spark plugs JEEP CJ 1953 Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 186 of 376

ELECTRICALJ

SYSTEM

d.

Inspect for

excessive

wear

between

centrifugal

weights

and advance cam and pivot pins.

Turn

weight

base plate in a clockwise direction until

weights

are fully extended. Release and allow

springs to return

weights

to

retard

position. Repeat several times. Springs should return

weights

to

stop

without sticking and there should be no

excessive

free

movement

in the

retard

position. Inspect

springs for distortion and fatigue.

e. Inspect cam

lobes

for scoring or

excessive

wear.

Check

weight

base plate for binding or

excessive

looseness

on distributor shaft.

f.

Check

breaker plate for

excessive

looseness

on

outside

diameter of upper distributor shaft bushing.

Check

breaker plate ground lead for poor

spot

we

Id

at plate end and for

loose

or frayed terminal con

nections.

g.

Check

for

excessive

wear

between

distributor

shaft and bushings in housing. Inspect shaft for distortion. Inspect gear for scoring of

teeth

or

excessive

wear.

h.

Inspect rod end of vacuum advance mechanism

for

excessive

wear. Push rod

into

unit as far as

possible, hold finger tightly over nipple, then re

lease

rod. After about 15 seconds, remove finger

from nipple, and

notice

if air is drawn

into

unit.

If

not, diaphragm is leaking and unit must be

replaced.

H-29.

Distributor Reassembly

Refer

to Fig. H-l5.

a.

Install

distributor

primary

lead and rubber grommet in distributor housing. Mount vacuum

advance unit on housing with two

slotted

attaching

screws; insert ground lead terminal of breaker plate under outer mounting screw.

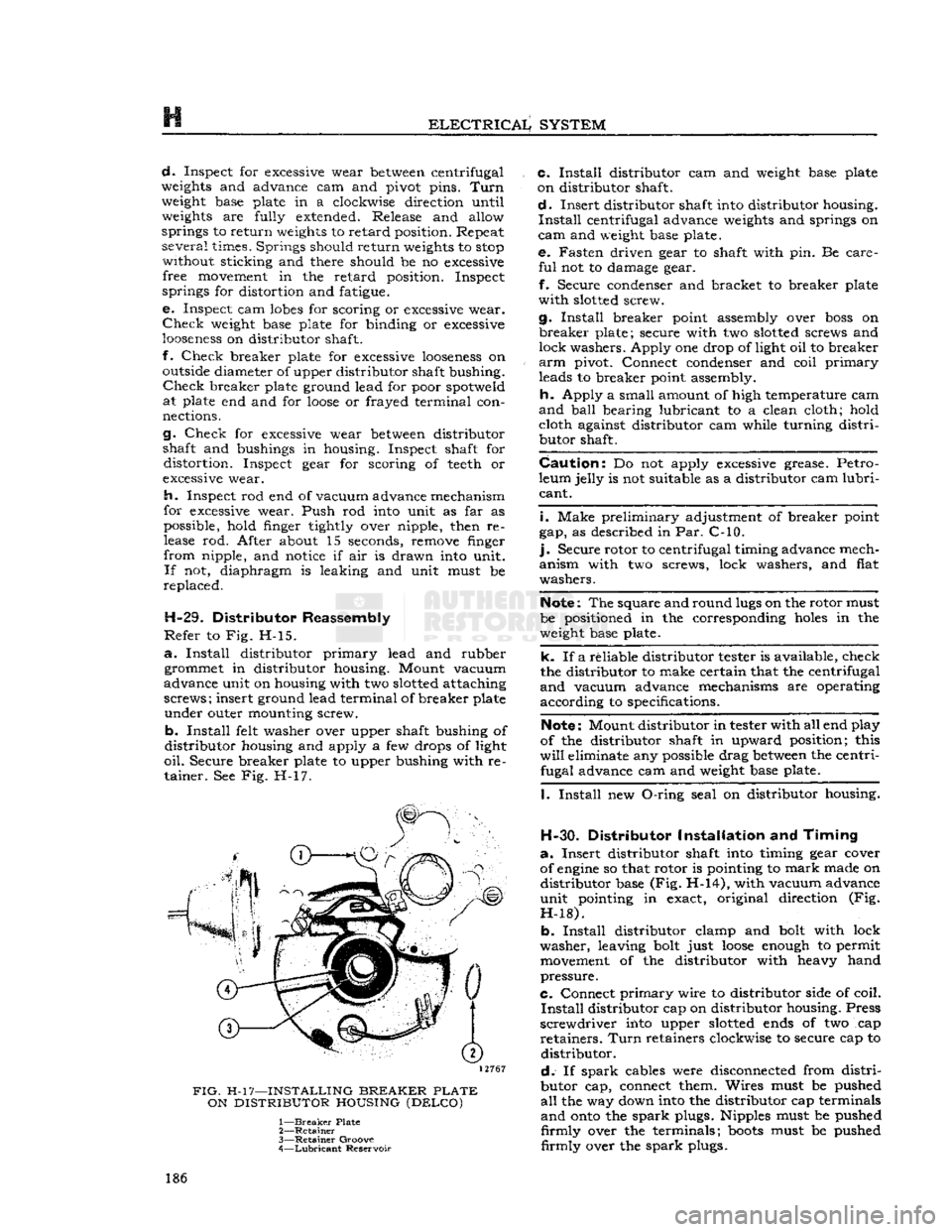

b.

Install

felt

washer over upper shaft bushing of

distributor housing and apply a few drops of light

oil.

Secure breaker plate to upper bushing with re tainer. See Fig. H-17.

12767

FIG.

H-17—INSTALLING

BREAKER

PLATE

ON

DISTRIBUTOR

HOUSING

(DELCO)

1—

Breaker

Plate

2—

Retainer

3—

Retainer

Groove

4—

Lubricant

Reservoir c.

Install

distributor cam and

weight

base plate

on distributor shaft.

d.

Insert distributor shaft

into

distributor housing.

Install

centrifugal advance

weights

and springs on

cam

and

weight

base plate. e. Fasten driven gear to shaft with pin. Be care

ful

not to damage gear.

f.

Secure condenser and bracket to breaker plate

with

slotted

screw.

g.

Install

breaker point assembly over

boss

on

breaker

plate; secure with two

slotted

screws and

lock washers. Apply one drop of light oil to breaker

arm

pivot. Connect condenser and coil

primary

leads to breaker point assembly.

h.

Apply a small amount of high temperature cam

and

ball

bearing lubricant to a clean cloth; hold cloth against distributor cam while turning

distri

butor shaft.

Caution:

Do not apply

excessive

grease. Petro

leum jelly is not suitable as a distributor cam

lubri

cant.

i.

Make preliminary adjustment of breaker point

gap, as described in Par. C-10.

].

Secure rotor to centrifugal timing advance mech

anism with two screws, lock washers, and flat

washers.

Note:

The square and round

lugs

on the rotor must

be positioned in the corresponding

holes

in the

weight

base plate.

k. If a reliable distributor tester is available, check

the distributor to make certain that the centrifugal

and

vacuum advance mechanisms are operating

according to specifications.

Note:

Mount distributor in tester with all end play

of the distributor shaft in upward position; this

will

eliminate any possible drag

between

the centri fugal advance cam and

weight

base plate.

I.

Install

new

O-ring

seal on distributor housing.

H-30.

Distributor

Installation

and

Timing

a.

Insert distributor shaft

into

timing gear cover

of

engine

so that rotor is pointing to

mark

made on distributor base (Fig. H-14), with vacuum advance

unit pointing in exact, original direction (Fig.

H-18).

b.

Install

distributor clamp and

bolt

with lock

washer, leaving

bolt

just

loose

enough

to permit

movement

of the distributor with heavy hand

pressure.

C.

Connect

primary

wire to distributor side of coil.

Install

distributor cap on distributor housing. Press

screwdriver

into

upper

slotted

ends

of two cap

retainers.

Turn

retainers clockwise to secure cap to distributor.

d.

If

spark

cables were disconnected from

distri

butor cap, connect them. Wires must be pushed

all

the way down

into

the distributor cap terminals

and

onto

the

spark

plugs. Nipples must be pushed

firmly

over the terminals;

boots

must be pushed

firmly

over the

spark

plugs. 186

Page 187 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

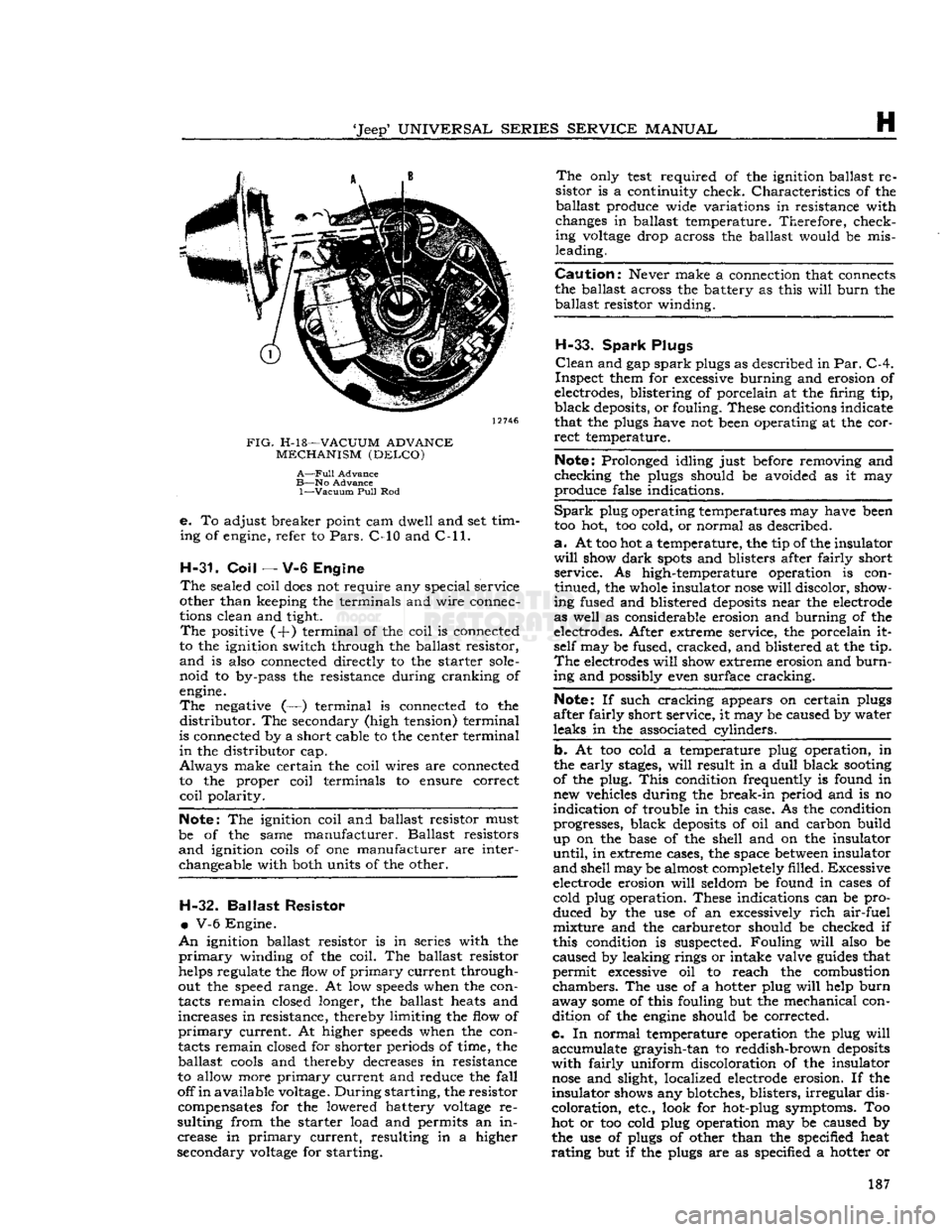

12746

FIG.

H-l8—VACUUM

ADVANCE

MECHANISM

(DELCO)

A—Full

Advance

B—No

Advance

1—Vacuum

Pull

Rod

e.

To adjust breaker point cam dwell and set tim

ing of engine, refer to

Pars.

C-10 and

C-ll.

H-31. Coil

— V-6 Engine

The

sealed coil

does

not require any special service

other than keeping the terminals and wire connec

tions clean and tight.

The

positive (+) terminal of the coil is connected

to the ignition switch through the ballast resistor,

and

is also connected directly to the starter

sole

noid to by-pass the resistance during cranking of

engine.

The

negative (—) terminal is connected to the

distributor.

The secondary (high tension) terminal

is connected by a short cable to the center terminal

in

the distributor cap.

Always

make certain the coil wires are connected to the proper coil terminals to ensure correct

coil

polarity.

Note:

The ignition coil and ballast resistor must

be of the same manufacturer. Ballast resistors

and

ignition coils of one manufacturer are interchangeable with both units of the other. H-32.

Ballast

Resistor

•

V-6 Engine.

An

ignition ballast resistor is in series with the

primary

winding of the coil. The ballast resistor

helps regulate the flow of

primary

current through

out the speed range. At low

speeds

when the con

tacts remain closed longer, the ballast heats and

increases in resistance, thereby limiting the flow of

primary

current. At higher

speeds

when the con

tacts remain closed for shorter periods of time, the ballast

cools

and thereby decreases in resistance

to allow more

primary

current and reduce the

fall

off

in

available voltage.

During

starting, the resistor compensates for the lowered battery

voltage

re

sulting from the starter load and permits an in crease in

primary

current, resulting in a higher

secondary

voltage

for starting.

The

only

test

required of the ignition ballast re

sistor is a continuity check. Characteristics of the ballast produce wide variations in resistance with

changes in ballast temperature. Therefore, check ing

voltage

drop across the ballast would be mis

leading.

Caution:

Never make a connection that connects

the ballast across the battery as this

will

burn

the ballast resistor winding.

H-33.

Spark

Plugs

Clean

and gap

spark

plugs as described in

Par.

C-4.

Inspect them for excessive burning and erosion of

electrodes, blistering of porcelain at the firing tip,

black

deposits, or fouling. These conditions indicate

that the plugs have not been operating at the cor

rect

temperature.

Note:

Prolonged idling just before removing and

checking the plugs should be avoided as it may

produce false indications.

Spark

plug operating temperatures may have been

too hot, too cold, or normal as described.

a.

At too hot a temperature, the tip of the insulator

will

show

dark

spots

and blisters after fairly short service. As high-temperature operation is con

tinued, the whole insulator

nose

will

discolor, show

ing fused and blistered

deposits

near the electrode

as well as considerable erosion and burning of the

electrodes. After extreme service, the porcelain it self may be fused, cracked, and blistered at the tip.

The

electrodes

will

show extreme erosion and

burn

ing and possibly even surface cracking.

Note:

If such cracking appears on certain plugs

after fairly short service, it may be caused by water

leaks in the associated cylinders.

b. At too cold a temperature plug operation, in

the early

stages,

will

result in a

dull

black

sooting

of the plug.

This

condition frequently is found in new vehicles during the break-in period and is no

indication of trouble in this case. As the condition progresses, black

deposits

of oil and carbon build

up on the base of the shell and on the insulator

until,

in extreme cases, the space

between

insulator

and

shell may be almost completely filled. Excessive

electrode erosion

will

seldom be found in cases of cold plug operation. These indications can be pro

duced by the use of an excessively

rich

air-fuel mixture and the carburetor should be checked if

this condition is suspected. Fouling

will

also be

caused by leaking rings or intake valve

guides

that

permit excessive oil to reach the combustion

chambers.

The use of a hotter plug

will

help

burn

away

some

of this fouling but the mechanical con dition of the

engine

should be corrected.

c. In normal temperature operation the plug

will

accumulate grayish-tan to reddish-brown

deposits

with

fairly uniform discoloration of the insulator

nose

and slight, localized electrode erosion. If the

insulator shows any blotches, blisters,

irregular

dis

coloration, etc., look for hot-plug symptoms. Too

hot or too cold plug operation may be caused by

the use of plugs of other than the specified heat

rating

but if the plugs are as specified a hotter or 187

Page 188 of 376

H

ELECTRICAL

SYSTEM

colder plug may be desirable. However, under- or

over-heating is usually caused by factors other than the type of

spark

plugs and the cause should be determined before changing plugs. The design of the

engine

calls for plugs equivalent to Champion

J-8

for F4

engines

and

A.C.

44S or

UJ12Y

Champ

ion for the V6 engines, (as installed in production)

though any factor that consistently affects

engine

operating temperature may cause this requirement

to change. Overheating may be caused by in sufficient tightening of the plug in the head, which interferes with the flow of heat away from the firing

tip.

If this is the case, the plug gasket

will

show very

little flattening. Over-tightening, in

turn,

will

pro duce too easy a heat flow path and result in cold

plug operation.

This

will

be evident by excessive

flattening

and

deformation of the gasket.

Prevailing

temperatures, condition of the cooling system, and

air-fuel

mixture can affect the

engine

operating temperature and should be taken into consideration.

H-34.

GENERATOR

— F4

ENGINE

The

generator is an air-cooled, two-brush unit

which

cannot be adjusted to increase or decrease output. For replacement,

voltage

regulator and generator must be matched for

voltage

and capa

city,

polarity, and common source of manufacture.

Otherwise,

either a

loss

of ampere capacity or a

burned

out generator

will

result. Generators for

these

vehicles are 12-volt. Par. H-l explains the 12-volt system. Refer to the specifications at the

end of this section for information on correct generator rating for a specific model series.

The

circuit

breaker,

voltage

regulator, and current-

limiting

regulator are built into one combination

unit.

Because the regulator and battery are part

of the generator

circuit,

the output of the generator

depends upon the

state

of charge and temperature

of the battery.

With

a discharged battery, the

output

will

be high, decreasing proportionally as the battery

becomes

charged. For service informa

tion covering current regulator see Par. H-41.

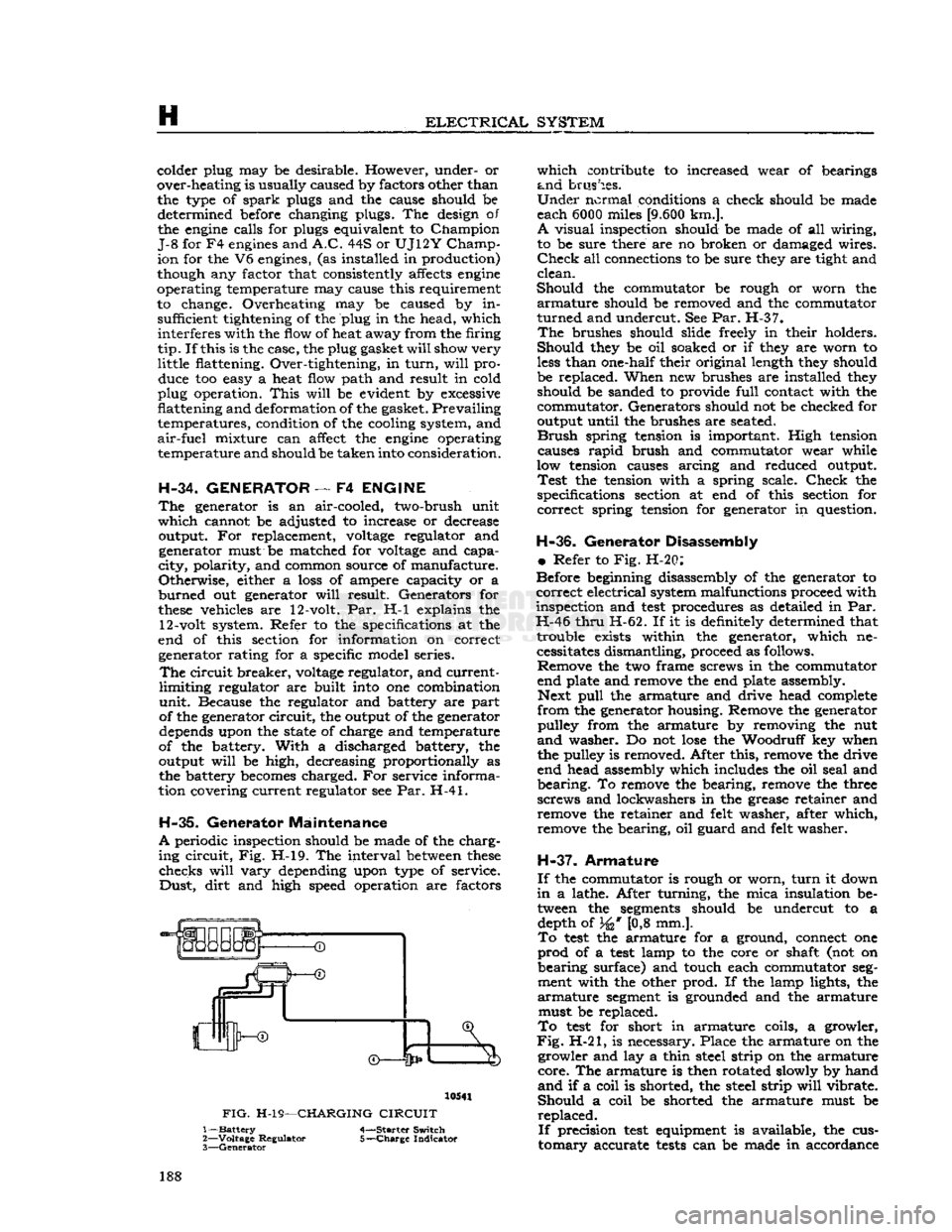

H-36.

Generator

Maintenance

A

periodic inspection should be made of the charg

ing

circuit,

Fig. H-l9. The interval

between

these

checks

will

vary

depending upon type of service.

Dust,

dirt

and high speed operation are factors 10541

FIG.

H-19—CHARGING

CIRCUIT

1—

Battery

4-—Starter Switch

2—

Voltage

Regulator 5-—Charge Indicator

3—

Generator

which

contribute to increased wear of bearings

and

brushes.

Under

normal conditions a check should be made

each 6000 miles

[9.600

km.].

A

visual inspection should be made of all wiring,

to be sure there are no broken or damaged wires.

Check

all connections to be sure they are tight and

clean.

Should

the commutator be rough or worn the

armature

should be removed and the commutator

turned

and undercut. See Par. H-37.

The

brushes should slide freely in their holders.

Should

they be oil soaked or if they are worn to

less

than one-half their original length they should

be replaced. When new brushes are installed they should be sanded to provide

full

contact with the

commutator. Generators should not be checked for

output until the brushes are seated.

Brush

spring tension is important. High tension causes

rapid

brush and commutator wear while

low tension causes arcing and reduced output.

Test

the tension with a spring scale.

Check

the

specifications section at end of this section for

correct

spring tension for generator in question.

H-36.

Generator Disassembly

•

Refer to Fig. H-20:

Before beginning disassembly of the generator to

correct

electrical system malfunctions proceed with

inspection and

test

procedures as detailed in Par.

H-46

thru

H-62. If it is definitely determined that trouble exists within the generator, which necessitates dismantling, proceed as follows. Remove the two frame screws in the commutator

end plate and remove the end plate assembly. Next

pull

the armature and drive head complete

from

the generator housing. Remove the generator pulley from the armature by removing the nut

and

washer. Do not

lose

the Woodruff key when

the pulley is removed. After this, remove the drive

end head assembly which includes the oil seal and

bearing.

To remove the bearing, remove the three

screws and lockwashers in the grease retainer and remove the retainer and felt washer, after which,

remove the bearing, oil guard and felt washer.

H-37.

Armature

If

the commutator is rough or worn,

turn

it down

in

a lathe. After turning, the mica insulation be tween the

segments

should be undercut to a depth of 34* [0,8 mm.].

To

test

the armature for a ground, connect one

prod

of a

test

lamp to the core or shaft (not on

bearing

surface) and touch each commutator

seg

ment with the other prod. If the lamp lights, the

armature

segment

is grounded and the armature must be replaced.

To

test

for short in armature coils, a growler,

Fig.

H-21, is necessary. Place the armature on the growler and lay a thin steel strip on the armature

core.

The armature is then rotated slowly by hand

and

if a coil is shorted, the steel strip

will

vibrate.

Should

a coil be shorted the armature must be

replaced.

If

precision

test

equipment is available, the cus

tomary

accurate

tests

can be made in accordance 188

Page 224 of 376

H

ELECTRICAL

SYSTEM

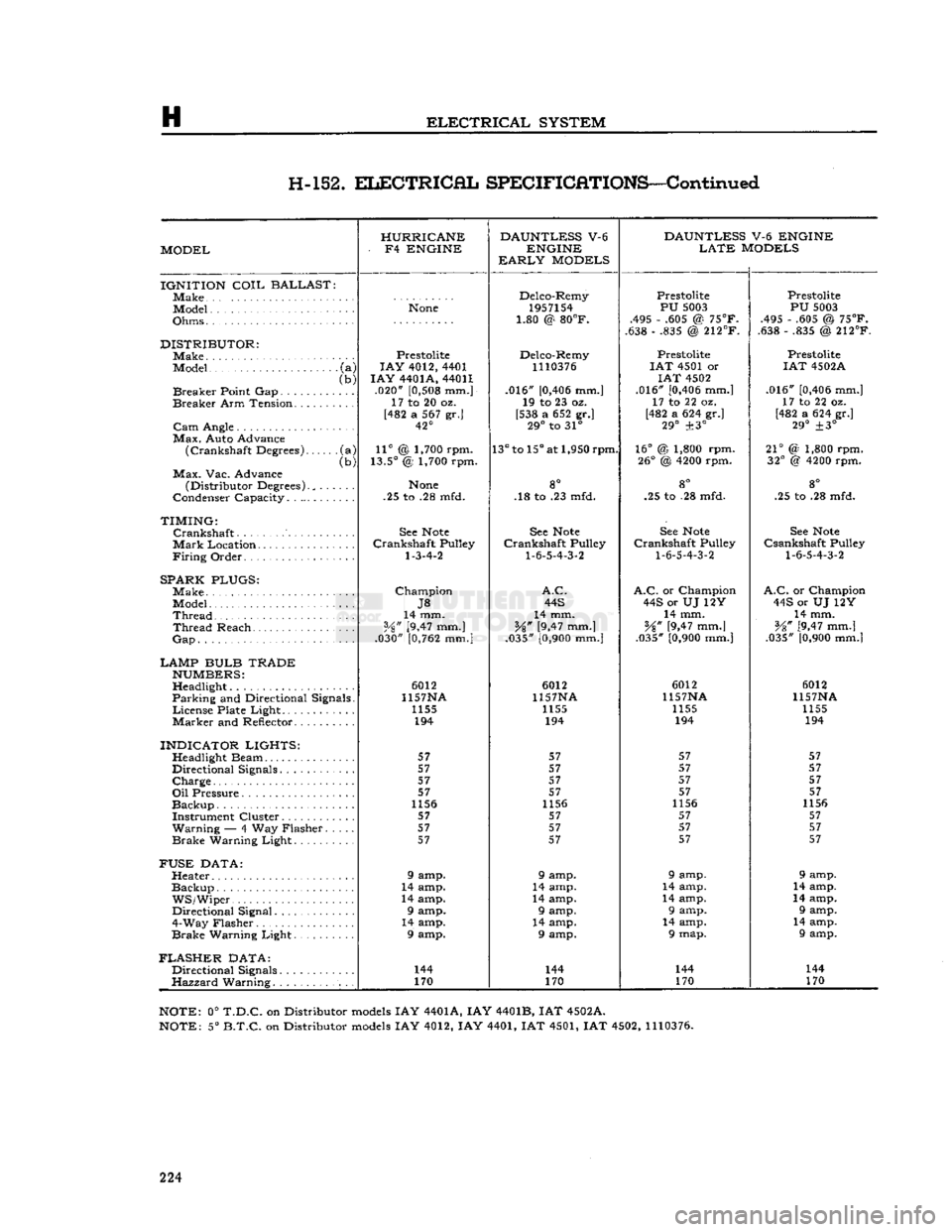

H-152.

ELECTRICAL

SPECIFICATIONS—Continued

HURRICANE DAUNTLESS

V-6

DAUNTLESS

V-6 ENGINE

MODEL -

F4

ENGINE

ENGINE

LATE

MODELS

EARLY

MODELS

IGNITION

COIL

BALLAST

]Make Delco-Remy

Prestolite Prestolite

Model

None

1957154

PU

5003

PU

5003

Ohms • • 1.80 @

80°F.

.495 - .605 @

75°F.

.495 - .605 @

75°F.

1.80 @

80°F.

.638 - .835 @

212°F.

.638 - .835 @

212°F.

DISTRIBUTOR:

Prestolite Delco-Remy Prestolite Prestolite

Model

•

(a)

LAY

4012, 4401

1110376

I

AT

4501 or

IAT

4502A

(b)

I

AY

4401A, 44011

IAT

4502

Breaker

Point Gap (b)

.020"

[0,508

mm.] .016"

[0,406

mm.] .016"

[0,406

mm.]

.016"

[0,406

mm.]

Breaker

Arm Tension. ..... 17 to 20 oz.

19 to 23 oz. 17 to 22 oz. 17 to 22 oz.

[482 a 567 gr.] [538 a 652 gr.] [482 a 624 gr.]

[482 a 624 gr.]

42° 29°

to 31°

29°

±3°

29°

±3°

Max.

Auto Advance

(Crankshaft

Degrees) •(a)

11°

@ 1,700 rpm.

13°

to

15°

at 1,950 rpm.

16°

@ 1,800 rpm.

21°

(2 1,800 rpm.

(Crankshaft

Degrees)

(b)

13.5°

@ 1,700 rpm.

26°

@

4200

rpm.

32°

@

4200

rpm.

Max.

Vac. Advance go

(Distributor Degrees)., . .

None

8° 8°

go

Condenser Capacity. . .25 to .28 mfd. .18 to .23 mfd. .25 to .28 mfd. .25 to .28 mfd.

TIMING:

Crankshaft

See

Note

See

Note

See

Note

See

Note

Mark

Location............

Crankshaft

Pulley

Crankshaft

Pulley

Crankshaft

Pulley

Csankshaft

Pulley

Firing

Order

1-3-4-2

1-6-5-4-3-2

1-6-5-4-3-2 1-6-5-4-3-2

SPARK PLUGS:

Make

Champion

A.C. A.C.

or Champion

A.C.

or Champion

J8

44S

44S or UJ 12Y 44S or UJ 12Y

Thread

14 mm.

14 mm. 14 mm. 14 mm.

Thread

Reach

Vz"

[9,47 mm.]

%"

[9,47 mm.]

¥%"

[9,47 mm.]

V8" [9,47 mm.]

Gap

.030"

[0,762

mm.]

.035"

[0,900

mm.] .035"

[0,900

mm.] .035"

[0,900

mm.|

LAMP BULB TRADE

NUMBERS:

Headlight 6012

6012 6012 6012

Parking

and Directional Signals. 1157NA

1157NA 1157NA 1157NA

License

Plate Light........ 1155

1155 1155 1155

Marker

and Reflector 194

194 194 194

INDICATOR LIGHTS:

57 57 57 57

Directional Signals........ 57

57 57 57

Charge

57

57 57 57

57 57 57 57

1156 1156 1156 1156

Instrument Cluster 57 57 57 57

Warning

— 4 Way Flasher. . 57

57 57 57

Brake

Warning Light 57

57 57 57

FUSE

DATA:

Heater 9 amp. 9 amp. 9 amp. 9 amp.

Backup

14 amp. 14 amp. 14 amp. 14 amp.

WS/Wiper.

14 amp. 14 amp. 14 amp. 14 amp.

Directional Signal 9 amp. 9 amp. 9 amp. 9 amp.

4-Way Flasher 14 amp. 14 amp. 14 amp. 14 amp.

Brake

Warning Light 9 amp. 9 amp. 9 map. 9 amp.

FLASHER

DATA:

Directional Signals. 144

144 144 144

Hazzard

Warning. 170

170 170 170

NOTE:

0°

T.D.C.

on Distributor

models

IAY 4401A, IAY 4401B, IAT 4502A.

NOTE:

5°

B.T.C.

on Distributor

models

IAY 4012, IAY 4401, IAT 4501, IAT 4502,

1110376.

224

Page 362 of 376

u

MISCELLANEOUS

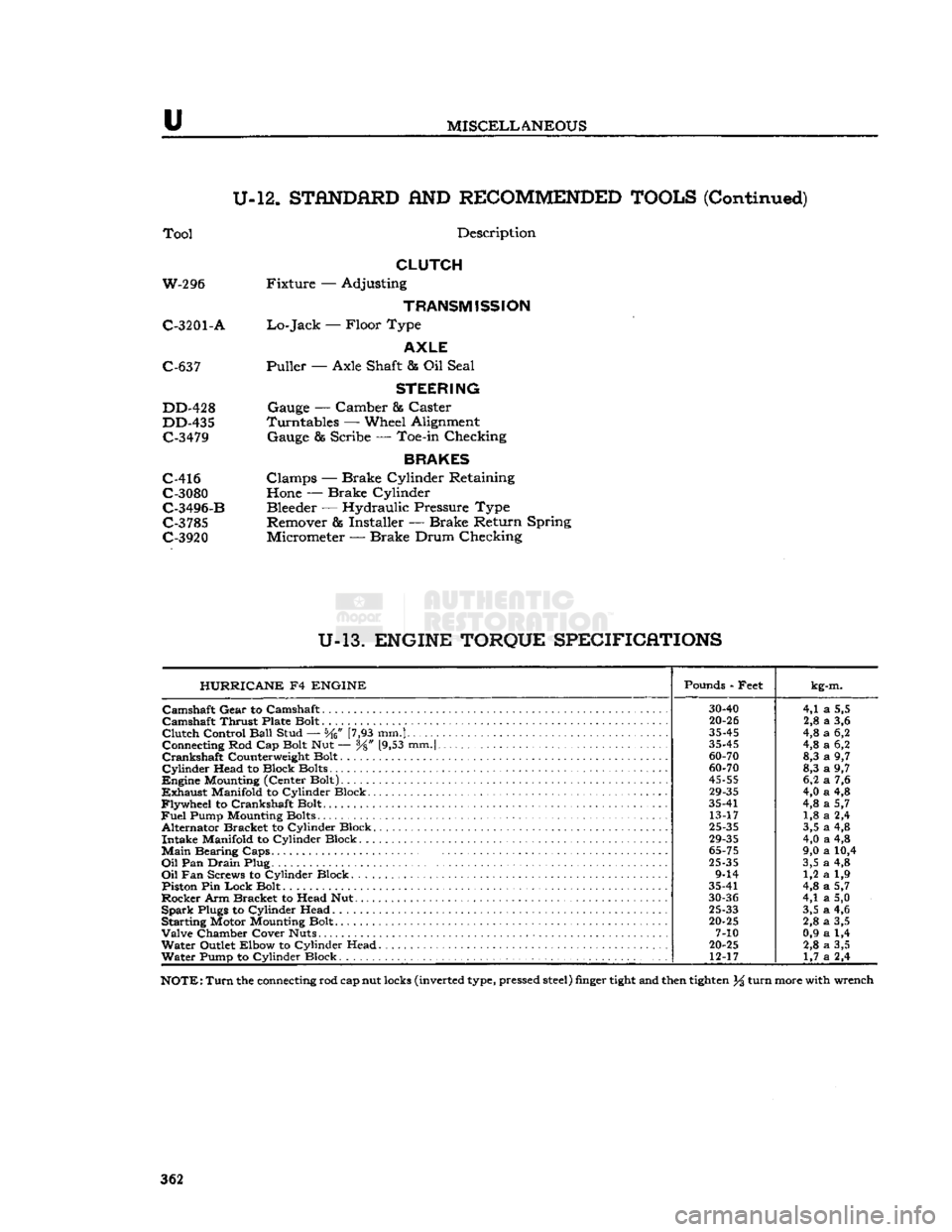

U-12.

STANDARD

AND

RECOMMENDED TOOLS

(Continued)

Tool

Description

CLUTCH

W-296 Fixture — Adjusting

TRANSMISSION

C-3201

- A

Lo-Jack

— Floor Type

AXLE

C-637 Puller — Axle Shaft & Oil Seal

STEERING

DD-428 Gauge — Camber & Caster

DD-435 Turntables — Wheel Alignment C-3479 Gauge & Scribe — Toe-in Checking

BRAKES

C-416 Clamps — Brake Cylinder Retaining C-3080 Hone — Brake Cylinder

C-3496-B Bleeder — Hydraulic Pressure Type C-3785 Remover & Installer — Brake Return Spring

C-3920 Micrometer — Brake Drum Checking

U-13.

ENGINE TORQUE SPECIFICATIONS HURRICANE

F4

ENGINE

Pounds - Feet

kg-m.

30-40

4,1

a

5,5

Camshaft

Thrust Plate Bolt

20-26

2,8

a

3,6

Clutch

Control

Ball

Stud — [7,93 mm.]

35-45

4,8

a

6,2

Connecting Rod Cap Bolt Nut — y8" [9,53 mm.|

35-45

4,8

a

6,2

60-70

8,3

a

9,7

Cylinder

Head to Block Bolts

60-70

8,3

a

9,7

45-55

6,2

a

7,6

29-35

4,0

a

4,8

Flywheel

to Crankshaft Bolt. 35-41

4,8

a

5,7

Fuel

Pump Mounting Bolts 13-17 1,8

a

2,4

Alternator Bracket to Cylinder Block.

25-35

3,5

a

4,8

29-35

4,0

a

4,8

Main

Bearing

Caps.

.

65-75

9,0

a

10,4

Oil

Pan

Drain

Plug

25-35

3,5

a

4,8

9-14 1,2

a

1,9

Piston Pin

Lock

Bolt 35-41

4,8

a

5,7

30-36

4,1

a

5,0

Spark

Plugs to Cylinder Head

25-33

3,5

a

4,6

Starting Motor Mounting Bolt.

20-25

2,8

a

3,5

7-10 0,9

a

1,4

Water

Outlet Elbow to Cylinder Head

20-25

2,8

a

3,5

Water

Pump to Cylinder Block 12-17

1,7

a

2,4

NOTE:

Turn

the connecting rod cap nut locks (inverted type, pressed

steel)

finger

tight

and then

tighten

% turn more with wrench

362

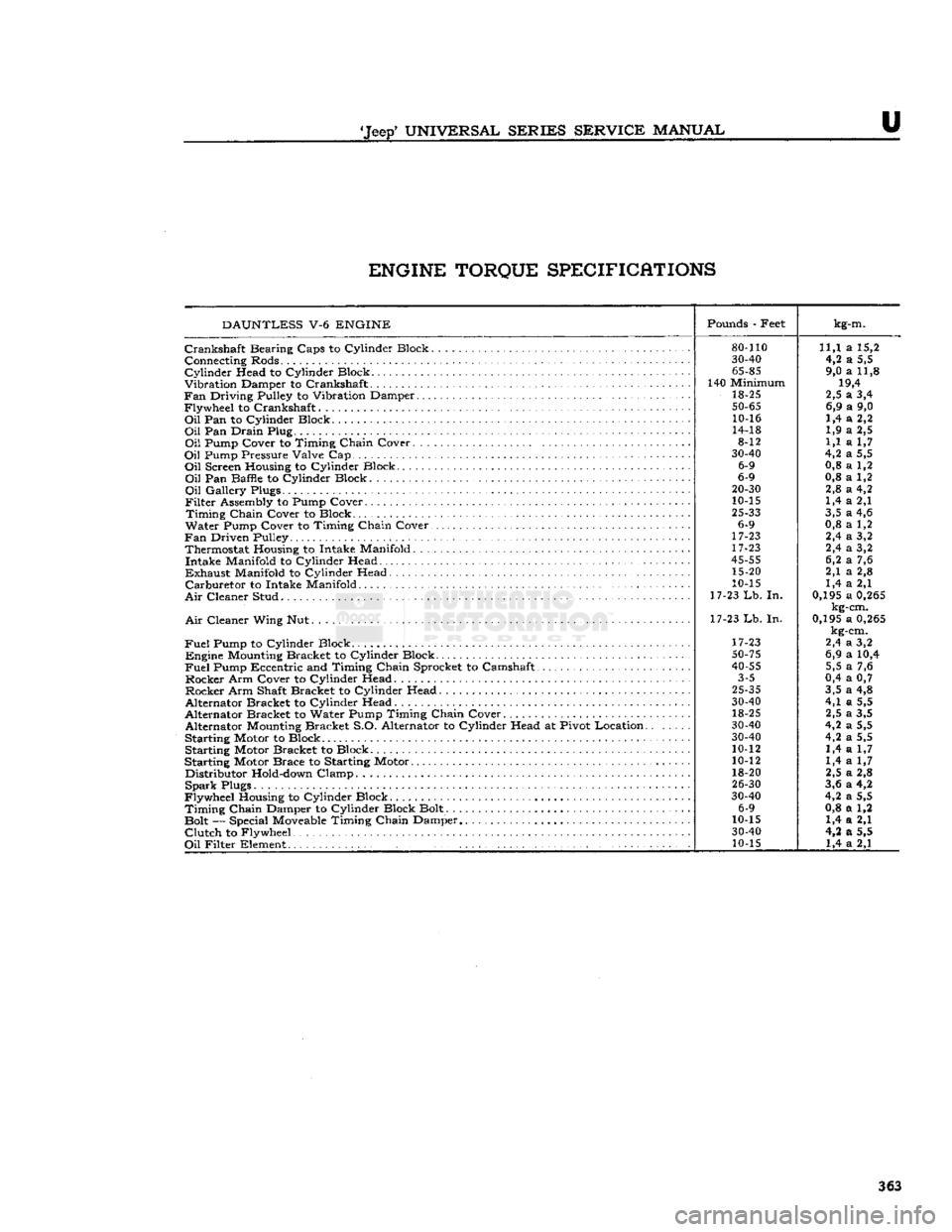

Page 363 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

U ENGINE TORQUE SPECIFICATIONS

DAUNTLESS

V-6

ENGINE

Pounds

- Feet

kg-m.

80-110

11,1 a 15,2

30-40

4,2 a 5,5

65-85

9,0 a 11,8

140 Minimum 19,4

18-25 2,5 a 3,4

50-65

6,9 a 9,0

10-16 1,4 a 2,2

14-18 1,9 a 2,5

8-12 1,1 a 1,7

30-40

4,2 a 5,5

6-9 0,8 a 1,2

6-9 0,8 a 1,2

20-30

2,8 a 4,2

10-15 1,4 a 2,1

25-33

3,5 a 4,6

6-9 0,8 a 1,2

17-23 2,4 a 3,2

17-23 2,4 a 3,2

45-55

6,2 a 7,6

15-20 2,1 a 2,8

10-15 1,4 a 2,1

17-23

Lb.

In. 0,195 a

0,265

kg-cm.

17-23 Lb. In. 0,195 a

0,265

kg-cm.

17-23 2,4 a 3,2

50-75

6,9 a 10,4

40-55

5,5 a 7,6

3-5 0,4 a 0,7

25-35

3,5 a 4,8

30-40

4,1 a 5,5

18-25 2,5 a 3,5

30-40

4,2 a 5,5

30-40

4,2 a 5,5

10-12 1,4 a 1,7

10-12 1,4 a 1,7

18-20 2,5 a 2,8

26-30

3,6 a 4,2

30-40

4,2 a 5,5

6-9 0,8 a 1,2

10-15 1,4 a 2,1

30-40

4,2 a 5,5

10-15 1,4 a 2,1

Crankshaft

Bearing Caps to Cylinder Block.

Connecting Rods.

Cylinder

Head to Cylinder Block

Vibration Damper to Crankshaft

Fan

Driving Pulley to Vibration Damper

Flywheel to Crankshaft

Oil

Pan to Cylinder Block

Oil

Pan Drain Plug

Oil

Pump Cover to Timing Chain Cover. . .

Oil

Pump Pressure Valve Cap

Oil

Screen Housing to Cylinder Block

Oil

Pan Baffle to Cylinder Block

Oil

Gallery Plugs.

Filter

Assembly to Pump Cover

Timing

Chain Cover to Block

Water Pump Cover to Timing Chain Cover.

Fan

Driven Pulley Thermostat Housing to Intake Manifold. . . Intake Manifold to Cylinder Head

Exhaust

Manifold to Cylinder Head

Carburetor

to Intake Manifold

Air

Cleaner Stud

Air

Cleaner Wing Nut.

Fuel

Pump to Cylinder Block . . Engine

Mounting

Bracket to Cylinder Block

Fuel

Pump Eccentric and Timing Chain Sprocket to Camshaft

Rocker Arm Cover to Cylinder Head Rocker Arm Shaft Bracket to Cylinder Head

Alternator Bracket to Cylinder Head

Alternator Bracket to Water Pump Timing Chain Cover Alternator

Mounting

Bracket S.O. Alternator to Cylinder Head at Pivot Location.

Starting Motor to Block Starting Motor Bracket to Block

Starting Motor Brace to Starting Motor Distributor

Hold-down

Clamp

Spark

Plugs

Flywheel Housing to Cylinder Block

Timing

Chain Damper to Cylinder Block Bolt.

Bolt — Special

Moveable

Timing Chain Damper

Clutch

to Flywheel

Oil

Filter Element .' 363

Page 372 of 376

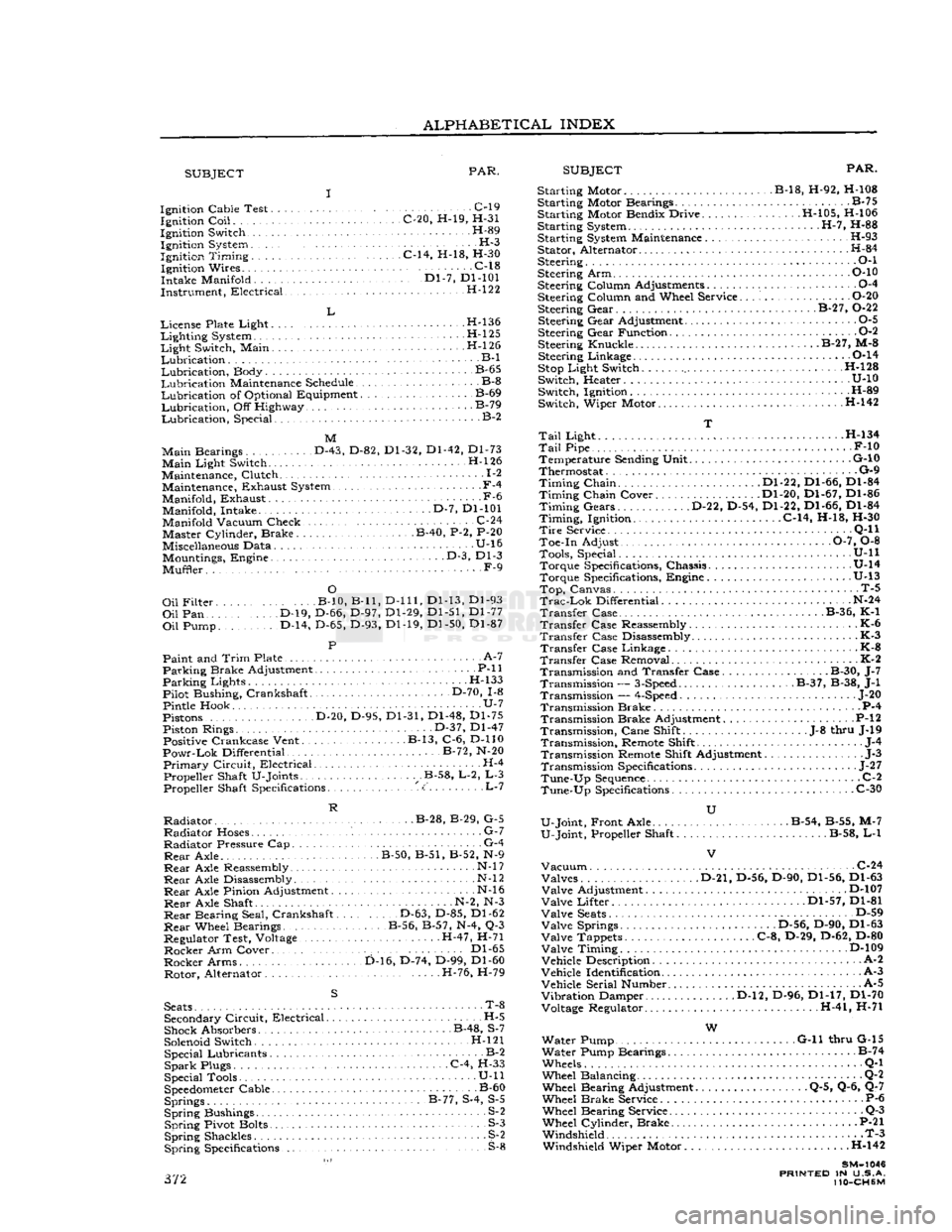

ALPHABETICAL

INDEX

SUBJECT

PAR.

SUBJECT

PAR.

Ignition Cable Test C-l9 Ignition

Coil

C-20, H-19, H-31

Ignition Switch H-89 Ignition System H-3

Ignition

Timing

C-14, H-18, H-30 Ignition Wires C-18

Intake Manifold '." Dl-7, Dl-101

Instrument, Electrical H-122

L

License Plate Light H-l36

Lighting

System H-l25

Light

Switch, Main . H-l 26

Lubrication

B-l

Lubrication,

Body B-65

Lubrication

Maintenance Schedule B-8

Lubrication

of Optional Equipment B-69

Lubrication,

Off Highway B-79

Lubrication,

Special. B-2

M

Main

Bearings D-43, D-82, Dl-32, Dl-42, Dl-73

Main

Light Switch. H-l26

Maintenance, Clutch 1-2 Maintenance, Exhaust System.,

-

F-4

Manifold, Exhaust -F-6 Manifold, Intake D-7, Dl-101

Manifold Vacuum Check. .C-24 Master Cylinder, Brake B-40, P-2, P-20

Miscellaneous Data U-16 Mountings, Engine • • •

-

D-3, Dl-3

Muffler. F-9

O

Oil

Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Oil

Pan D-19, D-66, D-97, Dl-29, Dl-51, Dl-77

Oil

Pump. D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

P

Paint and

Trim

Plate • • A-7

Parking

Brake Adjustment P-ll

Parking

Lights H-133

Pilot Bushing, Crankshaft D-70, 1-8

Pintle Hook U-7

Pistons D-20, D-95, Dl-31, Dl-48, Dl-75 Piston Rings. • • •

•

D-37, Dl-47 Positive Crankcase Vent. B-13, C-6, D-110

Powr-Lok

Differential B-72, N-20

Primary

Circuit,

Electrical H-4 Propeller Shaft U-Joints .B-58, L-2, L-3 Propeller Shaft Specifications <:' L-7

R

Radiator

B-28, B-29, G-5

Radiator

Hoses. G-7

Radiator

Pressure Cap G-4

Rear

Axle. B-50, B-51, B-52, N-9

Rear

Axle Reassembly • N-l

7

Rear

Axle Disassembly N-l

2

Rear

Axle Pinion Adjustment N-l6

Rear

Axle Shaft N-2, N-3

Rear

Bearing Seal, Crankshaft D-63, D-85, Dl-62

Rear

Wheel Bearings B-56, B-57, N-4, Q-3

Regulator Test, Voltage H-47, H-71

Rocker

Arm Cover.. . Dl-65

Rocker

Arms D-16, D-74, D-99, Dl-60 Rotor, Alternator H-76, H-79

S

Seats

• T-8 Secondary

Circuit,

Electrical H-5

Shock Absorbers B-48, S-7

Solenoid Switch. H-l21 Special Lubricants B-2

Spark

Plugs C-4, H-33

Special Tools • U-ll

Speedometer

Cable B-60 Springs B-77, S-4, S-5

Spring

Bushings S-2

Spring

Pivot Bolts S-3

Spring

Shackles S^2

Spring

Specifications S-8 372 Starting Motor B-18, H-92, H-108

Starting Motor Bearings B-75

Starting Motor Bendix Drive H-105, H-106

Starting System H-7, H-88

Starting System Maintenance H-93 Stator, Alternator H-84

Steering • • •

•

O-l

Steering Arm P-10

Steering Column Adjustments 0-4

Steering Column and Wheel Service O-20 Steering Gear. . B-27, 0-22

Steering Gear Adjustment 0-5

Steering Gear Function 0-2

Steering Knuckle. B-27, M-8 Steering Linkage 0-14

Stop

Light Switch H-128

Switch, Heater U-10 Switch, Ignition H-89

Switch, Wiper Motor H-142

T

Tail

Light . H-134

Tail

Pipe F-10 Temperature Sending Unit G-10

Thermostat G-9

Timing

Chain Dl-22, Dl-66, Dl-84

Timing

Chain Cover Dl-20, Dl-67, Dl-86

Timing

Gears D-22, D-54, Dl-22, Dl-66, Dl-84

Timing,

Ignition. C-14, H-18, H-30

Tire

Service . •

•

Q-l

1

Toe-in Adjust 0-7, 0-8 Tools, Special. . .

........

U-ll Torque Specifications, Chassis U-14

Torque Specifications, Engine .U-13

Top,

Canvas. T-5

Trac-Lok

Differential N-24

Transfer

Case B-36, K-1

Transfer

Case Reassembly K-6

Transfer

Case Disassembly K-3

Transfer

Case Linkage - K-8

Transfer

Case Removal K-2 Transmission and Transfer Case. B-30, J-7 Transmission —

3-Speed

B-37, B-38, J-l

Transmission —

4-Speed

... J-20

Transmission Brake P-4 Transmission Brake Adjustment P-l

2

Transmission,

Cane Shift .J-8 thru J-19

Transmission,

Remote Shift J-4

Transmission Remote Shift Adjustment J-3

Transmission Specifications

-

J-27

Tune-Up

Sequence

C-2

Tune-Up

Specifications C-30

U

U-Joint, Front Axle . . B-54, B-55, M-7

U-Joint, Propeller Shaft B-58, L-l

Vacuum

C-24 Valves D-21, D-56, D-90, Dl-56, Dl-63

Valve

Adjustment D-107

Valve

Lifter Dl-57, Dl-81

Valve

Seats

D-59

Valve

Springs .D-56, D-90, Dl-63

Valve

Tappets C-8, D-29, D-62, D-80

Valve

Timing D-109

Vehicle Description A-2

Vehicle Identification A-3

Vehicle Serial Number. A-5

Vibration

Damper D-l2, D-96, Dl-17, Dl-70 Voltage Regulator. H-41, H-71

W

Water Pump G-ll thru G-15

Water Pump Bearings B-74

Wheels Q-l

Wheel Balancing Q-2 Wheel Bearing Adjustment Q-5, Q-6, Q-7

Wheel Brake Service P-6 Wheel Bearing Service Q-3

Wheel Cylinder, Brake P-21 Windshield T-3 Windshield Wiper Motor . .H-142

SM-1046

PRINTED

IN U.S.A.

110-CH6M