Console JEEP GRAND CHEROKEE 2002 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1599 of 2199

INCORRECT if the engine starts in one but not both

positions. If the engine starts in any position other

than PARK or NEUTRAL, or if the engine will not

start at all, the park/neutral position switch or TRS

may be faulty.

(1) Shift transmission into PARK.

(2) Remove floor console as necessary for access to

the shift cable adjustment. (Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL)

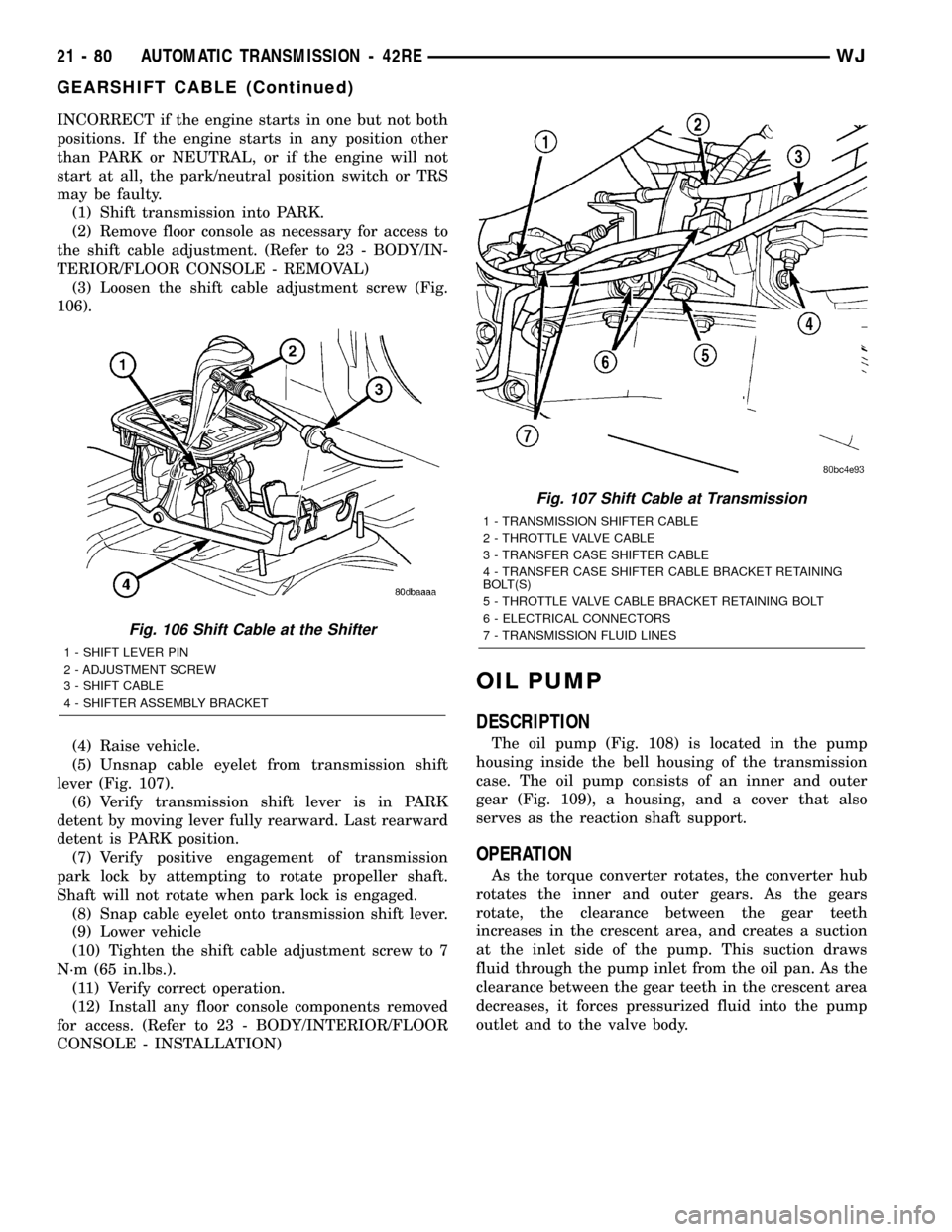

(3) Loosen the shift cable adjustment screw (Fig.

106).

(4) Raise vehicle.

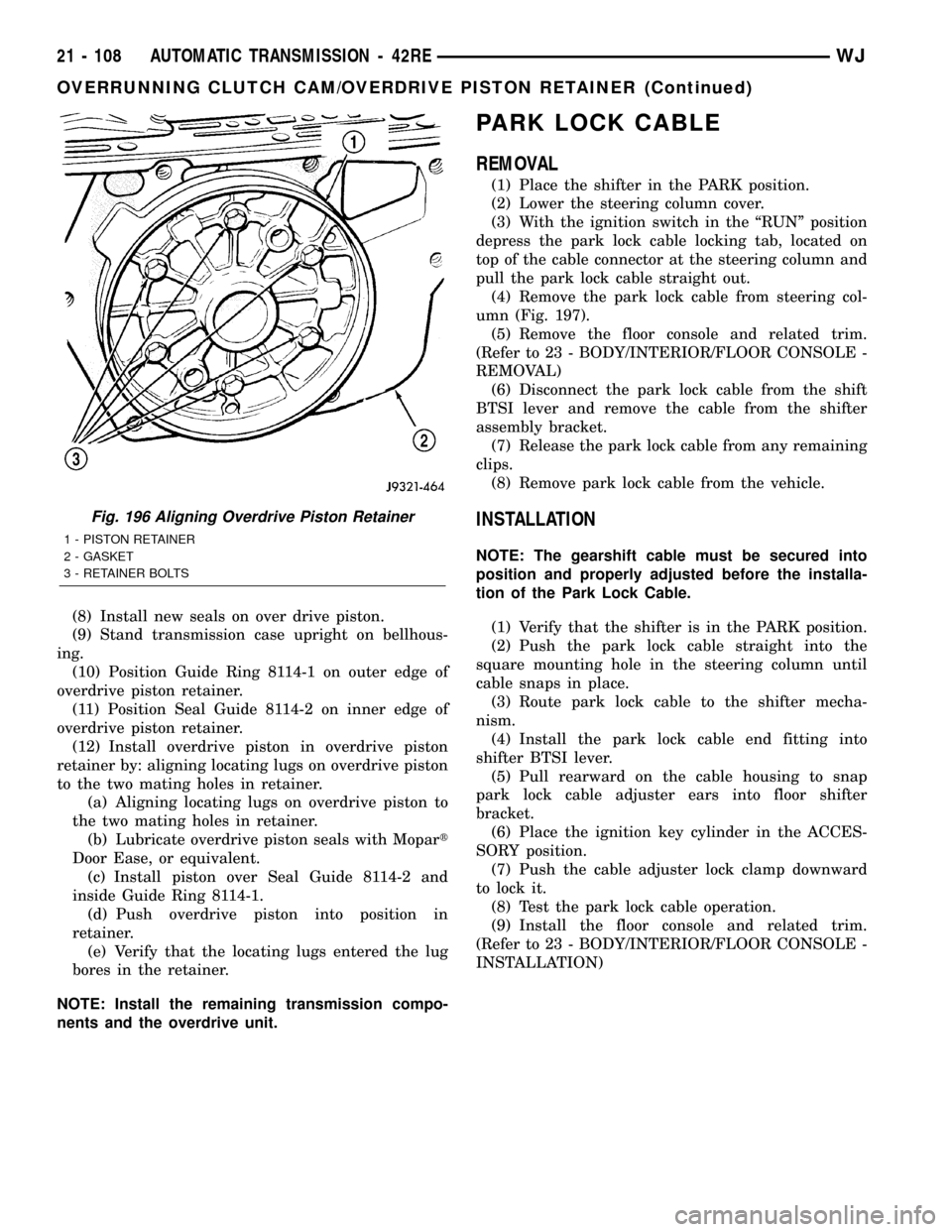

(5) Unsnap cable eyelet from transmission shift

lever (Fig. 107).

(6) Verify transmission shift lever is in PARK

detent by moving lever fully rearward. Last rearward

detent is PARK position.

(7) Verify positive engagement of transmission

park lock by attempting to rotate propeller shaft.

Shaft will not rotate when park lock is engaged.

(8) Snap cable eyelet onto transmission shift lever.

(9) Lower vehicle

(10) Tighten the shift cable adjustment screw to 7

N´m (65 in.lbs.).

(11) Verify correct operation.

(12) Install any floor console components removed

for access. (Refer to 23 - BODY/INTERIOR/FLOOR

CONSOLE - INSTALLATION)

OIL PUMP

DESCRIPTION

The oil pump (Fig. 108) is located in the pump

housing inside the bell housing of the transmission

case. The oil pump consists of an inner and outer

gear (Fig. 109), a housing, and a cover that also

serves as the reaction shaft support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

Fig. 106 Shift Cable at the Shifter

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

Fig. 107 Shift Cable at Transmission

1 - TRANSMISSION SHIFTER CABLE

2 - THROTTLE VALVE CABLE

3 - TRANSFER CASE SHIFTER CABLE

4 - TRANSFER CASE SHIFTER CABLE BRACKET RETAINING

BOLT(S)

5 - THROTTLE VALVE CABLE BRACKET RETAINING BOLT

6 - ELECTRICAL CONNECTORS

7 - TRANSMISSION FLUID LINES

21 - 80 AUTOMATIC TRANSMISSION - 42REWJ

GEARSHIFT CABLE (Continued)

Page 1627 of 2199

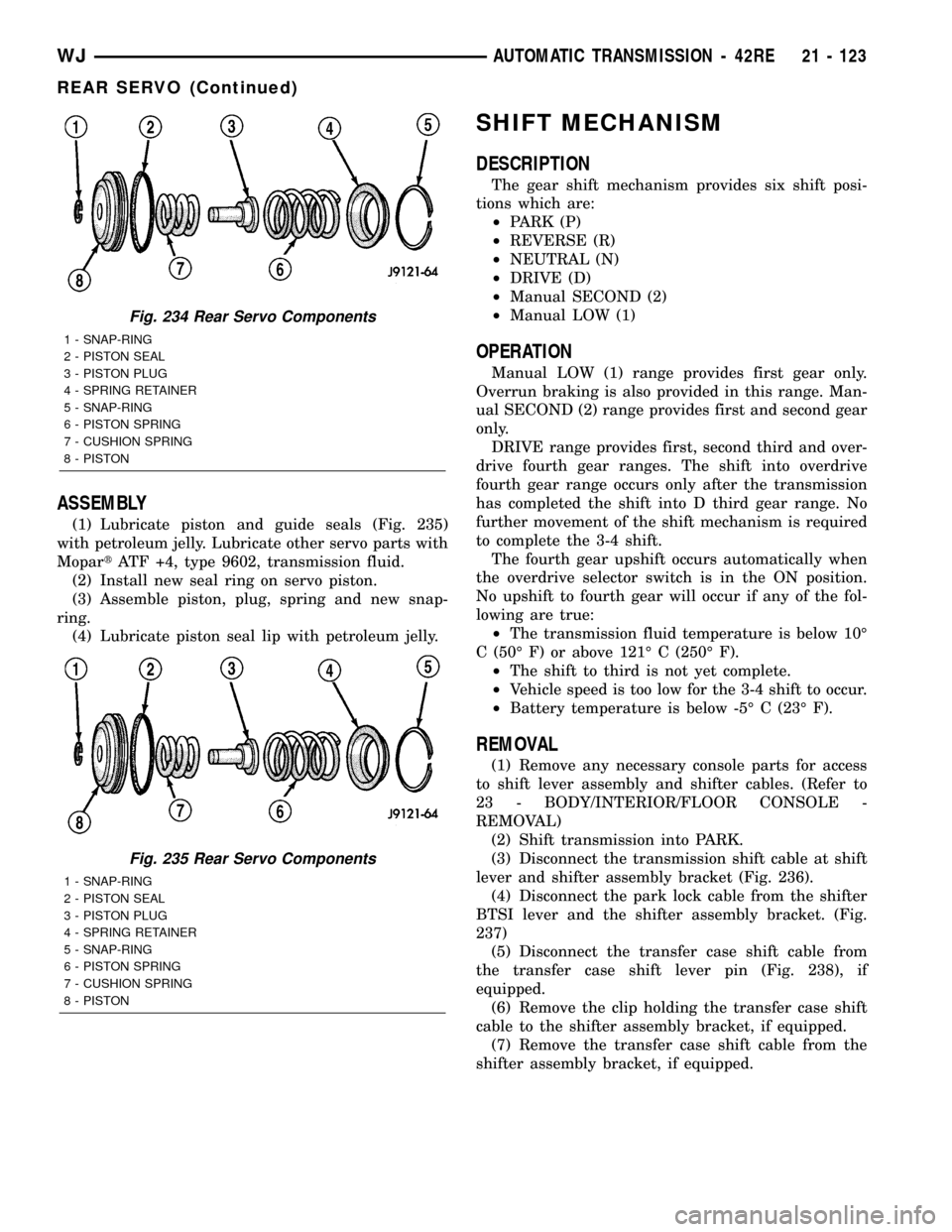

(8) Install new seals on over drive piston.

(9) Stand transmission case upright on bellhous-

ing.

(10) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(11) Position Seal Guide 8114-2 on inner edge of

overdrive piston retainer.

(12) Install overdrive piston in overdrive piston

retainer by: aligning locating lugs on overdrive piston

to the two mating holes in retainer.

(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.

(b) Lubricate overdrive piston seals with Mopart

Door Ease, or equivalent.

(c) Install piston over Seal Guide 8114-2 and

inside Guide Ring 8114-1.

(d) Push overdrive piston into position in

retainer.

(e) Verify that the locating lugs entered the lug

bores in the retainer.

NOTE: Install the remaining transmission compo-

nents and the overdrive unit.

PARK LOCK CABLE

REMOVAL

(1) Place the shifter in the PARK position.

(2) Lower the steering column cover.

(3) With the ignition switch in the ªRUNº position

depress the park lock cable locking tab, located on

top of the cable connector at the steering column and

pull the park lock cable straight out.

(4) Remove the park lock cable from steering col-

umn (Fig. 197).

(5) Remove the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(6) Disconnect the park lock cable from the shift

BTSI lever and remove the cable from the shifter

assembly bracket.

(7) Release the park lock cable from any remaining

clips.

(8) Remove park lock cable from the vehicle.

INSTALLATION

NOTE: The gearshift cable must be secured into

position and properly adjusted before the installa-

tion of the Park Lock Cable.

(1) Verify that the shifter is in the PARK position.

(2) Push the park lock cable straight into the

square mounting hole in the steering column until

cable snaps in place.

(3) Route park lock cable to the shifter mecha-

nism.

(4) Install the park lock cable end fitting into

shifter BTSI lever.

(5) Pull rearward on the cable housing to snap

park lock cable adjuster ears into floor shifter

bracket.

(6) Place the ignition key cylinder in the ACCES-

SORY position.

(7) Push the cable adjuster lock clamp downward

to lock it.

(8) Test the park lock cable operation.

(9) Install the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION)

Fig. 196 Aligning Overdrive Piston Retainer

1 - PISTON RETAINER

2 - GASKET

3 - RETAINER BOLTS

21 - 108 AUTOMATIC TRANSMISSION - 42REWJ

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 1642 of 2199

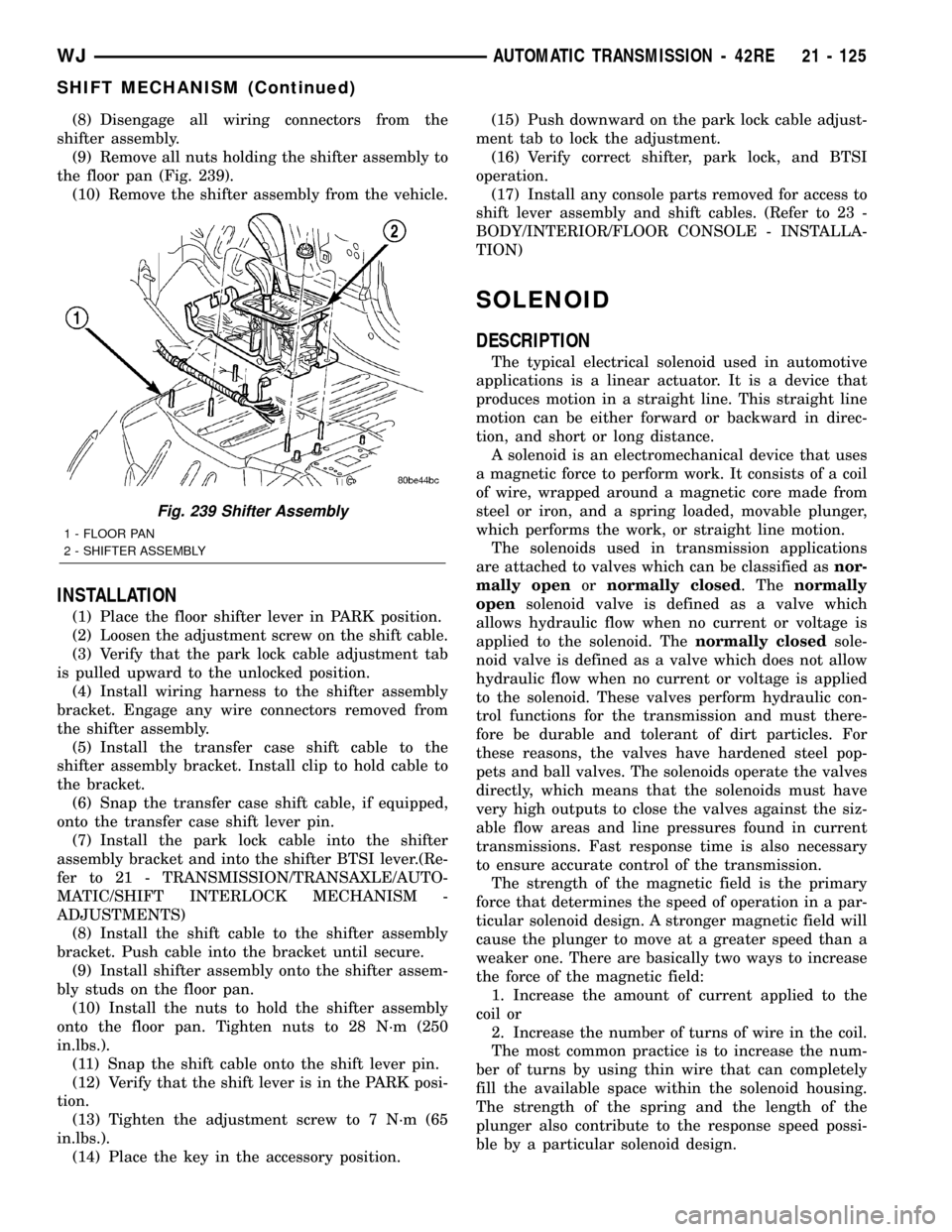

ASSEMBLY

(1) Lubricate piston and guide seals (Fig. 235)

with petroleum jelly. Lubricate other servo parts with

MopartATF +4, type 9602, transmission fluid.

(2) Install new seal ring on servo piston.

(3) Assemble piston, plug, spring and new snap-

ring.

(4) Lubricate piston seal lip with petroleum jelly.

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²PARK (P)

²REVERSE (R)

²NEUTRAL (N)

²DRIVE (D)

²Manual SECOND (2)

²Manual LOW (1)

OPERATION

Manual LOW (1) range provides first gear only.

Overrun braking is also provided in this range. Man-

ual SECOND (2) range provides first and second gear

only.

DRIVE range provides first, second third and over-

drive fourth gear ranges. The shift into overdrive

fourth gear range occurs only after the transmission

has completed the shift into D third gear range. No

further movement of the shift mechanism is required

to complete the 3-4 shift.

The fourth gear upshift occurs automatically when

the overdrive selector switch is in the ON position.

No upshift to fourth gear will occur if any of the fol-

lowing are true:

²The transmission fluid temperature is below 10É

C (50É F) or above 121É C (250É F).

²The shift to third is not yet complete.

²Vehicle speed is too low for the 3-4 shift to occur.

²Battery temperature is below -5É C (23É F).

REMOVAL

(1) Remove any necessary console parts for access

to shift lever assembly and shifter cables. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(2) Shift transmission into PARK.

(3) Disconnect the transmission shift cable at shift

lever and shifter assembly bracket (Fig. 236).

(4) Disconnect the park lock cable from the shifter

BTSI lever and the shifter assembly bracket. (Fig.

237)

(5) Disconnect the transfer case shift cable from

the transfer case shift lever pin (Fig. 238), if

equipped.

(6) Remove the clip holding the transfer case shift

cable to the shifter assembly bracket, if equipped.

(7) Remove the transfer case shift cable from the

shifter assembly bracket, if equipped.

Fig. 234 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

Fig. 235 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

WJAUTOMATIC TRANSMISSION - 42RE 21 - 123

REAR SERVO (Continued)

Page 1644 of 2199

(8) Disengage all wiring connectors from the

shifter assembly.

(9) Remove all nuts holding the shifter assembly to

the floor pan (Fig. 239).

(10) Remove the shifter assembly from the vehicle.

INSTALLATION

(1) Place the floor shifter lever in PARK position.

(2) Loosen the adjustment screw on the shift cable.

(3) Verify that the park lock cable adjustment tab

is pulled upward to the unlocked position.

(4) Install wiring harness to the shifter assembly

bracket. Engage any wire connectors removed from

the shifter assembly.

(5) Install the transfer case shift cable to the

shifter assembly bracket. Install clip to hold cable to

the bracket.

(6) Snap the transfer case shift cable, if equipped,

onto the transfer case shift lever pin.

(7) Install the park lock cable into the shifter

assembly bracket and into the shifter BTSI lever.(Re-

fer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC/SHIFT INTERLOCK MECHANISM -

ADJUSTMENTS)

(8) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(9) Install shifter assembly onto the shifter assem-

bly studs on the floor pan.

(10) Install the nuts to hold the shifter assembly

onto the floor pan. Tighten nuts to 28 N´m (250

in.lbs.).

(11) Snap the shift cable onto the shift lever pin.

(12) Verify that the shift lever is in the PARK posi-

tion.

(13) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(14) Place the key in the accessory position.(15) Push downward on the park lock cable adjust-

ment tab to lock the adjustment.

(16) Verify correct shifter, park lock, and BTSI

operation.

(17) Install any console parts removed for access to

shift lever assembly and shift cables. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

SOLENOID

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

Fig. 239 Shifter Assembly

1 - FLOOR PAN

2 - SHIFTER ASSEMBLY

WJAUTOMATIC TRANSMISSION - 42RE 21 - 125

SHIFT MECHANISM (Continued)

Page 1746 of 2199

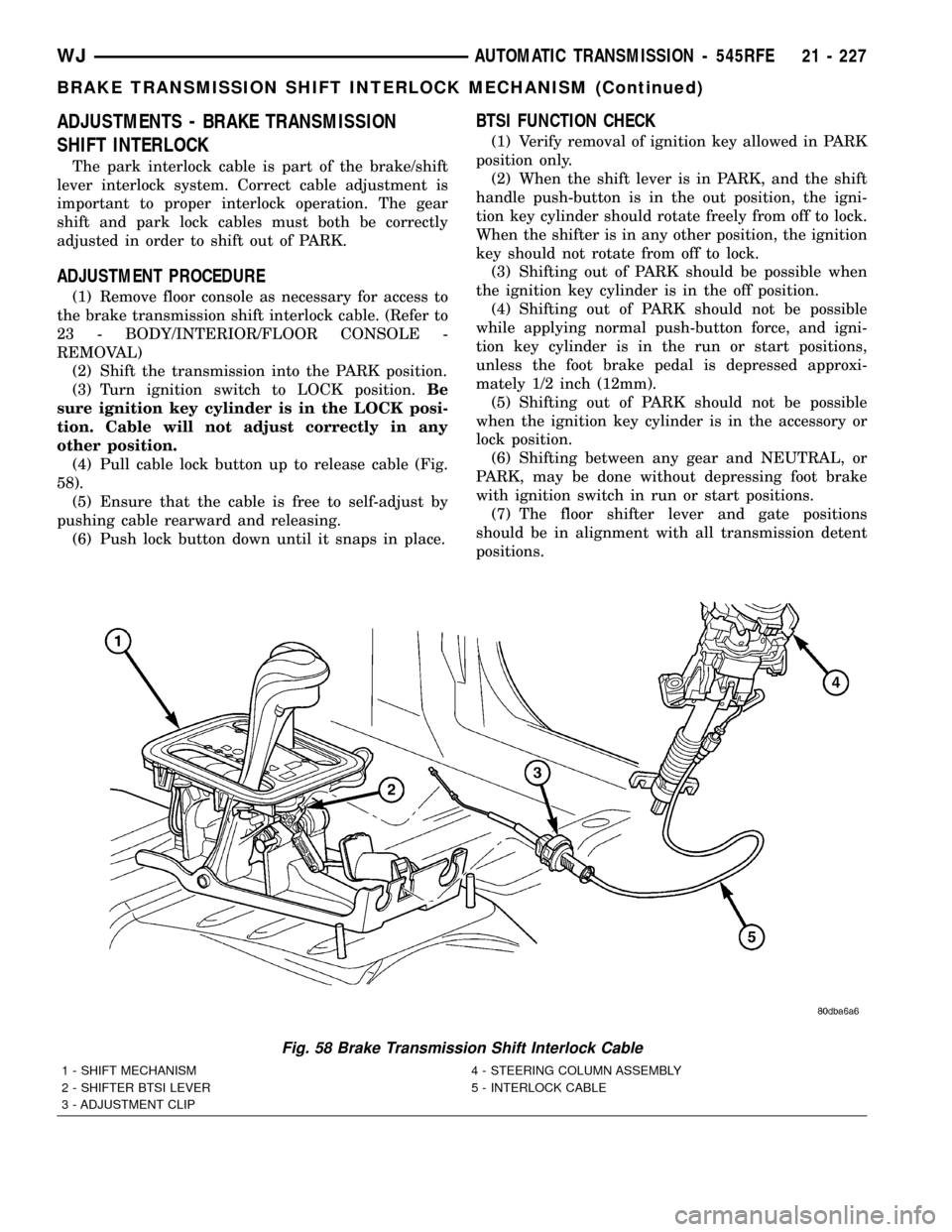

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK

The park interlock cable is part of the brake/shift

lever interlock system. Correct cable adjustment is

important to proper interlock operation. The gear

shift and park lock cables must both be correctly

adjusted in order to shift out of PARK.

ADJUSTMENT PROCEDURE

(1) Remove floor console as necessary for access to

the brake transmission shift interlock cable. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(2) Shift the transmission into the PARK position.

(3) Turn ignition switch to LOCK position.Be

sure ignition key cylinder is in the LOCK posi-

tion. Cable will not adjust correctly in any

other position.

(4) Pull cable lock button up to release cable (Fig.

58).

(5) Ensure that the cable is free to self-adjust by

pushing cable rearward and releasing.

(6) Push lock button down until it snaps in place.

BTSI FUNCTION CHECK

(1) Verify removal of ignition key allowed in PARK

position only.

(2) When the shift lever is in PARK, and the shift

handle push-button is in the out position, the igni-

tion key cylinder should rotate freely from off to lock.

When the shifter is in any other position, the ignition

key should not rotate from off to lock.

(3) Shifting out of PARK should be possible when

the ignition key cylinder is in the off position.

(4) Shifting out of PARK should not be possible

while applying normal push-button force, and igni-

tion key cylinder is in the run or start positions,

unless the foot brake pedal is depressed approxi-

mately 1/2 inch (12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the accessory or

lock position.

(6) Shifting between any gear and NEUTRAL, or

PARK, may be done without depressing foot brake

with ignition switch in run or start positions.

(7) The floor shifter lever and gate positions

should be in alignment with all transmission detent

positions.

Fig. 58 Brake Transmission Shift Interlock Cable

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 227

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1750 of 2199

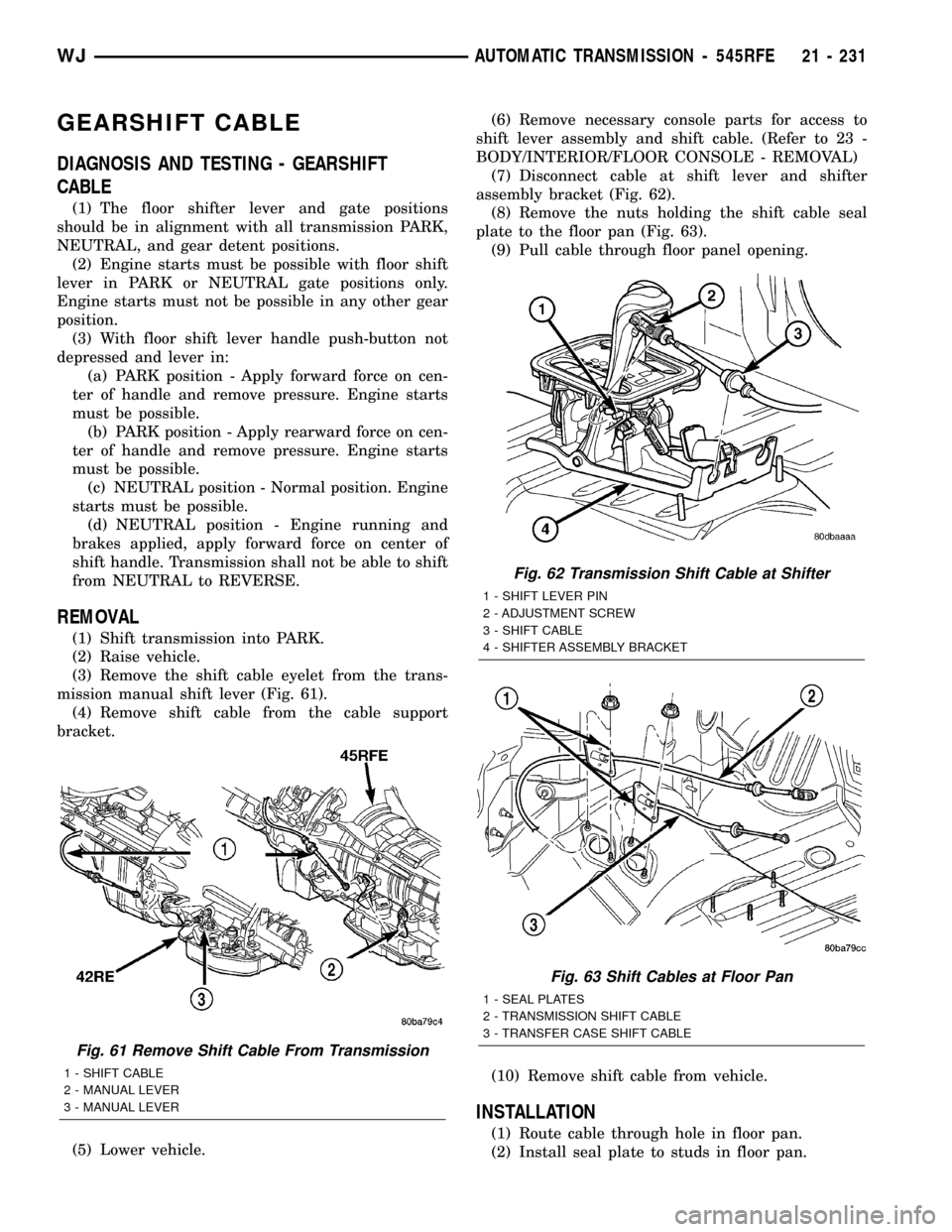

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) The floor shifter lever and gate positions

should be in alignment with all transmission PARK,

NEUTRAL, and gear detent positions.

(2) Engine starts must be possible with floor shift

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gear

position.

(3) With floor shift lever handle push-button not

depressed and lever in:

(a) PARK position - Apply forward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(b) PARK position - Apply rearward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply forward force on center of

shift handle. Transmission shall not be able to shift

from NEUTRAL to REVERSE.

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove the shift cable eyelet from the trans-

mission manual shift lever (Fig. 61).

(4) Remove shift cable from the cable support

bracket.

(5) Lower vehicle.(6) Remove necessary console parts for access to

shift lever assembly and shift cable. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - REMOVAL)

(7) Disconnect cable at shift lever and shifter

assembly bracket (Fig. 62).

(8) Remove the nuts holding the shift cable seal

plate to the floor pan (Fig. 63).

(9) Pull cable through floor panel opening.

(10) Remove shift cable from vehicle.

INSTALLATION

(1) Route cable through hole in floor pan.

(2) Install seal plate to studs in floor pan.

Fig. 61 Remove Shift Cable From Transmission

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

Fig. 62 Transmission Shift Cable at Shifter

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

Fig. 63 Shift Cables at Floor Pan

1 - SEAL PLATES

2 - TRANSMISSION SHIFT CABLE

3 - TRANSFER CASE SHIFT CABLE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 231

Page 1751 of 2199

(3) Install nuts to hold seal plate to floor pan.

Tighten nuts to 7 N´m (65 in.lbs.).

(4) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(5) Place the floor shifter lever in PARK position.

(6) Loosen the adjustment screw on the shift cable.

(7) Snap the shift cable onto the shift lever pin.

(8) Raise the vehicle.

(9) Install the shift cable to the shift cable support

bracket.

(10) Shift the transmission into PARK. PARK is

the rearmost detent position on the transmission

manual shift lever.

(11) Snap the shift cable onto the transmission

manual shift lever.

(12) Lower vehicle.

(13) Verify that the shift lever is in the PARK posi-

tion.

(14) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(15) Verify correct shifter operation.

(16) Install any console parts removed for access to

shift lever assembly and shift cable. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

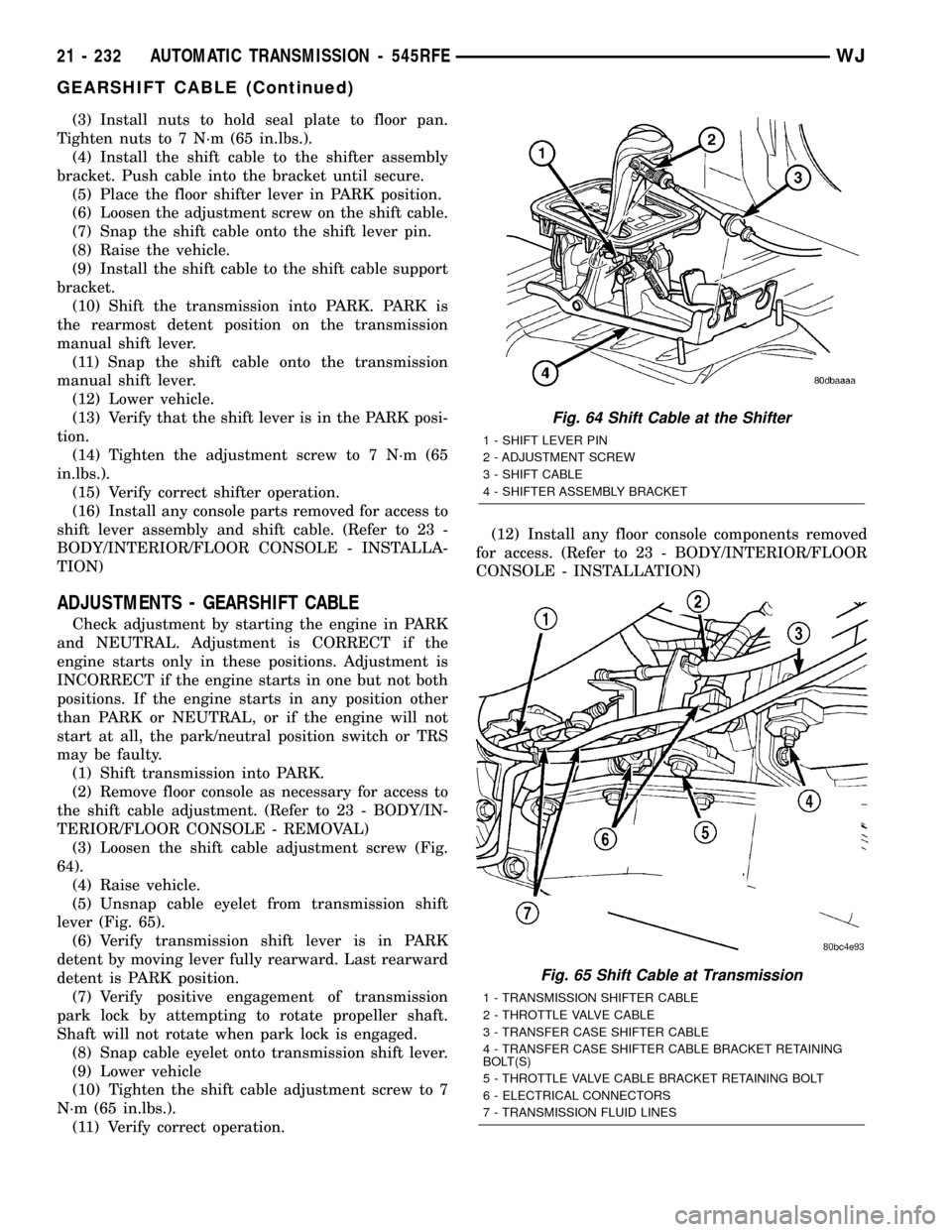

ADJUSTMENTS - GEARSHIFT CABLE

Check adjustment by starting the engine in PARK

and NEUTRAL. Adjustment is CORRECT if the

engine starts only in these positions. Adjustment is

INCORRECT if the engine starts in one but not both

positions. If the engine starts in any position other

than PARK or NEUTRAL, or if the engine will not

start at all, the park/neutral position switch or TRS

may be faulty.

(1) Shift transmission into PARK.

(2) Remove floor console as necessary for access to

the shift cable adjustment. (Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL)

(3) Loosen the shift cable adjustment screw (Fig.

64).

(4) Raise vehicle.

(5) Unsnap cable eyelet from transmission shift

lever (Fig. 65).

(6) Verify transmission shift lever is in PARK

detent by moving lever fully rearward. Last rearward

detent is PARK position.

(7) Verify positive engagement of transmission

park lock by attempting to rotate propeller shaft.

Shaft will not rotate when park lock is engaged.

(8) Snap cable eyelet onto transmission shift lever.

(9) Lower vehicle

(10) Tighten the shift cable adjustment screw to 7

N´m (65 in.lbs.).

(11) Verify correct operation.(12) Install any floor console components removed

for access. (Refer to 23 - BODY/INTERIOR/FLOOR

CONSOLE - INSTALLATION)

Fig. 64 Shift Cable at the Shifter

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

Fig. 65 Shift Cable at Transmission

1 - TRANSMISSION SHIFTER CABLE

2 - THROTTLE VALVE CABLE

3 - TRANSFER CASE SHIFTER CABLE

4 - TRANSFER CASE SHIFTER CABLE BRACKET RETAINING

BOLT(S)

5 - THROTTLE VALVE CABLE BRACKET RETAINING BOLT

6 - ELECTRICAL CONNECTORS

7 - TRANSMISSION FLUID LINES

21 - 232 AUTOMATIC TRANSMISSION - 545RFEWJ

GEARSHIFT CABLE (Continued)

Page 1774 of 2199

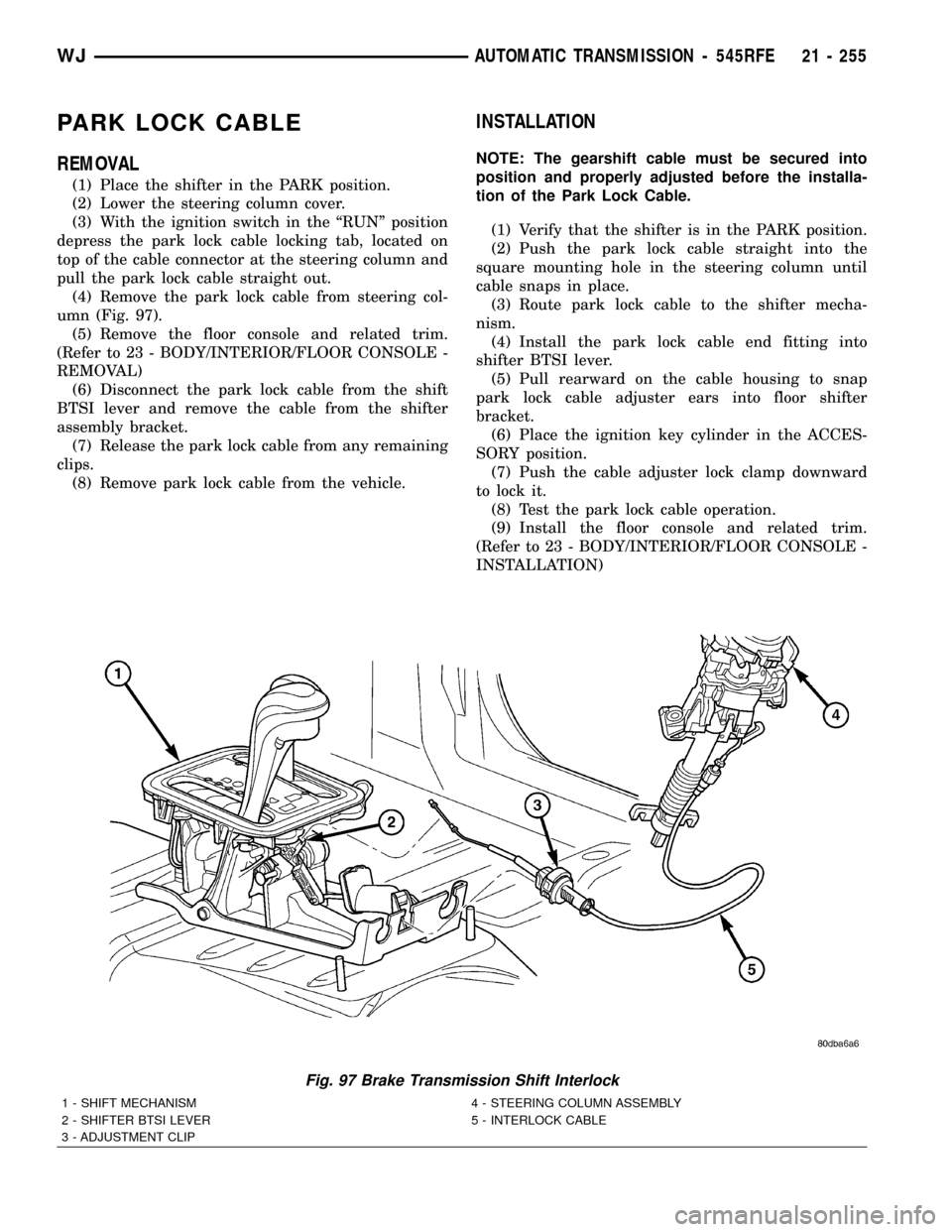

PARK LOCK CABLE

REMOVAL

(1) Place the shifter in the PARK position.

(2) Lower the steering column cover.

(3) With the ignition switch in the ªRUNº position

depress the park lock cable locking tab, located on

top of the cable connector at the steering column and

pull the park lock cable straight out.

(4) Remove the park lock cable from steering col-

umn (Fig. 97).

(5) Remove the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(6) Disconnect the park lock cable from the shift

BTSI lever and remove the cable from the shifter

assembly bracket.

(7) Release the park lock cable from any remaining

clips.

(8) Remove park lock cable from the vehicle.

INSTALLATION

NOTE: The gearshift cable must be secured into

position and properly adjusted before the installa-

tion of the Park Lock Cable.

(1) Verify that the shifter is in the PARK position.

(2) Push the park lock cable straight into the

square mounting hole in the steering column until

cable snaps in place.

(3) Route park lock cable to the shifter mecha-

nism.

(4) Install the park lock cable end fitting into

shifter BTSI lever.

(5) Pull rearward on the cable housing to snap

park lock cable adjuster ears into floor shifter

bracket.

(6) Place the ignition key cylinder in the ACCES-

SORY position.

(7) Push the cable adjuster lock clamp downward

to lock it.

(8) Test the park lock cable operation.

(9) Install the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION)

Fig. 97 Brake Transmission Shift Interlock

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 255

Page 1780 of 2199

Replace the driving shell if worn, cracked or dam-

aged.

Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annulus

gears and supports if either component is worn or

damaged.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also

replace the shaft if the splines are damaged, or

exhibits cracks at any location.

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install the number 11 bearing into the input

planetary carrier so that the inner race will be

toward the front of the transmission (Fig. 104).

(3) Install the input sun gear into the input carrier

(Fig. 104).

(4) Install the number 10 bearing onto the rear of

the reverse planetary carrier with the inner race

toward the carrier (Fig. 104).

(5) Install the number 9 bearing onto the front of

the reverse planetary carrier with the outer race

toward the carrier and the inner race facing upward

(Fig. 104).

(6) Install the reverse planetary gear carrier into

the input carrier (Fig. 104).

(7) Install the input annulus gear into the input

carrier (Fig. 104).

(8) Install the snap-ring to hold the input annulus

gear into the input carrier (Fig. 104).

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²Park (P)

²Reverse (R)

²Neutral (N)

²Drive (D)

²Manual second (2)

²Manual low (1)

OPERATION

MANUAL LOW (1) range provides FIRST gear

only. Overrun braking is also provided in this range.

MANUAL SECOND (2) range provides FIRST and

SECOND gear only.

DRIVE range provides FIRST, SECOND, THIRD

and OVERDRIVE FOURTH and FIFTH gear ranges.

The shift into OVERDRIVE FOURTH and FIFTH

gear range occurs only after the transmission hascompleted the shift into D THIRD gear range. No

further movement of the shift mechanism is required

to complete the 3-4 or 4-5 shifts.

The FOURTH and FIFTH gear upshifts occurs

automatically when the overdrive selector switch is

in the ON position. An upshift to FOURTH and

FIFTH gears may not occur or may be delayed in

some of the possible shift schedules. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/TRANSMISSION CONTROL MODULE -

OPERATION)

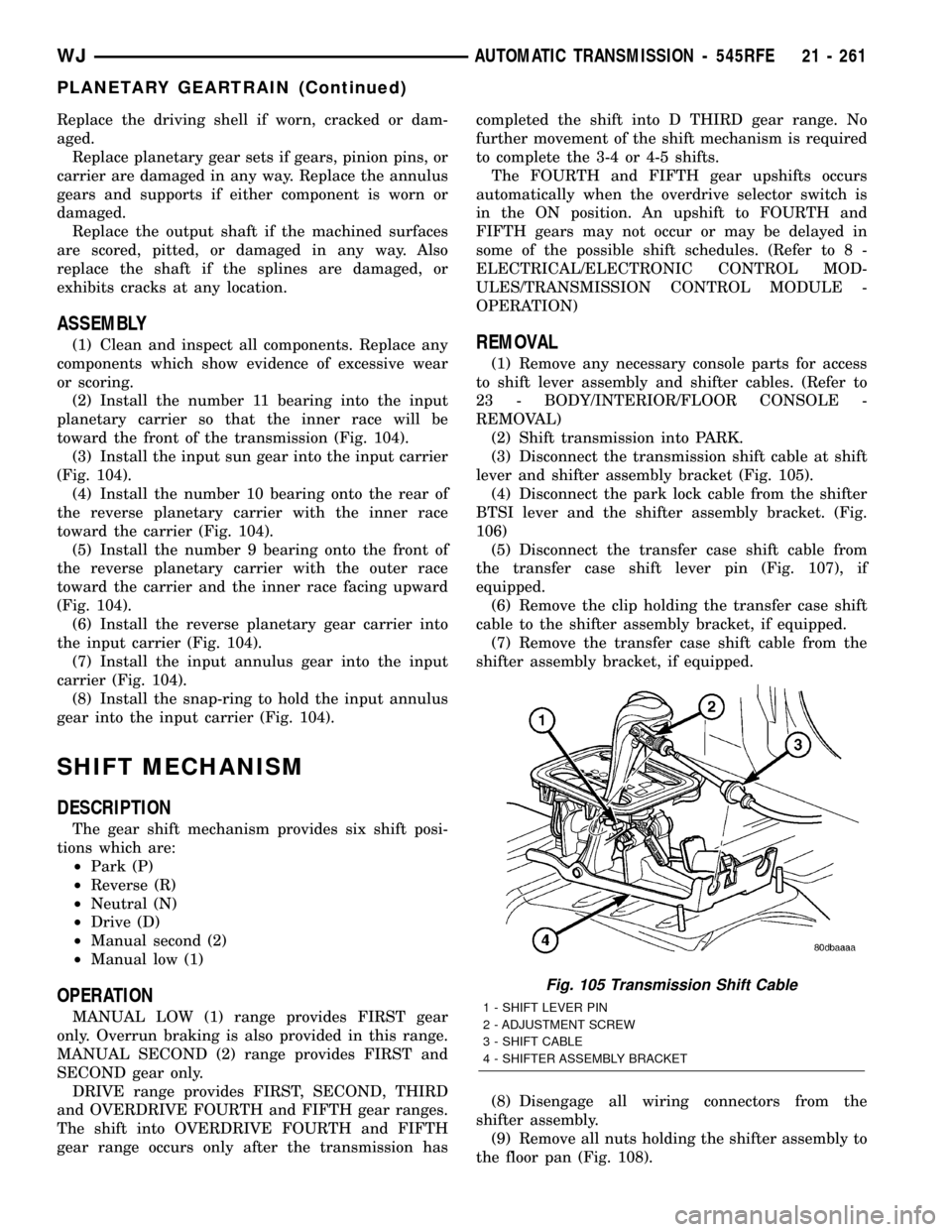

REMOVAL

(1) Remove any necessary console parts for access

to shift lever assembly and shifter cables. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(2) Shift transmission into PARK.

(3) Disconnect the transmission shift cable at shift

lever and shifter assembly bracket (Fig. 105).

(4) Disconnect the park lock cable from the shifter

BTSI lever and the shifter assembly bracket. (Fig.

106)

(5) Disconnect the transfer case shift cable from

the transfer case shift lever pin (Fig. 107), if

equipped.

(6) Remove the clip holding the transfer case shift

cable to the shifter assembly bracket, if equipped.

(7) Remove the transfer case shift cable from the

shifter assembly bracket, if equipped.

(8) Disengage all wiring connectors from the

shifter assembly.

(9) Remove all nuts holding the shifter assembly to

the floor pan (Fig. 108).

Fig. 105 Transmission Shift Cable

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 261

PLANETARY GEARTRAIN (Continued)

Page 1782 of 2199

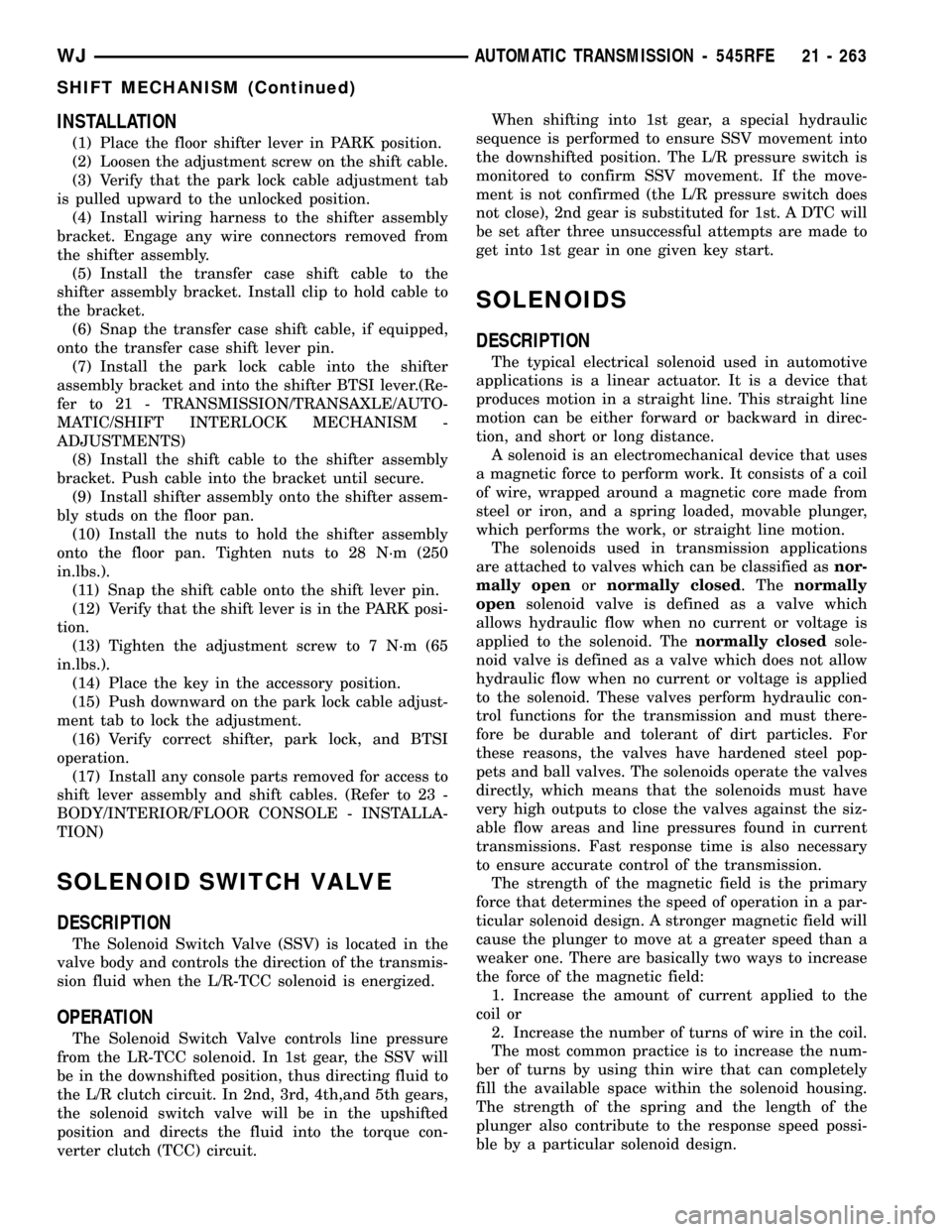

INSTALLATION

(1) Place the floor shifter lever in PARK position.

(2) Loosen the adjustment screw on the shift cable.

(3) Verify that the park lock cable adjustment tab

is pulled upward to the unlocked position.

(4) Install wiring harness to the shifter assembly

bracket. Engage any wire connectors removed from

the shifter assembly.

(5) Install the transfer case shift cable to the

shifter assembly bracket. Install clip to hold cable to

the bracket.

(6) Snap the transfer case shift cable, if equipped,

onto the transfer case shift lever pin.

(7) Install the park lock cable into the shifter

assembly bracket and into the shifter BTSI lever.(Re-

fer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC/SHIFT INTERLOCK MECHANISM -

ADJUSTMENTS)

(8) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(9) Install shifter assembly onto the shifter assem-

bly studs on the floor pan.

(10) Install the nuts to hold the shifter assembly

onto the floor pan. Tighten nuts to 28 N´m (250

in.lbs.).

(11) Snap the shift cable onto the shift lever pin.

(12) Verify that the shift lever is in the PARK posi-

tion.

(13) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(14) Place the key in the accessory position.

(15) Push downward on the park lock cable adjust-

ment tab to lock the adjustment.

(16) Verify correct shifter, park lock, and BTSI

operation.

(17) Install any console parts removed for access to

shift lever assembly and shift cables. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

SOLENOID SWITCH VALVE

DESCRIPTION

The Solenoid Switch Valve (SSV) is located in the

valve body and controls the direction of the transmis-

sion fluid when the L/R-TCC solenoid is energized.

OPERATION

The Solenoid Switch Valve controls line pressure

from the LR-TCC solenoid. In 1st gear, the SSV will

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th,and 5th gears,

the solenoid switch valve will be in the upshifted

position and directs the fluid into the torque con-

verter clutch (TCC) circuit.When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

SOLENOIDS

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 263

SHIFT MECHANISM (Continued)