JEEP RENEGADE 2014 1.G Owners Manual

Manufacturer: JEEP, Model Year: 2014, Model line: RENEGADE, Model: JEEP RENEGADE 2014 1.GPages: 212, PDF Size: 17.48 MB

Page 161 of 212

WARNING

164)Never smoke when performing

operations in the engine compartment.

Flammable gases and fumes may be

present and risk igniting.

165)Be very careful when working in the

engine compartment when the engine

is hot: you may get burned.

166)If the engine oil is being topped up,

wait for the engine to cool down before

loosening the filler plug, particularly for

vehicles with aluminium plug (where

provided). CAUTION: risk of burns!

167)The cooling system is pressurised. If

necessary, only replace the cap with

another original one or the operation of the

system may be adversely affected. Do

not remove the reservoir cap when the

engine is hot: risk of burns.

168)Do not travel with the windscreen

washer reservoir empty: the windscreen

washer is essential for improving visibility.

Repeated operation of the system without

fluid could damage or cause rapid

deterioration of some system components.

169)Certain commercial additives for

windscreen washer fluids are inflammable.

The engine compartment contains hot

components which may set it on fire.

170)Brake fluid is poisonous and highly

corrosive. In the event of accidental

contact, immediately wash the affected

parts with water and mild soap. Then rinse

thoroughly. Call a doctor immediately if

swallowed.171)The

symbol on the container

indicates a synthetic brake fluid, which is

different from a mineral fluid. Using a

mineral fluid will damage the special rubber

seals of the braking system beyond repair.

172)Battery fluid is poisonous and

corrosive. Avoid contact with the skin and

eyes. Keep open flames away from the

battery and do not use objects that might

create sparks: risk of explosion and fire.

173)Using the battery with insufficient

fluid irreparably damages the battery and

may cause an explosion.

174)If the vehicle must remain unused for

a long time at a very low temperature,

remove the battery and take it to a warm

place, to avoid freezing.

175)When performing any operation on

the battery or near it, always protect your

eyes with special goggles.

WARNING

58)Be careful not to confuse the various

types of fluids while topping up: they

are not compatible with each other!

Topping up with an unsuitable fluid could

severely damage your vehicle.

59)The oil level should never exceed the

MAX mark.

60)Do not add oil with specifications other

than those of the oil already in the engine.61)PARAFLU

UPanti-freeze fluid is used in

the engine cooling system; use the same

fluid type as that already in the cooling

system when topping up. PARAFLU

UP

may not be mixed with other types of

anti-freeze fluids. In the event of topping up

with an unsuitable product, under no

circumstances start the engine and contact

a Jeep Dealership.

62)Avoid allowing brake fluid, which is

extremely corrosive, to come into contact

with painted areas. Should it happen, wash

immediately with water.

63)Incorrect assembly of electrical and

electronic accessories may cause severe

damage to your vehicle. Go to a Jeep

Dealership if you want to install accessories

(e.g. anti-theft, radio phone, etc.): they will

suggest the most suitable devices and

advise you whether a higher capacity

battery needs to be installed.

WARNING

4)Used engine oil and oil filters contain

substances which are harmful to the

environment. You are advised to contact a

Jeep Dealership to have the oil and filters

changed.

5)Used transmission fluid contains

substances that are harmful to the

environment. It is advisable to contact a

Jeep Dealership for oil changes.

6)Batteries contain substances which are

very dangerous for the environment. For

battery replacement, contact a Jeep

Dealership.

159

Page 162 of 212

BATTERY

RECHARGING

IMPORTANT

IMPORTANT After placing the ignition

device to STOP and having closed

the driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

device is in the STOP position and

the driver side door is closed.

IMPORTANT Charging should be slow

at a low ampere rating for

approximately 24 hours. Charging for a

longer time may damage the battery.IMPORTANT The cables of the

electrical system must be correctly

reconnected to the battery, i.e. the

positive cable (+) to the positive

terminal and the negative cable (–) to

the negative terminal. The battery

terminals are marked with the positive

(+) and negative (–) symbols, and are

shown on the battery cover. The battery

terminals must also be corrosion-free

and firmly secured to the terminals. If a

"quick-type" battery charger is used

with the battery fitted on the vehicle,

before connecting it disconnect both

cables of the battery itself. Do not use a

"quick-type" battery charger to provide

the starting voltage.

VERSIONS WITHOUT

STOP/START SYSTEM

To recharge, proceed as follows:

❒disconnect the terminal from the

negative battery pole;

❒connect the charger cables to the

battery terminals, observing the polarity;

❒turn on the charger;

❒when it is recharged, turn the charger

off before disconnecting it from the

battery;

❒reconnect the negative battery

terminal.

VERSIONS WITH

STOP/START SYSTEM

To recharge, proceed as follows:

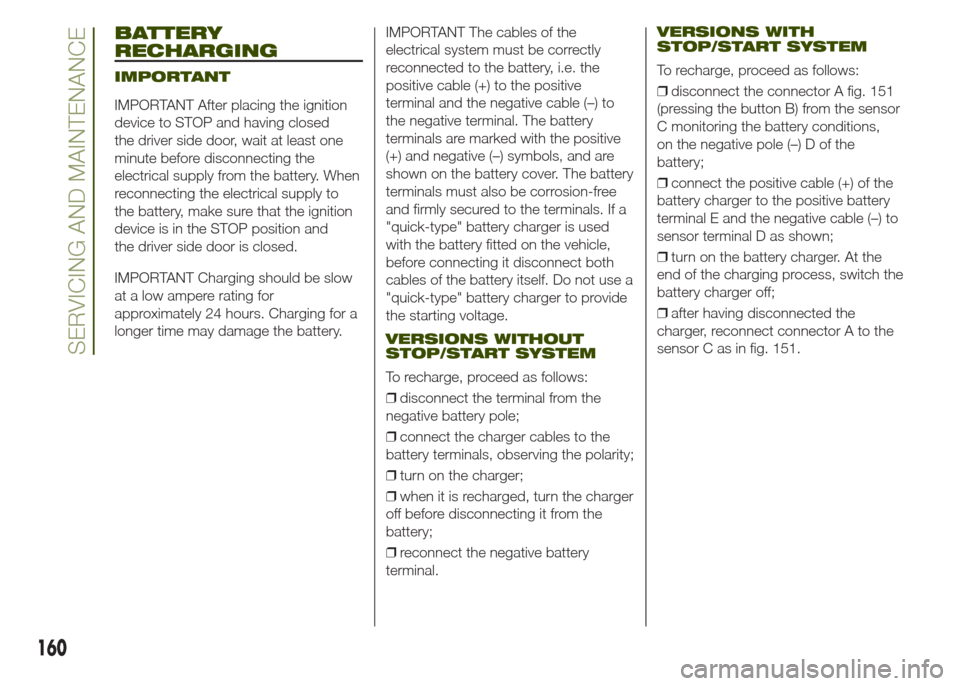

❒disconnect the connector A fig. 151

(pressing the button B) from the sensor

C monitoring the battery conditions,

on the negative pole (–) D of the

battery;

❒connect the positive cable (+) of the

battery charger to the positive battery

terminal E and the negative cable (–) to

sensor terminal D as shown;

❒turn on the battery charger. At the

end of the charging process, switch the

battery charger off;

❒after having disconnected the

charger, reconnect connector A to the

sensor C as in fig. 151.

160

SERVICING AND MAINTENANCE

Page 163 of 212

SERVICING

PROCEDURES

176) 177) 178)

64) 65) 66) 67) 68) 69) 70) 71)

WINDSCREEN/REAR

WINDOW WIPER

Replacing the windscreen

wiper blades

Proceed as follows:

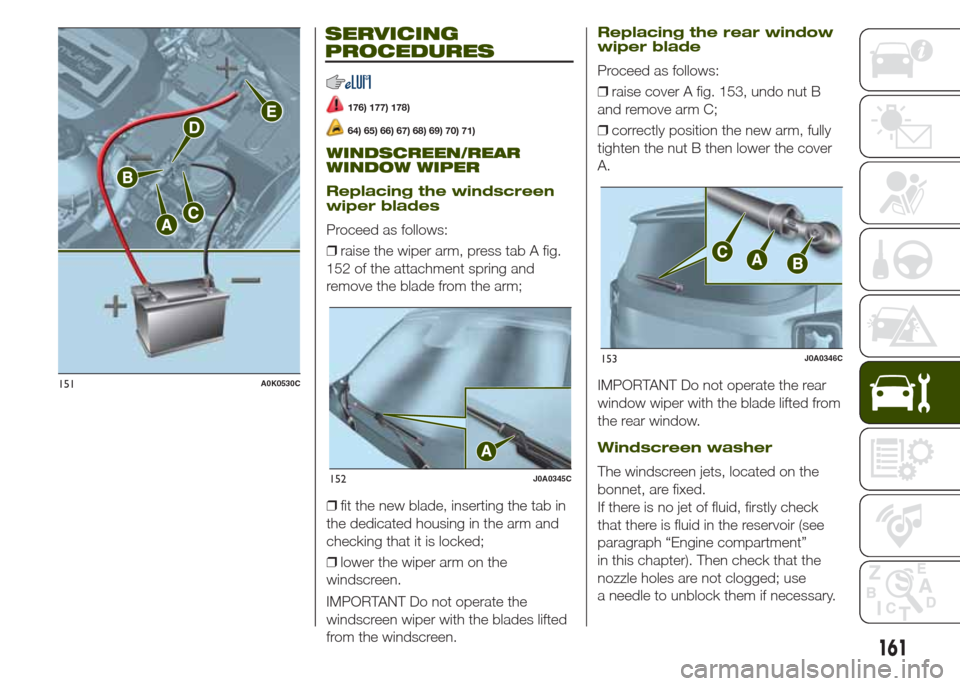

❒raise the wiper arm, press tab A fig.

152 of the attachment spring and

remove the blade from the arm;

❒fit the new blade, inserting the tab in

the dedicated housing in the arm and

checking that it is locked;

❒lower the wiper arm on the

windscreen.

IMPORTANT Do not operate the

windscreen wiper with the blades lifted

from the windscreen.

Replacing the rear window

wiper blade

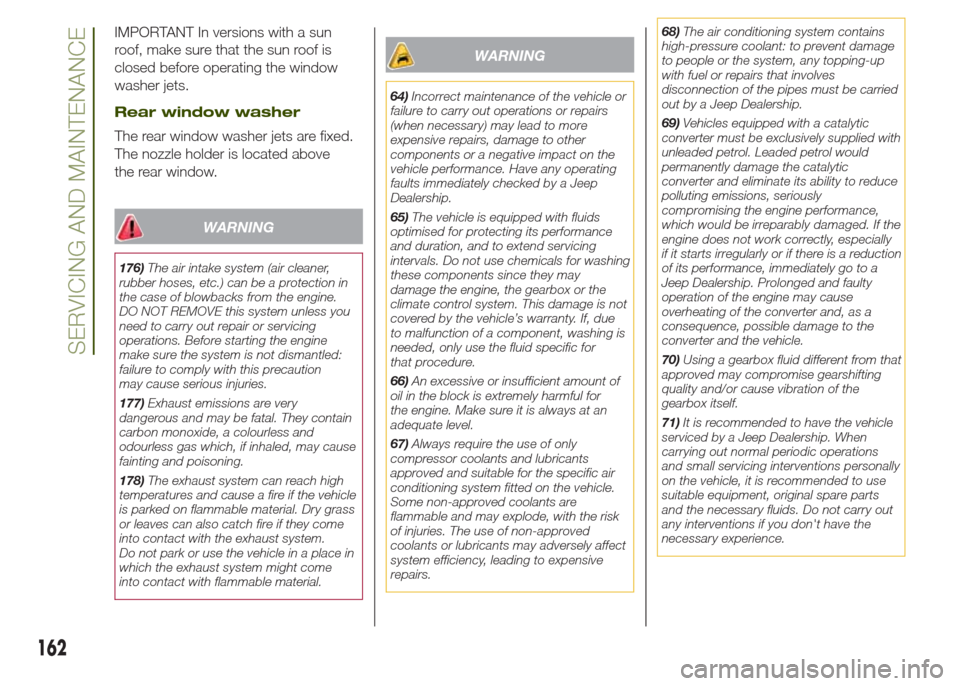

Proceed as follows:

❒raise cover A fig. 153, undo nut B

and remove arm C;

❒correctly position the new arm, fully

tighten the nut B then lower the cover

A.

IMPORTANT Do not operate the rear

window wiper with the blade lifted from

the rear window.

Windscreen washer

The windscreen jets, located on the

bonnet, are fixed.

If there is no jet of fluid, firstly check

that there is fluid in the reservoir (see

paragraph “Engine compartment”

in this chapter). Then check that the

nozzle holes are not clogged; use

a needle to unblock them if necessary.

151A0K0530C

152J0A0345C

153J0A0346C

161

Page 164 of 212

IMPORTANT In versions with a sun

roof, make sure that the sun roof is

closed before operating the window

washer jets.

Rear window washer

The rear window washer jets are fixed.

The nozzle holder is located above

the rear window.

WARNING

176)The air intake system (air cleaner,

rubber hoses, etc.) can be a protection in

the case of blowbacks from the engine.

DO NOT REMOVE this system unless you

need to carry out repair or servicing

operations. Before starting the engine

make sure the system is not dismantled:

failure to comply with this precaution

may cause serious injuries.

177)Exhaust emissions are very

dangerous and may be fatal. They contain

carbon monoxide, a colourless and

odourless gas which, if inhaled, may cause

fainting and poisoning.

178)The exhaust system can reach high

temperatures and cause a fire if the vehicle

is parked on flammable material. Dry grass

or leaves can also catch fire if they come

into contact with the exhaust system.

Do not park or use the vehicle in a place in

which the exhaust system might come

into contact with flammable material.

WARNING

64)Incorrect maintenance of the vehicle or

failure to carry out operations or repairs

(when necessary) may lead to more

expensive repairs, damage to other

components or a negative impact on the

vehicle performance. Have any operating

faults immediately checked by a Jeep

Dealership.

65)The vehicle is equipped with fluids

optimised for protecting its performance

and duration, and to extend servicing

intervals. Do not use chemicals for washing

these components since they may

damage the engine, the gearbox or the

climate control system. This damage is not

covered by the vehicle’s warranty. If, due

to malfunction of a component, washing is

needed, only use the fluid specific for

that procedure.

66)An excessive or insufficient amount of

oil in the block is extremely harmful for

the engine. Make sure it is always at an

adequate level.

67)Always require the use of only

compressor coolants and lubricants

approved and suitable for the specific air

conditioning system fitted on the vehicle.

Some non-approved coolants are

flammable and may explode, with the risk

of injuries. The use of non-approved

coolants or lubricants may adversely affect

system efficiency, leading to expensive

repairs.68)The air conditioning system contains

high-pressure coolant: to prevent damage

to people or the system, any topping-up

with fuel or repairs that involves

disconnection of the pipes must be carried

out by a Jeep Dealership.

69)Vehicles equipped with a catalytic

converter must be exclusively supplied with

unleaded petrol. Leaded petrol would

permanently damage the catalytic

converter and eliminate its ability to reduce

polluting emissions, seriously

compromising the engine performance,

which would be irreparably damaged. If the

engine does not work correctly, especially

if it starts irregularly or if there is a reduction

of its performance, immediately go to a

Jeep Dealership. Prolonged and faulty

operation of the engine may cause

overheating of the converter and, as a

consequence, possible damage to the

converter and the vehicle.

70)Using a gearbox fluid different from that

approved may compromise gearshifting

quality and/or cause vibration of the

gearbox itself.

71)It is recommended to have the vehicle

serviced by a Jeep Dealership. When

carrying out normal periodic operations

and small servicing interventions personally

on the vehicle, it is recommended to use

suitable equipment, original spare parts

and the necessary fluids. Do not carry out

any interventions if you don't have the

necessary experience.

162

SERVICING AND MAINTENANCE

Page 165 of 212

LIFTING THE

VEHICLE

If the vehicle is to be lifted, go to a Jeep

Dealership which is equipped with the

arm lift or workshop lift.

WHEELS AND TYRES

SUGGESTIONS ABOUT

THE ROTATION OF THE

TYRES

179)72) 73) 74) 75)The front and rear tyres are subject to

different loads and stress due to

steering, manoeuvres and braking. For

this reason they are subject to uneven

wear.

To resolve this problem, tyres should be

rotated at the appropriate time. This

operation is recommended for tyres

with a deep tread pattern, suitable both

for on-road and off-road driving.

Tyre rotation contributes to the

preservation of the grip and traction

performance on wet, muddy or snowy

roads, guaranteeing optimal driveability

of the vehicle.

In the case of irregular wear of the

tyres, the reason must be identified and

corrected before rotating them.

WARNING

179)Do not cross switch the tyres if they

are "unidirectional" type. In this case,

always take care not to fit the tyres with a

direction of rotation that is opposite to that

indicated: you would risk losing grip and

control of the vehicle.

WARNING

72)Road holding depends also on the

correct tyre inflating pressure.

73)If the pressure is too low the tyre

overheats and this can cause it serious

damage.

74)Do not cross switch the tyres, moving

them from the right of the vehicle to the left

and vice versa.

75)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

163

Page 166 of 212

BODYWORK

PRESERVING THE

BODYWORK

Paintwork

76)7)

Touch up abrasions and scratches

immediately to prevent the formation of

rust.

Some parts of the vehicle are painted

with a matte paintwork which requires

special care for its preservation

77)To correctly wash the vehicle, follow

these instructions:

❒is the vehicle is washed remove the

aerial from the roof;

❒if high pressure jets or cleaners are

used to wash the vehicle, keep a

distance of at least 40 cm from the

bodywork to avoid damage or

alteration. Build up of water could

cause damage to the vehicle in the long

term.

WARNING

76)In order to preserve the aesthetic

appearance of the paint abrasive products

and/or polishes should not be used for

cleaning the vehicle.

77)Avoid washing with rollers and/or

brushes in washing stations. Wash the

vehicle only by hand using neutral pH

detergents; dry it with a wet chamois

leather. Abrasive products and/or polishes

should not be used for cleaning the vehicle.

Bird droppings must be washed off

immediately and thoroughly as the acid

they contain is particularly aggressive.

Avoid (if at all possible) parking the vehicle

under trees; remove vegetable resins

immediately as, when dried, it may only be

possible to remove them with abrasive

products and/or polishes, which is highly

inadvisable as they could alter the typical

opaqueness of the paint. Do not use pure

screen washer fluid for cleaning the

windscreen and rear window; dilute it min.

50% with water. Only use pure screen

washer fluid when strictly necessary due to

outside temperature conditions.

WARNING

7)Detergents cause water pollution. Only

wash your vehicle in areas equipped to

collect and treat wastewater from this type

of activity.

164

SERVICING AND MAINTENANCE

Page 167 of 212

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................166

ENGINE ..........................................167

WHEELS .........................................169

DIMENSIONS ..................................171

WEIGHTS........................................174

SUPPLIES .......................................175

FLUIDS AND LUBRICANTS ............176

PERFORMANCE .............................178

FUEL CONSUMPTION ....................178

CO2 EMISSIONS ............................179

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................179

165

Page 168 of 212

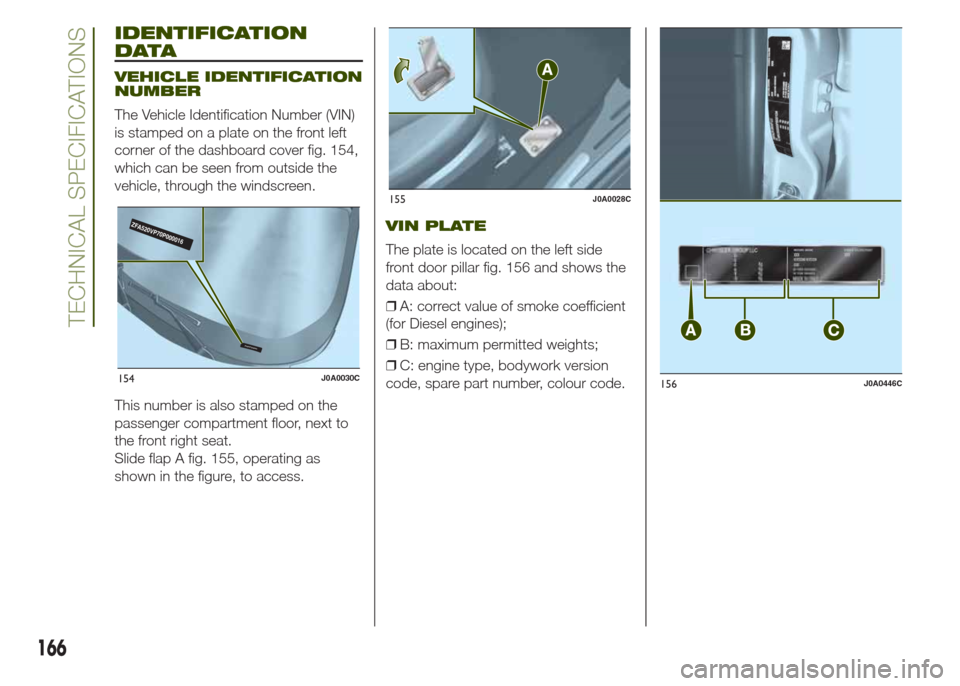

IDENTIFICATION

DATA

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN)

is stamped on a plate on the front left

corner of the dashboard cover fig. 154,

which can be seen from outside the

vehicle, through the windscreen.

This number is also stamped on the

passenger compartment floor, next to

the front right seat.

Slide flap A fig. 155, operating as

shown in the figure, to access.

VIN PLATE

The plate is located on the left side

front door pillar fig. 156 and shows the

data about:

❒A: correct value of smoke coefficient

(for Diesel engines);

❒B: maximum permitted weights;

❒C: engine type, bodywork version

code, spare part number, colour code.

Z

FA520VP70P000016

ZFA520VP70P000016

154J0A0030C

155J0A0028C

156J0A0446C

166

TECHNICAL SPECIFICATIONS

Page 169 of 212

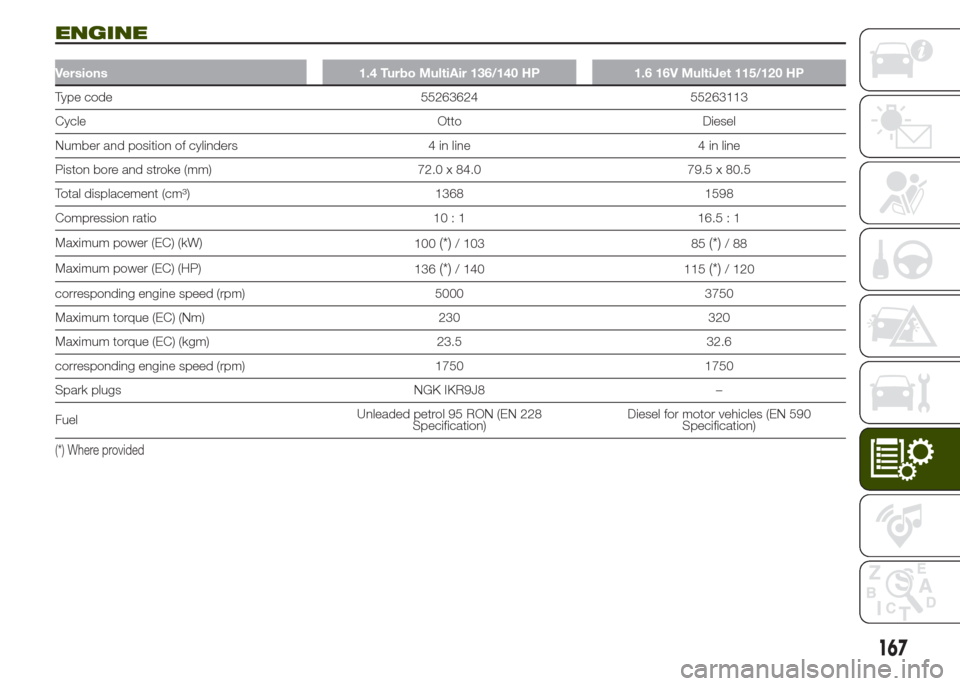

ENGINE

Versions 1.4 Turbo MultiAir 136/140 HP 1.6 16V MultiJet 115/120 HP

Type code 55263624 55263113

Cycle Otto Diesel

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 72.0 x 84.0 79.5 x 80.5

Total displacement (cm³) 1368 1598

Compression ratio 10 : 1 16.5 : 1

Maximum power (EC) (kW)

100

(*)/ 103 85(*)/88

Maximum power (EC) (HP)

136

(*)/ 140 115(*)/ 120

corresponding engine speed (rpm) 5000 3750

Maximum torque (EC) (Nm) 230 320

Maximum torque (EC) (kgm) 23.5 32.6

corresponding engine speed (rpm) 1750 1750

Spark plugs NGK IKR9J8 –

FuelUnleaded petrol 95 RON (EN 228

Specification)Diesel for motor vehicles (EN 590

Specification)

(*) Where provided

167

Page 170 of 212

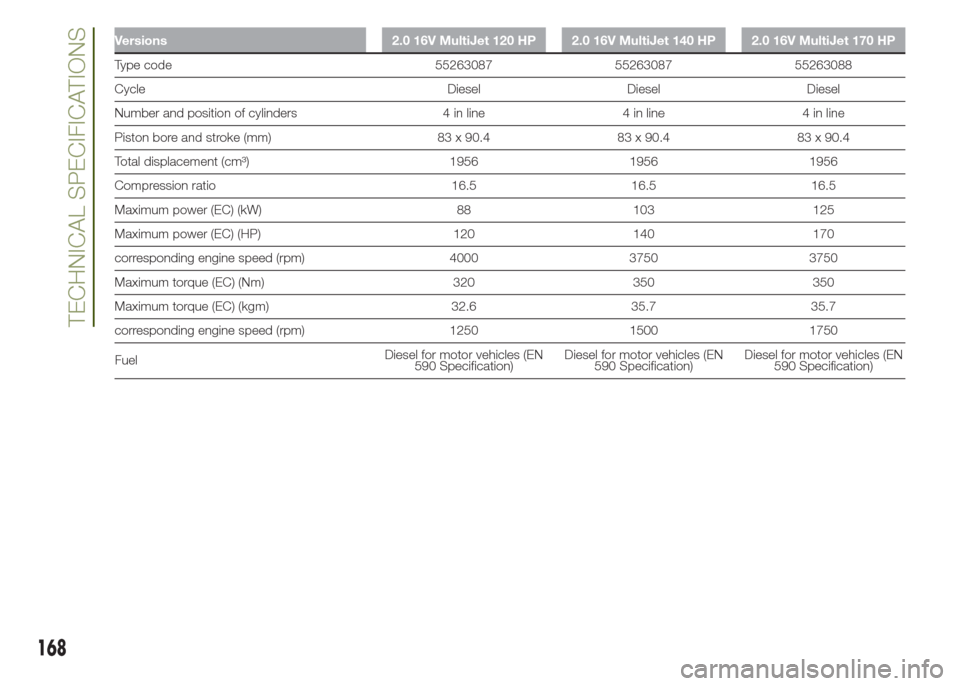

Versions 2.0 16V MultiJet 120 HP 2.0 16V MultiJet 140 HP 2.0 16V MultiJet 170 HP

Type code 55263087 55263087 55263088

Cycle Diesel Diesel Diesel

Number and position of cylinders 4 in line 4 in line 4 in line

Piston bore and stroke (mm) 83 x 90.4 83 x 90.4 83 x 90.4

Total displacement (cm³) 1956 1956 1956

Compression ratio 16.5 16.5 16.5

Maximum power (EC) (kW) 88 103 125

Maximum power (EC) (HP) 120 140 170

corresponding engine speed (rpm) 4000 3750 3750

Maximum torque (EC) (Nm) 320 350 350

Maximum torque (EC) (kgm) 32.6 35.7 35.7

corresponding engine speed (rpm) 1250 1500 1750

FuelDiesel for motor vehicles (EN

590 Specification)Diesel for motor vehicles (EN

590 Specification)Diesel for motor vehicles (EN

590 Specification)

168

TECHNICAL SPECIFICATIONS