Specifications JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2010 of 2199

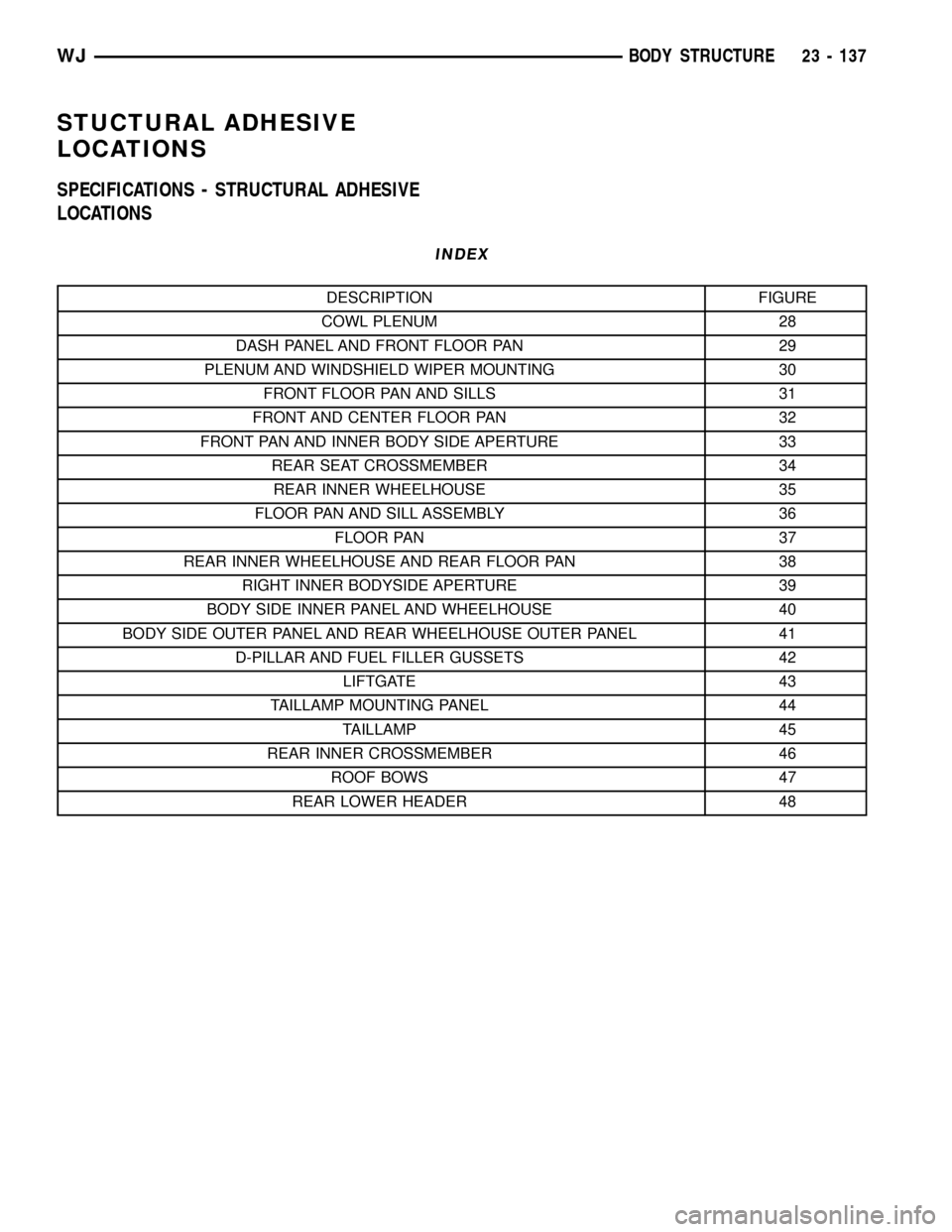

STUCTURAL ADHESIVE

LOCATIONS

SPECIFICATIONS - STRUCTURAL ADHESIVE

LOCATIONS

INDEX

DESCRIPTION FIGURE

COWL PLENUM 28

DASH PANEL AND FRONT FLOOR PAN 29

PLENUM AND WINDSHIELD WIPER MOUNTING 30

FRONT FLOOR PAN AND SILLS 31

FRONT AND CENTER FLOOR PAN 32

FRONT PAN AND INNER BODY SIDE APERTURE 33

REAR SEAT CROSSMEMBER 34

REAR INNER WHEELHOUSE 35

FLOOR PAN AND SILL ASSEMBLY 36

FLOOR PAN 37

REAR INNER WHEELHOUSE AND REAR FLOOR PAN 38

RIGHT INNER BODYSIDE APERTURE 39

BODY SIDE INNER PANEL AND WHEELHOUSE 40

BODY SIDE OUTER PANEL AND REAR WHEELHOUSE OUTER PANEL 41

D-PILLAR AND FUEL FILLER GUSSETS 42

LIFTGATE 43

TAILLAMP MOUNTING PANEL 44

TAILLAMP 45

REAR INNER CROSSMEMBER 46

ROOF BOWS 47

REAR LOWER HEADER 48

WJBODY STRUCTURE 23 - 137

Page 2026 of 2199

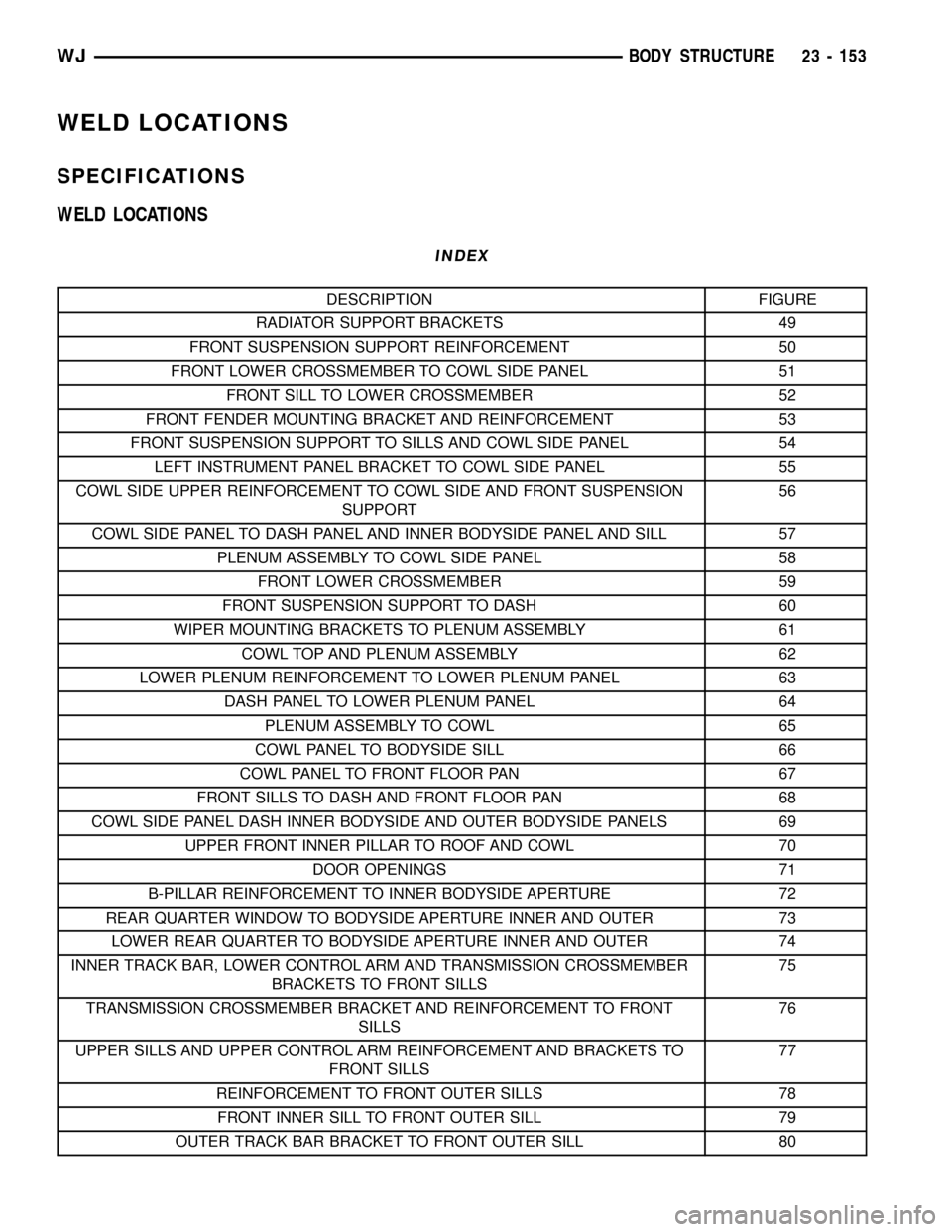

WELD LOCATIONS

SPECIFICATIONS

WELD LOCATIONS

INDEX

DESCRIPTION FIGURE

RADIATOR SUPPORT BRACKETS 49

FRONT SUSPENSION SUPPORT REINFORCEMENT 50

FRONT LOWER CROSSMEMBER TO COWL SIDE PANEL 51

FRONT SILL TO LOWER CROSSMEMBER 52

FRONT FENDER MOUNTING BRACKET AND REINFORCEMENT 53

FRONT SUSPENSION SUPPORT TO SILLS AND COWL SIDE PANEL 54

LEFT INSTRUMENT PANEL BRACKET TO COWL SIDE PANEL 55

COWL SIDE UPPER REINFORCEMENT TO COWL SIDE AND FRONT SUSPENSION

SUPPORT56

COWL SIDE PANEL TO DASH PANEL AND INNER BODYSIDE PANEL AND SILL 57

PLENUM ASSEMBLY TO COWL SIDE PANEL 58

FRONT LOWER CROSSMEMBER 59

FRONT SUSPENSION SUPPORT TO DASH 60

WIPER MOUNTING BRACKETS TO PLENUM ASSEMBLY 61

COWL TOP AND PLENUM ASSEMBLY 62

LOWER PLENUM REINFORCEMENT TO LOWER PLENUM PANEL 63

DASH PANEL TO LOWER PLENUM PANEL 64

PLENUM ASSEMBLY TO COWL 65

COWL PANEL TO BODYSIDE SILL 66

COWL PANEL TO FRONT FLOOR PAN 67

FRONT SILLS TO DASH AND FRONT FLOOR PAN 68

COWL SIDE PANEL DASH INNER BODYSIDE AND OUTER BODYSIDE PANELS 69

UPPER FRONT INNER PILLAR TO ROOF AND COWL 70

DOOR OPENINGS 71

B-PILLAR REINFORCEMENT TO INNER BODYSIDE APERTURE 72

REAR QUARTER WINDOW TO BODYSIDE APERTURE INNER AND OUTER 73

LOWER REAR QUARTER TO BODYSIDE APERTURE INNER AND OUTER 74

INNER TRACK BAR, LOWER CONTROL ARM AND TRANSMISSION CROSSMEMBER

BRACKETS TO FRONT SILLS75

TRANSMISSION CROSSMEMBER BRACKET AND REINFORCEMENT TO FRONT

SILLS76

UPPER SILLS AND UPPER CONTROL ARM REINFORCEMENT AND BRACKETS TO

FRONT SILLS77

REINFORCEMENT TO FRONT OUTER SILLS 78

FRONT INNER SILL TO FRONT OUTER SILL 79

OUTER TRACK BAR BRACKET TO FRONT OUTER SILL 80

WJBODY STRUCTURE 23 - 153

Page 2078 of 2199

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................2

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................6

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................6

SPECIFICATIONS

A/C APPLICATION TABLE................7

TORQUE SPECIFICATIONS..............8

CONTROLS.............................9

DISTRIBUTION..........................36

PLUMBING.............................51

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating-

air conditioning system, the engine cooling system

must be properly maintained. The use of a bug

screen is not recommended. Any obstructions in front

of the radiator or condenser will reduce the perfor-

mance of the air conditioning and engine cooling sys-

tems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Cooling for more infor-

mation before opening, or attempting any service to

the engine cooling system.

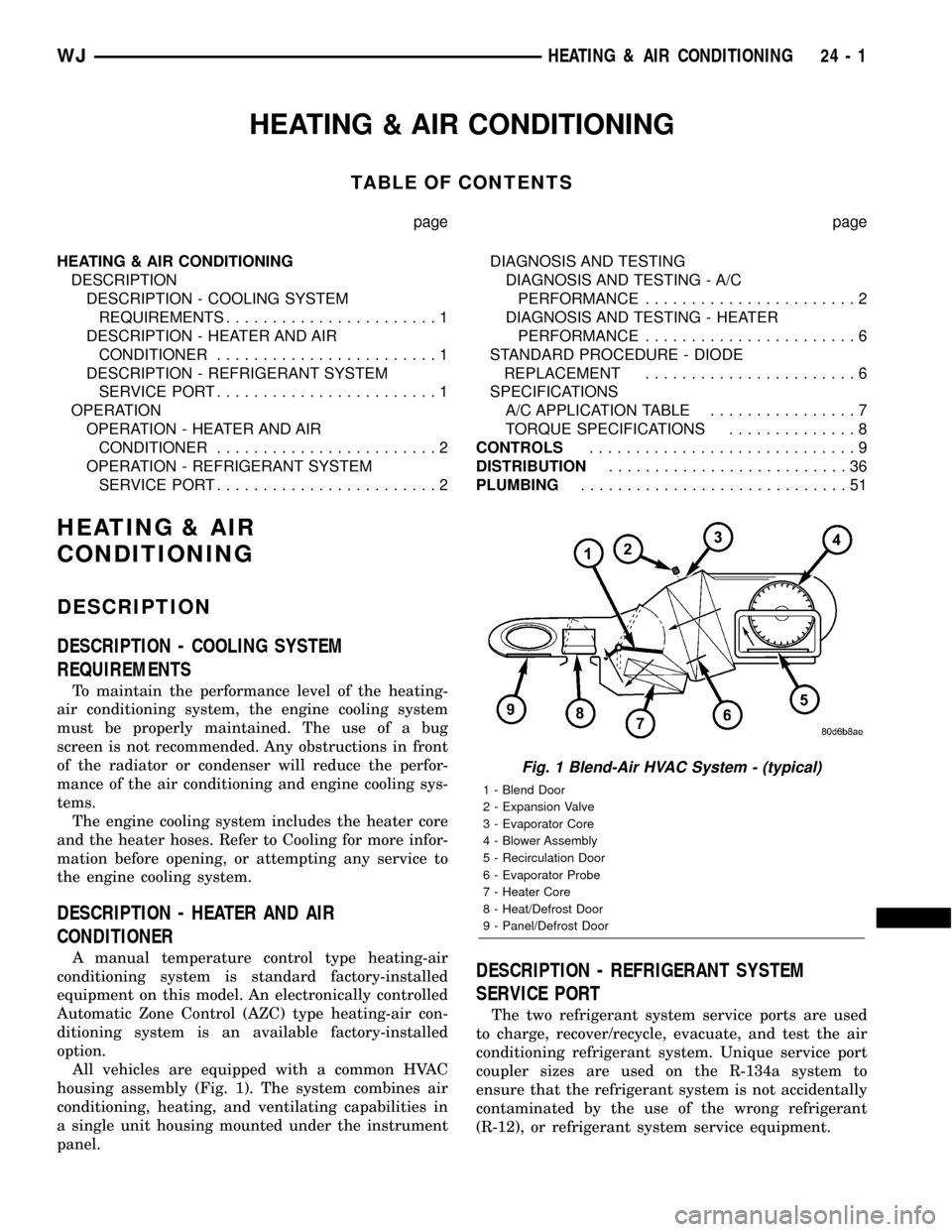

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manual temperature control type heating-air

conditioning system is standard factory-installed

equipment on this model. An electronically controlled

Automatic Zone Control (AZC) type heating-air con-

ditioning system is an available factory-installed

option.

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system to

ensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

Fig. 1 Blend-Air HVAC System - (typical)

1 - Blend Door

2 - Expansion Valve

3 - Evaporator Core

4 - Blower Assembly

5 - Recirculation Door

6 - Evaporator Probe

7 - Heater Core

8 - Heat/Defrost Door

9 - Panel/Defrost Door

WJHEATING & AIR CONDITIONING 24 - 1

Page 2083 of 2199

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the radiator coolant

level, serpentine drive belt tension, radiator air flow

and the radiator fan operation. Also be certain that

the accessory vacuum supply line is connected at the

engine intake manifold for the manual temperature

control system.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling at

normal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor heat position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

OBSTRUCTED COOLANT FLOW

Possible locations or causes of obstructed coolant

flow:

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible locations or causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A blend door not functioning properly.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob(s) on the

A/C Heater control panel, the following could require

service:

²The A/C heater control.

²The blend door actuator(s).

²The wire harness circuits for the A/C heater con-

trol or the blend door actuator(s).²The blend door(s).

²Improper engine coolant temperature.

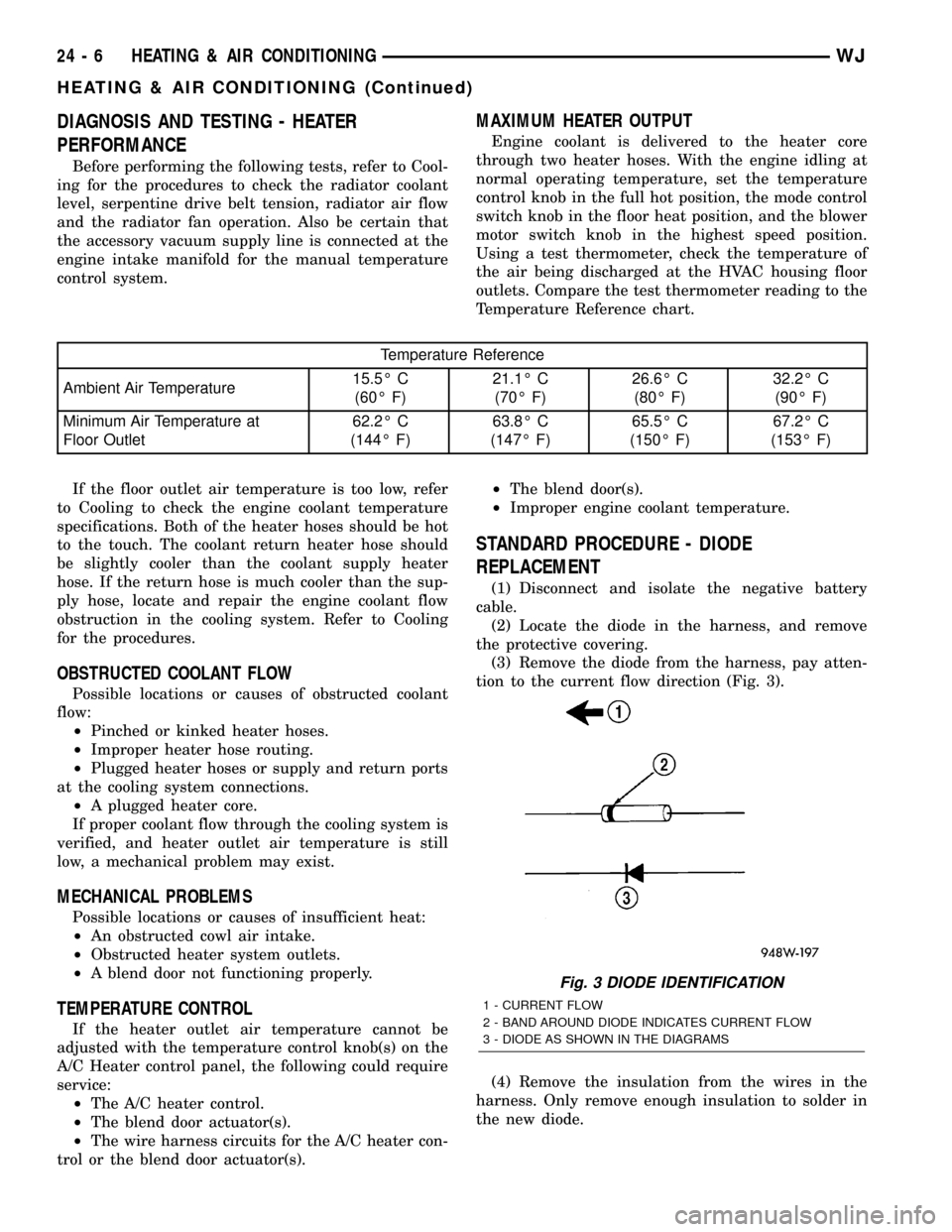

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the negative battery

cable.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 3).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

Fig. 3 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

24 - 6 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2084 of 2199

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

tems.SPECIFICATIONS

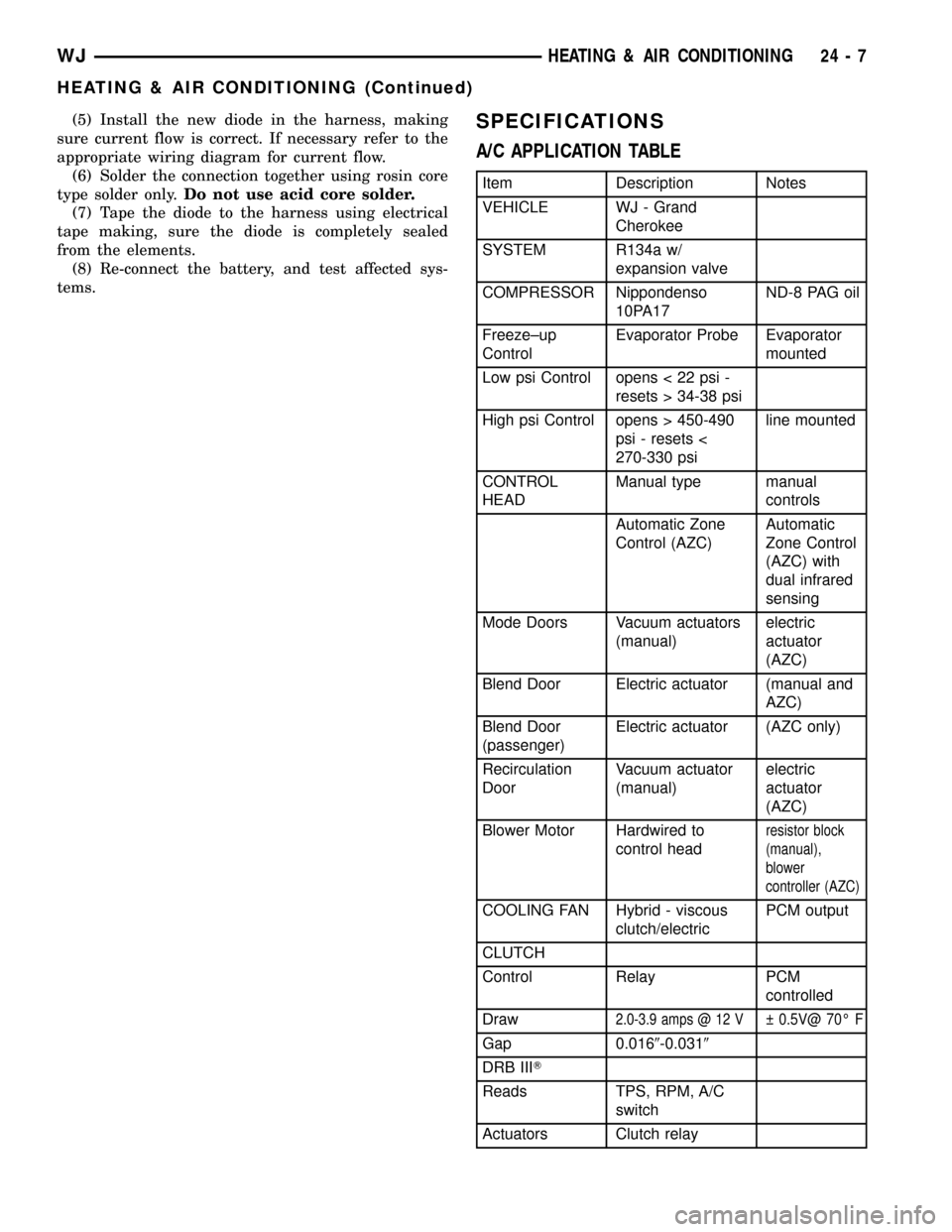

A/C APPLICATION TABLE

Item Description Notes

VEHICLE WJ - Grand

Cherokee

SYSTEM R134a w/

expansion valve

COMPRESSOR Nippondenso

10PA17ND-8 PAG oil

Freeze±up

ControlEvaporator Probe Evaporator

mounted

Low psi Control opens < 22 psi -

resets > 34-38 psi

High psi Control opens > 450-490

psi - resets <

270-330 psiline mounted

CONTROL

HEADManual type manual

controls

Automatic Zone

Control (AZC)Automatic

Zone Control

(AZC) with

dual infrared

sensing

Mode Doors Vacuum actuators

(manual)electric

actuator

(AZC)

Blend Door Electric actuator (manual and

AZC)

Blend Door

(passenger)Electric actuator (AZC only)

Recirculation

DoorVacuum actuator

(manual)electric

actuator

(AZC)

Blower Motor Hardwired to

control head

resistor block

(manual),

blower

controller (AZC)

COOLING FAN Hybrid - viscous

clutch/electricPCM output

CLUTCH

Control Relay PCM

controlled

Draw

2.0-3.9 amps @ 12 V 0.5V@ 70É F

Gap 0.0169-0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch

Actuators Clutch relay

WJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2085 of 2199

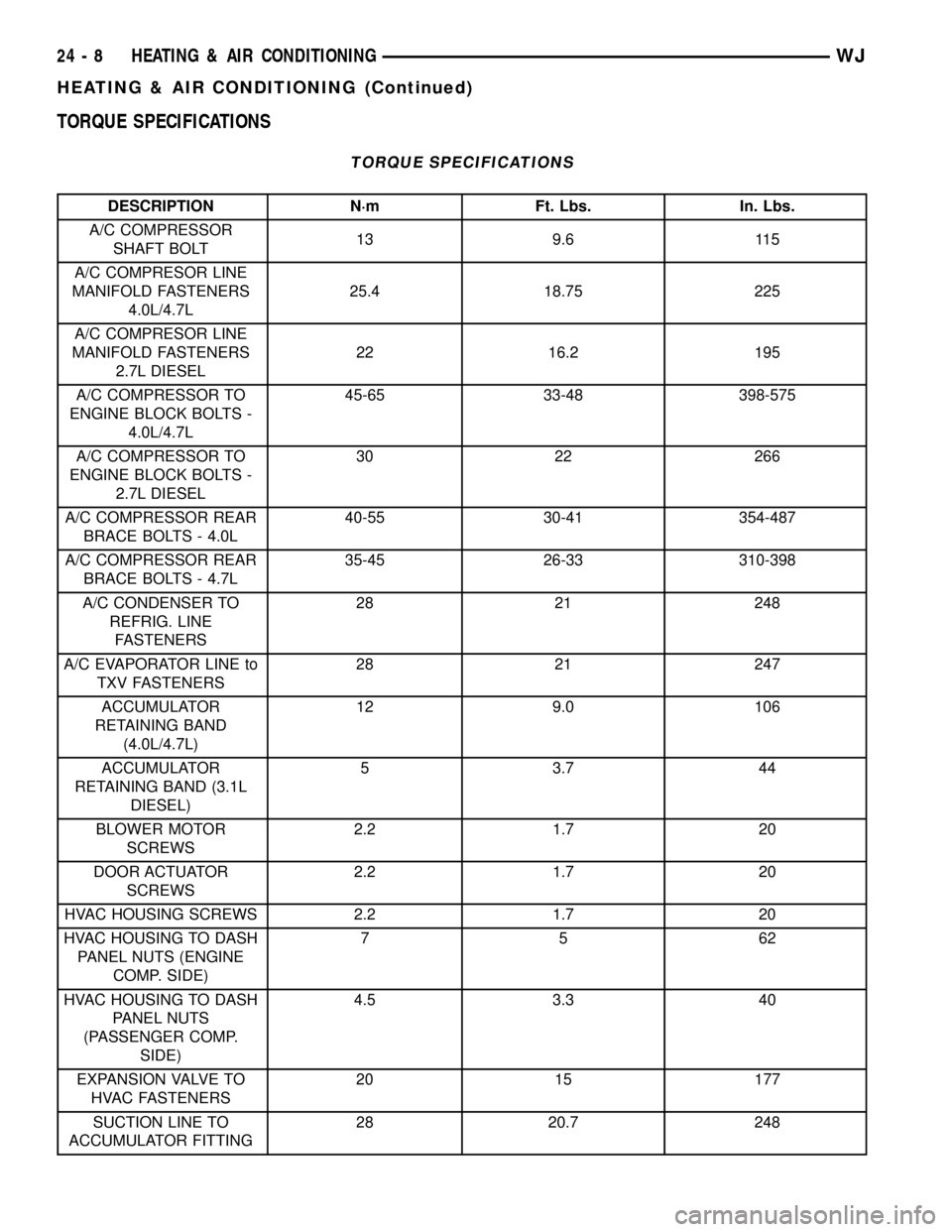

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

A/C COMPRESSOR

SHAFT BOLT13 9.6 115

A/C COMPRESOR LINE

MANIFOLD FASTENERS

4.0L/4.7L25.4 18.75 225

A/C COMPRESOR LINE

MANIFOLD FASTENERS

2.7L DIESEL22 16.2 195

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

4.0L/4.7L45-65 33-48 398-575

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

2.7L DIESEL30 22 266

A/C COMPRESSOR REAR

BRACE BOLTS - 4.0L40-55 30-41 354-487

A/C COMPRESSOR REAR

BRACE BOLTS - 4.7L35-45 26-33 310-398

A/C CONDENSER TO

REFRIG. LINE

FASTENERS28 21 248

A/C EVAPORATOR LINE to

TXV FASTENERS28 21 247

ACCUMULATOR

RETAINING BAND

(4.0L/4.7L)12 9.0 106

ACCUMULATOR

RETAINING BAND (3.1L

DIESEL)5 3.7 44

BLOWER MOTOR

SCREWS2.2 1.7 20

DOOR ACTUATOR

SCREWS2.2 1.7 20

HVAC HOUSING SCREWS 2.2 1.7 20

HVAC HOUSING TO DASH

PANEL NUTS (ENGINE

COMP. SIDE)75 62

HVAC HOUSING TO DASH

PANEL NUTS

(PASSENGER COMP.

SIDE)4.5 3.3 40

EXPANSION VALVE TO

HVAC FASTENERS20 15 177

SUCTION LINE TO

ACCUMULATOR FITTING28 20.7 248

24 - 8 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2128 of 2199

PLUMBING

TABLE OF CONTENTS

page page

PLUMBING

DESCRIPTION - REFRIGERANT LINE.......52

OPERATION - REFRIGERANT LINE.........52

WARNING.............................52

CAUTION

CAUTION...........................53

REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS.......................53

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS......................54

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT..........54

STANDARD PROCEDURE - REFRIGERANT

RECOVERY..........................55

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE...................55

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE.....................56

SPECIFICATIONS

CHARGE CAPACITY...................57

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR.......57

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE..............................57

OPERATION

OPERATION - A/C COMPRESSOR........57

OPERATION - HIGH PRESSURE RELIEF

VALVE..............................57

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE..............................58

REMOVAL

REMOVAL...........................58

REMOVAL - 2.7L TURBO DIESEL.........60

INSTALLATION

INSTALLATION.......................61

INSTALLATION - 2.7L TURBO DIESEL......61

A/C CONDENSER

DESCRIPTION.........................62

OPERATION...........................62

REMOVAL.............................62

INSTALLATION.........................63

A/C DISCHARGE LINE

REMOVAL

REMOVAL - 2.7L TURBO DIESEL.........63

REMOVAL...........................64INSTALLATION

INSTALLATION - 2.7L TURBO DIESEL......64

INSTALLATION.......................65

A/C EXPANSION VALVE

DESCRIPTION.........................65

OPERATION...........................65

DIAGNOSIS AND TESTING - A/C EXPANSION

VALVE ..............................65

REMOVAL.............................66

INSTALLATION.........................66

LIQUID LINE

REMOVAL

REMOVAL...........................66

REMOVAL - 2.7L TURBO DIESEL.........66

INSTALLATION

INSTALLATION.......................66

INSTALLATION - 2.7L TURBO DIESEL......67

SUCTION LINE

REMOVAL

REMOVAL...........................67

REMOVAL - 2.7L TURBO DIESEL.........68

INSTALLATION

INSTALLATION.......................68

INSTALLATION - 2.7L TURBO DIESEL......69

A/C EVAPORATOR

DESCRIPTION.........................69

OPERATION...........................69

REMOVAL.............................69

INSTALLATION.........................70

HEATER CORE

DESCRIPTION.........................71

OPERATION...........................71

REMOVAL.............................71

INSTALLATION.........................71

RECEIVER / DRIER

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................73

INSTALLATION.........................73

REFRIGERANT

DESCRIPTION.........................75

OPERATION...........................75

REFRIGERANT OIL

DESCRIPTION.........................75

OPERATION...........................75

STANDARD PROCEDURE - REFRIGERANT

OIL LEVEL...........................75

WJPLUMBING 24 - 51

Page 2134 of 2199

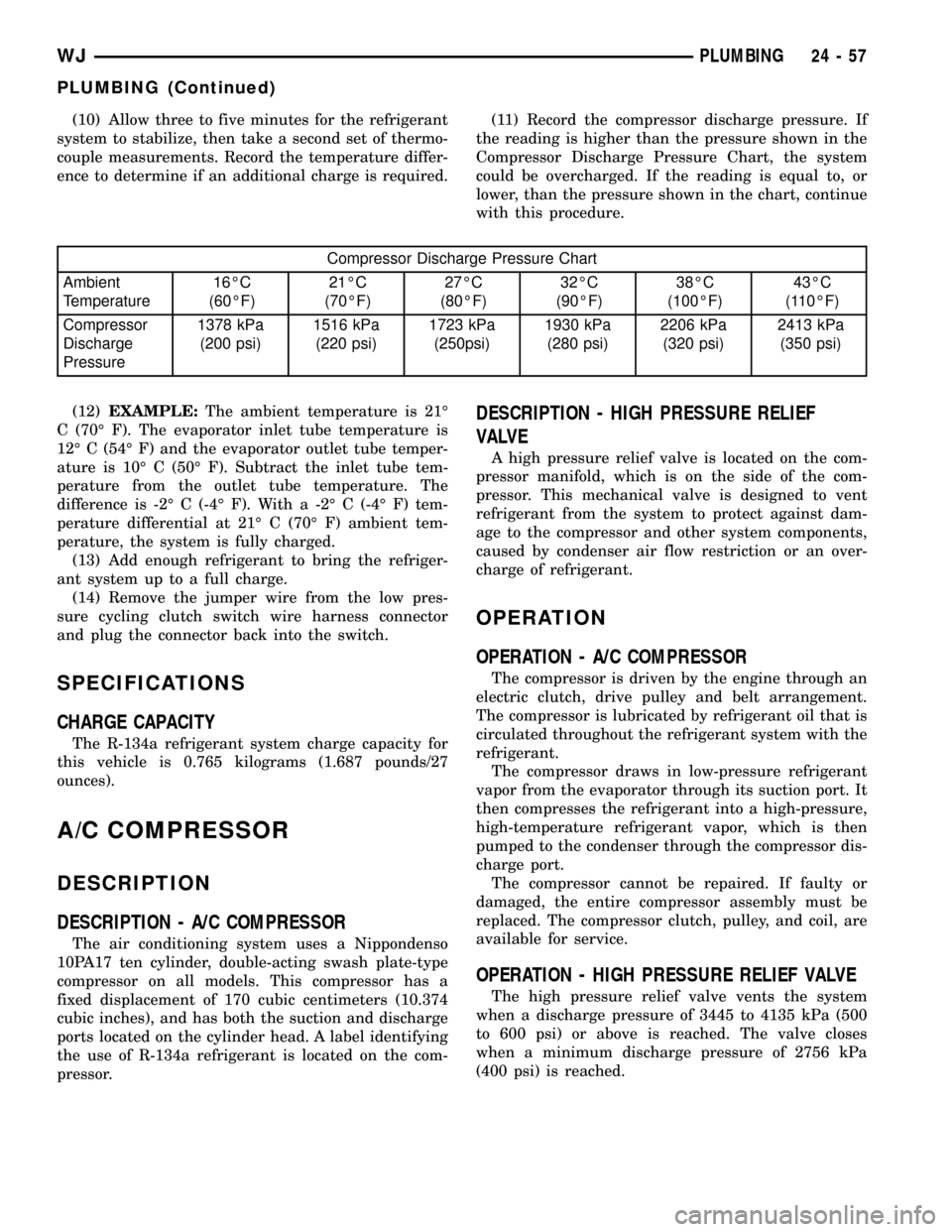

(10) Allow three to five minutes for the refrigerant

system to stabilize, then take a second set of thermo-

couple measurements. Record the temperature differ-

ence to determine if an additional charge is required.(11) Record the compressor discharge pressure. If

the reading is higher than the pressure shown in the

Compressor Discharge Pressure Chart, the system

could be overcharged. If the reading is equal to, or

lower, than the pressure shown in the chart, continue

with this procedure.

Compressor Discharge Pressure Chart

Ambient

Temperature16ÉC

(60ÉF)21ÉC

(70ÉF)27ÉC

(80ÉF)32ÉC

(90ÉF)38ÉC

(100ÉF)43ÉC

(110ÉF)

Compressor

Discharge

Pressure1378 kPa

(200 psi)1516 kPa

(220 psi)1723 kPa

(250psi)1930 kPa

(280 psi)2206 kPa

(320 psi)2413 kPa

(350 psi)

(12)EXAMPLE:The ambient temperature is 21É

C (70É F). The evaporator inlet tube temperature is

12É C (54É F) and the evaporator outlet tube temper-

ature is 10É C (50É F). Subtract the inlet tube tem-

perature from the outlet tube temperature. The

difference is -2É C (-4É F). With a -2É C (-4É F) tem-

perature differential at 21É C (70É F) ambient tem-

perature, the system is fully charged.

(13) Add enough refrigerant to bring the refriger-

ant system up to a full charge.

(14) Remove the jumper wire from the low pres-

sure cycling clutch switch wire harness connector

and plug the connector back into the switch.

SPECIFICATIONS

CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle is 0.765 kilograms (1.687 pounds/27

ounces).

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The air conditioning system uses a Nippondenso

10PA17 ten cylinder, double-acting swash plate-type

compressor on all models. This compressor has a

fixed displacement of 170 cubic centimeters (10.374

cubic inches), and has both the suction and discharge

ports located on the cylinder head. A label identifying

the use of R-134a refrigerant is located on the com-

pressor.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor manifold, which is on the side of the com-

pressor. This mechanical valve is designed to vent

refrigerant from the system to protect against dam-

age to the compressor and other system components,

caused by condenser air flow restriction or an over-

charge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The compressor is driven by the engine through an

electric clutch, drive pulley and belt arrangement.

The compressor is lubricated by refrigerant oil that is

circulated throughout the refrigerant system with the

refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley, and coil, are

available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

WJPLUMBING 24 - 57

PLUMBING (Continued)

Page 2135 of 2199

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and pulley are properly aligned and have

the correct air gap. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION)

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

to be certain that the discharge pressure does not

exceed 2760 kPa (400 psi).

(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which cancause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAU-

TION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(5) If the noise is from opening and closing of the

high pressure relief valve, reclaim, evacuate, and

recharge the refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT RECOVERY)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)If the high pressure relief valve still

does not seat properly, replace the a/c compressor.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C COMPRESSOR - REMOVAL)

(6) If the noise is from liquid slugging on the suc-

tion line, check the refrigerant oil level and the

refrigerant system charge. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT OIL - STANDARD PROCEDURE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

SPECIFICATIONS - CHARGE CAPACITY).

(7) If the noise continues, replace the compressor

and repeat Step 1.

REMOVAL

REMOVAL

The compressor may be removed and repositioned

without disconnecting the refrigerant lines or dis-

charging the refrigerant system. Discharging is not

necessary if servicing the compressor clutch or clutch

coil, the engine, the cylinder head, or the generator.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Recover the refrigerant from the system. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - REFRIGERANT

RECOVERY)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the serpentine drive belt. Refer to

Cooling for the procedures.

(4) Unplug the compressor clutch coil wire harness

connector.

24 - 58 PLUMBINGWJ

A/C COMPRESSOR (Continued)

Page 2173 of 2199

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º

water. The cycle rate of pump strokes is quite rapid

as the system begins to pump up to this pressure. As

the pressure increases, the cycle rate starts to drop

off. If there is no leak in the system, the pump would

eventually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the Air Fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S sensor output. The programmed

memory acts as a self calibration tool that the engine

controller uses to compensate for variations in engine

specifications, sensor tolerances and engine fatigue

over the life span of the engine. By monitoring the

actual fuel-air ratio with the O2S sensor (short term)

and multiplying that with the program long-term

(adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emis-

sions test. If a malfunction occurs such that the PCM

cannot maintain the optimum A/F ratio, then the

MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

25 - 18 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)