ECU JEEP CJ 1953 Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 281 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

M

If

the joint binds when assembled, tap the yoke

lightly to relieve any pressure on the bearings at the end of the

journal.

M-8-

Steering

Knuckle

Service

The

steering knuckle pins pivot on tapered roller

bearings. Replacement of

these

bearings requires

removal

of the hub and brake drum assembly,

wheel bearings, axle shaft, spindle, steering tie rod,

and

steering knuckle. Disassemble the steering

knuckle

as follows:

Remove the

eight

screws which hold the oil seal

retainer

in place. Remove the four screws holding

the lower pivot pin bearing cap. Remove the four screws holding the upper bearing cap in place. Re

move

the bearing cap. The steering knuckle can

now be removed from the axle. Wash all parts in cleaning solvent. Replace any damaged or worn

parts.

Inspect the bearing and races for scores,

cracks,

or chips. Should the bearing cups be damaged,

they

may be removed and installed with

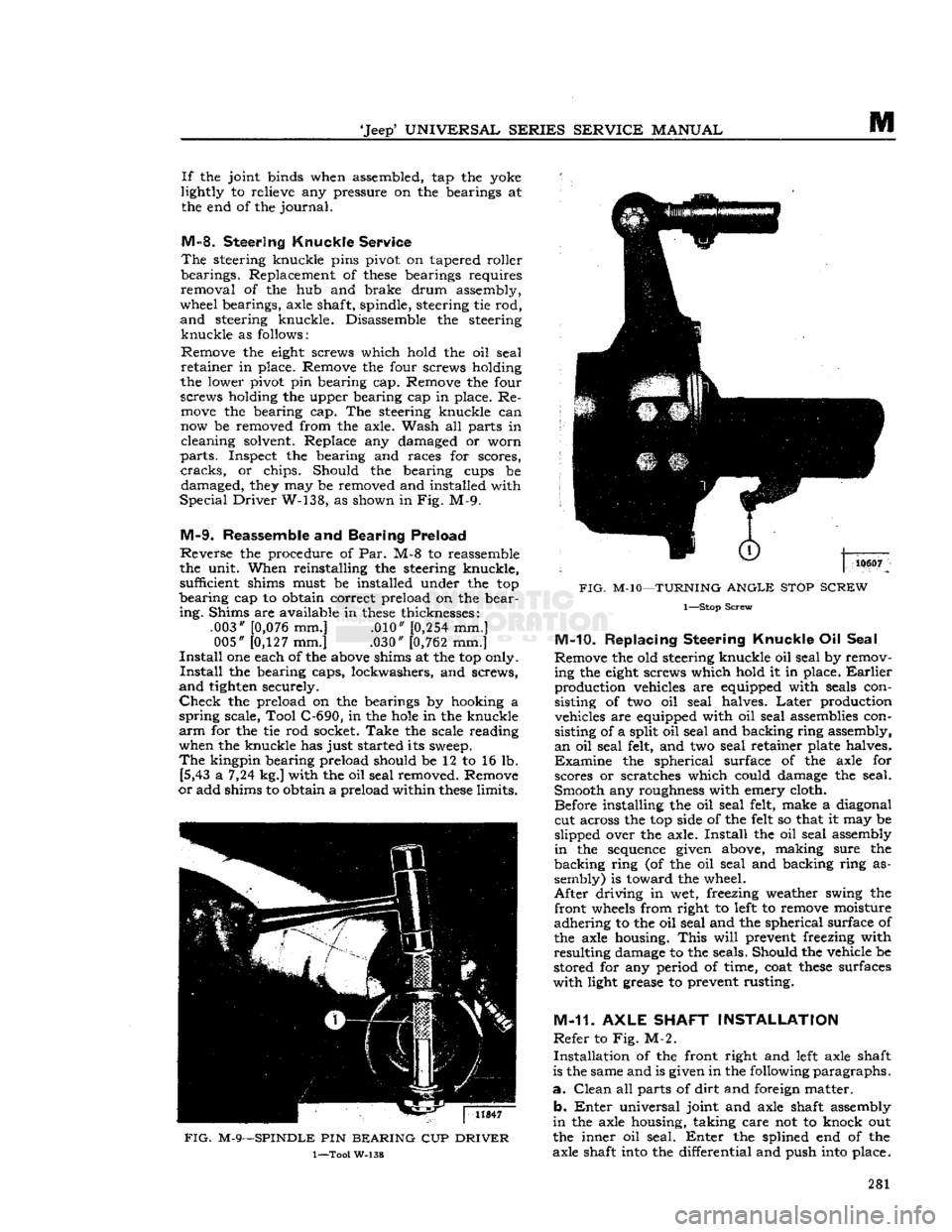

Special

Driver

W-138, as shown in Fig. M-9.

M-9.

Reassemble

and

Bearing Preload

Reverse

the procedure of Par. M-8 to reassemble

the unit. When reinstalling the steering knuckle, sufficient shims must be installed under the top

bearing

cap to obtain correct preload on the bear

ing.

Shims are available in

these

thicknesses: .003"

[0,076

mm.] .010"

[0,254

mm.] 005"

[0,127

mm.] .030"

[0,762

mm.]

Install

one each of the

above

shims at the top only.

Install

the bearing caps, lockwashers, and screws,

and

tighten securely.

Check

the preload on the bearings by hooking a

spring

scale, Tool C-690, in the

hole

in the knuckle

arm

for the tie rod socket.

Take

the scale reading when the knuckle has just started its

sweep.

The

kingpin bearing preload should be 12 to 16 lb. [5,43 a 7,24 kg.] with the oil seal removed. Remove

or

add shims to obtain a preload within

these

limits.

FIG.

M-9—SPINDLE

PIN

BEARING

CUP

DRIVER

1—Tool

W-138

FIG.

M-10—TURNING

ANGLE

STOP

SCREW

1—Stop

Screw

M-10.

Replacing Steering

Knuckle

Oil Seal

Remove the old steering knuckle oil seal by remov ing the

eight

screws which hold it in place.

Earlier

production vehicles are equipped with seals con sisting of two oil seal halves.

Later

production vehicles are equipped with oil seal assemblies con

sisting of a split oil seal and backing ring assembly,

an

oil seal felt, and two seal retainer plate halves.

Examine

the spherical surface of the axle for scores or scratches which could damage the seal.

Smooth any roughness with emery cloth. Before installing the oil seal felt, make a diagonal

cut across the top side of the

felt

so that it may be

slipped over the axle.

Install

the oil seal assembly

in

the

sequence

given above, making sure the

backing

ring (of the oil seal and backing ring as

sembly) is toward the wheel.

After

driving in wet, freezing weather swing the

front

wheels

from right to

left

to remove moisture

adhering

to the oil seal and the spherical surface of

the axle housing.

This

will

prevent freezing with

resulting

damage to the seals. Should the vehicle be

stored for any period of time, coat

these

surfaces

with

light grease to prevent rusting.

M-11.

AXLE

SHAFT

INSTALLATION

Refer

to Fig. M-2.

Installation

of the front right and

left

axle shaft

is the same and is given in the following

paragraphs.

a.

Clean

all parts of

dirt

and foreign matter.

b.

Enter

universal joint and axle shaft assembly

in

the axle housing, taking care not to knock out

the inner oil seal.

Enter

the splined end of the

axle shaft

into

the differential and push

into

place. 281

Page 282 of 376

FRONT

AXLE

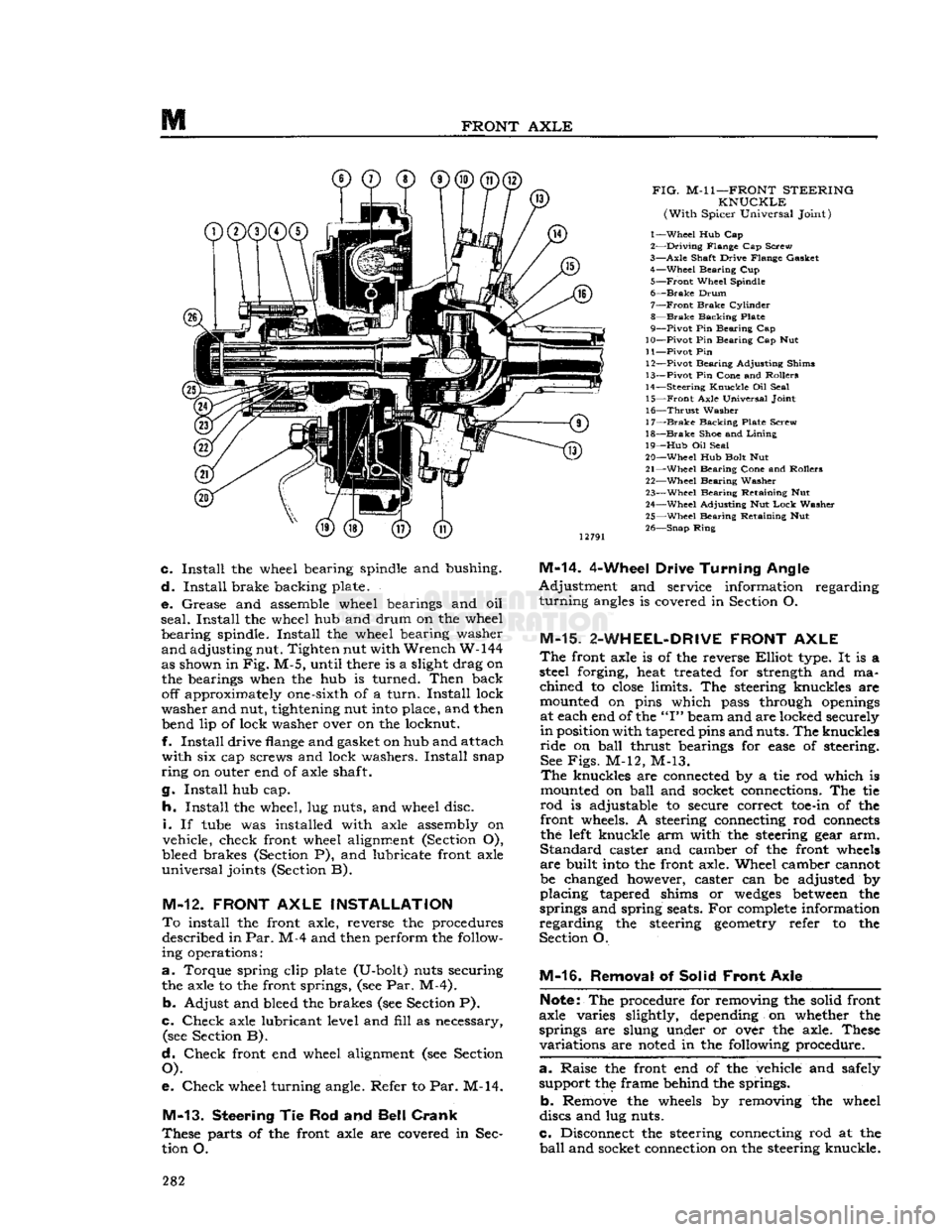

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 292 of 376

N

REAR

AXLE

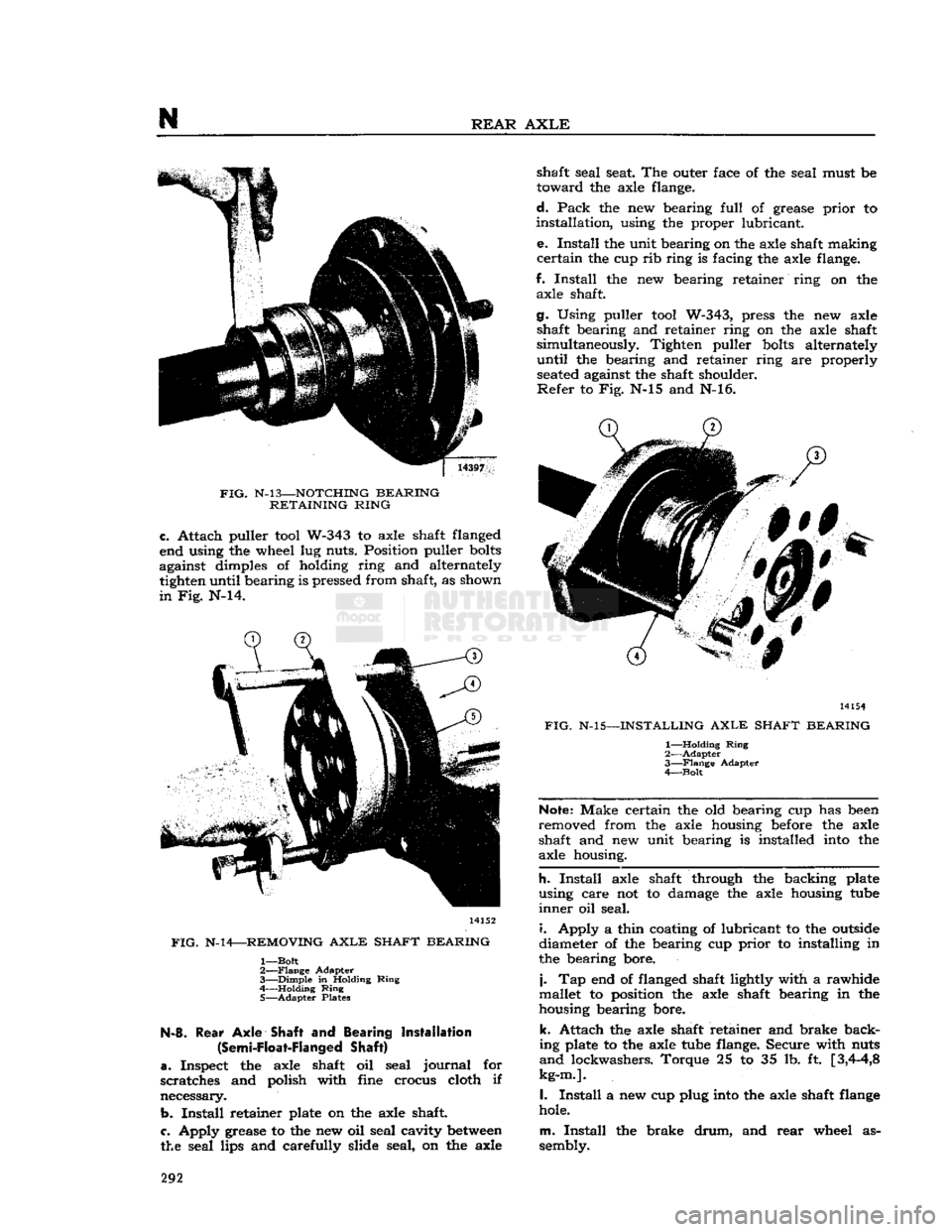

FIG.

N-l3—NOTCHING

BEARING

RETAINING

RING

c.

Attach puller

tool

W-343 to axle shaft flanged

end using the wheel lug nuts. Position puller

bolts

against dimples of holding ring and alternately tighten until bearing is pressed from shaft, as shown

in

Fig. N-14. 14152

FIG.

N-14—REMOVING

AXLE

SHAFT

BEARING

1—

Bolt

2—

Flange

Adapter

3—

Dimple

in Holding

Ring

4 Holding

Ring

5—

Adapter

Plates N-8.

Rear

Axle

Shaft and Bearing Installation

(Semi-Float-Flanged

Shaft)

a.

Inspect the axle shaft oil seal

journal

for

scratches and polish with fine crocus cloth if

necessary.

b.

Install

retainer plate on the axle shaft

c.

Apply grease to the new oil seal cavity

between

the seal lips and carefully slide seal, on the axle shaft seal seat. The outer face of the seal must be

toward

the axle flange.

d.

Pack

the new bearing

full

of grease

prior

to

installation,

using the proper lubricant.

e.

Install

the unit bearing on the axle shaft making

certain

the cup rib ring is facing the axle flange.

f.

Install

the new bearing retainer ring on the axle shaft.

g. Using puller

tool

W-343, press the new axle shaft bearing and retainer ring on the axle shaft

simultaneously. Tighten puller

bolts

alternately

until

the bearing and retainer ring are properly

seated

against the shaft shoulder.

Refer

to Fig. N-15 and N-16. 14154

FIG.

N-15—INSTALLING

AXLE

SHAFT

BEARING

1—

Holding

Ring

2—

Adapter

3—

Flange

Adapter

4—

Bolt

Note:

Make certain the old bearing cup has

been

removed from the axle housing

before

the axle

shaft and new unit bearing is installed

into

the

axle housing.

h.

Install

axle shaft through the backing plate

using care not to damage the axle housing

tube

inner

oil seal.

i.

Apply a thin coating of lubricant to the

outside

diameter of the bearing cup

prior

to installing in

the bearing bore.

j.

Tap end of flanged shaft lightly with a rawhide

mallet to position the axle shaft bearing in the

housing bearing bore.

k.

Attach the axle shaft retainer and brake back

ing plate to the axle

tube

flange. Secure with nuts

and

lockwashers. Torque 25 to 35 lb. ft

[3,4-4,8

kg-m.].

I.

Install

a new cup plug

into

the axle shaft

flange

hole.

m.

Install

the brake

drum,

and

rear

wheel as

sembly. 292

Page 314 of 376

STEERING

SYSTEM

O-L

GENERAL

The

steering system on all Jeep Universal vehicles

consists of the steering gear, steering wheel, steering column and shaft, and steering linkage.

This

section covers wheel alignment, steering linkage,

steering gear, steering column and steering wheel.

0-2. Steering

Gear

Function

The

steering gear is a reducing gear. It exchanges a

relatively

large amount of movement with a small force (applied by the driver at the steering wheel), for a much smaller amount of movement with a

greatly increased force through a cam and lever

action type steering gear. The steering gear ratio is 17.9 to 1 on vehicles equipped with the F4

engine

and

19 to 1 with the V6 engine.

0-3. Steering

Linkage

Refer

to Fig. O-l.

The

steering linkage consists of a steering arm at

tached to the steering gear, a steering connecting

rod,

(drag

link),

connecting the steering arm to the

beilcrank,

and a steering tie rod connecting the

beilcrank

to the axle tie rod. The beilcrank pivots

on a pin mounted just to the left of the frame front crossmember. The steering tie rod is connected to

the beilcrank and

extends

to the right

ball

joint as sembly of tie rod. The tie rod

extends

to the wheels,

being connected to their respective steering knuckle

arms

at the wheels.

With

this linkage arrangement,

as the steering arm

moves

rearward,

the front

wheels

turn

to the left. As the steering arm

moves

forward,

the wheels

turn

to the right.

Ball

joints are used to secure the drag

link,

steering

connecting rod and tie rod ends. The

ball

joints

assist in maintaining

good

steering control and con

stant toe-in of the front wheels under all driving conditions. If the

ball

joints

become

worn enough

to allow free motion in the linkage, they should be,

replaced.

Note:

Ball

joint replacement of the tie rod requires

resetting of the wheel toe-in adjustment.

0-4.

Steering

Column

and Gear

Alignment

When

adjusting a steering gear remove all loads

from

the unit by disconnecting the steering con

necting rod (drag

link)

from the steering arm and

also

loosen

the instrument panel bracket and the

steering gear to frame

bolts

to allow the steering

post

to correctly align itself. When retightening the

steering gear to frame

bolts

use a torque wrench

pull

of 45 to 55 lb-ft. [6,2 a 7,6 kg-m.] on the

Vk*

bolts

and 30 to 40 lb-ft. [4,15 a 5,5 kg-m.] on the

Vs"

bolts. 10811

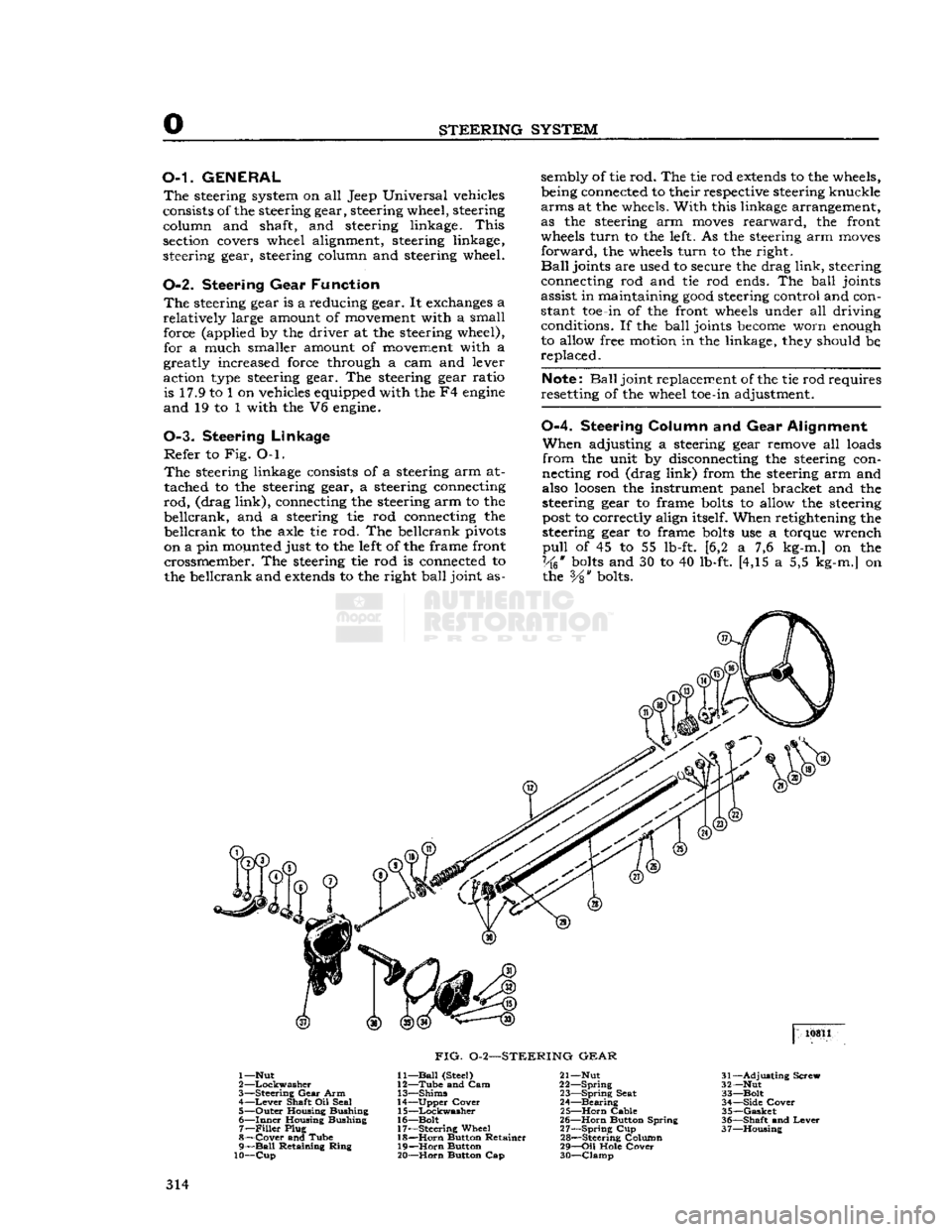

FIG.

0-2—STEERING

GEAR

1—Nut

2

—Lockwasher

3—

Steering

Gear

Arm 4—

Lever

Shaft Oil Seal

5—

Outer

Housing Bushing

6—

Inner

Housing Bushing 7—

Filler

Plug

8—

Cover

and Tube

9—

Ball

Retaining

Ring

10—Cup

11—

Ball

(Steel)

12—

Tube

and Cam

13—

Shims

14—

Upper

Cover

15—

Lockwasher

16—

Bolt

17—

Steering

Wheel 18—

Horn

Button Retainer

19—

Horn

Button

20—

Horn

Button Cap 21— Nut

22—

Spring

23—

Spring

Seat

24—

Bearing

25—

Horn

Cable

26—

Horn

Button Spring

27—

Spring

Cup

28—

Steering Column

29—

Oil

Hole

Cover

30—

Clamp

31—

Adjusting

Screw

32— Nut

33—

Bolt

34—

Side

Cover

35—

Gasket

36—

Shaft

and

Lever

37—

Housing

314

Page 317 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

The

purpose of caster Fig. O-S, is to provide steer

ing stability which

will

keep the front wheels in the

straight

ahead position and also assist in straighten

ing up the wheels when coming out of a

turn.

Caster

of the front wheels is preset. If the angle of

caster,

when accurately measured, is found to be

incorrect,

correct it to the specification given at

the end of this section by either installing new

parts

or installing caster shims

between

the axle

pad

and the springs.

If

the camber and toe-in are correct and it is known

the the axle is not twisted, a satisfactory check

may

be made by testing the vehicle on the road.

Before road testing, make sure all tires are properly

inflated,

being particularly careful that both front

tires are inflated to exactly the same pressure.

If

vehicle turns easily to either side but is

hard

to

straighten out, insufficient caster for easy handling of vehicle is indicated. If correction is necessary, it

can

usually be accomplished by installing shims

between

the springs and axle pads to secure the

desired

result.

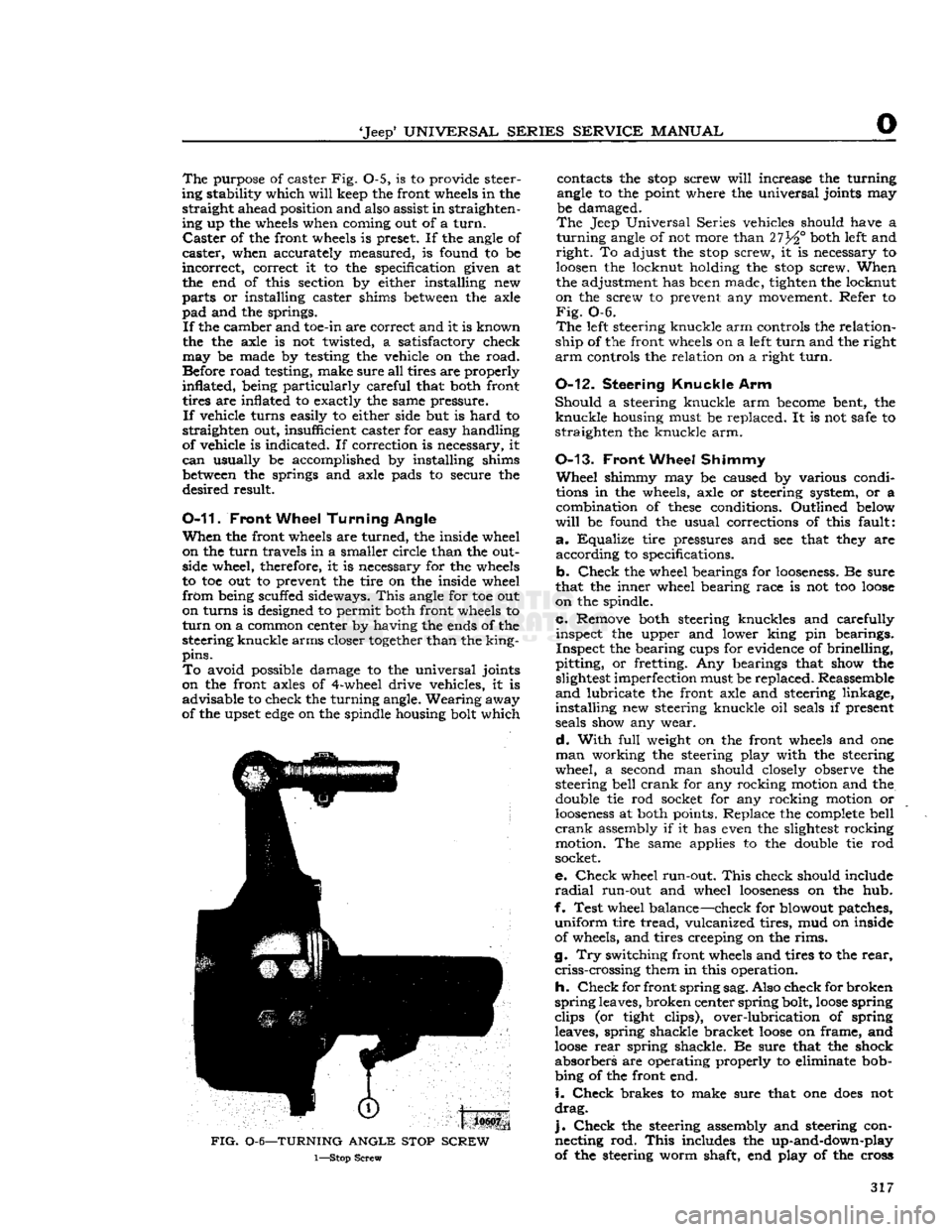

0-11-

Front

Wheel

Turning

Angle

When

the front wheels are turned, the inside wheel

on the

turn

travels in a smaller circle than the outside wheel, therefore, it is necessary for the wheels

to toe out to prevent the tire on the inside wheel

frOm

being scuffed sideways.

This

angle for toe out

on turns is designed to permit both front wheels to

turn

on a common center by having the ends of the

steering

knuckle

arms closer

together

than the king

pins.

To

avoid possible damage to the universal joints

on the front axles of 4-wheel drive vehicles, it is advisable to check the turning angle.

Wearing

away

of the upset

edge

on the spindle housing bolt which

10607

FIG.

0-6—TURNING

ANGLE

STOP

SCREW

1—Stop

Screw

contacts the

stop

screw

will

increase the turning

angle to the point where the universal joints may

be damaged.

The

Jeep Universal Series vehicles should have a

turning

angle of not more than 27^° both left and

right.

To adjust the

stop

screw, it is necessary to

loosen

the locknut holding the

stop

screw. When

the adjustment has been made, tighten the locknut

on the screw to prevent any movement. Refer to

Fig.

O 6.

The

left steering knuckle arm controls the relation

ship of the front wheels on a left

turn

and the right

arm

controls the relation on a right

turn.

0-12. Steering

Knuckle

Arm

Should

a steering knuckle arm

become

bent, the

knuckle

housing must be replaced. It is not safe to

straighten the knuckle arm.

0-13.

Front

Wheel

Shimmy

Wheel

shimmy may be caused by various condi

tions in the wheels, axle or steering system, or a

combination of

these

conditions. Outlined below

will

be found the usual corrections of this fault:

a.

Equalize

tire pressures and see that they are

according

to specifications.

b.

Check

the wheel bearings for

looseness.

Be sure

that the inner wheel bearing race is not too

loose

on the spindle.

c.

Remove both steering knuckles and carefully inspect the upper and lower king pin bearings.

Inspect

the bearing cups for evidence of brinelling,

pitting, or fretting. Any bearings that show the slightest imperfection must be

replaced.

Reassemble

and

lubricate the front axle and steering linkage,

installing

new steering knuckle oil seals if present

seals show any wear.

d.

With

full

weight on the front wheels and one

man

working the steering play with the steering

wheel, a second man should closely observe the steering bell

crank

for any rocking motion and the

double tie rod socket for any rocking motion or

looseness

at both points. Replace the complete bell

crank

assembly if it has even the slightest rocking motion. The same applies to the double tie rod

socket.

e.

Check

wheel run-out.

This

check should include

radial

run-out and wheel

looseness

on the hub.

f- Test wheel balance—check for blowout patches,

uniform

tire tread, vulcanized tires, mud on inside

of wheels, and tires creeping on the

rims.

g.

Try

switching front wheels and tires to the

rear,

criss-crossing

them in this operation.

h.

Check

for front

spring

sag. Also check for broken

spring

leaves, broken center

spring

bolt,

loose

spring

clips

(or tight clips), over-lubrication of spring leaves, spring shackle bracket

loose

on frame, and

loose

rear

spring shackle. Be sure that the shock

absorbers

are operating properly to eliminate bobbing of the front end.

i.

Check

brakes to make sure that one

does

not

drag.

j.

Check

the steering assembly and steering con necting rod.

This

includes the up-and-down-play

of the steering worm shaft, end play of the cross 317

Page 326 of 376

p

BRAKES

be either a defective master cylinder or the use of

low grade brake fluid which has expanded because

of heat. Use standard duty brake fluid conforming to

SAE-J1703

specification.

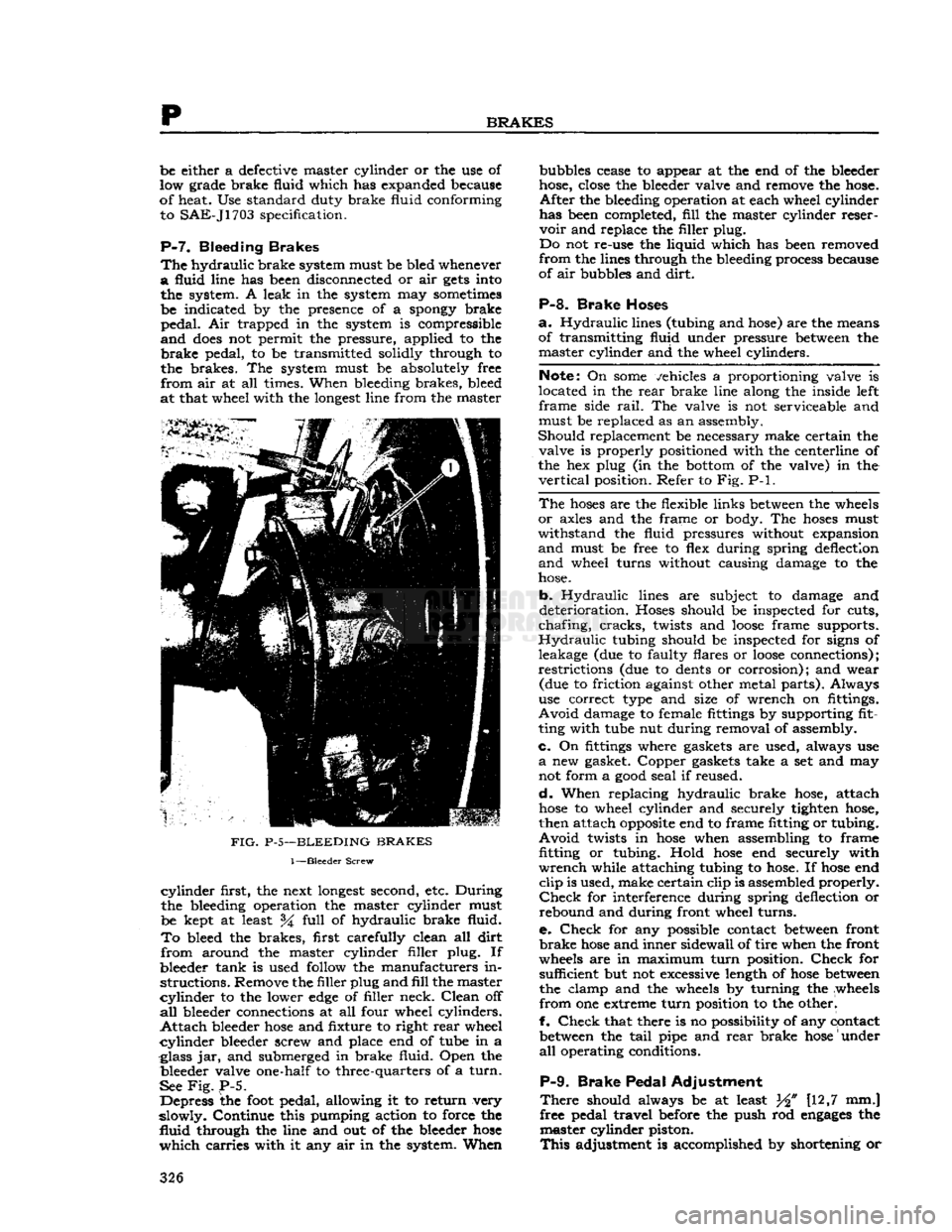

P-7.

Bleeding

Brakes

The

hydraulic

brake system must be bled whenever

a

fluid line has been disconnected or air

gets

into the system. A leak in the system may sometimes

be indicated by the presence of a spongy brake

pedal.

Air trapped in the system is compressible

and

does

not permit the pressure, applied to the

brake

pedal, to be transmitted solidly through to

the brakes. The system must be absolutely free

from

air at all times. When bleeding brakes, bleed

at that wheel with the

longest

line from the master

FIG.

P-5—BLEEDING

BRAKES

1—Bleeder

Screw

cylinder

first, the next

longest

second, etc. During

the bleeding operation the master cylinder must

be kept at least %

full

of hydraulic brake fluid.

To

bleed the brakes, first carefully clean all

dirt

from

around the master cylinder filler plug. If

bleeder tank is used follow the manufacturers in

structions.

Remove the filler plug and

fill

the master

cylinder

to the lower

edge

of filler neck.

Clean

off

all

bleeder connections at all four wheel cylinders.

Attach

bleeder

hose

and fixture to right

rear

wheel

cylinder

bleeder screw and place end of tube in a

glass jar, and submerged in brake fluid. Open the bleeder valve one-half to three-quarters of a

turn.

See

Fig.

P-5.

Depress the

foot

pedal, allowing it to return very

slowly. Continue this pumping action to force the

fluid

through the line and out of the bleeder

hose

which

carries with it any air in the system. When bubbles cease to appear at the end of the bleeder

hose, close the bleeder valve and remove the hose.

After

the bleeding operation at each wheel cylinder

has been completed,

fill

the master cylinder reser

voir

and replace the filler plug.

Do not re-use the liquid which has been removed

from

the lines through the bleeding process because

of air bubbles and

dirt.

P-8.

Brake Hoses

a.

Hydraulic

lines (tubing and hose) are the means

of transmitting fluid under pressure between the master cylinder and the wheel cylinders.

Note:

On

some

vehicles a proportioning valve is

located in the

rear

brake line along the inside left

frame

side

rail.

The valve is not serviceable and

must be replaced as an assembly.

Should

replacement be necessary make certain the valve is properly positioned with the centerline of

the hex plug (in the bottom of the valve) in the

vertical

position. Refer to Fig. P-l.

The

hoses

are the flexible links between the wheels

or

axles and the frame or body. The

hoses

must

withstand

the fluid pressures without expansion

and

must be free to flex during spring deflection

and

wheel turns without causing damage to the

hose.

b.

Hydraulic

lines are subject to damage and

deterioration. Hoses should be inspected for cuts,

chafing,

cracks,

twists and

loose

frame supports.

Hydraulic

tubing should be inspected for signs of

leakage (due to faulty flares or

loose

connections);

restrictions

(due to dents or corrosion); and wear (due to friction against other metal parts). Always

use correct type and size of wrench on fittings.

Avoid

damage to female fittings by supporting fit

ting with tube nut during removal of assembly.

c.

On fittings where gaskets are used, always use

a

new gasket. Copper gaskets take a set and may

not form a

good

seal if reused.

d.

When replacing hydraulic brake hose, attach

hose

to wheel cylinder and securely tighten hose,

then attach

opposite

end to frame fitting or tubing.

Avoid

twists in

hose

when assembling to frame fitting

or

tubing. Hold

hose

end securely with

wrench

while attaching tubing to hose. If

hose

end

clip

is used, make certain clip is assembled properly.

Check

for interference during spring deflection or

rebound and during front wheel turns.

e.

Check

for any possible contact between front

brake

hose

and inner sidewall of tire when the front

wheels are in maximum

turn

position.

Check

for sufficient but not excessive length of

hose

between

the clamp and the wheels by turning the wheels

from

one extreme

turn

position to the otherl

f.

Check

that there is no possibility of any contact between the

tail

pipe and

rear

brake

hose

under

all

operating conditions.

P-9.

Brake Pedal Adjustment

There

should always be at least W [12,7 mm.]

free pedal travel before the push rod

engages

the master cylinder piston.

This

adjustment is accomplished by shortening or 326

Page 327 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P

lengthening of the brake master cylinder eye bolt.

This

is

done

so the primary cup

will

clear the by

pass port when the piston is in the off position,

otherwise the compensating action of the master

cylinder

for expansion and contraction of the fluid

in

the system, due to temperature changes,

will

be destroyed and cause the brakes to drag.

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One

way to

compensate

for this wear is to install a pedal

slack

adjuster kit,

Part

No.

921936.

FIG.

P-6—HAND

BRAKE

ADJUSTMENT

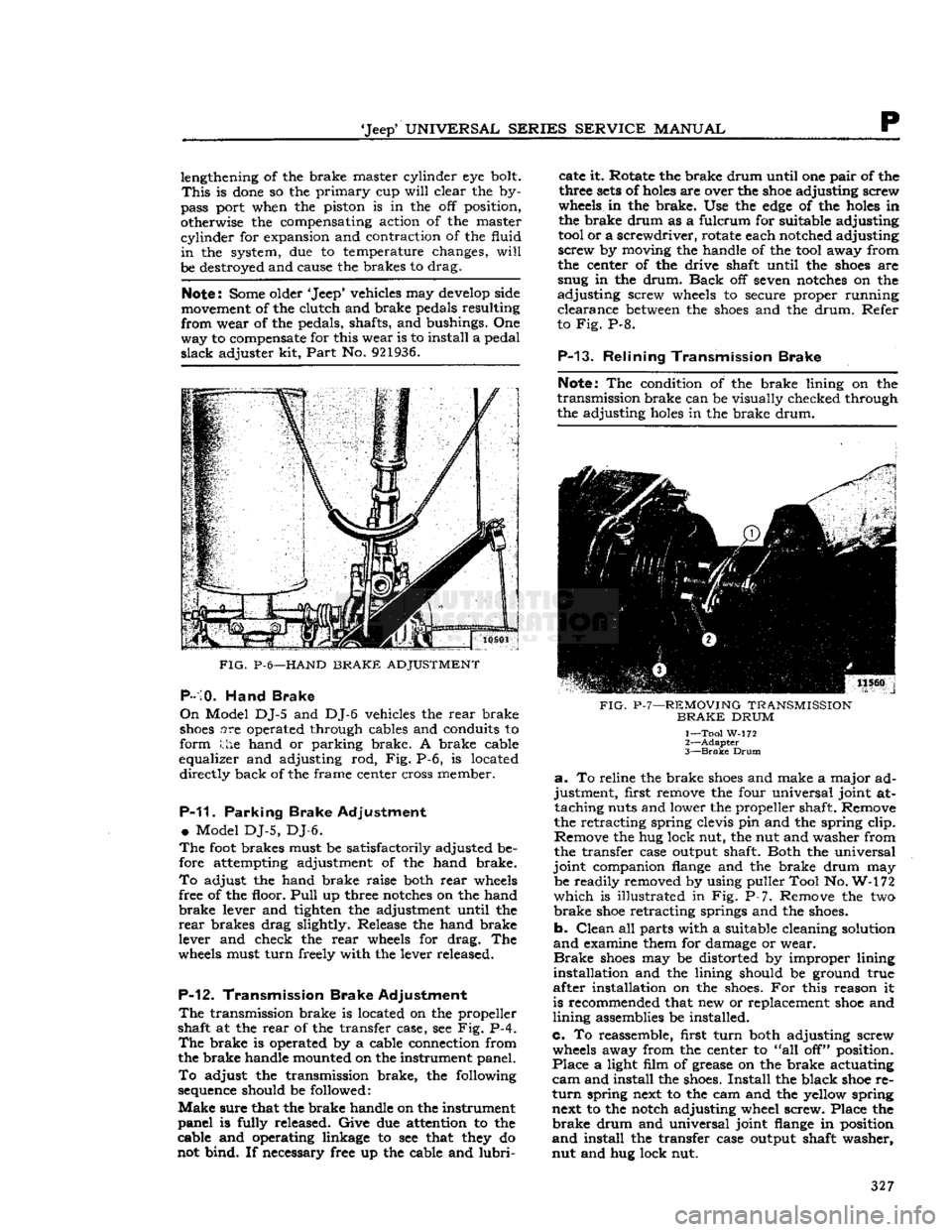

P-10.

Hand Brake

On

Model DJ-5 and DJ-6 vehicles the rear brake

shoes

are operated through cables and conduits to

form the hand or parking brake. A brake cable

equalizer and adjusting rod, Fig. P-6, is located directly back of the frame center cross member.

P-11.

Parking Brake Adjustment

•

Model DJ-5, DJ-6.

The

foot

brakes must be satisfactorily adjusted be

fore attempting adjustment of the hand brake.

To

adjust the hand brake raise both rear

wheels

free of the floor.

Pull

up three

notches

on the hand

brake

lever and tighten the adjustment until the

rear

brakes drag slightly. Release the hand brake

lever and check the rear

wheels

for drag. The

wheels

must turn freely with the lever released.

P-12.

Transmission Brake Adjustment

The

transmission brake is located on the propeller

shaft at the rear of the transfer case, see Fig. P-4.

The

brake is operated by a cable connection from

the brake handle mounted on the instrument panel.

To

adjust the transmission brake, the following

sequence

should be followed:

Make

sure that the brake handle on the instrument

panel is fully released. Give due attention to the

cable and operating linkage to see that

they

do

not bind. If necessary free up the cable and

lubri

cate it. Rotate the brake drum until one pair of the

three

sets

of

holes

are over the

shoe

adjusting screw

wheels

in the brake. Use the

edge

of the

holes

in

the brake drum as a fulcrum for suitable adjusting

tool

or a screwdriver, rotate each notched adjusting

screw by moving the handle of the

tool

away from

the center of the drive shaft until the

shoes

are

snug in the drum.

Back

off seven

notches

on the

adjusting screw

wheels

to secure proper running clearance

between

the

shoes

and the drum. Refer

to Fig. P-8.

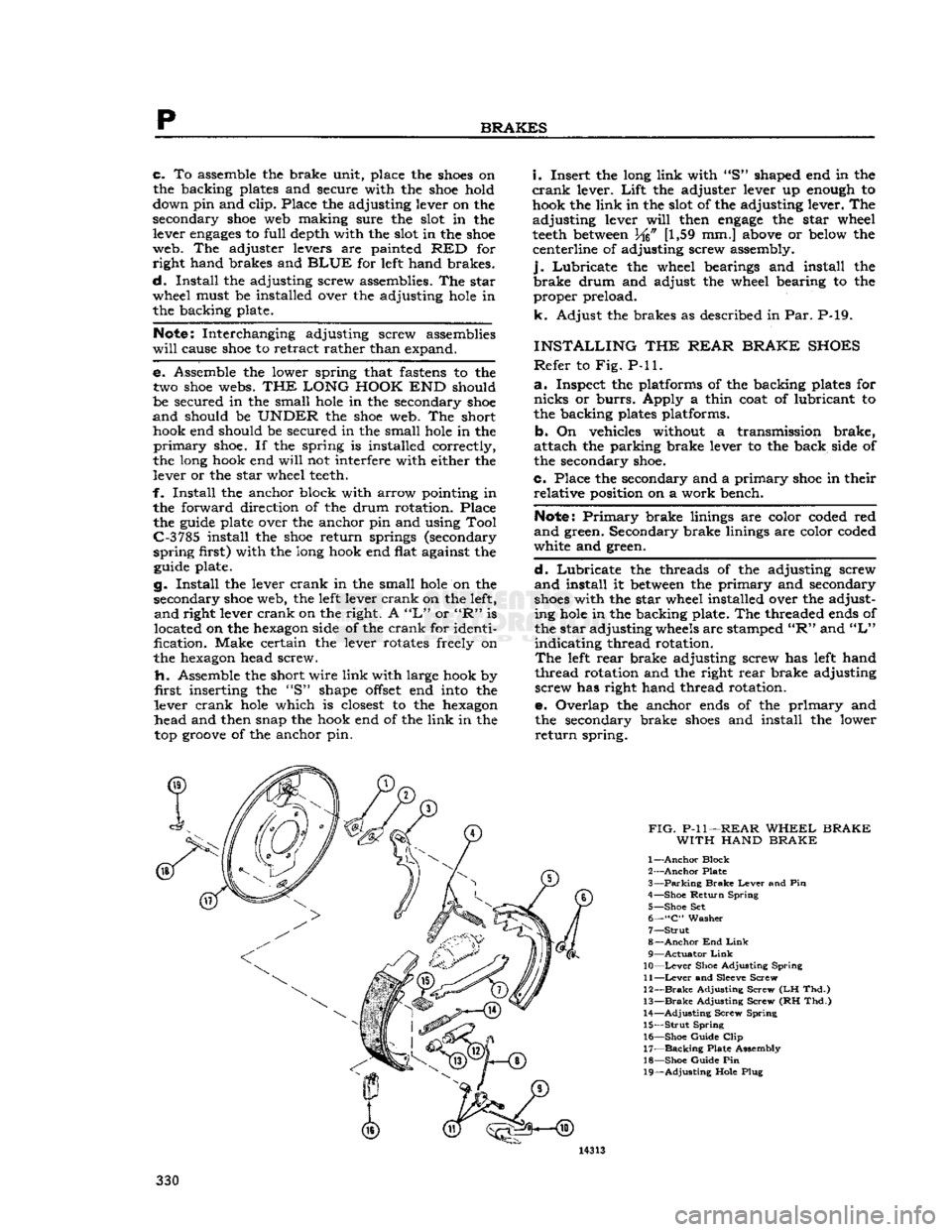

P-13.

Relining Transmission Brake

Note:

The condition of the brake lining on the

transmission brake can be visually checked through

the adjusting

holes

in the brake drum.

FIG.

P-7—REMOVING

TRANSMISSION

BRAKE

DRUM

1— Tool W-172

2—

Adapter

3—

Brake

Drum

a.

To reline the brake

shoes

and make a major ad

justment, first remove the four universal joint at taching nuts and lower the propeller shaft. Remove

the retracting spring clevis pin and the spring clip.

Remove the hug lock nut, the nut and washer from

the transfer case output shaft. Both the universal

joint companion

flange

and the brake drum may be readily removed by using puller Tool No. W-172

which

is illustrated in Fig. P-7. Remove the two

brake

shoe

retracting springs and the

shoes.

b. Clean all parts with a suitable cleaning solution

and

examine them for damage or wear.

Brake

shoes

may be distorted by improper lining

installation and the lining should be ground true

after installation on the

shoes.

For this reason it

is recommended that new or replacement

shoe

and

lining assemblies be installed.

c. To reassemble, first turn both adjusting screw

wheels

away from the center to "all off" position.

Place a light film of grease on the brake actuating

cam

and install the

shoes.

Install the black

shoe

re

turn

spring next to the cam and the yellow spring next to the notch adjusting wheel screw. Place the

brake

drum and universal joint

flange

in position

and

install the transfer case output shaft washer,

nut and hug lock nut. 327

Page 330 of 376

p

BRAKES

c. To assemble the brake unit, place the

shoes

on

the backing plates and secure with the

shoe

hold

down pin and clip. Place the adjusting lever on the

secondary

shoe

web making sure the

slot

in the lever

engages

to full depth with the

slot

in the

shoe

web. The adjuster levers are painted RED for right hand brakes and

BLUE

for

left

hand brakes.

d.

Install the adjusting screw assemblies. The star

wheel must be installed over the adjusting

hole

in the backing plate.

Notes

Interchanging adjusting screw assemblies

will

cause

shoe

to retract rather than expand.

e. Assemble the lower spring that

fastens

to the

two

shoe

webs.

THE LONG HOOK

END should

be secured in the small

hole

in the secondary

shoe

and

should be

UNDER

the

shoe

web. The short hook end should be secured in the small

hole

in the

primary

shoe.

If the spring is installed correctly,

the long hook end

will

not interfere with either the lever or the star wheel

teeth.

f. Install the anchor block with arrow pointing in the forward direction of the drum rotation. Place the

guide

plate over the anchor pin and using Tool

C-3

785 install the

shoe

return springs (secondary

spring

first) with the long hook end flat against the

guide

plate.

g. Install the lever crank in the small

hole

on the secondary

shoe

web, the

left

lever crank on the left,

and

right lever crank on the right. A

"L"

or

"R"

is

located on the

hexagon

side of the crank for identi

fication.

Make

certain the lever rotates freely on

the

hexagon

head screw.

fi.

Assemble the short wire link with large hook by

first

inserting the "S" shape

offset

end

into

the

lever crank

hole

which is

closest

to the

hexagon

head and then snap the hook end of the link in the top

groove

of the anchor pin.

i.

Insert the long link with "S" shaped end in the

crank

lever.

Lift

the adjuster lever up

enough

to hook the link in the

slot

of the adjusting lever. The

adjusting lever

will

then

engage

the star wheel

teeth

between

M%

[1,59 mm.]

above

or

below

the centerline of adjusting screw assembly,

j.

Lubricate the wheel bearings and install the

brake

drum and adjust the wheel bearing to the proper preload.

k. Adjust the brakes as described in Par. P-19.

INSTALLING

THE

REAR BRAKE SHOES

Refer

to Fig. P-ll.

a.

Inspect the platforms of the backing plates for

nicks

or

burrs.

Apply a thin coat of lubricant to

the backing plates platforms.

b. On vehicles without a transmission brake,

attach the parking brake lever to the back side of

the secondary

shoe.

c. Place the secondary and a primary

shoe

in their relative position on a work bench.

Note:

Primary

brake linings are color coded red

and

green. Secondary brake linings are color coded

white and green.

d.

Lubricate the threads of the adjusting screw

and

install it

between

the primary and secondary

shoes

with the star wheel installed over the adjusting

hole

in the backing plate. The threaded

ends

of

the star adjusting

wheels

are stamped

"R"

and

"L"

indicating thread rotation.

The

left

rear brake adjusting screw has

left

hand

thread rotation and the right rear brake adjusting screw has right hand thread rotation.

e. Overlap the anchor

ends

of the primary and the secondary brake

shoes

and install the lower

return

spring.

Page 332 of 376

BRAKES

12519

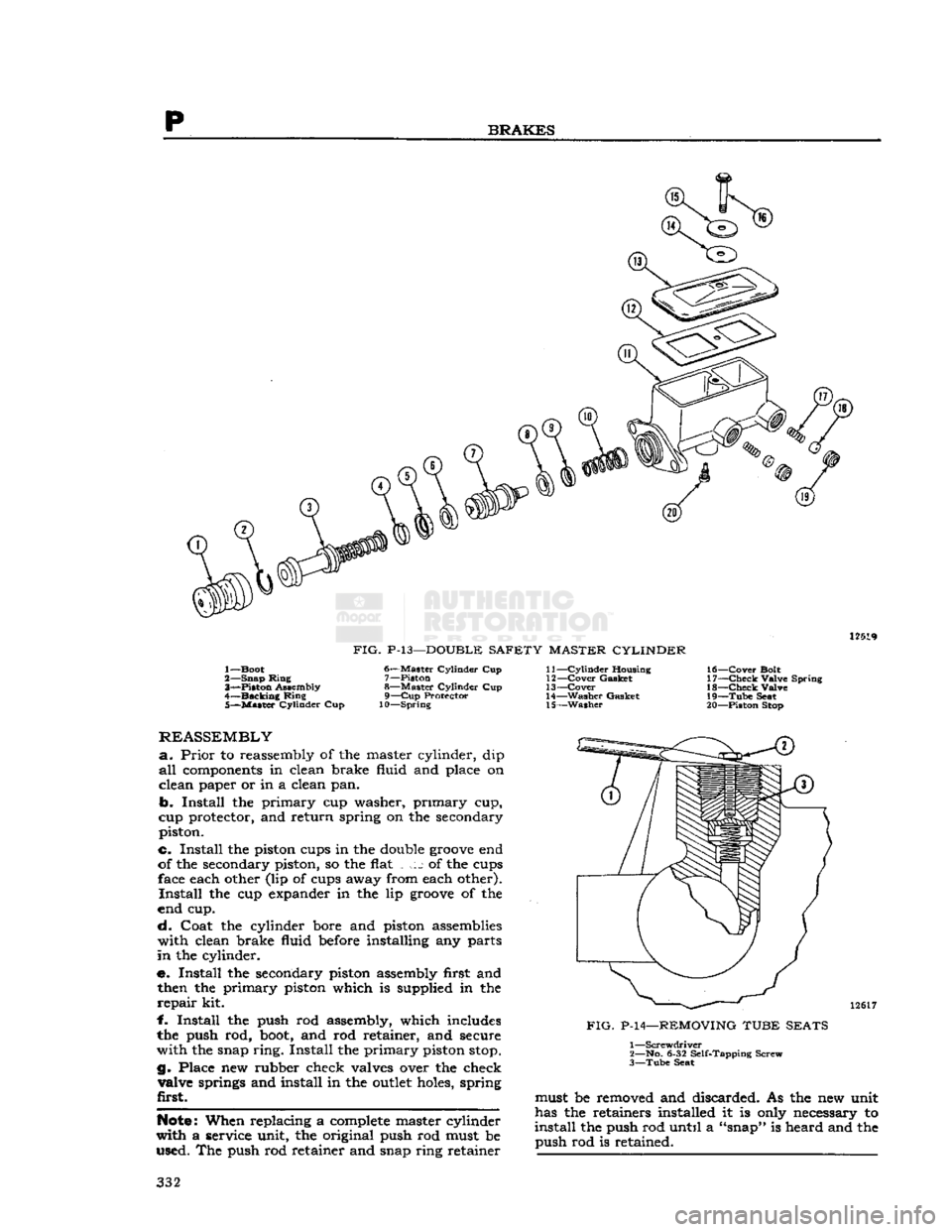

FIG.

P-13—DOUBLE

SAFETY MASTER CYLINDER

1— Boot

2— Snap Ming 3"*—Piston Assembly

4—

Backing

Ring 5—

Master

Cylinder Cup 6—

Master

Cylinder Cup

7— Piston

8—

Master

Cylinder Cup 9—

Cup

Protector

10—Spring 11—

Cylinder

Housing

12—

Cover

Gasket

13—

Cover

14—

Washer

Gasket 15—

Washer

16—

Cover

Bolt

17—

Check

Valve Spring 18—

Check

Valve

19—

Tube

Seat

20— Piston Stop

REASSEMBLY

a.

Prior

to reassembly of the master cylinder, dip

all

components

in clean brake fluid and place on

clean paper or in a clean pan.

b.

Install the primary cup washer, primary cup,

cup protector, and return spring on the secondary piston.

c. Install the piston cups in the double

groove

end

of the secondary piston, so the flat j of the cups face each other (lip of cups away from each other).

Install

the cup expander in the lip

groove

of the

end cup.

cL

Coat the cylinder bore and piston assemblies with clean brake fluid

before

installing any parts

in

the cylinder.

e. Install the secondary piston assembly first and then the primary piston which is supplied in the

repair

kit.

f.

Install the push rod assembly, which includes

the push rod,

boot,

and rod retainer, and secure

with the snap ring. Install the primary piston

stop.

g. Place new rubber check valves over the check valve springs and install in the

outlet

holes, spring

first.

Note:

When replacing a

complete

master cylinder

with a service unit, the original push rod must be used. The push rod retainer and snap ring retainer 12617

FIG.

P-14—REMOVING TUBE SEATS 1

—Screwdriver

2— No. 6-32 Self-Tapping Screw

3—

Tube

Seat must be removed and discarded. As the new unit

has the retainers installed it is only necessary to

install

the push rod until a "snap" is heard and the push rod is retained. 332

Page 333 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P h.

Install

the tube seats, flat side toward the check

valve,

and press in with tube nuts or the master

cylinder

brake pipe tube nuts.

BLEEDING

a.

Before the master cylinder is installed on the

car,

the unit must be bled.

b.

Support the cylinder assembly in a vise and

fill

both fluid reservoirs with approved brake fluid,

e.

Loosely install a plug in each

outlet

of the

cylinder.

Depress the push rod several times until

air

bubbles cease to appear in the brake fluid.

d.

Tighten the plugs and attempt to depress the piston. The piston travel should be restricted after

all

air is expelled.

e.

Install

the master cylinder on the car and bleed

the hydraulic lines at the wheel cylinder. Refer to

Par.

P-7.

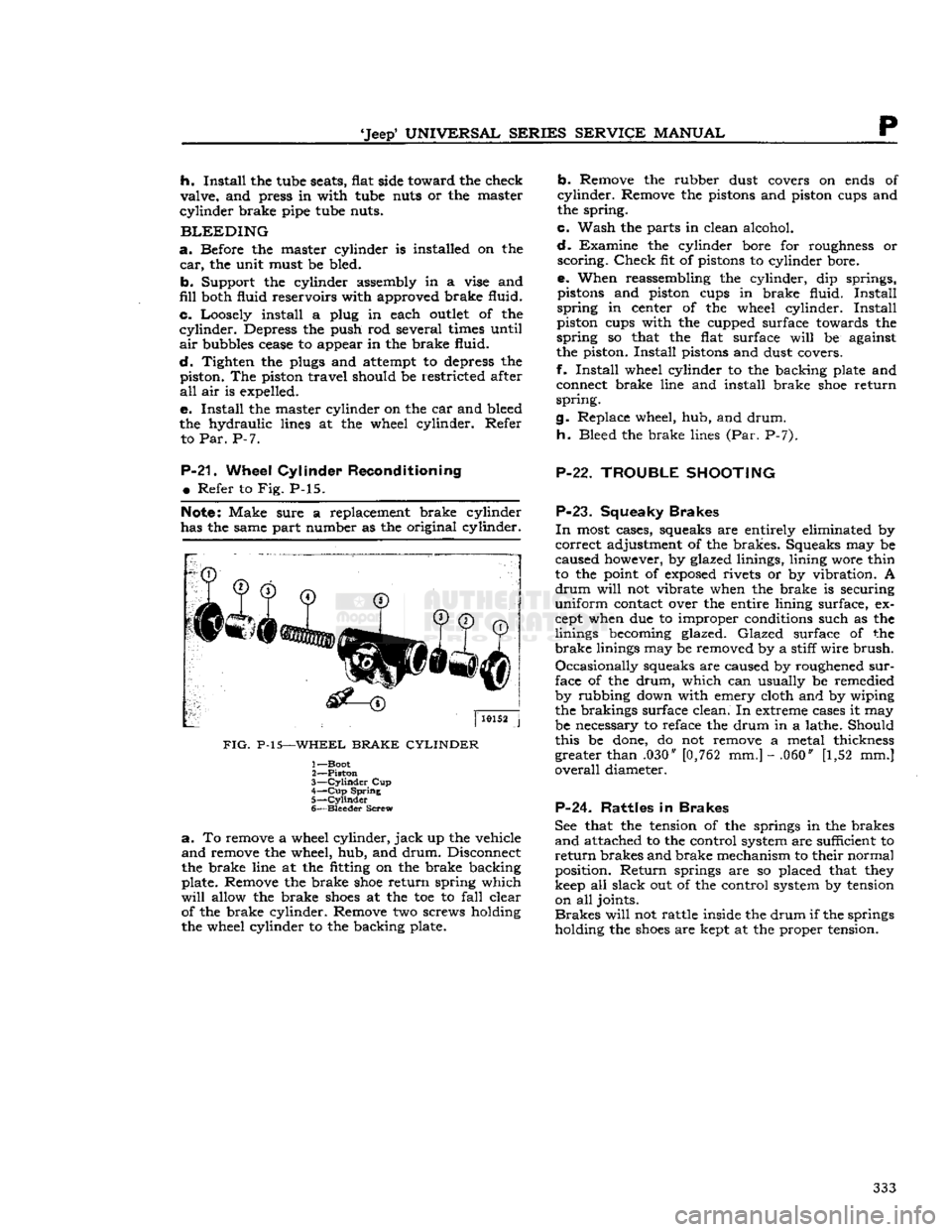

P-21.

Wheel

Cylinder

Reconditioning

•

Refer to Fig. P-15.

Note:

Make sure a replacement brake cylinder

has the same part number as the original cylinder.

FIG.

P-15—WHEEL

BRAKE CYLINDER

1— Boot

2—

Piston

3—

Cylinder

Cup

4—

Cup

Spring

5—

Cylinder

6—

Bleeder

Screw

a.

To remove a wheel cylinder,

jack

up the vehicle

and

remove the wheel, hub, and

drum.

Disconnect

the brake line at the fitting on the brake backing

plate. Remove the brake

shoe

return spring which

will

allow the brake

shoes

at the toe to

fall

clear of the brake cylinder. Remove two screws holding

the wheel cylinder to the backing plate.

b.

Remove the rubber dust covers on ends of

cylinder.

Remove the pistons and piston cups and

the spring.

c.

Wash the parts in clean alcohol.

d.

Examine the cylinder bore for roughness or

scoring.

Check

fit of pistons to cylinder bore.

e. When reassembling the cylinder, dip springs, pistons and piston cups in brake fluid.

Install

spring

in center of the wheel cylinder.

Install

piston cups with the cupped surface towards the

spring

so that the flat surface

will

be against

the piston.

Install

pistons and dust covers.

f.

Install

wheel cylinder to the backing plate and connect brake line and install brake

shoe

return

spring.

g. Replace wheel, hub, and

drum.

h.

Bleed the brake lines (Par. P-7).

P-22. TROUBLE

SHOOTING

P-23.

Squeaky

Brakes

In

most cases, squeaks are entirely eliminated by

correct

adjustment of the brakes. Squeaks may be

caused however, by glazed linings, lining wore thin

to the point of

exposed

rivets or by vibration. A

drum

will

not vibrate when the brake is securing

uniform

contact over the entire lining surface, ex

cept when due to improper conditions such as the

linings becoming glazed.

Glazed

surface of the

brake

linings may be removed by a stiff

wire

brush.

Occasionally

squeaks are caused by roughened

sur

face of the

drum,

which can usually be remedied

by rubbing down with emery cloth and by wiping

the brakings surface clean. In extreme cases it may

be necessary to reface the drum in a lathe. Should

this be done, do not remove a metal thickness greater than .030" [0,762 mm.] - .060" [1,52 mm.]

overall

diameter.

P-24. Rattles

in

Brakes

See that the tension of the springs in the brakes

and

attached to the control system are sufficient to

return

brakes and brake mechanism to their normal

position.

Return

springs are so placed that they

keep all slack out of the control system by tension on all joints.

Brakes

will

not rattle inside the

drum

if the springs

holding the

shoes

are kept at the proper tension. 333