removal JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 348 of 1803

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The stator winding connections deliver the induced

AC current to 3 positive and 3 negative diodes for

rectification. From the diodes, rectified DC current is

delivered to the vehicle electrical system through the

generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Spec-

ifications and see Generator Ratings for amperage

ratings and part numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley; incorrect, worn, damaged or misad-

justed fan drive belt; loose mounting bolts; a

misaligned drive pulley or a defective stator or diode.

REMOVAL

Gasoline Powered Engines

CAUTION: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

(1) Disconnect and isolate negative battery cable

at battery.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

(2) Remove generator drive belt. Refer to 7, Cool-

ing System for procedures.

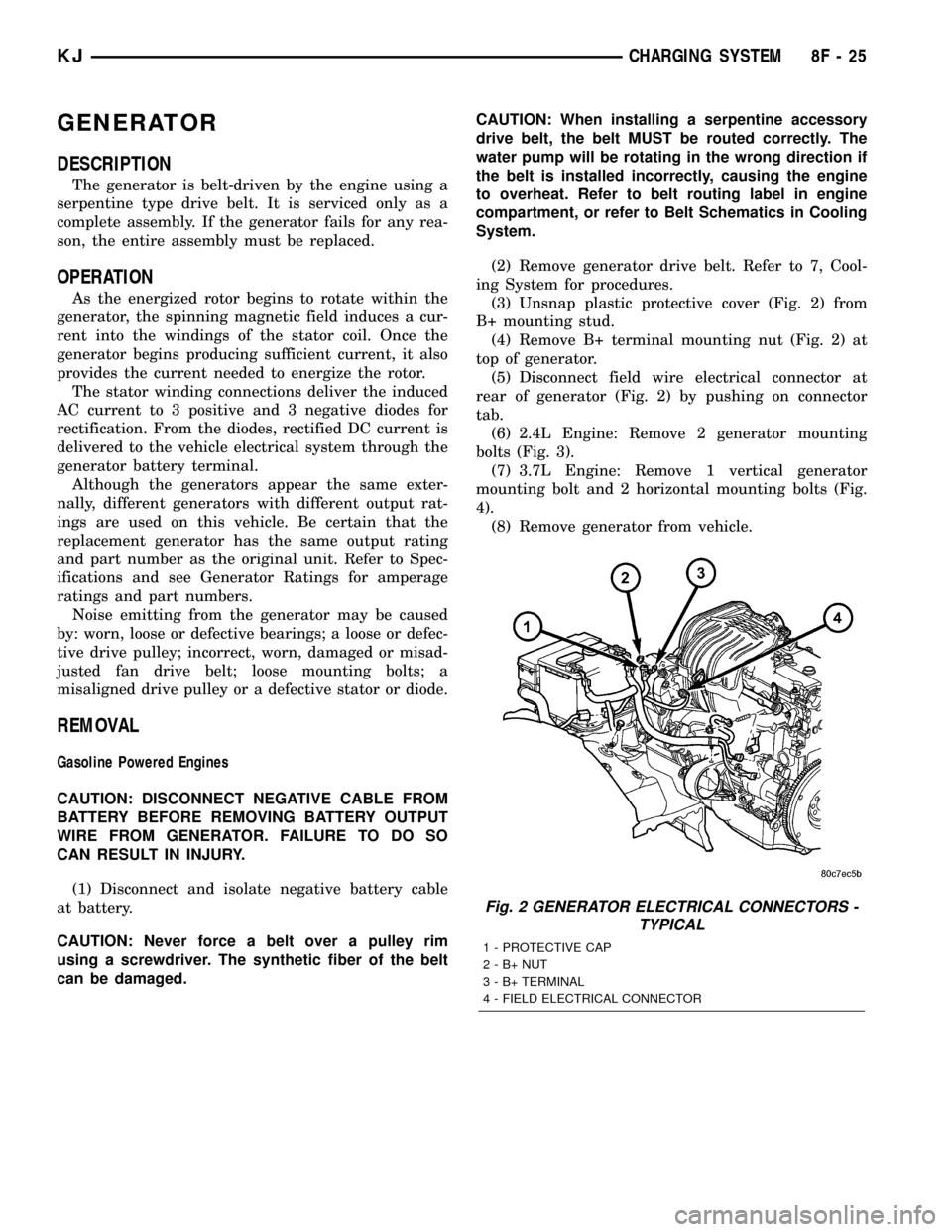

(3) Unsnap plastic protective cover (Fig. 2) from

B+ mounting stud.

(4) Remove B+ terminal mounting nut (Fig. 2) at

top of generator.

(5) Disconnect field wire electrical connector at

rear of generator (Fig. 2) by pushing on connector

tab.

(6) 2.4L Engine: Remove 2 generator mounting

bolts (Fig. 3).

(7) 3.7L Engine: Remove 1 vertical generator

mounting bolt and 2 horizontal mounting bolts (Fig.

4).

(8) Remove generator from vehicle.

Fig. 2 GENERATOR ELECTRICAL CONNECTORS -

TYPICAL

1 - PROTECTIVE CAP

2-B+NUT

3 - B+ TERMINAL

4 - FIELD ELECTRICAL CONNECTOR

KJCHARGING SYSTEM 8F - 25

Page 350 of 1803

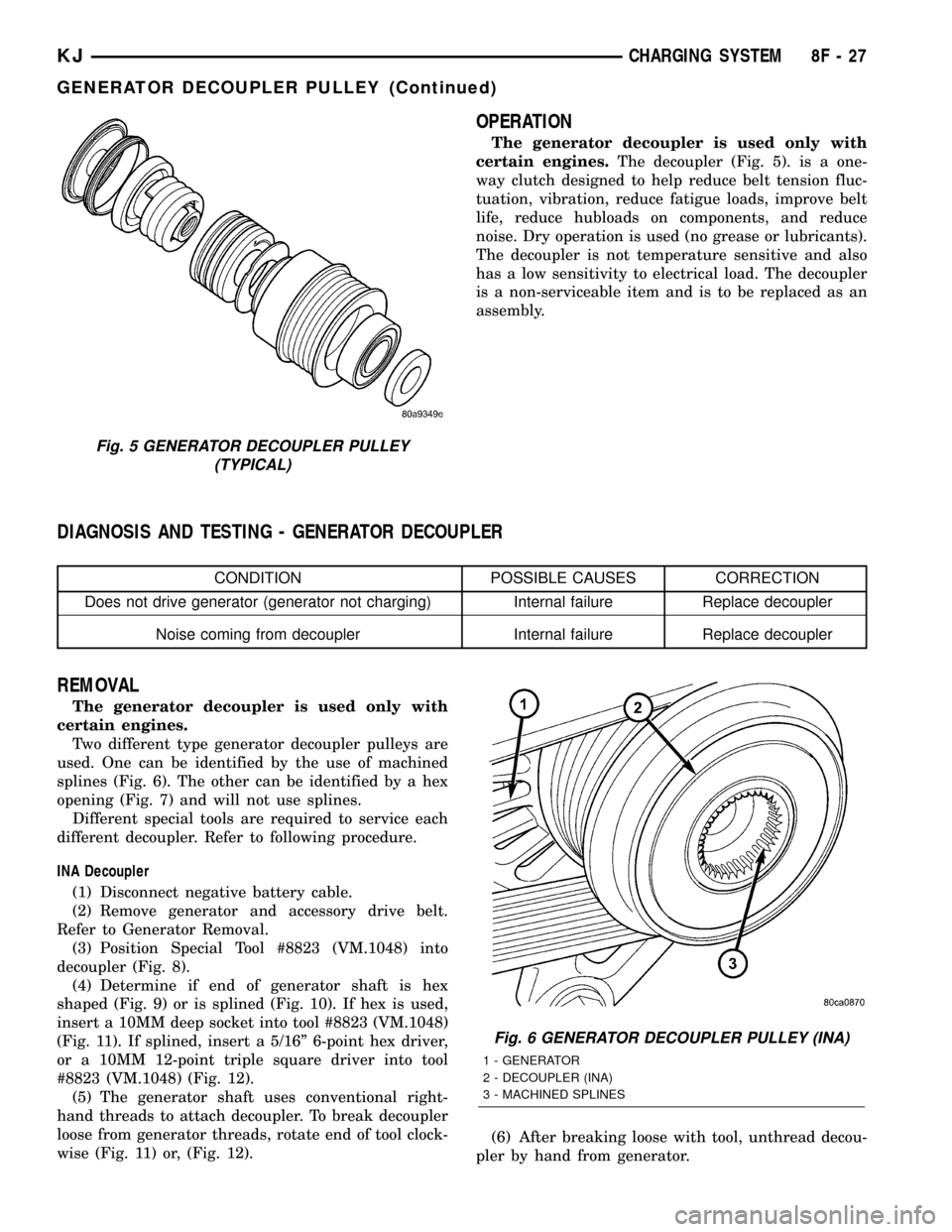

OPERATION

The generator decoupler is used only with

certain engines.The decoupler (Fig. 5). is a one-

way clutch designed to help reduce belt tension fluc-

tuation, vibration, reduce fatigue loads, improve belt

life, reduce hubloads on components, and reduce

noise. Dry operation is used (no grease or lubricants).

The decoupler is not temperature sensitive and also

has a low sensitivity to electrical load. The decoupler

is a non-serviceable item and is to be replaced as an

assembly.

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER

CONDITION POSSIBLE CAUSES CORRECTION

Does not drive generator (generator not charging) Internal failure Replace decoupler

Noise coming from decoupler Internal failure Replace decoupler

REMOVAL

The generator decoupler is used only with

certain engines.

Two different type generator decoupler pulleys are

used. One can be identified by the use of machined

splines (Fig. 6). The other can be identified by a hex

opening (Fig. 7) and will not use splines.

Different special tools are required to service each

different decoupler. Refer to following procedure.

INA Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

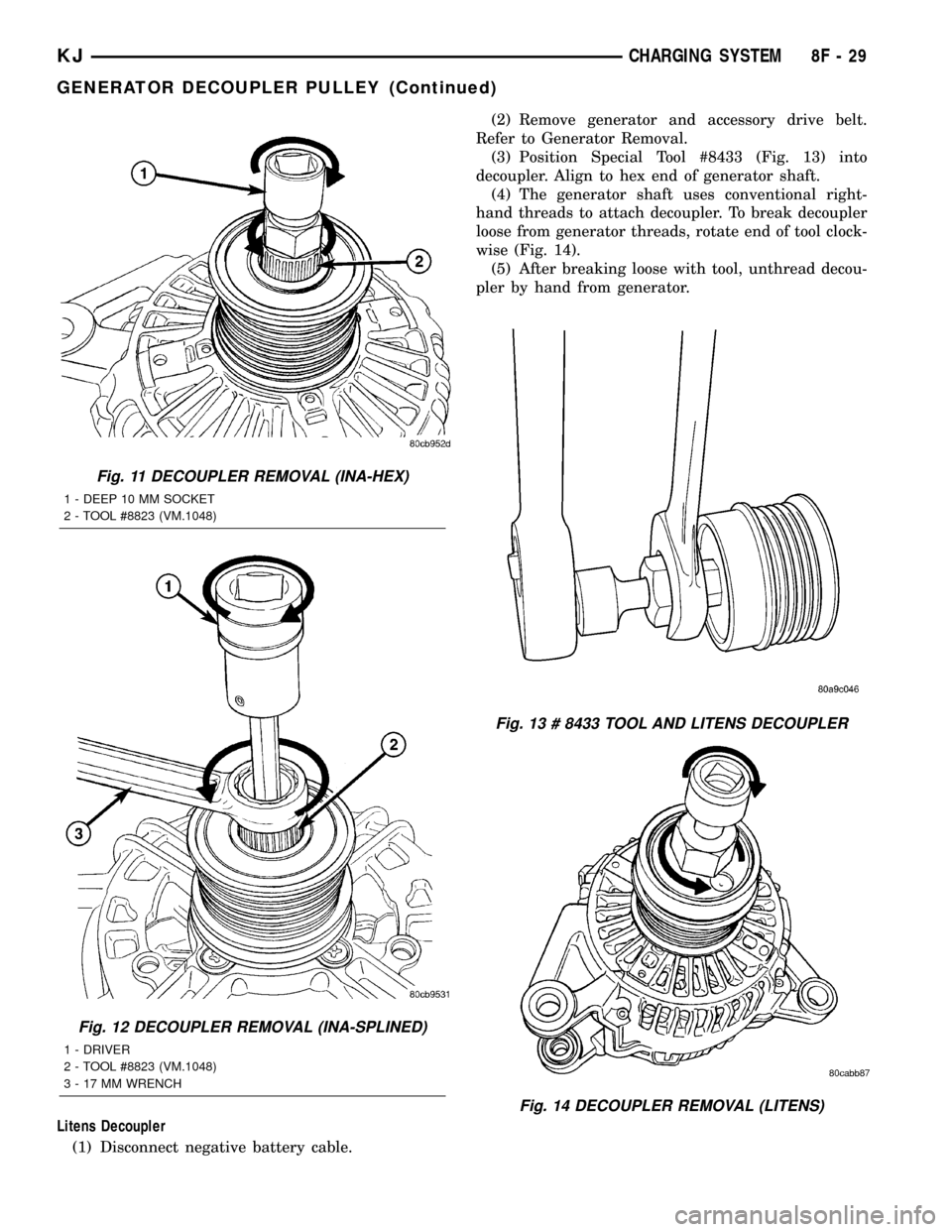

(3) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 8).

(4) Determine if end of generator shaft is hex

shaped (Fig. 9) or is splined (Fig. 10). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 11). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 12).

(5) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 11) or, (Fig. 12).(6) After breaking loose with tool, unthread decou-

pler by hand from generator.

Fig. 5 GENERATOR DECOUPLER PULLEY

(TYPICAL)

Fig. 6 GENERATOR DECOUPLER PULLEY (INA)

1 - GENERATOR

2 - DECOUPLER (INA)

3 - MACHINED SPLINES

KJCHARGING SYSTEM 8F - 27

GENERATOR DECOUPLER PULLEY (Continued)

Page 352 of 1803

Litens Decoupler

(1) Disconnect negative battery cable.(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8433 (Fig. 13) into

decoupler. Align to hex end of generator shaft.

(4) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 14).

(5) After breaking loose with tool, unthread decou-

pler by hand from generator.

Fig. 11 DECOUPLER REMOVAL (INA-HEX)

1 - DEEP 10 MM SOCKET

2 - TOOL #8823 (VM.1048)

Fig. 12 DECOUPLER REMOVAL (INA-SPLINED)

1 - DRIVER

2 - TOOL #8823 (VM.1048)

3 - 17 MM WRENCH

Fig. 13 # 8433 TOOL AND LITENS DECOUPLER

Fig. 14 DECOUPLER REMOVAL (LITENS)

KJCHARGING SYSTEM 8F - 29

GENERATOR DECOUPLER PULLEY (Continued)

Page 355 of 1803

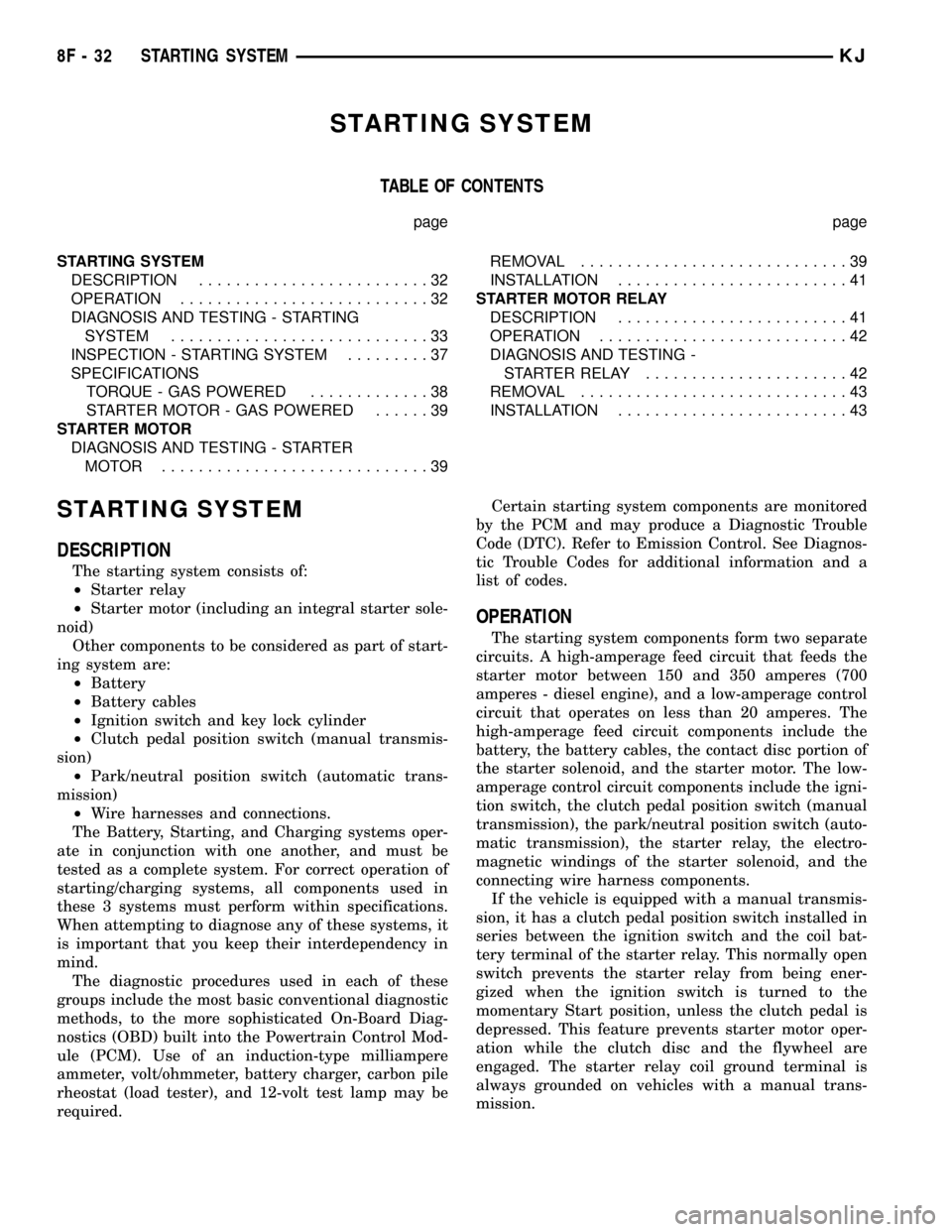

STARTING SYSTEM

TABLE OF CONTENTS

page page

STARTING SYSTEM

DESCRIPTION.........................32

OPERATION...........................32

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................33

INSPECTION - STARTING SYSTEM.........37

SPECIFICATIONS

TORQUE - GAS POWERED.............38

STARTER MOTOR - GAS POWERED......39

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER

MOTOR .............................39REMOVAL.............................39

INSTALLATION.........................41

STARTER MOTOR RELAY

DESCRIPTION.........................41

OPERATION...........................42

DIAGNOSIS AND TESTING -

STARTER RELAY......................42

REMOVAL.............................43

INSTALLATION.........................43

STARTING SYSTEM

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.Certain starting system components are monitored

by the PCM and may produce a Diagnostic Trouble

Code (DTC). Refer to Emission Control. See Diagnos-

tic Trouble Codes for additional information and a

list of codes.

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor between 150 and 350 amperes (700

amperes - diesel engine), and a low-amperage control

circuit that operates on less than 20 amperes. The

high-amperage feed circuit components include the

battery, the battery cables, the contact disc portion of

the starter solenoid, and the starter motor. The low-

amperage control circuit components include the igni-

tion switch, the clutch pedal position switch (manual

transmission), the park/neutral position switch (auto-

matic transmission), the starter relay, the electro-

magnetic windings of the starter solenoid, and the

connecting wire harness components.

If the vehicle is equipped with a manual transmis-

sion, it has a clutch pedal position switch installed in

series between the ignition switch and the coil bat-

tery terminal of the starter relay. This normally open

switch prevents the starter relay from being ener-

gized when the ignition switch is turned to the

momentary Start position, unless the clutch pedal is

depressed. This feature prevents starter motor oper-

ation while the clutch disc and the flywheel are

engaged. The starter relay coil ground terminal is

always grounded on vehicles with a manual trans-

mission.

8F - 32 STARTING SYSTEMKJ

Page 357 of 1803

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer toBatteryin 8, Battery.Note: If

equipped with diesel engine, a dual battery sys-

tem may be used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-

tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

8F - 34 STARTING SYSTEMKJ

STARTING SYSTEM (Continued)

Page 361 of 1803

Clutch Pedal Position Switch

²If vehicle is equipped with a manual transmis-

sion, visually inspect clutch pedal position switch for

indications of physical damage and loose or corroded

wire harness connections. Clean corroded connections

as required. Refer toClutch Hydraulic Linkagefor

clutch pedal position switch service procedures.

Park/Neutral Position Switch

²If vehicle is equipped with an automatic trans-

mission, visually inspect park/neutral position switch

for indications of physical damage and loose or cor-

roded wire harness connections. Clean corroded con-

nections as required. Refer toPark/Neutral

Position Switchfor park/neutral position switch

service procedures.

Starter Relay

²Visually inspect starter relay for indications of

physical damage and loose or corroded wire harness

connections. Clean corroded connections as required.

Refer toStarter Relayfor starter relay service pro-

cedures.

Starter Motor

²Visually inspect starter motor for indications of

physical damage and loose or corroded wire harness

connections. Clean corroded connections as required.

If problem being diagnosed involves improper starter

engagement, disengagement or noise complaints,

starter motor should be removed. With starter motor

removed, inspect starter pinion and ring gears for

damaged or missing teeth. Replace faulty compo-

nents as required. Refer toStarter Motorfor

removal/installation procedures.

Starter Solenoid

²Visually inspect starter solenoid for indications

of physical damage and loose or corroded wire har-

ness connections. Clean corroded connections as

required. Refer toStarter Motorfor starter solenoid

service procedures.

Wiring

²Visually inspect starting system wire harnesses

for indications of physical damage. Repair or replace

any faulty wiring, as required. Refer toWiring Dia-

gramsfor repair or connector and terminal service

procedures.

SPECIFICATIONS

TORQUE - GAS POWERED

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Starter Solenoid Battery

Cable Nut11 - 100

Starter Mounting Bolts -

2.4L54 40 -

Starter Mounting Bolts

-3.7L54 40 -

Starter Heat Shield

Mounting Bolts6-55

8F - 38 STARTING SYSTEMKJ

STARTING SYSTEM (Continued)

Page 362 of 1803

STARTER MOTOR - GAS POWERED

Starter Motor and Solenoid

Manufacturer Mitsubishi

Engine Application 2.4L / 3.7L

Power Rating 1.4 Kilowatt (1.9 Horsepower)

Voltage12 Volts

** Number of Permanent Magnets 6

Number of Brushes 4

Drive Type Planetary Gear Reduction

Free Running Test Voltage 11.2 Volts

Free Running Test Maximum Amperage Draw 90 Amperes

Free Running Test Minimum Speed 2400 rpm

Solenoid Closing Maximum Voltage Required 7.8 Volts

* Cranking Amperage Draw Test 160 Amperes

*Test at operating temperature. Cold engine, tight (new) engine, or heavy oil will increase starter amperage draw.

**The starter is equipped with permanent magnets. Never strike the starter case to attempt to loosen a sticking/

stuck armature as permanent magnets may crack or break.

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with starter motor

removed from vehicle. Refer to Specifications for

starter motor specifications.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Mount starter motor securely in a soft-jawed

bench vise. The vise jaws should be clamped on the

mounting flange of starter motor. Never clamp on

starter motor by field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to starter motor in series, and set

ammeter to 100 ampere scale. See instructions pro-

vided by manufacturer of volt-ampere tester being

used.

(4) Install jumper wire from solenoid terminal to

solenoid battery terminal. The starter motor should

operate. If starter motor fails to operate, replace

faulty starter motor assembly.

(5) Adjust carbon pile load of tester to obtain free

running test voltage. Refer to Specifications for

starter motor free running test voltage specifications.

(6) Note reading on ammeter and compare reading

to free running test maximum amperage draw. Refer

to Specifications for starter motor free running test

maximum amperage draw specifications.(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity

tester (Fig. 7). There should be continuity. If OK, go

to Step 4. If not OK, replace faulty starter motor

assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.

REMOVAL

2.4L 4±Cylinder

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Remove solenoid wire from solenoid terminal

(Fig. 11).

(4) Remove battery cable from stud on starter sole-

noid (Fig. 11).

(5) Remove 2 starter mounting bolts (Fig. 9) and

remove starter from vehicle.

KJSTARTING SYSTEM 8F - 39

STARTING SYSTEM (Continued)

Page 363 of 1803

3.7L V-6

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Remove 2 flange bolts securing left exhaust

downpipe to crossover pipe. Lower pipe slightly to

allow front propeller shaft removal.

(4) Remove front propeller shaft.

(5) Remove 2 starter heat shield bolts at side of

starter (Fig. 10).

(6) Remove starter heat shield nut at front of

starter (Fig. 10).

(7) Remove starter heat shield.

(8) Remove solenoid wire from solenoid terminal

(Fig. 11).

(9) Remove battery cable from stud on starter sole-

noid (Fig. 11).

(10) Remove 2 starter mounting bolts (Fig. 12).

(11) Position front of starter to face rear of vehicle.

Rotate starter until solenoid position is located below

starter.

(12) Remove starter from vehicle by passing it

between exhaust pipe and transmission bellhousing.

Fig. 7 CONTINUITY BETWEEN SOLENOID AND

FIELD COIL TERMINALS - TYPICAL

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

Fig. 8 CONTINUITY BETWEEN SOLENOID

TERMINAL AND CASE - TYPICAL

1 - SOLENOID TERMINAL

2 - OHMMETER

3 - SOLENOID

Fig. 9 STARTER - 2.4L

1-STARTER

2 - MOUNTING BOLTS (2)

Fig. 10 STARTER HEAT SHIELD - 3.7L

1 - STARTER HEAT SHIELD

2 - HEAT SHIELD BOLTS

3 - HEAT SHIELD BOLTS

4-STARTER

8F - 40 STARTING SYSTEMKJ

STARTER MOTOR (Continued)

Page 366 of 1803

REMOVAL

The starter relay is located in the Power Distribu-

tion Center (PDC) (Fig. 14). Refer to label on PDC

cover for relay location.(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

(1) Refer to Power Distribution Center (PDC) cover

for starter relay location.

(2) Install relay to PDC.

(3) Install cover to PDC.

Fig. 14 POWER DISTRIBUTION CENTER (PDC)

1 - BATTERY

2 - PDC

3 - PDC COVER

KJSTARTING SYSTEM 8F - 43

STARTER MOTOR RELAY (Continued)

Page 368 of 1803

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED MIRRORS......................... 1

WINDOW DEFOGGER....................... 3HEATED SEAT SYSTEM.................... 10

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION..........................1

OPERATION............................1DIAGNOSIS AND TESTING - HEATED

MIRRORS............................1

HEATED MIRRORS

DESCRIPTION

Vehicles equipped with the optional heated mirror

package have an electric heating grid located behind

the mirror glass of each outside rear view mirror.

The heated mirrors are controlled by the rear win-

dow defogger switch. Electrical current is directed to

the heating grid inside the mirror only when the rear

window defogger switch is in the On position.

If the outside mirror heating grids and the rear

window heating grid are all inoperative, (Refer to 8 -

ELECTRICAL/HEATED GLASS - DIAGNOSIS AND

TESTING). If the outside mirror heating grids are

inoperative, but the rear window heating grid is

operating as designed, (Refer to 8 - ELECTRICAL/

HEATED MIRRORS - DIAGNOSIS AND TESTING).

The heating grid behind each outside mirror glass

cannot be repaired and, if faulty or damaged, the

entire power mirror unit must be replaced(Refer to 8

- ELECTRICAL/POWER MIRRORS/SIDEVIEW MIR-

ROR - REMOVAL) and (Refer to 8 - ELECTRICAL/

POWER MIRRORS/SIDEVIEW MIRROR -

INSTALLATION).

OPERATION

The heated mirror is controlled by the rear window

defogger switch. The only time that the heated mir-

ror is on is when the rear window defogger is on. The

mirror should become warm to the touch.

DIAGNOSIS AND TESTING - HEATED MIRRORS

For circuit descriptions and diagrams (Refer to

Appropriate Wiring Information).

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the front door trim panel on the side

of the vehicle with the inoperative mirror heating

grid. Unplug the wire harness connector at the mir-

ror. Check for continuity between the ground circuit

cavity in the body half of the power mirror wire har-

ness connector and a good ground. If OK, go to Step

4. If not OK, repair the open circuit to ground as

required.

(4) Connect the battery negative cable. Turn the

ignition switch to the On position. Turn on the rear

window defogger system. Check for battery voltage at

the rear window defogger relay output circuit cavity

in the body half of the power mirror wire harness

connector. If OK, go to Step 5. If not OK, repair the

open circuit to the rear window defogger relay as

required.

KJHEATED SYSTEMS 8G - 1