tailgate JEEP GLADIATOR 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 114 of 448

112GETTING TO KNOW YOUR VEHICLE

There are two adjustable utility rail cleats on each

side of the bed that can be used to assist in

securing cargo.

Adjustable Cleat Assembly

Each utility rail cleat must be tightened down in

one of the detents along either utility rail in order to

keep cargo properly secured.

To move the utility rail cleat to any position on the

utility rail, turn the cleat retainer nut counter-

clockwise several times. Then, pull out on the

utility rail cleat and slide it to the detent nearest

the desired location. Make sure the utility rail cleat

is seated in the detent, and tighten the nut. To remove the utility rail cleats from the side utility

rails, slide the cleat to the rectangular cutout

located at the end of the rail toward the front of the

vehicle.

To remove the utility rail cleat from the front utility

rail, slide the cleat to the rectangular cutout

located on the left side of the rail.

TONNEAU COVER — IF EQUIPPED

The Tonneau Cover can be installed on the truck

bed to keep cargo out of view, and protect from

inclement weather.

The Tonneau Cover consists of the following

features:

Easy roll up cover

Tonneau fore/aft locator

Crossbar inside bed locator

Rear latches

Stowage straps

NOTE:The Tonneau Cover can be rolled up and secured

at the front of the truck bed without removing it

completely.

TONNEAU COVER INSTALLATION

To install the Tonneau Cover, proceed as follows:

1. Position the rolled up Tonneau Cover on the

truck bed and align it to the two fastener

locations at the front of the bed.

Fastener Locations

2. Using a #T50 Torx head driver, secure the fasteners to the bed.

3. Lower the tailgate to the fully open position before unrolling the Tonneau Cover.

1 — Utility Rail Detent

2 — Cleat Retainer Nut

3 — Utility Rail Cleat

23_JT_OM_EN_USC_t.book Page 112

Page 115 of 448

GETTING TO KNOW YOUR VEHICLE113

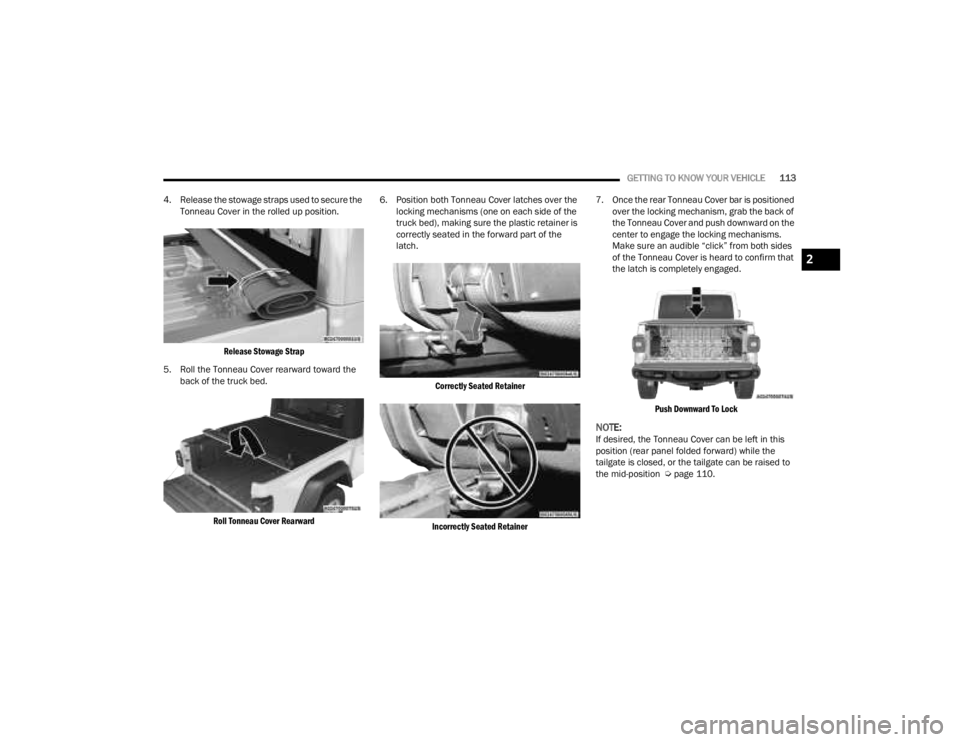

4. Release the stowage straps used to secure the Tonneau Cover in the rolled up position.

Release Stowage Strap

5. Roll the Tonneau Cover rearward toward the back of the truck bed.

Roll Tonneau Cover Rearward

6. Position both Tonneau Cover latches over the

locking mechanisms (one on each side of the

truck bed), making sure the plastic retainer is

correctly seated in the forward part of the

latch.

Correctly Seated Retainer

Incorrectly Seated Retainer

7. Once the rear Tonneau Cover bar is positioned

over the locking mechanism, grab the back of

the Tonneau Cover and push downward on the

center to engage the locking mechanisms.

Make sure an audible “click” from both sides

of the Tonneau Cover is heard to confirm that

the latch is completely engaged.

Push Downward To Lock

NOTE:If desired, the Tonneau Cover can be left in this

position (rear panel folded forward) while the

tailgate is closed, or the tailgate can be raised to

the mid-position Ú page 110.

2

23_JT_OM_EN_USC_t.book Page 113

Page 116 of 448

114GETTING TO KNOW YOUR VEHICLE

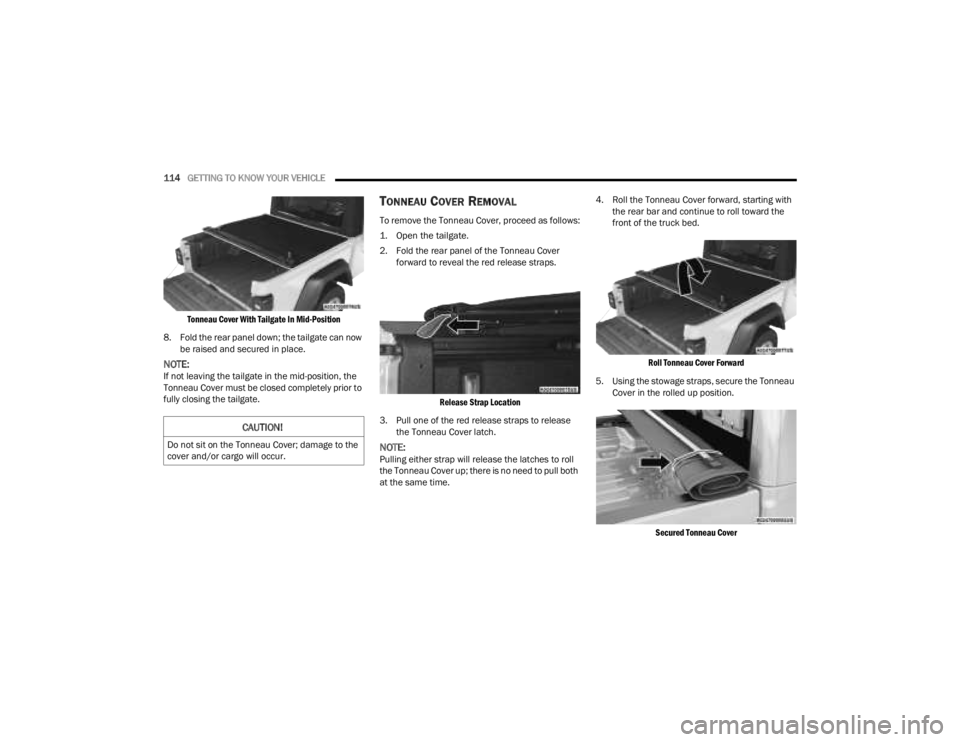

Tonneau Cover With Tailgate In Mid-Position

8. Fold the rear panel down; the tailgate can now be raised and secured in place.

NOTE:If not leaving the tailgate in the mid-position, the

Tonneau Cover must be closed completely prior to

fully closing the tailgate.

TONNEAU COVER REMOVAL

To remove the Tonneau Cover, proceed as follows:

1. Open the tailgate.

2. Fold the rear panel of the Tonneau Cover forward to reveal the red release straps.

Release Strap Location

3. Pull one of the red release straps to release the Tonneau Cover latch.

NOTE:Pulling either strap will release the latches to roll

the Tonneau Cover up; there is no need to pull both

at the same time. 4. Roll the Tonneau Cover forward, starting with

the rear bar and continue to roll toward the

front of the truck bed.

Roll Tonneau Cover Forward

5. Using the stowage straps, secure the Tonneau Cover in the rolled up position.

Secured Tonneau Cover

CAUTION!

Do not sit on the Tonneau Cover; damage to the

cover and/or cargo will occur.

23_JT_OM_EN_USC_t.book Page 114

Page 190 of 448

188STARTING AND OPERATING

(Continued)

PARKSENSE SYSTEM USAGE

P

RECAUTIONS

NOTE:

Ensure that the front and rear fascia/bumpers

are free of snow, ice, mud, dirt and debris to

keep the ParkSense system operating properly.

Jackhammers, large trucks, and other vibra -

tions could affect the performance of Park -

Sense.

When you turn the ParkSense system off, the

instrument cluster display will show a vehicle

graphic of the ParkSense on/off state for two

seconds. Furthermore, once you turn Park -

Sense off, it remains off until you turn it on

again, even if you cycle the ignition.

When you move the gear selector to the

REVERSE position and ParkSense is turned off,

the instrument cluster display will show the

“ParkSense OFF” message. This message will

be displayed for as long as the vehicle is in

REVERSE.

ParkSense, when on, will reduce the volume of

the radio when it is sounding a tone.

Clean the ParkSense sensors regularly, taking

care not to scratch or damage them. The

sensors must not be covered with ice, snow,

slush, mud, dirt or debris. Failure to do so can

result in the system not working properly. The ParkSense system might not detect an obstacle

behind or in front of the fascia/bumper, or it

could provide a false indication that an obstacle

is behind or in front of the fascia/bumper.

Use the ParkSense switch to turn the ParkSense

system off if obstacles such as bicycle carriers,

trailer hitches, etc. are placed within 12 inches

(30 cm) of the rear fascia/bumper. Failure to do

so can result in the system misinterpreting a

close obstacle as a sensor problem, causing the

“PARKSENSE UNAVAILABLE SERVICE

REQUIRED” message to appear in the instru

-

ment cluster display.

ParkSense should be disabled when the tailgate

is in the lowered or open position. A lowered tail -

gate could provide a false indication that an

obstacle is behind the vehicle.

WARNING!

Drivers must be careful when backing up even

when using ParkSense. Always check carefully

behind your vehicle, look behind you, and be

sure to check for pedestrians, animals, other

vehicles, obstructions, and blind spots before

backing up. You are responsible for safety and

must continue to pay attention to your

surroundings. Failure to do so can result in

serious injury or death.

Before using ParkSense, it is strongly recom -

mended that the ball mount and hitch ball

assembly be disconnected from the vehicle

when the vehicle is not used for towing.

Failure to do so can result in injury or damage

to vehicles or obstacles because the hitch ball

will be much closer to the obstacle than the

rear fascia/bumper when the vehicle sounds

the continuous tone. Also, the sensors could

detect the ball mount and hitch ball assembly,

depending on its size and shape, giving a false

indication that an obstacle is behind the

vehicle.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle, including

small obstacles. Parking curbs might be

temporarily detected or not detected at all.

Obstacles located above or below the sensors

will not be detected when they are in close

proximity.

The vehicle must be driven slowly when using

ParkSense in order to be able to stop in time

when an obstacle is detected. It is recom -

mended that the driver looks over his/her

shoulder when using ParkSense.

WARNING!

23_JT_OM_EN_USC_t.book Page 188

Page 191 of 448

STARTING AND OPERATING189

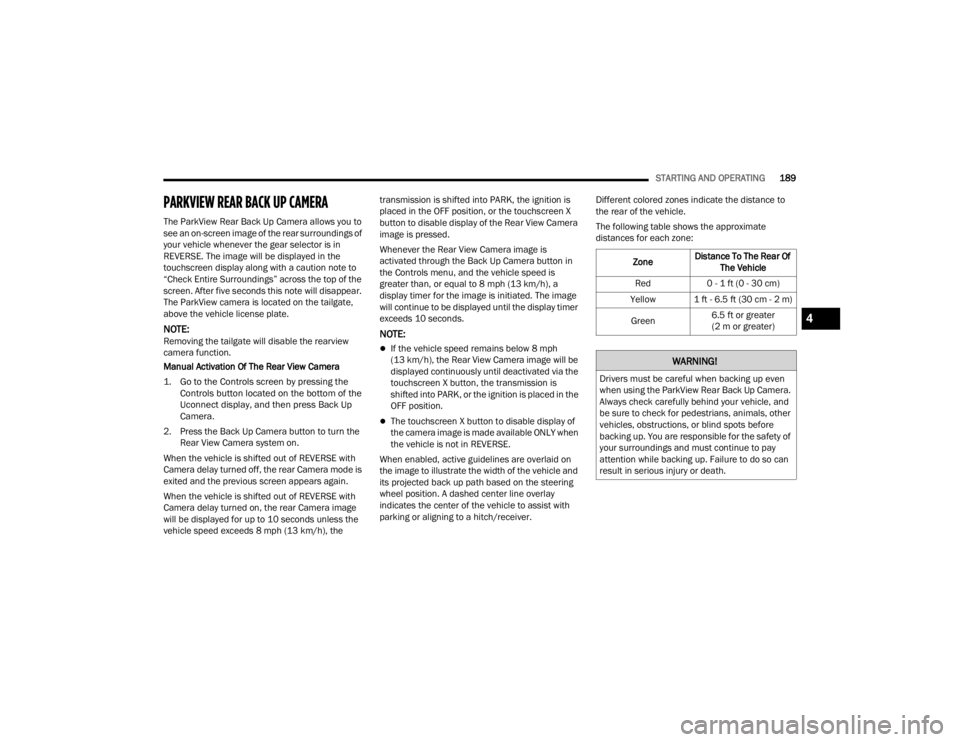

PARKVIEW REAR BACK UP CAMERA

The ParkView Rear Back Up Camera allows you to

see an on-screen image of the rear surroundings of

your vehicle whenever the gear selector is in

REVERSE. The image will be displayed in the

touchscreen display along with a caution note to

“Check Entire Surroundings” across the top of the

screen. After five seconds this note will disappear.

The ParkView camera is located on the tailgate,

above the vehicle license plate.

NOTE:Removing the tailgate will disable the rearview

camera function.

Manual Activation Of The Rear View Camera

1. Go to the Controls screen by pressing the

Controls button located on the bottom of the

Uconnect display, and then press Back Up

Camera.

2. Press the Back Up Camera button to turn the Rear View Camera system on.

When the vehicle is shifted out of REVERSE with

Camera delay turned off, the rear Camera mode is

exited and the previous screen appears again.

When the vehicle is shifted out of REVERSE with

Camera delay turned on, the rear Camera image

will be displayed for up to 10 seconds unless the

vehicle speed exceeds 8 mph (13 km/h), the transmission is shifted into PARK, the ignition is

placed in the OFF position, or the touchscreen X

button to disable display of the Rear View Camera

image is pressed.

Whenever the Rear View Camera image is

activated through the Back Up Camera button in

the Controls menu, and the vehicle speed is

greater than, or equal to 8 mph (13 km/h), a

display timer for the image is initiated. The image

will continue to be displayed until the display timer

exceeds 10 seconds.NOTE:

If the vehicle speed remains below 8 mph

(13 km/h), the Rear View Camera image will be

displayed continuously until deactivated via the

touchscreen X button, the transmission is

shifted into PARK, or the ignition is placed in the

OFF position.

The touchscreen X button to disable display of

the camera image is made available ONLY when

the vehicle is not in REVERSE.

When enabled, active guidelines are overlaid on

the image to illustrate the width of the vehicle and

its projected back up path based on the steering

wheel position. A dashed center line overlay

indicates the center of the vehicle to assist with

parking or aligning to a hitch/receiver. Different colored zones indicate the distance to

the rear of the vehicle.

The following table shows the approximate

distances for each zone:

Zone Distance To The Rear Of

The Vehicle

Red 0 - 1 ft (0 - 30 cm)

Yellow 1 ft - 6.5 ft (30 cm - 2 m)

Green 6.5 ft or greater

(2 m or greater)

WARNING!

Drivers must be careful when backing up even

when using the ParkView Rear Back Up Camera.

Always check carefully behind your vehicle, and

be sure to check for pedestrians, animals, other

vehicles, obstructions, or blind spots before

backing up. You are responsible for the safety of

your surroundings and must continue to pay

attention while backing up. Failure to do so can

result in serious injury or death.

4

23_JT_OM_EN_USC_t.book Page 189

Page 339 of 448

IN CASE OF EMERGENCY337

(Continued)

3. Release the tool bag straps from the jack and

remove tools from bag.

Jack And Tool Bag

4. Remove tool kit and assemble tools.

Jack And Tool Bag

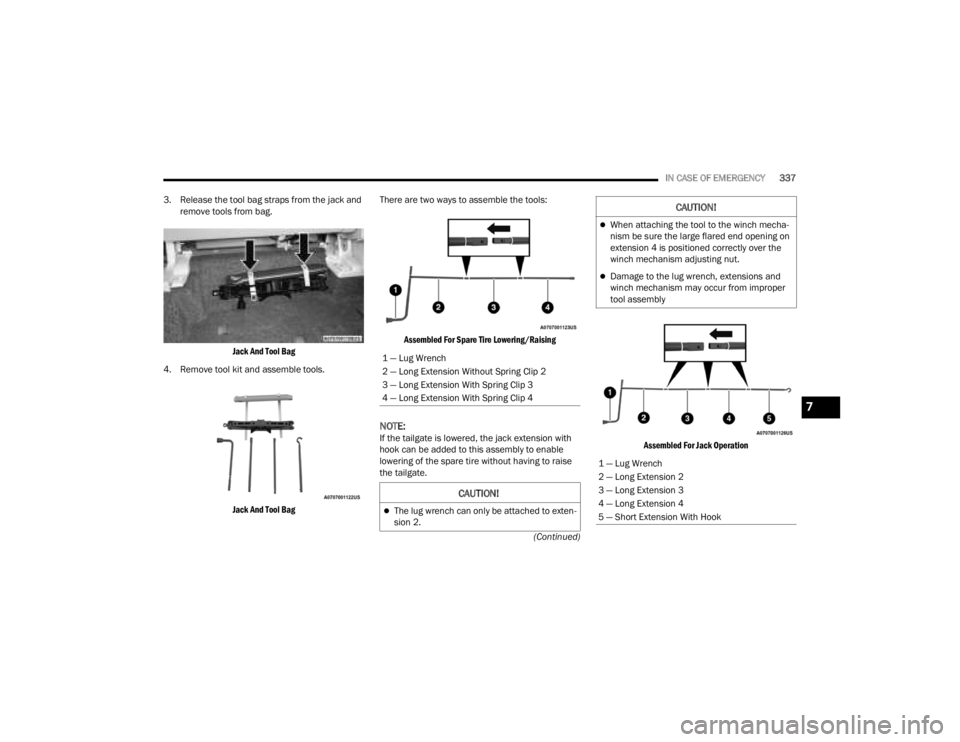

There are two ways to assemble the tools:

Assembled For Spare Tire Lowering/Raising

NOTE:If the tailgate is lowered, the jack extension with

hook can be added to this assembly to enable

lowering of the spare tire without having to raise

the tailgate.

Assembled For Jack Operation

1 — Lug Wrench

2 — Long Extension Without Spring Clip 2

3 — Long Extension With Spring Clip 3

4 — Long Extension With Spring Clip 4

CAUTION!

The lug wrench can only be attached to exten

-

sion 2.

When attaching the tool to the winch mecha -

nism be sure the large flared end opening on

extension 4 is positioned correctly over the

winch mechanism adjusting nut.

Damage to the lug wrench, extensions and

winch mechanism may occur from improper

tool assembly

1 — Lug Wrench

2 — Long Extension 2

3 — Long Extension 3

4 — Long Extension 4

5 — Short Extension With Hook

CAUTION!

7

23_JT_OM_EN_USC_t.book Page 337

Page 340 of 448

338IN CASE OF EMERGENCY

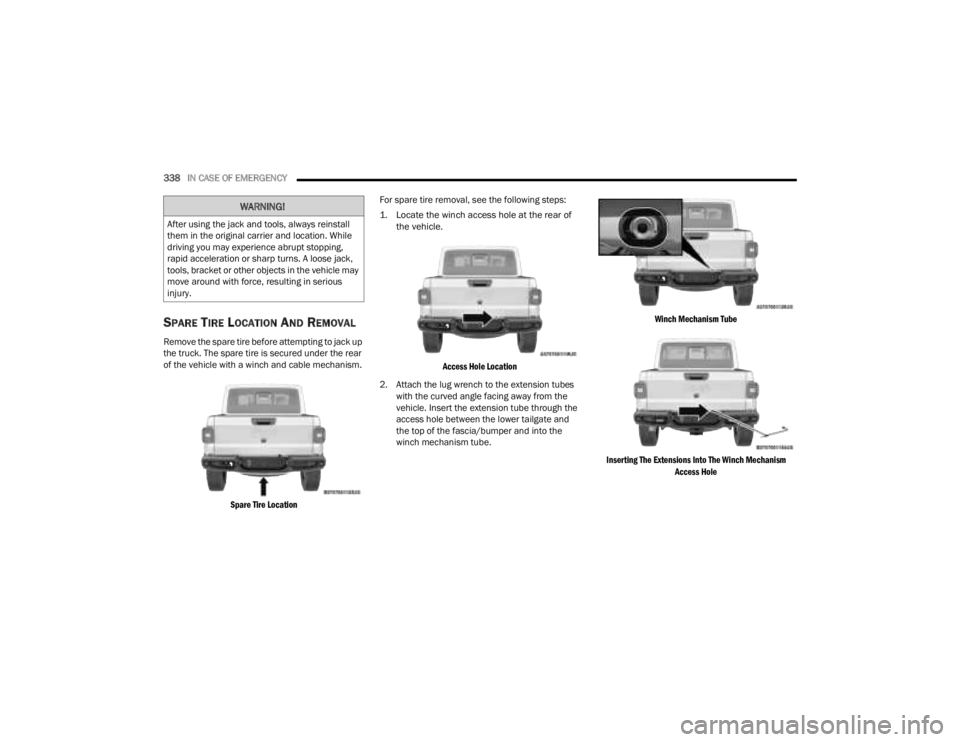

SPARE TIRE LOCATION AND REMOVAL

Remove the spare tire before attempting to jack up

the truck. The spare tire is secured under the rear

of the vehicle with a winch and cable mechanism.

Spare Tire Location

For spare tire removal, see the following steps:

1. Locate the winch access hole at the rear of

the vehicle.

Access Hole Location

2. Attach the lug wrench to the extension tubes with the curved angle facing away from the

vehicle. Insert the extension tube through the

access hole between the lower tailgate and

the top of the fascia/bumper and into the

winch mechanism tube.

Winch Mechanism Tube

Inserting The Extensions Into The Winch Mechanism Access Hole

WARNING!

After using the jack and tools, always reinstall

them in the original carrier and location. While

driving you may experience abrupt stopping,

rapid acceleration or sharp turns. A loose jack,

tools, bracket or other objects in the vehicle may

move around with force, resulting in serious

injury.

23_JT_OM_EN_USC_t.book Page 338

Page 344 of 448

342IN CASE OF EMERGENCY

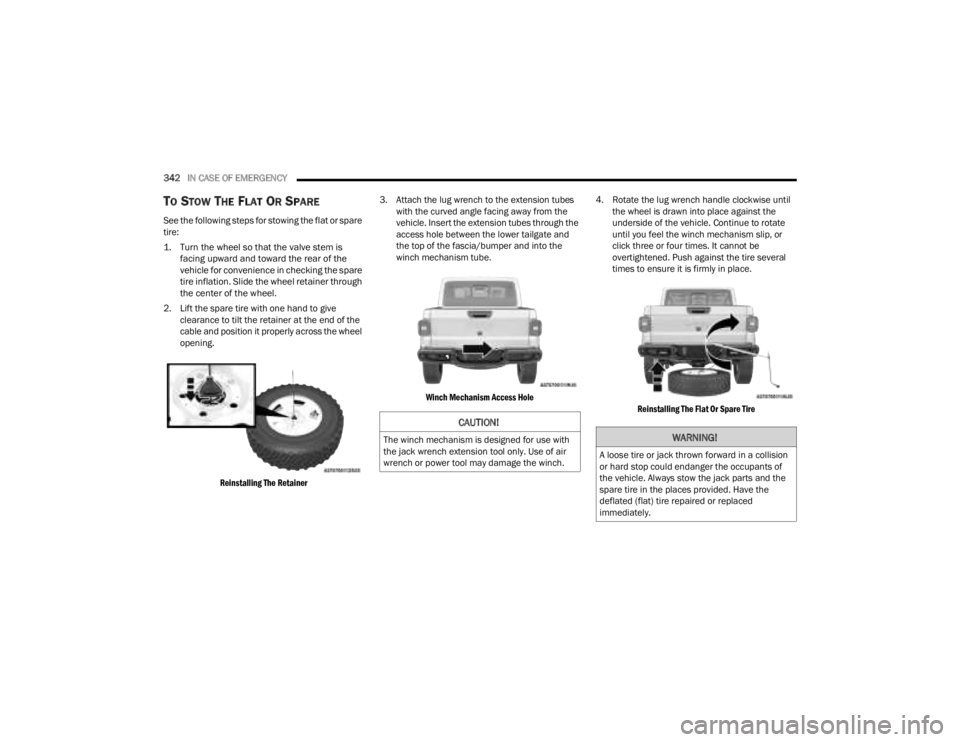

TO STOW THE FLAT OR SPARE

See the following steps for stowing the flat or spare

tire:

1. Turn the wheel so that the valve stem is

facing upward and toward the rear of the

vehicle for convenience in checking the spare

tire inflation. Slide the wheel retainer through

the center of the wheel.

2. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of the

cable and position it properly across the wheel

opening.

Reinstalling The Retainer

3. Attach the lug wrench to the extension tubes

with the curved angle facing away from the

vehicle. Insert the extension tubes through the

access hole between the lower tailgate and

the top of the fascia/bumper and into the

winch mechanism tube.

Winch Mechanism Access Hole

4. Rotate the lug wrench handle clockwise until

the wheel is drawn into place against the

underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or

click three or four times. It cannot be

overtightened. Push against the tire several

times to ensure it is firmly in place.

Reinstalling The Flat Or Spare Tire

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

23_JT_OM_EN_USC_t.book Page 342

Page 376 of 448

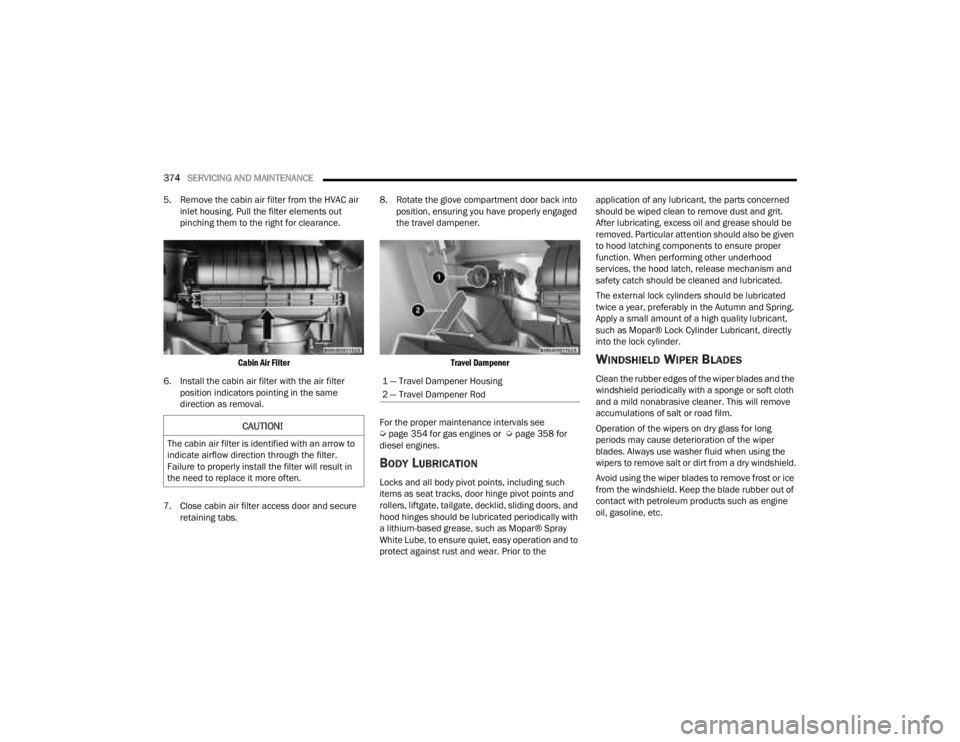

374SERVICING AND MAINTENANCE

5. Remove the cabin air filter from the HVAC air inlet housing. Pull the filter elements out

pinching them to the right for clearance.

Cabin Air Filter

6. Install the cabin air filter with the air filter position indicators pointing in the same

direction as removal.

7. Close cabin air filter access door and secure retaining tabs. 8. Rotate the glove compartment door back into

position, ensuring you have properly engaged

the travel dampener.

Travel Dampener

For the proper maintenance intervals see

Ú page 354 for gas engines or Ú page 358 for

diesel engines.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors, and

hood hinges should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube, to ensure quiet, easy operation and to

protect against rust and wear. Prior to the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit.

After lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant, directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

CAUTION!

The cabin air filter is identified with an arrow to

indicate airflow direction through the filter.

Failure to properly install the filter will result in

the need to replace it more often.

1 — Travel Dampener Housing

2 — Travel Dampener Rod

23_JT_OM_EN_USC_t.book Page 374

Page 397 of 448

SERVICING AND MAINTENANCE395

LED Front Fog Lamp

If your vehicle is equipped with LED fog lamps they

are replaced as an assembly.

NOTE:We recommend seeing an authorized dealer for

service.

REAR TAIL, STOP, TURN SIGNAL, AND BACKUP

LAMP — IF EQUIPPED

See the following steps to replace:

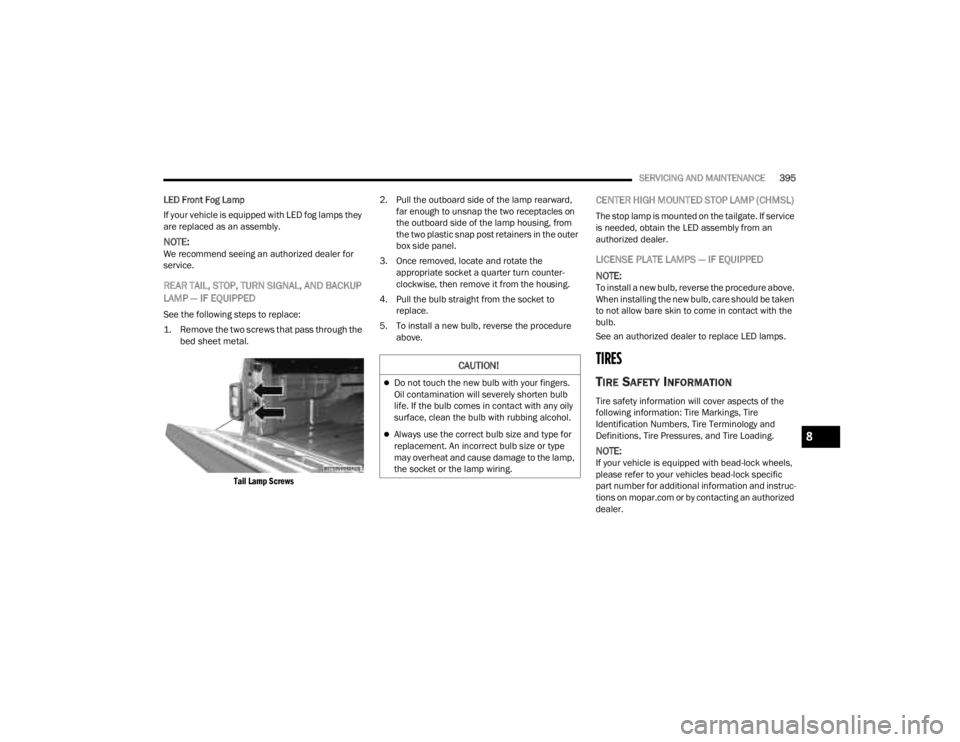

1. Remove the two screws that pass through the bed sheet metal.

Tail Lamp Screws

2. Pull the outboard side of the lamp rearward,

far enough to unsnap the two receptacles on

the outboard side of the lamp housing, from

the two plastic snap post retainers in the outer

box side panel.

3. Once removed, locate and rotate the appropriate socket a quarter turn counter -

clockwise, then remove it from the housing.

4. Pull the bulb straight from the socket to replace.

5. To install a new bulb, reverse the procedure above.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

The stop lamp is mounted on the tailgate. If service

is needed, obtain the LED assembly from an

authorized dealer.

LICENSE PLATE LAMPS — IF EQUIPPED

NOTE:

To install a new bulb, reverse the procedure above.

When installing the new bulb, care should be taken

to not allow bare skin to come in contact with the

bulb.

See an authorized dealer to replace LED lamps.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

NOTE:If your vehicle is equipped with bead-lock wheels,

please refer to your vehicles bead-lock specific

part number for additional information and instruc -

tions on mopar.com or by contacting an authorized

dealer.

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb

life. If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

Always use the correct bulb size and type for

replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp,

the socket or the lamp wiring.8

23_JT_OM_EN_USC_t.book Page 395