ECU JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 186 of 376

ELECTRICALJ

SYSTEM

d.

Inspect for

excessive

wear

between

centrifugal

weights

and advance cam and pivot pins.

Turn

weight

base plate in a clockwise direction until

weights

are fully extended. Release and allow

springs to return

weights

to

retard

position. Repeat several times. Springs should return

weights

to

stop

without sticking and there should be no

excessive

free

movement

in the

retard

position. Inspect

springs for distortion and fatigue.

e. Inspect cam

lobes

for scoring or

excessive

wear.

Check

weight

base plate for binding or

excessive

looseness

on distributor shaft.

f.

Check

breaker plate for

excessive

looseness

on

outside

diameter of upper distributor shaft bushing.

Check

breaker plate ground lead for poor

spot

we

Id

at plate end and for

loose

or frayed terminal con

nections.

g.

Check

for

excessive

wear

between

distributor

shaft and bushings in housing. Inspect shaft for distortion. Inspect gear for scoring of

teeth

or

excessive

wear.

h.

Inspect rod end of vacuum advance mechanism

for

excessive

wear. Push rod

into

unit as far as

possible, hold finger tightly over nipple, then re

lease

rod. After about 15 seconds, remove finger

from nipple, and

notice

if air is drawn

into

unit.

If

not, diaphragm is leaking and unit must be

replaced.

H-29.

Distributor Reassembly

Refer

to Fig. H-l5.

a.

Install

distributor

primary

lead and rubber grommet in distributor housing. Mount vacuum

advance unit on housing with two

slotted

attaching

screws; insert ground lead terminal of breaker plate under outer mounting screw.

b.

Install

felt

washer over upper shaft bushing of

distributor housing and apply a few drops of light

oil.

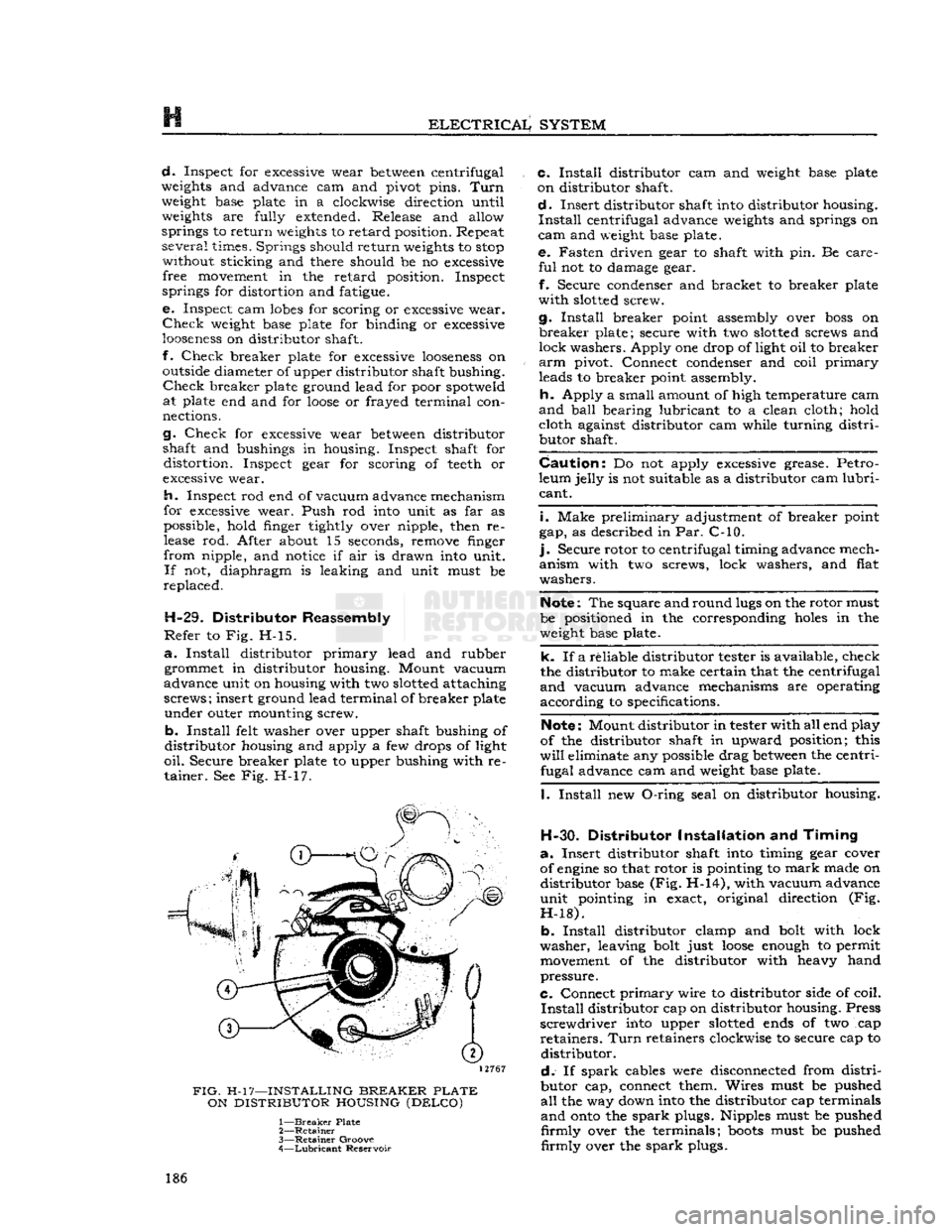

Secure breaker plate to upper bushing with re tainer. See Fig. H-17.

12767

FIG.

H-17—INSTALLING

BREAKER

PLATE

ON

DISTRIBUTOR

HOUSING

(DELCO)

1—

Breaker

Plate

2—

Retainer

3—

Retainer

Groove

4—

Lubricant

Reservoir c.

Install

distributor cam and

weight

base plate

on distributor shaft.

d.

Insert distributor shaft

into

distributor housing.

Install

centrifugal advance

weights

and springs on

cam

and

weight

base plate. e. Fasten driven gear to shaft with pin. Be care

ful

not to damage gear.

f.

Secure condenser and bracket to breaker plate

with

slotted

screw.

g.

Install

breaker point assembly over

boss

on

breaker

plate; secure with two

slotted

screws and

lock washers. Apply one drop of light oil to breaker

arm

pivot. Connect condenser and coil

primary

leads to breaker point assembly.

h.

Apply a small amount of high temperature cam

and

ball

bearing lubricant to a clean cloth; hold cloth against distributor cam while turning

distri

butor shaft.

Caution:

Do not apply

excessive

grease. Petro

leum jelly is not suitable as a distributor cam

lubri

cant.

i.

Make preliminary adjustment of breaker point

gap, as described in Par. C-10.

].

Secure rotor to centrifugal timing advance mech

anism with two screws, lock washers, and flat

washers.

Note:

The square and round

lugs

on the rotor must

be positioned in the corresponding

holes

in the

weight

base plate.

k. If a reliable distributor tester is available, check

the distributor to make certain that the centrifugal

and

vacuum advance mechanisms are operating

according to specifications.

Note:

Mount distributor in tester with all end play

of the distributor shaft in upward position; this

will

eliminate any possible drag

between

the centri fugal advance cam and

weight

base plate.

I.

Install

new

O-ring

seal on distributor housing.

H-30.

Distributor

Installation

and

Timing

a.

Insert distributor shaft

into

timing gear cover

of

engine

so that rotor is pointing to

mark

made on distributor base (Fig. H-14), with vacuum advance

unit pointing in exact, original direction (Fig.

H-18).

b.

Install

distributor clamp and

bolt

with lock

washer, leaving

bolt

just

loose

enough

to permit

movement

of the distributor with heavy hand

pressure.

C.

Connect

primary

wire to distributor side of coil.

Install

distributor cap on distributor housing. Press

screwdriver

into

upper

slotted

ends

of two cap

retainers.

Turn

retainers clockwise to secure cap to distributor.

d.

If

spark

cables were disconnected from

distri

butor cap, connect them. Wires must be pushed

all

the way down

into

the distributor cap terminals

and

onto

the

spark

plugs. Nipples must be pushed

firmly

over the terminals;

boots

must be pushed

firmly

over the

spark

plugs. 186

Page 189 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

U029p 1—

Oil

Retainer

2—

Bearing

3—

-Felt

Wick

4—

Oiler

5—

Commutator

End Head

6—

Brush

Lead

Screw

7—

Lockwasher

8—

Brush

Set

9—

Brush

Spring

10—

Brush

Arm

11—

Frame

12—

Insulating

Bushing

13—

Washer

14—

Lockwasher

15—

Hex

Nut

16—

Lockwasher

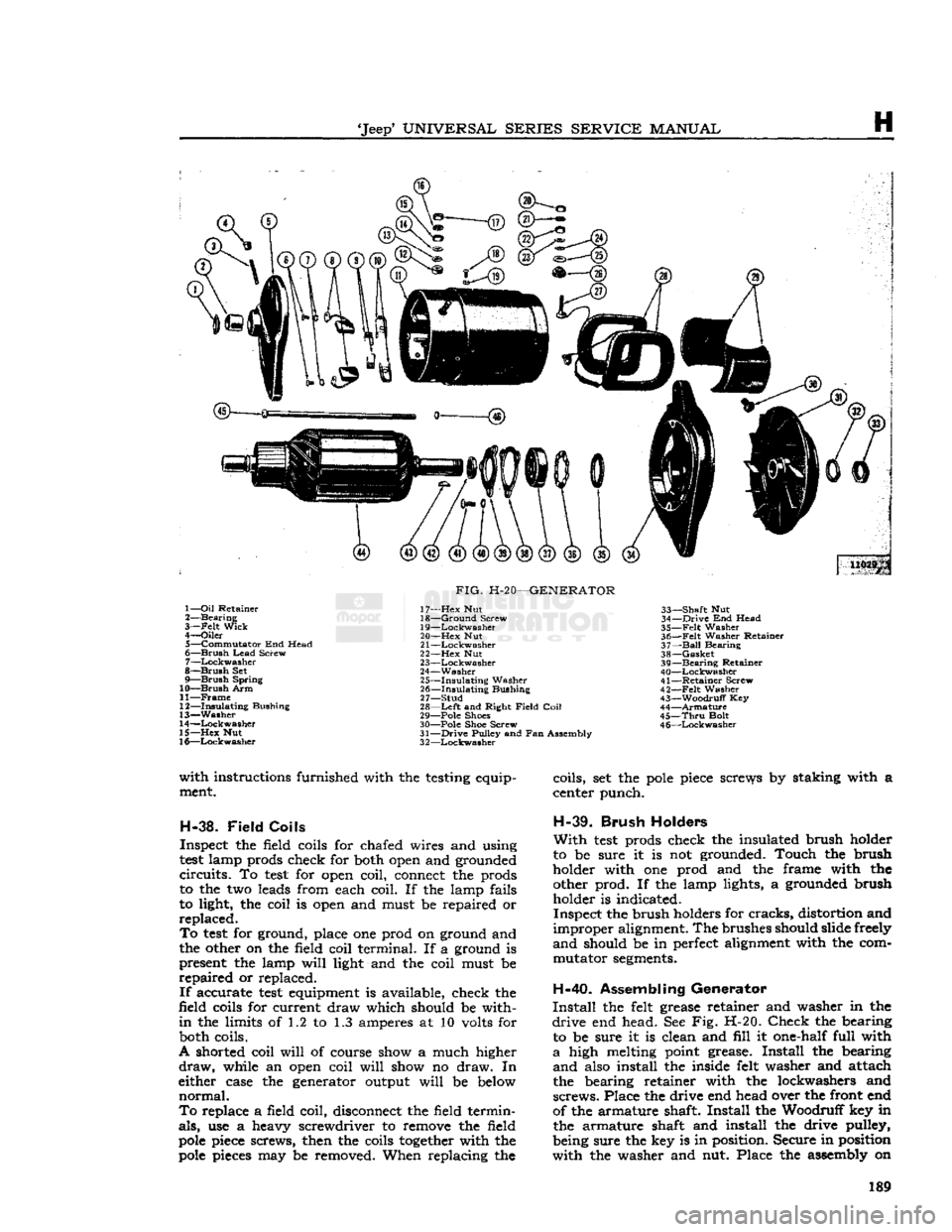

FIG.

H-20—GENERATOR

17—

Hex

Nut

18—

Ground

Screw

19—

Lockwasher

20—

Hex

Nut

21

—Lockwasher

22—

Hex

Nut

23—

Lockwasher

24—

Washer

25—

Insulating

Washer

26—

Insulating

Bushing

27—

Stud

28—

Left

and Right

Field

Coil

29— Pole Shoes

30— Pole Shoe Screw

31—

Drive

Pulley and Fan Assembly

3

2—Lockwasher

33—

Shaft

Nut

34—

Drive

End Head

35—

Felt

Washer

36—

Felt

Washer Retainer

37—

Ball

Bearing

38—

Gasket

39—

Bearing

Retainer

40—

Lockwasher

41—

Retainer

Screw

42—

-Felt

Washer

43—

Woodruff

Key

44—

Armature

45—

Thru

Bolt

4

6—Lockwasher

with

instructions furnished with the testing equip ment.

H-38.

Field

Coils

Inspect the field coils for chafed wires and using

test

lamp prods check for both open and grounded

circuits.

To

test

for open coil, connect the prods

to the two leads from each coil. If the lamp fails

to light, the coil is open and must be repaired or

replaced.

To

test

for ground, place one prod on ground and

the other on the field coil terminal. If a ground is present the lamp

will

light and the coil must be

repaired

or replaced.

If

accurate

test

equipment is available, check the

field coils for current draw which should be with

in

the limits of 1.2 to 1.3 amperes at 10 volts for both coils.

A shorted coil

will

of course show a much higher

draw,

while an open coil

will

show no draw. In

either case the generator output

will

be below

normal.

To

replace a field coil, disconnect the field termin

als,

use a heavy screwdriver to remove the field

pole

piece screws, then the coils

together

with the

pole

pieces may be removed. When replacing the coils, set the

pole

piece screws by staking with a

center punch.

H-39.

Brush

Holders

With

test

prods check the insulated brush holder

to be sure it is not grounded. Touch the brush

holder with one prod and the frame with the other prod. If the lamp lights, a grounded brush holder is indicated.

Inspect the brush holders for

cracks,

distortion and

improper

alignment. The brushes should slide freely

and

should be in perfect alignment with the com mutator

segments.

H-40.

Assembling Generator

Install

the felt grease retainer and washer in the

drive

end head. See Fig. H-20.

Check

the bearing to be sure it is clean and

fill

it one-half full with

a

high melting point grease.

Install

the bearing

and

also install the inside felt washer and attach

the bearing retainer with the lockwashers and

screws.

Place the drive end head over the front end

of the armature shaft.

Install

the Woodruff key in the armature shaft and install the drive pulley,

being sure the key is in position. Secure in position

with

the washer and nut. Place the assembly on 189

Page 201 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

Resistance

should be approximately 0.1 ohm.

An

extremely accurate instrument would be neces

sary

to ascertain shorted turns.

Only

an open condi

tion can be detected with a commercial ohmmeter.

If

the alternator has been disassembled because of

an

electrical malfunction, replace stator only after

all

components have been checked and found to

be satisfactory.

H-85.

Out-Of-Circuit

Rectifier Diode Test

With

the rectifier diode heat sinks disconnected

from

the stator assembly (Par. H-80), the diodes

can

be individually checked with the Diode Tester

C-3829.

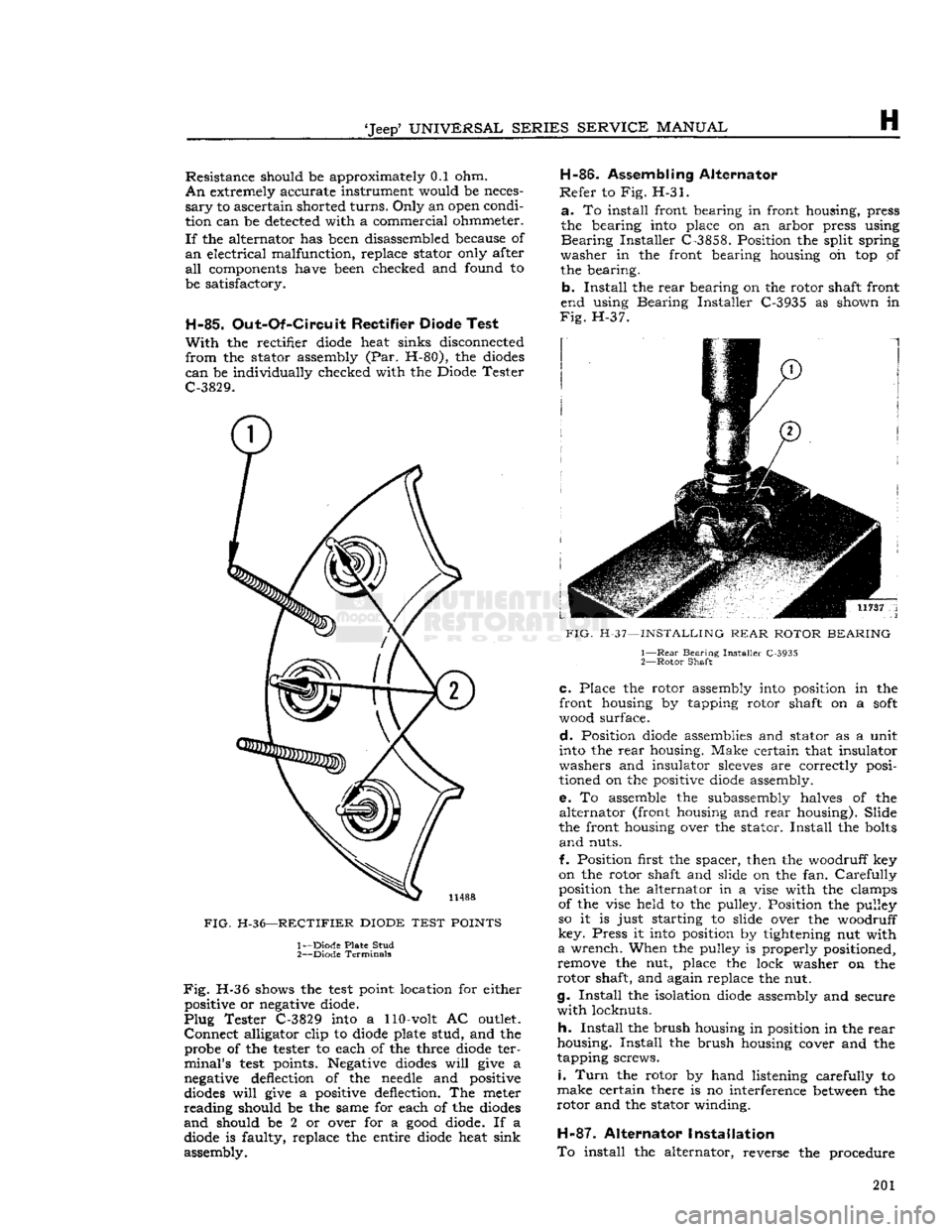

FIG.

H-36—RECTIFIER

DIODE

TEST

POINTS

1— Diode Plate Stud

2—

Diode Terminals

Fig.

H-36 shows the

test

point location for either positive or negative diode.

Plug

Tester C-3829 into a 110-volt AC outlet.

Connect

alligator clip to diode plate stud, and the probe of the tester to each of the three diode ter

minal's

test

points. Negative diodes

will

give a

negative deflection of the needle and positive

diodes

will

give a positive deflection. The meter

reading

should be the same for each of the diodes

and

should be 2 or over for a

good

diode. If a diode is faulty, replace the entire diode heat sink

assembly. H-86.

Assembling Alternator

Refer

to Fig. H-31.

a.

To install front bearing in front housing, press

the bearing into place on an arbor press using

Bearing

Installer C-3858. Position the split spring

washer

in the front bearing housing oh top of the bearing.

b.

Install

the

rear

bearing on the rotor shaft front

end using Bearing Installer C-3935 as shown in

Fig.

H-37.

FIG.

H-37—INSTALLING

REAR

ROTOR

BEARING

1—

Rear

Bearing Installer C-3935

2—

Rotor

Shaft

C.

Place the rotor assembly

into

position in the

front housing by tapping rotor shaft on a

soft

wood surface.

d.

Position diode assemblies and stator as a unit

into the

rear

housing. Make certain that insulator

washers and insulator

sleeves

are correctly posi

tioned on the positive diode assembly.

e.

To assemble the subassembly halves of the

alternator

(front

housing and

rear

housing). Slide

the front housing over the stator.

Install

the bolts

and

nuts.

f. Position first the spacer, then the woodruff key

on the rotor shaft and slide on the fan.

Carefully

position the alternator in a vise with the clamps

of the vise held to the pulley. Position the pulley

so it is just starting to slide over the woodruff

key.

Press it into position by tightening nut with

a

wrench. When the pulley is properly positioned,

remove the nut, place the lock washer on the

rotor

shaft, and again replace the nut.

g.

Install

the isolation diode assembly and secure

with

locknuts.

h.

Install

the brush housing in position in the

rear

housing.

Install

the brush housing cover and the

tapping screws.

i.

Turn

the rotor by hand listening carefully to

make

certain there is no interference between the

rotor

and the stator winding.

H-87.

Alternator Installation

To

install the alternator, reverse the procedure 201

Page 202 of 376

H

ELECTRICAL

SYSTEM

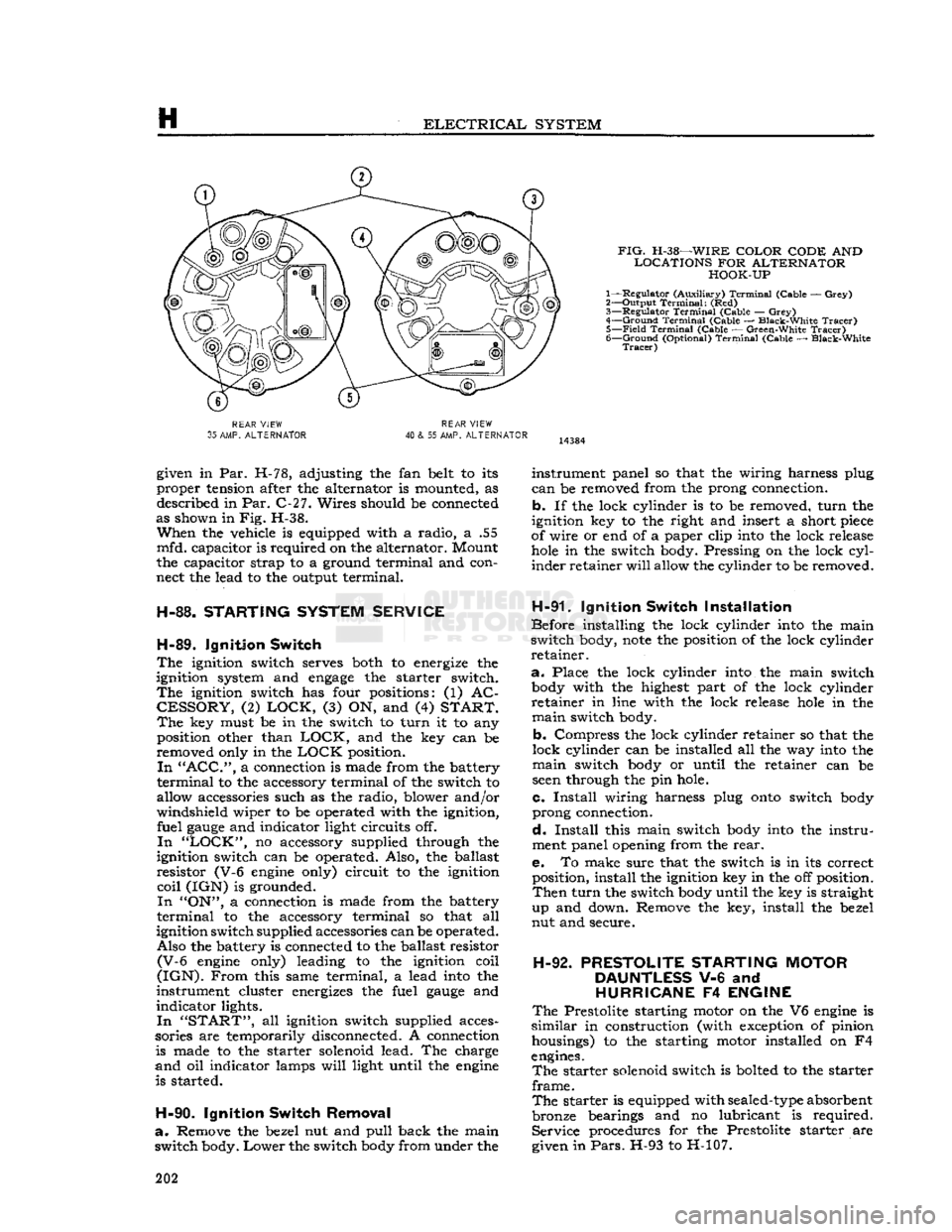

FIG.

H-38—WIRE

COLOR CODE

AND

LOCATIONS

FOR

ALTERNATOR HOOK-UP

1— Regulator (Auxiliary)

Terminal

(Cable —

Grey)

2— Output

Terminal:

(Red)

3—

Regulator

Terminal

(Cable —

Grey)

4—

Ground

Terminal

(Cable — Black-White

Tracer)

5—

Field

Terminal

(Cable — Green-White

Tracer)

6—

Ground

(Optional)

Terminal

(Cable — Black-White

Tracer)

REAR

VIEW

35

AMP.

ALTERNATOR

REAR

VIEW

40

& 55 AMP.

ALTERNATOR

given in Par. H-78, adjusting the fan belt to its

proper tension after the alternator is mounted, as described in Par. C-27. Wires should be connected

as shown in Fig. H-38.

When

the vehicle is equipped with a radio, a .55

mfd. capacitor is required on the alternator. Mount

the capacitor strap to a ground terminal and con

nect the lead to the output terminal.

H-88.

STARTING

SYSTEM

SERVICE

H-89.

Ignition

Switch

The

ignition switch serves both to energize the

ignition system and

engage

the starter switch.

The

ignition switch has four positions: (1) AC

CESSORY,

(2)

LOCK,

(3) ON, and (4)

START. The

key must be in the switch to turn it to any position other than

LOCK,

and the key can be

removed only in the

LOCK

position.

In "ACC",

a connection is made from the battery

terminal

to the accessory terminal of the switch to

allow accessories such as the radio, blower and/or

windshield wiper to be operated with the ignition, fuel

gauge

and indicator light circuits off.

In "LOCK",

no accessory supplied through the

ignition switch can be operated. Also, the ballast

resistor (V-6

engine

only) circuit to the ignition

coil

(IGN) is grounded.

In

"ON", a connection is made from the battery

terminal

to the accessory terminal so that all

ignition switch supplied accessories can be operated. Also the battery is connected to the ballast resistor

(V-6

engine

only) leading to the ignition coil

(IGN).

From

this same terminal, a lead

into

the

instrument cluster energizes the fuel

gauge

and

indicator lights.

In "START",

all ignition switch supplied acces

sories are temporarily disconnected. A connection is made to the starter solenoid lead. The charge

and

oil indicator lamps

will

light until the

engine

is started.

H-90.

Ignition

Switch

Removal

a.

Remove the bezel nut and pull back the main

switch body.

Lower

the switch

body

from under the instrument panel so that the wiring harness plug

can

be removed from the prong connection,

b. If the lock cylinder is to be removed, turn the

ignition key to the right and insert a short

piece

of wire or end of a paper clip

into

the lock release

hole

in the switch body. Pressing on the lock

cyl

inder retainer

will

allow the cylinder to be removed.

H-91.

Ignition

Switch

Installation

Before installing the lock cylinder

into

the main

switch body,

note

the position of the lock cylinder

retainer.

a.

Place the lock cylinder

into

the main switch

body

with the highest part of the lock cylinder

retainer in line with the lock release

hole

in the

main

switch body.

b. Compress the lock cylinder retainer so that the

lock cylinder can be installed all the way

into

the

main

switch

body

or until the retainer can be

seen

through the pin hole.

c.

Install

wiring harness plug

onto

switch

body

prong connection.

d.

Install

this main switch

body

into

the instru

ment panel opening from the

rear.

e. To make sure that the switch is in its correct position, install the ignition key in the off position.

Then

turn the switch

body

until the key is straight

up and down. Remove the key, install the bezel

nut and secure.

H-92.

PRESTOLITE

STARTING

MOTOR

DAUNTLESS

V-6 and

HURRICANE

F4

ENGINE

The

Prestolite starting motor on the V6

engine

is

similar

in construction (with exception of pinion housings) to the starting motor installed on F4

engines.

The

starter solenoid switch is bolted to the starter

frame.

The

starter is equipped with

sealed-type

absorbent

bronze bearings and no lubricant is required. Service procedures for the Prestolite starter are

given in

Pars.

H-93 to H-107. 202

Page 205 of 376

SERIES

SERVICE

MANUAL

H

t

^

12956

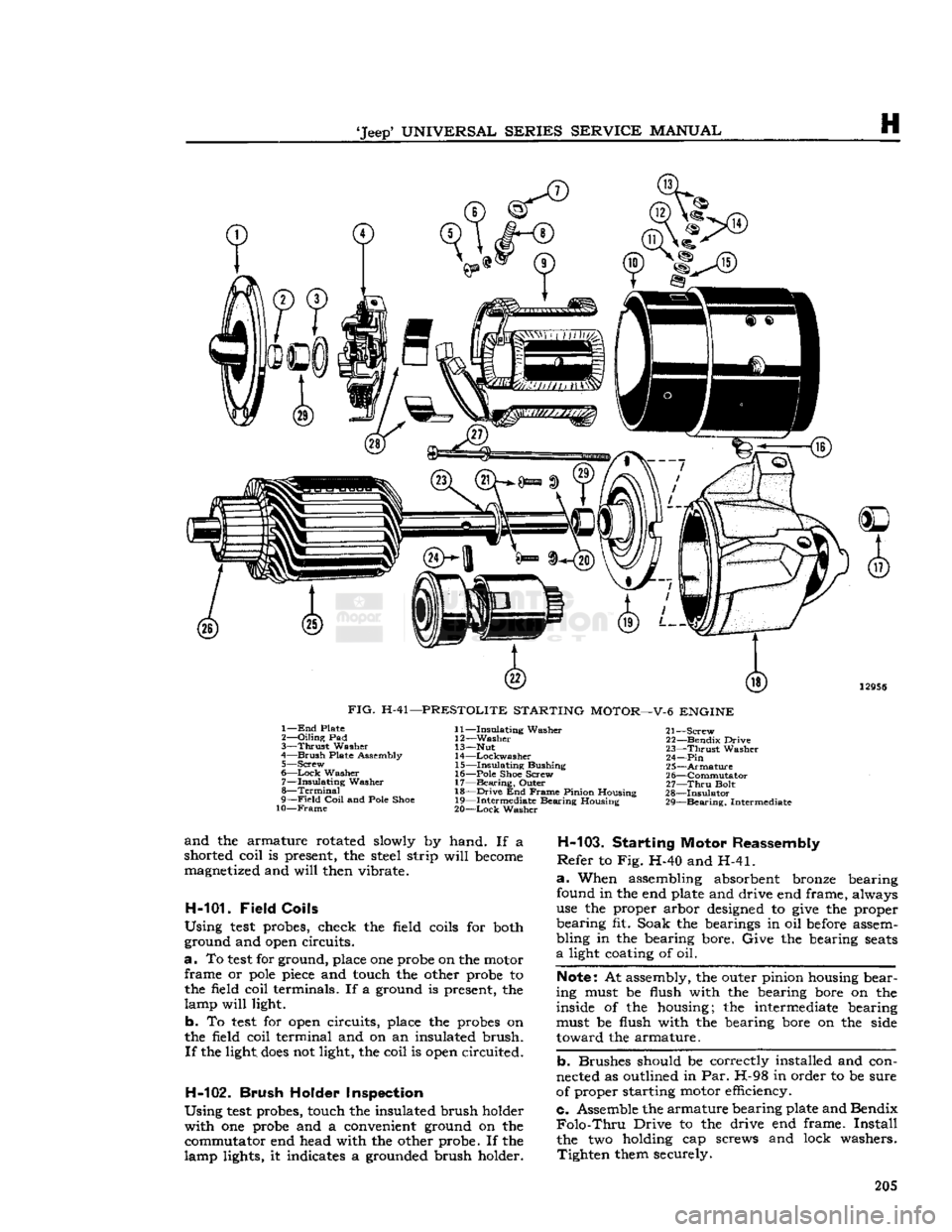

FIG.

H-41—PRESTOLITE

STARTING

MOTOR—V-6

ENGINE

1—

End

Plate

2—

Oiling

Pad

3—

Thrust

Washer

4—

Brush

Plate Assembly 5—

Screw

6—

Lock

Washer 7—

Insulating

Washer

8—

Terminal

9—

Field

Coil

and Pole Shoe

10—Frame

11—

Insulating

Washer

12—

Washer

13— Nut

14

—Lockwasher

15—

Insulating

Bushing

16— Pole Shoe Screw

17—

Bearing,

Outer

18—

Drive

End

Frame

Pinion Housing

19— Intermediate Bearing Housing

20—

Lock

Washer 21—

Screw

22— Bendix Drive

23—

Thrust

Washer

24—Pin

25—

Armature

2 6—Commutator

27—

Thru

Bolt

28—

Insulator

29—

Bearing,

Intermediate

and

the armature rotated slowly by hand. If a

shorted coil is present, the steel strip

will

become

magnetized and

will

then vibrate.

H-101-

Field

Coils

Using

test

probes, check the field coils for both

ground and

open

circuits.

a.

To

test

for ground, place one probe on the motor frame or

pole

piece

and touch the other probe to the field coil terminals. If a ground is present, the

lamp

will

light.

b.

To

test

for

open

circuits, place the probes on

the field coil terminal and on an insulated brush.

If

the light,

does

not light, the coil is

open

circuited.

H-102.

Brush

Holder Inspection

Using

test

probes, touch the insulated brush holder with one probe and a convenient ground on the commutator end head with the other probe. If the

lamp lights, it indicates a grounded brush holder.

H-103.

Starting Motor Reassembly

Refer

to Fig. H-40 and H-41.

a.

When assembling absorbent bronze bearing

found in the end plate and drive end frame, always

use the proper arbor

designed

to

give

the proper

bearing fit. Soak the bearings in oil

before

assem

bling in the bearing bore. Give the bearing

seats

a

light coating of oil.

Note:

At assembly, the outer pinion housing bear

ing must be flush with the bearing bore on the inside of the housing; the intermediate bearing

must be flush with the bearing bore on the side

toward the armature.

b.

Brushes should be correctly installed and con

nected as outlined in Par. H-98 in order to be sure

of proper starting motor efficiency.

c. Assemble the armature bearing plate and Bendix

Folo-Thru

Drive to the drive end frame.

Install

the two holding cap screws and lock washers. Tighten them securely. 205

Page 206 of 376

H

ELECTRICAL

SYSTEM

FIG.

H-42—GROWLER

d.

Install

the armature in starter motor frame,

using care to align the four brushes and brush

springs on the commutator so that they are free to

move

and are square on the commutator.

e.

Install

the thrust washer on the shaft.

Lubricate

the plug and bearing in the end plate.

Install

the

end plate.

Install

the two through

bolts

and tighten securely.

f.

On Prestolite V6 starting motors, check pinion position by measuring from the centerline of the

pinion housing mounting bolt

holes

to the outside

edge

of the pinion.

Correct

measurement with the

Bendix

drive retracted is [19,05 mm.] to

%"

[22,23 mm.]; with drive extended, 1%"

[34,93

mm.] to 1^" [38,10]. Adjust by installing

thrust

washers just inside the commutator end

head or intermediate bearing as required. The

Bendix

drive retaining pin must not project

beyond the outside diameter of the pinion

sleeve.

H-104.

Bench Test

The

motor should first be checked to see that the

free running

voltage

and current are within specifi cations. To

test,

connect the motor to a battery,

ammeter and voltmeter. If the current is too high

check

the bearing alignment and end play to make

sure

there is no binding or interference. Using a

spring

scale and torque arm check the stall torque to see that the motor is producing its rated

crank

ing power. The stall torque

will

be product of the

spring

scale reading and the length of the arm

in

feet.

If the torque is not up to specifications

check

the seating of the brushes on the commutator

and

the internal connection of the motor for high

resistance. The Bendix

Folo-Thru-Drive

should be checked for correct operation. The Bendix pinion

should be checked to see that it shifts when the motor is operated under no load.

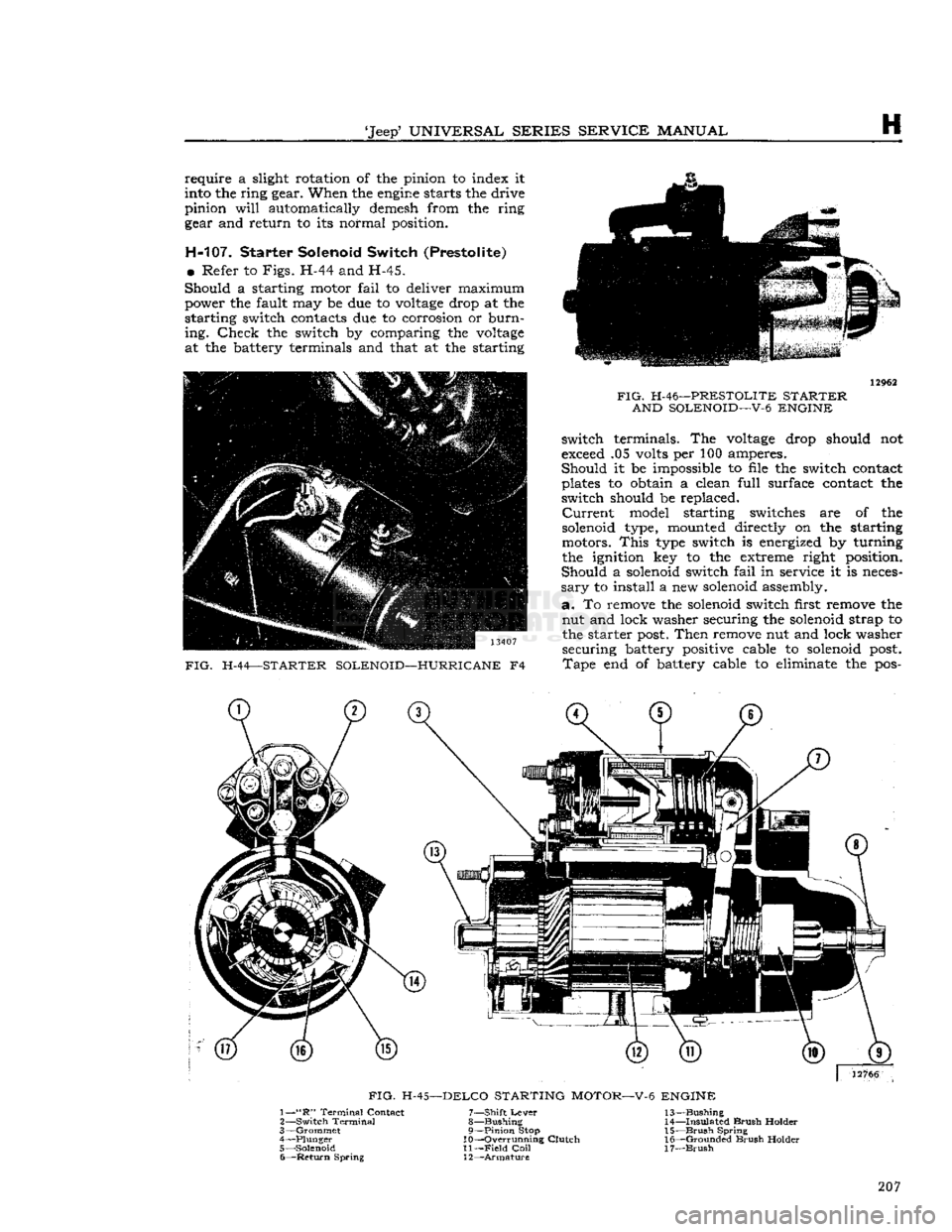

H-105.

Bendix Folo-Thru Drive (Prestolite)

The

Bendix

Folo-Thru

Drive is designed to over

come

premature demeshing of the drive pinion

from

the flywheel ring gear until a predetermined

engine

speed is reached. See Fig. H-43. No repairs or adjustments are possible on this

drive

and a

complete

new unit must be installed

if

trouble develops.

H-106.

Lubrication

of

Folo-Thru Drive

A

periodic cleaning and relubrication of the drive is advisable, the frequency of which

will

depend on

the type of service to which the vehicle is sub

jected and the locale of operation.

a.

Remove the starting motor from the

engine

and take off the outboard housing. The pinion and

barrel

assembly

will

be in the demeshed position

on the screwshaft. Do not

move

it forward

until

after

that portion of the armature shaft ahead

of the pinion has been cleaned. If accidentally ro

tated to the outer end of the screwshaft it

will

lock

in that position and cannot be forced back.

b.

Do not disassemble the drive for any reason.

c.

Do not dip or wash the drive in any cleaning solution.

d.

Do not remove the drive from the armature

shaft. Remove

excess

oil, grease or foreign matter

from

the armature shaft by wiping it with a clean cloth.

3

10859

FIG.

H-43—BENDIX

FOLO-THRU DRIVE

Dampen

the cloth with kerosene if necessary. A

light film of

SAE

10 oil may then be applied to the shaft.

e.

Now rotate the pinion and

barrel

assembly to the

fully

extended position, thereby exposing the screw shaft triple threads. Use a cloth dampened with

kerosene to wipe them clean. Do not use

gaso

line

or any

commercial cleaner.

If the dirt is

thick

and gummy, apply the kerosene with a small

brush.

Tilt

the starting motor so that a small

amount

will

run under the control nut. Relubricate

with

a thin film of

SAE

10 oil. Use SAE 5 at ex tremely low temperatures.

f.

Reassemble the starting motor to the

engine

with the drive in the extended position.

Carefully

mesh the pinion with the flywheel ring gear before

tightening the starter motor mounting bolts. It may 206

Page 207 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

require

a slight rotation of the pinion to index it

into the ring gear. When the

engine

starts the drive

pinion

will

automatically demesh from the ring

gear and return to its normal position.

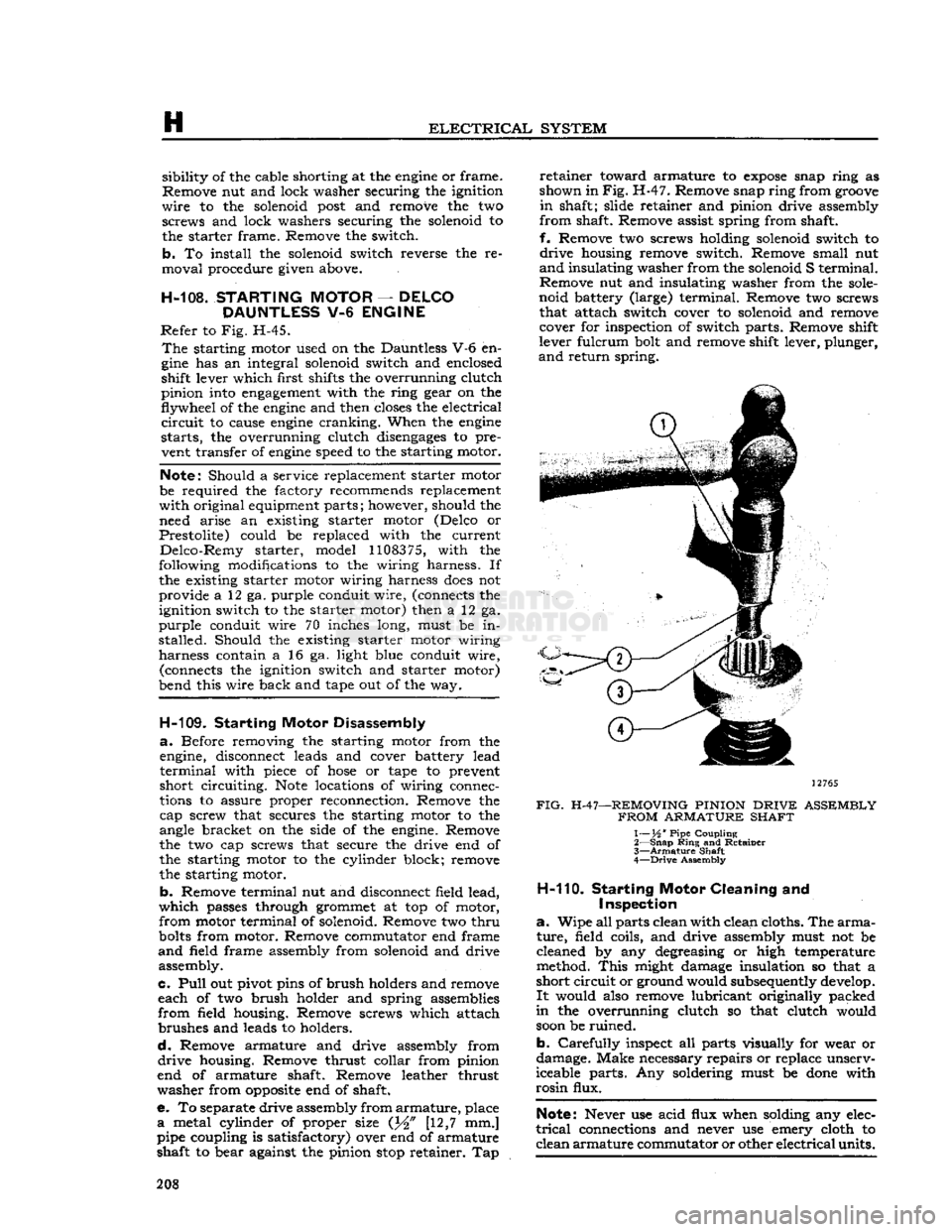

H-107. Starter Solenoid Switch (Prestolite)

•

Refer to

Figs.

H-44 and H-45.

Should

a starting motor

fail

to deliver maximum power the fault may be due to

voltage

drop at the

starting switch contacts due to corrosion or

burn

ing.

Check

the switch by comparing the

voltage

at the battery terminals and that at the starting 13407

FIG.

H-44—STARTER SOLENOID—HURRICANE

F4

FIG.

H-46—PRESTOLITE STARTER

AND SOLENOID—V-6 ENGINE

switch terminals. The

voltage

drop should not

exceed .05 volts per 100 amperes.

Should

it be impossible to file the switch contact

plates to obtain a clean

full

surface contact the

switch should be replaced.

Current

model starting switches are of the

solenoid type, mounted directly on the starting

motors.

This

type switch is energized by turning

the ignition key to the extreme right position.

Should

a solenoid switch

fail

in service it is neces

sary

to install a new solenoid assembly,

a.

To remove the solenoid switch first remove the nut and lock washer securing the solenoid strap to the starter

post.

Then

remove nut and lock washer securing battery positive cable to solenoid

post.

Tape

end of battery cable to eliminate the pos- 207

Page 208 of 376

H

ELECTRICAL

SYSTEM

sibility

of the cable shorting at the

engine

or frame.

Remove nut and lock washer securing the ignition

wire

to the solenoid

post

and remove the two screws and lock washers securing the solenoid to

the starter frame. Remove the switch,

b.

To install the solenoid switch reverse the re

moval

procedure given above.

H-10S.

STARTING MOTOR

—

DELCO

DAUNTLESS

V-6

ENGINE

Refer

to Fig. H-45.

The

starting motor used on the Dauntless V-6 en

gine

has an integral solenoid switch and enclosed

shift lever which first shifts the overrunning clutch

pinion into

engagement

with the ring gear on the

flywheel of the

engine

and then

closes

the electrical

circuit

to cause

engine

cranking. When the

engine

starts,

the overrunning clutch

disengages

to pre vent transfer of

engine

speed to the starting motor.

Note:

Should a service replacement starter motor

be required the factory recommends replacement

with

original equipment parts; however, should the need arise an existing starter motor (Delco or

Prestolite) could be replaced with the current

Delco-Remy

starter, model 1108375, with the

following modifications to the wiring harness. If

the existing starter motor wiring harness

does

not

provide a 12 ga. purple conduit wire, (connects the ignition switch to the starter motor) then a 12 ga.

purple

conduit wire 70 inches long, must be in

stalled.

Should the existing starter motor wiring

harness

contain a 16 ga. light blue conduit wire, (connects the ignition switch and starter motor)

bend this wire back and tape out of the way.

H-109.

Starting Motor Disassembly

a.

Before removing the starting motor from the

engine, disconnect leads and cover battery lead

terminal

with piece of

hose

or tape to prevent

short circuiting.

Note

locations of wiring connec

tions to assure proper reconnection. Remove the cap screw that secures the starting motor to the

angle bracket on the side of the engine. Remove

the two cap screws that secure the drive end of

the starting motor to the cylinder block; remove

the starting motor.

b.

Remove terminal nut and disconnect field lead,

which

passes through grommet at top of motor,

from

motor terminal of solenoid. Remove two

thru

bolts

from motor. Remove commutator end frame

and

field frame assembly from solenoid and drive assembly.

e.

Pull

out pivot pins of brush holders and remove each of two brush holder and spring assemblies

from

field housing. Remove screws which attach

brushes and leads to holders.

d.

Remove armature and drive assembly from

drive

housing. Remove thrust collar from pinion

end of armature shaft. Remove leather thrust

washer

from

opposite

end of shaft.

e. To separate drive assembly from

armature,

place

a

metal cylinder of proper size (J^" [12,7 mm.]

pipe coupling is satisfactory) over end of armature

shaft to bear against the pinion

stop

retainer. Tap

retainer

toward armature to

expose

snap ring as

shown in

Fig.

H-47. Remove snap ring from

groove

in

shaft; slide retainer and pinion drive assembly

from

shaft. Remove assist spring from shaft,

f.

Remove two screws holding solenoid switch to

drive

housing remove switch. Remove small nut

and

insulating washer from the solenoid S terminal.

Remove nut and insulating washer from the

sole

noid battery (large) terminal. Remove two screws that attach switch cover to solenoid and remove cover for inspection of switch parts. Remove shift

lever fulcrum bolt and remove shift lever, plunger,

and

return spring.

12765

FIG.

H-47—REMOVING PINION

DRIVE

ASSEMBLY

FROM

ARMATURE SHAFT

1— XA ' Pipe Coupling

2—

Snap

Ring

and Retainer

3—

Armature

Shaft

4—

Drive

Assembly

H-110.

Starting

Motor

Cleaning and

Inspection

a.

Wipe all parts clean with clean cloths. The

arma

ture,

field coils, and drive assembly must not be

cleaned by any degreasing or high temperature

method.

This

might damage insulation so that a

short

circuit

or ground would subsequently develop.

It

would also remove lubricant originally packed

in

the overrunning clutch so that clutch would

soon

be ruined.

b.

Carefully

inspect all parts visually for wear or

damage. Make necessary repairs or replace unserv

iceable parts. Any soldering must be

done

with

rosin

flux.

Note:

Never use acid flux when solding any elec

trical

connections and never use emery cloth to

clean

armature

commutator or other

electrical

units. 208

Page 210 of 376

H

ELECTRICAL

SYSTEM

FIG.

H-49—INSTALLING PINION

STOP RETAINER AND THRUST

COLLAR

ON ARMATURE SHAFT

1—

Retainer

2—

Snap

Ring

3—

Thrust

Collar

4—

Drive

Assembly 5—

Retainer

6—

Groove

in Armature Shaft 7—

Snap

Ring

e. Place thrust collar on armature shaft with shoulder next to snap

ring.

Move the retainer

into contact with

ring.

Using pliers on

opposite

sides of shaft,

squeeze

retainer and thrust collar

together

until snap ring is forced into the retainer.

See Fig. H-49, right hand view.

f.

Lubricate

bearing of drive housing with silicone grease and install armature and drive assembly

in

housing.

g. If field coils were removed from field frame, position coils of replacement field coil assembly

on

pole

shoes

and mount each

pole

shoe

in field

frame

with a

pole

shoe

screw. Use care in tighten ing screws to avoid distortion of parts. Be certain

that screws are securely tightened. Insert ends of

field

coil

leads through rubber bushing in field

frame.

h.

Position field frame assembly over armature as

sembly so that its dowel pin

engages

the

hole

in

drive

housing. Use care to prevent damage to brushes and brush holders. Make sure that brushes

are

properly sealed on commutator.

i.

Install

leather thrust washer on commutator end

of armature assembly.

Lubricate

bearing in com

mutator end frame with silicone grease and position

end frame to field frame so that armature shaft

enters bearing. Secure field frame and end frame

to drive housing with two

thru

bolts. Connect field leads to motor terminal of solenoid with connecting nut.

j.

Whenever the starting motor is disassembled

and

reassembled, the pinion clearance should be

checked.

This

is to make sure that proper clear

ance exists

between

the pinion and the pinion

stop

retainer when pinion is in cranking position.

Lack

of clearance would prevent solenoid starter

switch

from closing properly; too much clearance

would cause improper pinion

engagement

in ring gear.

k.

Supply 6 volts (3 battery cells or a

6-volt

bat

tery)

between

S terminal of the solenoid and ground (starter frame).

Caution:

Do not supply more than 6 volts or the

motor

will

operate. As a further precaution to

prevent motor operation, connect a heavy jumper

wire

from the solenoid motor terminal to ground.

I.

After energizing the solenoid, push the drive as

sembly away from the

stop

retainer as far as pos

sible and use a feeler

gauge

to check clearance

between

pinion and retainer. See Fig. H-50. If pinion clearance is not .010" to .140" [0,25 a 3,55

mm.],

there is either excessive wear or improper as

sembly of solenoid linkage or shift lever mechanism.

12771

FIG.

H-50—MEASURING PINION CLEARANCE

1—

Press

Rearward

2—

Pinion

3—

Retainer

4— .010* to .140* Clearance 5—

Feeler

Gauge

210

Page 211 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

Note:

Pinion clearance cannot be adjusted. If

clearance is not correct, motor must be disassem

bled and checked for the above mentioned defects.

Any

defective parts must be replaced.

H-118. Starting Motor Test —

Genera!

To

obtain

full

performance data on a starting motor, or to determine the cause of abnormal

operation, the motor should be submitted to no-

load and locked armature

tests,

with equipment designed for such

tests.

A high-current variable resistance is required to obtain the specified volt

age at the starting motor.

This

is necessary since

a

small variation in the

voltage

will

produce a

marked

difference in the current

drawn.

H-119.

Starting Motor No-Load Test

This

test

requires a DC voltmeter capable of

read

ing

voltages

in a 12-volt

circuit,

a DC ammeter

with

maximum range of several hundred amperes,

a

high-current variable resistance, an rpm. in

dicator,

and a fully-charged, 12-volt battery.

a.

Connect a jumper lead

between

S terminal

and

large battery terminal of starter solenoid.

Con

nect voltmeter

between

either of

these

terminals (positive) and motor frame (negative, ground).

Connect

ammeter and variable resistance in series

between

positive terminal of battery and battery

terminal

of solenoid. Set up rpm. indicator to show starting motor speed.

b.

Initially,

adjust variable resistance to a value of

approximately .25 ohm. To complete the

circuit,

connect negative terminal of battery to motor

frame.

Adjust variable resistance to obtain a volt meter reading of 10.6 volts;

note

speed of starting motor and ammeter reading. Motor speed should

be

6750

to

10,500

rpm.; ammeter reading should

be 50 to 80 amperes.

c. Rated speed and current indicate normal condi

tion of the starting motor. Low speed and high

cur

rent

may show friction; this could be caused by

tight, dirty, or worn bearings, bent armature shaft,

or

a

loose

field

pole

shoe

dragging against the

armature.

It could also be caused by a short-cir cuited armature, or by grounded armature or field

coils.

d.

Failure

to operate and high current indicates

a

direct short circuit to ground at either the battery

terminal

or field coils.

e.

Failure

to operate and no current are usually

caused by broken brush springs, worn brushes, high insulation

between

commutator

bars,

or

some

other

condition preventing

good

contact

between

the brushes and commutator. It can also be caused by

open circuit in either the field coils or armature coils.

f. Low speed and low current show high resistance due to poor connections, defective leads, dirty com

mutator, or one of the conditions mentioned in e,

above.

g. High speed and high current indicates a short

circuit

in the field coils. H-120-

Locked

Armature Test

This

test

requires a DC voltmeter with range ap

propriate

to read

voltages

in a 12-volt

circuit,

a DC

ammeter with maximum range of several hundred

amperes, a high-current variable resistance, a

clamping fixture to lock

together

the motor shaft

and

case, and a fully-charged 12-volt battery.

a.

Connect a jumper lead

between

S terminal and

large battery terminal of starter solenoid. Connect

voltmeter

between

either of

these

terminals (posi

tive) and motor frame (negative, ground). Connect

ammeter and variable resistance in series

between

positive terminal of battery and battery terminal

of solenoid.

Install

clamping fixture to lock motor

shaft and case

together

securely.

b.

Initially,

adjust variable resistance to approxi

mately .05 ohm. To complete the

circuit,

connect

negative terminal of battery to motor frame. Ad

just

variable resistance to obtain a voltmeter

read

ing of 4.0 volts. Ammeter reading should be 280

to 320 amperes.

H-121.

Solenoid Starter Switch — Delco

The

solenoid-type switch is mounted directly on

the starting motor.

This

type of switch is energized

by turning the ignition key to the extreme right position. Should the solenoid switch

fail

in service

it

is necessary to install a new assembly.

Should

a starting motor

fail

to deliver maximum power the fault may be due to

voltage

drop at the

starter

switch contacts due to corrosion or burning.

Check

the switch by comparing the

voltage

at the

battery across the terminals. The

voltage

drop

should not exceed .05 volts per 100 amperes.

In

order to remove the starter solenoid, it is neces

sary

to remove the starter assembly.

H-122.

ELECTRICAL

INSTRUMENTS

H-123.

Fuel

Gauge —

CJ-3B

The

fuel

gauge

circuit is composed of the indicating

unit,

mounted on the instrument panel, and the

fuel tank unit, connected by a single wire through the ignition switch.

Should

the

gauge

fail

to register, check all wire con nections to be sure they are tight and clean; also

be sure both units are well grounded. If, after this

check, the

gauge

does

not indicate properly, remove

the wire from the tank unit and connect it to a

new tank unit which must be grounded to the tank

or

frame for

test.

Turn

the ignition switch "ON"

and

move

the float arm through its range of travel,

watching the dash unit to determine if it indicates

correctly.

If it fails to do so the trouble is probably

in

the dash unit and it should be replaced.

Should

a new tank unit be unavailable for this

test,

disconnect tank unit wire at the instrument panel

gauge.

Connect one lead of a 12 V, 1 CP

test

light

to the instrument panel unit terminal and with the

ignition switch

"ON"

ground the other lead. If the

unit is operating correctly the pointer

will

move

approximately three-quarter across the

dial.

Do not attempt to repair either unit; replacement

is the only precedure. 211