JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1801 of 2158

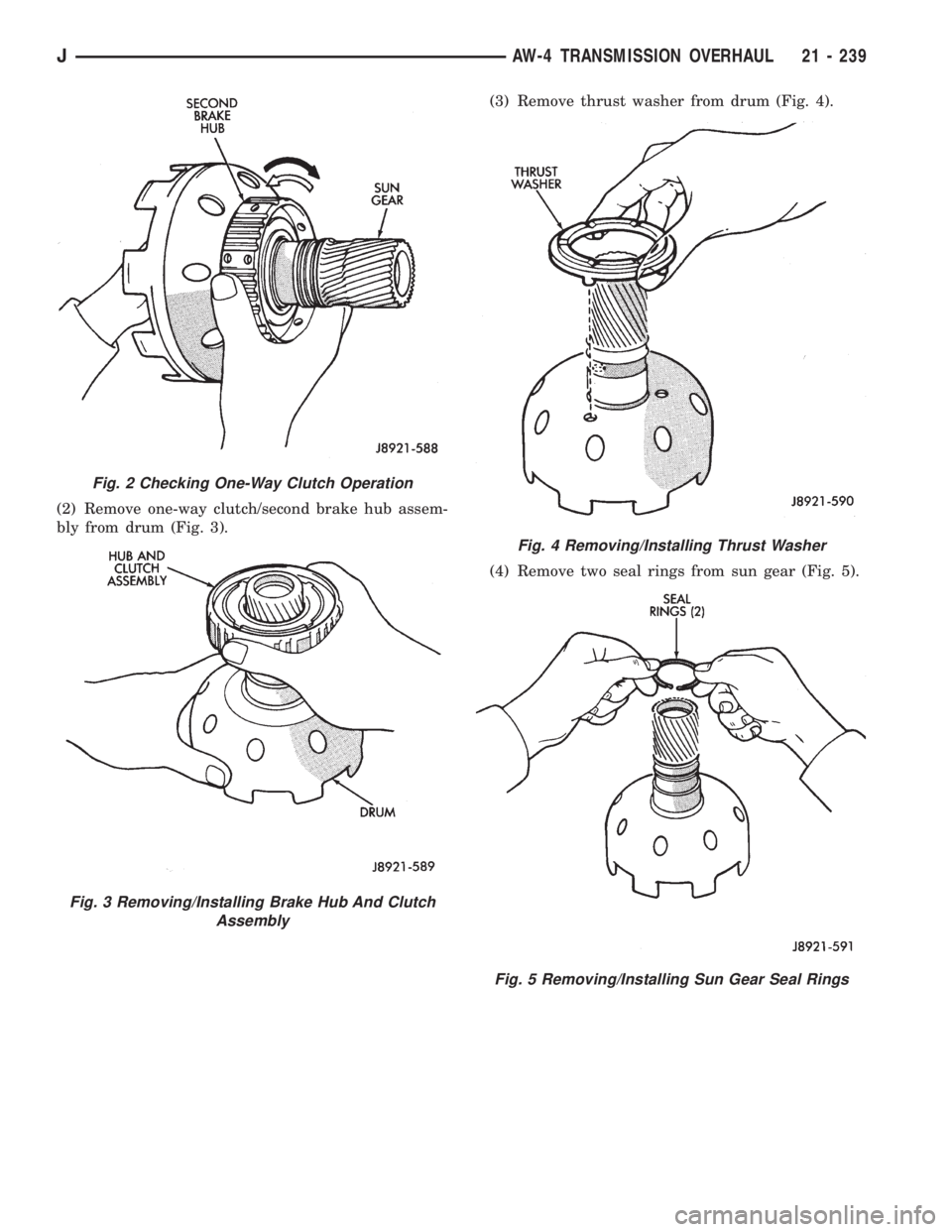

(2) Remove one-way clutch/second brake hub assem-

bly from drum (Fig. 3).(3) Remove thrust washer from drum (Fig. 4).

(4) Remove two seal rings from sun gear (Fig. 5).

Fig. 2 Checking One-Way Clutch Operation

Fig. 3 Removing/Installing Brake Hub And Clutch

Assembly

Fig. 4 Removing/Installing Thrust Washer

Fig. 5 Removing/Installing Sun Gear Seal Rings

JAW-4 TRANSMISSION OVERHAUL 21 - 239

Page 1802 of 2158

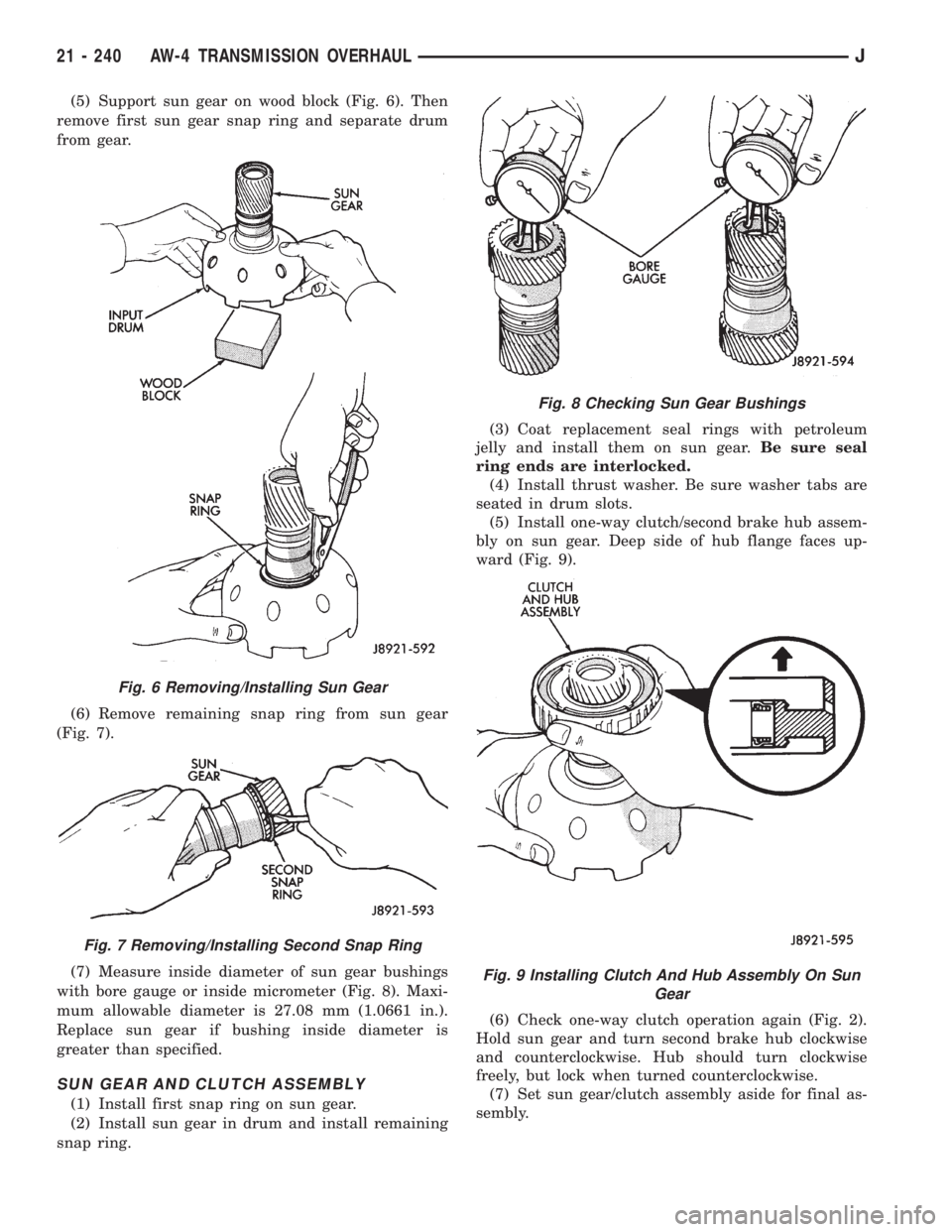

(5) Support sun gear on wood block (Fig. 6). Then

remove first sun gear snap ring and separate drum

from gear.

(6) Remove remaining snap ring from sun gear

(Fig. 7).

(7) Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 8). Maxi-

mum allowable diameter is 27.08 mm (1.0661 in.).

Replace sun gear if bushing inside diameter is

greater than specified.

SUN GEAR AND CLUTCH ASSEMBLY

(1) Install first snap ring on sun gear.

(2) Install sun gear in drum and install remaining

snap ring.(3) Coat replacement seal rings with petroleum

jelly and install them on sun gear.Be sure seal

ring ends are interlocked.

(4) Install thrust washer. Be sure washer tabs are

seated in drum slots.

(5) Install one-way clutch/second brake hub assem-

bly on sun gear. Deep side of hub flange faces up-

ward (Fig. 9).

(6) Check one-way clutch operation again (Fig. 2).

Hold sun gear and turn second brake hub clockwise

and counterclockwise. Hub should turn clockwise

freely, but lock when turned counterclockwise.

(7) Set sun gear/clutch assembly aside for final as-

sembly.

Fig. 6 Removing/Installing Sun Gear

Fig. 7 Removing/Installing Second Snap Ring

Fig. 8 Checking Sun Gear Bushings

Fig. 9 Installing Clutch And Hub Assembly On Sun

Gear

21 - 240 AW-4 TRANSMISSION OVERHAULJ

Page 1803 of 2158

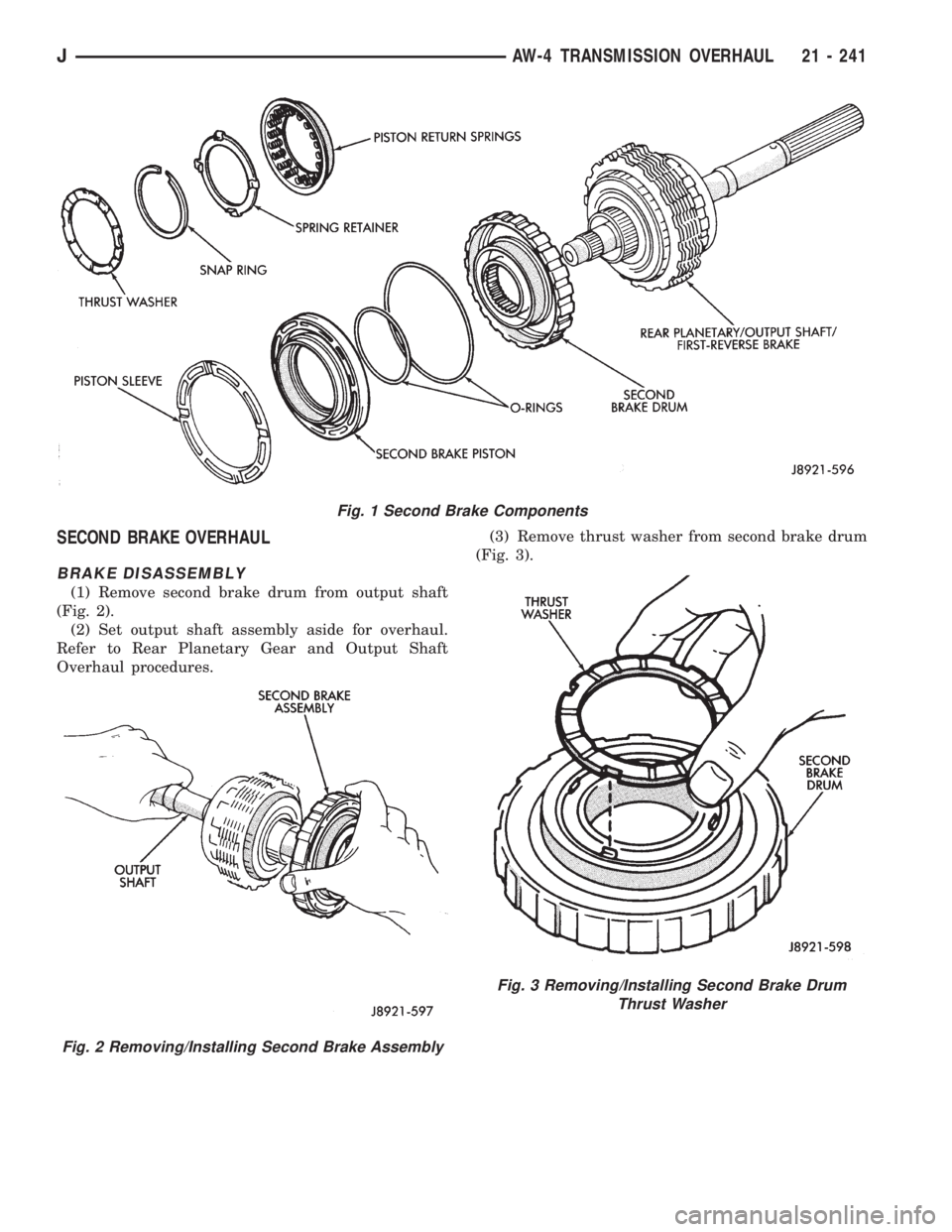

SECOND BRAKE OVERHAUL

BRAKE DISASSEMBLY

(1) Remove second brake drum from output shaft

(Fig. 2).

(2) Set output shaft assembly aside for overhaul.

Refer to Rear Planetary Gear and Output Shaft

Overhaul procedures.(3) Remove thrust washer from second brake drum

(Fig. 3).

Fig. 1 Second Brake Components

Fig. 2 Removing/Installing Second Brake Assembly

Fig. 3 Removing/Installing Second Brake Drum

Thrust Washer

JAW-4 TRANSMISSION OVERHAUL 21 - 241

Page 1804 of 2158

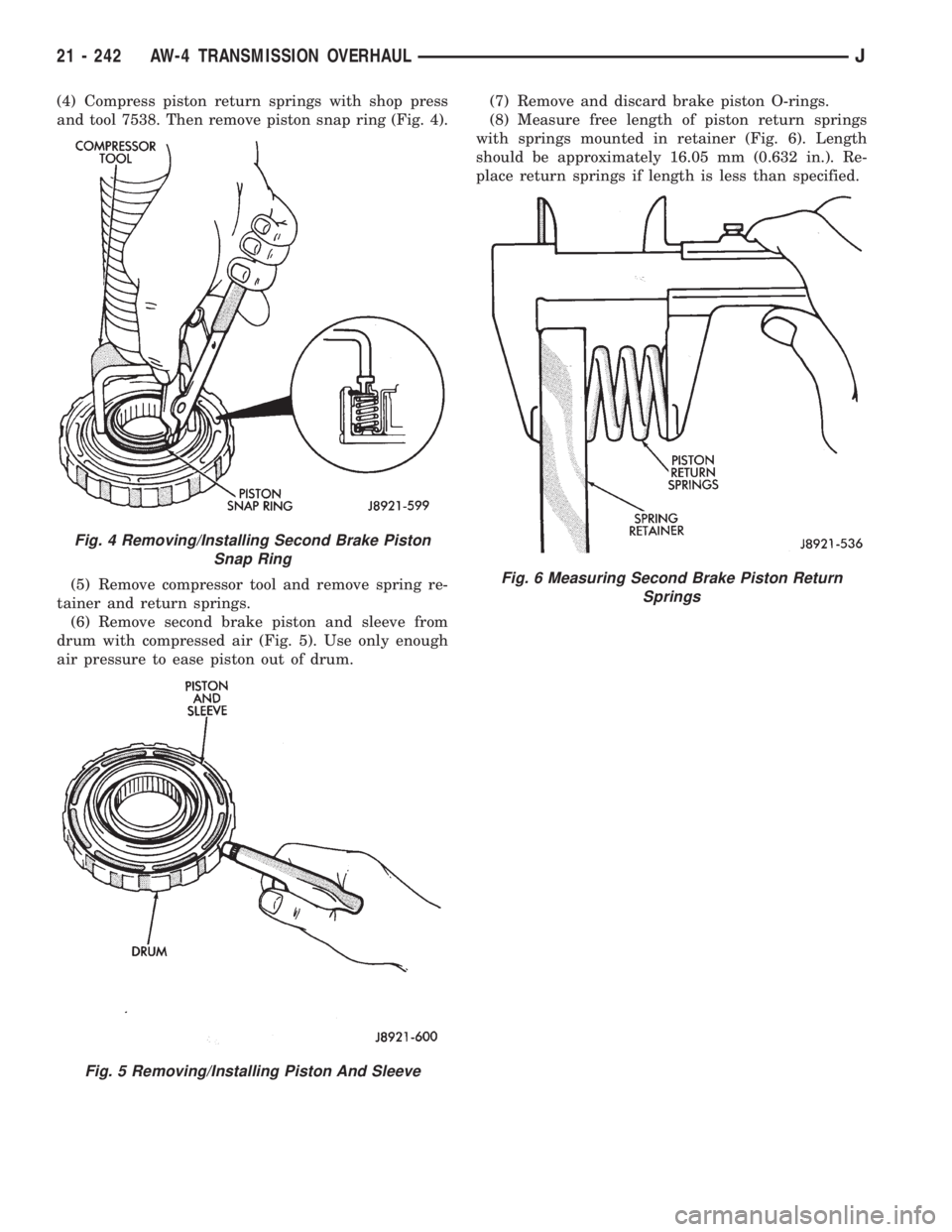

(4) Compress piston return springs with shop press

and tool 7538. Then remove piston snap ring (Fig. 4).

(5) Remove compressor tool and remove spring re-

tainer and return springs.

(6) Remove second brake piston and sleeve from

drum with compressed air (Fig. 5). Use only enough

air pressure to ease piston out of drum.(7) Remove and discard brake piston O-rings.

(8) Measure free length of piston return springs

with springs mounted in retainer (Fig. 6). Length

should be approximately 16.05 mm (0.632 in.). Re-

place return springs if length is less than specified.

Fig. 4 Removing/Installing Second Brake Piston

Snap Ring

Fig. 5 Removing/Installing Piston And Sleeve

Fig. 6 Measuring Second Brake Piston Return

Springs

21 - 242 AW-4 TRANSMISSION OVERHAULJ

Page 1805 of 2158

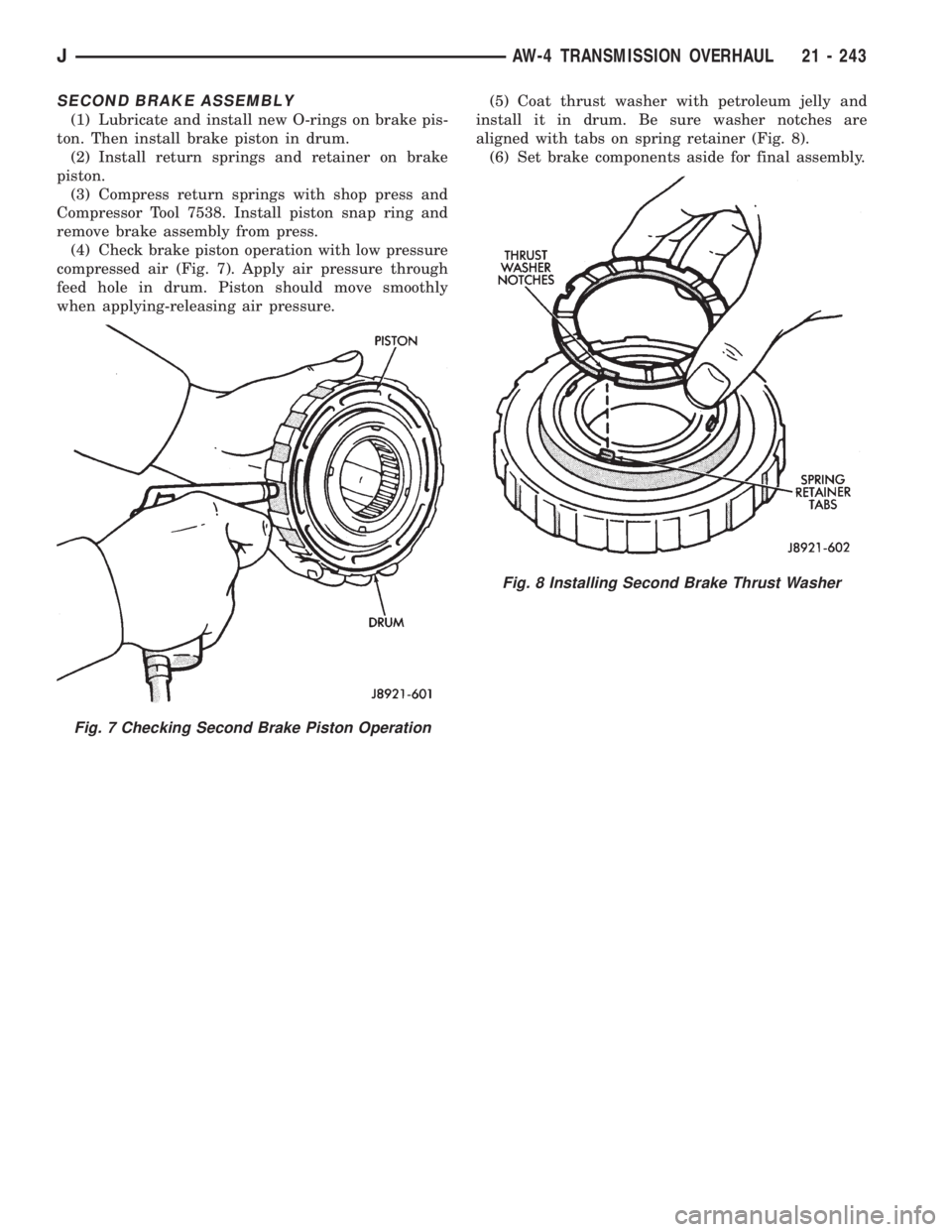

SECOND BRAKE ASSEMBLY

(1) Lubricate and install new O-rings on brake pis-

ton. Then install brake piston in drum.

(2) Install return springs and retainer on brake

piston.

(3) Compress return springs with shop press and

Compressor Tool 7538. Install piston snap ring and

remove brake assembly from press.

(4) Check brake piston operation with low pressure

compressed air (Fig. 7). Apply air pressure through

feed hole in drum. Piston should move smoothly

when applying-releasing air pressure.(5) Coat thrust washer with petroleum jelly and

install it in drum. Be sure washer notches are

aligned with tabs on spring retainer (Fig. 8).

(6) Set brake components aside for final assembly.

Fig. 7 Checking Second Brake Piston Operation

Fig. 8 Installing Second Brake Thrust Washer

JAW-4 TRANSMISSION OVERHAUL 21 - 243

Page 1806 of 2158

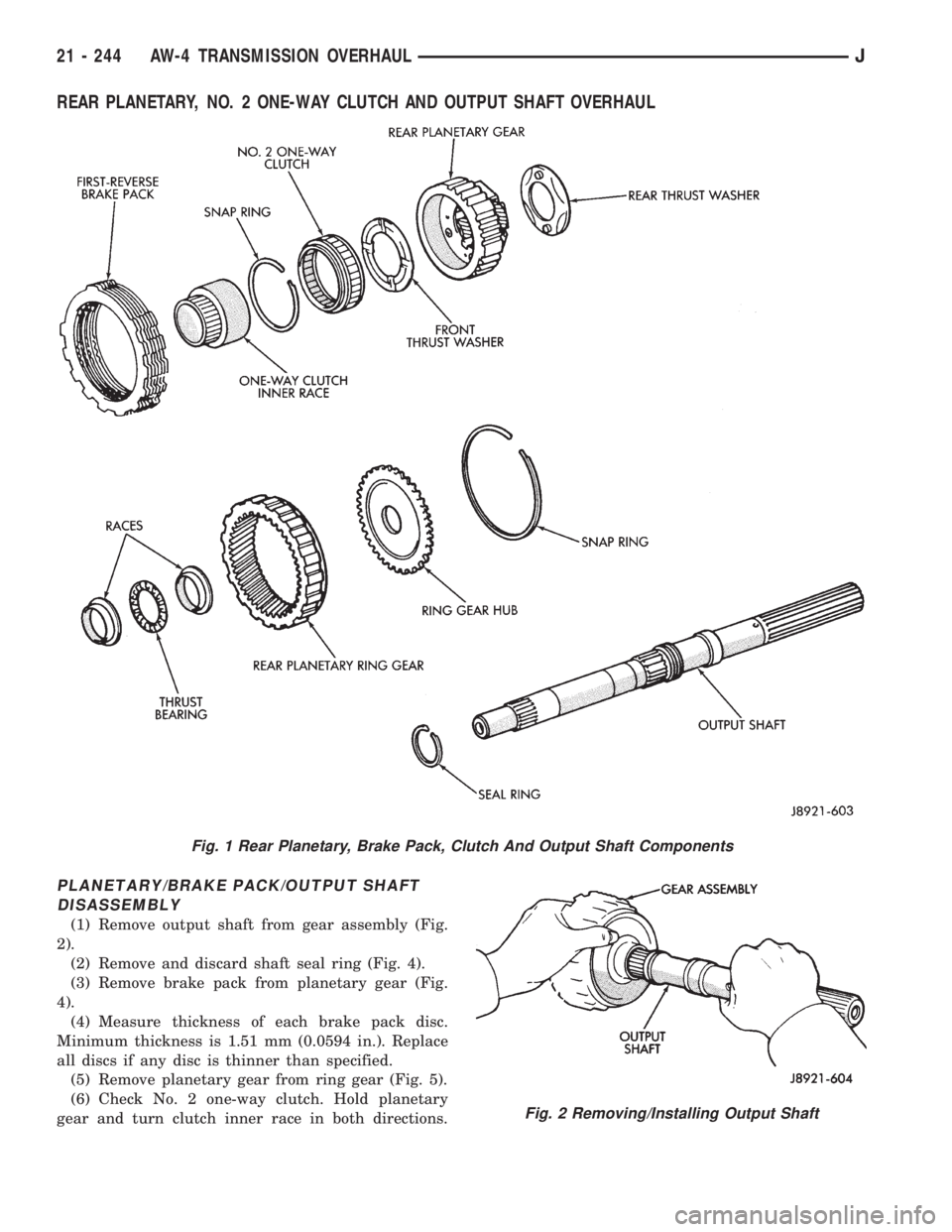

REAR PLANETARY, NO. 2 ONE-WAY CLUTCH AND OUTPUT SHAFT OVERHAUL

PLANETARY/BRAKE PACK/OUTPUT SHAFT

DISASSEMBLY

(1) Remove output shaft from gear assembly (Fig.

2).

(2) Remove and discard shaft seal ring (Fig. 4).

(3) Remove brake pack from planetary gear (Fig.

4).

(4) Measure thickness of each brake pack disc.

Minimum thickness is 1.51 mm (0.0594 in.). Replace

all discs if any disc is thinner than specified.

(5) Remove planetary gear from ring gear (Fig. 5).

(6) Check No. 2 one-way clutch. Hold planetary

gear and turn clutch inner race in both directions.

Fig. 1 Rear Planetary, Brake Pack, Clutch And Output Shaft Components

Fig. 2 Removing/Installing Output Shaft

21 - 244 AW-4 TRANSMISSION OVERHAULJ

Page 1807 of 2158

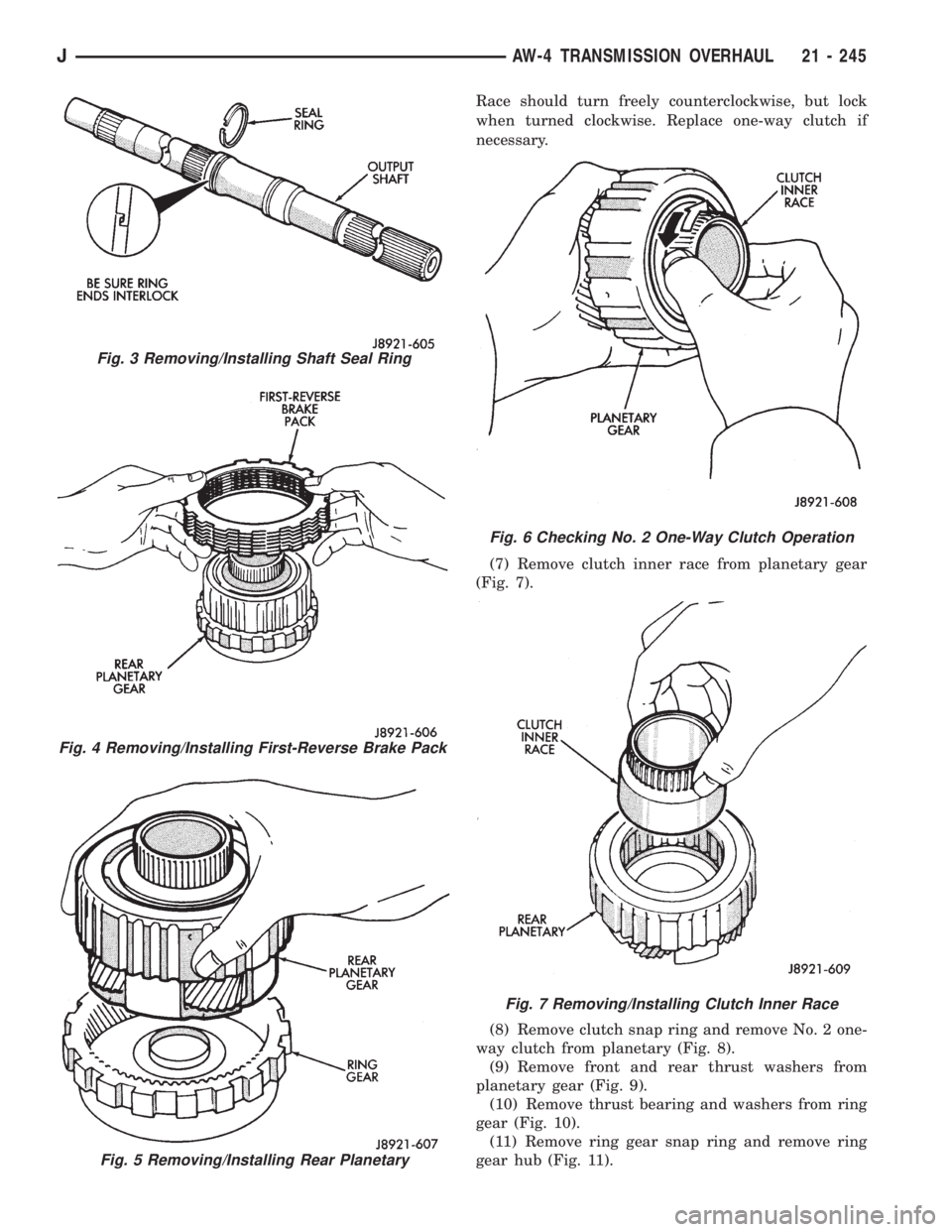

Race should turn freely counterclockwise, but lock

when turned clockwise. Replace one-way clutch if

necessary.

(7) Remove clutch inner race from planetary gear

(Fig. 7).

(8) Remove clutch snap ring and remove No. 2 one-

way clutch from planetary (Fig. 8).

(9) Remove front and rear thrust washers from

planetary gear (Fig. 9).

(10) Remove thrust bearing and washers from ring

gear (Fig. 10).

(11) Remove ring gear snap ring and remove ring

gear hub (Fig. 11).

Fig. 3 Removing/Installing Shaft Seal Ring

Fig. 4 Removing/Installing First-Reverse Brake Pack

Fig. 5 Removing/Installing Rear Planetary

Fig. 6 Checking No. 2 One-Way Clutch Operation

Fig. 7 Removing/Installing Clutch Inner Race

JAW-4 TRANSMISSION OVERHAUL 21 - 245

Page 1808 of 2158

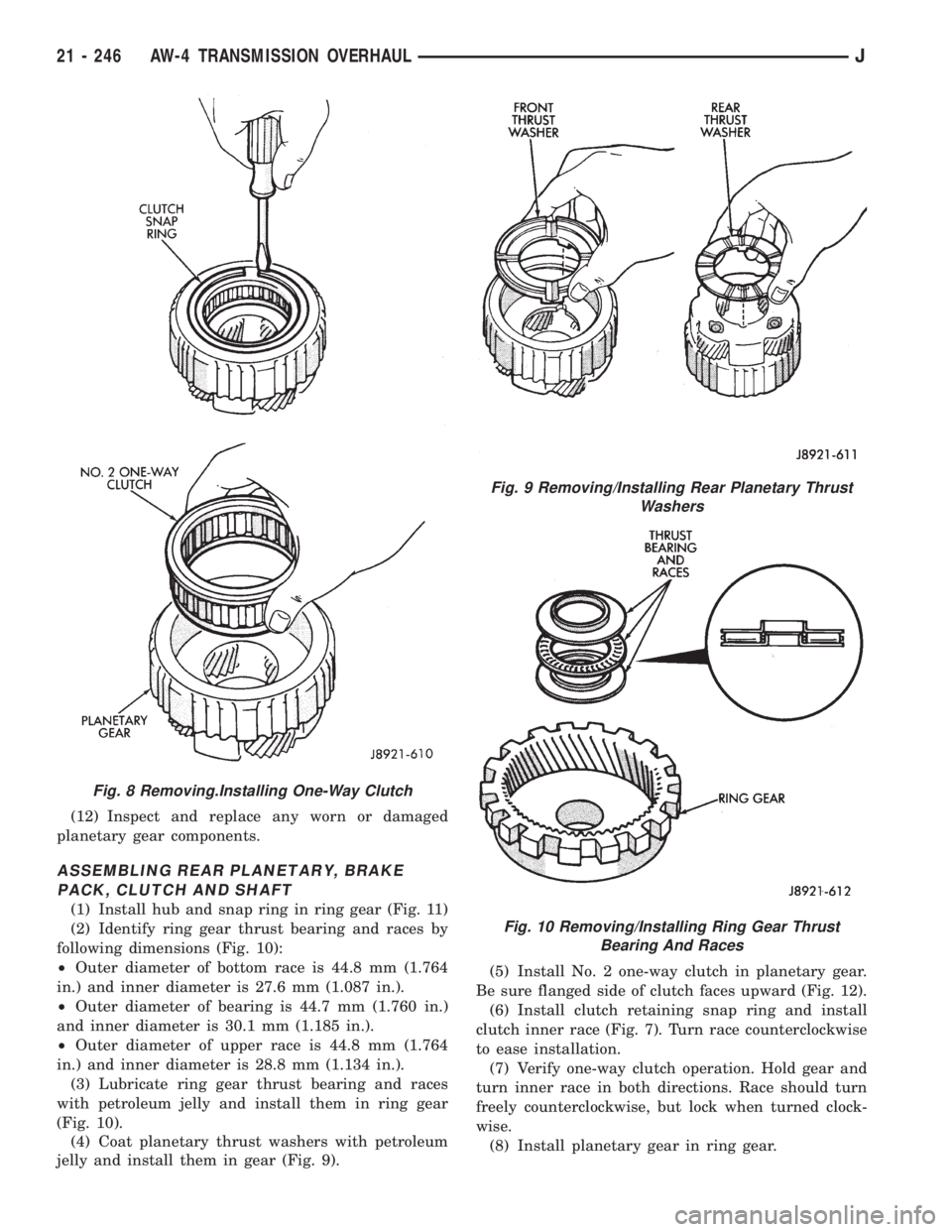

(12) Inspect and replace any worn or damaged

planetary gear components.

ASSEMBLING REAR PLANETARY, BRAKE

PACK, CLUTCH AND SHAFT

(1) Install hub and snap ring in ring gear (Fig. 11)

(2) Identify ring gear thrust bearing and races by

following dimensions (Fig. 10):

²Outer diameter of bottom race is 44.8 mm (1.764

in.) and inner diameter is 27.6 mm (1.087 in.).

²Outer diameter of bearing is 44.7 mm (1.760 in.)

and inner diameter is 30.1 mm (1.185 in.).

²Outer diameter of upper race is 44.8 mm (1.764

in.) and inner diameter is 28.8 mm (1.134 in.).

(3) Lubricate ring gear thrust bearing and races

with petroleum jelly and install them in ring gear

(Fig. 10).

(4) Coat planetary thrust washers with petroleum

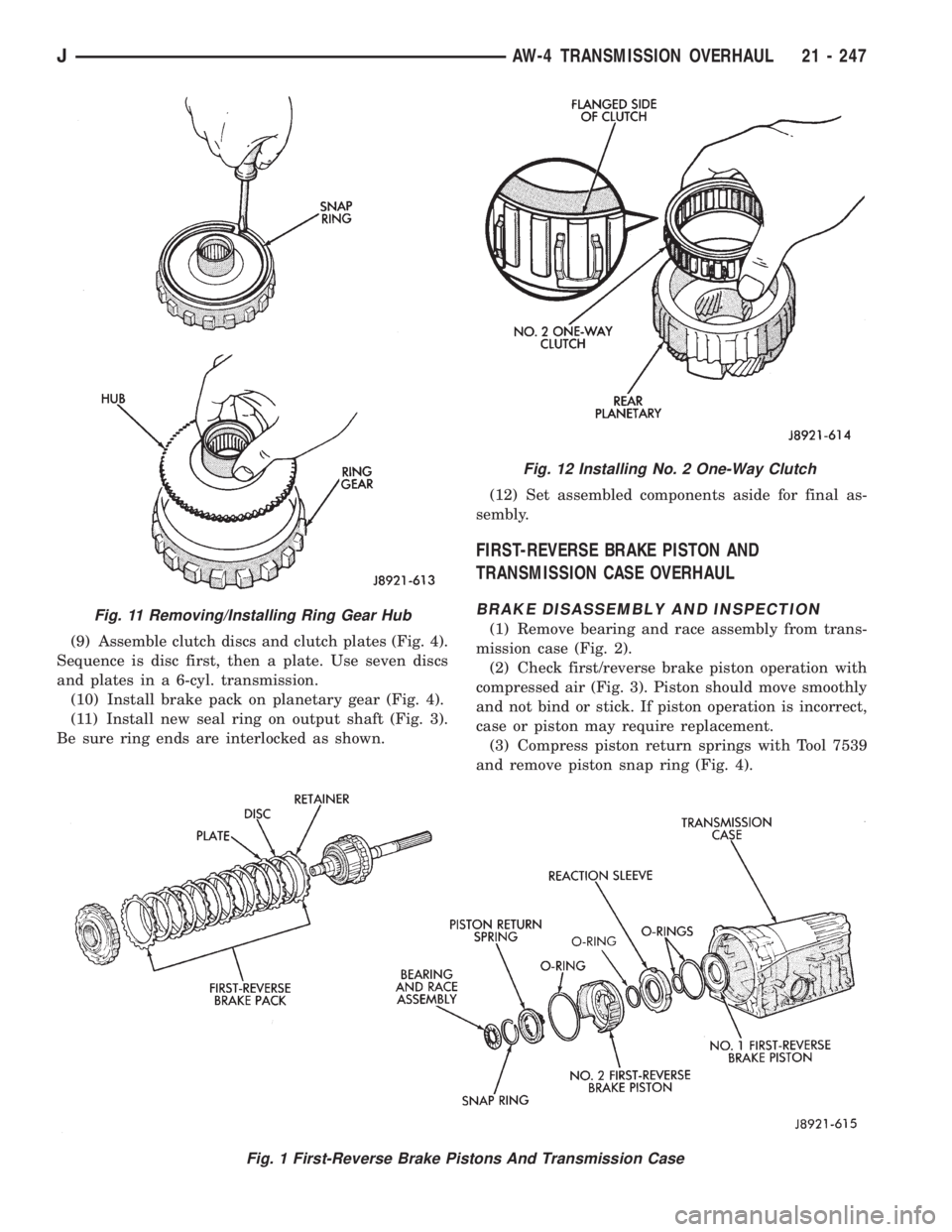

jelly and install them in gear (Fig. 9).(5) Install No. 2 one-way clutch in planetary gear.

Be sure flanged side of clutch faces upward (Fig. 12).

(6) Install clutch retaining snap ring and install

clutch inner race (Fig. 7). Turn race counterclockwise

to ease installation.

(7) Verify one-way clutch operation. Hold gear and

turn inner race in both directions. Race should turn

freely counterclockwise, but lock when turned clock-

wise.

(8) Install planetary gear in ring gear.

Fig. 8 Removing.Installing One-Way Clutch

Fig. 9 Removing/Installing Rear Planetary Thrust

Washers

Fig. 10 Removing/Installing Ring Gear Thrust

Bearing And Races

21 - 246 AW-4 TRANSMISSION OVERHAULJ

Page 1809 of 2158

(9) Assemble clutch discs and clutch plates (Fig. 4).

Sequence is disc first, then a plate. Use seven discs

and plates in a 6-cyl. transmission.

(10) Install brake pack on planetary gear (Fig. 4).

(11) Install new seal ring on output shaft (Fig. 3).

Be sure ring ends are interlocked as shown.(12) Set assembled components aside for final as-

sembly.

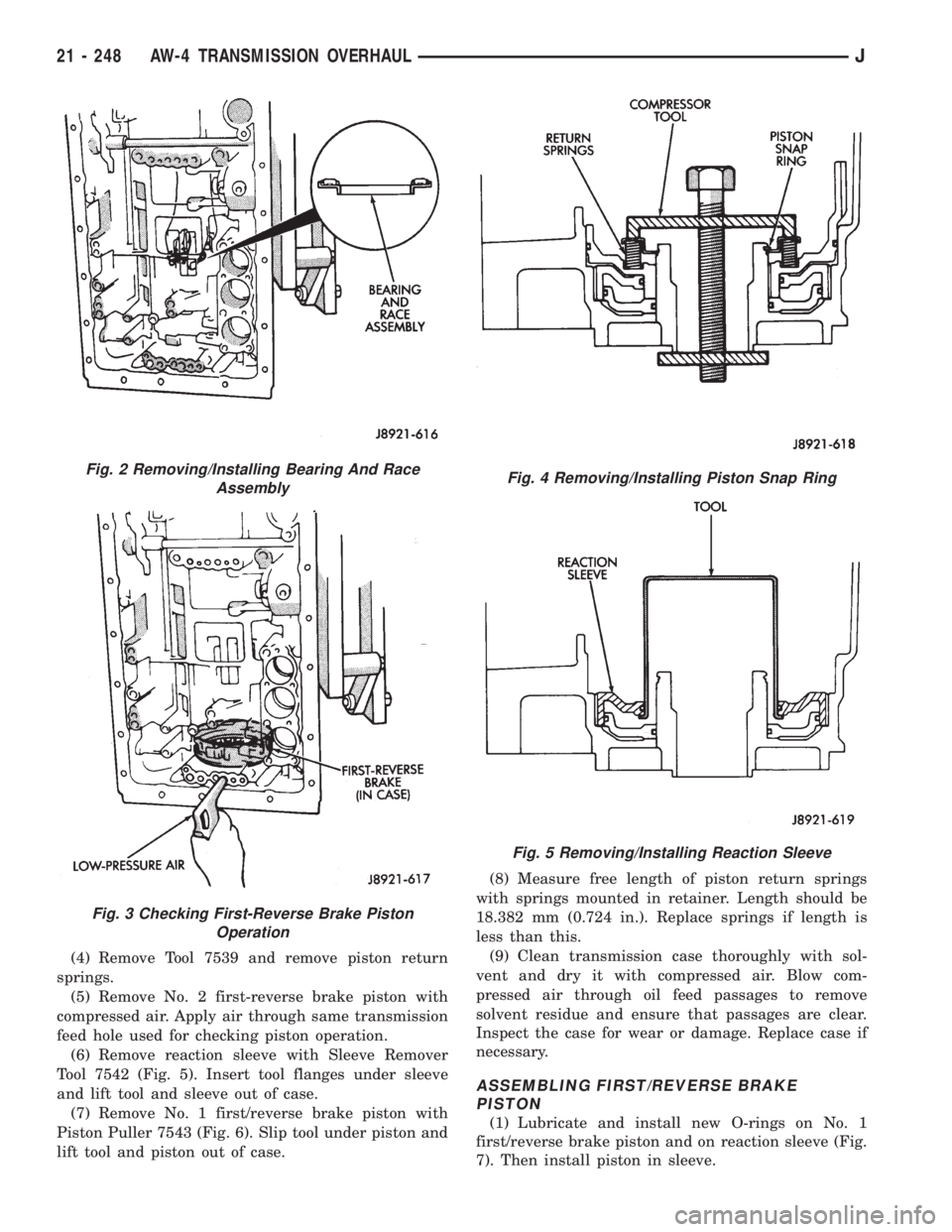

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL

BRAKE DISASSEMBLY AND INSPECTION

(1) Remove bearing and race assembly from trans-

mission case (Fig. 2).

(2) Check first/reverse brake piston operation with

compressed air (Fig. 3). Piston should move smoothly

and not bind or stick. If piston operation is incorrect,

case or piston may require replacement.

(3) Compress piston return springs with Tool 7539

and remove piston snap ring (Fig. 4).

Fig. 12 Installing No. 2 One-Way Clutch

Fig. 1 First-Reverse Brake Pistons And Transmission Case

Fig. 11 Removing/Installing Ring Gear Hub

JAW-4 TRANSMISSION OVERHAUL 21 - 247

Page 1810 of 2158

(4) Remove Tool 7539 and remove piston return

springs.

(5) Remove No. 2 first-reverse brake piston with

compressed air. Apply air through same transmission

feed hole used for checking piston operation.

(6) Remove reaction sleeve with Sleeve Remover

Tool 7542 (Fig. 5). Insert tool flanges under sleeve

and lift tool and sleeve out of case.

(7) Remove No. 1 first/reverse brake piston with

Piston Puller 7543 (Fig. 6). Slip tool under piston and

lift tool and piston out of case.(8) Measure free length of piston return springs

with springs mounted in retainer. Length should be

18.382 mm (0.724 in.). Replace springs if length is

less than this.

(9) Clean transmission case thoroughly with sol-

vent and dry it with compressed air. Blow com-

pressed air through oil feed passages to remove

solvent residue and ensure that passages are clear.

Inspect the case for wear or damage. Replace case if

necessary.

ASSEMBLING FIRST/REVERSE BRAKE

PISTON

(1) Lubricate and install new O-rings on No. 1

first/reverse brake piston and on reaction sleeve (Fig.

7). Then install piston in sleeve.

Fig. 2 Removing/Installing Bearing And Race

Assembly

Fig. 3 Checking First-Reverse Brake Piston

Operation

Fig. 4 Removing/Installing Piston Snap Ring

Fig. 5 Removing/Installing Reaction Sleeve

21 - 248 AW-4 TRANSMISSION OVERHAULJ