ECU JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 141 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

F F-8.

Exhaust

Pipe Replacement

When

replacing the exhaust pipe(s) refer to

Figs.

Fl,

F2 and

F-3.

Remove the nuts securing the ex

haust pipe(s) to the exhaust manifold(s), loosen

and

disconnect mounting

clamp

(s)

as necessary, loosen clamp securing exhaust pipe to muffler and

remove exhaust pipe(s).

Note: Always use new gasket(s) between exhaust

pipe(s) and exhaust manifold(s). After installation

of exhaust pipe(s), check the exhaust system for

alignment and leaks.

F-9.

Muffler Removal and Replacement

Disconnect the support bracket and clamps on each

side of the muffler. Loosen the

tail

pipe support

clamp

bolt and

pull

the

tail

pipe to the

rear

until

it

is free of the muffler. Remove the muffler. To

install

the muffler, reverse the above

steps

and

properly

align the complete system, then tighten

connecting support brackets securely. Operate the engine and check for possible leaks.

F-10.

Tail

Pipe Removal and Replacement

Refer

to

Figs.

F-l,

F-2 and

F-3.

Disconnect the support bracket and clamps both at the

rear

of the muffler and also at outlet end of

the

tail

pipe.

Free

the

tail

pipe from the muffler. To

assemble, position

tail

pipe to the muffler and secure clamps, being careful to align the exhaust

system so it doesn't contact body or frame.

Check

system for exhaust gas leaks.

F-ll.

EXHAUST SYSTEM SPECIFICATIONS

EARLY

MODEL

HURRICANE

F4

ENGINE

EARLY

MODEL

DAUNTLESS

V-6

ENGINE

TYPE:

Muffler:

Type

Exhaust

Pipe:

Wall

Thickness

Tail

Pipe:

Crossover

Pipe

Diameter

Single

Reverse

Flow

1.625*

[4,13 cm.] .065* [1,6 ram.]

1.625*

[4,13 cm.] Single

With

Cross-Over

Reverse

Flow

2.00* [5,08 cm.] .065* [1,6 mm.]

2.00* [5,08 cm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

Wall

Thickness Single

With

Cross-Over

Reverse

Flow

2.00* [5,08 cm.] .065* [1,6 mm.]

2.00* [5,08 cm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

LATE

MODEL

HURRICANE

F4

ENGINE

LATE

MODEL

DAUNTLESS

V6

ENGINE

TYPE:

Muffler:

Exhaust

Pipe:

Wall

Thickness

Exhaust

Pipe Extension:

Wall

Thickness

Crossover

Pipe: Single

Reverse

Flow

2.005* [5,09 cm.]

1.755*

[4,46 cm.]

1.625*

[4,13 cm.]

.065* [1,6 mm.]

1.629*

[4,14 cm.] 2.00* [5,08 cm.] .065* [1,6 mm.] Single with

Cross-Over

Reverse

Flow

2.005* [5,09 cm.]

1.755*

[4,46 cm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

1.753*

[4,45 cm 1

Wall

Thickness

Tail

Pipe

1.753*

[4,45 cm.] Single with

Cross-Over

Reverse

Flow

2.005* [5,09 cm.]

1.755*

[4,46 cm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

2.00* [5,08 cm.] .065* [1,6 mm.]

1.753*

[4,45 cm 1 141

Page 144 of 376

Fl

EXHAUST EMISSION CONTROL SYSTEMS

12793

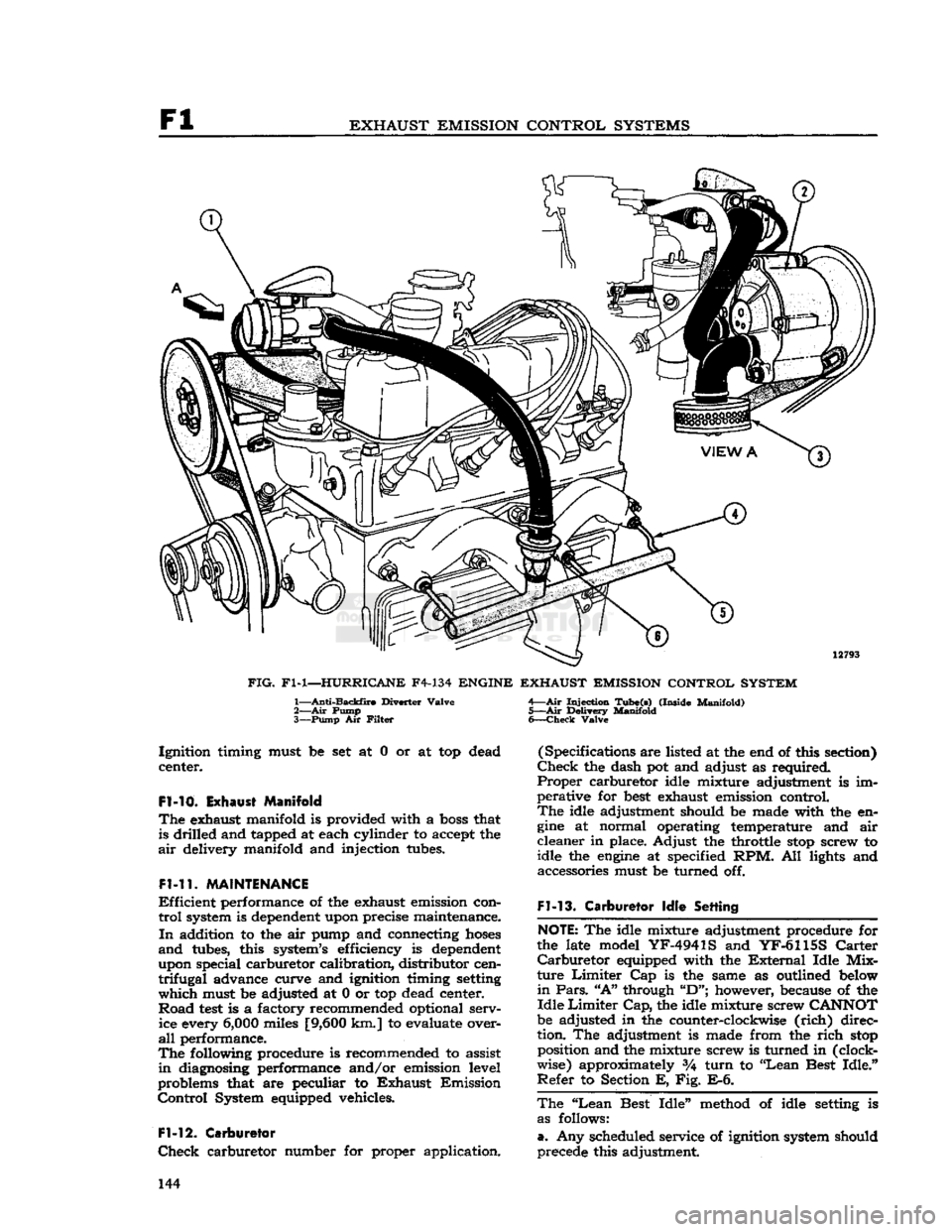

FIG.

Fl-1—HURRICANE

F4-134

ENGINE EXHAUST EMISSION CONTROL SYSTEM

1—

Anti-Backfire

Diverter

Valve

2— Air

Pump

3—

Pump

Air

Filter

Injection

Tube(s)

(Inside

Manifold)

5—Air

Delivery

Manifold

6—

Check

Valve

Ignition

timing must be set at 0 or at top dead

center.

Fl-10.

Exhaust Manifold

The

exhaust manifold is provided with a

boss

that is drilled and tapped at each cylinder to accept the

air

delivery manifold and injection tubes.

Fl-11.

MAINTENANCE

Efficient

performance of the exhaust emission con

trol

system is dependent upon precise maintenance.

In

addition to the air pump and connecting

hoses

and

tubes, this system's efficiency is dependent

upon special carburetor calibration, distributor cen

trifugal

advance curve and ignition timing setting

which

must be adjusted at 0 or top dead center.

Road

test

is a factory recommended optional serv ice every

6,000

miles

[9,600

km.] to evaluate over

all

performance.

The

following procedure is recommended to assist

in

diagnosing performance and/or emission level

problems that are peculiar to

Exhaust

Emission

Control

System equipped vehicles.

Fl-12.

Carburetor

Check

carburetor number for proper application. (Specifications are listed at the end of this section)

Check

the dash pot and adjust as required.

Proper

carburetor idle mixture adjustment is im

perative for

best

exhaust emission control.

The

idle adjustment should be made with the en

gine

at normal operating temperature and air

cleaner

in place. Adjust the throttle

stop

screw to

idle the

engine

at specified RPM. All lights and accessories must be turned off.

Fl-13.

Carburetor

Idle

Setting

NOTE:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

Carburetor

equipped with the

External

Idle

Mix

ture

Limiter

Cap is the same as outlined below

in

Pars.

"A"

through

"D";

however, because of the

Idle

Limiter

Cap,

the idle mixture screw

CANNOT

be adjusted in the counter-clockwise

(rich)

direc

tion. The adjustment is made from the

rich

stop

position and the mixture screw is turned in (clock

wise) approximately %

turn

to "Lean Best

Idle."

Refer

to Section E, Fig. E-6.

The

"Lean

Best

Idle"

method of idle setting is as follows:

a.

Any scheduled service of ignition system should

precede this adjustment. 144

Page 151 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

F2

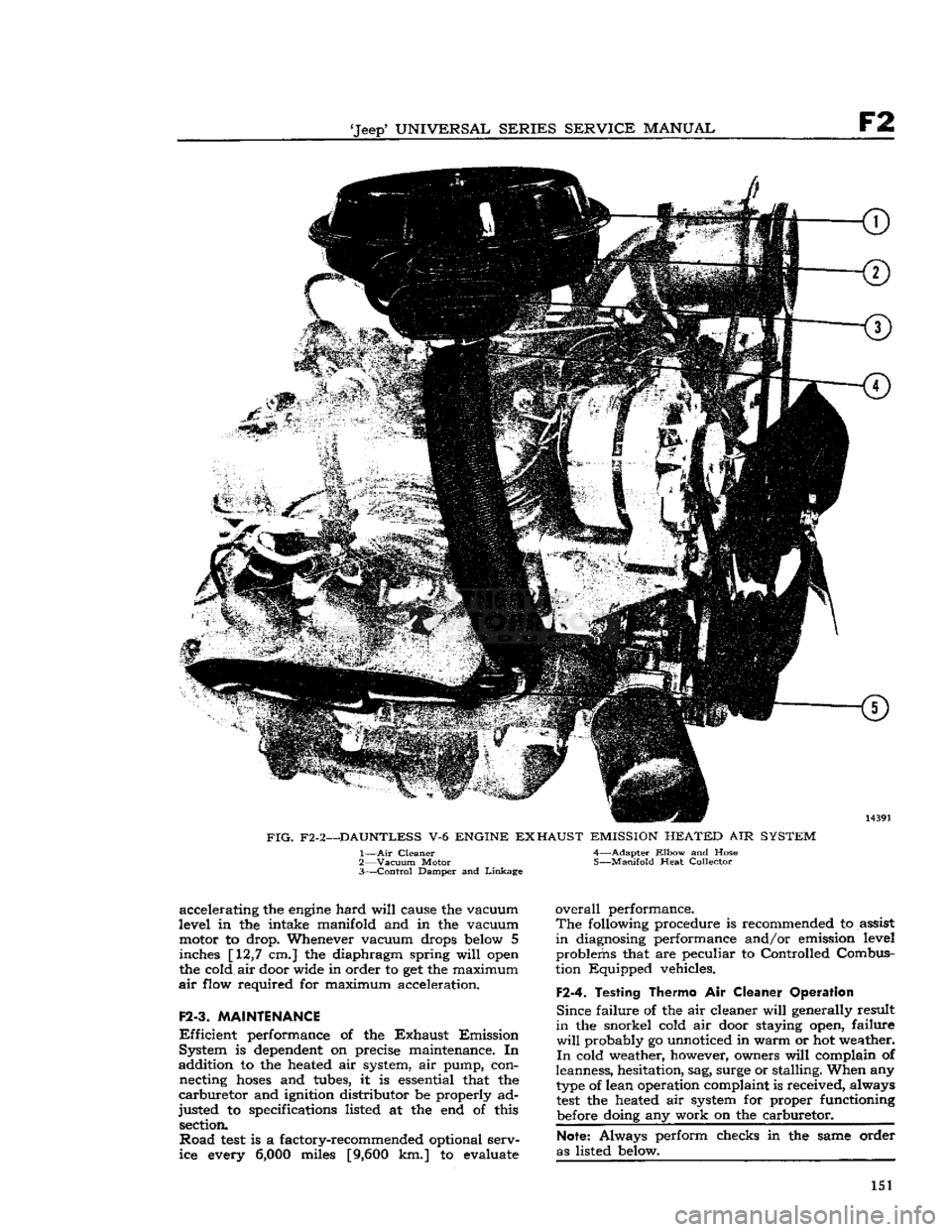

FIG.

F2-2—DAUNTLESS

V-6

ENGINE

EXHAUST

EMISSION

HEATED

AIR

SYSTEM

1—

Air

Cleaner 4—Adapter

Elbow

and Hose

2—

Vacuum

Motor 5—Manifold Heat Collector

3—

Control

Damper and

Linkage

accelerating the

engine

hard

will

cause the vacuum

level in the intake manifold and in the vacuum motor to drop. Whenever vacuum drops

below

5 inches [12,7 cm.] the diaphragm spring

will

open

the cold air door wide in order to get the maximum

air

flow required for maximum acceleration.

F2-3.

MAINTENANCE

Efficient

performance of the

Exhaust

Emission

System is

dependent

on precise maintenance. In

addition to the heated air system, air pump, con necting

hoses

and tubes, it is essential that the

carburetor

and ignition distributor be properly ad

justed to specifications listed at the end of this section.

Road

test

is a factory-recommended optional serv

ice every

6,000

miles

[9,600

km.] to evaluate

overall

performance.

The

following procedure is recommended to assist

in

diagnosing performance and/or emission level problems that are peculiar to Controlled Combus

tion Equipped vehicles.

F2-4.

Testing Thermo

Air

Cleaner Operation

Since

failure of the air cleaner

will

generally result

in

the snorkel cold air door staying open, failure

will

probably go unnoticed in warm or hot weather.

In

cold weather, however, owners

will

complain of

leanness, hesitation, sag, surge or stalling. When any

type

of lean operation complaint is received, always

test

the heated air system for proper functioning

before

doing any work on the carburetor.

Note:

Always perform checks in the same order

as listed

below.

151

Page 155 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

F2

14043

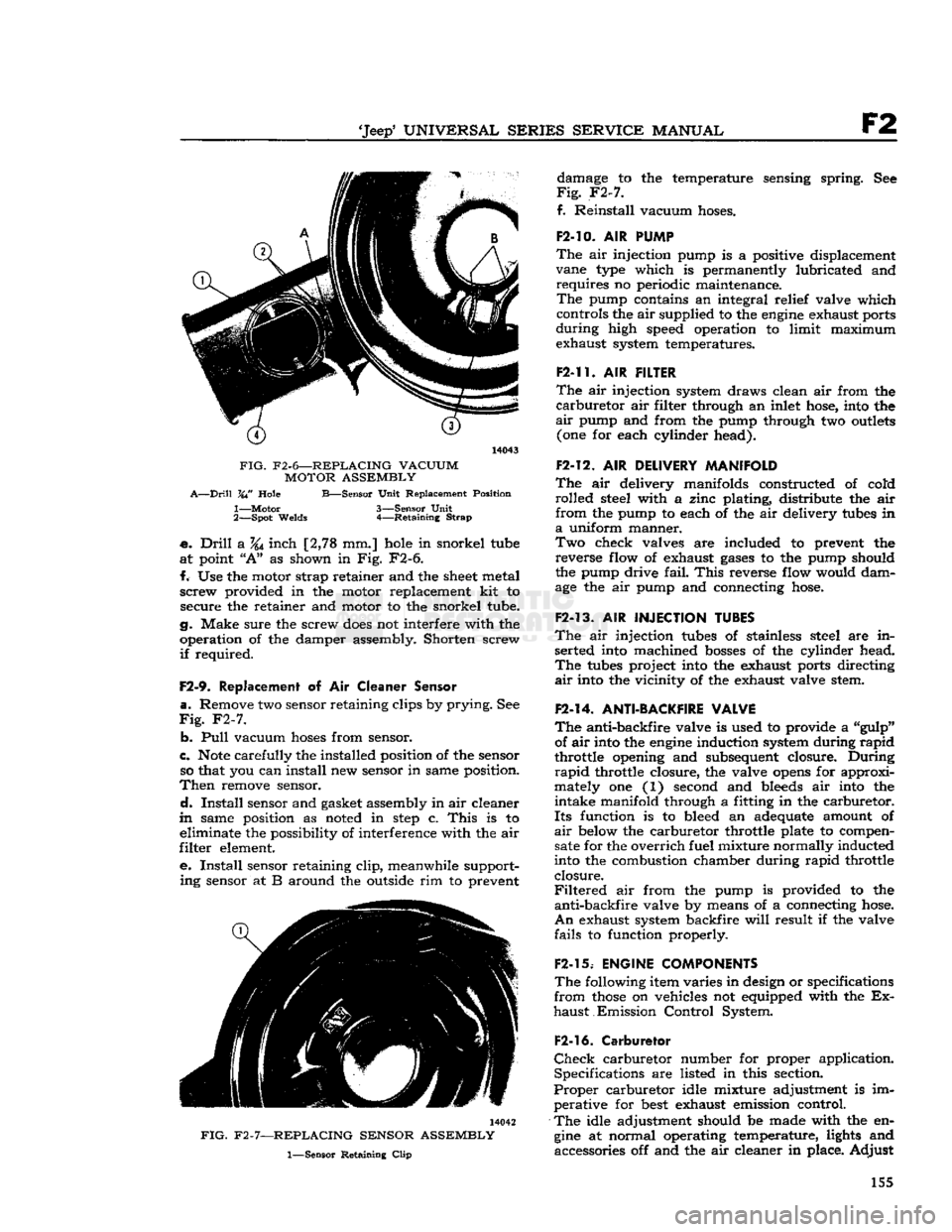

FIG.

F2-6—REPLACING VACUUM MOTOR ASSEMBLY

A—Drill

VW

Hole

B—Sensor

Unit

Replacement Position

1—

Motor

3—Sensor

Unit

2—

Spot

Welds

4—Retaining

Strap

•e.

Drill

a

%j

inch [2,78 mm.] hole in snorkel tube

at

point

"A"

as shown in Fig.

F2-6.

f.

Use the motor strap retainer and the

sheet

metal

screw

provided in the motor replacement kit to secure the retainer and motor to the snorkel tube.

g. Make sure the screw

does

not interfere with the

operation of the damper assembly. Shorten screw

if

required.

F2-9.

Replacement

of Air

Cleaner Sensor

a.

Remove two sensor retaining clips by

prying.

See

Fig.

F2-7.

b.

Pull

vacuum

hoses

from sensor.

c.

Note

carefully the installed position of the sensor so that you can install new sensor in same position.

Then

remove sensor.

d.

Install

sensor and gasket assembly in air cleaner

m

same position as noted in

step

c.

This

is to eliminate the possibility of interference with the air

filter

element.

e.

Install

sensor retaining

clip,

meanwhile support

ing

sensor at B around the outside rim to prevent 14042

FIG.

F2-7—REPLACING SENSOR ASSEMBLY

1—Sensor

Retaining

Clip

damage to the temperature sensing spring. See

Fig.

F2-7.

f.

Reinstall

vacuum hoses.

F2-10.

AIR

PUMP

The

air injection pump is a positive displacement

vane type which is permanently lubricated and

requires

no periodic maintenance.

The

pump contains an integral relief valve which

controls the

air

supplied to the

engine

exhaust ports

during

high speed operation to limit maximum exhaust system temperatures.

F2-11.

AIR

FILTER

The

air injection system draws clean air from the

carburetor

air filter through an inlet hose, into the

air

pump and from the pump through two

outlets

(one for each cylinder head).

F2-12.

AIR

DELIVERY MANIFOLD

The

air delivery manifolds constructed of cold

rolled

steel with a zinc plating, distribute the air

from

the pump to each of the air delivery tubes in

a

uniform manner.

Two

check valves are included to prevent the

reverse

flow of exhaust

gases

to the pump should

the pump drive

fail.

This

reverse flow would dam

age the air pump and connecting hose.

F2-13.

AIR

INJECTION TUBES

The

air injection tubes of stainless steel are in serted into machined

bosses

of the cylinder head.

The

tubes project into the exhaust ports directing

air

into the vicinity of the exhaust valve stem.

F2-14.

ANTI-BACKFIRE VALVE

The

anti-backfire valve is used to provide a "gulp" of air into the

engine

induction system during

rapid

throttle opening and subsequent closure.

During

rapid

throttle closure, the valve

opens

for approxi

mately one (1) second and bleeds air into the

intake

manifold through a fitting in the carburetor.

Its

function is to bleed an adequate amount of

air

below the carburetor throttle plate to compen sate for the

overrich

fuel mixture normally inducted

into the combustion chamber during

rapid

throttle

closure.

Filtered

air from the pump is provided to the

anti-backfire

valve by means of a connecting hose.

An

exhaust system backfire

will

result if the valve

fails

to function properly.

F2-15.

ENGINE COMPONENTS

The

following item varies in design or specifications

from

those

on vehicles not equipped with the Ex

haust

Emission

Control

System.

F2-16.

Carburetor

Check

carburetor number for proper application. Specifications are listed in this section.

Proper

carburetor idle mixture adjustment is im perative for

best

exhaust emission control.

The

idle adjustment should be made with the en

gine

at normal operating temperature, lights and accessories off and the air cleaner in place.

Adjust

155

Page 165 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

G

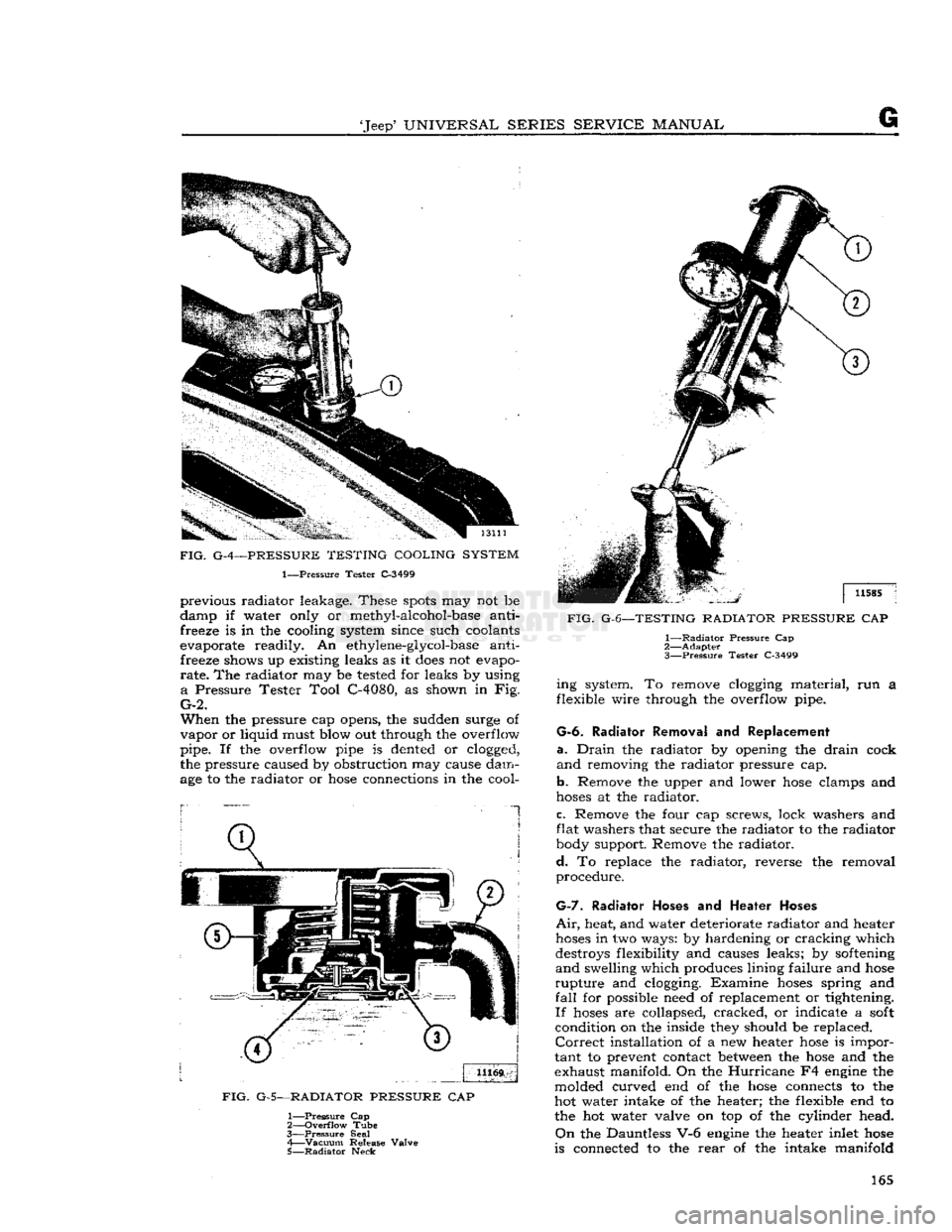

FIG.

G-4—PRESSURE TESTING COOLING SYSTEM

1—Pressure Tester C-3499 previous radiator leakage. These

spots

may not be

damp if water only or methyl-alcohol-base anti freeze is in the cooling system since such coolants

evaporate readily. An ethylene-glycol-base anti freeze shows up existing leaks as it

does

not evapo

rate.

The radiator may be tested for leaks by using

a

Pressure Tester Tool C-4080, as shown in Fig.

G-2.

When

the pressure cap opens, the sudden surge of

vapor

or liquid must blow out through the overflow

pipe. If the overflow pipe is dented or clogged,

the pressure caused by obstruction may cause dam

age to the radiator or

hose

connections in the cool-

1

FIG.

G-5—RADIATOR PRESSURE

CAP

1—

Pressure

Cap

2—

Overflow

Tube

3—

Pressure

Seal 4—

Vacuum

Release Valve

5—

Radiator

Neck

FIG.

G-6—TESTING RADIATOR PRESSURE

CAP

1—

Radiator

Pressure Cap

2—

Adapter

3—

Pressure

Tester C-3499 ing system. To remove clogging material, run a

flexible wire through the overflow pipe.

G-6.

Radiator Removal

and

Replacement

a.

Drain

the radiator by opening the

drain

cock

and

removing the radiator pressure cap.

b.

Remove the upper and lower

hose

clamps and

hoses

at the radiator.

c.

Remove the four cap screws, lock washers and

flat washers that secure the radiator to the radiator

body support. Remove the radiator.

d.

To replace the radiator, reverse the removal

procedure.

G-7.

Radiator

Hoses

and

Heater Hoses

Air,

heat, and water deteriorate radiator and heater

hoses

in two ways: by hardening or cracking which

destroys flexibility and causes leaks; by softening

and

swelling which produces lining failure and

hose

rupture

and clogging. Examine

hoses

spring and

fall

for possible need of replacement or tightening.

If

hoses

are collapsed, cracked, or indicate a

soft

condition on the inside they should be replaced.

Correct

installation of a new heater

hose

is impor

tant to prevent contact between the

hose

and the

exhaust manifold. On the

Hurricane

F4 engine the

molded curved end of the

hose

connects to the

hot water intake of the heater; the flexible end to the hot water valve on top of the cylinder head.

On

the Dauntless V-6 engine the heater inlet

hose

is connected to the

rear

of the intake manifold 165

Page 166 of 376

G

COOLING SYSTEM and

the outlet

hose

is connected to the water pump

housing.

When

installing a new hose, clean the pipe connec

tions and apply a thin layer of nonhardening seal

ing compound. Hose clamps should be properly

located over the connections to provide secure fastening. The pressurized cooling system pressure

can

blow off improperly installed hoses.

G-8.

Cylinder

Block

Any

coolant leaks at the engine block water joints

are

aggravated by pump pressure in the water

jacket

and by pressure developed in the cooling system when the pressure cap is in place.

Small

leaks showing up only as moist

spots

often

cannot

be detected when the engine is hot except by the

appearance of rust, corrosion, and dye stains where

leakage evaporated. Also, expansion and contrac tion of the engine block resulting from extreme

temperature changes can aggravate leaks. For

these

reasons, when checking for coolant leaks inspect

the block when it is cold and while the engine is

running.

A

leaking

drain

cock or plug that cannot be stopped

leaking

by tightening should be replaced.

Leaking

core-hole expansion plugs should be replaced.

If

tightening gasketed joints

will

not correct leak

age, install new gaskets. Use a sealing compound

where recommended.

G-9.

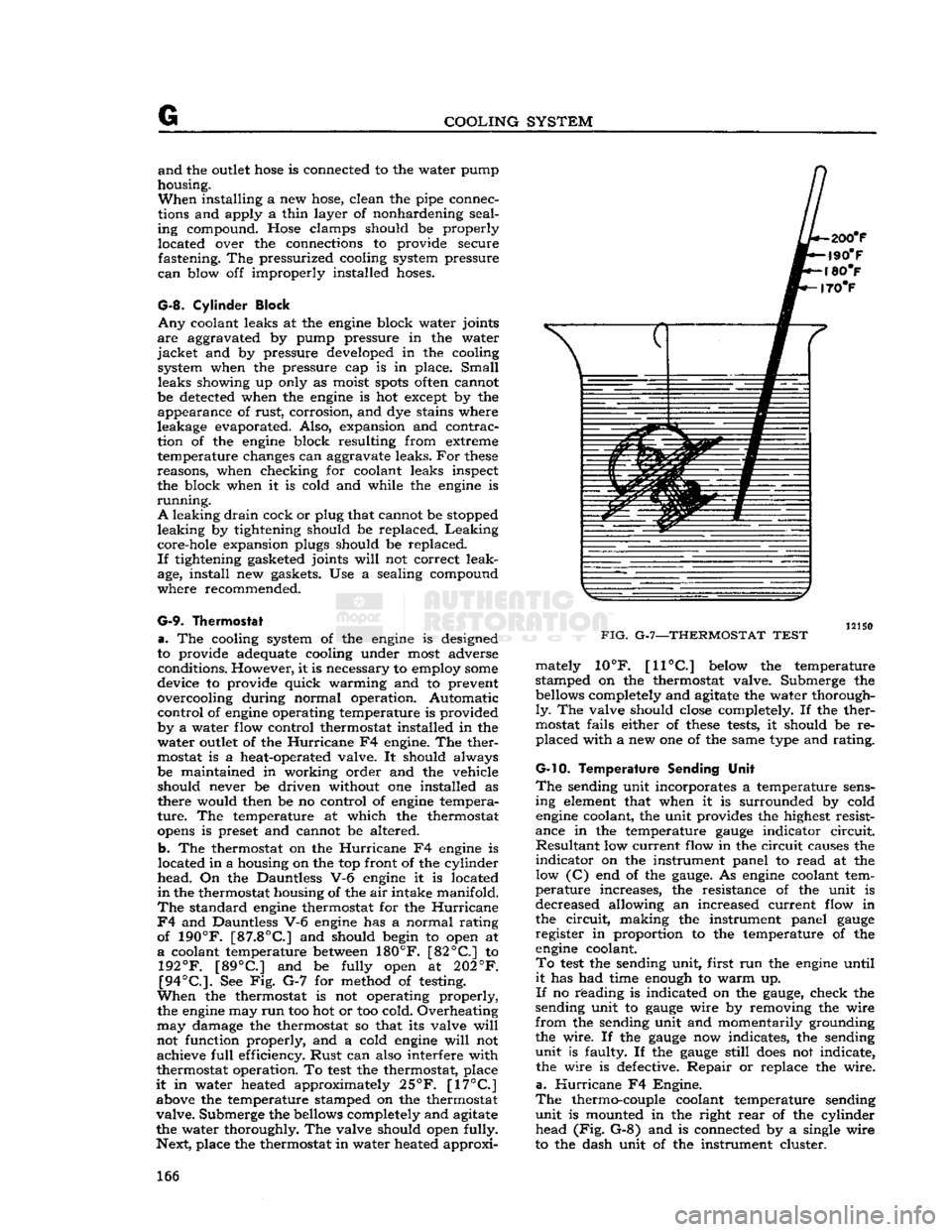

Thermostat

a.

The cooling system of the engine is designed

to provide adequate cooling under most adverse conditions. However, it is necessary to employ

some

device to provide quick warming and to prevent

overcooling during normal operation. Automatic

control

of engine operating temperature is provided

by a water flow control thermostat installed in the

water

outlet of the

Hurricane

F4 engine. The ther

mostat is a heat-operated valve. It should always

be maintained in working order and the vehicle

should never be driven without one installed as there would then be no control of engine tempera

ture.

The temperature at which the thermostat

opens

is preset and cannot be altered.

b.

The thermostat on the

Hurricane

F4 engine is

located in a housing on the top front of the cylinder

head.

On the Dauntless V-6 engine it is located

in

the thermostat housing of the air intake manifold.

The

standard engine thermostat for the

Hurricane

F4

and Dauntless V-6 engine has a normal rating

of

190°F.

[87.8°C]

and should begin to open at

a

coolant temperature between

180°F.

[82°C]

to

192°F.

[89°C]

and be fully open at

202°F.

[94°C.].

See Fig. G-7 for method of testing.

When

the thermostat is not operating properly, the engine may

run

too hot or too cold. Overheating

may

damage the thermostat so that its valve

will

not function properly, and a cold engine

will

not achieve

full

efficiency.

Rust

can also interfere with

thermostat operation. To

test

the thermostat, place

it

in water heated approximately

25°F.

[17°C]

above the temperature stamped on the thermostat

valve.

Submerge the bellows completely and agitate

the water thoroughly. The valve should open fully.

Next, place the thermostat in water heated approxi-

FIG.

G-7—THERMOSTAT

TEST

mately 10°F.

[11°C]

below the temperature

stamped on the thermostat valve. Submerge the bellows completely and agitate the water thorough

ly.

The valve should close completely. If the ther

mostat fails either of

these

tests, it should be re placed with a new one of the same type and rating.

G-10. Temperature

Sending Unit

The

sending unit incorporates a temperature sens ing element that when it is surrounded by cold engine coolant, the unit provides the highest resist

ance in the temperature

gauge

indicator

circuit.

Resultant

low current flow in the circuit causes the

indicator

on the instrument panel to read at the low (C) end of the

gauge.

As engine coolant tem

perature

increases, the resistance of the unit is

decreased allowing an increased current flow in

the

circuit,

making the instrument panel

gauge

register in proportion to the temperature of the engine coolant.

To

test

the sending unit, first run the engine until

it

has had time enough to warm up.

If

no reading is indicated on the

gauge,

check the

sending unit to

gauge

wire by removing the wire

from

the sending unit and momentarily grounding

the wire. If the

gauge

now indicates, the sending

unit

is faulty. If the

gauge

still

does

not indicate, the wire is defective.

Repair

or replace the wire,

a.

Hurricane

F4 Engine.

The

thermo-couple coolant temperature sending

unit

is mounted in the right

rear

of the cylinder head (Fig. G-8) and is connected by a single wire

to the dash unit of the instrument cluster. 166

Page 168 of 376

G

COOLING SYSTEM

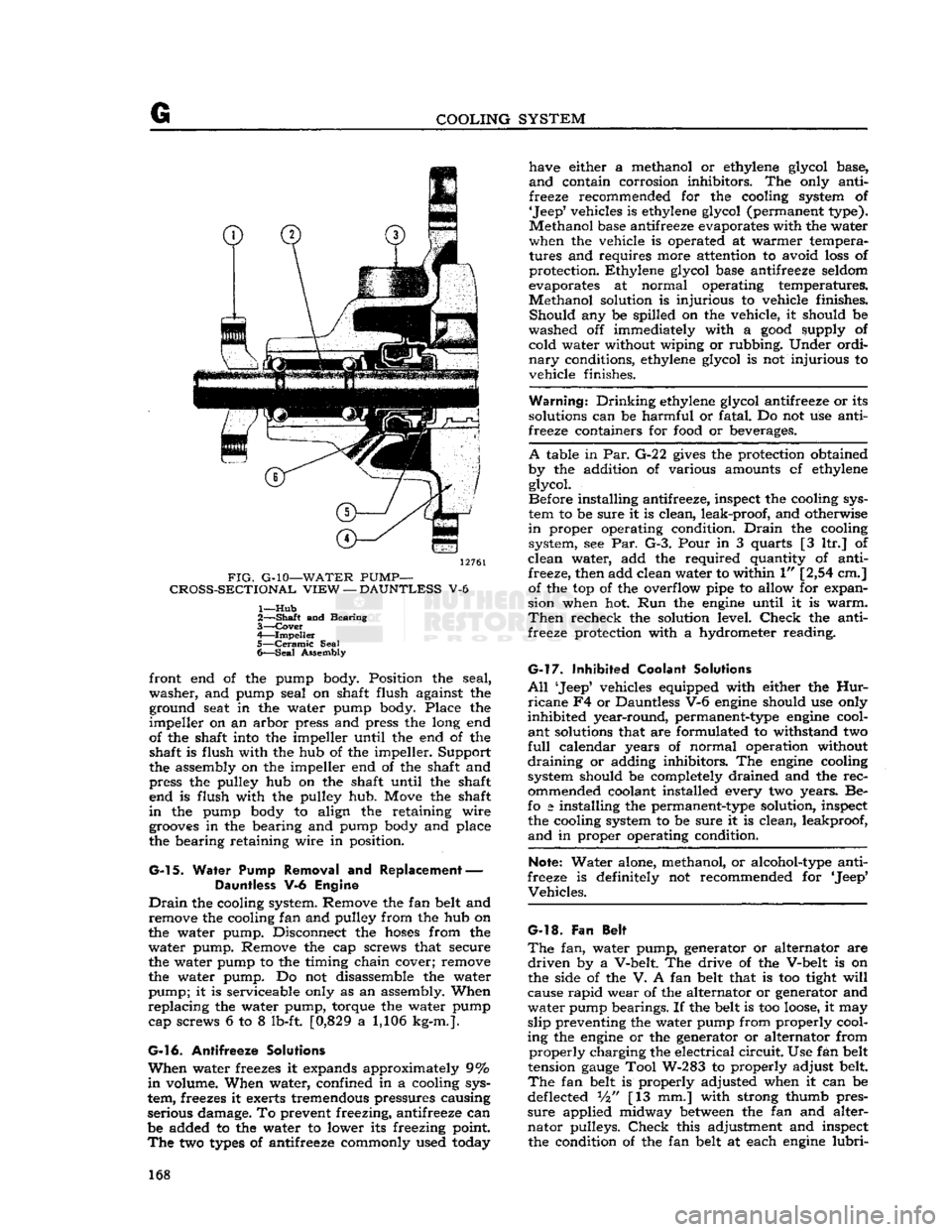

12761

FIG.

G-10—WATER

PUMP—

CROSS-SECTIONAL

VIEW

—

DAUNTLESS

V-6

1—

Hub

2—

—Shaft

and Bearing

3—

Cover

4—

Impeller

5—

Ceramic

Seal

6—

Seal

Assembly front end of the pump body. Position the seal,

washer,

and pump seal on shaft flush against the ground seat in the water pump body. Place the

impeller

on an arbor press and press the long end

of the shaft into the impeller until the end of the shaft is flush with the hub of the impeller. Support

the assembly on the impeller end of the shaft and

press the pulley hub on the shaft until the shaft end is flush with the pulley hub. Move the shaft

in

the pump body to align the retaining wire

grooves

in the bearing and pump body and place

the bearing retaining wire in position.

G-l

5. Water Pump Removal and Replacement — Dauntless V-6 Engine

Drain

the cooling system. Remove the fan belt and remove the cooling fan and pulley from the hub on

the water pump. Disconnect the

hoses

from the

water

pump. Remove the cap screws that secure

the water pump to the timing chain cover; remove

the water pump. Do not disassemble the water

pump;

it is serviceable only as an assembly. When

replacing

the water pump, torque the water pump cap screws 6 to 8 lb-ft. [0,829 a 1,106 kg-m.].

G-16.

Antifreeze Solutions

When

water freezes it expands approximately 9%

in

volume. When water, confined in a cooling sys

tem, freezes it exerts tremendous pressures causing

serious damage. To prevent freezing, antifreeze can

be added to the water to lower its freezing point.

The

two

types

of antifreeze commonly used today have either a methanol or ethylene glycol base,

and

contain corrosion inhibitors. The only anti

freeze recommended for the cooling system of

'Jeep'

vehicles is ethylene glycol (permanent type).

Methanol

base antifreeze evaporates with the water

when the vehicle is operated at warmer tempera

tures and requires more attention to avoid

loss

of

protection. Ethylene glycol base antifreeze seldom

evaporates at normal operating temperatures.

Methanol

solution is injurious to vehicle finishes.

Should

any be spilled on the vehicle, it should be

washed off immediately with a

good

supply of cold water without wiping or rubbing. Under ordi

nary

conditions, ethylene glycol is not injurious to

vehicle finishes.

Warning.*

Drinking

ethylene glycol antifreeze or its

solutions can be harmful or fatal. Do not use anti

freeze containers for

food

or beverages.

A

table in Par.

G-2

2

gives

the protection obtained

by the addition of various amounts cf ethylene glycol.

Before installing antifreeze, inspect the cooling sys

tem to be sure it is clean, leak-proof, and otherwise

in

proper operating condition.

Drain

the cooling system, see Par. G-3. Pour in 3 quarts [3 ltr.] of

clean

water, add the required quantity of anti freeze, then add clean water to within 1" [2,54 cm.] of the top of the overflow pipe to allow for expan

sion when hot. Run the

engine

until it is

warm.

Then

recheck the solution level.

Check

the anti

freeze protection with a hydrometer reading.

G-l7.

Inhibited Coolant Solutions

All

'Jeep5 vehicles equipped with either the

Hur

ricane

F4 or Dauntless V-6

engine

should use only

inhibited

year-round, permanent-type

engine

cool

ant

solutions that are formulated to withstand two

full

calendar years of normal operation without

draining

or adding inhibitors. The

engine

cooling

system should be completely drained and the

rec

ommended coolant installed every two years. Be-

fo

a

installing the permanent-type solution, inspect the cooling system to be sure it is clean, leakproof,

and

in proper operating condition.

Note:

Water alone, methanol, or alcohol-type anti

freeze is definitely not recommended for 'Jeep*

Vehicles.

G-l8.

Fan Belt

The

fan, water pump, generator or alternator are

driven

by a V-belt. The drive of the V-belt is on

the side of the V. A fan belt that is too tight

will

cause

rapid

wear of the alternator or generator and

water

pump bearings. If the belt is too

loose,

it may

slip

preventing the water pump from properly cool

ing the

engine

or the generator or alternator from

properly

charging the electrical

circuit.

Use fan belt

tension

gauge

Tool W-283 to properly adjust belt.

The

fan belt is properly adjusted when it can be

deflected Vi" [13 mm.] with strong thumb pres

sure

applied midway

between

the fan and alter

nator

pulleys.

Check

this adjustment and inspect the condition of the fan belt at each

engine

lubri-

168

Page 172 of 376

H

ELECTRICAL

SYSTEM SUBJECT

PAR.

Directional

Signal

Lamps

H-138

Hazard

Warning

Lamps

H-139

Head

Lamp

Replacement H-130

Head

Lamp

Aiming Procedure H-131 Headlight Dimmer Switch H-127

License

Plate

Lamp

H-136

Main

Light

Switch. H-126

Marker

Lights .H-l40

Parking

and

Turn

Signal

Light

H-133

Stop

Light

Switch. H-l28

Tail,

Stop and

Turn

Signal

Lamp

.H-134

H-1. GENERAL

All

'Jeep' Universal vehicles are equipped with 12- volt electrical systems. Use caution around the higher

voltage

of the 12-volt system as accidental

short

circuits are more capable of damaging electri

cal

units. Also, arcs around the 12-volt battery are

more apt to ignite any gas that may be escaping

from

it. In the following paragraphs

will

be found

information about the battery, distributor, coil,

generator, alternator,

voltage

regulator and start ing motor. These units with the connecting wires,

make

up the

engine

electrical system. The wiring

diagram

will

show the different circuits of the en

gine

electrical system and the various units which

make

up

those

circuits.

With

plastic-covered wiring harnesses use only

rubber-insulated

wiring clips.

Caution:

All current production vehicles are 12- volt, negative ground. Whenever servicing a 12-

volt electrical system, use caution, as an accidental

short

circuit is capable of damaging electrical units. Disconnect battery ground cable before changing

electrical

components.

H-2.

Battery

The

battery is a storage reservoir for electrical

energy produced by the alternator or generator.

The

battery should store sufficient energy for

operation of the entire electrical system when the

alternator

or generator is not pr 1,scing output,

such

as when the ignition is first turned on. Of

particular

importance is maintaining the electrolyte

at the correct level, regularly checking with a

hydrometer, and maintaining clean, tight cable connections.

Battery

service information is given in this section.

Caution:

Do not allow flames or sparks to be

brought near the vent

openings

of the battery since

hydrogen gas may be present in the battery and might explode.

Note:

The liquid in the battery (electrolyte) is a

solution of sulphuric acid which, on contact, can

injure

skin or

eyes,

or damage clothes. If it is spilled

on the skin or spattered in the

eyes,

promptly flush

it

away with quantities of clear water only. If the

acid

is spilled on clothes, wet it thoroughly with a

weak

solution of ammonia, or with a solution of sodium bicarbonate or baking soda.

SUBJECT

PAR.

HORN

H-137

ELECTRICAL

COMPONENT

REPLACEMENT

H-150

WINDSHIPLD

WIPER SYSTEM

H-141

thru

149

SERVICE

DIAGNOSIS.

. .H-151

ELECTRICAL

SPECIFICATIONS

H-152

Caution:

When installing the battery, the nega

tive terminal must be grounded. Reverse polarity of the battery can cause severe damage to the charging system.

Battery

Inspection

a.

Check

the specific gravity of the electrolyte in

each cell of the battery. A hydrometer reading of 1.260 indicates that the battery is fully charged.

If

the reading is 1.225 or below, the battery

needs

recharging.

If one or more cells is 25 "points" (.025) or more lower than the other cells, this in

dicates that the cell is shorted, the cell is about to

fail,

or there is a

crack

in the battery partition in

the case. Unless the battery is repaired or replaced, battery trouble

will

soon

be experienced.

b.

Check

the electrolyte level in each cell, add

distilled

water to maintain the solution [9,5 mm.] above the plates. Avoid overfilling. Replace

the filler caps and tighten securely. It is important to keep the electrolyte level above the plates at all

times because plates that are

exposed

for any

length of time

will

be seriously damaged.

c.

Check

the wing nuts on the hold-down frame for tightness. Tighten them only with finger pres

sure,

never with pliers or a wrench. Excessive

pressure

could damage the battery case.

d.

Clean

the battery terminals and cable con nectors. Prepare a strong solution of baking soda

and

water and brush it around the terminals to

remove any corrosion that is present. The cell caps must be tight and their vents sealed to prevent

cleaning solution entering the cells. After cleaning,

connect cables to battery and coat the terminals

with

heavy grease.

e.

Inspect the battery cables and replace if badly

corroded

or frayed.

Check

tightness

of terminal

screws to ensure

good

electrical connections.

Check

the

tightness

of the negative ground cable connection at the frame to ensure a

good

ground

connection.

f.

Load

test

the battery. Connect a voltmeter across the battery. Run the starting motor for 15 seconds. If the

voltage

does

not drop below 10

volts the battery is satisfactory. If the

voltage

falls

below the figure given, yet the specific gravity is

above

1.225,

the condition of the battery is questionable.

g. Be sure the

engine

ground strap connection, 172

Page 174 of 376

H

ELECTRICAL

SYSTEM

the condenser. Replace the condenser. If there is

no jump to full voltage, overhaul or replace the

distributor.

k.

With the points closed, connect the voltmeter

from

a clean, paint-free

post

on the distributor

body to the negative

post

of the battery. The volt

age drop should be practically zero, a hardly

readable deflection on the voltmeter. If the volt meter registers a

voltage

drop, perform the checks

in

steps

1

and m following.

I.

Check

for

voltage

drop in the battery ground

cable.

Clean

the battery

post,

cable terminals, and contact surface on the bellhousing, or on body if

a

noticeable deflection of the voltmeter occurs,

m.

Check

for any

voltage

drop

between

the dis

tributor

body and a clean, paint-free

spot

on the

cylinder

block. If there is any

voltage

drop, remove

the distributor and clean the mounting surfaces of

distributor

body and cylinder block.

H-5.

SECONDARY

CIRCUIT

If

satisfactory ignition is not obtainable with cor

rect

point gap and tension; satisfactory condenser;

sufficient primary voltage; and correctly cleaned, gapped, and installed spark plugs; the secondary

circiut

should be investigated.

a.

Test the coil.

Bring

the coil up to operating

temperature using the coil heat feature of a coil tester, if available. Refer to the coil tester manu

facturer's

instructions for specific hook-ups for

performing the checks given in

steps

b, c, and d following.

b. Connect the positive lead of the tester to the

battery terminal of the coil primary winding.

Con

nect the tester ground lead to the coil tower. Mea

sure

the resistance of the secondary winding. If the

resistance is more than

20,000

ohms, a fault in the

secondary winding is indicated.

c.

Check

for a grounded secondary by touching the tester ground lead to the coil cover. If resistance

is not over

100,000

ohms, the secondary is grounded

to the cover.

d.

If the secondary winding is satisfactory, mea

sure

the primary current draw in accordance with

the instructions of the

test

equipment manu

facturer.

e.

Check

the secondary circuit for leakage. With the coil primary in the circuit with the breaker unit of the tester, connect a long, high-tension

test

lead

to the coil tower.

Check

the secondary circuit for

leakage by performing the checks given in

steps

f. g, h, and i following.

Note:

In the following

tests,

a slight sparking and

meter deflection

will

usually be

seen

just as contact

is made.

This

is caused by capacitance and

does

not

indicate defective insulation.

f.

Check

distributor cap. Remove the coil lead from the cap and touch the

test

lead to the center contact

inside the cap. If the meter reading drops when the contact is touched or if sparking is seen, a leakage

path is present

between

the center contact and one

of the plug towers.

This

leakage path

will

be in the

form

of a

crack

or carbon track in the cap. Discon nect the spark plug wires from the cap one at a

time and

test

each plug contact with the high-

voltage

lead and with all other plug wires con

nected. Any sparking or meter drop indicates that

a

leakage path exists

between

that particular con

tact and an adjacent one. Testing the adjacent contacts

will

determine which pair is at fault,

g-

Check

distributor rotor. Touch the

test

lead to

the spring contact in the center of the distributor

rotor.

Any leakage in the rotor insulation

between

the contact and the shaft

will

cause a drop in the meter reading and usually sparking

will

be seen.

h.

Check

spark plug wires. Disconnect the spark

plug wires from the plugs and

test

the plug terminal of each. The meter reading should not drop below

the open secondary value (value before making contact). If it

does

or if a large spark occurs when

the

test

lead and the plug wire are separated, there

is a break in the insulation on that wire.

i.

Check

the coil tower insulation. Remove the

high-tension

test

lead from the coil tower and touch

the ground lead of the coil tester to several points

around

the base of the tower. Any sparking or deflection of the meter indicates a leakage path in

the tower insulation.

H-6.

Alternator Charging System

All

Jeep

Universal

Series vehicles have, as standard

equipment a 35-amp., 12-volt, negative ground

alternator and a transistorized

voltage

regulator.

For

repairing the alternator, many of its major components are furnished as complete assemblies

including:

complete brush assembly which requires no soldering or unsoldering of leads; two complete

rectifying

diode

assemblies which eliminate the need for removing and replacing individual diodes;

a

complete isolation

diode

assembly; and a rotor assembly complete with shaft,

pole

pieces, field coil,

and

slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining the system

voltage

at the output

terminal.

The out

put current is determined by the battery electrical

load;

such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed unit,

has no adjustments, and must be replaced as a

complete unit.

H-7.

Starting System

The

operation of the starter motor is controlled by

the ignition switch. The starter is made up of a

frame,

field coil, armature, and brushes.

The

starter solenoid electrically

closes

the circuit

between

the battery and the starter motor. When the ignition key is turned to its extreme right, the

solenoid is energized and

closes

the battery-to- starter-motor circuit.

Note:

All Jeep Universal Series vehicles have the

starter

solenoid switch secured to the starter motor

assembly. The Hurricane F4 and Dauntless V-6

engine

Prestolite starter drive is of the inertia type

(rexr

continued on

page

176) 174

Page 180 of 376

H

ELECTRICAL

SYSTEM

ffKHs)

3—<§)

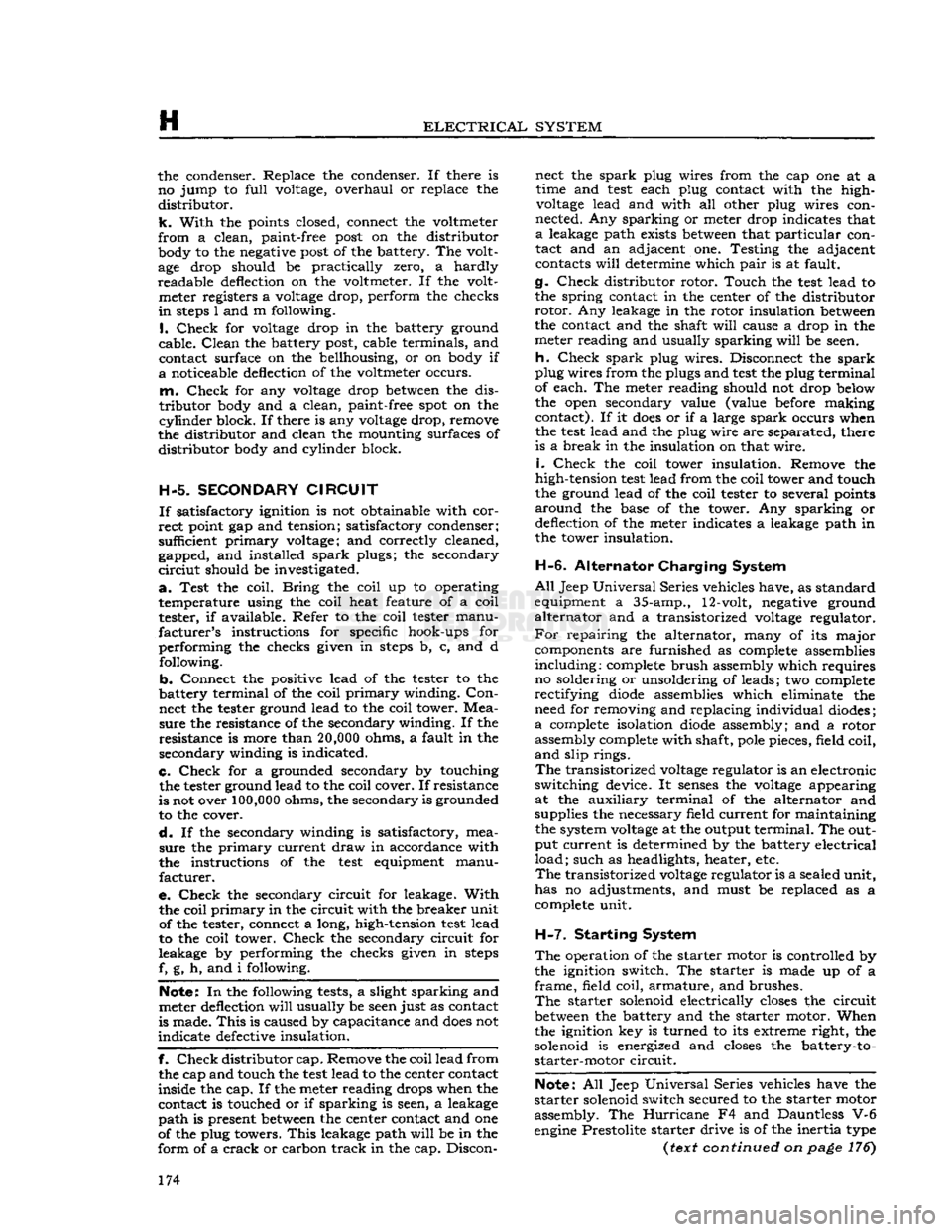

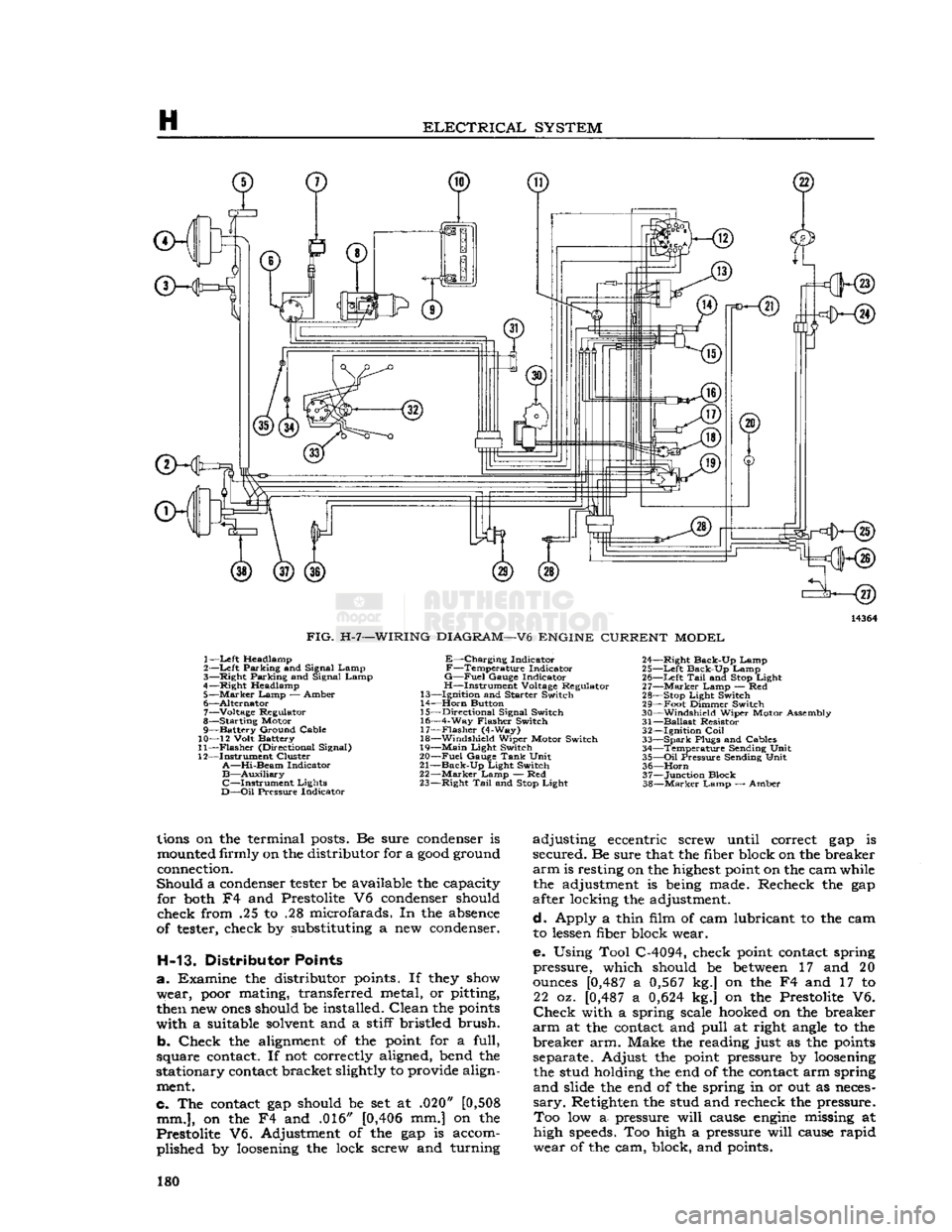

FIG.

H-7—WIRING

DIAGRAM—V6

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—Left Parking and Signal Lamp

3— Right Parking and Signal Lamp

4—Right Headlamp 5—

Marker

Lamp — Amber

6— Alternator 7— Voltage Regulator

8— Starting Motor

9— Battery Ground Cable

10— 12 Volt Battery

11—

Flasher

(Directional Signal)

12— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge Indicator

H—Instrument Voltage Regulator

13— Ignition and Starter Switch

14—

Horn

Button

15— Directional Signal Switch

16— 4-Way Flasher Switch 17—

Flasher

(4-Way)

18— Windshield Wiper Motor Switch

19—

Main

Light Switch

20—

Fuel

Gauge

Tank

Unit

21—

Back-Up

Light Switch

22—

Marker

Lamp — Red

23— Right

Tail

and

Stop

Light 24— Right Back-Up Lamp

25—

Left

Back-Up Lamp 26—

Left

Tail

and

Stop

Light

27—

Marker

Lamp — Red

28—

Stop

Light Switch

29— Foot Dimmer Switch

30— Windshield Wiper Motor Assembly

31—

Ballast

Resistor 32— Ignition

Coil

33—

Spark

Plugs and Cables 34— Temperature Sending Unit

35—

Oil

Pressure Sending Unit 36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

lions

on the terminal

posts.

Be sure

condenser

is

mounted

firmly on the distributor for a

good

ground

connection.

Should a

condenser

tester

be available the capacity for

both

F4 and Prestolite V6

condenser

should

check from .25 to .28 microfarads. In the

absence

of

tester,

check by substituting a new

condenser.

H-13. Distributor Points

a. Examine the distributor

points.

If

they

show

wear,

poor

mating, transferred metal, or pitting,

then

new

ones

should be installed. Clean the

points

with a suitable

solvent

and a stiff bristled brush.

b. Check the

alignment

of the

point

for a full,

square

contact.

If not correctly aligned, bend the

stationary

contact

bracket slightly to provide align

ment.

c. The

contact

gap should be set at .020"

[0,508

mm.],

on the F4 and .016"

[0,406

mm.] on the

Prestolite V6. Adjustment of the gap is accom plished by

loosening

the lock screw and turning adjusting eccentric screw until correct gap is

secured. Be sure that the fiber block on the breaker

arm

is resting on the

highest

point

on the cam while the adjustment is

being

made. Recheck the gap

after locking the adjustment.

d. Apply a thin film of cam lubricant to the cam to

lessen

fiber block wear.

e. Using Tool C-4094, check

point

contact

spring

pressure, which should be

between

17 and 20

ounces

[0,487

a

0,567

kg.] on the F4 and 17 to 22 oz.

[0,487

a

0,624

kg.] on the Prestolite V6.

Check

with a spring scale

hooked

on the breaker

arm

at the

contact

and pull at right

angle

to the

breaker arm. Make the reading just as the

points

separate. Adjust the

point

pressure by

loosening

the stud holding the end of the

contact

arm spring

and slide the end of the spring in or out as

neces

sary.

Retighten the stud and recheck the pressure. Too low a- pressure will

cause

engine

missing at

high

speeds.

Too high a pressure will

cause

rapid

wear of the cam, block, and

points.

180