JEEP RENEGADE 2014 1.G Owners Manual

Manufacturer: JEEP, Model Year: 2014, Model line: RENEGADE, Model: JEEP RENEGADE 2014 1.GPages: 212, PDF Size: 17.48 MB

Page 141 of 212

146)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. It must not

be used, for example, to jack other vehicle

models or objects. Never use the jack to

carry out maintenance or repairs under the

vehicle. Never position yourself under a

jacked vehicle. Should it be necessary to

work under the vehicle, contact a Jeep

Dealership. Incorrectly positioning the jack

may cause the vehicle to fall: use it only

in the positions indicated. Do not use the

jack for loads higher than the one shown

on its label.

147)The space-saver wheel cannot be

fitted with snow chains. If a front (drive) tyre

is punctured and chains are needed, use

a standard wheel from the rear axle and

install the space-saver wheel on the rear

axle. In this way, with two normal drive

wheels at the front axle, it is possible to use

snow chains.

148)Incorrect hub cap assembly, if

present, may cause it to come off when the

vehicle is moving. Never tamper with the

inflation valve. Never introduce tools of any

kind between the rim and the tyre. Check

tyre and space-saver wheel pressures

regularly, complying with the values given in

the "Technical specifications" chapter.TIREKIT

(where provided)

DESCRIPTION

The TireKit is located in the luggage

compartment inside a dedicated

container.

The container is also equipped with a

screwdriver, the tow hook and the

refuelling adaptor.

To access the TireKit, open the tailgate,

remove the reconfigurable load platform

and lift the carpet.

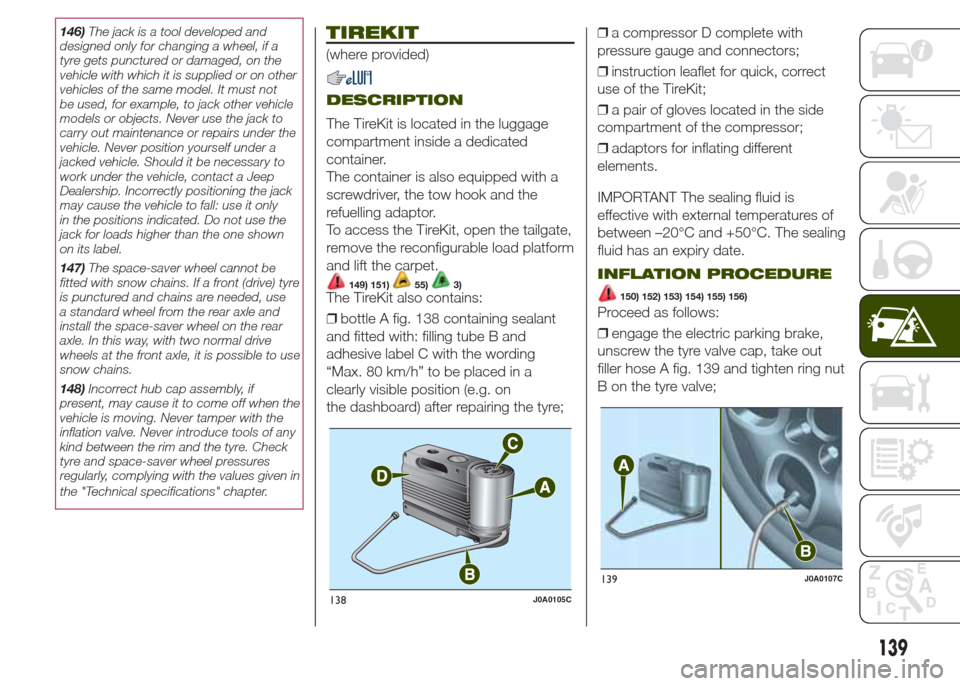

149) 151)55)3)The TireKit also contains:

❒bottle A fig. 138 containing sealant

and fitted with: filling tube B and

adhesive label C with the wording

“Max. 80 km/h” to be placed in a

clearly visible position (e.g. on

the dashboard) after repairing the tyre;❒a compressor D complete with

pressure gauge and connectors;

❒instruction leaflet for quick, correct

use of the TireKit;

❒a pair of gloves located in the side

compartment of the compressor;

❒adaptors for inflating different

elements.

IMPORTANT The sealing fluid is

effective with external temperatures of

between –20°C and +50°C. The sealing

fluid has an expiry date.

INFLATION PROCEDURE

150) 152) 153) 154) 155) 156)

Proceed as follows:

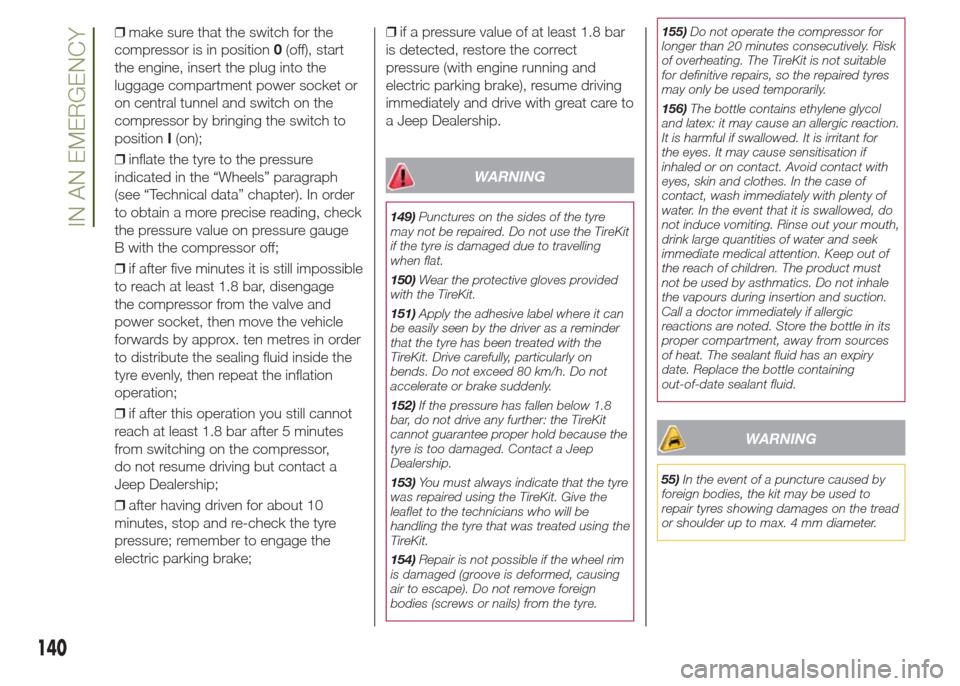

❒engage the electric parking brake,

unscrew the tyre valve cap, take out

filler hose A fig. 139 and tighten ring nut

B on the tyre valve;

138J0A0105C

139J0A0107C

139

Page 142 of 212

❒make sure that the switch for the

compressor is in position0(off), start

the engine, insert the plug into the

luggage compartment power socket or

on central tunnel and switch on the

compressor by bringing the switch to

positionI(on);

❒inflate the tyre to the pressure

indicated in the “Wheels” paragraph

(see “Technical data” chapter). In order

to obtain a more precise reading, check

the pressure value on pressure gauge

B with the compressor off;

❒if after five minutes it is still impossible

to reach at least 1.8 bar, disengage

the compressor from the valve and

power socket, then move the vehicle

forwards by approx. ten metres in order

to distribute the sealing fluid inside the

tyre evenly, then repeat the inflation

operation;

❒if after this operation you still cannot

reach at least 1.8 bar after 5 minutes

from switching on the compressor,

do not resume driving but contact a

Jeep Dealership;

❒after having driven for about 10

minutes, stop and re-check the tyre

pressure; remember to engage the

electric parking brake;❒if a pressure value of at least 1.8 bar

is detected, restore the correct

pressure (with engine running and

electric parking brake), resume driving

immediately and drive with great care to

a Jeep Dealership.

WARNING

149)Punctures on the sides of the tyre

may not be repaired. Do not use the TireKit

if the tyre is damaged due to travelling

when flat.

150)Wear the protective gloves provided

with the TireKit.

151)Apply the adhesive label where it can

be easily seen by the driver as a reminder

that the tyre has been treated with the

TireKit. Drive carefully, particularly on

bends. Do not exceed 80 km/h. Do not

accelerate or brake suddenly.

152)If the pressure has fallen below 1.8

bar, do not drive any further: the TireKit

cannot guarantee proper hold because the

tyre is too damaged. Contact a Jeep

Dealership.

153)You must always indicate that the tyre

was repaired using the TireKit. Give the

leaflet to the technicians who will be

handling the tyre that was treated using the

TireKit.

154)Repair is not possible if the wheel rim

is damaged (groove is deformed, causing

air to escape). Do not remove foreign

bodies (screws or nails) from the tyre.155)Do not operate the compressor for

longer than 20 minutes consecutively. Risk

of overheating. The TireKit is not suitable

for definitive repairs, so the repaired tyres

may only be used temporarily.

156)The bottle contains ethylene glycol

and latex: it may cause an allergic reaction.

It is harmful if swallowed. It is irritant for

the eyes. It may cause sensitisation if

inhaled or on contact. Avoid contact with

eyes, skin and clothes. In the case of

contact, wash immediately with plenty of

water. In the event that it is swallowed, do

not induce vomiting. Rinse out your mouth,

drink large quantities of water and seek

immediate medical attention. Keep out of

the reach of children. The product must

not be used by asthmatics. Do not inhale

the vapours during insertion and suction.

Call a doctor immediately if allergic

reactions are noted. Store the bottle in its

proper compartment, away from sources

of heat. The sealant fluid has an expiry

date. Replace the bottle containing

out-of-date sealant fluid.

WARNING

55)In the event of a puncture caused by

foreign bodies, the kit may be used to

repair tyres showing damages on the tread

or shoulder up to max. 4 mm diameter.

140

IN AN EMERGENCY

Page 143 of 212

WARNING

3)Dispose of the bottle and the sealant

properly. Dispose of the components

in compliance with national and local

regulations.

JUMP STARTING

If the battery is flat, a jump starting can

be performed using the battery and

the cables of another vehicle, or using a

booster battery.

IMPORTANT

When using booster battery is used,

comply with the utilisation and

precaution instructions specified by the

producer.

Do not use the booster battery or any

other source of external supply with

a voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is wet. The battery could break

and explode!

PREPARATION TO JUMP

STARTING

157) 158) 159)56)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

cover. Lift the cover to access the

positive terminal.

Proceed as follows:❒operate the parking brake, move the

automatic transmission lever to P

(Park) or, for versions with manual

gearbox, to neutral and bring the

ignition device to STOP;

❒switch off all the other electrical

appliances in the vehicle;

❒if another vehicle is ready for

emergency starting, park the vehicle

within the reach of the cables to be

used for starting, operate the parking

brake and make sure that the ignition is

deactivated.

IMPORTANT Avoid contact between

the two vehicles since this could cause

a connection to earth and may result

in serious injury to any people nearby.

PROCEDURE FOR JUMP

STARTING

IMPORTANT If the procedure below is

carried out incorrectly can cause severe

injuries to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Cable connection

Proceed as follows to carry out a jump

starting:

❒connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

141

Page 144 of 212

❒connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

❒connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

❒Connect the other end of the cable

used for negative (–) to an engine earth

(the visible metal part of the vehicle

engine with flat battery) away from the

battery and the fuel injection system;

❒start the vehicle engine with the

auxiliary battery, let it run for a

few minutes at idling. Start the engine

of the vehicle with flat battery.

Cable disconnection.

Once the engine has been started,

remove the cables proceeding as

follows:

❒disconnect the end of the cable used

for negative (–) from the engine earth

of the vehicle with flat battery;

❒disconnect the other end of the cable

used for negative (–) to the negative

terminal (–) of the auxiliary battery;

❒disconnect the end of the cable used

for positive (+) to the positive terminal

(+) of the auxiliary battery;

❒disconnect one end of the cable

used for positive (+) from the positive

terminal (+) of the vehicle with flat

battery;If it is often necessary to perform an

emergency starting, have the vehicle

battery and the recharging system

checked by a Jeep Dealership.

IMPORTANT Any accessories (e.g.

mobile phones, etc.) connected to the

vehicle current sockets, draw current

even if they are not used. These

devices, if left connected too much time

with engine off, may cause the battery

to drain with following reduction of

its life and/or failure to start the engine.

WARNING

157)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Pay attention to scarves,

ties and other loose clothing which might

be pulled by moving parts.

158)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

159)Batteries contain acid which may burn

skin and eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Thus keep away flames or

devices which may cause sparks.

WARNING

56)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

142

IN AN EMERGENCY

Page 145 of 212

FUEL CUT-OFF

SYSTEM

This intervenes in the case of an impact

causing:

❒the interruption of the fuel supply with

the engine consequently cutting out;

❒the automatic unlocking of the doors;

❒turning on of the lights inside the

vehicle;

❒deactivation of climate control system

ventilation;

❒switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or

near the tank area. After a collision,

bring the ignition device to STOP to

prevent the battery from running down.

To restore correct operation of the

vehicle, carry out the following

procedure (this procedure must be

started and completed within less than

one minute):❒move the ignition device to MAR;

❒turn on the direction indicators on the

right, then on the left, then again on

the right and again on the left;

❒now deactivate the direction

indicators on the left;

❒bring the ignition device to STOP;

❒move the ignition device to MAR.

160)

WARNING

160)If, after an impact, you smell fuel or

notice leaks from the fuel system, do

not reactivate the system to avoid the risk

of fire.

AUTOMATIC

TRANSMISSION

GEAR LEVER

UNLOCKING

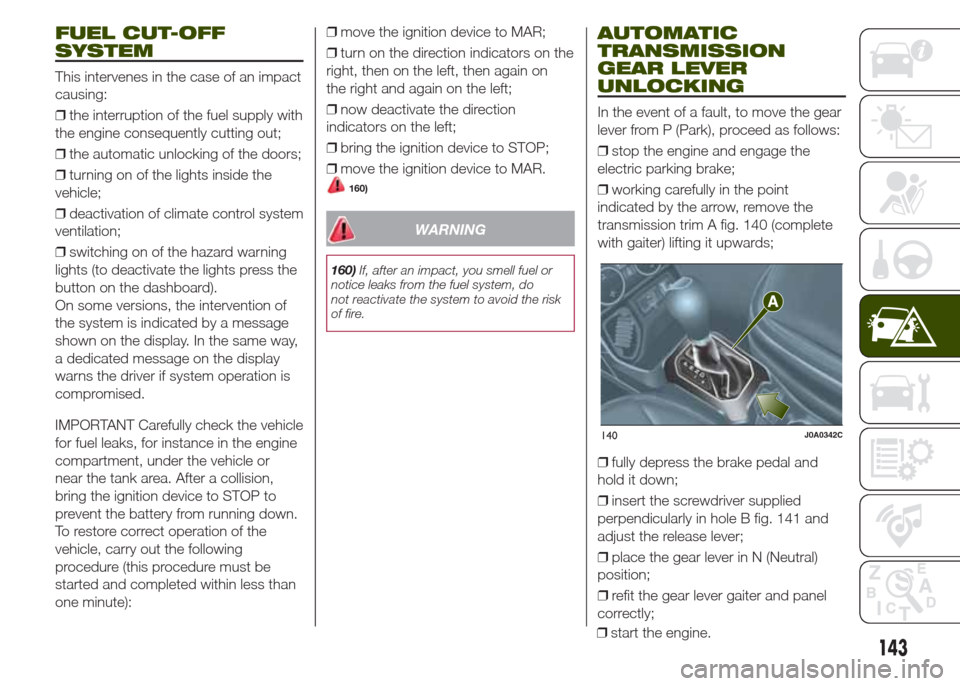

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

❒stop the engine and engage the

electric parking brake;

❒working carefully in the point

indicated by the arrow, remove the

transmission trim A fig. 140 (complete

with gaiter) lifting it upwards;

❒fully depress the brake pedal and

hold it down;

❒insert the screwdriver supplied

perpendicularly in hole B fig. 141 and

adjust the release lever;

❒place the gear lever in N (Neutral)

position;

❒refit the gear lever gaiter and panel

correctly;

140J0A0342C

143

❒start the engine.

Page 146 of 212

EMERGENCY REMOVAL

OF THE IGNITION KEY

57)

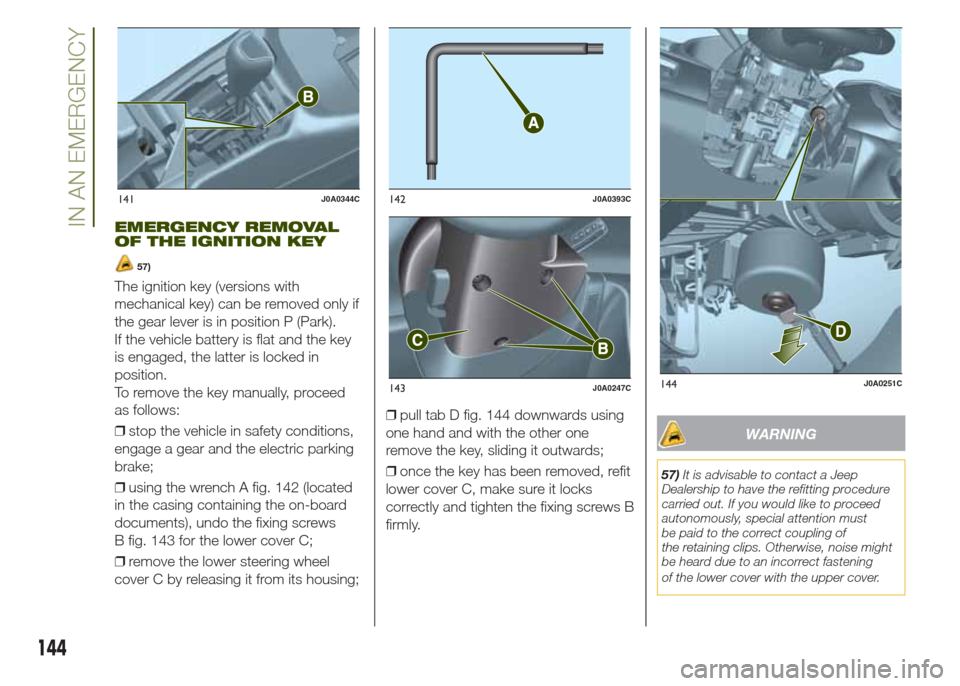

The ignition key (versions with

mechanical key) can be removed only if

the gear lever is in position P (Park).

If the vehicle battery is flat and the key

is engaged, the latter is locked in

position.

To remove the key manually, proceed

as follows:

❒stop the vehicle in safety conditions,

engage a gear and the electric parking

brake;

❒using the wrench A fig. 142 (located

in the casing containing the on-board

documents), undo the fixing screws

B fig. 143 for the lower cover C;

❒remove the lower steering wheel

cover C by releasing it from its housing;❒pull tab D fig. 144 downwards using

one hand and with the other one

remove the key, sliding it outwards;

❒once the key has been removed, refit

lower cover C, make sure it locks

correctly and tighten the fixing screws B

firmly.

WARNING

57)It is advisable to contact a Jeep

Dealership to have the refitting procedure

carried out. If you would like to proceed

autonomously, special attention must

be paid to the correct coupling of

the retaining clips. Otherwise, noise might

be heard due to an incorrect fastening

of the lower cover with the upper cover.

141J0A0344C142J0A0393C

143J0A0247C144J0A0251C

144

IN AN EMERGENCY

Page 147 of 212

TOWING THE

VEHICLE

ATTACHING THE TOW

HOOK

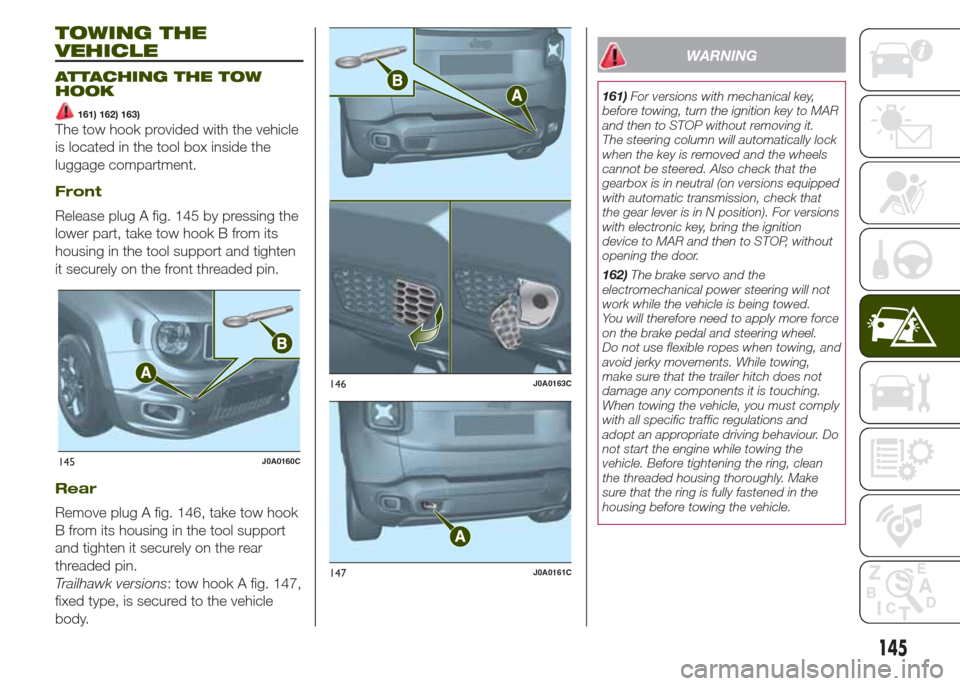

161) 162) 163)

The tow hook provided with the vehicle

is located in the tool box inside the

luggage compartment.

Front

Release plug A fig. 145 by pressing the

lower part, take tow hook B from its

housing in the tool support and tighten

it securely on the front threaded pin.

Rear

Remove plug A fig. 146, take tow hook

B from its housing in the tool support

and tighten it securely on the rear

threaded pin.

Trailhawk versions: tow hook A fig. 147,

fixed type, is secured to the vehicle

body.

WARNING

161)For versions with mechanical key,

before towing, turn the ignition key to MAR

and then to STOP without removing it.

The steering column will automatically lock

when the key is removed and the wheels

cannot be steered. Also check that the

gearbox is in neutral (on versions equipped

with automatic transmission, check that

the gear lever is in N position). For versions

with electronic key, bring the ignition

device to MAR and then to STOP, without

opening the door.

162)The brake servo and the

electromechanical power steering will not

work while the vehicle is being towed.

You will therefore need to apply more force

on the brake pedal and steering wheel.

Do not use flexible ropes when towing, and

avoid jerky movements. While towing,

make sure that the trailer hitch does not

damage any components it is touching.

When towing the vehicle, you must comply

with all specific traffic regulations and

adopt an appropriate driving behaviour. Do

not start the engine while towing the

vehicle. Before tightening the ring, clean

the threaded housing thoroughly. Make

sure that the ring is fully fastened in the

housing before towing the vehicle.

145J0A0160C

146J0A0163C

147J0A0161C

145

Page 148 of 212

163)The front and rear tow hooks should

be used only for emergencies on the road.

You are allowed to tow the vehicle for

short distances using an appropriate

device in accordance with the highway

code (a rigid bar), to move the vehicle on

the road in readiness for towing or

transport via a breakdown vehicle. Tow

hooks MUST NOT be used to tow vehicles

off the road or where there are obstacles

and/or for towing operations using ropes or

other non-rigid devices. Respecting the

above conditions, towing must take place

with two vehicles (one towing, the other

towed) aligned as much as possible along

the same centre line.BROKEN-DOWN

VEHICLE TOWING

It is recommended to tow the vehicle

with all four wheels lifted from the

ground on the platform of a rescue

vehicle.

VERSIONS WITH FOUR-WHEEL

DRIVE (4WD) AND AUTOMATIC

TRANSMISSION

IMPORTANT Avoid lifting the front (or

rear) wheels only. Lifting the front (or

rear) wheels only while towing might

damage the transmission or the transfer

unit.

IMPORTANT If a vehicle is towed

without complying with the above

requirements, the transmission and/or

the transfer unit might be seriously

damaged. Damage due to an incorrect

towing will not be covered by the

warranty.

146

IN AN EMERGENCY

Page 149 of 212

SERVICING AND MAINTENANCE

Correct maintenance permits the

performance of the vehicle to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SCHEDULED SERVICING ...............148

ENGINE COMPARTMENT ...............155

BATTERY RECHARGING ................160

SERVICING PROCEDURES ............161

LIFTING THE VEHICLE....................163

WHEELS AND TYRES.....................163

BODYWORK ...................................164

147

Page 150 of 212

SCHEDULED

SERVICING

Correct servicing is crucial for

guaranteeing a long life for the vehicle

under the best conditions. For this

reason, Jeep has planned a series of

checks and services at fixed distance

intervals and, where provided, at fixed

time intervals, as described in the

Scheduled Servicing Plan.

Before each service, it is always

necessary to carefully follow the

instructions in the Scheduled Servicing

Plan (e.g. periodically check level of

fluids, tyre pressure, etc.).

Scheduled Servicing is offered by all

Jeep Dealerships according to a set

time schedule. If, during each

operation, in addition to the ones

scheduled, the need arises for further

replacements or repairs, these may

be carried out with your explicit

agreement only. If your vehicle is used

frequently for towing, the interval

between one service operation and the

next should be reduced.IMPORTANT Scheduled Servicing

Coupons are required by the

Manufacturer. Failure to have them

carried out may invalidate the warranty.

It is advisable to inform a Jeep

Dealership of any small operating

irregularities without waiting for the next

service.

PERIODIC CHECKS

Every1,000km or before long

journeys, check and if necessary, top

up: engine coolant level; brake fluid

level; screen washer fluid level; tyre

inflation pressure and condition; lighting

system operation (headlights, direction

indicators, hazard warning lights, etc.);

screen washer/wiper system operation

and positioning/wear of windscreen/

rear window wiper blades.

Every3,000km, check and top up if

required: engine oil level.

HEAVY-DUTY USE OF THE

VEHICLE

If the vehicle is used under one of the

following conditions: towing a trailer

or caravan; dusty roads; short (less

than 7-8 km), repeated journeys with

sub-zero outside temperatures; engine

often idling or driving long distances

at low speed or long periods of

inactivity, the following checks must be

carried out more often than indicated

in the Scheduled Servicing Plan:❒check front disc brake pad condition

and wear;

❒check cleanliness of bonnet and

luggage compartment locks,

cleanliness and lubrication of linkage;

❒visually inspect condition of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (boots/sleeves/

bushes, etc.);

❒check battery charge and battery

fluid level (electrolyte);

❒visually inspect condition of the

accessory drive belts;

❒check and, if necessary, change

engine oil and replace oil filter;

❒check and, if necessary, replace

pollen filter;

❒check and, if necessary, replace air

cleaner.

On versions with automatic

transmission, change transmission oil

and replace oil filter every 60,000 km

(40,000) or every 4 years.

148

SERVICING AND MAINTENANCE