torque JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 146 of 376

Fl

EXHAUST

EMISSION CONTROL SYSTEMS The

air distribution manifold should be installed

after the exhaust manifold assembly is torqued

to the cylinder head. The recommended procedure

for exhaust manifold assembly installation is as follows:

Clean

the mating surface of both the

manifold and cylinder head.

Install

the exhaust manifold to the cylinder head using a new gasket.

Tighten

the manifold to cylinder head, attaching

bolts

down evenly.

Finish

torque tightening to 29

to 35 ft. lbs. [3,4 a 4,8 kg-m.].

Fl-23.

REQUIRED

EQUIPMENT

Each

station licensed to perform repair and main

tenance on the Exhaust Emission Control System

must be equipped with that equipment necessary

for major

engine

tune-up analysis which shall in clude at least the following or equivalent.

Ignition Analyzer Oscilloscope

Ammeter

Ohmmeter

Voltmeter Tachometer

2 Vacuum Gages

Pressure

Gage (0-10 psi.)

Cam

Angle Dwell Meter Ignition Timing

Light

Engine

Exhaust Combustion Analyzer Compression Tester

Fl-24.

REPLACEMENT

PARTS

Parts

necessary to repair and/or maintain the

Exhaust

Emission Control System are available through any Jeep

SALES CORPORATION

ware

house.

Fl-25.

WARRANTY

All

parts of the Exhaust Emission Control System

are

covered by the Manufacturer's Warranty as stated in the Warranty Service and 'Jeep' Quality

Maintenance Plan booklet.

Fl-26.

EXHAUST EMISSION CONTROL

SYSTEM

DIAGNOSIS GUIDE

Pump Noisy

Hoses Touching Other Parts of Engine or Body (Hood).

Note:

The air pump is not completely noiseless.

Under

normal conditions, pump

noise

rises in pitch as

engine

speed

increases. It is also desirable to

allow for normal break-in wear of the pump prior

to replacement for excessive noise.

Pump Seized

Replace

pump.

Leak

In

Hose

Check

for leaks; using

soap

and water — tighten

clamps or replace

hoses.

Pump

Inoperative

Loose Belt — tighten belt — do not pry on housing.

Filter

Plugged — replace.

Exhaust Backfire

Check

for vacuum leaks — correct as necessary.

Check

air filter for excessive

restriction

— replace as necessary.

Check

anti-backfire valve — replace as necessary.

Induction System Backfire

Verify

engine

timing and distributor dwell.

Verify

accelerator pump charge. 146

Page 156 of 376

F2

EXHAUST EMISSION CONTROL SYSTEMS

the throttle

stop

screw to idle the

engine

at 650

to 700 rpm.

F2-17. Carburetor Idle Setting

The

"Lean

Best

Idle"

Method of Idle Setting is as

follows:

a.

Any scheduled service of ignition system should

precede this adjustment

b.

Connect tachometer to engine.

c.

Warm

up

engine

and stabilize temperatures.

d.

Adjust

engine

idle to speed desired, using throt

tle idle speed adjusting screw.

e.

Turn

idle mixture screws out (counterclockwise)

until

a

loss

of

engine

speed is indicated; then slowly

turn

mixture screws in (clockwise-leaner)

until

maximum speed (rpm) is reached. Continue

turning

in (clockwise) until speed begins to drop;

turn

mixture adjustment back out (counterclock

wise-richer)

until maximum speed is just regained

at

a "lean as possible" mixture adjustment.

F2-18. Distributor

The

ignition distributor used with the

Exhaust

Emission

Control

System is the same as that used

on

engines

without

Exhaust

Emission

Control.

Check

the distributor cam dwell angle and point

condition.

Check

ignition timing and adjust to specifications shown on the last

page

of this section.

F2-19.

Anti-Backfire

Valve

The

anti-backfire valve remains closed except when

the throttle is closed rapidly from an open position.

To

check the valve for proper operation, accelerate

the

engine

in neutral, allowing the throttle to close

rapidly.

The valve is operating satisfactorily when

no exhaust system backfire occurs. A further check

to determine whether the valve is functioning can

be made by removing from the anti-backfire valve

the large

hose

which connects the valve to the

pump.

With

a finger placed over the open end of

the

hose

(not the valve), accelerate the

engine

and allow the throttle to close rapidly. The valve is

operating satisfactorily if a momentary air rushing

noise is audible.

F2-20.

Check

Valve

The

check valves in the lines to the air distribution manifolds prevent the reverse flow of exhaust

gases

to the pump in the event the pump should, for

any

reason,

become

inoperative or should exhaust

pressure

ever exceed pump pressure.

To

check this valve for proper operation, remove the air supply

hose

from the pump at the check

valve.

With

the

engine

running, listen for exhaust

leakage at the check valve which is connected to

the distribution manifold.

F2-21.

Air

Pump

Check

for proper drive belt tension with belt tension

gauge

W-283. The belt strand tension should be 60 pounds measured on the

longest

accessible span

between two pulleys. DO NOT PRY ON THE

DIE

CAST

PUMP

HOUSING. To

check the pump for proper operation, remove

the air

outlet

hose

at the pump.

With

the

engine

running,

air discharge should be felt at one of

the pump

outlet

openings. The pump

outlet

air

pressure,

as determined by the relief valve, is preset

and

is not adjustable.

The

air pump

rear

cover assembly, housing the pressed in inlet and discharge tubes, and the pres

sure

relief valve are the only pump components

recommended for service replacement. These parts

are

to be replaced only when damaged as a result

of handling or in the event the relief valve was

tampered with.

F2-22.

Intake Manifold

Intake

manifold leaks must not be overlooked. Air

leakage at the intake manifold may be compen

sated for by

richer

idle mixture setting, however, this

will

usually cause uneven fuel-air distribution

and

will

always result in

loss

of performance and

exhaust emission control. To check for air leakage

into the intake manifold, apply kerosene or naph

tha,

on the intake manifold to cylinder head joints

and

observe whether any changes in

engine

rpm

occur.

If an air leak is indicated, check the mani

fold to cylinder head bolt torque. The correct torque is 25-35 lbs. ft. [3,46 a 4,84 kg-m.]. If the

leak

is

still

evident,

loosen

the manifold assembly

and

torque-tighten the bolts evenly.

Start

from the center and use proper torque values. Replace the

manifold

gasket if the leak

still

exists.

Clean

both

mating surfaces and check for

burrs

or other ir

regularities.

Always

torque the bolts evenly to the specified

torque value to prevent warpage.

F2-23.

Carburetor

Air

Cleaner

—Oil

Bath

Every

6,000

miles [9,600 km.] disconnect attach

ing

hoses

and unscrew the wing nut from the top

of the air cleaner and lift it off the carburetor.

Lift

the cover and filter element off the oil sump.

Clean

the inside surface of the sump and

refill

to

indicated

oil level with SAE 40 or 50

engine

oil

above 32 F; SAE 20 below 32 F.

Wash

filter element in kerosene and

drain.

Reassemble the air

cleaner

and install on carburetor.

More

frequent cleaning and replacement are advis able when the car is operated in dusty areas or on

unpaved

roads. Accumulated

dirt

restricts air flow,

reducing

fuel economy and performance.

F2-24.

REMOVAL PROCEDURES

The

following paragraphs

give

the procedures for removing the major units of the exhaust emission

control

system and the required equipment needed.

F2-2S.

Air

Pump

Loosen

the air pump mounting bracket bolts. Re move the air pump air hose(s). Separate the air pump from its mounting bracket. At time of install

ation,

torque tighten the air pump mounting bolts

to

30-40

lbs.-ft [4,15 a 5,53 kg-m.].

Adjust

the

belt strand tension to 60 pounds. 156

Page 158 of 376

F2

EXHAUST EMISSION CONTROL SYSTEMS

F2-3L

EXHAUST EMISSION CONTROL SYSTEM

DIAGNOSIS

GUIDE

Pump Noisy

Hoses Touching Other Parts of Engine or Body (Hood).

Note:

The Air Pump is not completely noiseless.

Under

normal conditions, pump

noise

rises in pitch as

engine

speed

increases. It is desirable to allow

for normal break-in wear of the pump prior to re

placement for

excessive

noise.

Pump Seized

Replace pump.

-

do not pry on housing.

Leak

In Hose

Check

for leaks; using

soap

and water, tighten clamps or replace

hoses.

Pump Inoperative

Loose Belt — tighten belt

-

Filter

Plugged — replace.

Exhaust

Backfire

Check

for vacuum leaks — correct as necessary.

Check

anti-backfire valve — replace as necessary

Induction System Backfire

Verify

engine

timing and distributor dwell.

Verify

accelerator pump charge.

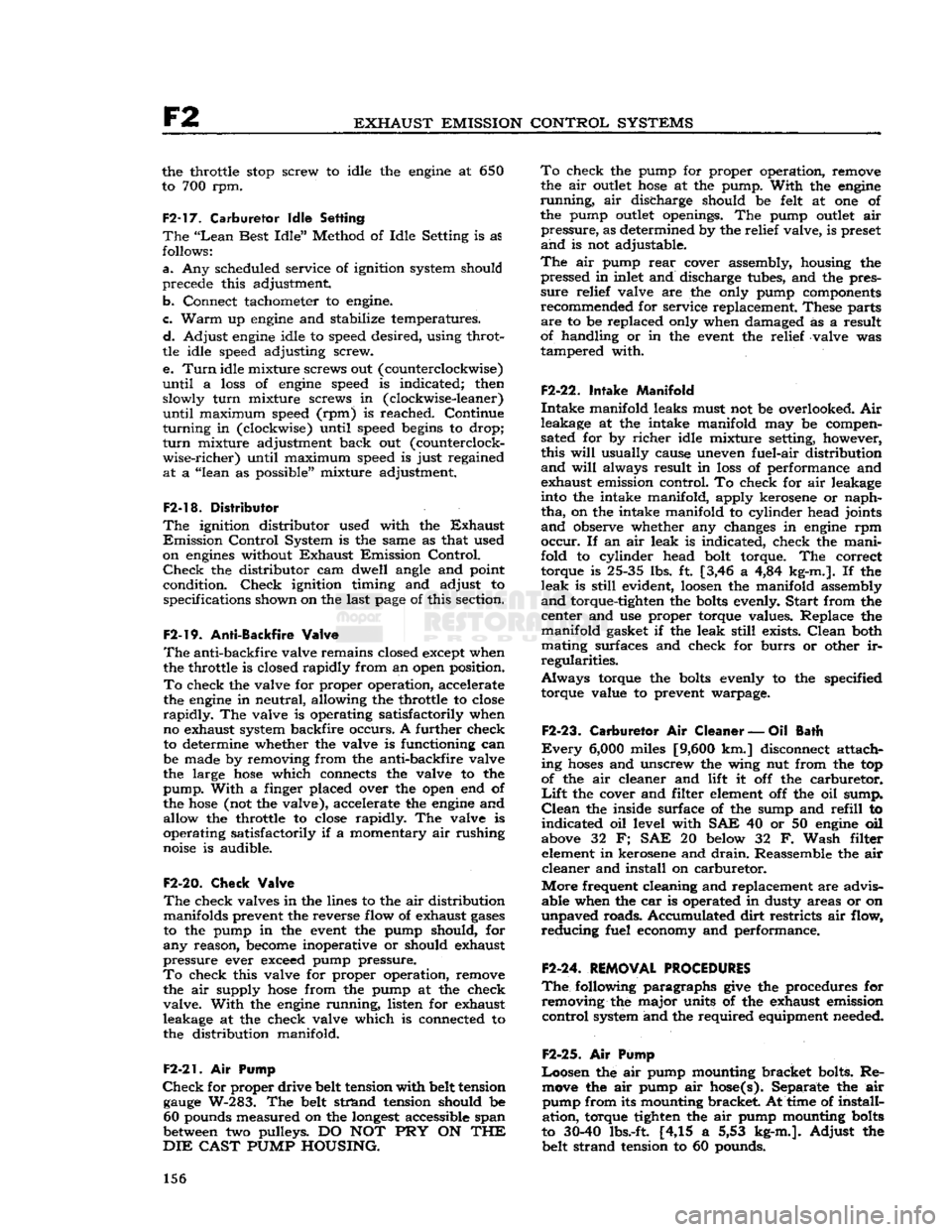

F2-32.

EXHAUST EMISSION CONTROL SYSTEM MAINTENANCE CHART

Efficient

performance of the Exhaust Emission very important that all of the maintenance require-

Control

System is

dependent

upon precise main-

ments

are performed with extreme care at the

tenance. As indicated in the following chart, it is specific interval indicated.

Thousands of miles* or

OPERATION

number of months whichever occurs first 2 6 12 18 24 30

Inspect engine-driven

belts

for condition and tension R R

Replace positive crankcase ventilation valve

(PCV)

R R

Check

for free operation of exhaust manifold heat control valve O O O O O

Clean

carburetor air cleaner — Oil Bath O O O O O

Replace carburetor air cleaner

element

— Dry Type O

Check

heated air system O O

Engine

tune-up O O

Check

engine

timing R O O O

Adjust

carburetor idle

speed

and mixture R O O O

Perform

factory-recommended road

test

for evaluation of overall performance and handling O O O O O

R

— Required Services O — Recommended Services

*

Miles Kilometers

2,000

—

3,200

6,000

—

9,600

12,000

—

19,200 18,000

—

28,800

24,000

—

38,400

30,000

—

48,000

F2-33.

GENERAL SPECIFICATIONS

Air

Pump Belt Tension 60 lb.

Rotor

Ring Screw Torque . 37 lb-in.

Housing Cover Bolt Torque 10 lb-ft. Speed Ratio, Air Pump to Engine

1

\i to 1

F2-34.

EXHAUST EMISSION CONTROL SYSTEM CARBURETOR SPECIFICATIONS

Make

Rochester Model Designation 2G Code Number

7027082

—

7041185

Choke

Manual

Number of Barrels 2

Throttle

Bore... \W [3,65 cm.]

Main

Metering Jet Production .051" - 60° [1,29 mm.]

High

Altitude — over

5000

ft .049" - 60° [1,24 mm.]

—

over

10,000

ft .047" - 60° [1,19 mm.]

Float

Level

Adjustment* 1%," [2,94 cm.]

Float

Drop Adjustment l%" [4,76 cm.]

Pump Rod Adjustment** 1%" [2,94 cm.]

Engine

Idle

R.P.M.

(In Neutral) 650 to 700

Initial

Idle Speed-screw

setting

3 turns in

Initial

Idle Mixture-screw

setting

2 turns out

Dash

Pot Setting. Y%w [3,75 mm.]

*From

air horn gasket to top of float at toe.

**From

air cleaner ring to top of pump rod.

158

Page 168 of 376

G

COOLING SYSTEM

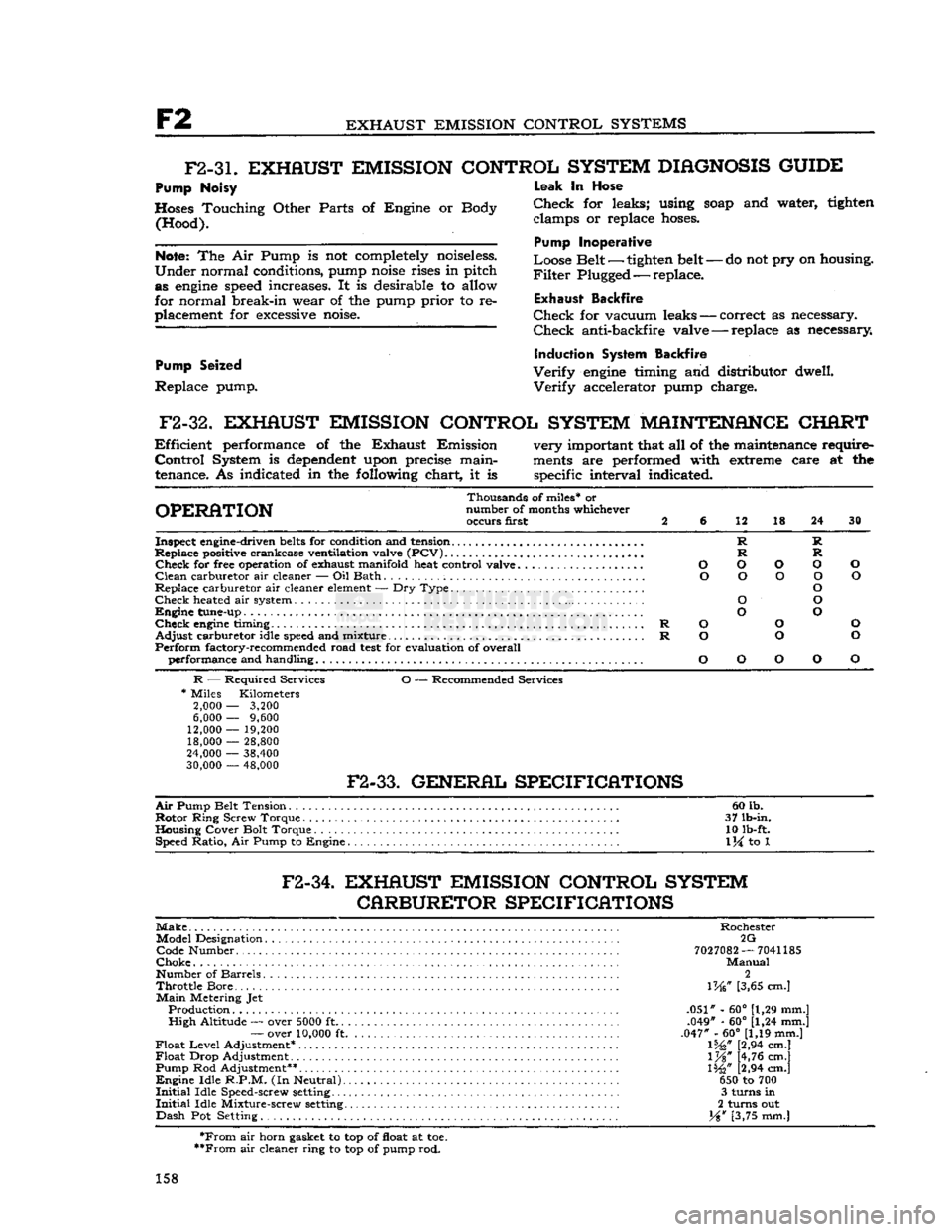

12761

FIG.

G-10—WATER

PUMP—

CROSS-SECTIONAL

VIEW

—

DAUNTLESS

V-6

1—

Hub

2—

—Shaft

and Bearing

3—

Cover

4—

Impeller

5—

Ceramic

Seal

6—

Seal

Assembly front end of the pump body. Position the seal,

washer,

and pump seal on shaft flush against the ground seat in the water pump body. Place the

impeller

on an arbor press and press the long end

of the shaft into the impeller until the end of the shaft is flush with the hub of the impeller. Support

the assembly on the impeller end of the shaft and

press the pulley hub on the shaft until the shaft end is flush with the pulley hub. Move the shaft

in

the pump body to align the retaining wire

grooves

in the bearing and pump body and place

the bearing retaining wire in position.

G-l

5. Water Pump Removal and Replacement — Dauntless V-6 Engine

Drain

the cooling system. Remove the fan belt and remove the cooling fan and pulley from the hub on

the water pump. Disconnect the

hoses

from the

water

pump. Remove the cap screws that secure

the water pump to the timing chain cover; remove

the water pump. Do not disassemble the water

pump;

it is serviceable only as an assembly. When

replacing

the water pump, torque the water pump cap screws 6 to 8 lb-ft. [0,829 a 1,106 kg-m.].

G-16.

Antifreeze Solutions

When

water freezes it expands approximately 9%

in

volume. When water, confined in a cooling sys

tem, freezes it exerts tremendous pressures causing

serious damage. To prevent freezing, antifreeze can

be added to the water to lower its freezing point.

The

two

types

of antifreeze commonly used today have either a methanol or ethylene glycol base,

and

contain corrosion inhibitors. The only anti

freeze recommended for the cooling system of

'Jeep'

vehicles is ethylene glycol (permanent type).

Methanol

base antifreeze evaporates with the water

when the vehicle is operated at warmer tempera

tures and requires more attention to avoid

loss

of

protection. Ethylene glycol base antifreeze seldom

evaporates at normal operating temperatures.

Methanol

solution is injurious to vehicle finishes.

Should

any be spilled on the vehicle, it should be

washed off immediately with a

good

supply of cold water without wiping or rubbing. Under ordi

nary

conditions, ethylene glycol is not injurious to

vehicle finishes.

Warning.*

Drinking

ethylene glycol antifreeze or its

solutions can be harmful or fatal. Do not use anti

freeze containers for

food

or beverages.

A

table in Par.

G-2

2

gives

the protection obtained

by the addition of various amounts cf ethylene glycol.

Before installing antifreeze, inspect the cooling sys

tem to be sure it is clean, leak-proof, and otherwise

in

proper operating condition.

Drain

the cooling system, see Par. G-3. Pour in 3 quarts [3 ltr.] of

clean

water, add the required quantity of anti freeze, then add clean water to within 1" [2,54 cm.] of the top of the overflow pipe to allow for expan

sion when hot. Run the

engine

until it is

warm.

Then

recheck the solution level.

Check

the anti

freeze protection with a hydrometer reading.

G-l7.

Inhibited Coolant Solutions

All

'Jeep5 vehicles equipped with either the

Hur

ricane

F4 or Dauntless V-6

engine

should use only

inhibited

year-round, permanent-type

engine

cool

ant

solutions that are formulated to withstand two

full

calendar years of normal operation without

draining

or adding inhibitors. The

engine

cooling

system should be completely drained and the

rec

ommended coolant installed every two years. Be-

fo

a

installing the permanent-type solution, inspect the cooling system to be sure it is clean, leakproof,

and

in proper operating condition.

Note:

Water alone, methanol, or alcohol-type anti

freeze is definitely not recommended for 'Jeep*

Vehicles.

G-l8.

Fan Belt

The

fan, water pump, generator or alternator are

driven

by a V-belt. The drive of the V-belt is on

the side of the V. A fan belt that is too tight

will

cause

rapid

wear of the alternator or generator and

water

pump bearings. If the belt is too

loose,

it may

slip

preventing the water pump from properly cool

ing the

engine

or the generator or alternator from

properly

charging the electrical

circuit.

Use fan belt

tension

gauge

Tool W-283 to properly adjust belt.

The

fan belt is properly adjusted when it can be

deflected Vi" [13 mm.] with strong thumb pres

sure

applied midway

between

the fan and alter

nator

pulleys.

Check

this adjustment and inspect the condition of the fan belt at each

engine

lubri-

168

Page 169 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

G

cation period. It is

good

preventive maintenance to

replace a badly frayed, worn or cracked fan belt

before it breaks in operation.

To

replace the fan belt,

loosen

the attaching

bolts

at each generator or alternator brace-to-engine mounting and pivot the alternator or generator to

ward

the

engine

to gain slack needed to install the new belt Remove the old belt. Position the new

belt over the fan pulley, over the crankshaft pulley,

then over the generator or alternator pulley.

Pull

the generator or alternator away from the

engine

until

belt tension is

firm.

Then tighten the generator

or

alternator mounting

bolts

and check the tension

as indicated above. Reset the generator or alternator as necessary for correct belt tension.

Finally,

torque

the generator or alternator mounting

bolts

25 to 35 lb-ft. [3,4 a 4,8 kg-m.].

Note:

On the Dauntless V-6

engine

when adjusting

the fan belt tension, the alternator mounting

bolts

should be torqued 30 to 40 lb-ft. [4,14 to 5,53

kg-m.].

If a fan belt tension

gauge

(W-283) is

avail

able, proper tension should be 80 pounds [36,2 kg.].

G-l

9. Engine Overheating

An

engine

will

not be damaged by high coolant

temperatures unless the coolant boils. The pres

surized

cooling system on the 'Jeep' vehicles raises the boiling point of the coolant solution. Should

overheating be encountered, and the fault is be

lieved to be in the cooling system check for the

following:

a.

Proper coolant level. See

Filling

Cooling Sys

tem Par. G-2.

b. Poor air flow.

Check

for dirty radiator core. (See Radiator Par. G-5).

Check

for faulty belt

pulley operation, worn or

loose

fan belt, or dam aged fan.

Clean,

repair, replace or adjust as neces

sary.

c. Foaming coolant.

Check

for air leaks at water

pump,

hose

connection and filler cap. Tighten, re

pair

or replace as necessary.

d.

Surging or "after boil".

Check

pressure cap and

replace if valves or gasket are faulty.

e.

External

leaks.

Check

the following for leaks:

Hoses and clamps, water pump, radiator, head gas

ket, core plugs and drain cocks, as well as the cylin der head or block for

cracks.

f.

Internal

leaks.

Check

for faulty head gasket,

cracked

cylinder head or block.

g. Poor coolant flow.

Check

hose

condition, water pump, fan belt, and repair or replace as necessary. Inspect block for rust or scale, and clean and flush

the system, if necessary.

h.

Check

the temperature

gauge.

169

Page 190 of 376

H

ELECTRICAL

SYSTEM

FIG.

H-21—GROWLER

end so it rests on the pulley with the commutator

end up.

While

holding brushes clear of commutator with

the thumbs, place generator housing and field coils assembly in position, turning front end

bracket

so the dowel pin in housing enters

hole

in

end head. Place commutator end plate on shaft

and

install long frame screws.

When

reinstalling the generator on the engine, the

bracket

bolt torque wrench reading is 25 to 35 lb-ft. [3,4 a 4,8 kg-m.].

H-41.

CURRENT-VOLTAGE REGULATORS •

F4 Engine

H-42.

Description and

Operation

For

replacement,

voltage

regulator and generator must be matched for

voltage

and capacity, polarity,

and

common source of manufacture. Otherwise,

either a

loss

of ampere capacity or a burned out generator

will

result.

These

regulators are used with shunt-type gen

erators

and have three units each with a separate function to perform. These units are the circuit

breaker

unit, the

voltage

regulator unit, and the

current

limiting regulator unit.

H-43.

Circuit

Breaker

It

consists of

an

electromagnet and a set of contacts.

The

contacts are mounted with one on a stationary

bracket,

and the other on a movable armature

which

is controlled by the electromagnet. The movable contact is mounted on a spring arm so that as the contacts open and

close

a slight wiping

action is produced.

The

electromagnet of the circuit breaker has two

windings, one, the shunt coil which is connected across the generator output like a voltmeter and

the other a series coil connected in series with the

generator output like an ammeter.These two coils

are

wound in the same direction so that when the

generator is charging the battery, the magnetism

of the series coil increases the total magnetism.

When

the battery discharges back through the generator, the magnetism of the series coil is re versed and the magnetism of the two coils is

opposed.

This

results in a decreased

pull

on the

armature

and spring action

opens

the contacts.

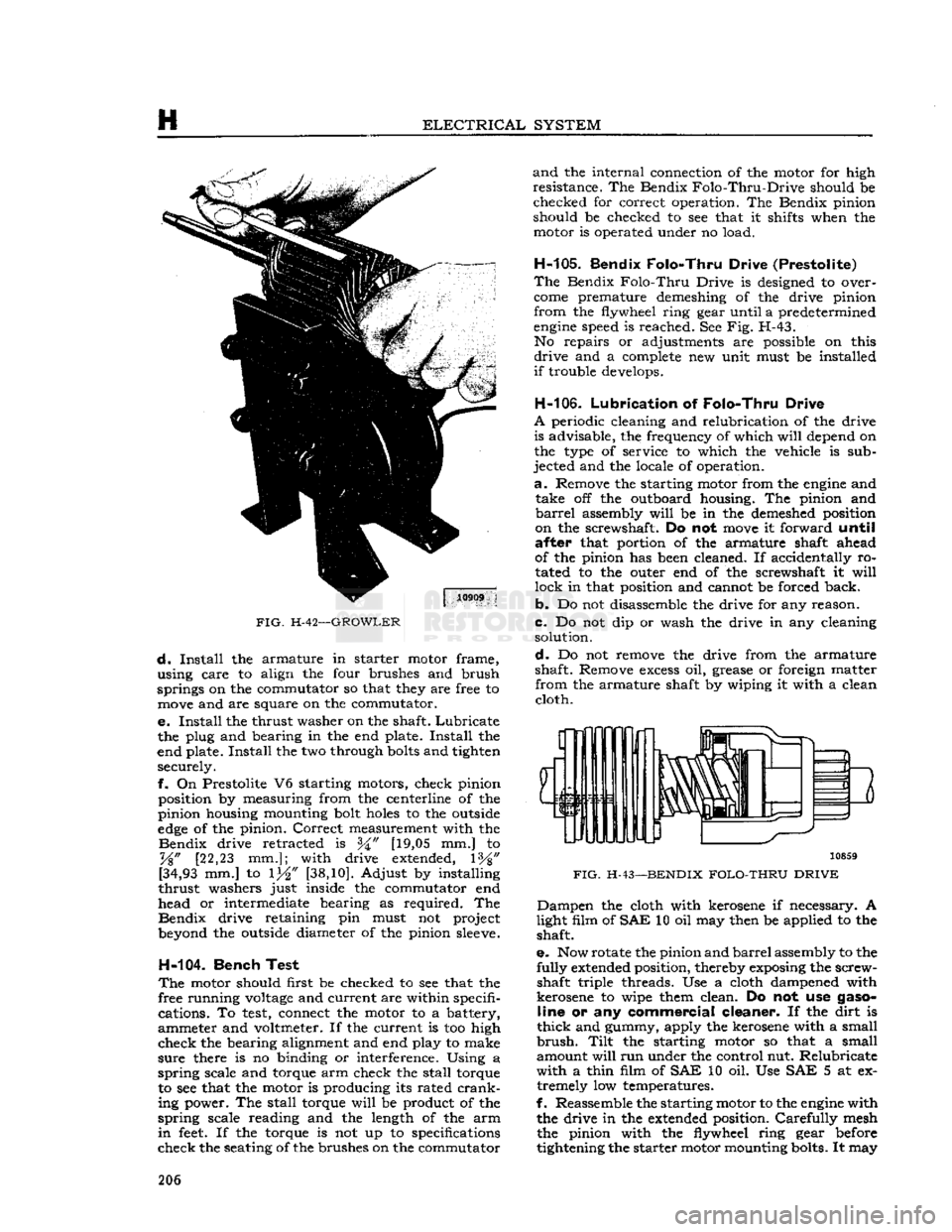

10240

FIG.

H-22—PRESTOLITE VOLTAGE REGULATOR

1—

"ARM"

Terminal

2—

"FLD"

Terminal

3— "BAT"

Terminal

The

sequence of operation of the circuit breaker is

as follows:

When

the generator is not running, the contacts

are

open. When the generator is started, the

voltage

builds up at the armature terminal and in the shunt

coil

and as

soon

as it reaches the value for which

the circuit breaker is calibrated, there is sufficient magnetism created by the shunt coil to

pull

down

the armature, closing the contacts which auto

matically

connects the generator to the battery.

With

the contacts thus closed the current in the

series coil is flowing from the generator to the battery or in the same direction as the current in

the shunt coil, so that the

pull

on the armature is

increased

by the magnetism of the series coil.

When

the

engine

is stopped and the generator

loses

speed, the

voltage

falls, and as

soon

as the gener

ator

voltage

drops below the battery terminal vol

tage,

the current flows from the battery to the generator, reversing the direction of current in the

series coil so that the magnetism created by the series coil

opposes

and reduces the magnetism of

the shunt

coil.

This

reduces the

pull

on the

armature

to a point where spring action

opens

the contacts.

H-44.

Voltage

Regulator

The

function of the

voltage

regulator is to hold

the generated

voltage

at a predetermined value as 190

Page 206 of 376

H

ELECTRICAL

SYSTEM

FIG.

H-42—GROWLER

d.

Install

the armature in starter motor frame,

using care to align the four brushes and brush

springs on the commutator so that they are free to

move

and are square on the commutator.

e.

Install

the thrust washer on the shaft.

Lubricate

the plug and bearing in the end plate.

Install

the

end plate.

Install

the two through

bolts

and tighten securely.

f.

On Prestolite V6 starting motors, check pinion position by measuring from the centerline of the

pinion housing mounting bolt

holes

to the outside

edge

of the pinion.

Correct

measurement with the

Bendix

drive retracted is [19,05 mm.] to

%"

[22,23 mm.]; with drive extended, 1%"

[34,93

mm.] to 1^" [38,10]. Adjust by installing

thrust

washers just inside the commutator end

head or intermediate bearing as required. The

Bendix

drive retaining pin must not project

beyond the outside diameter of the pinion

sleeve.

H-104.

Bench Test

The

motor should first be checked to see that the

free running

voltage

and current are within specifi cations. To

test,

connect the motor to a battery,

ammeter and voltmeter. If the current is too high

check

the bearing alignment and end play to make

sure

there is no binding or interference. Using a

spring

scale and torque arm check the stall torque to see that the motor is producing its rated

crank

ing power. The stall torque

will

be product of the

spring

scale reading and the length of the arm

in

feet.

If the torque is not up to specifications

check

the seating of the brushes on the commutator

and

the internal connection of the motor for high

resistance. The Bendix

Folo-Thru-Drive

should be checked for correct operation. The Bendix pinion

should be checked to see that it shifts when the motor is operated under no load.

H-105.

Bendix Folo-Thru Drive (Prestolite)

The

Bendix

Folo-Thru

Drive is designed to over

come

premature demeshing of the drive pinion

from

the flywheel ring gear until a predetermined

engine

speed is reached. See Fig. H-43. No repairs or adjustments are possible on this

drive

and a

complete

new unit must be installed

if

trouble develops.

H-106.

Lubrication

of

Folo-Thru Drive

A

periodic cleaning and relubrication of the drive is advisable, the frequency of which

will

depend on

the type of service to which the vehicle is sub

jected and the locale of operation.

a.

Remove the starting motor from the

engine

and take off the outboard housing. The pinion and

barrel

assembly

will

be in the demeshed position

on the screwshaft. Do not

move

it forward

until

after

that portion of the armature shaft ahead

of the pinion has been cleaned. If accidentally ro

tated to the outer end of the screwshaft it

will

lock

in that position and cannot be forced back.

b.

Do not disassemble the drive for any reason.

c.

Do not dip or wash the drive in any cleaning solution.

d.

Do not remove the drive from the armature

shaft. Remove

excess

oil, grease or foreign matter

from

the armature shaft by wiping it with a clean cloth.

3

10859

FIG.

H-43—BENDIX

FOLO-THRU DRIVE

Dampen

the cloth with kerosene if necessary. A

light film of

SAE

10 oil may then be applied to the shaft.

e.

Now rotate the pinion and

barrel

assembly to the

fully

extended position, thereby exposing the screw shaft triple threads. Use a cloth dampened with

kerosene to wipe them clean. Do not use

gaso

line

or any

commercial cleaner.

If the dirt is

thick

and gummy, apply the kerosene with a small

brush.

Tilt

the starting motor so that a small

amount

will

run under the control nut. Relubricate

with

a thin film of

SAE

10 oil. Use SAE 5 at ex tremely low temperatures.

f.

Reassemble the starting motor to the

engine

with the drive in the extended position.

Carefully

mesh the pinion with the flywheel ring gear before

tightening the starter motor mounting bolts. It may 206

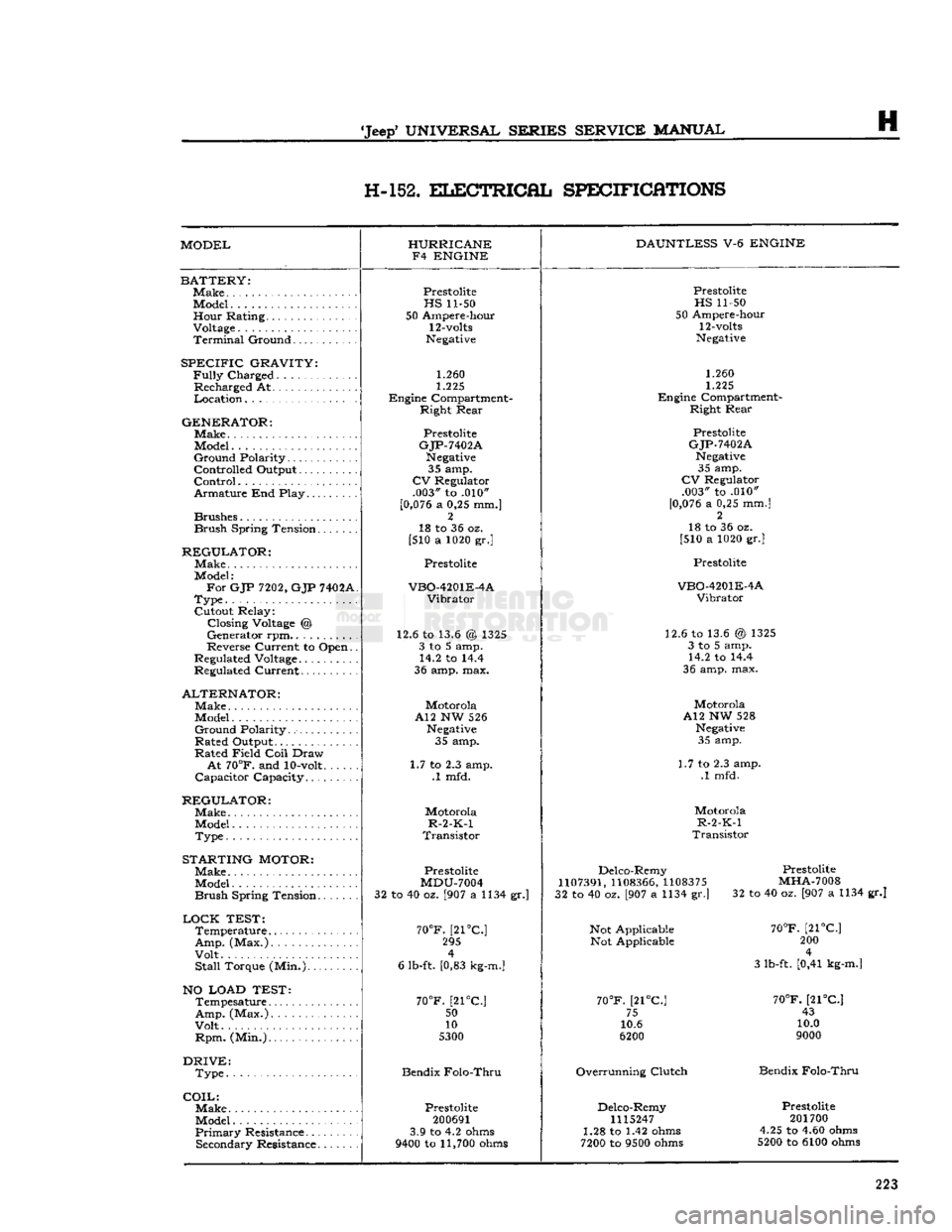

Page 223 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

H

H-152.

ELECTRICAL

SPECIFICATIONS

MODEL HURRICANE

F4 ENGINE DAUNTLESS

V-6

ENGINE

BATTERY:

Make

Model Hour Rating.

Voltage

Terminal

Ground

SPECIFIC

GRAVITY:

Fully

Charged

Recharged At

Location

GENERATOR:

Make.

Model

Ground

Polarity

Controlled Output

Control

Armature End Play

Brushes

Brush

Spring Tension

REGULATOR:

Make

Model:

For

GJP

7202,

GJP

7402A

Type

Cutout Relay: Closing

Voltage

@

Generator rpm..........

Reverse Current to Open.

Regulated

Voltage

Regulated Current

ALTERNATOR:

Make

Model

Ground

Polarity

Rated Output

Rated Field

Coil

Draw

At

70°F.

and

10-volt

Capacitor Capacity

REGULATOR:

Make

Model

Type

STARTING

MOTOR:

Make

Model

Brush

Spring Tension

LOCK

TEST:

Temperature

Amp.

(Max.)

Volt

Stall

Torque (Min.)

NO LOAD TEST:

Tempesature

Amp.

(Max.)

Volt

Rpm.

(Min.)

DRIVE:

Type

COIL:

Make.

Model

Primary

Resistance Secondary Resistance

Prestolite

HS

11-50

50 Ampere-hour

12-volts

Negative

1.260

1.225

Engine Compartment- Right Rear

Prestolite

GJP-7402A

Negative

35 amp.

CV

Regulator .003" to .010"

[0,076

a 0,25 mm.] 2

18 to 36 oz.

[510 a 1020 gr.]

Prestolite

VBO-4201E-4A

Vibrator

12.6 to 13.6 @ 1325 3 to 5 amp. 14.2 to 14.4

36 amp. max.

Motorola

A12 NW 526

Negative

35 amp.

1.7 to 2.3 amp. .1 mfd.

Motorola

R-2-K-1

Transistor

Prestolite

MDU-7004

32 to 40 oz. [907 a 1134 gr.]

70°F.

[21°C] 295 4

6 lb-ft. [0,83

kg-m.]

70°F.

[21°C.;

50

10

5300

Bendix Folo-Thru

Prestolite

200691

3.9 to 4.2

ohms

9400

to

11,700

ohms

Prestolite

HS

11-50

50 Ampere-hour

12-volts

Negative

1.260

1.225

Engine Compartment- Right Rear

Prestolite

GJP-7402A

Negative

35 amp.

CV

Regulator .003" to .010"

[0,076

a 0,25 mm.] 2

18 to 36 oz.

[510 a 1020 gr.]

Prestolite

VBO-4201E-4A

Vibrator

12.6 to 13.6 @ 1325 3 to 5 amp. 14.2 to 14.4

36 amp. max.

Motorola

A12 NW 528

Negative

35 amp.

1.7 to 2.3 amp. .1 mfd.

Motorola

R-2-K-1

Transistor

Delco-Remy

1107391,

1108366,

1108375

32 to 40 oz. [907 a 1134 gr.]

Not Applicable Not Applicable

70°F.

[21°C] 75

10.6

6200

Overrunning Clutch Delco-Remy

1115247

1.28 to 1.42

ohms

7200

to

9500

ohms

Prestolite

MHA-7008

32 to 40 oz. [907 a 1134 gr.]

70°F.

[21°C] 200 4

3 lb-ft. [0,41

kg-m.]

70°F.

[21°C] 43

10.0

9000

Bendix Folo-Thru

Prestolite

201700

4.25 to 4.60

ohms

5200

to 6100

ohms

223

Page 232 of 376

CLUTCH

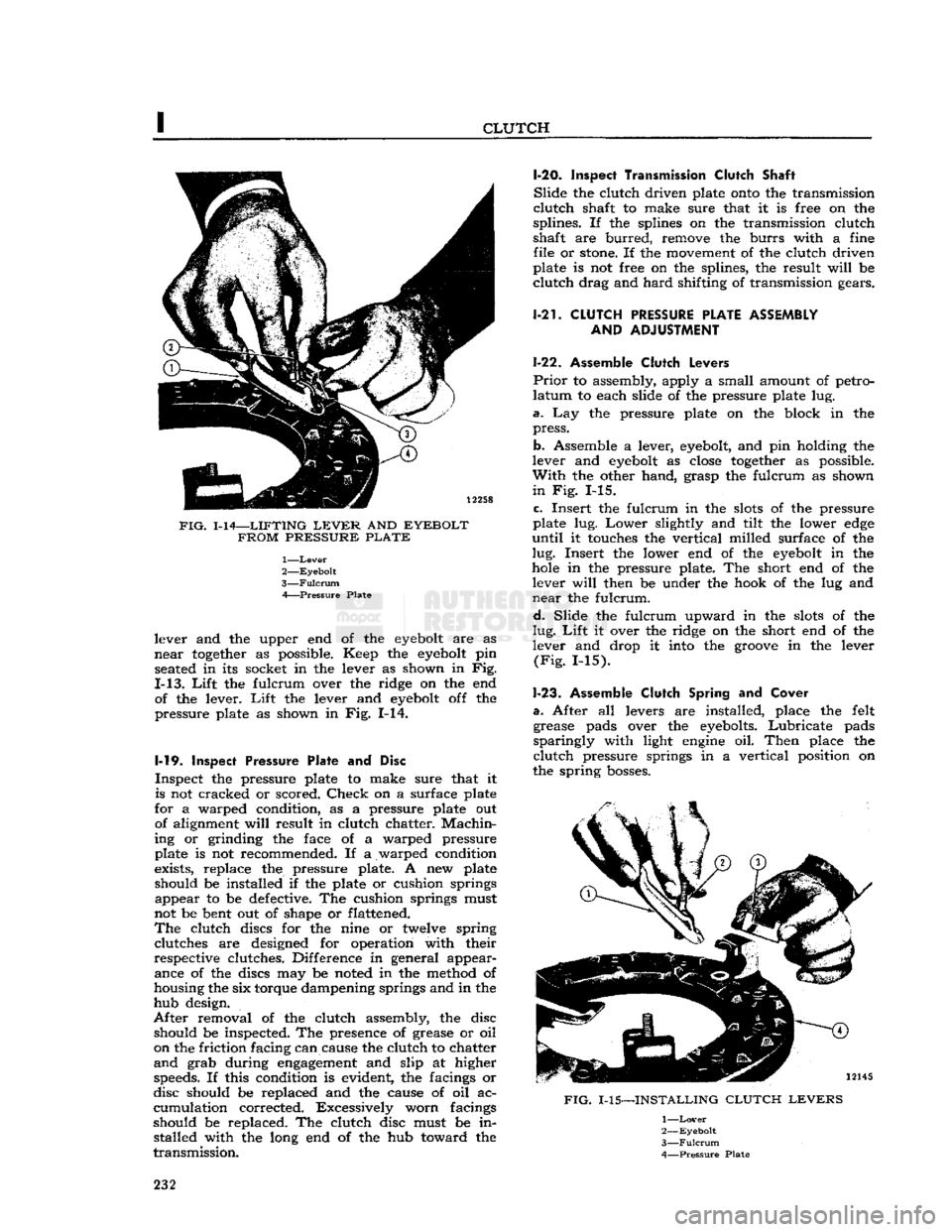

FIG.

1-14—LIFTING

LEVER

AND

EYEBOLT FROM PRESSURE PLATE

1—

Lever

2—

Eyebolt

3—

Fulcrum

A Pressure Plate

lever and the upper end of the

eyebolt

are as

near

together

as possible. Keep the

eyebolt

pin seated in its socket in the lever as shown in Fig.

1-13.

Lift

the fulcrum over the ridge on the end of the lever.

Lift

the lever and

eyebolt

off the

pressure plate as shown in Fig. 1-14.

1-19.

Inspect

Pressure Plate and Disc

Inspect the pressure plate to make sure that it is not cracked or scored.

Check

on a surface plate

for a warped condition, as a pressure plate out of alignment

will

result in clutch chatter.

Machin

ing or grinding the face of a warped pressure

plate is not recommended. If a warped condition

exists, replace the pressure plate. A new plate

should be installed if the plate or cushion springs appear to be defective. The cushion springs must

not be bent out of shape or flattened.

The

clutch discs for the nine or twelve spring clutches are designed for operation with their

respective clutches. Difference in general appear ance of the discs may be noted in the method of

housing the six torque dampening springs and in the

hub design.

After

removal of the clutch assembly, the disc should be inspected. The presence of grease or oil

on the friction facing can cause the clutch to chatter

and

grab during

engagement

and slip at higher speeds. If this condition is evident, the facings or

disc should be replaced and the cause of oil ac

cumulation corrected. Excessively worn facings

should be replaced. The clutch disc must be in stalled with the long end of the hub toward the

transmission.

1-20.

Inspect Transmission Clutch

Shaft

Slide

the clutch driven plate

onto

the transmission

clutch

shaft to make sure that it is free on the

splines. If the splines on the transmission clutch

shaft are

burred,

remove the

burrs

with a fine file or

stone.

If the movement of the clutch driven

plate is not free on the splines, the result

will

be

clutch

drag and

hard

shifting of transmission gears.

1-21.

CLUTCH

PRESSURE

PLATE ASSEMBLY AND

ADJUSTMENT

1-22. Assemble

Clutch

Levers

Prior

to assembly, apply a small amount of petro

latum

to each slide of the pressure plate lug.

a.

Lay the pressure plate on the block in the

press.

b. Assemble a lever,

eyebolt,

and pin holding the

lever and

eyebolt

as

close

together

as possible.

With

the other hand, grasp the fulcrum as shown

in

Fig. 1-15.

c.

Insert the fulcrum in the

slots

of the pressure

plate lug.

Lower

slightly and tilt the lower

edge

until

it touches the vertical milled surface of the

lug.

Insert the lower end of the

eyebolt

in the

hole

in the pressure plate. The short end of the lever

will

then be under the hook of the lug and

near

the fulcrum.

d.

Slide the fulcrum upward in the

slots

of the

lug.

Lift

it over the ridge on the short end of the

lever and drop it into the

groove

in the lever

(Fig.

1-15).

1-23.

Assemble

Clutch

Spring and

Cover

a.

After all levers are installed, place the felt grease pads over the eyebolts.

Lubricate

pads

sparingly

with light

engine

oil.

Then

place the

clutch

pressure springs in a vertical position on

the spring

bosses.

FIG.

1-15—INSTALLING

CLUTCH LEVERS

1—

Lover

2—

Eyebolt

3—

Fulcrum

4—

Pressure

Plate

232

Page 235 of 376

![JEEP CJ 1953 Workshop Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta JEEP CJ 1953 Workshop Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta](/img/16/57040/w960_57040-234.png)

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

stamped thereon.

c.

From

flat bar stock at least Vfe" [3 mm.] thick,

make a

gauge

as shown in Fig. 1-22. Harden, grind

to size, and stamp sizes on the

gauge.

1-27.

Clutch Installation

a.

Very

sparingly, apply wheel bearing lubricant

to inner surface of pilot bushing in crankshaft.

Caution:

If

excessive

lubricant is applied to pilot bushing, it

will

run out on face of flywheel when

hot and

ruin

the driven plate facings.

b. Make sure that splines in the driven plate hub

are

clean; apply a light coat of lubricant to splines

of hub and transmission drive gear shaft. Slide plate over gear shaft several times; remove plate

from shaft and wipe off

excess

lubricant.

Caution:

Driven plate facings must be kept clean

and

dry.

c.

Fill

groove

in throwout bearing collar with wheel bearing lubricant. See Fig. 1-23. Make sure

that front bearing retainer of transmission is clean;

apply a light coat of wheel bearing lubricant. Slide

throwout bearing over bearing retainer several times. Remove bearing from retainer and wipe off

excess

lubricant.

12736

FIG.

1-23—LUBRICATION

POINTS

—

CLUTCH

THROWOUT

BEARING

COLLAR

1—Coat

This

Groove 2—Pack

This

Recess

d.

Clean

and apply wheel bearing lubricant to ball

stud in flywheel housing and to the

seat

in clutch

fork.

e.

If disassembled, install pressure plate in the cover assembly, lining up the

groove

on its

edge

with the

groove

on the

edge

of the cover.

Install

pressure plate retracting springs, and the three

drive

strap-to-pressure plate

bolts

and lock washers.

Torque

bolts

11 lb-ft. [1,51 kg-m.].

Note:

The diaphragm

type

clutch assembly is fac

tory calibrated and requires no adjustment

before

installation. Refer to Par. 1-14 to adjust Borg and

Beck

coil spring

type

clutch assembly.

f.

Install

the pressure plate and driven plate on

flywheel. Support both assemblies with a spare

main

drive gear.

Note:

Be certain that

mark

on clutch cover is

aligned with the

mark

made on the flywheel during

clutch removal.

g.

Install

clutch attaching

bolts

and tighten alter nately so that clutch is drawn squarely

into

position

on flywheel.

Each

bolt

must be

tightened

one turn at a time to avoid bending the clutch cover flange.

Torque

bolts

30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

h.

Lubricate

the ball stud and clutch fork with

wheel bearing lubricant and install clutch fork.

Note:

Be certain that fork retaining spring is

tight

on pivot ball stud.

i.

Install

flywheel housing on

engine

cylinder

block.

Caution:

Be certain that dowel pins are installed

in

cylinder block.

j.

Lubricate

the recess on the inside of the throw-

out bearing collar. Be careful not to use too much

lubricant.

See Fig. 1-23.

Caution:

Make certain that the lips of the spring

retainer (attached to the clutch fork) are in

groove

of the bearing. See Fig. 1-24.

k.

Install

throwout bearing assembly and connect

clutch linkage.

I.

Install

transmission as described in Section J. m. Adjust clutch for %"

[19,05

mm.] free travel,

see

Par.

1-3. 235