ECU JEEP CJ 1953 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 215 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

FIG.

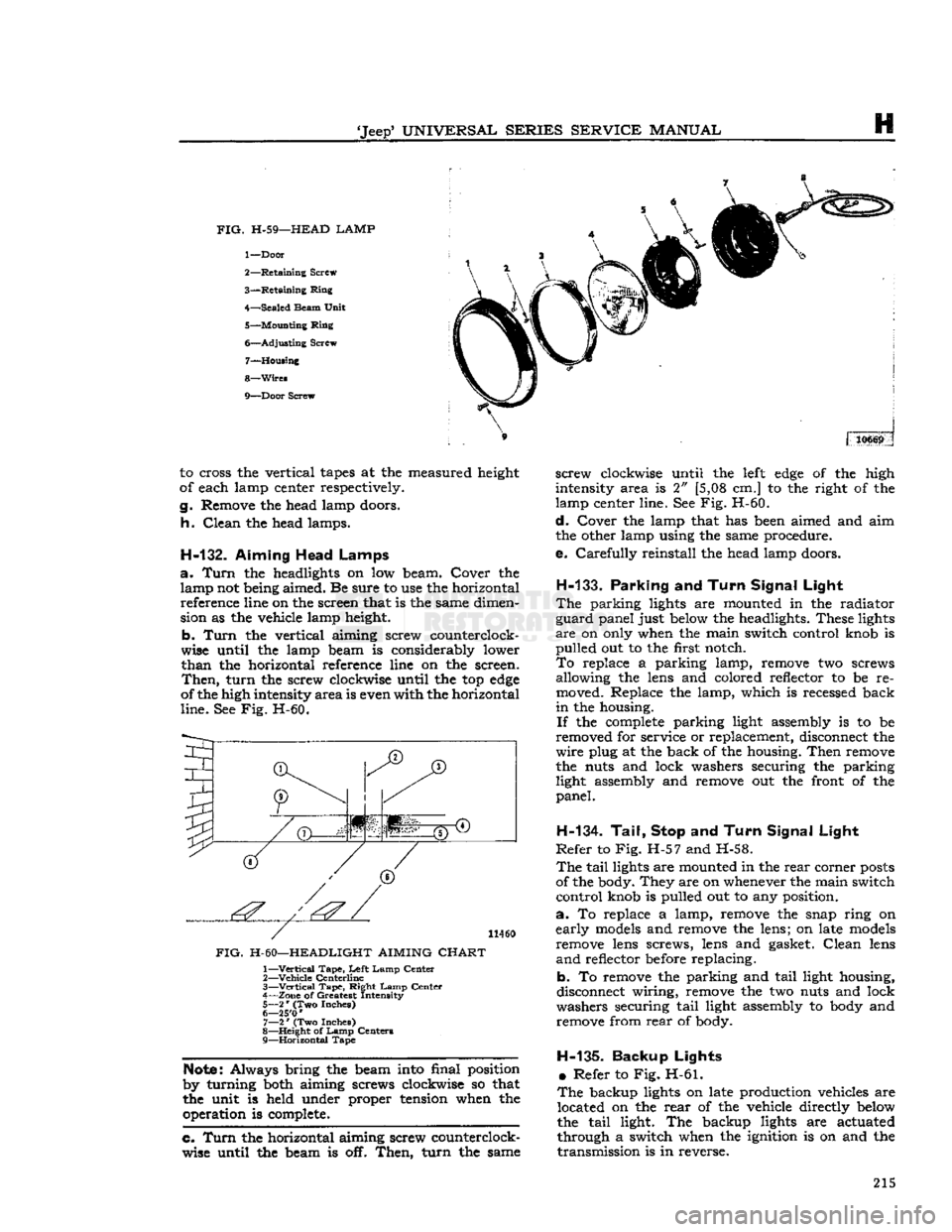

H-59—HEAD LAMP

1—

Door

2—

Retaining

Screw

3—

Retaining

Ring

4—

Sealed

Beam

Unit

5—

Mounting

Ring

6—

Adjusting

Screw 7—

Housing

8—

Wires

9—

Door

Screw 310669

to cross the vertical

tapes

at the measured height

of each lamp center respectively.

g.

Remove the head lamp doors.

h.

Clean

the head lamps.

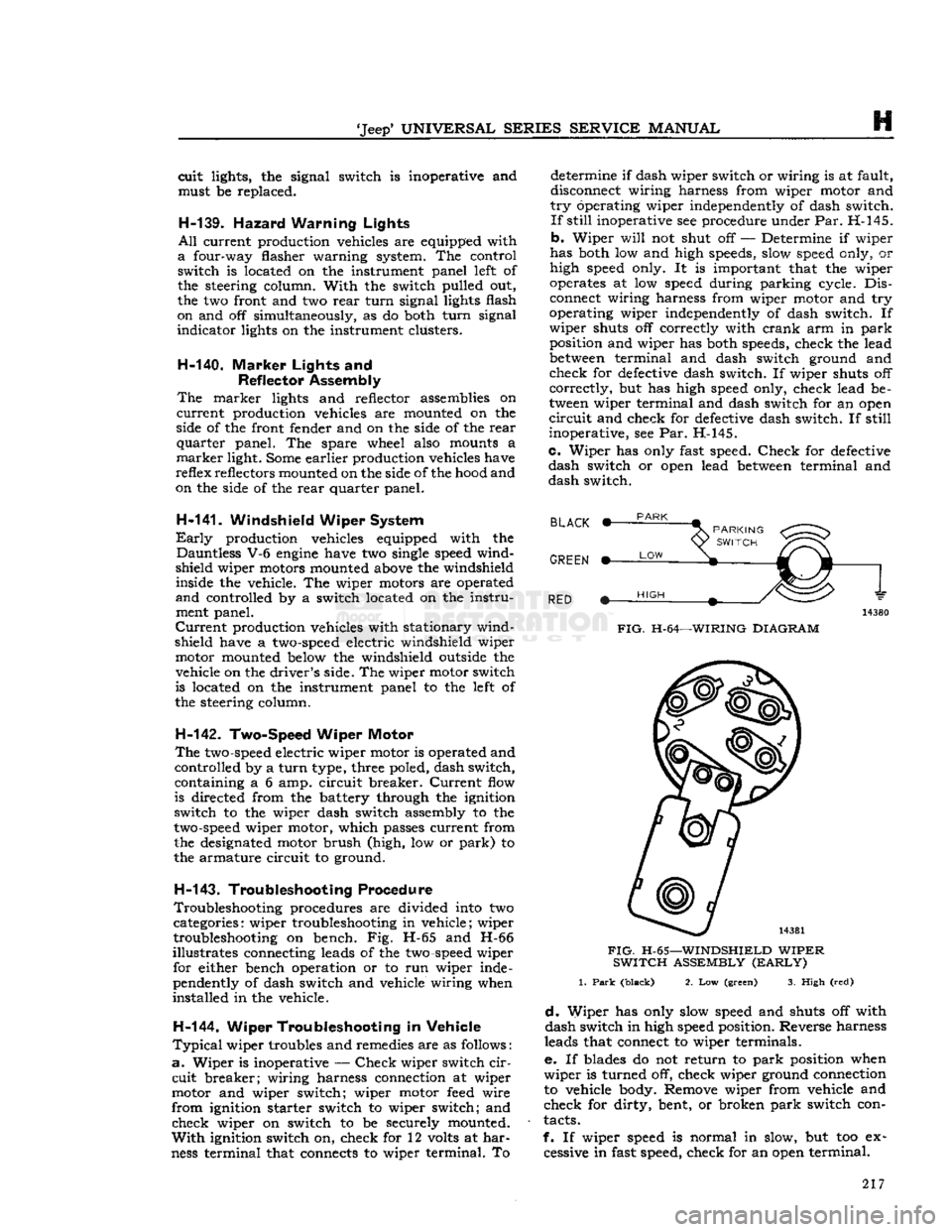

H-132.

Aiming Head Lamps

a.

Turn

the headlights on low beam. Cover the lamp not being aimed. Be sure to use the horizontal reference line on the screen that is the same dimen

sion as the vehicle lamp height.

b.

Turn

the vertical aiming screw counterclock

wise until the lamp beam is considerably lower

than

the horizontal reference line on the screen.

Then,

turn

the screw clockwise until the top

edge

of the high intensity

area

is even with the horizontal

line.

See Fig. H-60.

I

(T)

JT)

1'.'' | '':'

11460

FIG.

H-60—HEADLIGHT AIMING

CHART

1—

Vertical

Tape,

Left

Lamp

Center

2—

Vehicle

Centerline

3—

—Vertical

Tape,

Right

Lamp

Center

4—

Zone

of Greatest Intensity

5—

2

*

(Two Inches)

6— 25'0

'

7—

2

*

(Two Inches)

8—

Height

of

Lamp

Centers

9—

Horizontal

Tape

Note:

Always bring the beam into final position

by turning both aiming screws clockwise so that

the unit is held under proper tension when the operation is complete.

c. Turn

the horizontal aiming screw counterclock

wise until the beam is off.

Then,

turn

the same

screw

clockwise until the

left

edge

of the high

intensity area is 2" [5,08 cm.] to the right of the

lamp center line. See Fig. H-60.

d.

Cover the lamp that has been aimed and aim

the other lamp using the same procedure.

e.

Carefully

reinstall the head lamp doors.

H-133.

Parking

and

Turn Signal Light

The

parking lights are mounted in the radiator

guard

panel just below the headlights. These lights

are

on only when the main switch control knob is

pulled

out to the first notch.

To

replace a parking lamp, remove two screws allowing the lens and colored reflector to be re

moved. Replace the lamp, which is recessed back

in

the housing.

If

the

complete

parking light assembly is to be

removed for service or replacement, disconnect the

wire

plug at the back of the housing.

Then

remove

the nuts and lock washers securing the parking light assembly and remove out the front of the

panel.

H-134. Tail, Stop

and

Turn Signal Light

Refer

to Fig. H-57 and H-58.

The

tail

lights are mounted in the

rear

corner

posts

of the body. They are on whenever the main switch

control

knob is pulled out to any position.

a.

To replace a lamp, remove the snap ring on

early

models

and remove the lens; on late

models

remove lens screws, lens and gasket.

Clean

lens

and

reflector before replacing.

b. To remove the parking and

tail

light housing,

disconnect wiring, remove the two nuts and lock

washers securing

tail

light assembly to body and remove from

rear

of body.

H-135-

Backup Lights •

Refer to Fig. H-61.

The

backup lights on late production vehicles are located on the

rear

of the vehicle directly below

the

tail

light. The backup lights are actuated

through a switch when the ignition is on and the

transmission

is in reverse. 215

Page 217 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

cuit

lights,

the

signal switch

is

inoperative

and

must

be

replaced.

H-139.

Hazard

Warning Lights

All

current production vehicles

are

equipped with

a

four-way flasher warning system.

The

control switch

is

located

on the

instrument panel left

of

the steering column.

With

the

switch pulled

out,

the

two

front and

two

rear

turn

signal lights flash

on and

off

simultaneously,

as do

both

turn

signal

indicator

lights

on the

instrument clusters.

H-140.

Marker

Lights and Reflector Assembly

The

marker

lights

and

reflector assemblies

on

current

production vehicles

are

mounted

on the

side

of

the front fender and

on the

side

of

the

rear

quarter

panel.

The

spare wheel also mounts

a

marker

light. Some earlier production vehicles have

reflex reflectors mounted on the side of the hood and

on

the

side

of

the

rear

quarter panel. determine

if

dash wiper switch or wiring

is at

fault,

disconnect wiring harness from wiper motor

and

try

operating wiper independently

of

dash switch.

If

still

inoperative

see

procedure under

Par.

H-145.

b. Wiper

will

not

shut

off

— Determine

if

wiper

has both

low

and high speeds, slow speed only,

or

high speed only.

It is

important that

the

wiper

operates

at low

speed during parking cycle.

Dis

connect wiring harness from wiper motor

and try

operating wiper independently

of

dash switch.

If

wiper

shuts

off

correctly with

crank

arm

in

park

position and wiper has both speeds, check

the

lead

between

terminal

and

dash switch ground

and

check

for

defective dash switch.

If

wiper shuts

off

correctly,

but has

high speed only, check lead

be

tween wiper terminal and dash switch

for an

open

circuit

and check

for

defective dash switch.

If

still

inoperative,

see

Par. H-145.

c. Wiper

has

only fast speed.

Check

for

defective dash switch

or

open lead

between

terminal

and

dash switch.

H-141.

Windshield Wiper System

Early

production vehicles equipped with

the

Dauntless V-6

engine

have

two

single speed wind

shield wiper motors mounted above

the

windshield inside

the

vehicle. The wiper motors

are

operated

and

controlled

by a

switch located

on the

instru

ment panel.

Current

production vehicles with stationary wind

shield have

a

two-speed

electric windshield wiper motor mounted below

the

windshield outside

the

vehicle on the driver's side. The wiper motor switch is located

on the

instrument panel

to the

left

of

the steering column.

H-142.

Two-Speed Wiper Motor

The

two-speed

electric wiper motor

is

operated and

controlled

by a

turn

type, three poled, dash switch,

containing

a 6

amp. circuit breaker.

Current

flow

is directed from

the

battery through

the

ignition

switch

to the

wiper dash switch assembly

to the

two-speed

wiper motor, which passes current from the designated motor brush (high,

low or

park)

to

the armature circuit

to

ground.

H-143.

Troubleshooting Procedure

Troubleshooting procedures

are

divided into

two

categories: wiper troubleshooting

in

vehicle; wiper

troubleshooting

on

bench.

Fig. H-65 and H-66

illustrates connecting leads

of the

two-speed

wiper for either bench operation

or to run

wiper inde

pendently

of

dash switch and vehicle wiring when

installed

in the

vehicle.

H-144. Wiper Troubleshooting

in

Vehicle

Typical

wiper troubles and remedies are

as

follows

:

a.

Wiper

is

inoperative

—

Check

wiper switch

cir

cuit

breaker; wiring harness connection

at

wiper

motor

and

wiper switch; wiper motor

feed

wire

from

ignition starter switch

to

wiper switch;

and

check wiper

on

switch

to be

securely mounted.

With

ignition switch

on,

check

for 12

volts

at

har

ness

terminal that connects

to

wiper terminal.

To

BLACK

PARK

GREEN *-

RED m~

LOW

PARKING

<^^>

SWITCH

V^-O*'

HIGH

FIG.

H-64—WIRING

DIAGRAM

FIG.

H-65—WINDSHIELD

WIPER

SWITCH

ASSEMBLY

(EARLY)

1.

Park

(black)

2. Low (green)

3.

High (red)

d.

Wiper

has

only slow speed

and

shuts

off

with

dash switch in high speed position. Reverse harness

leads that connect

to

wiper terminals.

e. If

blades

do not

return

to

park

position when

wiper

is

turned

off,

check wiper ground connection

to vehicle body. Remove wiper from vehicle

and

check

for

dirty, bent,

or

broken

park

switch con

tacts.

f.

If

wiper speed

is

normal

in

slow,

but too ex

cessive

in

fast speed, check for an open terminal. 217

Page 219 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

a

0"—®

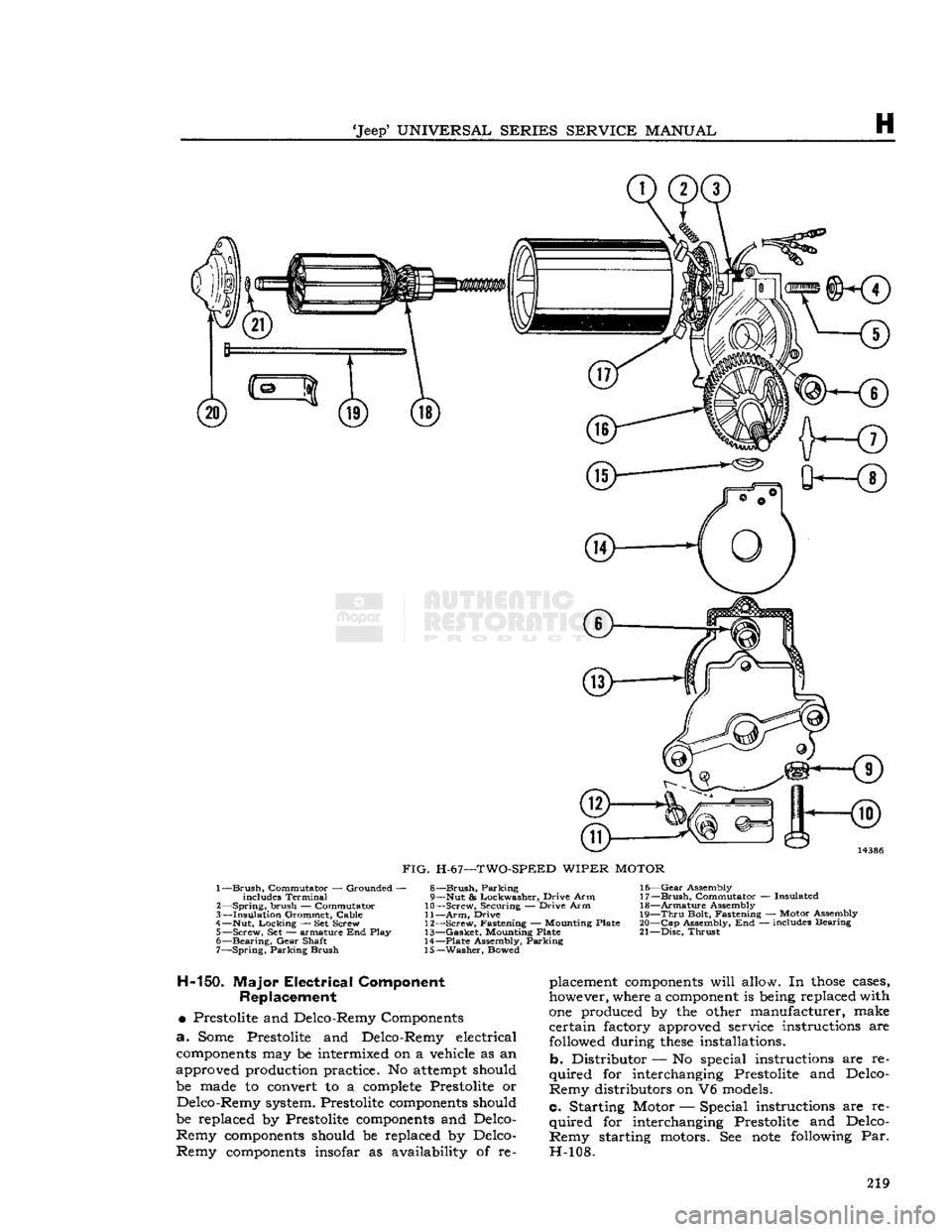

FIG.

H-67—-TWO-SPEED

WIPER

MOTOR

1—

Brush,

Commutator — Grounded - includes Terminal

2—

Spring,

brush — Commutator

3—

Insulation

Grommet, Cable

4—

Nut,

Locking

— Set Screw

5— Screw, Set — armature End Play

6—

Bearing,

Gear

Shaft

7—

Spring,

Parking Brush 8—

Brush,

Parking

9—

Nut

& Lockwasher,

Drive

Arm

10—

Screw, Securing —

Drive

Arm

11—

Arm,

Drive

12—

Screw, Fastening — Mounting

Plate

13—

Gasket,

Mounting

Plate

14—

Plate

Assembly, Parking

15—

Washer, Bowed

16—

Gear

Assembly

17—

Brush,

Commutator — Insulated

18—

Armature

Assembly

19—

Thru

Bolt,

Fastening — Motor Assembly

20—

Cap Assembly, End — includes Bearing

21—

Disc,

Thrust H-150. Major

Electrical

Component

Replacement

•

Prestolite and Delco-Remy Components

a.

Some

Prestolite and Delco-Remy electrical

components may be intermixed on a vehicle as an

approved production practice. No attempt should

be

made

to convert to a complete Prestolite or Delco-Remy system. Prestolite components should

be replaced by Prestolite components and Delco- Remy components should be replaced by Delco-

Remy components insofar as

availability

of re placement components

will

allow.

In

those

cases,

however, where a component is being replaced

with

one produced by the other manufacturer, make

certain factory approved service instructions are

followed

during

these

installations.

b. Distributor — No special instructions are re

quired

for interchanging Prestolite and Delco-

Remy distributors on V6 models.

c. Starting Motor — Special instructions are re

quired

for interchanging Prestolite and Delco-

Remy starting motors. See note

following

Par.

H-108. 219

Page 230 of 376

CLUTCH

is deeply scored or grooved, the part should be

replaced.

b. Inspect driven plate for wear or damage to fac

ings,

loose

rivets, broken or

loose

torsion springs,

and

flattened cushion springs. If facings are worn

near

rivets or are oily, replace the plate assembly.

A

slight amount of oil on clutch facings

will

cause

clutch

grab and chatter; excessive oil on facings

will

cause slippage. It is not practical to remove

oil

with solvents or by buffing since oil

will

con

tinue to bleed from facing material when hot. If

oil

is found on driven plate facings, examine trans

mission drainback hole, pilot bushing,

engine

rear

main

bearing and other points of possible oil leakage. Test the fit of driven plate hub on trans

mission main drive gear for an easy sliding fit.

c. Inspect clutch release bearing for scoring or ex cessive wear on front contact face. Test for rough

ness

of balls and races by pressing and turning

front race slowly. Inspect main drive gear pilot

bushing in crankshaft. Replace bushing if it is rough or worn. Regardless of whether the old plate

or

a new plate is to be installed, check the plate

for runout. Slide the driven plate, front side first,

over the transmission main drive gear shaft so that

it

is tight on the spline. Index a

dial

indicator to the plate facing as shown in

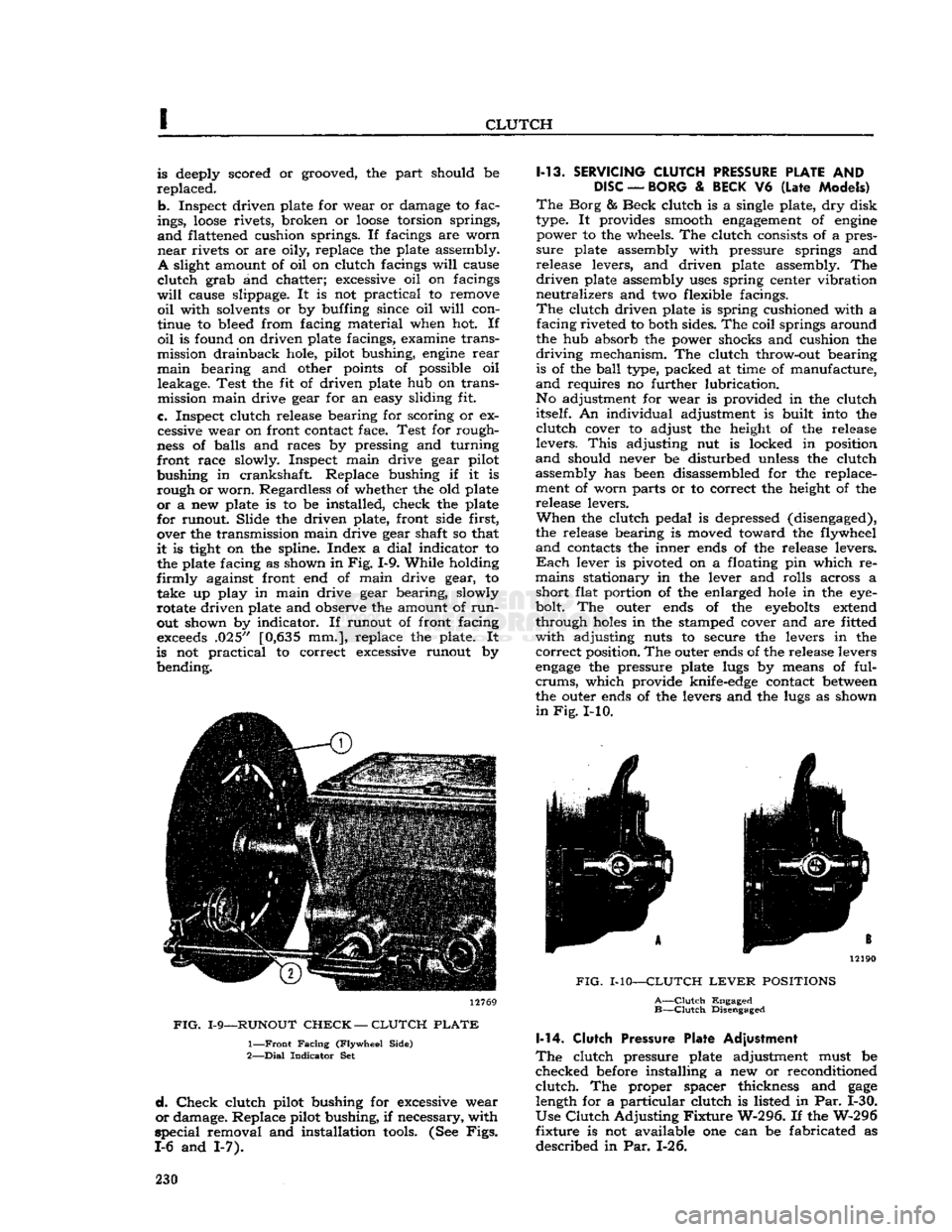

Fig.

1-9. While holding

firmly

against front end of main drive gear, to take up play in main drive gear bearing, slowly

rotate driven plate and observe the amount of

run

out shown by indicator. If runout of front facing

exceeds

.025" [0,635 mm.], replace the plate. It

is not practical to correct excessive runout by bending. 12769

FIG.

1-9—RUNOUT

CHECK

—

CLUTCH

PLATE

1—

Front

Facing

(Flywheel

Side)

2—

Dial

Indicator

Set

d.

Check

clutch pilot bushing for excessive wear

or

damage. Replace pilot bushing, if necessary, with

special

removal and installation

tools.

(See

Figs.

1-6 and 1-7). 1-13.

SERVICING

CLUTCH

PRESSURE

PLATE

AND

DISC

—

BORG

&

BECK

V6

(Late

Models)

The

Borg & Beck clutch is a single plate, dry disk

type. It provides smooth

engagement

of

engine

power to the wheels. The clutch consists of a pres

sure

plate assembly with pressure springs and

release levers, and driven plate assembly. The

driven

plate assembly

uses

spring center vibration

neutralizes and two flexible facings.

The

clutch driven plate is spring cushioned with a facing riveted to both sides. The coil springs around

the hub absorb the power shocks and cushion the

driving

mechanism. The clutch throw-out bearing is of the

ball

type, packed at time of manufacture,

and

requires no further lubrication.

No adjustment for wear is provided in the clutch itself. An individual adjustment is built into the

clutch

cover to adjust the height of the release

levers.

This

adjusting nut is locked in position

and

should never be disturbed unless the clutch assembly has been disassembled for the replace

ment of worn parts or to correct the height of the release levers.

When

the clutch pedal is depressed (disengaged),

the release bearing is moved toward the flywheel

and

contacts the inner ends of the release levers.

Each

lever is pivoted on a floating pin which re

mains stationary in the lever and rolls across a short flat portion of the enlarged

hole

in the eye-

bolt. The outer ends of the

eyebolts

extend

through

holes

in the stamped cover and are fitted

with

adjusting nuts to secure the levers in the

correct

position. The outer ends of the release levers

engage

the pressure plate lugs by means of ful-

crums,

which provide knife-edge contact

between

the outer ends of the levers and the lugs as shown

in

Fig.

I-10. 12190

FIG.

MO—CLUTCH

LEVER

POSITIONS

A—Clutch

Engaged

B—Clutch

Disengaged 1-14.

Clutch

Pressure Plate Adjustment

The

clutch pressure plate adjustment must be

checked before installing a new or reconditioned

clutch.

The proper spacer thickness and

gage

length for a particular clutch is listed in Par. 1-30.

Use

Clutch

Adjusting

Fixture

W-296. If the W-296

fixture is not available one can be fabricated as

described in Par. 1-26. 230

Page 242 of 376

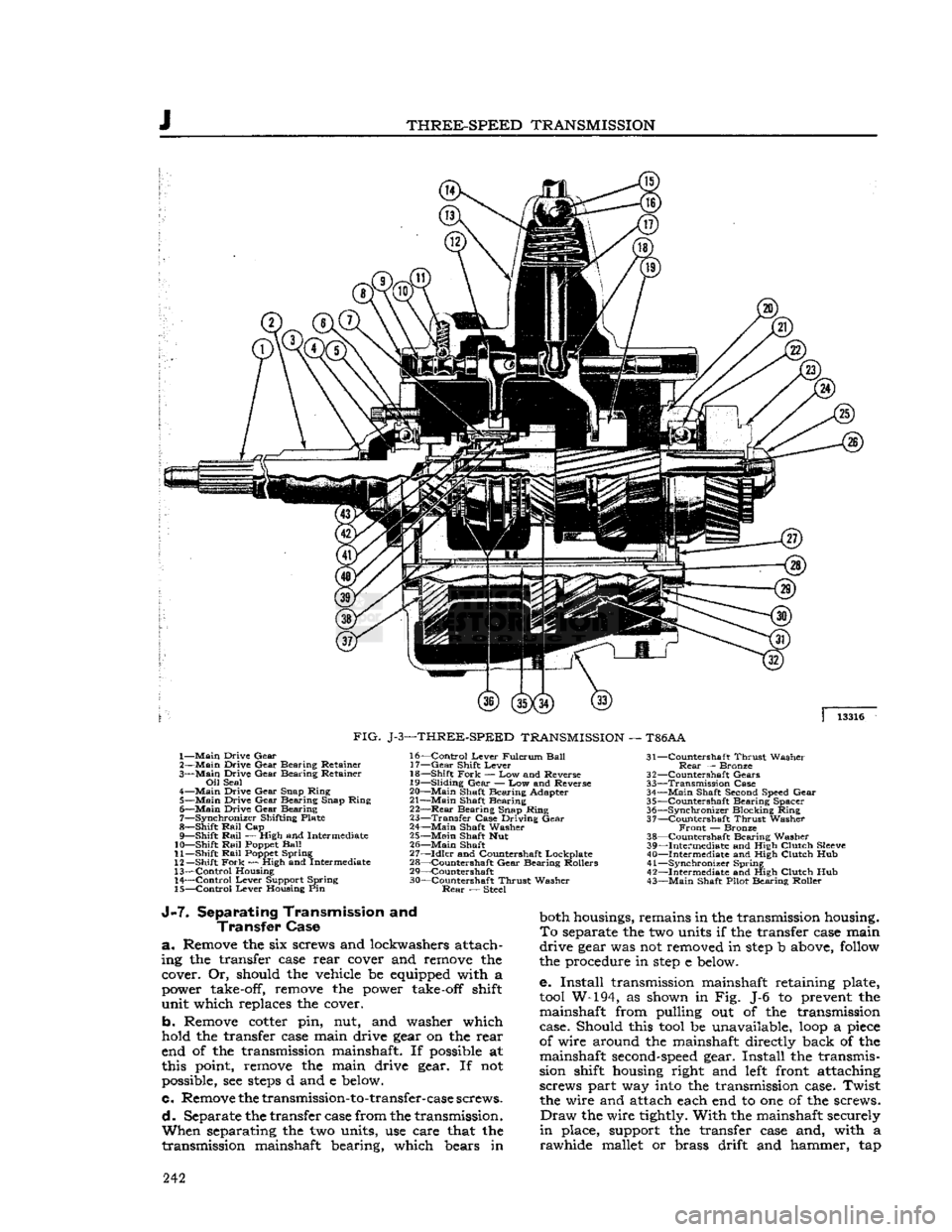

THREE-SPEED

TRANSMISSION

FIG.

J-3—THREE-SPEED

TRANSMISSION

—

T86AA

1—

Main

Drive

Gear

2—

Main

Drive

Gear

Bearing Retainer

3—

Main

Drive

Gear

Bearing Retainer

Oil

Seal

4—

Main

Drive

Gear

Snap Ring

5—

Main

Drive

Gear

Bearing Snap Ring

6—

Main

Drive

Gear

Bearing 7— Synchronizer Shifting Plate

8— Shift

Rail

Cap

9— Shift

Rail

— High and Intermediate

10— Shift

Rail

Poppet

Ball

11— Shift

Rail

Poppet

Spring

12— Shift

Fork

— High and Intermediate

13—

Control

Housing 14—

Control

Lever Support Spring

15—

Control

Lever Housing Pin 16—

Control

Lever

Fulcrum

Ball

17—

Gear

Shift Lever

18— Shift

Fork

— Low and Reverse

19— Sliding

Gear

— Low and Reverse

20—

Main

Shaft Bearing Adapter 21—

Main

Shaft Bearing

22—

Rear

Bearing Snap Ring

23—

Transfer

Case Driving

Gear

24—

Main

Shaft Washer

25—Main Shaft Nut

26—

Main

Shaft

27—

Idler

and Countershaft Lockplate

28— Countershaft

Gear

Bearing Rollers

29— Countershaft

30— Countershaft Thrust Washer

Rear

— Steel 31— Countershaft Thrust Washer

Rear

— Bronze

32— Countershaft Gears

33—

Transmission

Case

34—

Main

Shaft Second Speed

Gear

35— Countershaft Bearing Spacer

36— Synchronizer Blocking Ring 37— Countershaft Thrust Washer

Front

— Bronze

38— Countershaft Bearing Washer

39— Intermediate and High Clutch

Sleeve

40— Intermediate and High Clutch Hub

41

—Synchronizer Spring

42— Intermediate and High Clutch Hub

43—

Main

Shaft Pilot Bearing Roller J-7.

Separating Transmission

and

Transfer Case

a.

Remove the six screws and lockwashers attach

ing the transfer case rear cover and remove the cover. Or, should the vehicle be equipped with a

power

take-off,

remove the power take-off shift

unit which replaces the cover.

b. Remove

cotter

pin, nut, and washer which

hold the transfer case main drive gear on the rear

end of the transmission mainshaft. If

possible

at

this point, remove the main drive gear. If not possible, see

steps

d and e

below.

c. Remove the transmission-to-transfer-case screws.

d.

Separate the transfer case from the transmission.

When separating the two units, use care that the

transmission mainshaft bearing, which bears in

both

housings, remains in the transmission housing.

To

separate the two units if the transfer case main

drive gear was not removed in

step

b

above,

follow

the procedure in

step

e

below.

e.

Install transmission mainshaft retaining plate,

tool

W-194, as shown in Fig. J-6 to prevent the mainshaft from pulling out of the transmission

case. Should this

tool

be unavailable,

loop

a

piece

of wire around the mainshaft directly back of the mainshaft

second-speed

gear. Install the transmis

sion shift housing right and

left

front attaching

screws part way

into

the transmission case. Twist

the wire and attach each end to one of the screws.

Draw

the wire tightly. With the mainshaft securely

in

place, support the transfer case and, with a rawhide mallet or brass drift and hammer, tap 242

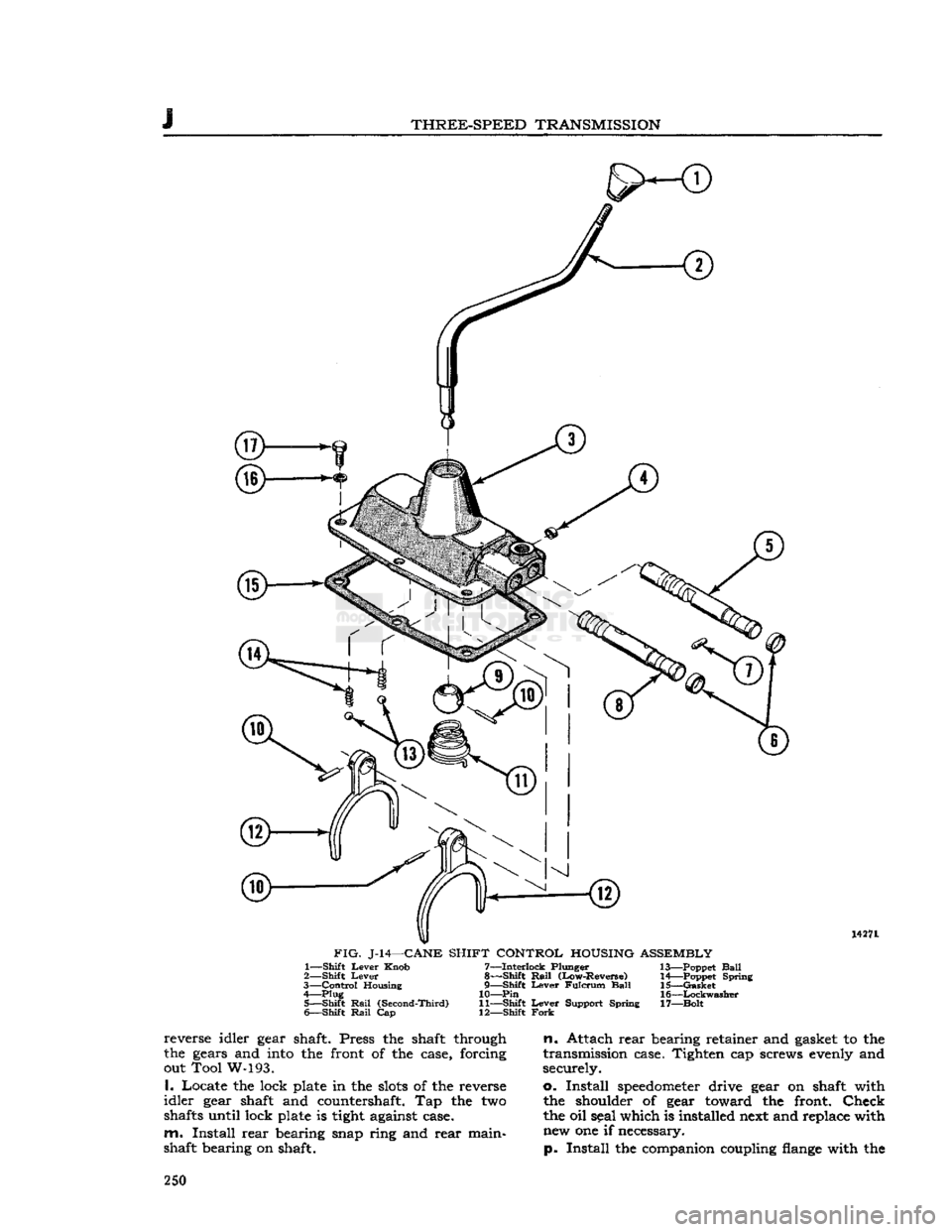

Page 250 of 376

THREE-SPEED

TRANSMISSION

14271

FIG.

J-14—-CANE

SHIFT

CONTROL

HOUSING

ASSEMBLY

1—

Shift

Lever

Knob

2—

Shift

Lever

3—

Control

Housing

4—

Plug

5—

Shift

Rail

(Second-Third) 6—

Shift

Rail

Cap 7—

Interlock

Plunger

8—

Shift

Rail

(Low-Reverse)

9—

Shift

Lever

Fulcrum

Ball

10—

-Pin

11—

Shift

Lever

Support Spring

12—

Shift

Fork

13— Poppet

Ball

14— Poppet Spring

15—

Gasket

16—

Lockwasher

17—Bolt reverse idler gear shaft. Press the shaft through

the gears and

into

the front of the case, forcing out Tool W-193.

I.

Locate the lock plate in the

slots

of the reverse

idler

gear shaft and countershaft. Tap the two

shafts until lock plate is

tight

against case, m. Install rear bearing snap ring and rear main-

shaft bearing on shaft.

n.

Attach rear bearing retainer and gasket to the

transmission case. Tighten cap screws evenly and

securely.

Install

speedometer

drive gear on shaft with

o.

the shoulder of gear toward the front. Check

the oil seal which is installed next and replace with

new one if necessary.

p.

Install the companion coupling

flange

with the 250

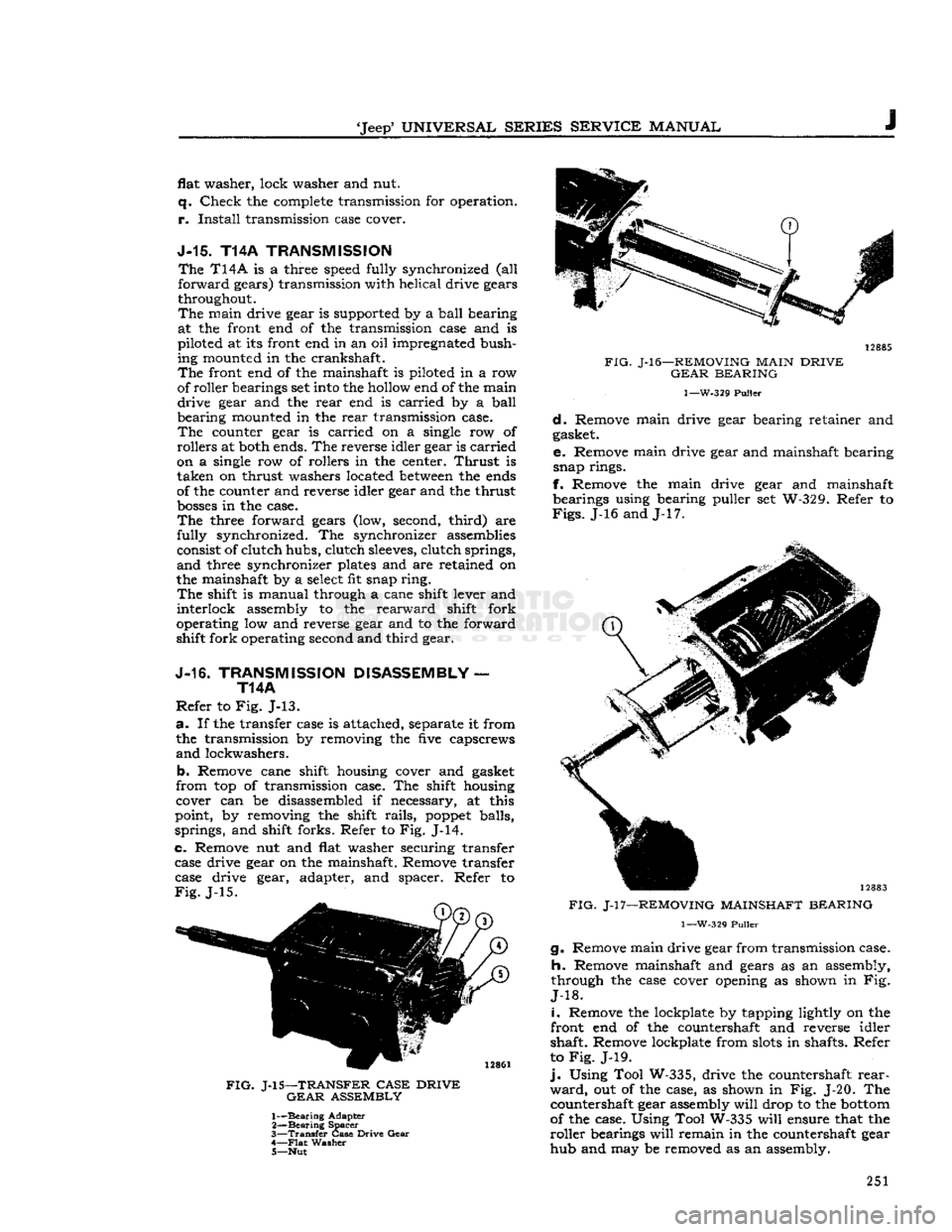

Page 251 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

J

flat washer, lock washer and nut.

q.

Check

the

complete

transmission for operation.

r.

Install

transmission case cover.

J-15.

T14A

TRANSMISSION

The

T14A is a three

speed

fully synchronized (all

forward

gears) transmission with helical drive gears

throughout.

The

main drive gear is supported by a

ball

bearing at the front end of the transmission case and is

piloted at its front end in an oil impregnated bush

ing mounted in the crankshaft.

The

front end of the mainshaft is piloted in a row

of

roller

bearings set

into

the hollow end of the main

drive

gear and the

rear

end is

carried

by a

ball

bearing

mounted in the

rear

transmission case.

The

counter gear is

carried

on a single row of

rollers

at both ends. The reverse idler gear is

carried

on a single row of rollers in the center.

Thrust

is

taken

on thrust washers located

between

the

ends

of the counter and reverse idler gear and the thrust

bosses

in the case.

The

three forward gears (low, second, third) are

fully

synchronized. The synchronizer assemblies

consist of

clutch

hubs, clutch

sleeves,

clutch springs,

and

three synchronizer plates and are retained on

the mainshaft by a

select

fit snap

ring.

The

shift is manual through a cane shift lever and

interlock

assembly to the

rearward

shift fork

operating low and reverse gear and to the forward

shift fork operating second and

third

gear.

J-16.

TRANSMISSION

DISASSEMBLY

—

T14A

Refer

to Fig. J-13.

a.

If the transfer case is attached, separate it from

the transmission by removing the five capscrews

and

lockwashers.

b.

Remove cane shift housing cover and gasket

from

top of transmission case. The shift housing

cover can be disassembled if necessary, at this

point, by removing the shift

rails,

poppet

balls,

springs,

and shift forks. Refer to Fig. J-14.

c.

Remove nut and flat washer securing transfer case drive gear on the mainshaft. Remove transfer case drive gear, adapter, and spacer. Refer to

Fig.

J-15.

FIG.

J-15—TRANSFER

CASE

DRIVE

GEAR

ASSEMBLY

1—

Bearing

Adapter

2—

Bearing

Spacer

3—

Transfer

Case

Drive

Gear

4—

Flat

Washer 5— Nut

12885

FIG.

J-16—REMOVING

MAIN

DRIVE

GEAR

BEARING

1—W-329 Puller

d.

Remove main drive gear bearing retainer and

gasket. e. Remove main drive gear and mainshaft bearing snap rings.

f. Remove the main drive gear and mainshaft

bearings using bearing puller set W-329. Refer to

Figs.

J-16 and J-l7.

FIG.

J-17—REMOVING

MAINSHAFT

BEARING

1—W-329

Puller g. Remove main drive gear from transmission case.

h.

Remove mainshaft and gears as an assembly,

through the case cover opening as shown in Fig.

J-18.

i.

Remove the lockplate by tapping lightly on the

front end of the countershaft and reverse idler

shaft. Remove lockplate from

slots

in shafts. Refer

to

Fig.

J-19.

j.

Using Tool W-335, drive the countershaft

rear

ward,

out of the case, as shown in Fig. J-20. The countershaft gear assembly

will

drop to the

bottom

of the case. Using Tool W-335

will

ensure that the

roller

bearings

will

remain in the countershaft gear

hub and may be removed as an assembly. 251

Page 263 of 376

![JEEP CJ 1953 Repair Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut JEEP CJ 1953 Repair Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut](/img/16/57040/w960_57040-262.png)

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut to

9.850*

{25,02

cm.] long.

Break

sharp

edges

with a

mill

file.) Keep the dummy shaft in contact with

the countershaft at all times to prevent dropping

the bearing rollers or thrust washers,

z.

With

the dummy shaft in position, place the

transmission

case on its side and carefully

roll

the countershaft gear cluster out of the case,

aa.

Complete the disassembly by removing the dummy shaft, thrust washers, four

sets

of bearing

rollers,

and spacers.

bb.

To disassemble the reverse idler gear assembly,

remove one of the snap rings and tap out the

washers,

both

sets

of bearing rollers, center spacer,

and

sleeve.

Remove the remaining snap

ring.

J1-4.

4-Speed

Transmission

Control

Housing

Disassembly

•

Refer to Fig. Jl-5.

The

gearshift lever, spring, and spring seat were previously removed for removal of the transmission

from

the vehicle.

a.

Remove the lock pins from the gearshift forks

and

gearshift rod ends. Remove the expansion plugs

from

the front and

rear

of the gearshift lever base. Remove back-up light switch.

b.

Remove the center (third and high) gearshift

rod

first. Drive this gearshift rod out the

rear

of the gearshift lever base. As the gearshift rod is

withdrawn

from the center section of the gearshift base, remove the interlock pin from the cross

over

hole

in the gearshift rod. Before the gearshift

rod

is removed from the center section of the gear

shift base, place a finger over the

hole

to prevent

loss

of the

ball

and spring.

Then

remove the rod.

c»

Remove the low- and second-speed gearshift rod

in

the same manner.

d.

Remove the gearshift rod lock balls and springs

and.

with a piece of

wire,

push the two gearshift rod

interlock

plungers out of the pockets in the center

section of the gearshift base.

In

the reverse gearshift rod end is a spring-loaded

plunger which prevents the

driver

from accidentally

shifting into reverse gear. Should this part require

servicing,

proceed as follows:

Remove the cotter key from the rod end assembly

and

at the same time hold a finger over the

hole

to prevent

loss

of the spring.

Then

shake out the

spring

and

ball.

Compress the plunger and spring

until

the C-washer

groove

just clears the end of

the casting. Remove the C-washer.

J1-5.

4-speed

Transmission Reassembly •

Refer to Fig. Jl-1.

Assemble the unit in the reverse order of dis

assembly noting the following points:

a.

Assemble the countershaft assembly with the

fabricated

dummy shaft. The bronze front thrust

washer

and the steel backed bronze

rear

thrust

washer

should be coated with stiff lubricant and

installed

with the lugs

engaged

in the notches

in

the end of the gear cluster. Place the assembly

in

the transmission case and install the counter

shaft from the

rear,

keeping the countershaft and

dummy shaft in contact to prevent dropping

bearing

rollers or washers. Tap the countershaft

lightly into position in the front of the case but

do not seat it until the reverse idler gear assembly

and

shaft have been installed in the case.

b.

Install

the reverse idler gear shaft in the case

until

the lock plate slot is adjacent to the slot in

the countershaft. Insert the lock plate in the

slots

of the shafts making sure the plate ends are square

with

the slots.

Install

the lock plate screw and

lockwasher

to act as a pilot while tapping the

shafts alternately into position in the case. Tighten

the lock plate screw securely.

c.

Begin assembly of the second speed synchronizer assembly (see

Fig.

Jl-6) by installing the low-and

-

second-speed clutch hub in the low-and-second-

speed gear.

Install

the retaining ring in the speed gear.

Install

the retaining ring in the low and

FIG.

Jl

-6—ASSEMBLING

SECOND-SPEED

SYNCHRONIZER

1—

Low

and Second

Clutch

Gear

2—

Ball

3—

Low

and Second

Clutch

Hub

4—

Shifting

Plate

second speed gear. Slide the hub out of the gear

in

the direction

opposite

the shift fork

groove

until

the

holes

in the hub are clear of the gear.

Install

the shifter plates and springs. Push the

hub back into the gear until the springs touch the

internal

teeth

of the gear. Push one of the shifter

plates toward the center of the gear while installing

ball.

See

Fig.

Jl-6 .

This

will

hold the

ball

in position.

Install

the other two balls in the same manner.

Be

careful when rotating the assembly to prevent the hub from slipping out of the gear. When the

balls

are installed, push the hub into the gear

until

the balls snap into the neutral position.

d.

Assemble the

direct

-

and

-

third

synchronizer as

sembly in accordance with the instructions given

in

Section J, Par.

J-lle.

e.

Start

assembly of the mainshaft assembly by 263

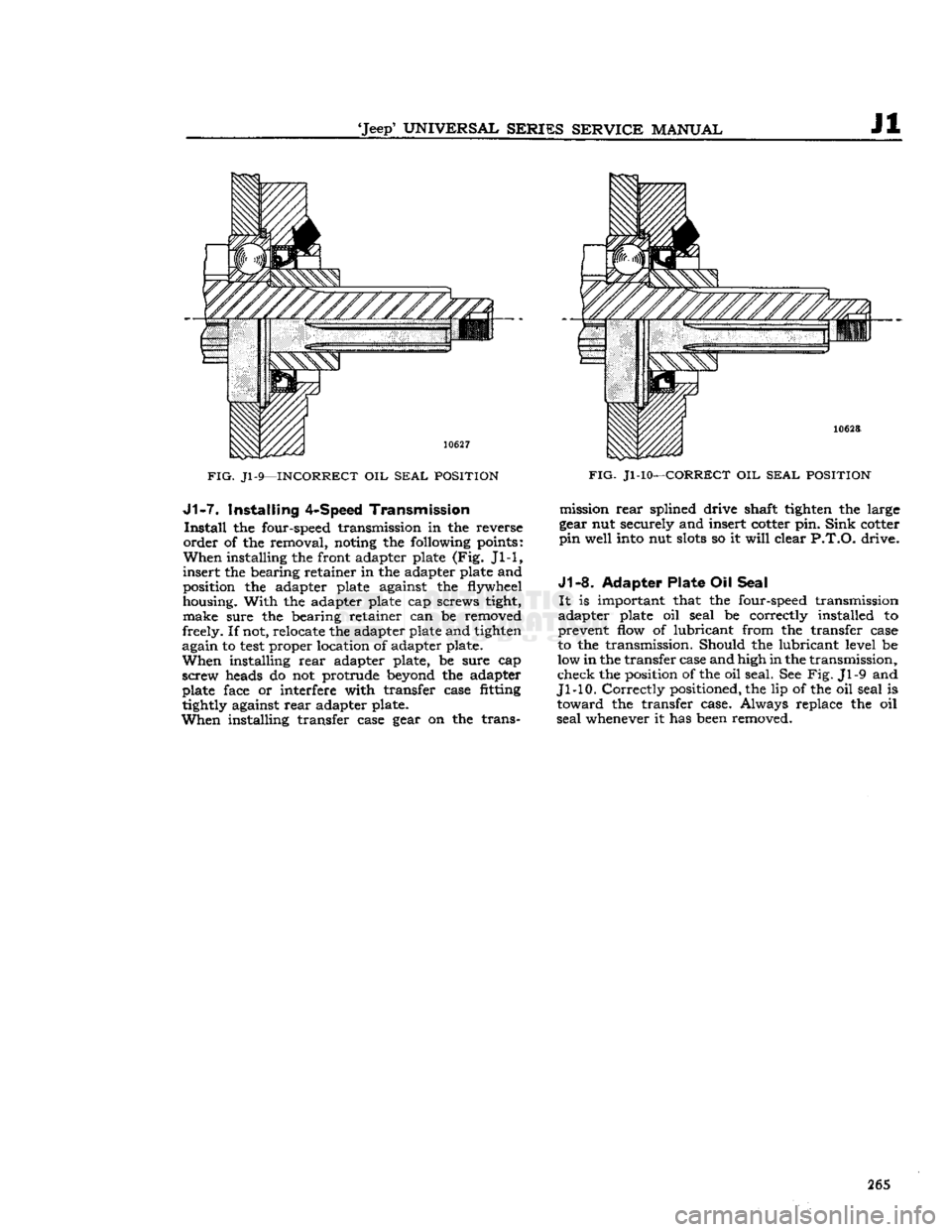

Page 265 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Jl

FIG.

Jl-9—INCORRECT

OIL

SEAL POSITION J1-7.

Installing

4-Speed

Transmission

Install

the four-speed transmission in the reverse

order

of the removal, noting the following points:

When

installing the front adapter plate (Fig. Jl-1,

insert

the bearing retainer in the adapter plate and

position the adapter plate against the flywheel

housing.

With

the adapter plate cap screws tight, make sure the bearing retainer can be removed

freely. If not, relocate the adapter plate and tighten

again to

test

proper location of adapter plate.

When

installing

rear

adapter plate, be sure cap

screw heads do not protrude beyond the adapter

plate face or interfere with transfer case fitting

tightly against

rear

adapter plate.

When

installing transfer case gear on the trans-

FIG.

Jl-10—CORRECT

OIL

SEAL POSITION

mission

rear

splined drive shaft tighten the large

gear nut securely and insert cotter pin.

Sink

cotter

pin

well into nut

slots

so it

will

clear

P.T.O.

drive.

J1-8.

Adapter Plate

Oil

Seal

It

is important that the four-speed transmission

adapter plate oil seal be correctly installed to

prevent flow of lubricant from the transfer case

to the transmission. Should the lubricant level be

low in the transfer case and high in the transmission,

check the position of the oil seal. See Fig. Jl-9 and

Jl-10.

Correctly

positioned, the lip of the oil seal is

toward

the transfer case. Always replace the oil

seal

whenever it has been removed. 265

Page 279 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

m f. Disconnect propeller shaft from the differential

companion flange.

g.

Disconnect both front springs from front spring hangers.

h.

Remove spring clip and spring clip plates secur

ing axle to front springs.

i.

Remove front

wheels

from axle assembly.

j.

Lower

jack

slightly and

pull

axle forward from

under

vehicle.

M-5.

FRONT AXLE SHAFT REMOVAL

Refer

to Fig. M-2.

The

following procedure applies to either right or

left

front axle shaft.

Note:

Axle shafts can be removed without remov

ing the axle housing from the vehicle. Use the fol

lowing procedure.

First

raise and support front end

of vehicle, and remove front wheels.

a.

Remove drive

flange

snap

ring.

b-

Remove the hub cap with a puller as shown in

Fig.

M-3.

c.

Remove the axle shaft driving

flange

bolts.

d.

Apply the

foot

brakes and remove the axle shaft

flange

with puller W-163 as illustrated in

Fig.

M-4.

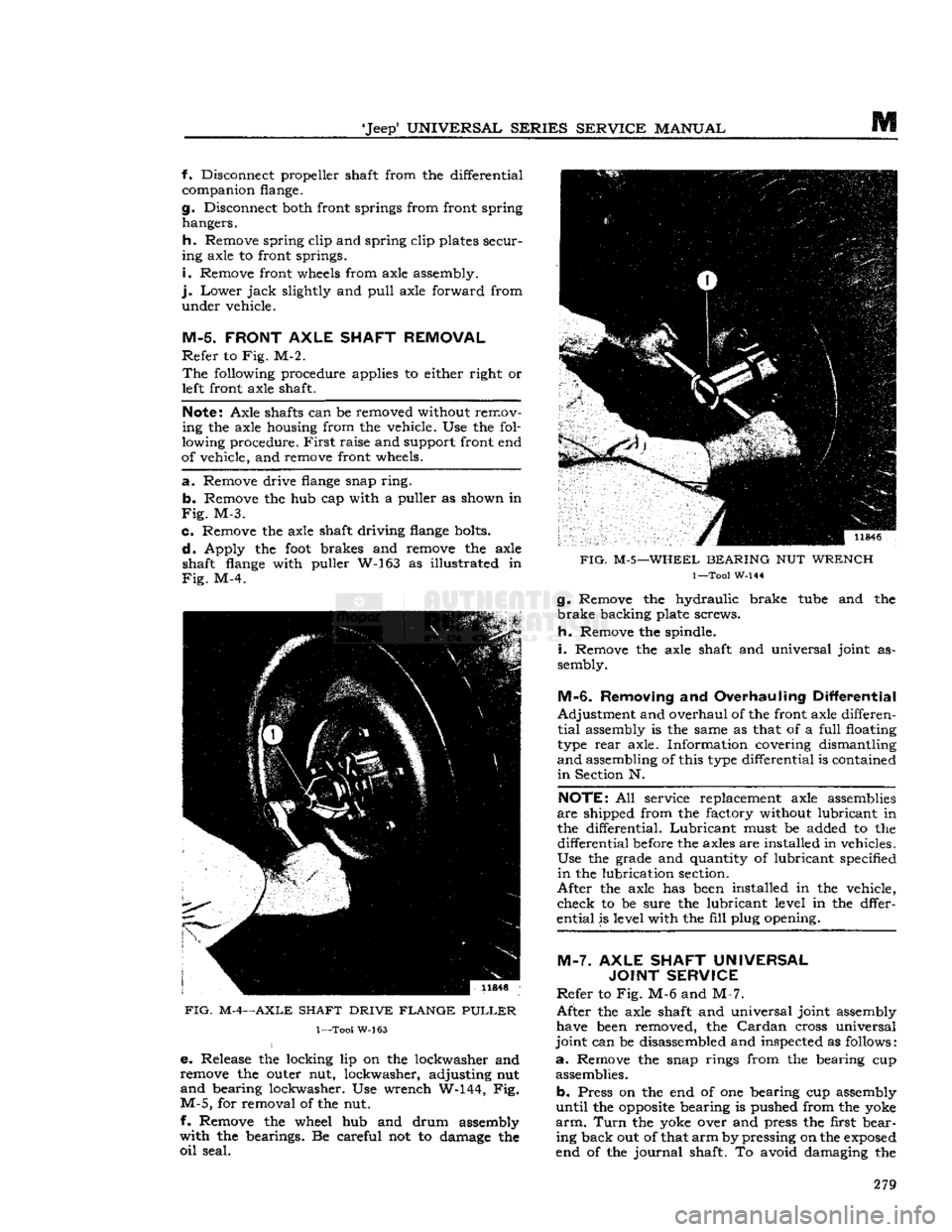

FIG.

M-4—AXLE

SHAFT

DRIVE

FLANGE

PULLER

1—Too!

W-163

e.

Release the locking lip on the lockwasher and

remove the outer nut, lockwasher, adjusting nut

and

bearing lockwasher. Use wrench W-144, Fig.

M-5,

for removal of the nut.

f- Remove the wheel hub and drum assembly

with

the bearings. Be careful not to damage the

oil

seal.

FIG.

M-5—WHEEL

BEARING

NUT

WRENCH

1—Tool

W-144

g.

Remove the hydraulic brake

tube

and the

brake

backing plate screws.

h.

Remove the spindle.

i.

Remove the axle shaft and universal joint as

sembly.

M-6.

Removing

and

Overhauling Differential

Adjustment

and overhaul of the front axle differen

tial

assembly is the same as that of a

full

floating

type

rear

axle. Information covering dismantling

and

assembling of this

type

differential is contained

in

Section N.

NOTE:

All service replacement axle assemblies

are

shipped from the factory without lubricant in

the differential.

Lubricant

must be added to the

differential

before

the axles are installed in vehicles.

Use

the grade and quantity of lubricant specified

in

the lubrication section.

After

the axle has

been

installed in the vehicle,

check

to be sure the lubricant level in the dffer-

ential

is level with the

fill

plug opening.

M-7.

AXLE SHAFT UNIVERSAL JOINT SERVICE

Refer

to Fig. M-6 and M-7.

After

the axle shaft and universal joint assembly have

been

removed, the

Cardan

cross universal

joint

can be disassembled and inspected as follows:

a.

Remove the snap rings from the bearing cup assemblies.

b.

Press on the end of one bearing cup assembly

until

the

opposite

bearing is pushed from the yoke

arm.

Turn

the yoke over and press the first bear ing back out of that

arm

by pressing on the

exposed

end of the

journal

shaft. To avoid damaging the 279