ECU JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 93 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl Caution:

Oil ports of the rocker arm shaft must

coincide with oil return passages of the rocker

arms.

If they do not,

engine

oil has no return path

from

the cylinder head to the crankcase; in that

case,

engine

oil flows down the valve

stems

and

burns

in the cylinders.

There

is a notch at one end of each rocker arm shaft. When rocker arms

are

properly installed on the shaft, this notch

will

be at front of right rocker arm shaft and at

rear

of left rocker arm shaft. Refer to

Figs.

Dl-25 and

Dl-26.

a.

Position center support on rocker arm shaft;

insert

one shaft assembly attaching bolt through

support and shaft to hold support in position.

b.

Install

center

pair

of rocker arms with notched

faces touching support.

Install

front and

rear

spacer

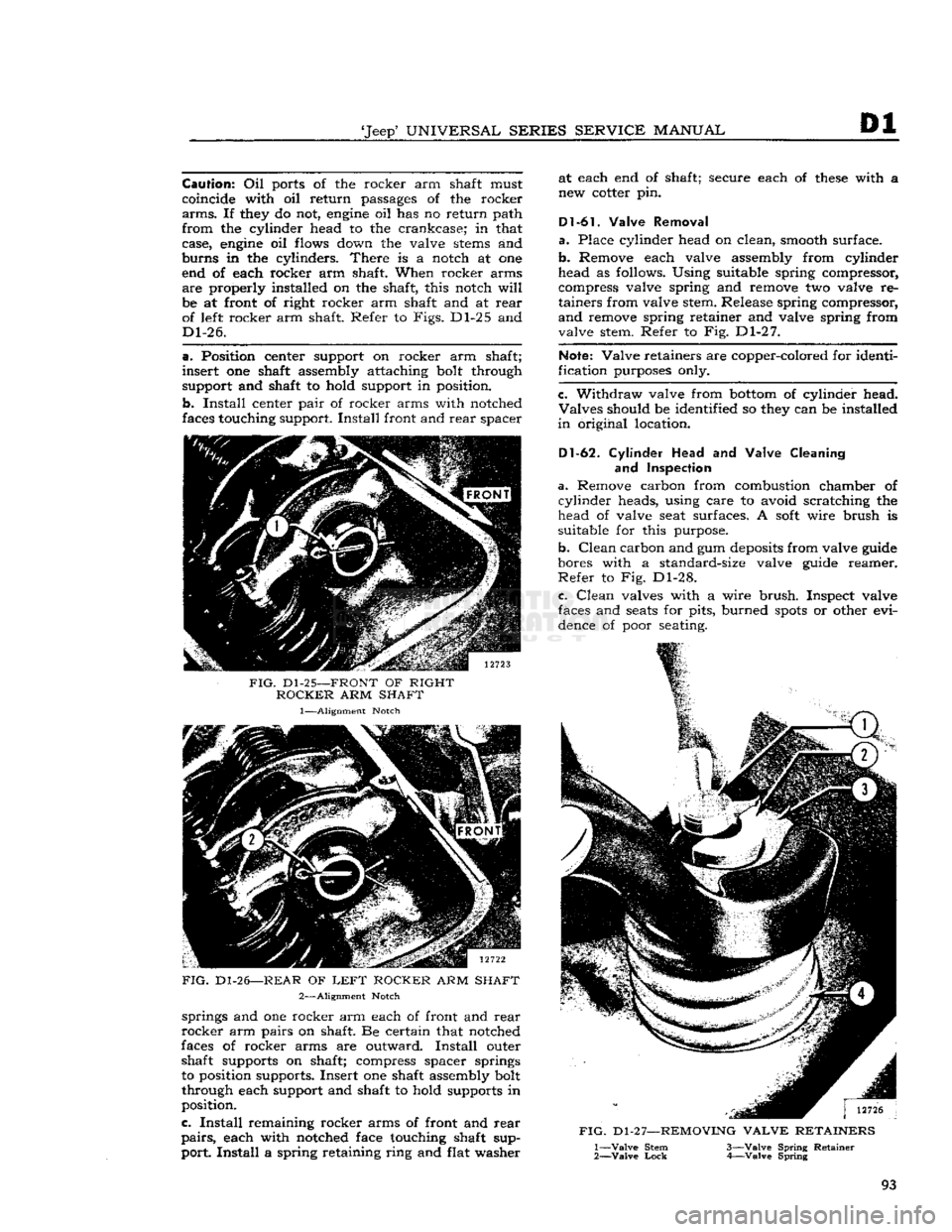

FIG.

Dl-25—FRONT

OF RIGHT

ROCKER

ARM SHAFT

1—Alignment Notch

FIG.

Dl-26—REAR OF

LEFT

ROCKER

ARM SHAFT 2—Alignment Notch springs and one rocker arm each of front and

rear

rocker

arm pairs on shaft. Be certain that notched

faces of rocker arms are outward.

Install

outer shaft supports on shaft; compress spacer springs

to position supports. Insert one shaft assembly bolt

through each support and shaft to hold supports in

position.

c.

Install

remaining rocker arms of front and

rear

pairs,

each with notched face touching shaft sup

port.

Install

a spring retaining ring and flat washer at each end of shaft; secure each of

these

with a

new cotter pin.

D1 -61.

Valve Removal

a.

Place cylinder head on clean, smooth surface.

b.

Remove each valve assembly from cylinder

head as follows. Using suitable spring compressor, compress valve spring and remove two valve re

tainers

from valve stem. Release spring compressor,

and

remove spring retainer and valve spring from

valve stem. Refer to Fig. Dl-27.

Note:

Valve retainers are copper-colored for identi

fication purposes only.

c.

Withdraw valve from

bottom

of cylinder head.

Valves

should be identified so they can be installed

in

original location.

D1-62.

Cylinder

Head and Valve Cleaning

and

Inspection

a.

Remove carbon from combustion chamber of

cylinder

heads, using care to avoid scratching the head of valve seat surfaces. A

soft

wire brush is

suitable for this purpose.

b.

Clean

carbon and gum

deposits

from valve guide

bores with a standard-size valve guide reamer.

Refer

to Fig. Dl-28.

c.

Clean

valves with a wire

brush.

Inspect valve

faces and

seats

for pits, burned

spots

or other evi dence of poor seating.

FIG.

D1 -2 7—REMOVING

VALVE

RETAINERS

1—

Valve

Stem 3—Valve Spring Retainer

2—

Valve

Lock

4—Valve Spring

93

Page 97 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

size have

been

selected. If necessary, check or

select

connecting rod bearings as described in Par. Dl-49.

Note:

When a piston and connecting rod assembly

is properly installed, the oil spurt

hole

in the con necting rod

will

face the camshaft. The rib on the

edge

of the bearing cap

will

be on the same side

as the conical

boss

on the connecting rod web;

these

marks (rib and boss)

will

be toward the other

connecting rod on the same crankpin. The notch

on the piston

will

face the front of the

engine.

a.

Be certain that cylinder bores, pistons, connect

ing rod bearings and crankshaft journals are absolutely clean. Coat all bearing surfaces with

engine

oil.

b. Before installing a piston and connecting rod as

sembly into its bore, rotate the crankshaft so that

the corresponding crankpin is moved downward, away from the cylinder bore.

c. Remove bearing cap from connecting rod. With

upper bearing half seated in connecting rod, install connecting rod guides. These

guides

hold the upper

bearing half in place and prevent damage to the

crankshaft

crankpin during installation of the con

necting rod and piston assembly.

d.

Be certain that the gap in the oil ring rails faces

upward,

toward center of

engine.

Gaps of the com

pression rings shall not be aligned with each other

or

with the oil ring

rails.

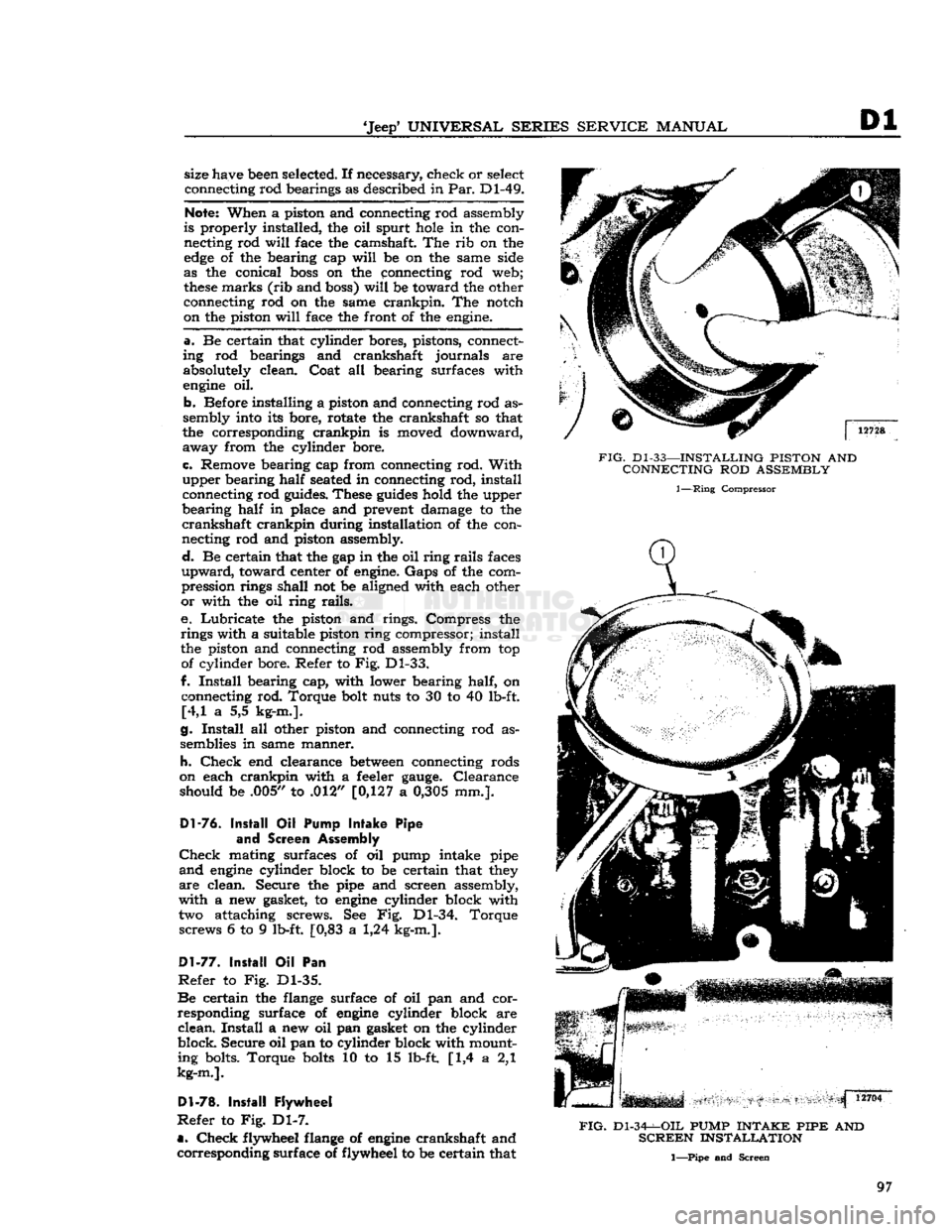

e. Lubricate the piston and rings. Compress the

rings with a suitable piston ring compressor; install

the piston and connecting rod assembly from top of cylinder bore. Refer to Fig. Dl-33.

f.

Install

bearing cap, with lower bearing half, on connecting rod. Torque bolt nuts to 30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

g.

Install

all other piston and connecting rod as

semblies in same manner.

h.

Check

end clearance

between

connecting rods

on each crankpin with a feeler

gauge.

Clearance should be .005,/ to .012" [0,127 a

0,305

mm.].

Dl-76.

Install

Oil

Pump

Intake

Pipe

and

Screen Assembly

Check

mating surfaces of oil pump intake pipe

and

engine

cylinder block to be certain that they

are

clean. Secure the pipe and screen assembly,

with a new gasket, to

engine

cylinder block with two attaching screws. See Fig. Dl-34. Torque screws 6 to 9 lb-ft. [0,83 a 1,24 kg-m.].

Dl-77.

Install

Oil Pan

Refer

to Fig. Dl-35.

Be

certain the flange surface of oil pan and cor

responding surface of

engine

cylinder block are

clean.

Install

a new oil pan gasket on the cylinder

block.

Secure

oil pan to cylinder block with mount ing bolts. Torque

bolts

10 to 15 lb-ft [1,4 a 2,1

kg-m.].

Dl-78.

Install

Flywheel

Refer

to Fig. Dl-7.

a.

Check

flywheel flange of

engine

crankshaft and corresponding surface of flywheel to

be

certain that

FIG.

Dl-33—INSTALLING

PISTON

AND

CONNECTING

ROD

ASSEMBLY

1—Ring

Compressor

FIG.

Dl-34-^-OIL

PUMP

INTAKE PIPE

AND

SCREEN

INSTALLATION

1—Pipe and Screen

97

Page 99 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Dl

both are clean. Any foreign material on either of

these

surfaces

will

cause flywheel run out and en

gine

vibration. Position flywheel to crankshaft and

secure with six mounting bolts. Torque mounting

bolts

50 to 65 lb-ft. [6,91 a 8,98 kg-m.].

Note:

Flywheel mounting

bolts

are unevenly

spaced so that flywheel can be installed in only

one position.

This

assures correct balance of fly

wheel and crankshaft.

b.

Mount a

dial

indicator on flywheel housing

flange of cylinder block and index its plunger to

the flywheel surface. Measure flywheel run out.

Maximum

allowable run out is .015"

[0,381

mm.].

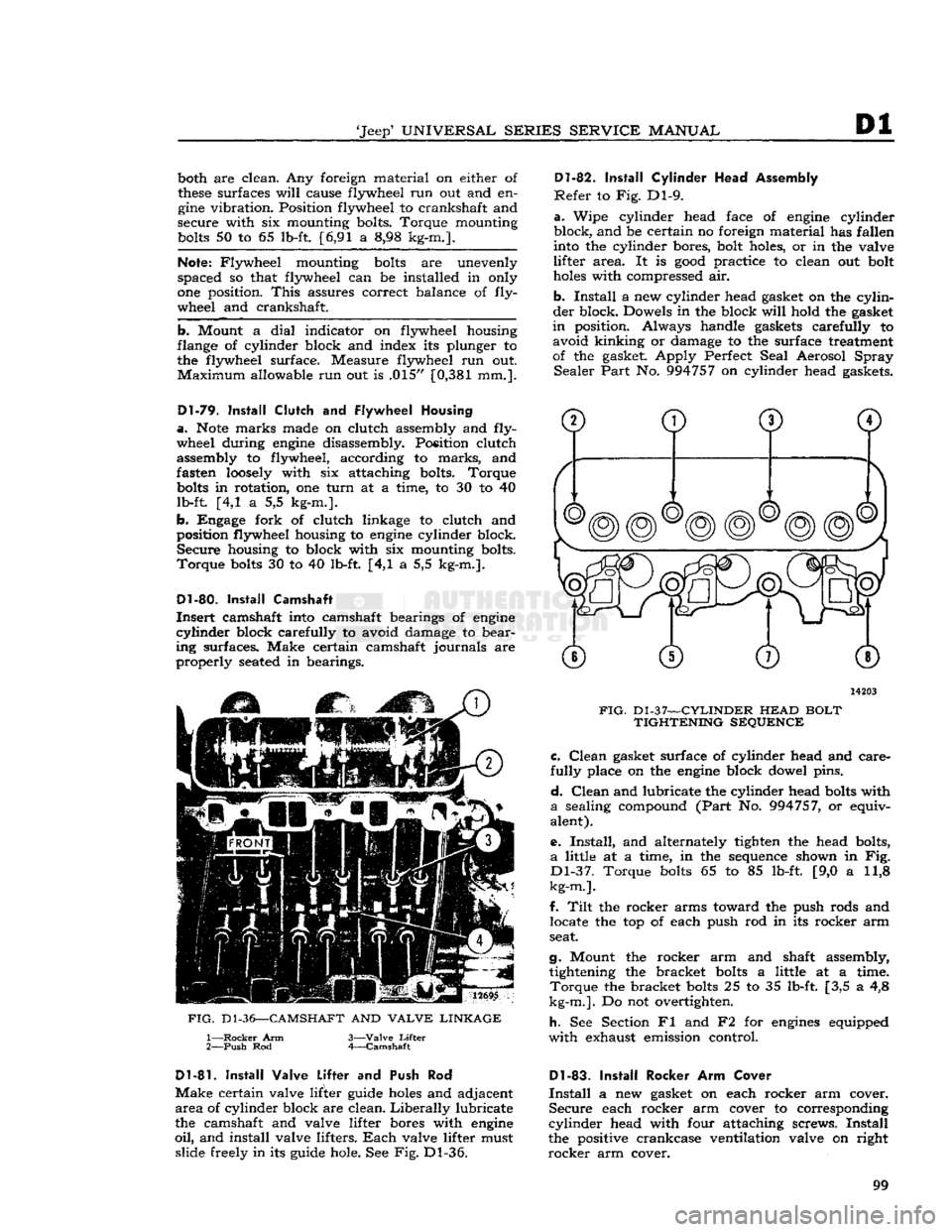

Dl-82.

Install

Cylinder

Head Assembly

Refer

to Fig. Dl-9.

a.

Wipe cylinder head face of

engine

cylinder

block, and be certain no foreign material has fallen

into the cylinder bores, bolt holes, or in the valve

lifter

area.

It is

good

practice to clean out bolt

holes

with compressed air.

b.

Install

a new cylinder head gasket on the

cylin

der

block. Dowels in the block

will

hold the gasket

in

position. Always handle gaskets carefully to

avoid

kinking or damage to the surface treatment

of the gasket. Apply Perfect Seal Aerosol

Spray

Sealer

Part

No.

994757

on cylinder head gaskets.

Dl-79.

Install

Clutch

and Flywheel Housing

a.

Note

marks made on clutch assembly and fly

wheel during

engine

disassembly. Position clutch

assembly to flywheel, according to

marks,

and

fasten

loosely

with six attaching bolts. Torque

bolts

in rotation, one

turn

at a time, to 30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

b.

Engage fork of clutch linkage to clutch and

position flywheel housing to

engine

cylinder block.

Secure

housing to block with six mounting bolts.

Torque

bolts

30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

D1-80.

Install

Camshaft

Insert

camshaft into camshaft bearings of

engine

cylinder

block carefully to avoid damage to bear

ing surfaces. Make certain camshaft journals are

properly

seated in bearings.

12695

FIG.

D1-36—CAMSHAFT

AND

VALVE LINKAGE

1—

Rocker

Arm

2—

Push

Rod 3—

Valve

Lifter

4—

Camshaft

14203

FIG.

Dl-37—CYLINDER

HEAD

BOLT TIGHTENING SEQUENCE c.

Clean

gasket surface of cylinder head and care

fully

place on the

engine

block dowel pins.

d.

Clean

and lubricate the cylinder head

bolts

with

a

sealing compound

(Part

No. 994757, or equiv

alent).

e.

Install,

and alternately tighten the head bolts,

a

little at a time, in the sequence shown in Fig.

Dl-37.

Torque

bolts

65 to 85 lb-ft. [9,0 a 11,8

kg-m.].

f.

Tilt

the rocker arms toward the push rods and locate the top of each push rod in its rocker arm

seat.

g.

Mount the rocker arm and shaft assembly, tightening the bracket

bolts

a little at a time.

Torque

the bracket

bolts

25 to 35 lb-ft. [3,5 a 4,8

kg-m.].

Do not overtighten.

h.

See Section Fl and F2 for

engines

equipped

with

exhaust emission control.

D1-81.

Install

Valve Lifter

and Push Rod

Make

certain valve lifter guide

holes

and adjacent

area

of cylinder block are clean.

Liberally

lubricate

the camshaft and valve lifter bores with

engine

oil,

and install valve lifters.

Each

valve lifter must slide freely in its guide hole. See Fig. Dl-36.

Dl-83.

Install

Rocker Arm Cover

Install

a new gasket on each rocker arm cover.

Secure

each rocker arm cover to corresponding

cylinder

head with four attaching screws.

Install

the positive crankcase ventilation valve on right

rocker

arm cover. 99

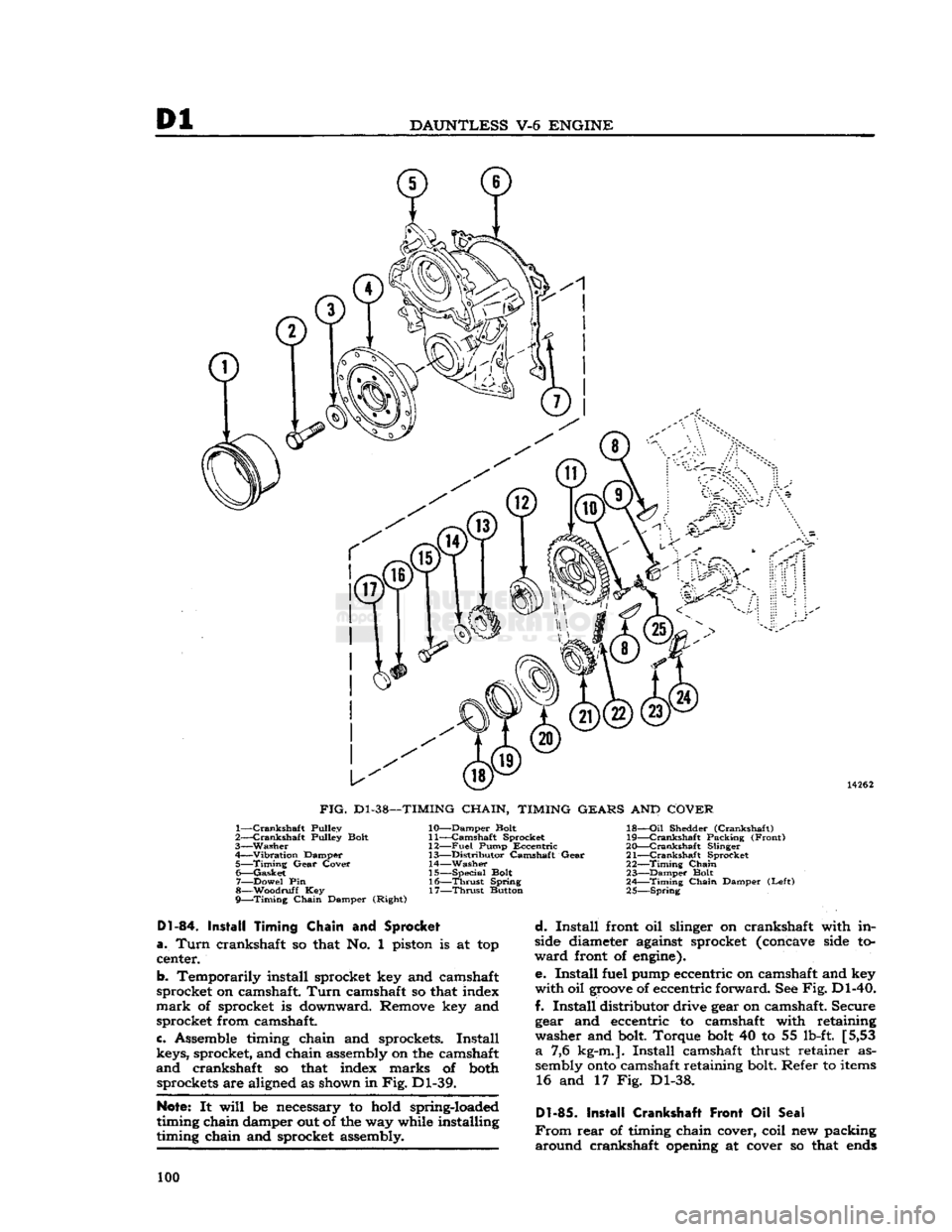

Page 100 of 376

Dl

DAUNTLESS

V-6

ENGINE

14262

FIG.

D1-38—TIMING

CHAIN,

TIMING

GEARS

AND

COVER

1—

Crankshaft

Pulley

2—

Crankshaft

Pulley Bolt

3—

Washer

4—

Vibration

Damper 5—

Timing

Gear

Cover

6—

Gasket

7—

Dowel

Pin

g—Woodruff Key

9—Timing

Chain

Damper (Right) 10—

Damper

Bolt

11—

Camshaft

Sprocket

12—

Fuel

Pump

Eccentric

13—

Distributor

Camshaft

Gear

14—

Washer

15—

Special

Bolt 16—

-Thrust

Spring

17—

Thrust

Button 18—

Oil

Shedder

(Crankshaft)

19—

-Crankshaft

Packing

(Front)

20—

-Crankshaft

Slinger •

21—

Crankshaft

Sprocket

22—

Timing

Chain

23—

Damper

Bolt .

2

A

Timing

Chain

Damper

(Left)

25

Spring

D1-84.

Install Timing Chain

and

Sprocket

a.

Turn

crankshaft so that No. 1 piston is at top

center.

b.

Temporarily install sprocket key and camshaft

sprocket on camshaft.

Turn

camshaft so that index

mark

of sprocket is downward. Remove key and sprocket from camshaft.

c.

Assemble timing chain and sprockets.

Install

keys, sprocket, and chain assembly on the camshaft

and

crankshaft so that index marks of both sprockets are aligned as shown in

Fig.

Dl-39.

Note:

It

will

be necessary to hold spring-loaded

timing chain damper out of the way while installing

timing chain and sprocket assembly.

d.

Install

front oil slinger on crankshaft with in

side diameter against sprocket (concave side to

ward

front of engine).

e.

Install

fuel pump eccentric on camshaft and key

with

oil

groove

of eccentric forward. See

Fig.

Dl-40.

f.

Install

distributor drive gear on camshaft. Secure gear and eccentric to camshaft with retaining

washer and bolt. Torque

bolt

40 to 55 lb-ft. [5,53

a

7,6 kg-m.].

Install

camshaft thrust retainer as

sembly

onto

camshaft retaining bolt. Refer to

items

16 and 17 Fig. Dl-38.

Dl-85.

Install Crankshaft Front

Oil

Seal

From

rear

of timing chain cover, coil new packing

around

crankshaft opening at cover so that

ends

100

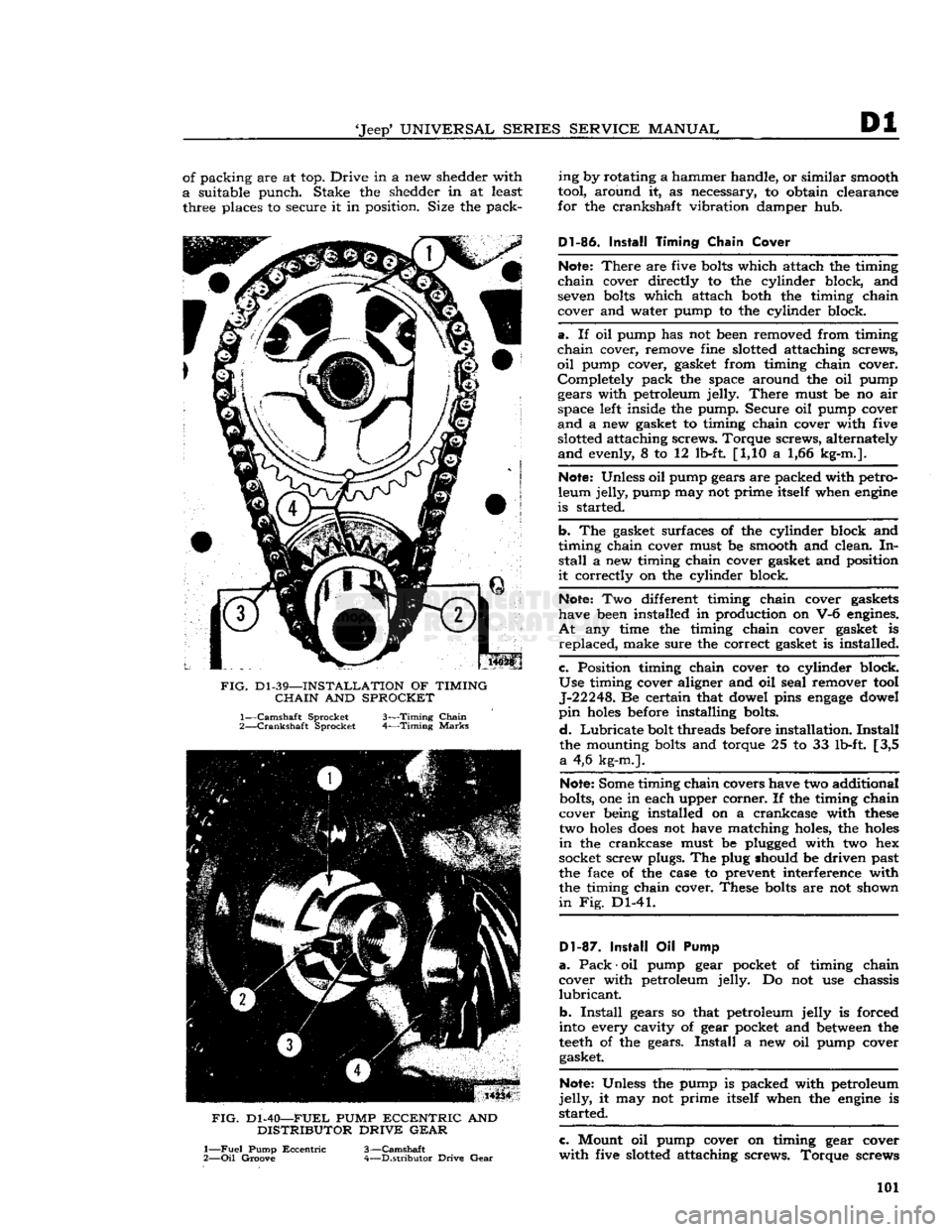

Page 101 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

of packing are at top. Drive in a new shedder with

a

suitable punch. Stake the shedder in at least three places to secure it in position. Size the pack-

FIG.

Dl-39—INSTALLATION

OF

TIMING

CHAIN

AND

SPROCKET

1—

Camshaft

Sprocket 3—Timing

Chain

2—

Crankshaft

Sprocket 4—Timing

Marks

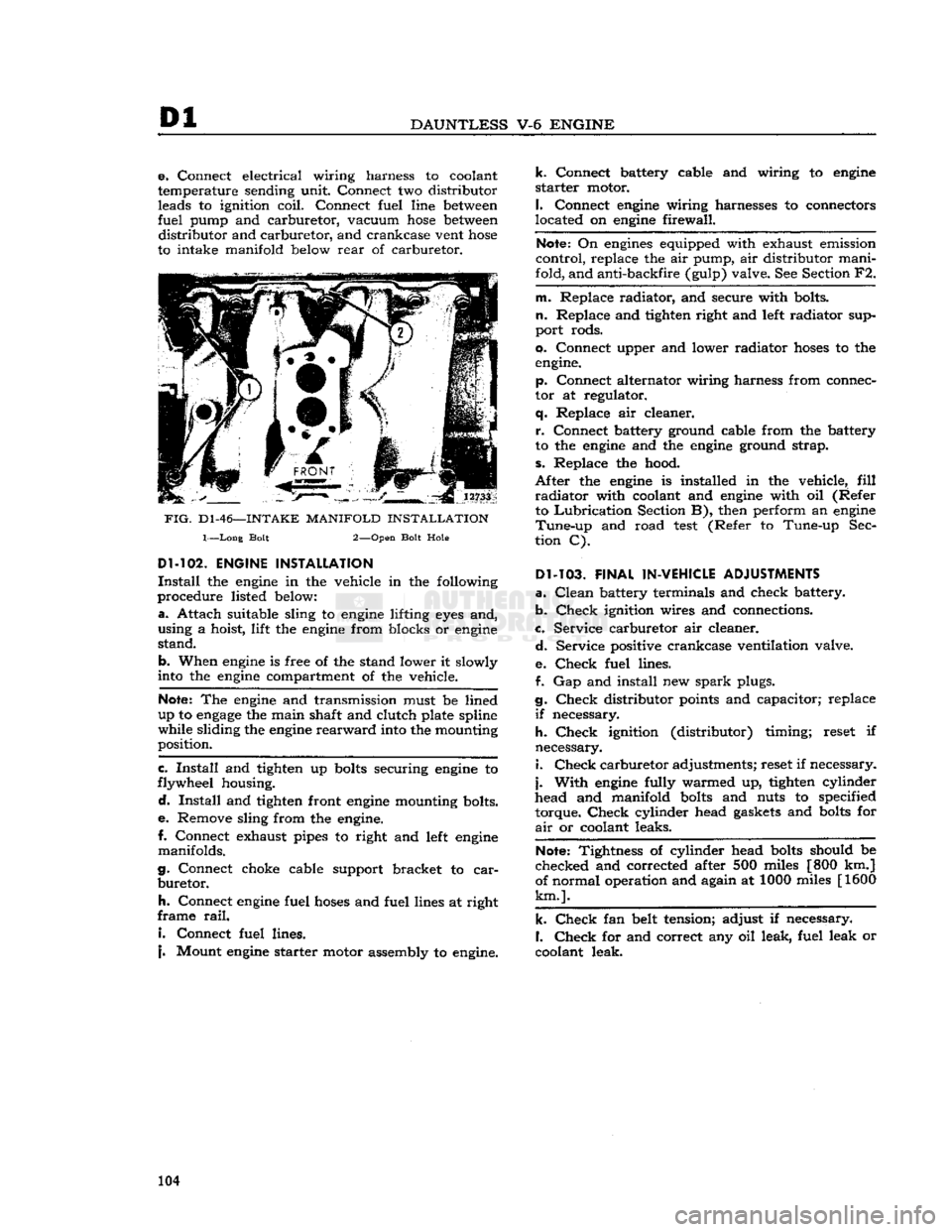

FIG.

Dl-40—FUEL

PUMP

ECCENTRIC

AND

DISTRIBUTOR

DRIVE GEAR

1—

Fuel

Pump

Eccentric

3—Camshaft

2—

Oil

Groove 4—Distributor Drive

Gear

ing by rotating a hammer handle, or similar smooth

tool, around it, as necessary, to obtain clearance

for the crankshaft vibration damper hub.

Dl-86.

Install

Timing

Chain

Cover

Note:

There

are five

bolts

which attach the timing

chain

cover directly to the cylinder block, and seven

bolts

which attach both the timing chain

cover and water pump to the cylinder block.

a.

If oil pump has not been removed from timing

chain

cover, remove fine slotted attaching screws,

oil

pump cover, gasket from timing chain cover. Completely pack the space around the oil pump gears with petroleum jelly.

There

must be no air

space left inside the pump. Secure oil pump cover

and

a new gasket to timing chain cover with five slotted attaching screws. Torque screws, alternately

and

evenly, 8 to 12 lb-ft [1,10 a 1,66 kg-m.].

Note:

Unless oil pump gears are packed with petro

leum jelly, pump may not prime itself when

engine

is started.

b.

The gasket surfaces of the cylinder block and

timing chain cover must be smooth and clean. In

stall

a new timing chain cover gasket and position

it

correctly on the cylinder block.

Note:

Two different timing chain cover gaskets

have been installed in production on V-6 engines.

At

any time the timing chain cover gasket is

replaced,

make sure the correct gasket is installed.

c.

Position timing chain cover to cylinder block.

Use

timing cover aligner and oil seal remover tool J-22248. Be certain that dowel pins

engage

dowel

pin

holes

before installing bolts.

d.

Lubricate

bolt threads before installation.

Install

the mounting

bolts

and torque 25 to 33 lb-ft. [3,5

a

4,6 kg-m.].

Note:

Some timing chain covers have two additional

bolts, one in each upper corner. If the timing chain

cover being installed on a crankcase with

these

two

holes

does

not have matching holes, the

holes

in

the crankcase must be plugged with two hex

socket screw plugs. The plug should be driven past

the face of the case to prevent interference with the timing chain cover. These

bolts

are not shown

in

Fig. Dl-41.

D1-87.

Install

Oil Pump

a.

Pack

•

oil pump gear pocket of timing chain

cover with petroleum jelly. Do not use chassis

lubricant.

b.

Install

gears so that petroleum jelly is forced

into every cavity of gear pocket and

between

the

teeth

of the gears.

Install

a new oil pump cover gasket.

Note:

Unless the pump is packed with petroleum

jelly,

it may not prime itself when the

engine

is

started.

c.

Mount oil pump cover on timing gear cover

with

five slotted attaching screws. Torque screws 101

Page 102 of 376

![JEEP CJ 1953 Owners Manual

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Cranksh JEEP CJ 1953 Owners Manual

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Cranksh](/img/16/57040/w960_57040-101.png)

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Crankshaft

Vibration

Damper

a.

Lubricate

the vibration damper hub

before

in

stallation to prevent

damage

to the crankshaft

front oil seal during installation and when the

engine

is first started.

b.

Install

the vibration damper on the crankshaft.

Secure it with its attaching flat washer and screw.

Torque

the screw to a minimum of 140 lb-ft.

[19,35

kg-m.].

Dl-89.

Install

Crankshaft Pulley

Secure the crankshaft pulley to the crankshaft

vibration

damper with six screws. Torque screws 18 to 25 lb-ft. [2,5 a 3,4 kg-m.].

Dl-90.

Install

Oil

Level

Dipstick

Insert

oil level dipstick

into

the dipstick tube.

Dl-91.

Install

Oil

Pressure Sending Unit

Install

oil pressure sending unit in cylinder block.

Connect electrical wiring harness to unit.

Dl-92.

Install Starting Motor

Secure starting motor and

solenoid

assembly to

the flywheel housing and cylinder block with two attaching screws. Torque screw, which attaches this

assembly to the flywheel housing, 30 to 40 lb-ft. [4,1 a 5,5 kg-m.]. Torque screw, which attaches

bracket

to cylinder block, 10 to 12 lb-ft. [1,4 a 1,7 kg-m.].

Dl-93.

Install

Oil

Filter

Install

a new oil filter

element

at oil filter nipple,

at

left

side

of timing chain cover. Torque 10 to 15 lb-ft. [1,38 a 2,07 kg-m.].

D1-94. Install Water Pump

Be

certain that mating surfaces of the water pump

and

timing chain cover are clean.

Install

a new

gasket

on the pump flange. Secure the pump and

alternator adjustment bracket to the cover with

nine attaching bolts. Torque

bolts

6 to 8 lb-ft. [0,83 a 1,10 kg-m.]. Refer to Fig. Dl-41.

D1-9S.

Install

Cooling Fan

Secure the cooling fan, fan hub, and fan drive

pulley to the water pump shaft

flange

with four

attaching screws. Torque screws 17 to 23 lb-ft. [2,35 a 3,18 kg-m.].

Dl-96.

Install

Alternator

and Fan

Belt

Mount the alternator and bracket assembly on

right

cylinder head with two attaching screws.

Torque

screws 30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

Fasten

the alternator

loosely

to its adjustment

bracket

with attaching flat washer and nut.

Install

the fan

belt

on its pulleys. Pivot the alternator

outward,

away from cylinder block, to apply fan

belt

tension. Adjust fan

belt

tension to 80 lb. [36,2 kg.];

tighten

alternator-to-adjustment bracket

nut to secure adjustment

setting.

Connect wiring

harness to alternator.

Dl-97.

Install

Fuel Pump

Install

two mounting

bolts

and new

gasket

on

flange

of fuel pump. Secure pump to timing chain cover with screws; torque screws 17 to 23 lb-ft. [2,35 a 3,8 kg-m.]. Connect

output

fuel line to

pump.

Dl-98.

Install Exhaust Manifold

Secure each of two exhaust manifolds to corre

sponding cylinder head with five attaching screws,

and

one nut. Torque screws and nut 15 to 20 lb-ft. [2,07 a 2,8 kg-m.]. See Fig. Dl-42.

Dl-99.

Install Distributor

Insert

distributor drive gear

into

distributor mount-

FIG.

Dl-42—EXHAUST

MANIFOLD INSTALLATION

1—Torque

Bolts—15

to 20

lb-ft.

[2,07 a 2,8

kg-m.]

102

Page 104 of 376

Dl

DAUNTLESS

V-6

ENGINE

e.

Connect electrical wiring harness to coolant

temperature sending unit. Connect two distributor leads to ignition coil. Connect fuel line

between

fuel pump and carburetor, vacuum

hose

between

distributor and carburetor, and crankcase vent

hose

to intake manifold

below

rear

of carburetor.

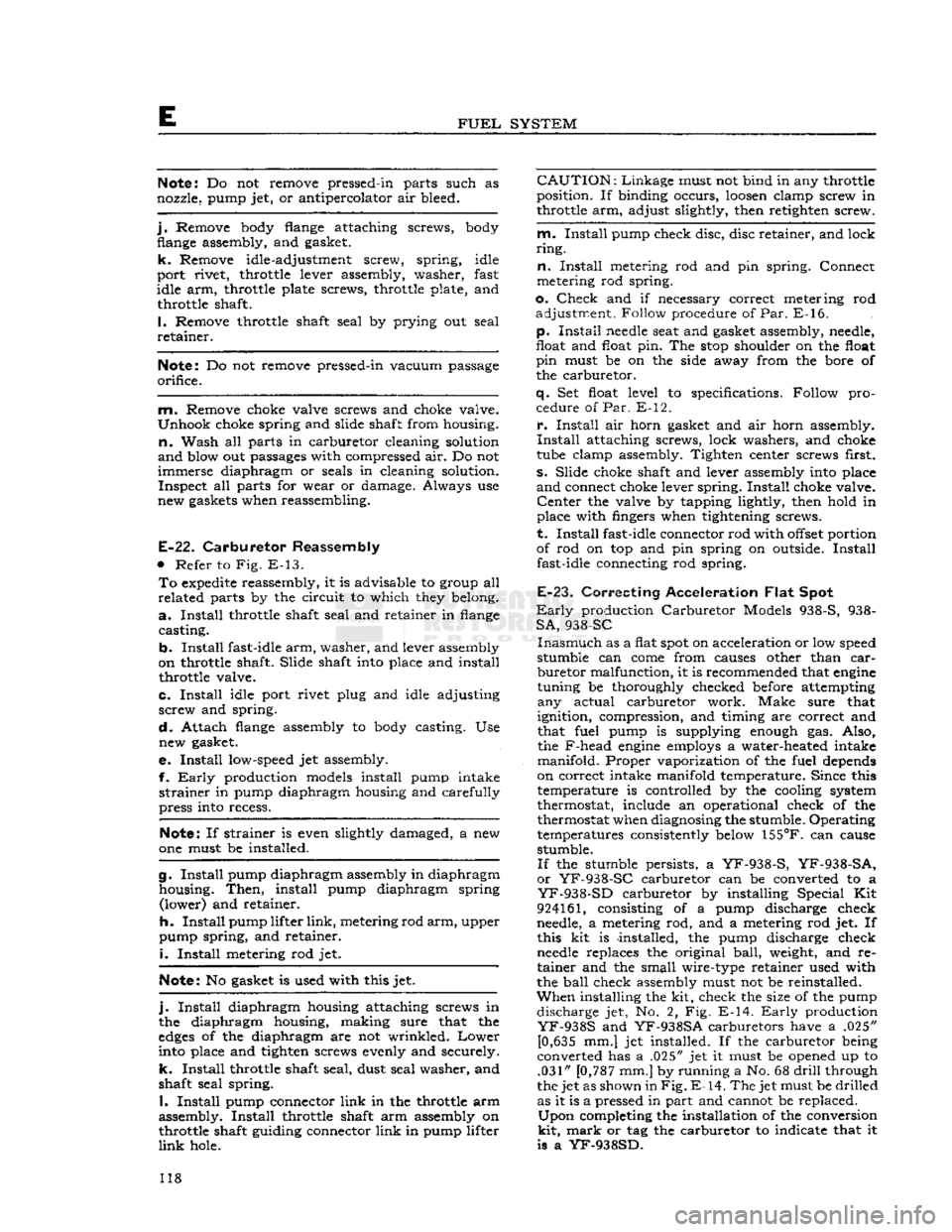

FIG.

D1-46—-INTAKE

MANIFOLD

INSTALLATION

1—Long Bolt 2—Open Bolt Hole

Dl-102.

ENGINE INSTALLATION

Install

the

engine

in the vehicle in the following

procedure listed

below:

a.

Attach suitable sling to

engine

lifting

eyes

and,

using a hoist, lift the

engine

from blocks or

engine

stand.

b. When

engine

is free of the stand lower it slowly

into

the

engine

compartment of the vehicle.

Note:

The

engine

and transmission must be lined

up to

engage

the main shaft and clutch plate spline

while sliding the

engine

rearward

into

the mounting

position.

c.

Install

and tighten up

bolts

securing

engine

to

flywheel housing.

d.

Install

and tighten front

engine

mounting bolts.

e.

Remove sling from the

engine.

I.

Connect exhaust pipes to right and

left

engine

manifolds.

g. Connect choke cable support bracket to

car

buretor.

h.

Connect

engine

fuel

hoses

and fuel lines at right

frame

rail.

I.

Connect fuel lines.

j.

Mount

engine

starter motor assembly to

engine.

k.

Connect battery cable and wiring to

engine

starter

motor.

I.

Connect

engine

wiring harnesses to connectors

located on

engine

firewall.

Note:

On

engines

equipped with exhaust emission

control, replace the air pump, air distributor mani

fold, and anti-backfire (gulp) valve. See Section F2.

m. Replace radiator, and secure with bolts,

n.

Replace and tighten right and

left

radiator sup

port rods.

0. Connect upper and lower radiator

hoses

to the

engine.

p. Connect alternator wiring harness from connec

tor at regulator,

q.

Replace air cleaner.

r.

Connect battery ground cable from the battery

to the

engine

and the

engine

ground strap,

s.

Replace the hood.

After

the

engine

is installed in the vehicle,

fill

radiator

with coolant and

engine

with oil (Refer to

Lubrication

Section B), then perform an

engine

Tune-up

and road

test

(Refer to Tune-up Sec

tion C).

Dl-103.

FINAL IN-VEHICLE ADJUSTMENTS

a.

Clean

battery terminals and check battery.

b.

Check

ignition wires and connections.

c. Service carburetor air cleaner.

d.

Service positive crankcase ventilation valve.

e.

Check

fuel lines.

f. Gap and install new

spark

plugs.

g.

Check

distributor

points

and capacitor; replace

if

necessary.

h.

Check

ignition (distributor) timing; reset if

necessary. 1.

Check

carburetor adjustments; reset if necessary,

j.

With

engine

fully warmed up, tighten cylinder

head and manifold

bolts

and nuts to specified

torque.

Check

cylinder head

gaskets

and

bolts

for

air

or coolant leaks.

Note:

Tightness of cylinder head

bolts

should be

checked and corrected after 500 miles [800 km.]

of normal operation and again at 1000 miles [1600

km.].

k.

Check

fan belt tension; adjust if necessary.

I.

Check

for and correct any oil leak, fuel leak or

coolant leak. 104

Page 118 of 376

E

FUEL

SYSTEM

Note:

Do not remove pressed-in parts such as

nozzle, pump jet, or antipercolator air bleed.

j.

Remove body flange attaching screws, body flange assembly, and gasket.

k.

Remove idle-adjustment screw, spring, idle

port

rivet, throttle lever assembly, washer, fast

idle arm, throttle plate screws, throttle plate, and throttle shaft.

1. Remove throttle shaft seal by prying out seal

retainer.

Note:

Do not remove pressed-in vacuum passage

orifice.

m.

Remove choke valve screws and choke valve.

Unhook

choke spring and slide shaft from housing,

n.

Wash all parts in carburetor cleaning solution

and

blow out passages with compressed air. Do not immerse diaphragm or seals in cleaning solution.

Inspect

all parts for wear or damage. Always use

new gaskets when reassembling.

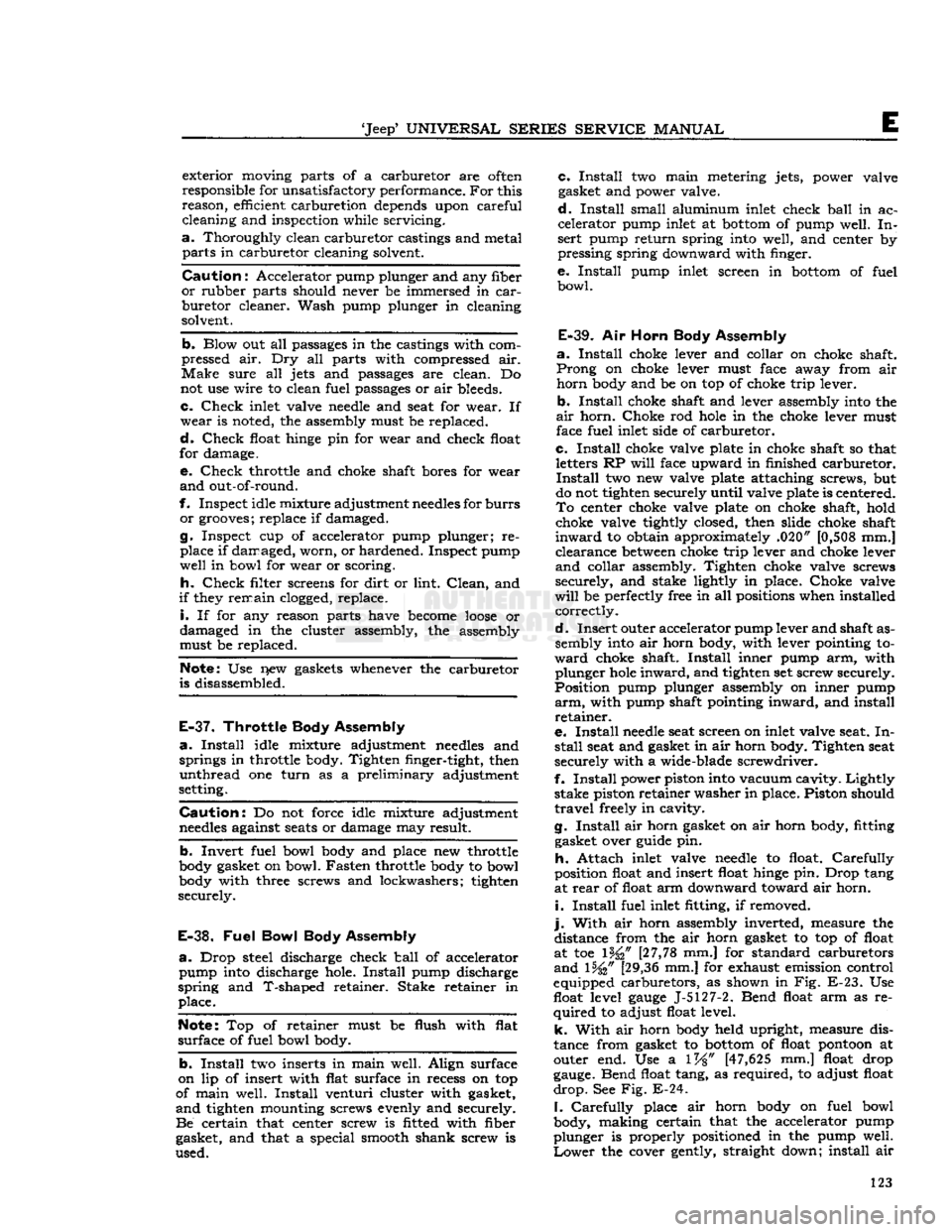

E-22.

Carburetor

Reassembly

•

Refer to Fig. E-13.

To

expedite

reassembly, it is advisable to group all

related

parts by the circuit to which they belong.

a.

Install

throttle shaft seal and retainer in flange casting.

b.

Install

fast-idle

arm,

washer, and lever assembly

on throttle shaft. Slide shaft into place and install throttle valve.

c.

Install

idle port rivet plug and idle adjusting

screw

and spring.

d.

Attach flange assembly to body casting. Use new gasket.

e.

Install

low-speed jet assembly.

f.

Early

production models install pump intake

strainer

in pump diaphragm housing and carefully

press into recess.

Note:

If strainer is even slightly damaged, a new

one must be installed.

g.

Install

pump diaphragm assembly in diaphragm housing.

Then,

install pump diaphragm spring

(lower)

and retainer.

h.

Install

pump lifter

link,

metering rod

arm,

upper

pump spring, and retainer.

I.

Install

metering rod jet.

Note:

No gasket is used with this jet.

j.

Install

diaphragm housing attaching screws in

the diaphragm housing, making sure that the

edges

of the diaphragm are not wrinkled.

Lower

into place and tighten screws evenly and securely,

k.

Install

throttle shaft seal, dust seal washer, and

shaft seal spring.

I.

Install

pump connector

link

in the throttle arm

assembly.

Install

throttle shaft arm assembly on

throttle shaft guiding connector

link

in pump lifter

link

hole.

CAUTION:

Linkage

must not bind in any throttle

position. If binding occurs,

loosen

clamp screw in

throttle arm, adjust slightly, then retighten screw.

m.

Install

pump check disc, disc retainer, and lock

ring.

n.

Install

metering rod and pin spring. Connect

metering rod spring.

o.

Check

and if necessary correct meter ing rod adjustment. Follow procedure of

Par.

E-16.

p.

Install

needle

seat and gasket assembly, needle,

float

and

float pin. The

stop

shoulder on the float

pin

must be on the side away from the bore of

the carburetor.

q.

Set float level to specifications. Follow pro cedure of

Par.

E-12.

r.

Install

air horn gasket and air horn assembly.

Install

attaching screws, lock washers, and choke

tube clamp assembly. Tighten center screws first,

s. Slide choke shaft and lever assembly into place

and

connect choke lever

spring.

Install

choke valve.

Center

the valve by tapping lightly, then hold in

place with fingers when tightening screws,

t.

Install

fast-idle connector rod with

offset

portion

of rod on top and pin spring on outside.

Install

fast-idle connecting rod spring.

E-23.

Correcting Acceleration

Flat

Spot

Early

production

Carburetor

Models 938-S, 938-

SA,

938-SC

Inasmuch

as a flat

spot

on acceleration or low speed

stumble can

come

from causes other than

car

buretor

malfunction, it is recommended that

engine

tuning be thoroughly checked before attempting

any

actual carburetor work. Make sure that

ignition, compression, and timing are correct and

that fuel pump is supplying enough gas. Also, the F-head

engine

employs a water-heated intake

manifold.

Proper vaporization of the fuel depends

on correct intake manifold temperature. Since this

temperature is controlled by the cooling system

thermostat, include an operational check of the

thermostat when diagnosing the stumble. Operating

temperatures consistently below

155°F.

can cause stumble.

If

the stumble persists, a

YF-938-S,

YF-938-SA,

or

YF-938-SC

carburetor can be converted to a

YF-938-SD

carburetor by installing Special Kit

924161, consisting of a pump discharge check

needle, a metering rod, and a metering rod jet. If this kit is installed, the pump discharge check

needle

replaces the original

ball,

weight, and re

tainer

and the small wire-type retainer used with

the

ball

check assembly must not be reinstalled.

When

installing the kit, check the size of the pump discharge jet, No. 2, Fig. E-14.

Early

production

YF-938S

and

YF-938SA

carburetors have a .025" [0,635 mm.] jet installed. If the carburetor being

converted has a .025" jet it must be opened up to .031" [0,787 mm.] by running a No. 68

drill

through

the jet as shown in

Fig.

E-14.

The jet must be drilled

as it is a pressed in part and cannot be replaced.

Upon

completing the installation of the conversion

kit,

mark

or tag the carburetor to indicate that it

is a

YF-938SD.

118

Page 123 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

E

exterior moving parts of a carburetor are

often

responsible for unsatisfactory performance.

For

this

reason,

efficient carburetion depends upon careful cleaning and inspection while servicing.

a.

Thoroughly clean carburetor castings and metal

parts

in carburetor cleaning solvent.

Caution:

Accelerator pump plunger and any fiber

or

rubber parts should never be immersed in

car

buretor

cleaner. Wash pump plunger in cleaning

solvent.

b.

Blow out all passages in the castings with com

pressed air. Dry all parts with compressed air.

Make

sure all jets and passages are clean. Do

not use wire to clean fuel passages or air bleeds.

c.

Check

inlet valve

needle

and seat for wear. If

wear

is noted, the assembly must be replaced.

d.

Check

float hinge pin for wear and check float

for damage.

e.

Check

throttle and choke shaft bores for wear

and

out-of-round.

f. Inspect idle mixture adjustment

needles

for

burrs

or

grooves; replace if damaged.

g. Inspect cup of accelerator pump plunger; re

place if damaged, worn, or hardened. Inspect pump

well

in bowl for wear or scoring.

h.

Check

filter screens for

dirt

or lint.

Clean,

and

if

they remain

clogged,

replace.

i.

If for any reason parts have

become

loose

or

damaged in the cluster assembly, the assembly

must be replaced.

Note:

Use ijew gaskets whenever the carburetor

is disassembled.

E-37.

Throttle Body Assembly

a.

Install

idle mixture adjustment

needles

and

springs in throttle body. Tighten finger-tight, then

unthread

one

turn

as a preliminary adjustment

setting.

Caution:

Do not force idle mixture adjustment

needles

against

seats

or damage may result.

b.

Invert

fuel bowl body and place new throttle

body gasket on bowl. Fasten throttle body to bowl

body with three screws and lockwashers; tighten

securely.

E-38.

Fuel

Bowl Body Assembly

a.

Drop steel discharge check

tall

of accelerator

pump into discharge hole.

Install

pump discharge

spring

and T-shaped retainer. Stake retainer in

place.

Note:

Top of retainer must be flush with flat

surface

of fuel bowl body.

b.

Install

two inserts in main well. Align surface

on lip of insert with flat surface in recess on top

of main well.

Install

venturi cluster with gasket,

and

tighten mounting screws evenly and securely.

Be

certain that center screw is fitted with fiber gasket, and that a special smooth shank screw is

used.

c.

Install

two main metering jets, power valve

gasket and power valve.

d.

Install

small aluminum inlet check

ball

in ac

celerator

pump inlet at

bottom

of pump well. In

sert

pump return spring into well, and center by

pressing spring downward with finger.

e.

Install

pump inlet screen in

bottom

of fuel

bowl.

E-39.

Air

Horn Body

Assembly

a.

Install

choke lever and collar on choke shaft.

Prong

on choke lever must face away from air

horn

body and be on top of choke trip lever.

b.

Install

choke shaft and lever assembly into the

air

horn. Choke rod

hole

in the choke lever must

face fuel inlet side of carburetor.

c.

Install

choke valve plate in choke shaft so that

letters RP

will

face upward in finished carburetor.

Install

two new valve plate attaching screws, but

do not tighten securely until valve plate is centered.

To

center choke valve plate on choke shaft, hold

choke valve tightly closed, then slide choke shaft

inward

to obtain approximately .020" [0,508 mm.]

clearance

between

choke trip lever and choke lever

and

collar assembly. Tighten choke valve screws

securely,

and stake lightly in place. Choke valve

will

be perfectly free in all positions when installed

correctly.

d.

Insert

outer accelerator pump lever and shaft as sembly into air horn body, with lever pointing to

ward

choke shaft.

Install

inner pump arm, with plunger

hole

inward,

and tighten set screw securely.

Position pump plunger assembly on inner pump

arm,

with pump shaft pointing

inward,

and install

retainer.

e.

Install

needle

seat screen on inlet valve seat. In

stall

seat and gasket in air horn body. Tighten seat

securely with a wide-blade screwdriver.

f.

Install

power piston into vacuum cavity.

Lightly

stake piston retainer washer in place. Piston should

travel

freely in cavity.

g.

Install

air horn gasket on air horn body, fitting

gasket over guide pin.

h.

Attach inlet valve

needle

to float.

Carefully

position float and insert float hinge pin. Drop tang

at

rear

of float arm downward toward air horn.

i.

Install

fuel inlet fitting, if removed.

j.

With

air horn assembly inverted, measure the distance from the air horn gasket to top of float

at toe \%£f [27,78 mm.] for standard carburetors

and

\%i [29,36 mm.] for exhaust emission control

equipped carburetors, as shown in Fig. E-23. Use

float level

gauge

J-5127-2. Bend float arm as re

quired

to adjust float level.

k.

With

air horn body held upright, measure dis

tance from gasket to

bottom

of float

pontoon

at outer end. Use a l7/s" [47,625 mm.] float drop

gauge.

Bend float tang, as required, to adjust float

drop.

See Fig. E-24.

I.

Carefully

place air horn body on fuel bowl

body, making certain that the accelerator pump

plunger is properly positioned in the pump well.

Lower

the cover gently, straight down; install air 123

Page 124 of 376

FUEL

SYSTEM

1-5/32

133S2

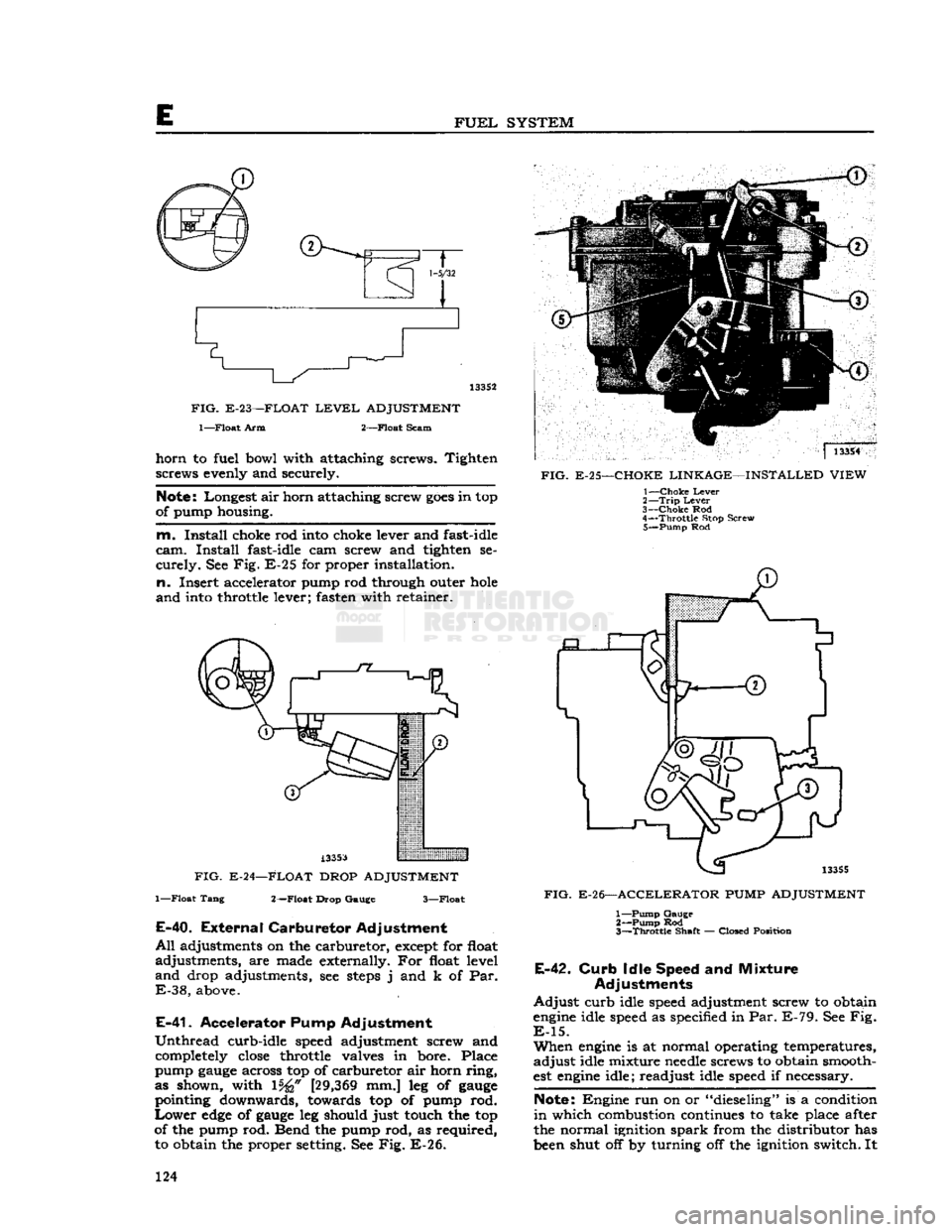

FIG.

E-23—FLOAT

LEVEL

ADJUSTMENT

l—Float

Arm 2—Float Scam

horn

to fuel bowl with attaching screws. Tighten screws evenly and securely.

Note:

Longest air horn attaching screw

goes

in top

of pump housing.

m.

Install

choke rod into choke lever and fast-idle

cam.

Install

fast-idle cam screw and tighten se

curely.

See Fig. E-25 for proper installation,

n.

Insert accelerator pump rod through outer

hole

and

into throttle lever; fasten with retainer.

A33S3

FIG. E-24—FLOAT DROP ADJUSTMENT

1—Float Tang 2—Float Drop Gauge 3—Float

E-40.

External

Carburetor

Adjustment

All

adjustments on the carburetor, except for float

adjustments, are made externally. For float level

and

drop adjustments, see

steps

j and k of Par.

E-38,

above.

E-41.

Accelerator Pump Adjustment

Unthread

curb-idle speed adjustment screw and completely

close

throttle valves in bore. Place

pump

gauge

across top of carburetor air horn ring,

as shown, with 15^" [29,369 mm.] leg of

gauge

pointing downwards, towards top of pump rod.

Lower

edge

of

gauge

leg should just touch the top

of the pump rod. Bend the pump rod, as required, to obtain the proper setting. See Fig. E-26. ]

13354

FIG.

E-25—CHOKE LINKAGE—INSTALLED VIEW 1—

Choke

Lever

2—

Trip

Lever

3—

Choke

Rod

4—

Throttle

Stop Screw 5—

Pump

Rod

13355

FIG.

E-26—ACCELERATOR

PUMP

ADJUSTMENT 1—

Pump

Gauge 2—

Pump

Rod

3—

Throttle

Shaft — Closed Position

E-42.

Curb

Idle Speed and Mixture

Adjustments

Adjust

curb idle speed adjustment screw to obtain

engine

idle speed as specified in Par. E-79. See Fig.

E-15.

When

engine

is at normal operating temperatures,

adjust

idle mixture

needle

screws to obtain smooth

est

engine

idle; readjust idle speed if necessary.

Note:

Engine run on or "dieseling" is a condition

in

which combustion continues to take place after

the normal ignition spark from the distributor has

been shut off by turning off the ignition switch. It 124