tow JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 192 of 376

H

ELECTRICAL

SYSTEM

Regulator

ground screw to battery ground post

—.03-volt maximum.

Generator

frame to battery ground post—.03-volt

maximum.

H-47.

Test Procedure

a.

Circuit

Breaker—Connect

an ammeter in series between the regulator B-terminal and the lead

wire

removed from that terminal. Connect a

voltmeter between the regulator

A-terminal

and the regulator mounting base. Disconnect the field lead

from

the regulator

F-terminal

and insert a variable resistance (3 amp., 50 ohm capacity) between the

lead

and the regulator terminal. Run the generator

at about 1000 generator rpm. Insert all the re

sistance in the field

circuit,

then slowly reduce the

resistance noting the voltage reading just before the change caused by the closing of the circuit

breaker.

Increase the charging rate to the figure

specified for the regulator being tested then reduce

the charging rate by inserting resistance in the

field

circuit.

Note

the voltmeter and ammeter

reading

just before the circuit breaker

opens

and

the ammeter reading drops to zero. The closing voltage and the opening voltage or current should

be within the limits specified. An accurate method

for noting the exact instant of the opening or closing

of the circuit breaker is to connect a headphone (2000 ohms or higher) to the battery and armature

terminals

of the regulator. When the contacts

open or close a

click

will

be

heard

in the headphones.

To

adjust the closing voltage change the armature

spring

tension by bending the hanger at the lower end of the spring. Increase the spring tension to

raise

the closing voltage or decrease the tension

to lower the closing voltage. To adjust the opening voltage raise or lower the stationary contact

keeping the contacts perfectly aligned. Increasing

the contact gap lowers the opening

'

voltage.

Change

the contact gap by expanding or contract

ing the stationary contact bracket, keeping the

contacts aligned. Do not adjust the gap between

the contacts to less than the specified minimum.

b.

Voltage Regulator—Connect the ammeter as in

step

a. Connect the voltmeter between the regulator

B-terminal

and the regulator base. Remove the

variable

resistance from the field

circuit.

Run the

generator at

half

output for 15 minutes to bring

the regulator to normal operating temperature.

Keep

the cover on the regulator during the

warm-

up period and also when taking readings.

Stop the engine then bring it up to approximately 2500 generator rpm. Adjust the amperage to

half

maximum

output by turning on lights or accessor

ies and then

note

the voltmeter reading.

This

read

ing should be within the limits specified for the voltage regulator operation. To adjust the oper

ating voltage change the

armature

spring tension by

bending the hanger at the lower end of the

arma

ture

spring. After each adjustment

stop

the engine then restart it.

Bring

it up to speed and adjust the

current

before taking a reading. In order to obtain

an

accurate indication of the operation of the volt

age regulator unit connect a headphone (2000 ohm

or

higher) between the

F-terminal

and ground to

pick

up the sound of the opening and closing of the

contacts. The clicks should be regular and clear without irregularities or missing. If the

tone

is not

clear

and regular remove the regulator cover and

inspect the contacts. The contacts should be flat

and

not burned excessively and should be aligned

to make

full

face contact. If the contacts need

cleaning refer to paragraph d for the method.

c.

Current

Regulator—Connect the regulator and the

test

equipment as in

step

b. Running the generator at approximately 3000 generator rpm.,

turn

on lights and accessories so that the generator must charge at maximum rate. The ammeter should give a reading within the limits specified.

To

adjust opening amperage, change the armature

spring

tension by bending the hanger at the lower

end of the armature spring. After each adjustment,

stop

the engine, then restart it.

Bring

the engine up to speed and take an ammeter reading. Keep

the cover on the regulator when taking

these

readings.

Connect

a headphone (2000 ohms or higher) be

tween the regulator

F-terminal

and ground to pick

up the sound of opening and closing of the contacts.

Clear,

regular clicks should be heard over the

headphones; they should not be

irregular

or missing.

If

the

tone

is not clear and regular remove the

regulator cover and inspect the contacts. The

contacts should be flat and not burned excessively

and

should be aligned to make

full

face contact. If

the contacts need cleaning refer to paragraph d.

below for the method.

d.

Contacts—Inspect the contacts on all three

units.

In normal use the contacts

will

become

grayed.

If the contacts are burned or dirty or if they are not smooth, file the contacts with a #6

American,

Swiss cut, equalling file. Move the file

parallel

and lengthwise to the armature.

File

just

enough so that the contacts present a smooth

sur

face toward each other. It is not necessary to remove every trace of pitting. After filing, dampen

a

piece of linen or lintless bond tape in refined

carbon

tetrachloride and draw the tape between

the contacts. Repeat with a dry piece of tape. Use

clean

tape for each set of contacts.

e. Recheck—Operate the unit at

half

maximum

output for five minutes with the cover on the regu

lator.

Repeat the testing procedure for all units as described in a, b, c above. Be sure cover is on regu

lator

when taking readings.

H-48.

Quick

Checks

H-49.

Low Charging Rate with a

Fully

Charged

Battery

A

fully charged battery and a low charging rate

indicates normal regulator operation.

A

further check of the regulator operation can be

made by using the starting motor for 5 to 10

seconds with the ignition switch in the "off" posi tion.

Then

start the engine and operate at a genera

tor speed of 2500 to 3000 rpm. The charging rate should rise to its maximum value then taper off to

a

minimum charge as the battery becomes charged.

H-50.

High Charging Rate with a

Fully

Charged

Battery

This

is usually an indication that the voltage regu

lator

is not operating correctly. The high voltage 192

Page 205 of 376

SERIES

SERVICE

MANUAL

H

t

^

12956

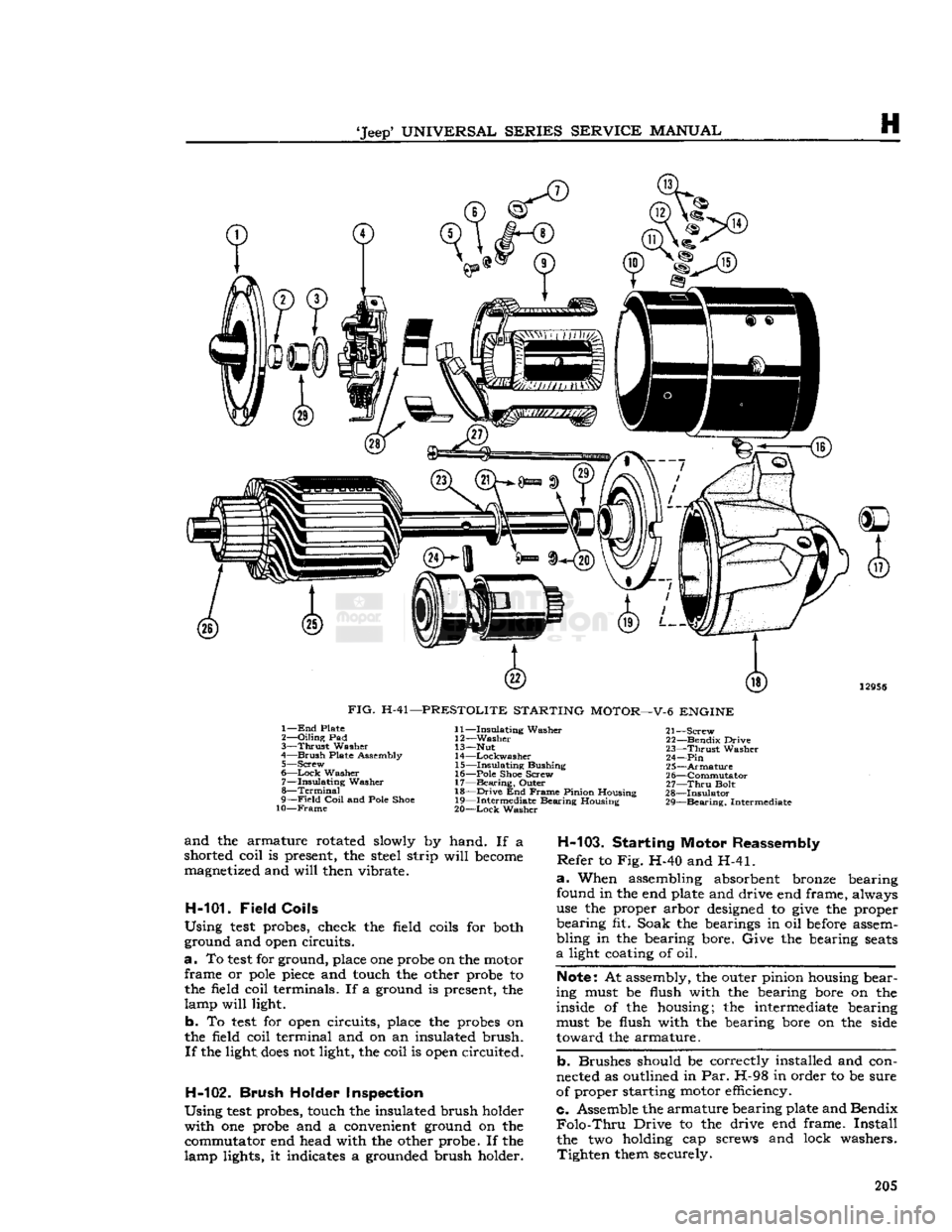

FIG.

H-41—PRESTOLITE

STARTING

MOTOR—V-6

ENGINE

1—

End

Plate

2—

Oiling

Pad

3—

Thrust

Washer

4—

Brush

Plate Assembly 5—

Screw

6—

Lock

Washer 7—

Insulating

Washer

8—

Terminal

9—

Field

Coil

and Pole Shoe

10—Frame

11—

Insulating

Washer

12—

Washer

13— Nut

14

—Lockwasher

15—

Insulating

Bushing

16— Pole Shoe Screw

17—

Bearing,

Outer

18—

Drive

End

Frame

Pinion Housing

19— Intermediate Bearing Housing

20—

Lock

Washer 21—

Screw

22— Bendix Drive

23—

Thrust

Washer

24—Pin

25—

Armature

2 6—Commutator

27—

Thru

Bolt

28—

Insulator

29—

Bearing,

Intermediate

and

the armature rotated slowly by hand. If a

shorted coil is present, the steel strip

will

become

magnetized and

will

then vibrate.

H-101-

Field

Coils

Using

test

probes, check the field coils for both

ground and

open

circuits.

a.

To

test

for ground, place one probe on the motor frame or

pole

piece

and touch the other probe to the field coil terminals. If a ground is present, the

lamp

will

light.

b.

To

test

for

open

circuits, place the probes on

the field coil terminal and on an insulated brush.

If

the light,

does

not light, the coil is

open

circuited.

H-102.

Brush

Holder Inspection

Using

test

probes, touch the insulated brush holder with one probe and a convenient ground on the commutator end head with the other probe. If the

lamp lights, it indicates a grounded brush holder.

H-103.

Starting Motor Reassembly

Refer

to Fig. H-40 and H-41.

a.

When assembling absorbent bronze bearing

found in the end plate and drive end frame, always

use the proper arbor

designed

to

give

the proper

bearing fit. Soak the bearings in oil

before

assem

bling in the bearing bore. Give the bearing

seats

a

light coating of oil.

Note:

At assembly, the outer pinion housing bear

ing must be flush with the bearing bore on the inside of the housing; the intermediate bearing

must be flush with the bearing bore on the side

toward the armature.

b.

Brushes should be correctly installed and con

nected as outlined in Par. H-98 in order to be sure

of proper starting motor efficiency.

c. Assemble the armature bearing plate and Bendix

Folo-Thru

Drive to the drive end frame.

Install

the two holding cap screws and lock washers. Tighten them securely. 205

Page 208 of 376

H

ELECTRICAL

SYSTEM

sibility

of the cable shorting at the

engine

or frame.

Remove nut and lock washer securing the ignition

wire

to the solenoid

post

and remove the two screws and lock washers securing the solenoid to

the starter frame. Remove the switch,

b.

To install the solenoid switch reverse the re

moval

procedure given above.

H-10S.

STARTING MOTOR

—

DELCO

DAUNTLESS

V-6

ENGINE

Refer

to Fig. H-45.

The

starting motor used on the Dauntless V-6 en

gine

has an integral solenoid switch and enclosed

shift lever which first shifts the overrunning clutch

pinion into

engagement

with the ring gear on the

flywheel of the

engine

and then

closes

the electrical

circuit

to cause

engine

cranking. When the

engine

starts,

the overrunning clutch

disengages

to pre vent transfer of

engine

speed to the starting motor.

Note:

Should a service replacement starter motor

be required the factory recommends replacement

with

original equipment parts; however, should the need arise an existing starter motor (Delco or

Prestolite) could be replaced with the current

Delco-Remy

starter, model 1108375, with the

following modifications to the wiring harness. If

the existing starter motor wiring harness

does

not

provide a 12 ga. purple conduit wire, (connects the ignition switch to the starter motor) then a 12 ga.

purple

conduit wire 70 inches long, must be in

stalled.

Should the existing starter motor wiring

harness

contain a 16 ga. light blue conduit wire, (connects the ignition switch and starter motor)

bend this wire back and tape out of the way.

H-109.

Starting Motor Disassembly

a.

Before removing the starting motor from the

engine, disconnect leads and cover battery lead

terminal

with piece of

hose

or tape to prevent

short circuiting.

Note

locations of wiring connec

tions to assure proper reconnection. Remove the cap screw that secures the starting motor to the

angle bracket on the side of the engine. Remove

the two cap screws that secure the drive end of

the starting motor to the cylinder block; remove

the starting motor.

b.

Remove terminal nut and disconnect field lead,

which

passes through grommet at top of motor,

from

motor terminal of solenoid. Remove two

thru

bolts

from motor. Remove commutator end frame

and

field frame assembly from solenoid and drive assembly.

e.

Pull

out pivot pins of brush holders and remove each of two brush holder and spring assemblies

from

field housing. Remove screws which attach

brushes and leads to holders.

d.

Remove armature and drive assembly from

drive

housing. Remove thrust collar from pinion

end of armature shaft. Remove leather thrust

washer

from

opposite

end of shaft.

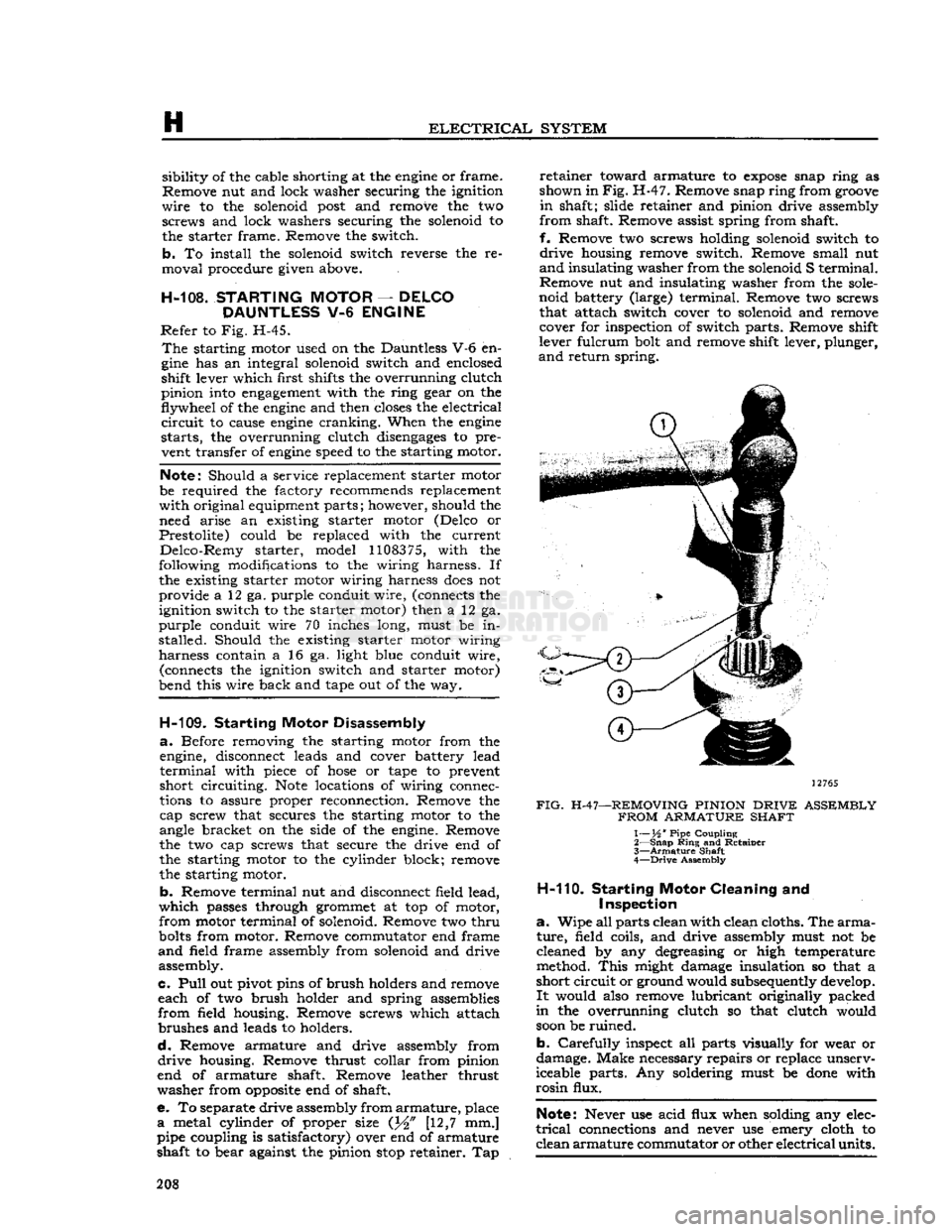

e. To separate drive assembly from

armature,

place

a

metal cylinder of proper size (J^" [12,7 mm.]

pipe coupling is satisfactory) over end of armature

shaft to bear against the pinion

stop

retainer. Tap

retainer

toward armature to

expose

snap ring as

shown in

Fig.

H-47. Remove snap ring from

groove

in

shaft; slide retainer and pinion drive assembly

from

shaft. Remove assist spring from shaft,

f.

Remove two screws holding solenoid switch to

drive

housing remove switch. Remove small nut

and

insulating washer from the solenoid S terminal.

Remove nut and insulating washer from the

sole

noid battery (large) terminal. Remove two screws that attach switch cover to solenoid and remove cover for inspection of switch parts. Remove shift

lever fulcrum bolt and remove shift lever, plunger,

and

return spring.

12765

FIG.

H-47—REMOVING PINION

DRIVE

ASSEMBLY

FROM

ARMATURE SHAFT

1— XA ' Pipe Coupling

2—

Snap

Ring

and Retainer

3—

Armature

Shaft

4—

Drive

Assembly

H-110.

Starting

Motor

Cleaning and

Inspection

a.

Wipe all parts clean with clean cloths. The

arma

ture,

field coils, and drive assembly must not be

cleaned by any degreasing or high temperature

method.

This

might damage insulation so that a

short

circuit

or ground would subsequently develop.

It

would also remove lubricant originally packed

in

the overrunning clutch so that clutch would

soon

be ruined.

b.

Carefully

inspect all parts visually for wear or

damage. Make necessary repairs or replace unserv

iceable parts. Any soldering must be

done

with

rosin

flux.

Note:

Never use acid flux when solding any elec

trical

connections and never use emery cloth to

clean

armature

commutator or other

electrical

units. 208

Page 229 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

I

Note:

The clutch release bearing is lubricated at

time of assembly and no attempt should be made

to lubricate it Refer to Fig. 1-23 when lubricating

the clutch throwout bearing collar. c. Reassembly

To

assemble the clutch to the flywheel, first put

a

small amount of light cup grease in the flywheel

pilot bushing, install the driven plate, with short

end of hub toward the flywheel, then place the pressure plate assembly in position.

With

a clutch

plate aligning arbor or a spare transmission main

shaft, align the driven plate splines leaving the

arbor

in position while tightening the pressure plate

screws evenly.

Next, assemble the flywheel housing to the

engine

and

reinstall the transmission and transfer case or

install

the

engine

in the vehicle, depending on the

procedure of removal. Make sure that the clutch

release bearing

carrier

return spring is hooked in place. For the remainder of the assembly reverse

the operations that were used in removing the

transmission and transfer case or the

engine

referring

to the instructions given in Section J for the transmission and Section D and Dl for the

engine.

d.

Adjust the clutch control cable so there is 3A" [19,05 mm.] free pedal travel. (Refer to Par. 1-3)

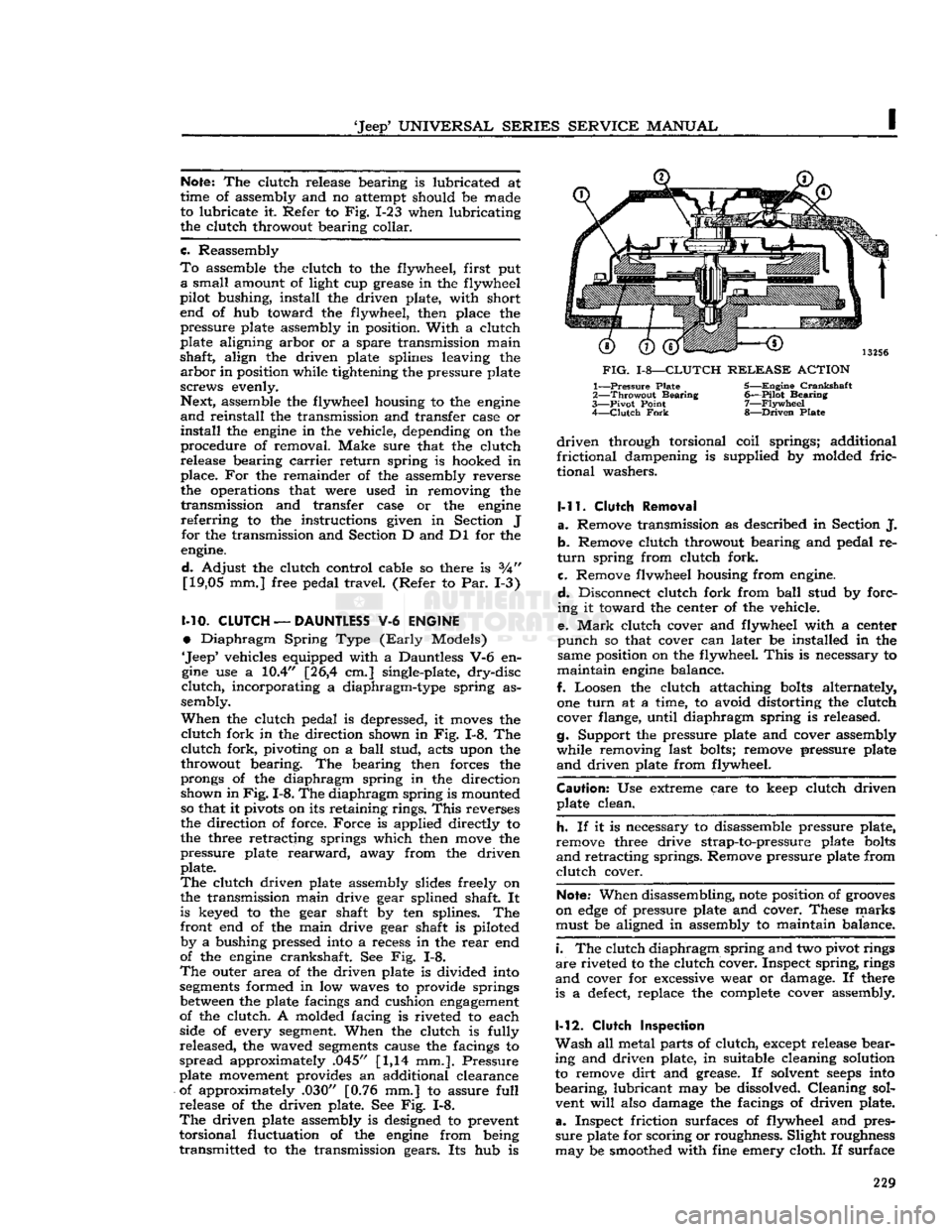

1-10.

CLUTCH

—

DAUNTLESS

V-6

ENGINE

•

Diaphragm Spring Type

(Early

Models)

*

Jeep' vehicles equipped with a Dauntless V-6 en

gine

use a 10.4" [26,4 cm.] single-plate, dry-disc

clutch,

incorporating a diaphragm-type spring as

sembly.

When

the clutch pedal is depressed, it

moves

the

clutch

fork in the direction shown in Fig. 1-8. The

clutch

fork, pivoting on a

ball

stud, acts upon the

throwout bearing. The bearing then forces the

prongs of the diaphragm spring in the direction shown in

Fig.

1-8. The diaphragm spring is mounted

so that it pivots on its retaining rings.

This

reverses

the direction of force.

Force

is applied directly to

the three retracting springs which then

move

the

pressure plate

rearward,

away from the driven plate.

The

clutch driven plate assembly slides freely on

the transmission main drive gear splined shaft. It is keyed to the gear shaft by ten splines. The

front end of the main drive gear shaft is piloted by a bushing pressed into a recess in the

rear

end

of the

engine

crankshaft. See Fig. 1-8.

The

outer area of the driven plate is divided into

segments

formed in low waves to provide springs

between

the plate facings and cushion

engagement

of the clutch. A molded facing is riveted to each

side of every

segment.

When the clutch is fully

released, the waved

segments

cause the facings to

spread

approximately .045" [1,14 mm.]. Pressure

plate movement provides an additional clearance

of approximately .030" [0.76 mm.] to assure

full

release of the driven plate. See Fig. 1-8.

The

driven plate assembly is designed to prevent

torsional fluctuation of the

engine

from being

transmitted to the transmission gears. Its hub is

FIG.

1-8—CLUTCH

RELEASE

ACTION

1—

Pressure

Plate 5—Engine

Crankshaft

2—

Throwout

Bearing

6—Pilot

Bearing

3—

Pivot

Point

7—Flywheel

4—

Clutch

Fork

8—Driven

Plate

driven

through torsional coil springs; additional

frictional

dampening is supplied by molded

fric-

tional washers.

1-11.

Clutch

Removal

a.

Remove transmission as described in Section J. b. Remove clutch throwout bearing and pedal re

turn

spring from clutch fork.

c. Remove flvwheel housing from engine.

d.

Disconnect clutch fork from

ball

stud by forc

ing it toward the center of the vehicle.

e.

Mark

clutch cover and flywheel with a center

punch

so that cover can later be installed in the same position on the flywheel.

This

is necessary to

maintain

engine

balance.

f. Loosen the clutch attaching

bolts

alternately,

one

turn

at a time, to avoid distorting the clutch

cover flange, until diaphragm spring is released.

g. Support the pressure plate and cover assembly

while removing last bolts; remove pressure plate

and

driven plate from flywheel.

Caution:

Use extreme care to keep clutch driven plate clean.

h.

If it is necessary to disassemble pressure plate,

remove three drive strap-to-pressure plate

bolts

and

retracting springs. Remove pressure plate from

clutch

cover.

Note:

When disassembling,

note

position of

grooves

on

edge

of pressure plate and cover. These marks must be aligned in assembly to maintain balance.

i.

The clutch diaphragm spring and two pivot rings

are

riveted to the clutch cover. Inspect spring, rings

and

cover for excessive wear or damage. If there

is a

defect,

replace the complete cover assembly.

1-12.

Clutch

inspection

Wash

all metal parts of clutch, except release bear

ing and driven plate, in suitable cleaning solution to remove

dirt

and grease. If solvent

seeps

into

bearing,

lubricant may be dissolved. Cleaning sol

vent

will

also damage the facings of driven plate,

a.

Inspect friction surfaces of flywheel and pres

sure

plate for scoring or roughness. Slight roughness

may be smoothed with fine emery cloth. If surface 229

Page 230 of 376

CLUTCH

is deeply scored or grooved, the part should be

replaced.

b. Inspect driven plate for wear or damage to fac

ings,

loose

rivets, broken or

loose

torsion springs,

and

flattened cushion springs. If facings are worn

near

rivets or are oily, replace the plate assembly.

A

slight amount of oil on clutch facings

will

cause

clutch

grab and chatter; excessive oil on facings

will

cause slippage. It is not practical to remove

oil

with solvents or by buffing since oil

will

con

tinue to bleed from facing material when hot. If

oil

is found on driven plate facings, examine trans

mission drainback hole, pilot bushing,

engine

rear

main

bearing and other points of possible oil leakage. Test the fit of driven plate hub on trans

mission main drive gear for an easy sliding fit.

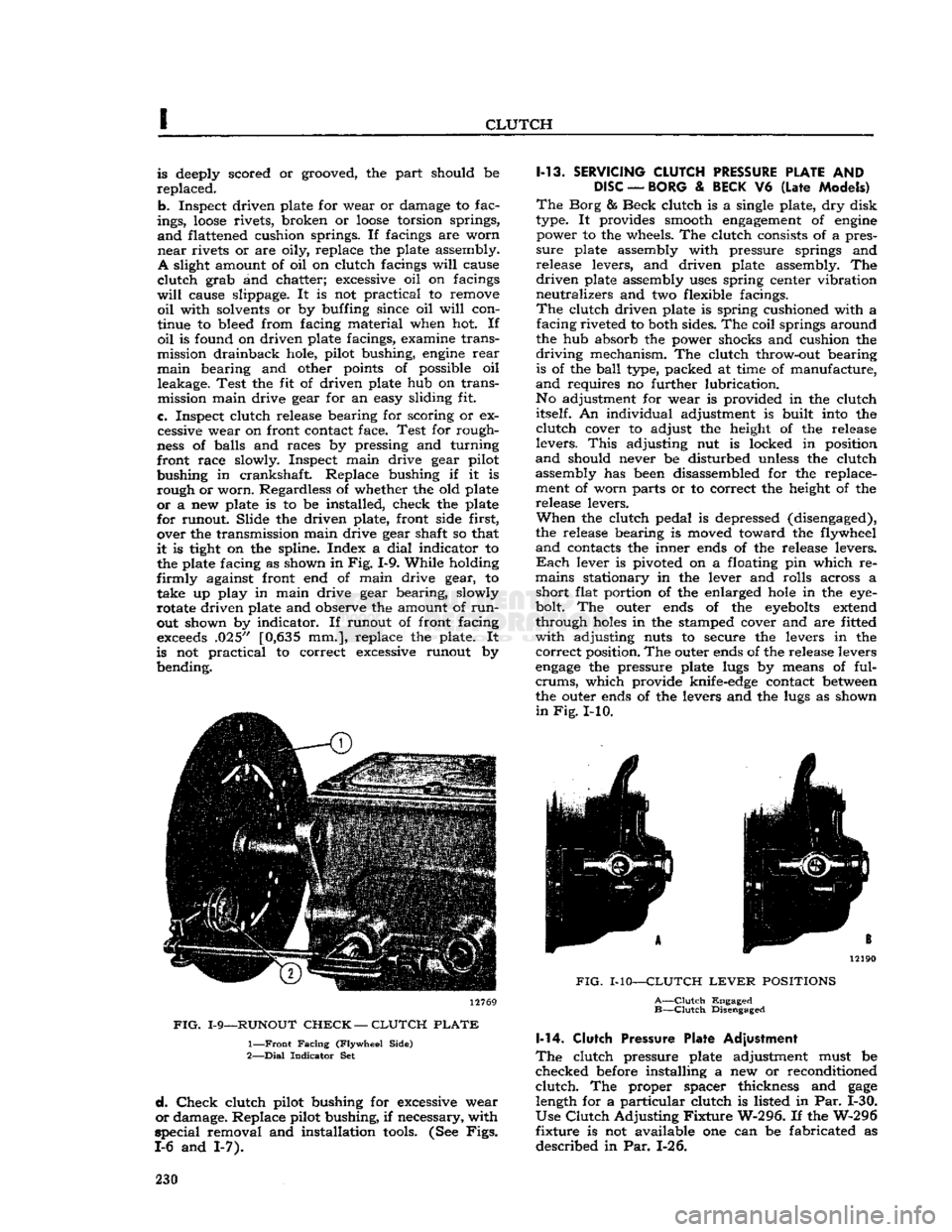

c. Inspect clutch release bearing for scoring or ex cessive wear on front contact face. Test for rough

ness

of balls and races by pressing and turning

front race slowly. Inspect main drive gear pilot

bushing in crankshaft. Replace bushing if it is rough or worn. Regardless of whether the old plate

or

a new plate is to be installed, check the plate

for runout. Slide the driven plate, front side first,

over the transmission main drive gear shaft so that

it

is tight on the spline. Index a

dial

indicator to the plate facing as shown in

Fig.

1-9. While holding

firmly

against front end of main drive gear, to take up play in main drive gear bearing, slowly

rotate driven plate and observe the amount of

run

out shown by indicator. If runout of front facing

exceeds

.025" [0,635 mm.], replace the plate. It

is not practical to correct excessive runout by bending. 12769

FIG.

1-9—RUNOUT

CHECK

—

CLUTCH

PLATE

1—

Front

Facing

(Flywheel

Side)

2—

Dial

Indicator

Set

d.

Check

clutch pilot bushing for excessive wear

or

damage. Replace pilot bushing, if necessary, with

special

removal and installation

tools.

(See

Figs.

1-6 and 1-7). 1-13.

SERVICING

CLUTCH

PRESSURE

PLATE

AND

DISC

—

BORG

&

BECK

V6

(Late

Models)

The

Borg & Beck clutch is a single plate, dry disk

type. It provides smooth

engagement

of

engine

power to the wheels. The clutch consists of a pres

sure

plate assembly with pressure springs and

release levers, and driven plate assembly. The

driven

plate assembly

uses

spring center vibration

neutralizes and two flexible facings.

The

clutch driven plate is spring cushioned with a facing riveted to both sides. The coil springs around

the hub absorb the power shocks and cushion the

driving

mechanism. The clutch throw-out bearing is of the

ball

type, packed at time of manufacture,

and

requires no further lubrication.

No adjustment for wear is provided in the clutch itself. An individual adjustment is built into the

clutch

cover to adjust the height of the release

levers.

This

adjusting nut is locked in position

and

should never be disturbed unless the clutch assembly has been disassembled for the replace

ment of worn parts or to correct the height of the release levers.

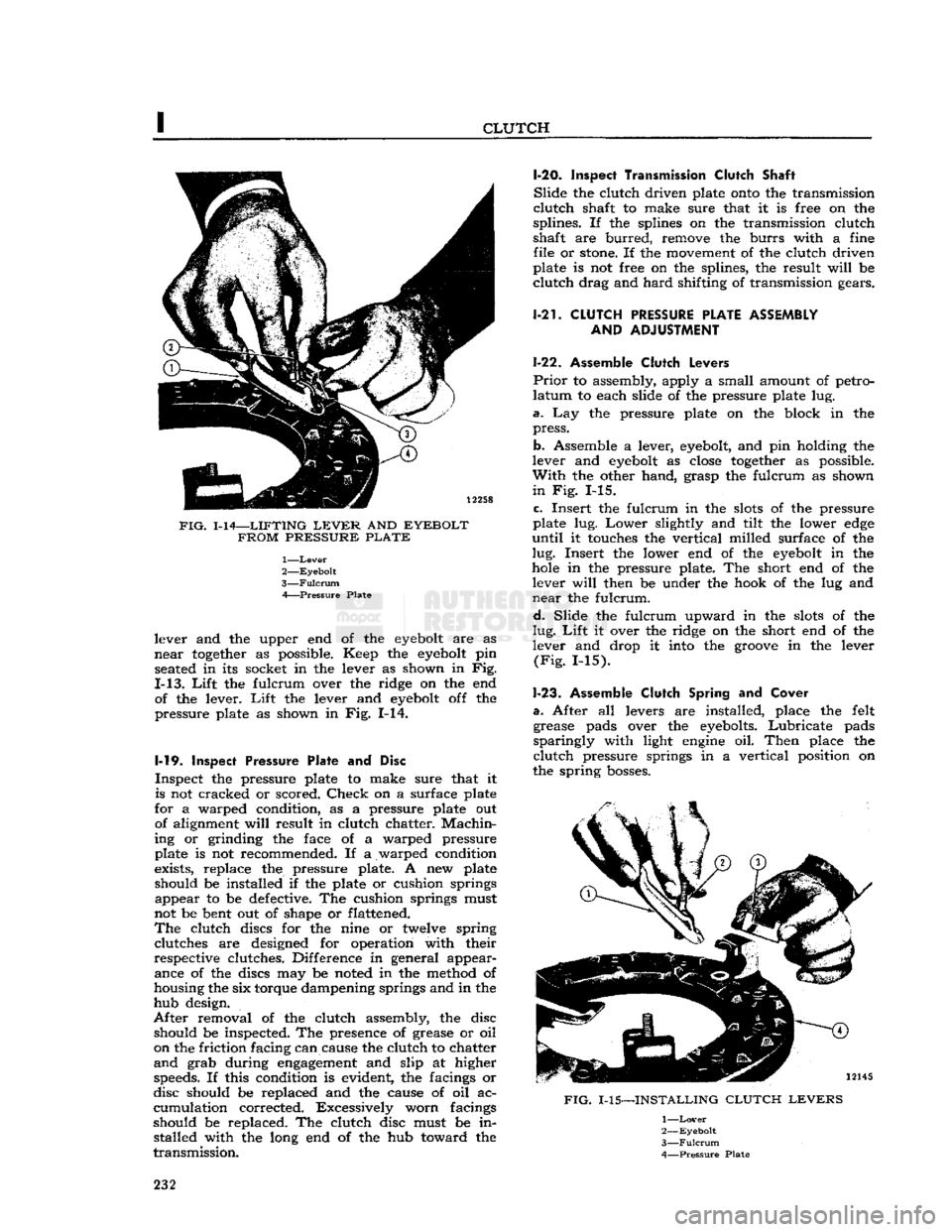

When

the clutch pedal is depressed (disengaged),

the release bearing is moved toward the flywheel

and

contacts the inner ends of the release levers.

Each

lever is pivoted on a floating pin which re

mains stationary in the lever and rolls across a short flat portion of the enlarged

hole

in the eye-

bolt. The outer ends of the

eyebolts

extend

through

holes

in the stamped cover and are fitted

with

adjusting nuts to secure the levers in the

correct

position. The outer ends of the release levers

engage

the pressure plate lugs by means of ful-

crums,

which provide knife-edge contact

between

the outer ends of the levers and the lugs as shown

in

Fig.

I-10. 12190

FIG.

MO—CLUTCH

LEVER

POSITIONS

A—Clutch

Engaged

B—Clutch

Disengaged 1-14.

Clutch

Pressure Plate Adjustment

The

clutch pressure plate adjustment must be

checked before installing a new or reconditioned

clutch.

The proper spacer thickness and

gage

length for a particular clutch is listed in Par. 1-30.

Use

Clutch

Adjusting

Fixture

W-296. If the W-296

fixture is not available one can be fabricated as

described in Par. 1-26. 230

Page 232 of 376

CLUTCH

FIG.

1-14—LIFTING

LEVER

AND

EYEBOLT FROM PRESSURE PLATE

1—

Lever

2—

Eyebolt

3—

Fulcrum

A Pressure Plate

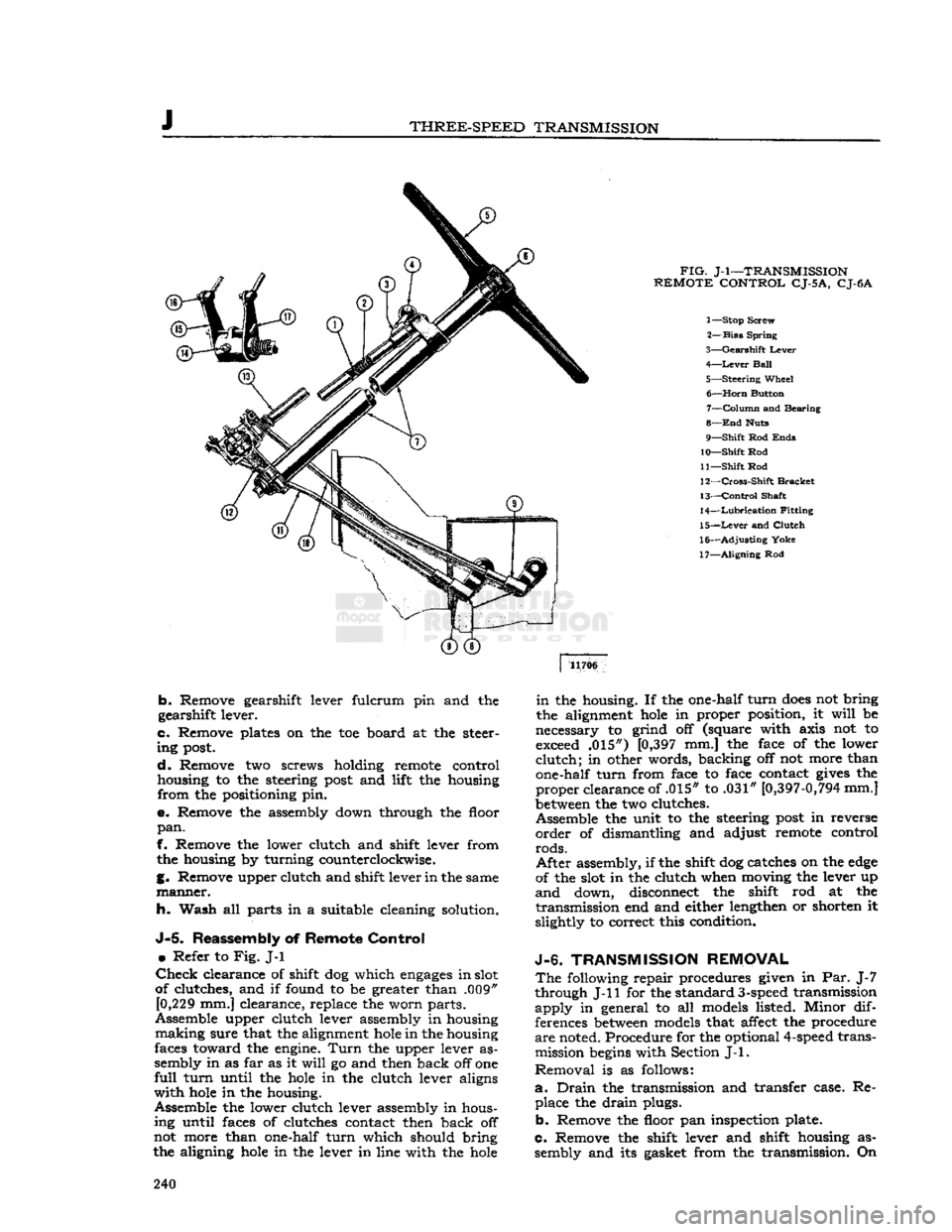

lever and the upper end of the

eyebolt

are as

near

together

as possible. Keep the

eyebolt

pin seated in its socket in the lever as shown in Fig.

1-13.

Lift

the fulcrum over the ridge on the end of the lever.

Lift

the lever and

eyebolt

off the

pressure plate as shown in Fig. 1-14.

1-19.

Inspect

Pressure Plate and Disc

Inspect the pressure plate to make sure that it is not cracked or scored.

Check

on a surface plate

for a warped condition, as a pressure plate out of alignment

will

result in clutch chatter.

Machin

ing or grinding the face of a warped pressure

plate is not recommended. If a warped condition

exists, replace the pressure plate. A new plate

should be installed if the plate or cushion springs appear to be defective. The cushion springs must

not be bent out of shape or flattened.

The

clutch discs for the nine or twelve spring clutches are designed for operation with their

respective clutches. Difference in general appear ance of the discs may be noted in the method of

housing the six torque dampening springs and in the

hub design.

After

removal of the clutch assembly, the disc should be inspected. The presence of grease or oil

on the friction facing can cause the clutch to chatter

and

grab during

engagement

and slip at higher speeds. If this condition is evident, the facings or

disc should be replaced and the cause of oil ac

cumulation corrected. Excessively worn facings

should be replaced. The clutch disc must be in stalled with the long end of the hub toward the

transmission.

1-20.

Inspect Transmission Clutch

Shaft

Slide

the clutch driven plate

onto

the transmission

clutch

shaft to make sure that it is free on the

splines. If the splines on the transmission clutch

shaft are

burred,

remove the

burrs

with a fine file or

stone.

If the movement of the clutch driven

plate is not free on the splines, the result

will

be

clutch

drag and

hard

shifting of transmission gears.

1-21.

CLUTCH

PRESSURE

PLATE ASSEMBLY AND

ADJUSTMENT

1-22. Assemble

Clutch

Levers

Prior

to assembly, apply a small amount of petro

latum

to each slide of the pressure plate lug.

a.

Lay the pressure plate on the block in the

press.

b. Assemble a lever,

eyebolt,

and pin holding the

lever and

eyebolt

as

close

together

as possible.

With

the other hand, grasp the fulcrum as shown

in

Fig. 1-15.

c.

Insert the fulcrum in the

slots

of the pressure

plate lug.

Lower

slightly and tilt the lower

edge

until

it touches the vertical milled surface of the

lug.

Insert the lower end of the

eyebolt

in the

hole

in the pressure plate. The short end of the lever

will

then be under the hook of the lug and

near

the fulcrum.

d.

Slide the fulcrum upward in the

slots

of the

lug.

Lift

it over the ridge on the short end of the

lever and drop it into the

groove

in the lever

(Fig.

1-15).

1-23.

Assemble

Clutch

Spring and

Cover

a.

After all levers are installed, place the felt grease pads over the eyebolts.

Lubricate

pads

sparingly

with light

engine

oil.

Then

place the

clutch

pressure springs in a vertical position on

the spring

bosses.

FIG.

1-15—INSTALLING

CLUTCH LEVERS

1—

Lover

2—

Eyebolt

3—

Fulcrum

4—

Pressure

Plate

232

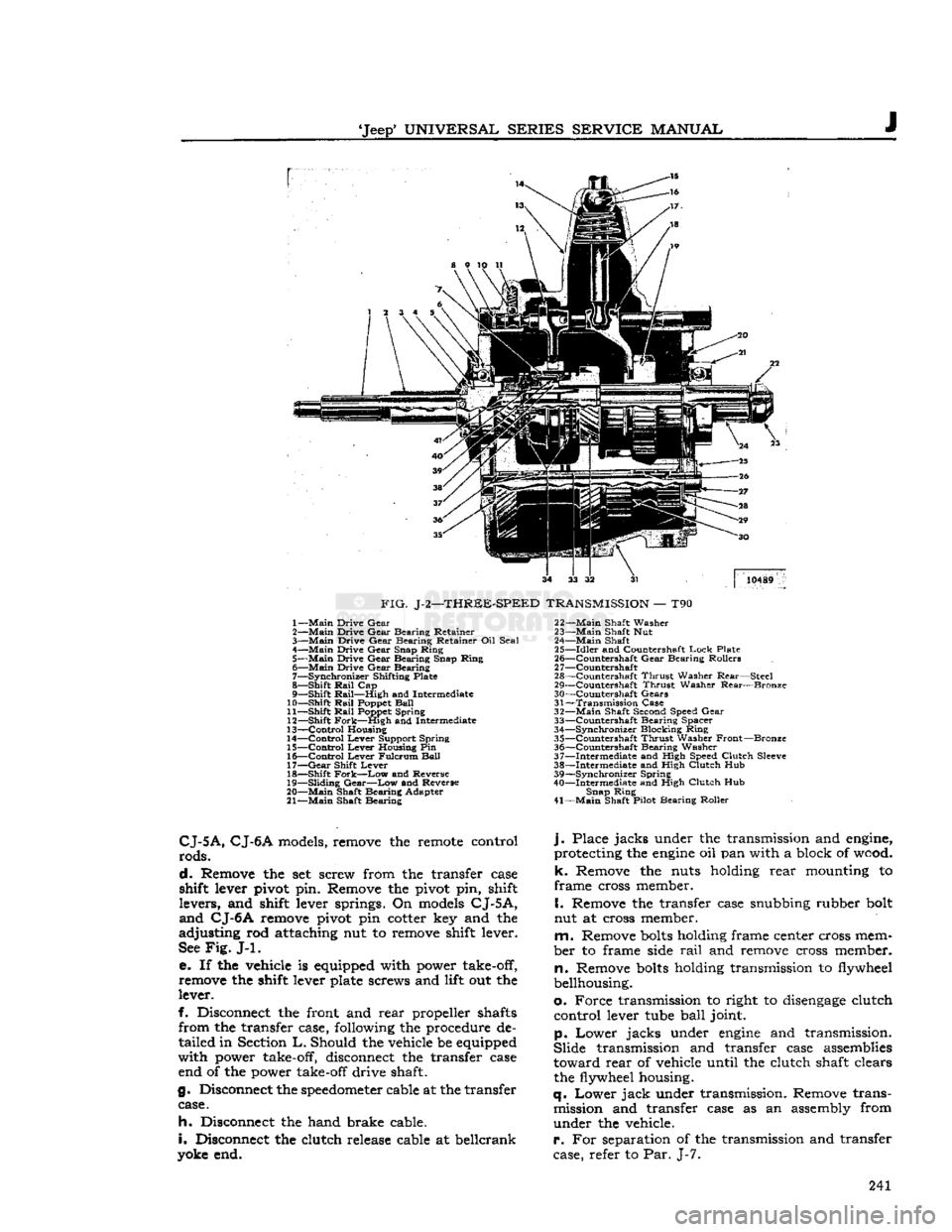

Page 240 of 376

THREE-SPEED

TRANSMISSION

FIG.

J-l—TRANSMISSION

REMOTE

CONTROL

CJ-5

A,

CJ-6A

1— Stop Screw

2—

Bias

Spring

3—

Gearshift

Lever

4—

Lever

Ball

5—

Steering

Wheel 6—

Horn

Button 7—

Column

and Bearing

8—

End

Huts

9—

Shift

Rod

Ends

10—

Shift

Rod

11—

Shift

Rod

12—

Cross-Shift

Bracket

13—

Control

Shaft

14—

Lubrication

Fitting

15—

Lever

and

Clutch

16—

Adjusting

Yoke

17—

Aligning

Rod 11706

b.

Remove gearshift lever fulcrum pin and the

gearshift lever.

c.

Remove plates on the toe board at the steer

ing

post.

d.

Remove two screws holding remote control

housing to the steering

post

and lift the housing

from

the positioning pin.

e.

Remove the assembly down through the floor

pan.

f. Remove the lower clutch and shift lever from the housing by turning counterclockwise.

g. Remove upper clutch and shift lever in the same

manner.

h. Wash all parts in a suitable cleaning solution.

J-5.

Reassembly of

Remote

Control

•

Refer to

Fig.

J-l

Check

clearance of shift dog which

engages

in slot

of clutches, and if found to be greater than .009" [0,229 mm.] clearance, replace the worn parts.

Assemble upper clutch lever assembly in housing

making

sure that the alignment

hole

in the housing

faces toward the engine.

Turn

the upper lever as

sembly in as far as it

will

go and then back off one

full

turn

until the

hole

in the clutch lever aligns

with

hole

in the housing.

Assemble the lower clutch lever assembly in hous ing until faces of clutches contact then back off

not more than one-half

turn

which should bring

the aligning

hole

in the lever in line with the

hole

in

the housing. If the one-half

turn

does

not bring

the alignment

hole

in proper position, it

will

be

necessary to grind off (square with axis not to exceed .015") [0,397 mm.] the face of the lower

clutch;

in other words, backing off not more than

one-half

turn

from face to face contact

gives

the

proper

clearance of .015" to .031"

[0,397-0,794

mm.]

between

the two clutches.

Assemble the unit to the steering

post

in reverse

order

of dismantling and adjust remote control

rods.

After

assembly, if the shift dog catches on the

edge

of the slot in the clutch when moving the lever up

and

down, disconnect the shift rod at the

transmission

end and either lengthen or shorten it

slightly to correct this condition.

J-6.

TRANSMISSION

REMOVAL

The

following repair procedures given in Par. J-7

through J-ll for the standard

3-speed

transmission

apply

in general to all models listed. Minor dif

ferences

between

models that affect the procedure

are

noted. Procedure for the optional

4-speed

transmission

begins

with Section

J-l.

Removal

is as follows:

a.

Drain

the transmission and transfer case. Re place the

drain

plugs.

b.

Remove the floor pan inspection plate.

c.

Remove the shift lever and shift housing as sembly and its gasket from the transmission. On 240

Page 241 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

J

10489

FIG.

J-2—THREE-SPEED

TRANSMISSION

— T90 1—

Main

Drive

Gear

2—

Main

Drive

Gear

Bearing

Retainer

3—

Main

Drive

Gear

Bearing

Retainer Oil

Seal

4—

Main

Drive

Gear

Snap

Ring

5—

Main

Drive

Gear

Bearing

Snap

Ring

6—

Main

Drive

Gear

Bearing

7—

Synchronizer

Shifting Plate

8—

Shift

Rail

Cap

9—

Shift

Rail—High

and Intermediate

10—

Shift

Rail

Poppet

Ball

11—

Shift

Rail

Poppet

Spring

12—

Shift

Fork—High

and Intermediate

13—

Control

Housing

14—

Control

Lever

Support

Spring

15—

Control

Lever

Housing Pin

16—

Control

Lever

Fulcrum

Ball

17—

Gear

Shift

Lever

18—

Shift

Fork—Low

and Reverse

19—

Sliding

Gear—Low

and Reverse

20—

Main

Shaft

Bearing

Adapter

21—

Main

Shaft

Bearing

22—

Main

Shaft

Washer

23—

Main

Shaft Nut

24—

Main

Shaft

25—

Idler

and Countershaft

Lock

Plate

26—

^Countershaft

Gear

Bearing

Rollers

2

7—Countershaft

28—

Countershaft

Thrust

Washer

Rear—Steel

29—

Countershaft

Thrust

Washer

Rear—Bronze

30—

Countershaft

Gears

31—

Transmission

Case

32—

Main

Shaft Second Speed

Gear

33—

Countershaft

Bearing

Spacer

34—

Synchronizer

Blocking

Ring

35—

Countershaft

Thrust

Washer

Front—Bronze

36—

Countershaft

Bearing

Washer

37—

Intermediate

and High Speed

Clutch

Sleeve

38—

Intermediate

and High

Clutch

Hub

39—

Synchronizer

Spring

40—

Intermediate

and High

Clutch

Hub

Snap

Ring

41—

Main

Shaft Pilot

Bearing

Roller

CJ-5A,

CJ-6A

models, remove the remote control

rods.

d.

Remove the set screw from the transfer case

shift lever pivot pin. Remove the pivot pin, shift

levers,

and shift lever springs. On models

CJ-5A,

and

CJ-6A

remove pivot pin cotter key and the

adjusting

rod attaching nut to remove shift lever.

See

Fig.

J-l.

e. If the vehicle is equipped with power take-off,

remove the shift lever plate screws and lift out the

lever.

f. Disconnect the front and

rear

propeller shafts

from

the transfer case, following the procedure de

tailed

in Section

L.

Should the vehicle be equipped

with

power take-off, disconnect the transfer case end of the power take-off drive shaft.

g. Disconnect the

speedometer

cable at the transfer case.

h.

Disconnect the hand brake cable.

i.

Disconnect the clutch release cable at beilcrank

yoke end.

j.

Place

jacks

under the transmission and engine,

protecting the

engine

oil pan with a block of wood,

k.

Remove the nuts holding

rear

mounting to

frame

cross member.

I.

Remove the transfer case snubbing rubber bolt

nut at cross member.

m.

Remove

bolts

holding frame center cross mem

ber

to frame side

rail

and remove cross member,

n.

Remove

bolts

holding transmission to flywheel

bellhousing.

o.

Force

transmission to right to

disengage

clutch

control

lever tube

ball

joint.

p.

Lower

jacks

under

engine

and transmission.

Slide

transmission and transfer case assemblies

toward

rear

of vehicle until the clutch shaft clears the flywheel housing.

q.

Lower

jack

under transmission. Remove trans mission and transfer case as an assembly from

under

the vehicle.

r.

For separation of the transmission and transfer

case, refer to Par. J-7. 241

Page 245 of 376

'Jeep*

UNIVERSAL

SERIES'

SERVICE

MANUAL

lightly

on the end of the

mainshaft

to

loosen

the

gear

and

separate

the two

units.

J-8.

Disassembly

—

T90,

T86AA

®

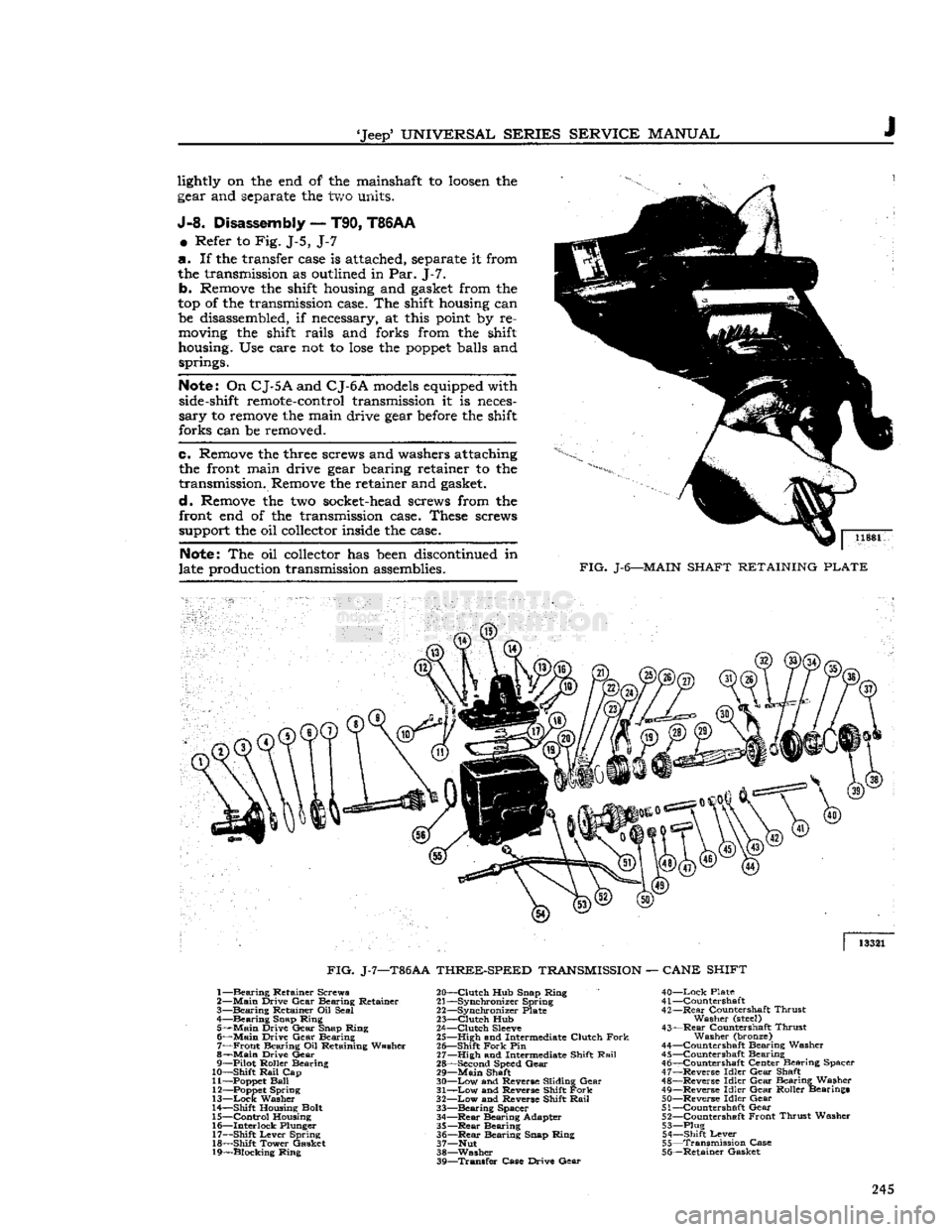

Refer to Fig. J-5, J-7

a. If the transfer

case

is

attached,

separate

it from

the

transmission

as

outlined

in Par. J-7. b.

Remove

the

shift

housing

and

gasket

from the

top of the

transmission

case.

The

shift

housing

can

be

disassembled,

if

necessary,

at

this

point

by re

moving

the

shift

rails and forks from the

shift

housing.

Use care not to

lose

the

poppet

balls

and

springs.

Note;

On

CJ-5

A

and

C

J-6A

models

equipped

with

side-shift

remote-control

transmission

it is

neces

sary to

remove

the main drive

gear

before

the

shift

forks can be

removed.

e.

Remove

the

three

screws

and

washers

attaching

the

front

main drive

gear

bearing

retainer to the

transmission.

Remove

the retainer and

gasket,

d.

Remove

the two

socket-head

screws

from the

front

end of the

transmission

case.

These

screws

support

the oil

collector

inside

the

case.

Note:

The oil

collector

has

been

discontinued

in

late

production

transmission

assemblies.

11881

FIG.

J-6—MAIN

SHAFT

RETAINING

PLATE

13321

FIG.

J-7—T86AA

THREE-SPEED

TRANSMISSION

—

CANE

SHIFT

1—

Bearing

Retainer Screws

2—

Main

Drive Gear Bearing Retainer

3—

Bearing

Retainer Oil Seal

,

4—Bearing Snap Ring

5—

Main

Drive Gear Snap Ring 6—

Main

Drive Gear Bearing 7—

Front

Bearing Oil Retaining Washer

8—

Main

Drive Gear

9— Pilot Roller Bearing

10— Shift

Rail

Cap

11—

Poppet

Ball

12—

Poppet

Spring

13—

Lock

Washer

14— Shift Housing Bolt

15—

Control

Housing 16— Interlock Plunger

17— Shift Lever Spring

18— Shift Tower Gasket

19— Blocking Ring 20—

Clutch

Hub Snap Ring

21— Synchronizer Spring

22— Synchronizer Plate

23—

Clutch

Hub

24—

Clutch

Sleeve

25— High and Intermediate Clutch

Fork

26— Shift

Fork

Pin

27— High and Intermediate Shift

Rail

28— Second Speed Gear 29—

Main

Shaft

30—

Low

and Reverse Sliding Gear

31—

Low

and Reverse Shift

Fork

32—

Low

and Reverse Shift

Rail

33—

Bearing

Spacer

34—

—Rear

Bearing Adapter

35—Rear

Bearing 36—

Rear

Bearing Snap Ring

37— Nut

38—Washer 39—

Transfer

Case Drive Gear

40—Lock

Plate

41 —Countershaft

42—

Rear

Countershaft Thrust Washer

(steel)

43—

Rear

Countershaft Thrust Washer (bronze)

44— Countershaft Bearing Washer

45— Countershaft Bearing 46— Countershaft Center Bearing Spacer

47— Reverse Idler Gear Shaft

48— Reverse Idler Gear Bearing Washer

49— Reverse Idler Gear Roller Bearings 50— Reverse Idler Gear

51— Countershaft Gear 52— Countershaft Front Thrust Washer

53— Plug 54— Shift Lever

55—

Transmission

Case

56— Retainer Gasket 245

Page 246 of 376

J

THREE-SPEED

TRANSMISSION

FIG.

J-8—SHAFT

LOCK

PLATE

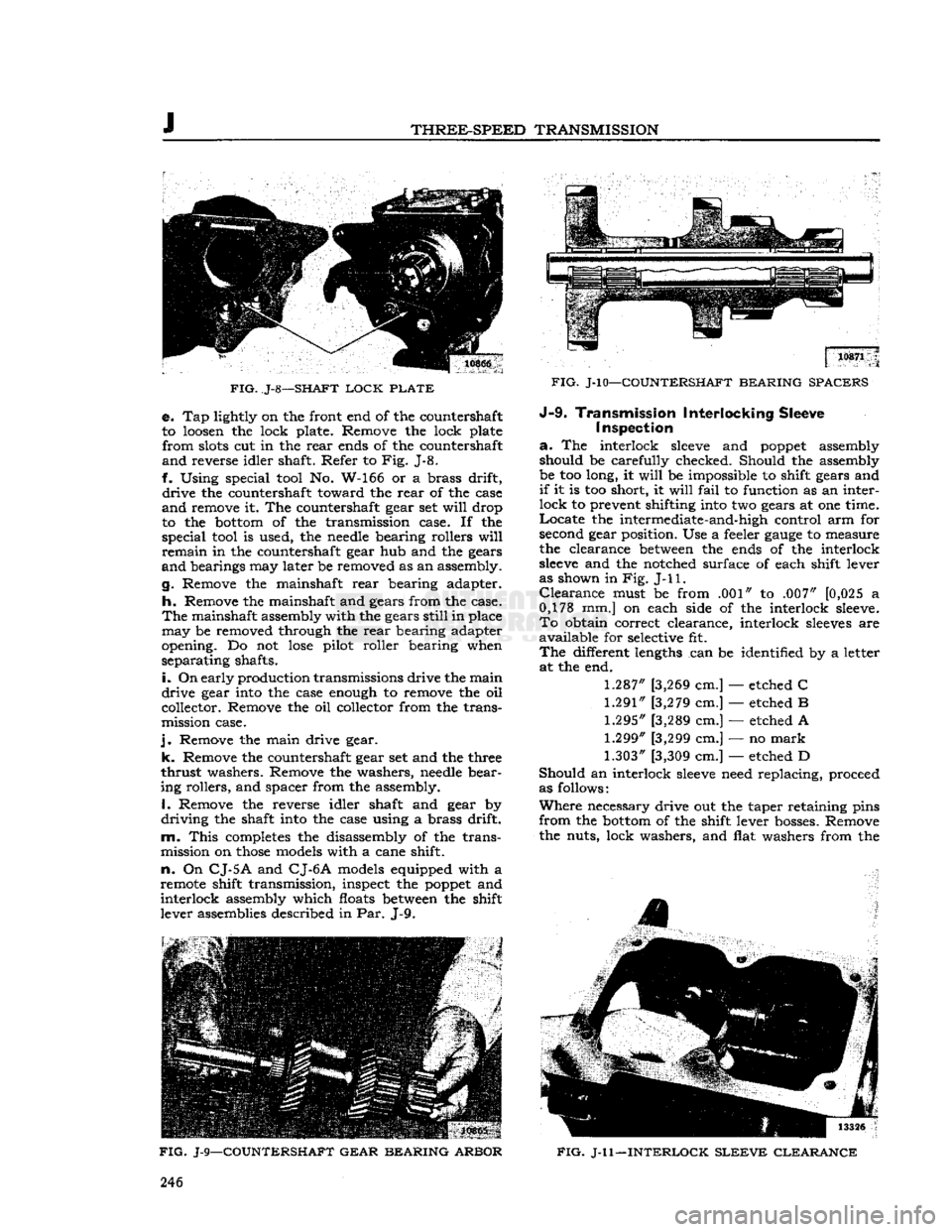

e. Tap lightly on the front end of the countershaft

to loosen the lock plate. Remove the lock plate

from

slots cut in the

rear

ends of the countershaft

and

reverse idler shaft. Refer to Fig. J-8.

f. Using special tool No. W-166 or a brass drift,

drive

the countershaft toward the

rear

of the case

and

remove it. The countershaft gear set

will

drop

to the bottom of the transmission case. If the

special

tool is used, the needle bearing rollers

will

remain

in the countershaft gear hub and the gears

and

bearings may later be removed as an assembly.

g. Remove the mainshaft

rear

bearing adapter.

h.

Remove the mainshaft and gears from the case.

The

mainshaft assembly with the gears

still

in place

may

be removed through the

rear

bearing adapter

opening. Do not

lose

pilot roller bearing when

separating

shafts.

i.

On

early production transmissions drive the main

drive

gear into the case enough to remove the oil

collector. Remove the oil collector from the trans

mission case.

j.

Remove the main drive gear,

k.

Remove the countershaft gear set and the three

thrust

washers. Remove the washers, needle bear

ing rollers, and spacer from the assembly. 1, Remove the reverse idler shaft and gear by

driving

the shaft into the case using a brass drift,

m.

This

completes the disassembly of the trans

mission on

those

models with a cane shift,

n.

On

CJ-5

A

and

CJ-6 A

models equipped with a

remote shift transmission, inspect the poppet and

interlock

assembly which floats between the shift

lever assemblies described in Par. J-9.

FIG.

J-9—COUNTERSHAFT GEAR BEARING ARBOR

FIG.

J-l0—COUNTERSHAFT BEARING SPACERS J-9-

Transmission Interlocking Sleeve

I

inspection

a.

The interlock

sleeve

and poppet assembly should be carefully checked. Should the assembly

be too long, it

will

be impossible to shift gears and

if

it is too short, it

will

fail

to function as an inter

lock

to prevent shifting into two gears at one time.

Locate

the intermediate-and-high control arm for

second gear position. Use a feeler

gauge

to measure

the clearance between the ends of the interlock

sleeve

and the notched surface of each shift lever

as shown in Fig.

J-l

1.

Clearance

must be from .001" to .007" [0,025 a

0,178 mm.] on each side of the interlock sleeve.

To

obtain correct clearance, interlock

sleeves

are

available

for selective fit.

The

different lengths can be identified by a letter at the end.

1.287"

[3,269 cm.] — etched C

1.291"

[3,279 cm.] — etched B

1.295"

[3,289 cm.] — etched A

1.299"

[3,299 cm.] — no

mark

1.303"

[3,309 cm.] — etched D

Should

an interlock

sleeve

need replacing, proceed

as follows:

Where

necessary drive out the taper retaining pins

from

the bottom of the shift lever bosses. Remove

the nuts, lock washers, and flat washers from the

4

FIG.

J-l 1—INTERLOCK

SLEEVE

CLEARANCE

246