ECU JEEP CJ 1953 Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 125 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

is generally caused by excessive

engine

idle speed

in

combination with retarded ignition timing,

engine

heat soak or the use cf low octane fuel.

Should

engine

dieseling

(engine

running after ignition key is turned off) be experienced on V-6

engine

equipped vehicles, installation of Idle Stop

Valve

Kit

Part

No.

991722

will

correct the

difficulty.

E-43.

Fast

Idle Adjustment

No fast idle speed adjustment is required.

Fast

idle is controlled by the curb idle speed adjustment

screw.

If curb idle speed is correctly set and the choke rod is properly adjusted, fast idle speed

will

be correct;

E-44.

Dash Pot Adjustment —

F4

and V-6 Engine

•

Refer to

Figs.

E-27 and E-28. Before adjusting the dash pot, the

engine

idle speed

and

mixture should be correctly adjusted.

With

the

engine

idling at normal operating temperature,

adjust

the dash pot as follows:

The

dash pot adjustment is made with the throttle

set at curb idle (not fast idle). Loosen dash pot lock

nut and

turn

the dash pot assembly until dash pot

plunger contacts the throttle lever without the plunger being depressed.

Then

turn

the dash pot

assembly 2turns against the throttle lever, de pressing the dash pot plunger. Tighten the lock nut

securely. As a final check, open carburetor and

allow throttle to snap closed. Time dash pot delay ing action from the point where the throttle lever

hits the dash pot to the point where the lever

stops

moving. The dash pot should delay or cushion

closing action for two seconds by saying, "One

thousand and one, one thousand and two."

14204

FIG.

E-27—DASH

POT

ADJUSTMENT—V6

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut

E-45.

FUEL

PUMP

(DOUBLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models

The

double-action fuel pump consists of a metal

body, a rubber diaphragm, rocker arm, valves,

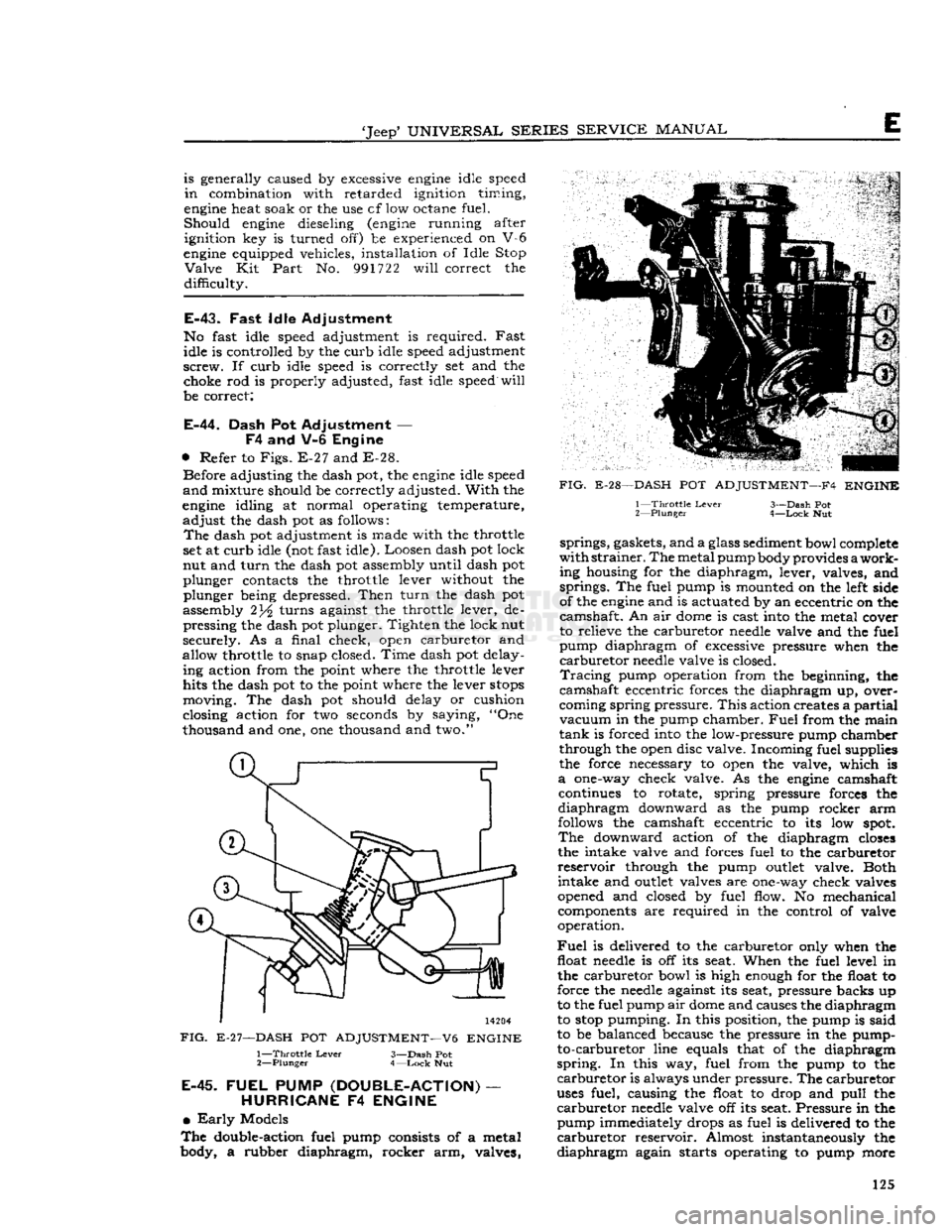

FIG.

E-28—DASH

POT

ADJUSTMENT—F4

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut springs, gaskets, and a glass sediment bowl complete

with

strainer.

The

metal pump body provides

a

work

ing housing for the diaphragm, lever, valves, and springs. The fuel pump is mounted on the left side

of the

engine

and is actuated by an eccentric on the

camshaft. An air

dome

is cast into the metal cover

to relieve the carburetor

needle

valve and the fuel

pump diaphragm of excessive pressure when the

carburetor

needle

valve is closed.

Tracing

pump operation from the beginning, the

camshaft eccentric forces the diaphragm up, over

coming spring pressure.

This

action creates a

partial

vacuum

in the pump chamber.

Fuel

from the main

tank

is forced into the low-pressure pump chamber

through the open disc valve. Incoming fuel supplies

the force necessary to open the valve, which is

a

one-way check valve. As the

engine

camshaft continues to rotate, spring pressure forces the

diaphragm

downward as the pump rocker arm

follows the camshaft eccentric to its low

spot.

The

downward action of the diaphragm

closes

the intake valve and forces fuel to the carburetor

reservoir

through the pump

outlet

valve. Both intake and

outlet

valves are one-way check valves

opened and closed by fuel flow. No mechanical components are required in the control of valve

operation.

Fuel

is delivered to the carburetor only when the float

needle

is off its seat. When the fuel level in the carburetor bowl is high enough for the float to

force the

needle

against its seat, pressure backs up

to the fuel pump air

dome

and causes the diaphragm

to

stop

pumping. In this position, the pump is said

to be balanced because the pressure in the pump- to-carburetor line equals that of the diaphragm

spring.

In this way, fuel from the pump to the

carburetor

is always under pressure. The carburetor

uses

fuel, causing the float to drop and

pull

the

carburetor

needle

valve off its seat. Pressure in the pump immediately drops as fuel is delivered to the

carburetor

reservoir. Almost instantaneously the

diaphragm

again starts operating to pump more 125

Page 126 of 376

FUEL

SYSTEM

|

11893

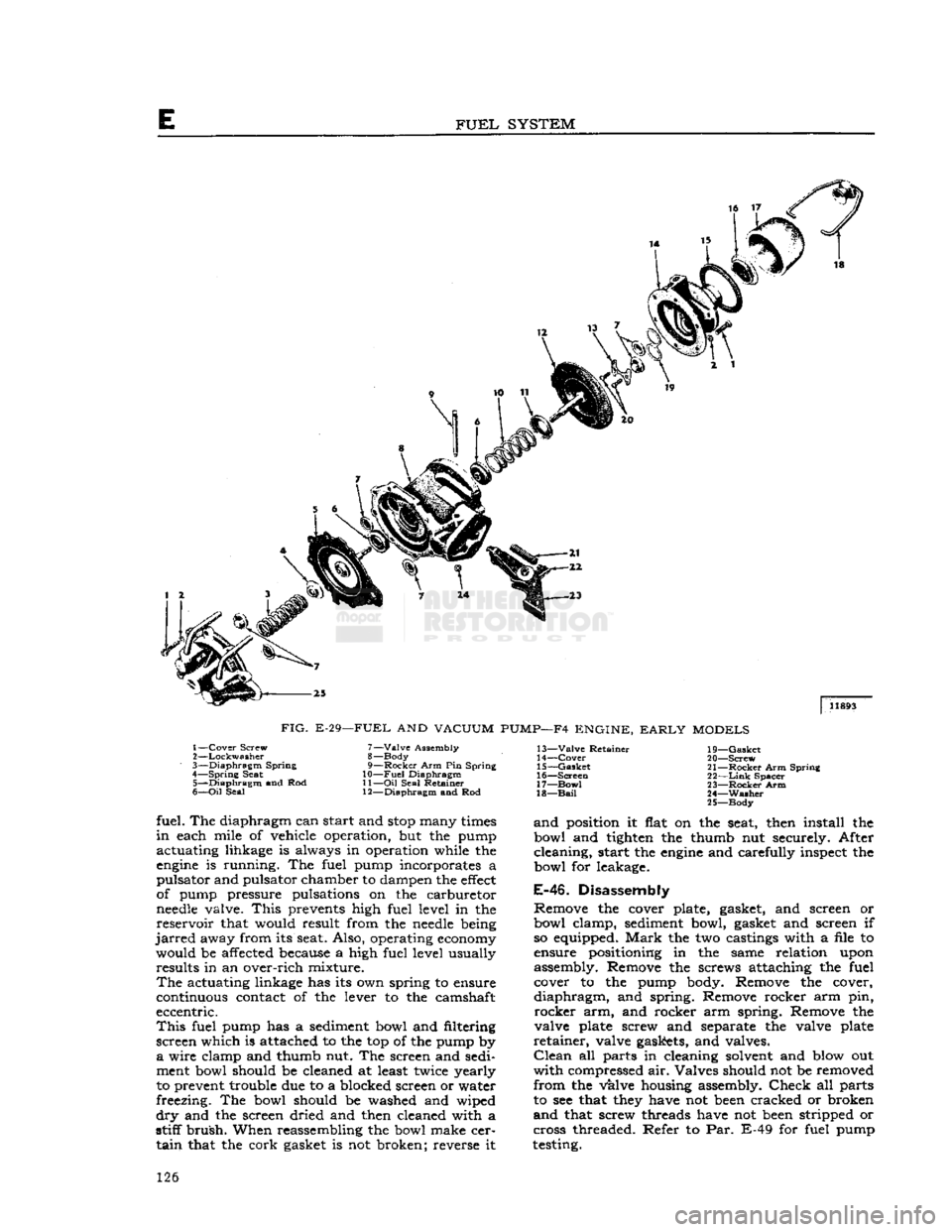

FIG.

E-29—FUEL

AND

VACUUM

PUMP—F4

ENGINE,

EARLY

MODELS

1—

Cover

Screw

2—

Lockwasher

3—

Diaphragm

Spring

4—

Spring

Seat 5—

Diaphragm

and Rod

6—

Oil

Seal 7—

Valve

Assembly

8— Body

9—

Rocker

Arm Pin Spring

10—

Fuel

Diaphragm

11—

Oil

Seal Retainer

12—

Diaphragm

and Rod 13—

Valve

Retainer

14—

Cover

15—

Gasket

16—

Screen

17—

Bow!

18—

Bail

19—

Gasket

20—

Screw

21—

Rocker

Arm Spring

22—

Link

Spacer

23—

Rocker

Arm

24—

Washer

25—

Body

fuel. The diaphragm can start and

stop

many

times

in

each mile of vehicle operation, but the pump

actuating lihkage is always in operation while the

engine

is running. The fuel pump incorporates a

pulsator and pulsator chamber to dampen the

effect

of pump pressure pulsations on the carburetor

needle

valve.

This

prevents high fuel level in the

reservoir

that would result from the

needle

being

jarred

away from its seat. Also, operating

economy

would be affected because a high fuel level usually results in an over-rich mixture.

The

actuating linkage has its own spring to ensure

continuous contact of the lever to the camshaft

eccentric.

This

fuel pump has a sediment bowl and filtering

screen which is attached to the top of the pump by

a

wire clamp and thumb nut. The screen and sedi

ment bowl should be cleaned at least twice yearly

to prevent trouble due to a blocked screen or water

freezing. The bowl should be washed and wiped

dry

and the screen dried and then cleaned with a

stiff

brush.

When reassembling the bowl make cer

tain

that the cork gasket is not broken; reverse it

and

position it flat on the seat, then install the

bowl and tighten the thumb nut securely. After

cleaning, start the

engine

and carefully inspect the

bowl for leakage.

E-46.

Disassembly

Remove the cover plate, gasket, and screen or

bowl clamp, sediment bowl, gasket and screen if so equipped.

Mark

the two castings with a file to

ensure positioning in the same relation upon

assembly. Remove the screws attaching the fuel cover to the pump body. Remove the cover,

diaphragm,

and spring. Remove rocker arm pin,

rocker

arm, and rocker arm spring. Remove the

valve plate screw and separate the valve plate

retainer,

valve gaskets, and valves.

Clean

all parts in cleaning solvent and blow out

with

compressed air. Valves should not be removed

from

the valve housing assembly.

Check

all parts

to see that

they

have not

been

cracked or broken

and

that screw threads have not

been

stripped or

cross threaded. Refer to Par. E-49 for fuel pump

testing. 126

Page 127 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

E-47.

Reassembly

•

Refer to Fig. E-29.

Install

the valve gaskets, valves, valve retainer and

secure them with the valve retainer screws. Make

sure that the inlet and

outlet

valves are in their proper positions. Place the diaphragm spring re

tainer in position on the diaphragm

pull

rod

and

install diaphragm spring. Position the

dia

phragm assembly in pump

body

and attach the

cover to pump body, with file marks aligned, with

the six attaching screws. Do not draw the screws

up tight.

Install

rocker arm spring, rocker arm

pin

washers, rocker arm and rocker arm pin.

With

rocker

arm positioned on the diaphragm rod, draw

the six pump

body

screws up evenly and securely.

Install

the filter screen, cork gasket and sediment

bowl and secure them firmly with the thumb screw

on the bowl clamp.

E-48.

Vacuum

Pump

The

double-action fuel pump resembles two single-

action pumps placed one

above

the other. A single

fuel pump rocker arm actuates the two separate diaphragms. One diaphragm is part of the fuel

delivery pump and operates as described in Par.

E-45.

The other diaphragm is part of the vacuum

pump and operates as described here.

As

the actuating lever forces the diaphragm upward against spring pressure, air is forced through the

outlet

port

into

the

engine's

intake manifold. On

the return stroke, spring pressure forces the

dia

phragm downward, creating a

partial

vacuum and

opening the inlet valve. In this manner, air is pumped out of the windshield wiper motor and

into

the intake manifold. When the wiper motor is shut off, manifold vacuum holds the diaphragm against its spring so that the

full

motion of the actuating

lever is not accompanied by a

complete

up-and-

down motion of the diaphragm.

When

the windshield wiper motor is turned on, but manifold vacuum is greater than the vacuum

created by the

booster

pump, air

flows

from the

wiper motor through both valves of the vacuum

booster.

As manifold vacuum drops off as a result

of the

engine

operating under low

speed

and high load, the vacuum created by the vacuum

booster

will

be greater than

engine

intake manifold vacuum

and

the pump

will

operate the wiper motor when the wiper control switch is turned on.

•

Refer to Fig. E-29. Remove the

eight

cover attaching screws and

lockwashers, and remove the cover, diaphragm

spring

and spring seat. Detach the diaphragm rod

from the rocker arm and remove the diaphragm.

The

valve assemblies are pressed

into

the cover

and

body

and lightly staked. They may be removed

with the point of a knife blade. If installing new valves be sure the inlet and

outlet

valves are

correctly positioned and stake them lightly with

a

small punch.

Assemble the vacuum pump in the reverse order

of disassembly, drawing the cover attaching screws up evenly and tightly.

E-49.

Fuel

Pump

Testing

Four

tests

are presented in following paragraphs to

test

for proper operation of the fuel pump. In addi

tion, check the following:

a.

Check

for secure mounting of the fuel pump.

The

rocker arm may be working the entire pump

up and down, rather than just the pump

dia

phragms.

b. Remove and clean the fuel sediment bowl.

c.

Check

all fuel lines.

E-50.

Volume

Check

To

measure fuel pump capacity (amount of fuel

delivered in a given time) disconnect the pump-to-

carburetor

line at the carburetor end. Place the

open

end of the line in a suitable container.

Start

the

engine

and operate at normal idle speed.

Delivery

should be one quart U.S. [1 ltr.] within

one minute.

E-51.

Pressure

Check

To

measure fuel pump pressure (force of fuel de

livery)

disconnect the pump-to-carburetor line

at the carburetor end. Plug a pressure

gauge

and T-fitting

into

the

open

end of this line and

into

the

carburetor.

Start

the

engine

and operate at normal

idle speed. Pressure should be 2J4 to 3% psi.

[0,716

a

0,264

kg-cm2] at 1800 rpm. and at 16"

[406 mm.]

above

the

outlet.

E-52.

Vacuum

Check

To

measure fuel pump vacuum (pull of. the pump

at the inlet side) disconnect the pump-to-fuel-tank

line at the fuel pump. Attach a vacuum

gauge

to the fuel pump inlet.

Start

the

engine,

accelerate to

specified speed, and hold this

engine

speed

while

taking a

gauge

reading. Permissible

gauge

reading

is 8* [203 mm.] of mercury [Hg] at 1200 rpm. and

10j^'

[267 mm.] at 1800 rpm.

E-53.

Vacuum

Booster

Check

To

test

the condition of the vacuum

booster

pump,

disconnect both inlet and

outlet

lines at the pump.

Attach

a vacuum

gauge

to the windshield wiper

connection at the pump.

Start

the

engine,

accelerate

to

2000

rpm., and hold this

engine

speed

while taking a

gauge

reading. Permissible

gauge

reading

is 10* to 14" [254 a 356 cm.] of mercury [Hg].

E-54.'

FUEL

PUMP

(SINGLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models.

Vehicles with electric windshield wiper motors are

equipped with a single-action fuel pump (Fig.

E-30).

The fuel pump cam lever is activated by an eccentric on the

engine

camshaft. When the

car

buretor float

needle

valve closes, accumulation of

fuel in the pump

extends

the diaphragm spring.

This

action causes the rocker arm linkage to be

come

inoperative until the pressure on the

dia

phragm and spring is reduced. The fuel pump dis

charge pressure is thus controlled by the diaphragm

spring.

This

provides a steady supply of fuel to the

carburetor

at a fairly constant pressure. 127

Page 128 of 376

E

FUEL

SYSTEM

E-55.

Fuel

Pump

Removal

To

remove the fuel pump from the engine, dis

connect the inlet and

outlet

fuel lines. Remove the two fuel pump body attaching nuts, lock

washers,

and washers, and pull the fuel pump and gasket free of the engine.

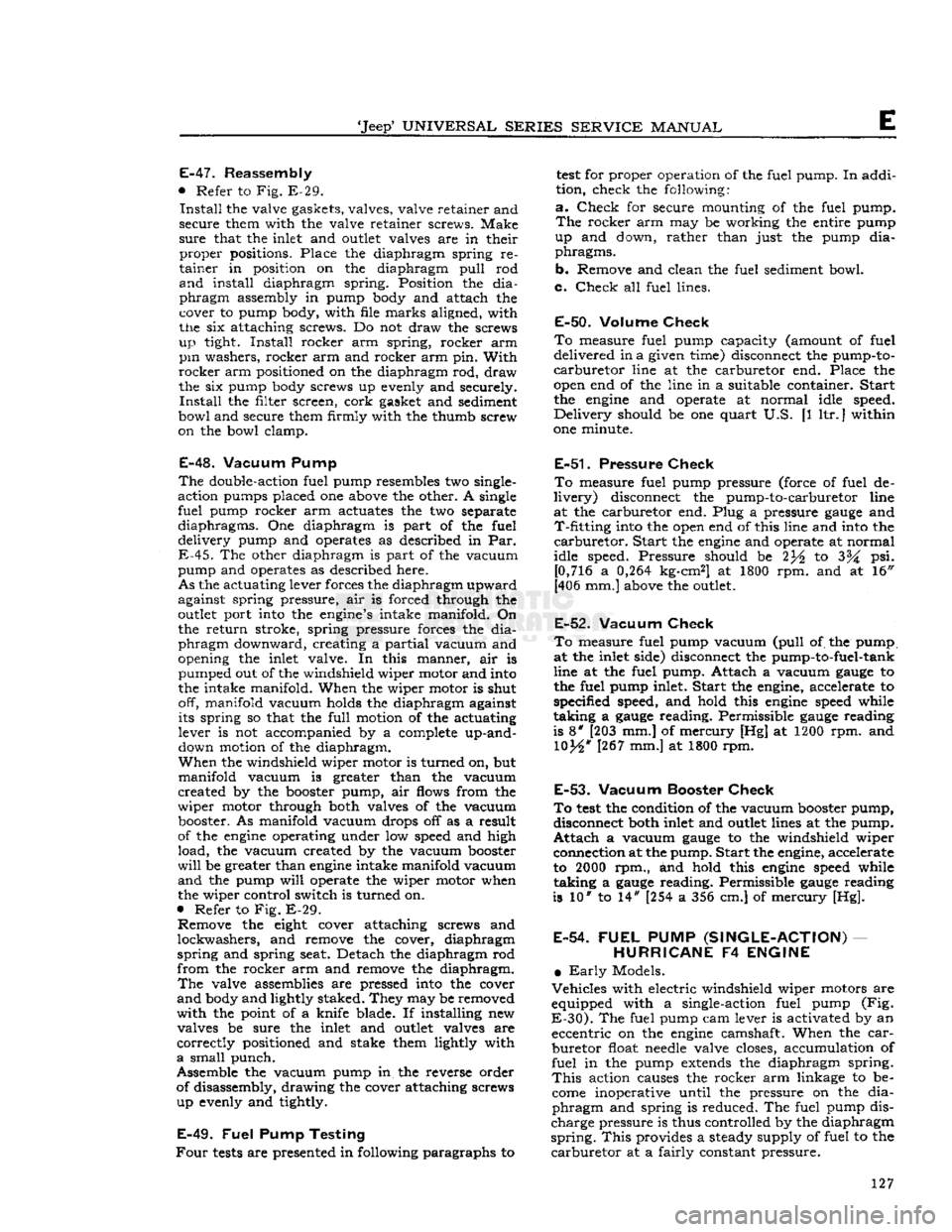

FIG.

E-30

—

FUEL

PUMP—HURRICANE

F4 ENGINE,

EARLY

MODELS

1—

Housing

Cover

2— Air

Dome

Diaphragm

3—

Strainer

4—

Screw

and

Washer

5—

Housing

6—

Cover

Screw

and

Lock

Washers

7—

Main

Diaphragm

8—

Pump

Body

9— Cam

Lever

Return

Spring

10— Pin

Retainer

11— Cam

Lever

12— Cam

Lever

Pin

13—

Lever

Seal

Shaft

Plug

E-56.

Fuel

Pump

Disassembly

Note:

The fuel pump is serviced with a repair kit.

Individual

service parts are also available. The

valves are not replaceable but are serviced as part of the valve housing.

a.

Before disassembly of the fuel pump,

mark

the

three castings (see Fig. E-30) to ensure positioning

in

the same relation upon assembly. b. Remove the inlet and

outlet

fuel fittings from

the pump.

c. Remove the screws and washers and separate the housing from the pump body.

d.

Remove cover screws and lock washers and

then remove housing cover,

dome

diaphragm and

strainer.

e.

Remove cam lever return spring and lever seal

shaft plug.

f. Remove retainer pin, cam lever pin and cam

lever.

g. Remove main diaphragm.

Note:

Do not remove valves from housing as they

are

serviced with the housing.

Note:

The oil seal (at top of spring in diaphragm

assembly) seals the spring side of the fuel

dia

phragm

from the crankcase. Any deposit, in

excess

of a few drops, of oil on the diaphragm, indicates

leakage past the oil seal. Be sure the seat for the

seal

in the pump body is clean and smooth.

E-57.

Fuel

Pump

Cleaning

and

Inspection

Caution:

Do not immerse valves or diaphragm in

-cleaning solvent; wipe clean.

Clean

all metal parts of the fuel pump in solvent.

Brush

with a stiff-bristled brush. Dry with com

pressed air.

Check

all parts to see that they are not

cracked

or broken and that the screw threads are

not damaged.

E-58.

Fuel

Pump

Reassembly

a.

Position the new main diaphragm on pump body

and

hold it in position while installing cam lever

in

position.

b.

Install

cam lever pin, pin retainer and lever

seal

shaft plug.

c.

Install

cam lever return spring.

d.

Position strainer, air

dome

diaphragm and hous

ing cover on housing and secure with screw and

lock

washers.

e.

Position housing on pump body and secure with screw and washers.

First

start all screws one or

two turns:

Then

tighten the screws alternately and

securely.

Note:

Before placing housing on pump body

note

position of align marks made before disassembly.

f.

Install

the fuel inlet and

outlet

fittings.

Note:

Lubricate

forked end of cam lever and cam

lever pin.

Caution:

Do not overtighten screw. 128

Page 129 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

E-59.

Fuel

Pump Installation

a.

Make certain mating surfaces of fuel pump and

engine

cylinder case are clean. Cement a new gasket

to mounting

flange

of fuel pump.

b. Position fuel pump on cylinder block, so that

cam

lever of pump rests on fuel pump cam of cam

shaft. Secure pump to block with two cap screws

and

lock washers.

c. Connect intake and

outlet

fuel lines to fuel

pump.

E-60.

FUEL

PUMP

(SINGLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Late

Models.

The

Hurricane F4

engine

is equipped with a single-

action fuel pump (Fig.

E-31).

The fuel pump cam lever is activated by an eccentric on the

engine

camshaft. When the carburetor float

needle

valve

closes, accumulation of fuel in the pump

extends

the diaphragm spring.

This

action causes the rocker

arm

linkage to

become

inoperative until the pres

sure on the diaphragm and spring is reduced. The fuel pump discharge pressure is thus controlled by

the diaphragm spring.

This

provides a steady sup ply of fuel to the carburetor at a fairly constant

pressure.

E-61.

Fuel

Pump Removal

To

remove the fuel pump from the

engine,

dis

connect the inlet and

outlet

fuel lines. Remove

the two fuel pump

body

attaching nuts, lock washers, and washers, and pull the fuel pump and

gasket free of the

engine.

E-62.

Fuel

Pump Disassembly

Note:

The fuel pump is serviced with a repair kit.

Individual

service parts are also available. The

valves are not replaceable but are serviced as part

of the valve housing.

•

Refer to Fig. E-32.

a.

Remove filter bail assembly, bowl,

element,

spring,

and gasket from filter cover. b.

File

a locating

mark

on the

edges

of the valve

housing and the pump body. Remove the six at-

14280

FIG.

E-32—FUEL

PUMp—

HURRICANE F4 ENGINE,

LATE

MODELS

12988

FIG.

E-31—FUEL

.PUMP-

HURRICANE F4 ENGINE,

LATE

MODELS 1—

Bail

2—

Bowl

3—

Spring

4—

Filter

5—

Gasket

6— Pump Body 7—

Gasket

8—

Valve

Assembly 9— Screws 10—

Valve

Housing

11—

Valve

Assembly

12— Screws

13—

Diaphragm

and Oil Seal 14— Pump Body

15—

Cam

Lever

Spring 16—

Cam

Lever

17—

Gasket

18—

Cam

Lever

Pin and Plug 129

Page 130 of 376

E

FUEL

SYSTEM

taching screws and valve housing from the fuel

pump body.

c.

Remove the two screws in the valve housing

and

separate the filter cover and air

dome

dia

phragm.

d.

Remove the cam lever return spring, plug,

cam

lever pin, and cam lever from the pump body.

Tap

the cam lever pin out of body, using a drift

inserted through the small

hole

in the pump body.

e. Remove diaphragm from pump body.

f. Under normal service, the pump may be cleaned without further disassembly.

Note:

The oil seal (at top of spring in diaphragm

assembly) seals the spring side of the fuel

dia

phragm

from the crankcase. Any deposit, in

excess

of a few drops, of oil on the diaphragm indicates leakage past the oil seal. Be sure the seat for the

seal

in the pump body is clean and smooth.

E-63.

Fuel

Pump Cleaning and Inspection

Caution:

Do not immerse valves or diaphragm

in

cleaning solvent; wipe clean.

Clean

all metal parts of the fuel pump in solvent.

Brush

with a stiff-bristled

brush.

Dry with com

pressed

air.

Check

all parts to see that they are not

cracked

or broken and that the screw threads are

not damaged.

E-64.

Fuel

Pump Reassembly

•

Refer to Fig. E-32.

a.

Assemble the valve housing and filter cover, using a new air

dome

diaphragm. The opening

in

the air

dome

diaphragm is located over the

intake

valve. The filter cover is positioned cor

rectly

when the inlet passage in the cover aligns

with

the inlet valve. Tighten the attaching screws

alternately and securely.

b.

Lubricate

diaphragm assembly shaft, around

oil

seal, with

engine

oil. Position diaphragm as sembly on valve housing and thread all the attach ing screws through diaphragm.

(This

helps avoid

damage to the screw

holes

in diaphragm.)

c.

Place diaphragm assembly and valve housing

in

position on pump body (align marks made

before disassembly).

First

start all screws one

or

two threads; then tighten the screws alternately

and

securely.

d.

Lubricate

forked end of cam lever, pin bore

of body, and corresponding

hole

in lever, and the

pin

itself with

engine

oil.

Note:

Forked

end of lever

goes

around diaphragm

shaft. Be sure

loose

bumper washer on diaphragm shaft is on top of lever and

between

lever and fixed

washer

on shaft.

e.

Install

lever and pin. To install pin, use a drift

and

tap pin into the

hole

in the body until it hits

the

stop

on the

bottom

of the hole;

move

the lever while tapping, to align

hole

in lever with the pin;

then install plug.

Install

lever return spring.

f.

Install

a new filter bowl gasket in filter cover.

Place

bail

assembly in ears on cover and swing

to one side.

Install

spring and new filter element in

bowl and install bowl on pump. Position

bail

as

sembly under bowl; tighten retainer screw.

Caution:

Do not overtighten screw.

E-65.

Fuel

Pump Installation

a.

Make certain mating surfaces of fuel pump and

engine

cylinder case are clean. Cement a new gasket to mounting flange of fuel pump.

b.

Position fuel pump on cylinder block, so that

cam

lever of pump rests on fuel pump cam of cam

shaft. Secure pump to block with two cap screws

and

lock washers. Torque

bolts

13 to 17 lb-ft. [1,8

a

2,3 kg-m.].

c.

Connect intake and

outlet

fuel lines to fuel

pump.

E-66.

Fuel

Pump Testing

Whenever

the fuel pump is to be checked for pres

sure

or volume, follow the procedure outline in

Par.

C-23 of this manual.

Fuel

pump pressure is

important

for low pressure

will

seriously affect en

gine

operation and high pressure can cause exces

sive fuel consumption and flooding of the carbure

tor.

Should there be any doubt of normal opera

tion, check the procedure as outlined in Par. C-23.

In

addition to proper fuel pressure, volume of the

pump is also important. When testing for proper

pump pressure, be certain to also

test

for volume

as the pump may build up sufficient pressure, but

fail

to produce sufficient volume.

E-67. FUEL

PUMP

—

DAUNTLESS

V-6

ENGINE

Jeep vehicles equipped with the Dauntless V6-225

engine

have a special fuel pump which has a metering

outlet

for a vapor return system. Any

vapor

which forms is returned to the fuel tank

along with hot fuel through a separate line along

side the fuel supply line.

This

greatly reduces any

FIG.

E-33—FUEL PUMP—DAUNTLESS V-6 ENGINE

1

—Fuel

Outlet 2—Vapor

Return

3—Fuel

Inlet

130

Page 131 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

E

possibility of vapor lock by keeping cool fuel from

the tank constantly circulating through the fuel

pump.

Fuel

pump pressure at carburetor (inlet) on Daunt

less

V6-225

engine

should be 3% lbs.

[0,264

kgm-cm2] minimum at idle with the vapor return

hose

squeezed off. With the vapor return

hose

open

pump pressure should be 2j^ lbs. [0,176 kg-cm2]

minimum.

The

Dauntless V-6

engine

is equipped with a sealed

unit,

non-repairable, single-action fuel pump (Fig.

E-33).

Note:

All Dauntless V-6

engines

are equipped with

a

throw-away can-type gasoline filter installed in

the fuel line

between

the fuel pump and the

car

buretor.

This

unit must be replaced every

12,000

miles

[19.200

km.] of vehicle operation.

E-68.

Fuel

Pump Removal

To

remove the fuel pump from the Dauntless V-6

engine, disconnect the fuel inlet, fuel

outlet

and fuel return lines from the pump. Remove the two

fuel pump body attaching cap screws and lock

washers.

Pull

the fuel filter bracket free and remove the pump and gasket. Discard pump and gasket.

Install

new pump in reverse procedure of removal.

E-69.

AIR

CLEANER

Servicing

of the air cleaner is properly taken care of as part of the periodic lubrication and servicing of the vehicle. For this reason, air cleaner servicing

information is given in the Lubrication Section.

Refer

to and follow the instructions given there.

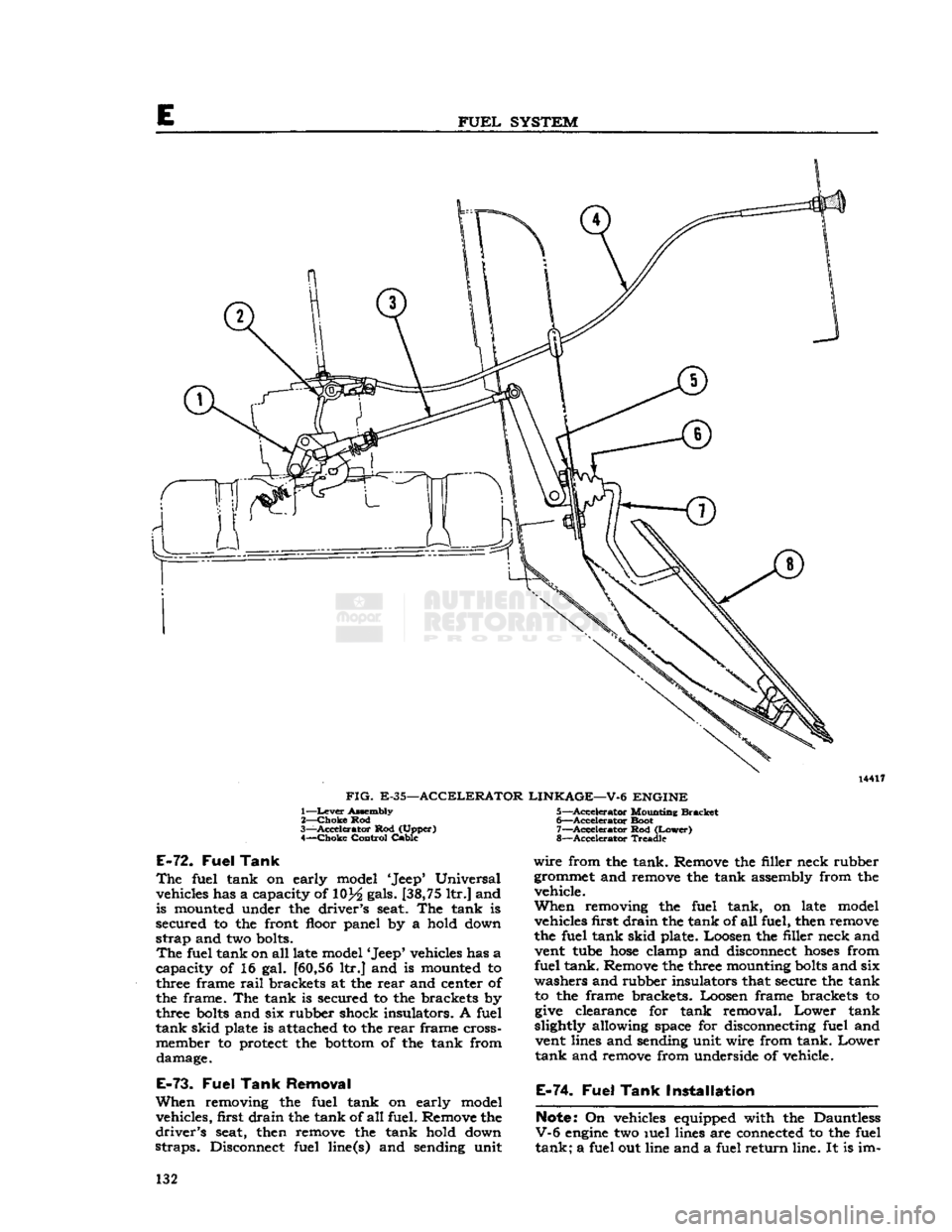

E-70. ACCELERATOR LINKAGE

The

accelerator linkage is properly adjusted when

the vehicle leaves the factory. However, in time

components parts

will

become

worn and require re

adjustment to maintain a smooth even control of

engine

speed. On Models equipped with F4

engines

the adjustment is made at the adjusting block,

Fig.

E-34. Loosen the lock nuts, and adjust the length of the accelerator rod so that when the

car

buretor throttle valve is wide open the accelerator

treadle

will

just strike the toe board. After correct

adjustment is made tighten both lock nuts firmly.

To

adjust the accelerator linkage on V6

engines

loosen

the lock nuts securing the accelerator rod

housing to its securing bracket and adjust the length

of the accelerator rod so that when the carburetor throttle valve is wide open the accelerator treadle

will

just strike the toe board. After correct adjust

ment is made, tighten lock nut firmly, see Fig. E-35 for Dauntless V-6 engine.

E-71. FUEL

TANK

AND

FUEL LINES

The

following paragraphs (E-70 through E-73) describe the removal, installation and services to

be performed when replacing the fuel tank or

servicing

the fuel system.

FIG.

E-34—ACCELERATOR LINKAGE,

F4

ENGINE

1—

Grommet

2— Nut and Lockwasher

3—

Throttle

Control

4—

Choke

Control 5—

Treadle

Rod Seal

6—

Accelerator

Treadle

7—

Treadle

Hinge Pin

8—

Treadle

Hinge 9— Nut and Lockwasher

10—

Screw

11—

Accelerator

Rod

12— Nut

13—

Adjusting

Block

14—

Retracting

Spring

15—

Cotter

Pin

16—

Lower

Beilcrank

17—

Washer

18—

Beilcrank

Link

Rod

19—

Bracket

20—

Throttle

Wire

Stop

21—

Beilcrank

Spring

22—

Rod

23—

Upper

Beilcrank

24—

Wesher

10731

131

Page 132 of 376

FUEL

SYSTEM

14417

FIG.

E-35—ACCELERATOR LINKAGE—V-6 ENGINE

1— Lever

Assembly

2—

Choke

Rod

3—

-Accelerator

Rod (Upper) 4—

Choke

Control Cable

E-72.

Fuel

Tank

The

fuel tank on early model 'Jeep* Universal vehicles has a capacity of 10}4 gals. [38,75 ltr.] and

is mounted under the driver's seat. The tank is

secured to the front floor panel by a hold down

strap

and two bolts.

The

fuel tank on all late model 'Jeep* vehicles has a

capacity of 16 gal. [60,56 ltr.] and is mounted to

three frame

rail

brackets at the

rear

and center of

the frame. The tank is secured to the brackets by

three

bolts

and six rubber shock insulators. A fuel

tank

skid plate is attached to the

rear

frame cross- member to protect the

bottom

of the tank from damage.

E-73.

Fuel

Tank

Removal

When

removing the fuel tank on early model vehicles, first drain the tank of

all

fuel. Remove the

driver's

seat, then remove the tank hold down

straps.

Disconnect fuel line(s) and sending unit 5—

Accelerator

Mounting Bracket

6—

-Accelerator

Boot

7—

Accelerator

Rod

(Lower)

8—

Accelerator

Treadle

wire

from the tank. Remove the filler neck rubber

grommet and remove the tank assembly from the vehicle.

When

removing the fuel tank, on late model vehicles first

drain

the tank of

all

fuel, then remove

the fuel tank skid plate. Loosen the filler neck and vent tube

hose

clamp and disconnect

hoses

from fuel tank. Remove the three mounting

bolts

and six

washers and rubber insulators that secure the tank to the frame brackets. Loosen frame brackets to

give

clearance for tank removal.

Lower

tank

slightly allowing space for disconnecting fuel and vent lines and sending unit wire from tank.

Lower

tank

and remove from underside of vehicle.

E-74.

Fuel Tank Installation

Note:

On vehicles equipped with the Dauntless

V-6

engine

two luel lines are connected to the fuel

tank;

a fuel out line and a fuel return line. It is im- 132

Page 133 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

portant that

these

lines are not accidentally re

versed.

When

installing the fuel tank on late model vehicles, position the tank

between

the frame

rail

to allow space to connect the fuel line(s), vent

hose

and

sending unit wire. After connecting

these

items, align and secure tank to frame brackets.

Position filler

hose

on tank filler neck and tighten

hose

clamp.

Fill

tank with fuel and check for leaks.

When

installing the fuel tank on early model vehicles, reverse the order of removal as given in

Par.

E-73.

E-75.

Fuel

Tank

Cap

A

surge pressure type fuel tank filler cap is used on

all

models.

This

is necessary to prevent fuel leakage

from

the cap vent opening when the vehicle is on a

side slope. Two spring loaded relief valves which

open when venting is required are built into the

cap.

Should the pressure valve

fail

to open, pressure

in

the tank may force fuel by the carburetor inlet

valve causing flooding.

Failure

of the vacuum valve may prevent flow of fuel to the carburetor. Should

the valves

fail

to vent install a new cap.

Note:

Vehicles having a

Fuel

Evaporative

Emis

sion System are equipped with a non-vent sealed gas cap. The sealed cap is designed to allow no

vapors to discharge to the atmosphere. No other type of cap is to be used on vehicles having this

type system.

E-76.

Fuel

Gauge Float Unit

The

fuel tank

gauge

float unit is mounted in the top

of the fuel tank and consists of a housing enclosing

a

rheostat that is actuated by the float arm, and a

float

which

moves

with the fuel level in the tank.

On

V-6 and current production F4

engine

equipped vehicles, the fuel

outlet

pipe is integral with the

float

unit.

The fuel

outlet

pipe has a mesh filter on the inner end.

Note:

Under no circumstances should a fuel tank

gauge

be installed without a mesh filter element.

The

filter,

outlet

pipe, and float unit are locked as

an

assembly to the top of the fuel tank. To remove,

turn

the lock plate that secures the float unit

assembly.

E-77.

Fuel

Lines

Check

lines and connections occasionally for leaks,

and

for severe kinks that might restrict the flow of

fuel. If an excessive amount of

dirt

is found in the

carburetor

or fuel pump, the fuel tank should be

drained

and the fuel lines blown out with com

pressed air.

All

rubber fuel lines and their respective clamps should be checked occasionally to be certain they

are

correctly positioned and not leaking. 133

Page 139 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

©

1

1

©-

IT

T"

I

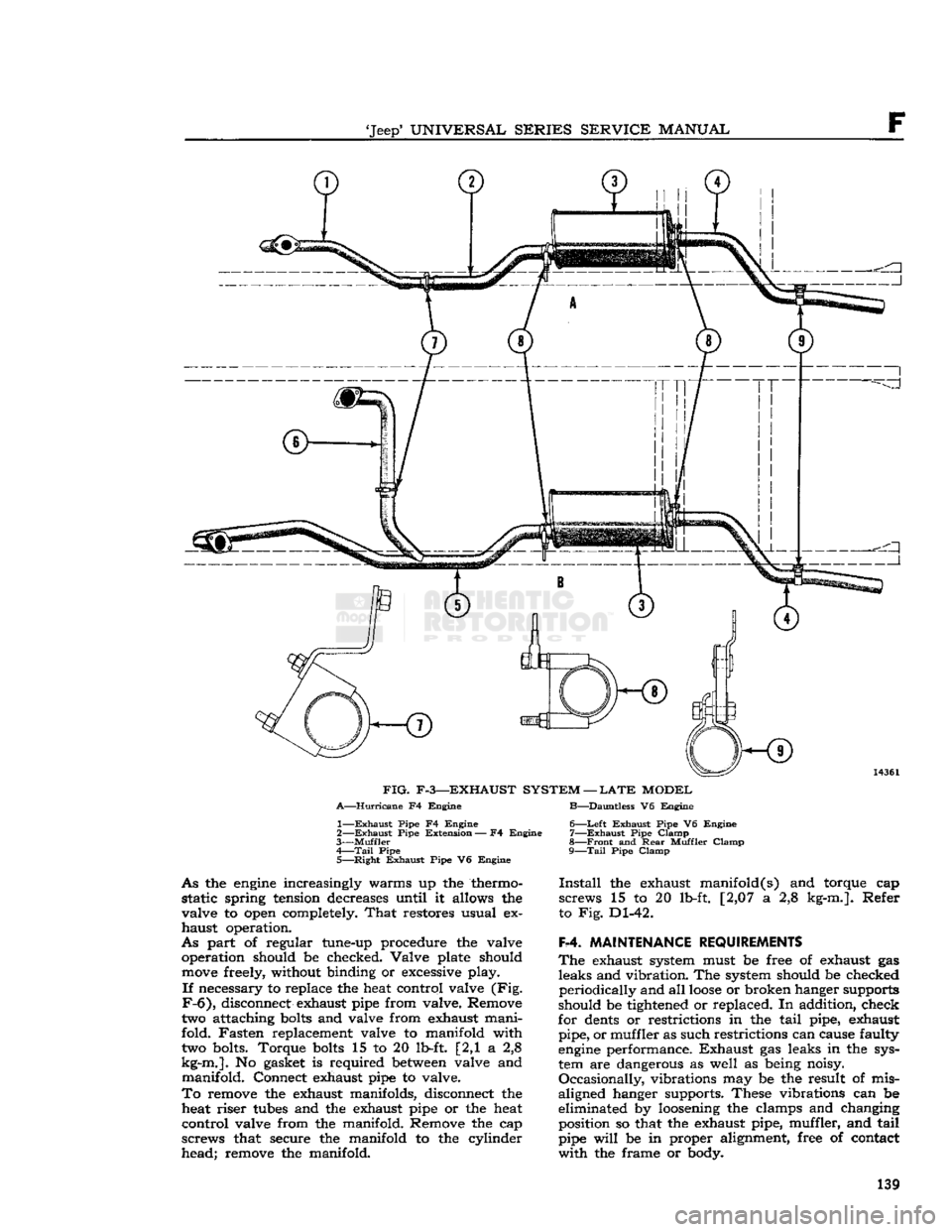

FIG.

F-3—EXHAUST SYSTEM —

LATE

MODEL

A—Hurricane

F4 Engine B—Dauntless V6 Engine

1—

Exhaust

Pipe F4 Engine

2—

Exhaust

Pipe

Extension

— F4 Engine

3—

Muffler

4—

Tail

Pipe

5—

Right

Exhaust

Pipe V6 Engine

As

the

engine

increasingly warms up the thermo static spring tension decreases until it allows the

valve to open completely.

That

restores usual ex haust operation.

As

part of regular tune-up procedure the valve operation should be checked. Valve plate should

move

freely, without binding or excessive play.

If

necessary to replace the heat control valve (Fig.

F-6),

disconnect exhaust pipe from valve. Remove

two attaching

bolts

and valve from exhaust mani

fold. Fasten replacement valve to manifold with two bolts. Torque

bolts

15 to 20 lb-ft [2,1 a 2,8

kg-m.].

No gasket is required

between

valve and manifold. Connect exhaust pipe to valve.

To

remove the exhaust manifolds, disconnect the heat riser

tubes

and the exhaust pipe or the heat

control valve from the manifold. Remove the cap screws that secure the manifold to the cylinder

head; remove the manifold. 6—

Left

Exhaust

Pipe V6 Engine

7—

Exhaust

Pipe

Clamp

8—

Front

and

Rear

Muffler

Clamp

9—

Tail

Pipe

Clamp

Install

the exhaust manifold(s) and torque cap

screws 15 to 20 lb-ft. [2,07 a 2,8 kg-m.]. Refer

to Fig. Dl-42.

F-4.

MAINTENANCE REQUIREMENTS

The

exhaust system must be free of exhaust gas leaks and vibration. The system should be checked periodically and all

loose

or broken hanger supports

should be tightened or replaced. In addition, check

for

dents

or restrictions in the tail pipe, exhaust pipe, or muffler as such restrictions can cause faulty

engine

performance. Exhaust gas leaks in the sys

tem are dangerous as well as being noisy.

Occasionally,

vibrations may be the result of mis

aligned hanger supports. These vibrations can be

eliminated by loosening the clamps and changing position so that the exhaust pipe, muffler, and tail

pipe

will

be in proper alignment, free of contact

with

the frame or body. 139