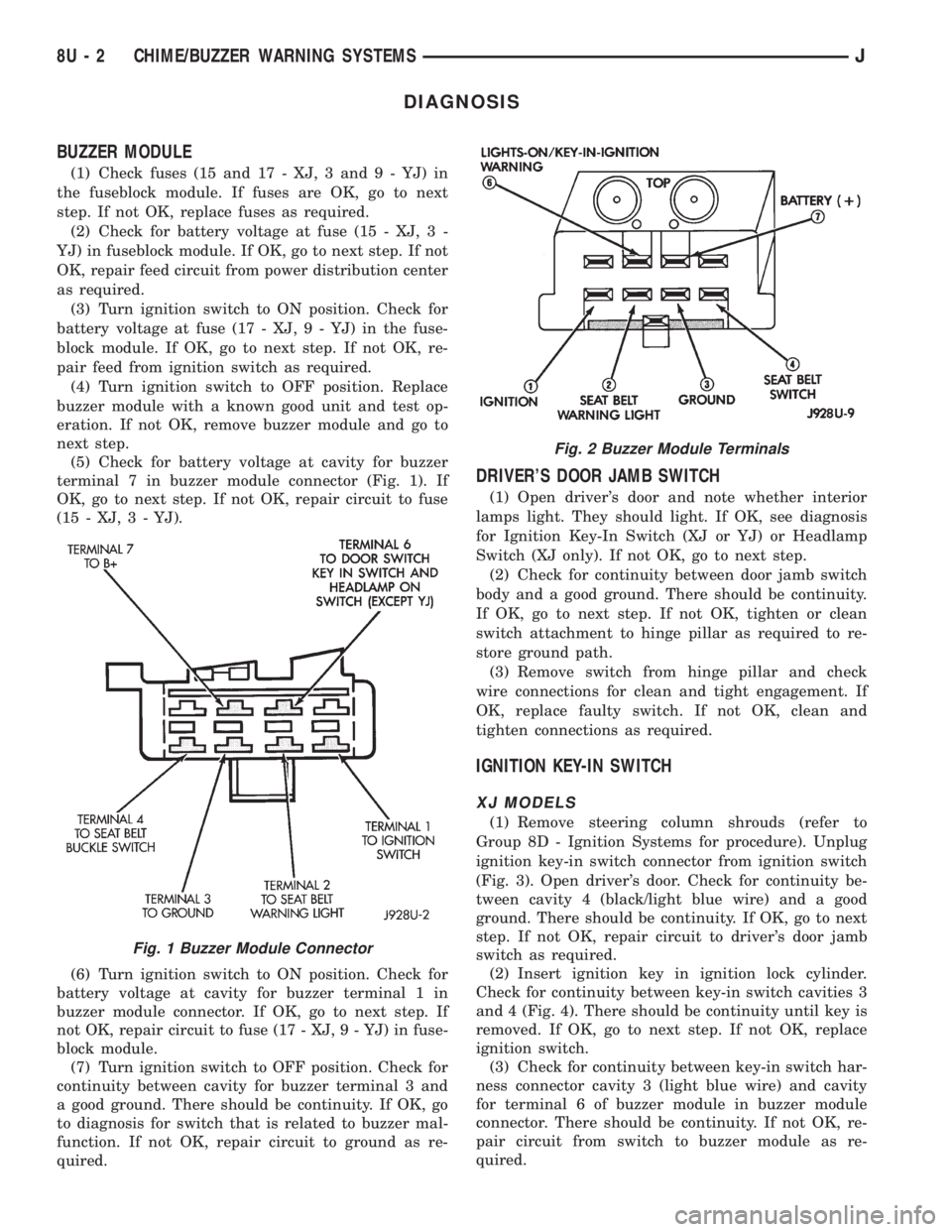

(5) Check for battery voltage at cavity for buzzer

terminal 7 in buzzer module connector (Fig. 1). If

OK, go to next step. If not OK, repair circuit to fuse

(15 - XJ, 3 - YJ).

(6) Turn ignition switch to ON position. Check for

battery voltage at cavity for buzzer terminal 1 in

buzzer module connector. If OK, go to next step. If

not OK, repair circuit to fuse (17 - XJ, 9 - YJ) in fuse-

block module.

(7) Turn ignition switch to OFF position. Check for

continuity between cavity for buzzer terminal 3 and

a good ground. There should be continuity. If OK, go

to diagnosis for switch that is related to buzzer mal-

function. If not OK, repair circuit to ground as re-

quired.

DRIVER'S DOOR JAMB SWITCH

(1) Open driver's door and note whether interior

lamps light. They should light. If OK, see diagnosis

for Ignition Key-In Switch (XJ or YJ) or Headlamp

Switch (XJ only). If not OK, go to next step.

(2) Check for continuity between door jamb switch

body and a good ground. There should be continuity.

If OK, go to next step. If not OK, tighten or clean

switch attachment to hinge pillar as required to re-

store ground path.

(3) Remove switch from hinge pillar and check

wire connections for clean and tight engagement. If

OK, replace faulty switch. If not OK, clean and

tighten connections as required.

IGNITION KEY-IN SWITCH

XJ MODELS

(1) Remove steering column shrouds (refer to

Group 8D - Ignition Systems for procedure). Unplug

ignition key-in switch connector from ignition switch

(Fig. 3). Open driver's door. Check for continuity be-

tween cavity 4 (black/light blue wire) and a good

ground. There should be continuity. If OK, go to next

step. If not OK, repair circuit to driver's door jamb

switch as required.

(2) Insert ignition key in ignition lock cylinder.

Check for continuity between key-in switch cavities 3

and 4 (Fig. 4). There should be continuity until key is

removed. If OK, go to next step. If not OK, replace

ignition switch.

(3) Check for continuity between key-in switch har-

ness connector cavity 3 (light blue wire) and cavity

for terminal 6 of buzzer module in buzzer module

connector. There should be continuity. If not OK, re-

pair circuit from switch to buzzer module as re-

quired.

Fig. 1 Buzzer Module Connector

Fig. 2 Buzzer Module Terminals

8U - 2 CHIME/BUZZER WARNING SYSTEMSJ

Page 530 of 2198

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS.................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES.......... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER......... 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE......... 8W-49-1

8W-50 FRONT LIGHTING............. 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS..................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS.......... 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ VEHICLES 8W - 1 - 1

Page 632 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp, Courtesy Lamps and Dome Lamp.... 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1

Ignition Switch Lamp........................ 1Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 2

Time Delay Relay.......................... 1

Underhood Lamp.......................... 2

Visor Vanity Mirror Lamps.................... 2

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

left courtesy lamp, right courtesy lamp, dome lamp,

and cargo lamp. The M1 circuit also connects to the

remote keyless entry module. Circuit M1 is protected

by the ignition off draw (IOD) fuse (fuse 9) in the fuse

block.

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 19 in the fuse block protects circuit E2. Circuit

Z1 provides ground for all of the illumination lamps

except for the cigar lighter lamp. The cigar lighter

lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

The time delay relay is used to allow a time-ON

function for the ignition switch lamp and the courtesy

lamp. Power for the relay is received on the M1

circuit from the IOD fuse (fuse F9) in the fuse block.

Circuit M2 provides ground for the time delay relay

through the right and left door ajar switches and the

headlamp switch. When a door is opened, or the

headlamp switch is moved to the dome lamp position,a ground path is provided for the relay on circuit M2.

This energizes the relay, causing the contacts to close.

When the relay contacts close, power is provided

through the relay to circuit M50. The M50 circuit

supplies current to the ignition switch lamp. Circuit

Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block powers the glove box lamp. A case grounded

switch, in series after the lamp, closes when the glove

box door is opened. The switch completes a path to

ground on circuit Z1.

CARGO LAMP, COURTESY LAMPS AND DOME

LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the cargo, courtesy lamps and

dome lamp. This circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches from the cour-

tesy and dome lamps. The switches are connected to

ground circuit Z1. When a door is opened, the plunger

in the switch closes, completing a path to ground.

The second way is through the liftgate switch. Cir-

cuit M2 connects to circuit M4 at the cargo lamp.

Circuit M4 connects to the liftgate switch. The lift-

gate switch connects to ground circuit Z1. When the

lift gate opens, the plunger in the switch closes, com-

pleting a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp switch

to the dome lamp ON position, a ground path is

provided through the switch.

J8W-44 INTERIOR LIGHTINGÐXJ VEHICLES 8W - 44 - 1

Page 633 of 2198

READING LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the reading lamps. Circuit

M1 is HOT at all times. When the operator depresses

the reading lamp, the reading lamp switch closes and

supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the vanity lamps. Circuit M1

is HOT at all times. When the vanity lamps switch

closes, voltage flows to vanity mirror lamps. The van-

ity mirror is case grounded.

UNDERHOOD LAMP

Circuit A6 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, circuit F87 from fuse 17 in the fuse block

supplies power to the chime/buzzer module. Circuit

A21 from the ignition switch supplies power to fuse

17.

Circuit L7 from fuse 15 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 15.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime/buzzer module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground forthe chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.

Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime\buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-7

Door Jamb Switches.....................8W-44-10

Fuse 3 (PDC).........................8W-44-4, 6

Fuse 5 (PDC).........................8W-44-3, 8

Fuse 6 (PDC)...........................8W-44-3

Fuse 9 (Fuse Block).....................8W-44-4, 6

Fuse 15 (Fuse Block)....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 17 (Fuse Block)......................8W-44-3

Fuse 19 (Fuse Block)......................8W-44-8

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch...................8W-44-3, 4, 5, 8

Headlamp Delay Module....................8W-44-4

Headlamp Delay Relay.....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster........................8W-44-3

Instrument Panel Illumination Lamps..........8W-44-8, 9

Intermittent Wiper Control Module.............8W-44-4

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-7

Remote Keyless Entry Module................8W-44-7

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

Vanity Lamps...........................8W-44-7

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ VEHICLESJ

Page 814 of 2198

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS...................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES........... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER........ 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE.......... 8W-49-1

8W-50 FRONT LIGHTING............ 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS.................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS............ 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ-RHD 8W - 1 - 1

Page 908 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp and Dome Lamp................. 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1Ignition Switch Lamp........................ 1

Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 1

Underhood Lamp.......................... 1

Visor Vanity Mirror Lamps.................... 1

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

dome lamp, reading lamps, cargo lamp and vanity

lamps. Circuit M1 is protected by fuse 16 in the

Power Distribution Center (PDC).

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window switch lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 25 in the fuse block protects circuit E2. Cir-

cuit Z1 provides ground for all of the illumination

lamps except for the cigar lighter lamp. The cigar

lighter lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

Circuit M50 supplies voltage to the ignition switch

lamp. Circuit Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) powers the glove box lamp. A case

grounded switch, in series after the lamp, closes

when the glove box door is opened. The switch com-

pletes a path to ground on circuit Z1.

CARGO LAMP AND DOME LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the cargo lamp anddome lamp. The M1 circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches to the dome

lamp and cargo lamp. The switches are connected to

ground circuit Z1. When a door is opened, the

plunger in the switch closes, completing a path to

ground.

The second way is through the liftgate switch. Cir-

cuit G71 connects to circuit M2 at the cargo lamp

connector. Circuit G71 connects to the liftgate switch.

The liftgate switch connects to ground circuit Z1.

When the lift gate opens, the plunger in the switch

closes, completing a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp

switch to the dome lamp ON position, a ground path

is provided through the switch.

READING LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the reading lamps.

Circuit M1 is HOT at all times. When the operator

depresses the reading lamp, the reading lamp switch

closes and supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the vanity lamps.

Circuit M1 is HOT at all times. When the vanity

lamps switch closes, voltage flows to vanity mirror

lamps. The vanity mirror is case grounded.

UNDERHOOD LAMP

Circuit A7 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

J8W-44 INTERIOR LIGHTINGÐXJ-RHD 8W - 44 - 1

Page 909 of 2198

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, fuse F87 from fuse 26 in the fuse block sup-

plies power to the chime/buzzer module. Circuit A21

from the ignition switch supplies power to fuse 26.

Circuit L7 from fuse 9 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 9.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground for

the chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-6

Door Jamb Switches......................8W-44-7

Fuse 3 (PDC)...........................8W-44-6

Fuse 5 (PDC).........................8W-44-5, 8

Fuse 6 (PDC)...........................8W-44-6

Fuse 9 (Fuse Block).....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 25 (Fuse Block)......................8W-44-8

Fuse 26 (Fuse Block)......................8W-44-3

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch....................8W-44-3, thru 8

Headlamp Delay Module....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster......................8W-44-3, 9

Instrument Panel Illumination Lamps..........8W-44-8, 9

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-6

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ-RHDJ

Page 1198 of 2198

FRAME AND BUMPERS

CONTENTS

page page

BUMPERS.............................. 5

BUMPERS............................. 16FRAME................................. 1

FRAME................................ 10

FRAME

INDEX

page page

Frame Dimensions......................... 1

Front Skid Plate........................... 1

Fuel Filler Hose Splash ShieldÐXJ Vehicles...... 4

Fuel Tank Skid Plate........................ 3Fuel Tank Support Strap..................... 4

General Information........................ 1

Transfer Case Skid Plate.................... 3

GENERAL INFORMATION

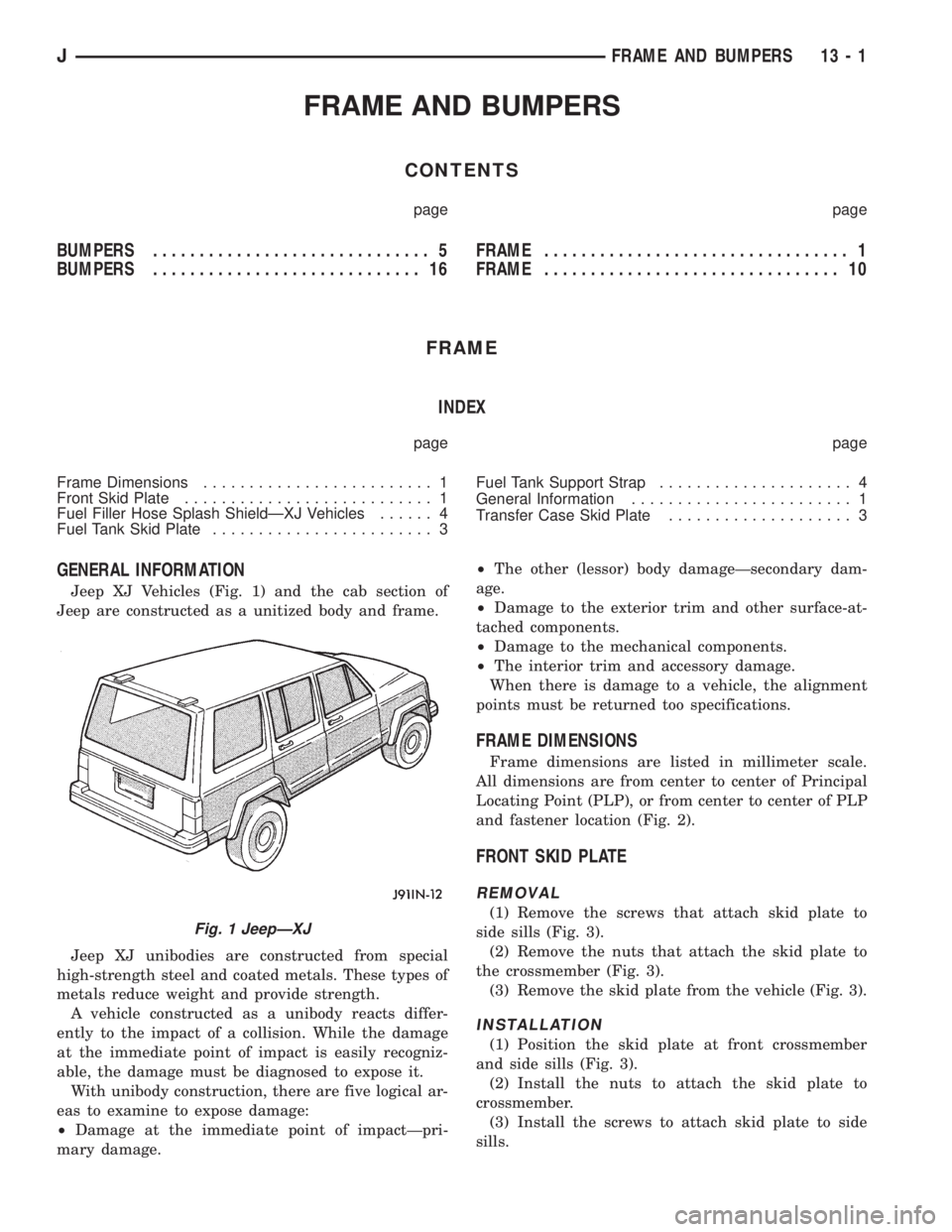

Jeep XJ Vehicles (Fig. 1) and the cab section of

Jeep are constructed as a unitized body and frame.

Jeep XJ unibodies are constructed from special

high-strength steel and coated metals. These types of

metals reduce weight and provide strength.

A vehicle constructed as a unibody reacts differ-

ently to the impact of a collision. While the damage

at the immediate point of impact is easily recogniz-

able, the damage must be diagnosed to expose it.

With unibody construction, there are five logical ar-

eas to examine to expose damage:

²Damage at the immediate point of impactÐpri-

mary damage.²The other (lessor) body damageÐsecondary dam-

age.

²Damage to the exterior trim and other surface-at-

tached components.

²Damage to the mechanical components.

²The interior trim and accessory damage.

When there is damage to a vehicle, the alignment

points must be returned too specifications.

FRAME DIMENSIONS

Frame dimensions are listed in millimeter scale.

All dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location (Fig. 2).

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 3).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 3).

(3) Remove the skid plate from the vehicle (Fig. 3).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 3).

(2) Install the nuts to attach the skid plate to

crossmember.

(3) Install the screws to attach skid plate to side

sills.

Fig. 1 JeepÐXJ

JFRAME AND BUMPERS 13 - 1

Page 1225 of 2198

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be re-

placed immediately if there is any evidence of degra-

dation that could result in failure.

Never attempt to repair a plastic fuel line/tube. Re-

place as necessary.

Avoid contact of any fuel tubes/hoses with other ve-

hicle components that could cause abrasions or scuff-

ing. Be sure that the plastic fuel lines/tubes are

properly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

The hose clamps used to secure rubber hoses on

fuel injected vehicles are of a special rolled edge con-

struction. This construction is used to prevent the

edge of the clamp from cutting into the hose. Only

these rolled edge type clamps may be used in this

system. All other types of clamps may cut into the

hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 1 Nzm (15 in. lbs.) torque.

QUICK-CONNECT FITTINGS

Also refer to the previous Fuel Tubes/Lines/Hoses

and Clamps section.

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type.

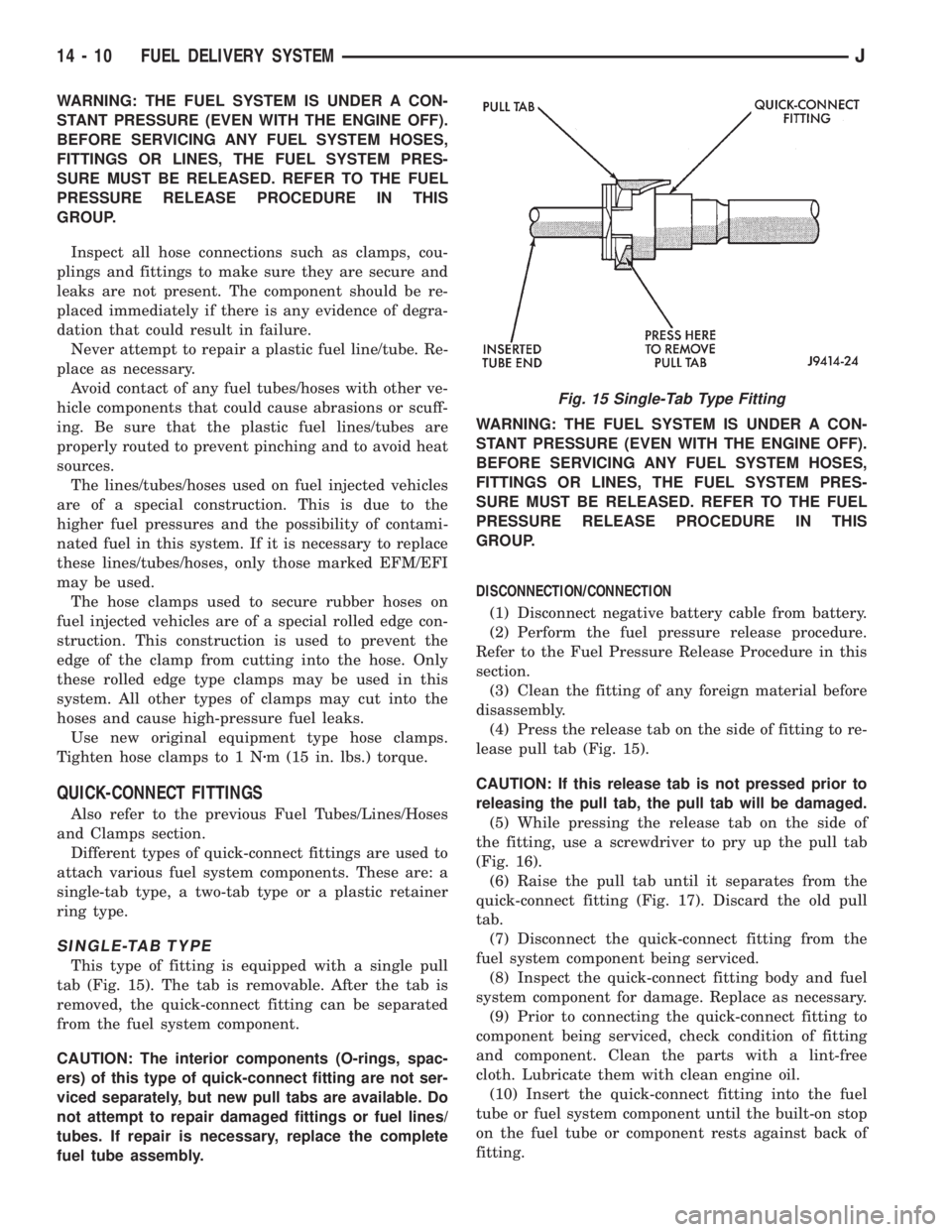

SINGLE-TAB TYPE

This type of fitting is equipped with a single pull

tab (Fig. 15). The tab is removable. After the tab is

removed, the quick-connect fitting can be separated

from the fuel system component.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new pull tabs are available. Do

not attempt to repair damaged fittings or fuel lines/

tubes. If repair is necessary, replace the complete

fuel tube assembly.WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Disconnect negative battery cable from battery.

(2) Perform the fuel pressure release procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Clean the fitting of any foreign material before

disassembly.

(4) Press the release tab on the side of fitting to re-

lease pull tab (Fig. 15).

CAUTION: If this release tab is not pressed prior to

releasing the pull tab, the pull tab will be damaged.

(5) While pressing the release tab on the side of

the fitting, use a screwdriver to pry up the pull tab

(Fig. 16).

(6) Raise the pull tab until it separates from the

quick-connect fitting (Fig. 17). Discard the old pull

tab.

(7) Disconnect the quick-connect fitting from the

fuel system component being serviced.

(8) Inspect the quick-connect fitting body and fuel

system component for damage. Replace as necessary.

(9) Prior to connecting the quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean the parts with a lint-free

cloth. Lubricate them with clean engine oil.

(10) Insert the quick-connect fitting into the fuel

tube or fuel system component until the built-on stop

on the fuel tube or component rests against back of

fitting.

Fig. 15 Single-Tab Type Fitting

14 - 10 FUEL DELIVERY SYSTEMJ