JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1811 of 2158

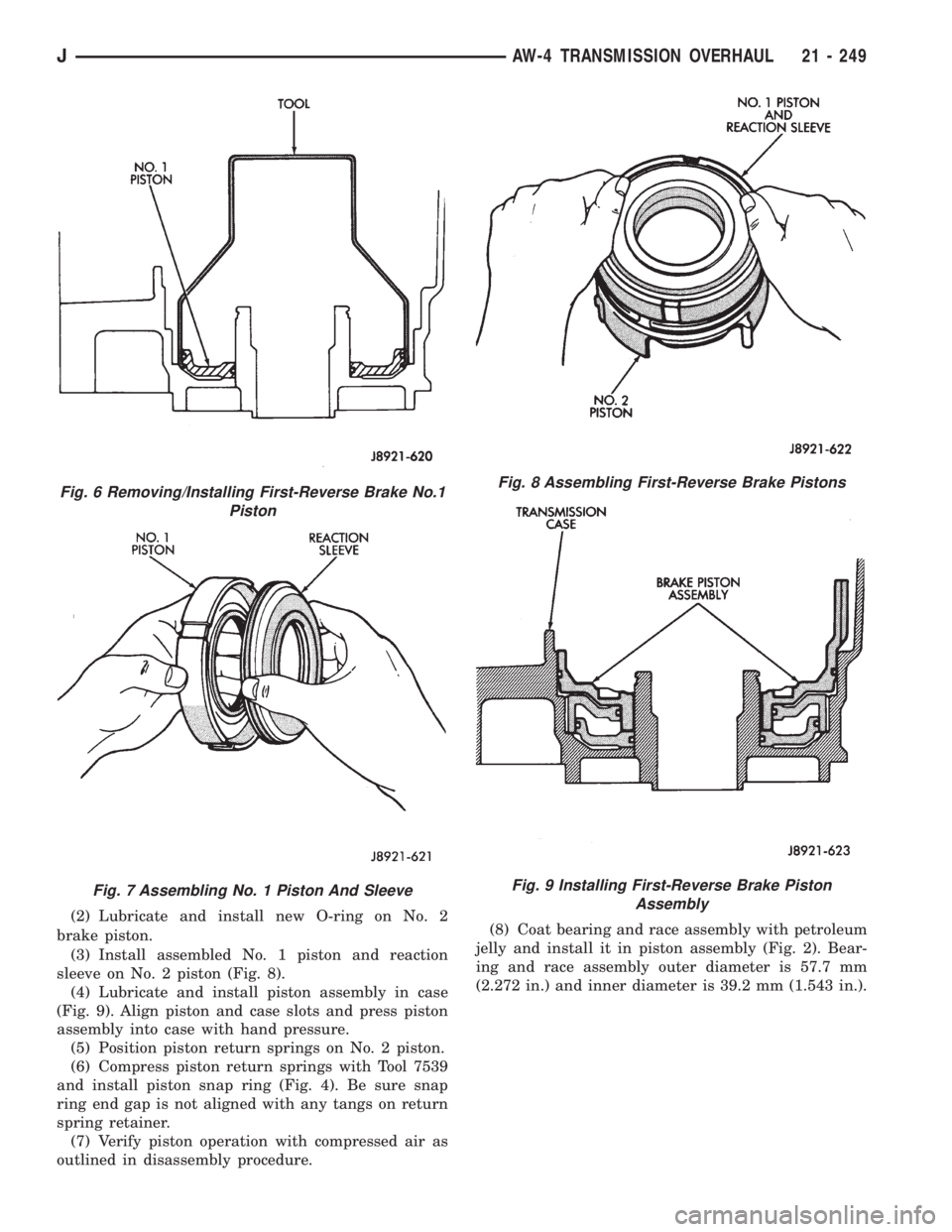

(2) Lubricate and install new O-ring on No. 2

brake piston.

(3) Install assembled No. 1 piston and reaction

sleeve on No. 2 piston (Fig. 8).

(4) Lubricate and install piston assembly in case

(Fig. 9). Align piston and case slots and press piston

assembly into case with hand pressure.

(5) Position piston return springs on No. 2 piston.

(6) Compress piston return springs with Tool 7539

and install piston snap ring (Fig. 4). Be sure snap

ring end gap is not aligned with any tangs on return

spring retainer.

(7) Verify piston operation with compressed air as

outlined in disassembly procedure.(8) Coat bearing and race assembly with petroleum

jelly and install it in piston assembly (Fig. 2). Bear-

ing and race assembly outer diameter is 57.7 mm

(2.272 in.) and inner diameter is 39.2 mm (1.543 in.).

Fig. 6 Removing/Installing First-Reverse Brake No.1

Piston

Fig. 7 Assembling No. 1 Piston And Sleeve

Fig. 8 Assembling First-Reverse Brake Pistons

Fig. 9 Installing First-Reverse Brake Piston

Assembly

JAW-4 TRANSMISSION OVERHAUL 21 - 249

Page 1812 of 2158

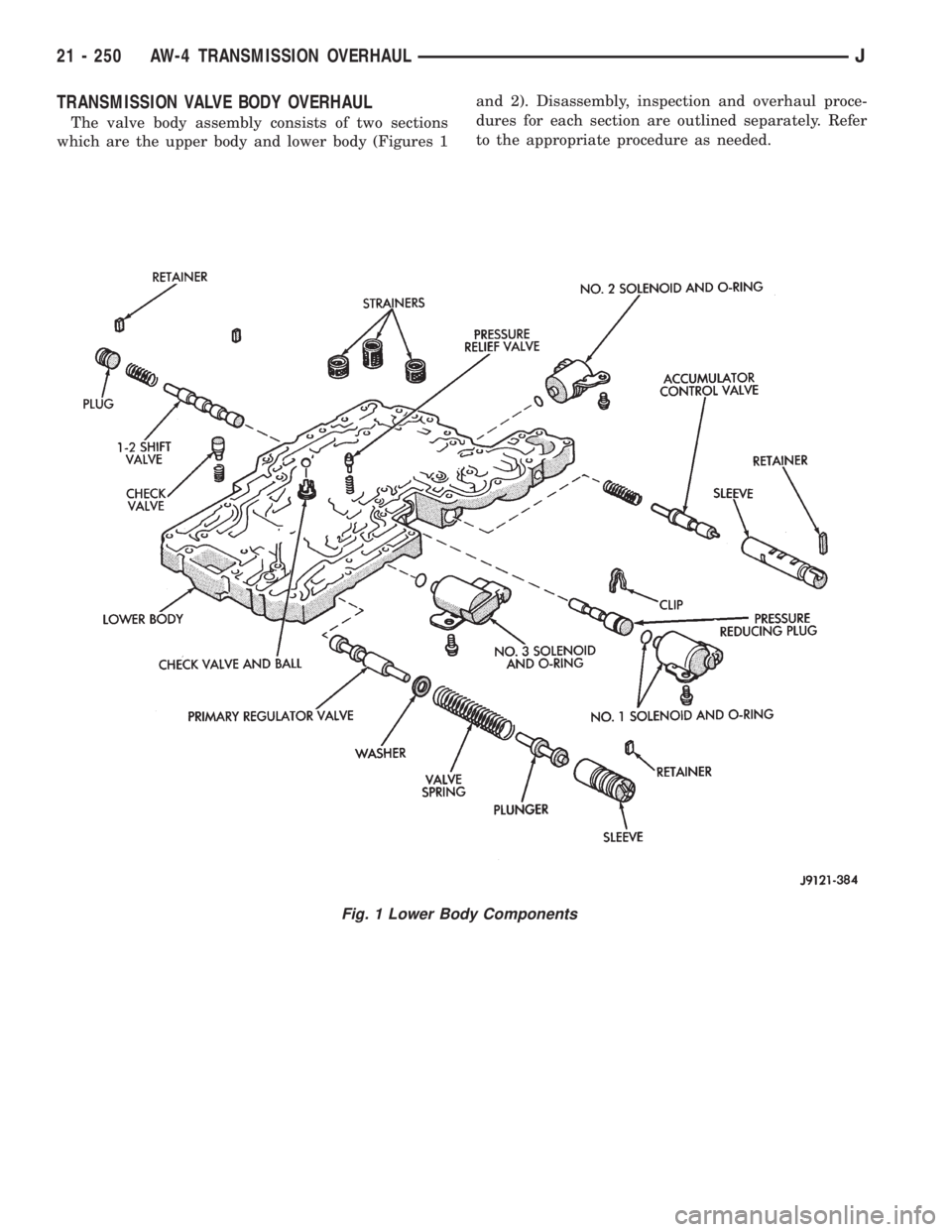

TRANSMISSION VALVE BODY OVERHAUL

The valve body assembly consists of two sections

which are the upper body and lower body (Figures 1and 2). Disassembly, inspection and overhaul proce-

dures for each section are outlined separately. Refer

to the appropriate procedure as needed.

Fig. 1 Lower Body Components

21 - 250 AW-4 TRANSMISSION OVERHAULJ

Page 1813 of 2158

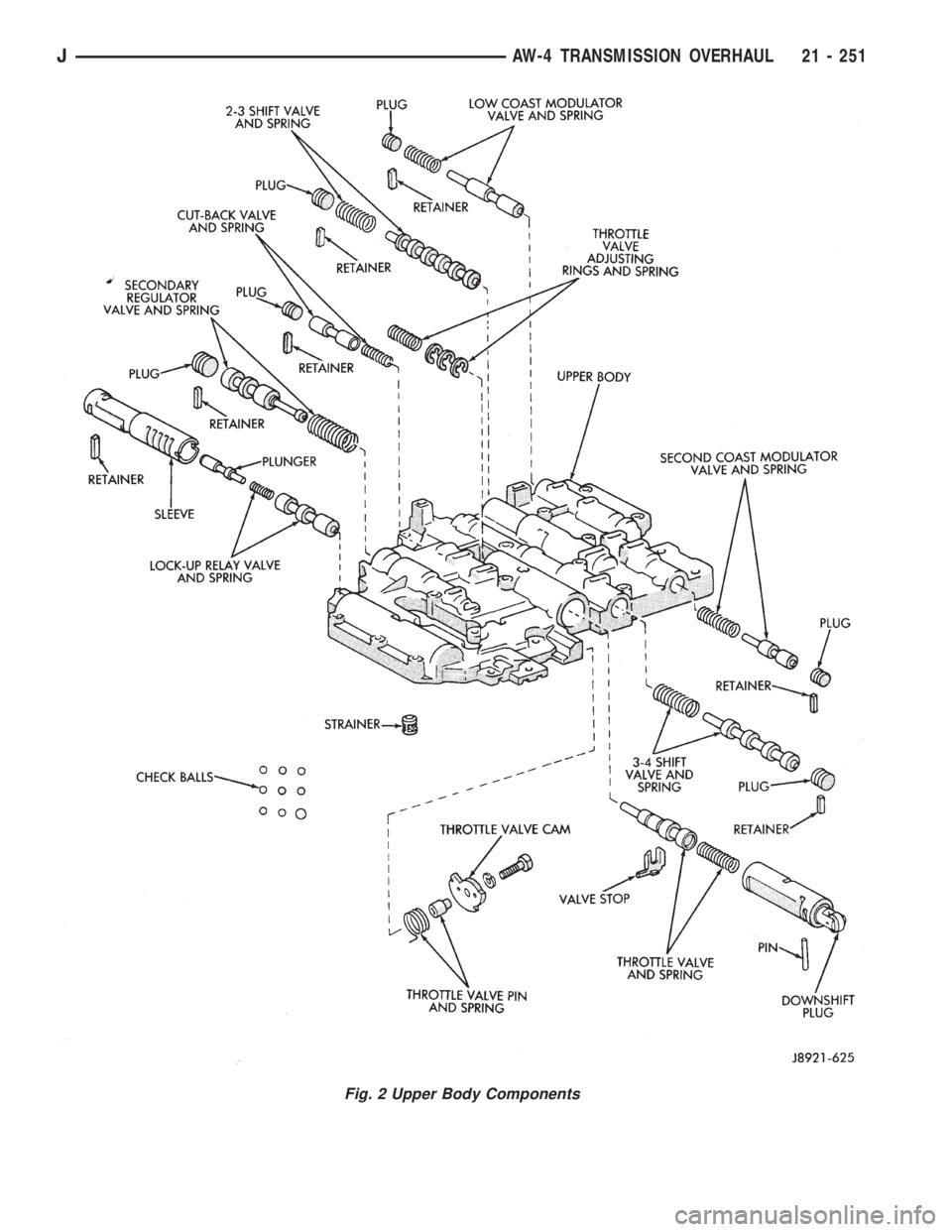

Fig. 2 Upper Body Components

JAW-4 TRANSMISSION OVERHAUL 21 - 251

Page 1814 of 2158

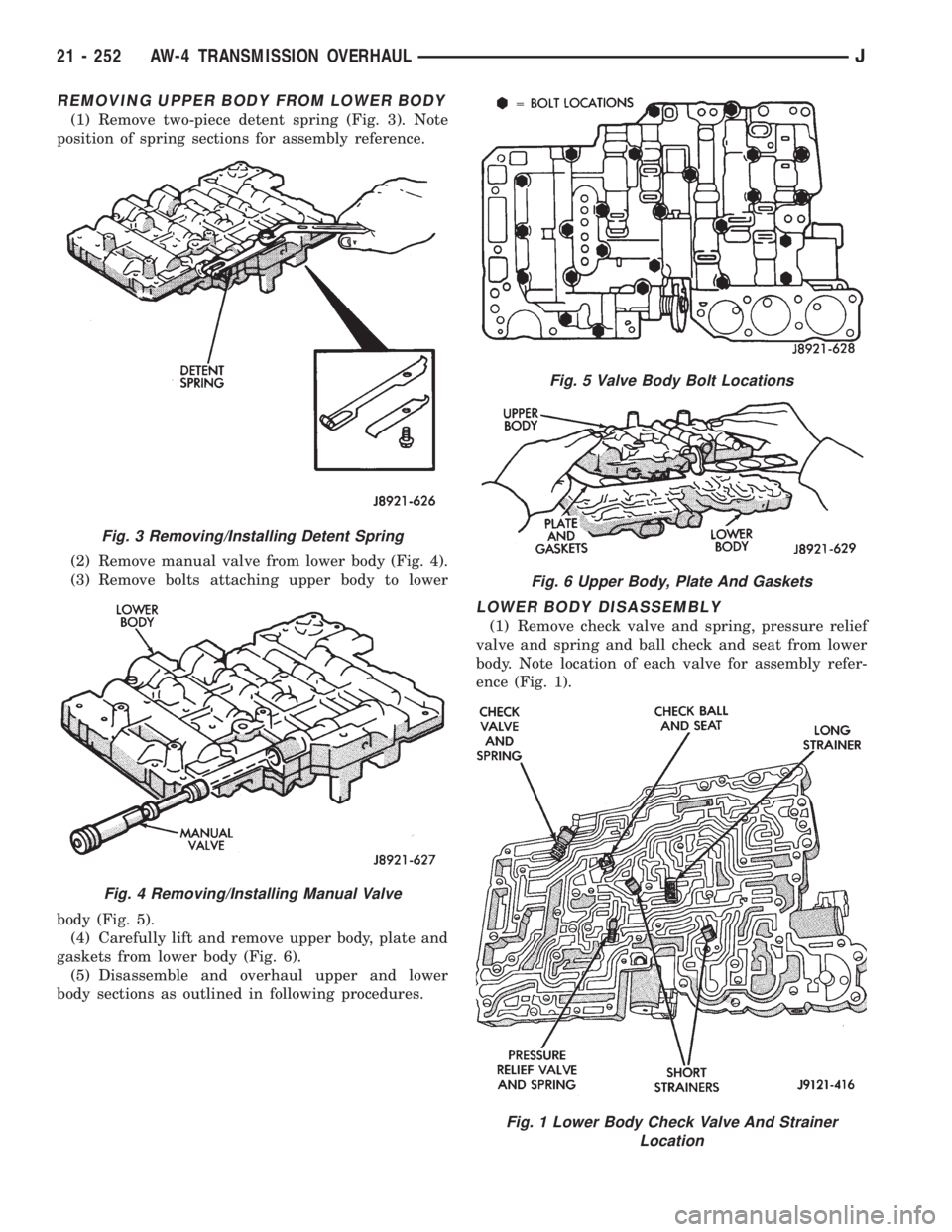

REMOVING UPPER BODY FROM LOWER BODY

(1) Remove two-piece detent spring (Fig. 3). Note

position of spring sections for assembly reference.

(2) Remove manual valve from lower body (Fig. 4).

(3) Remove bolts attaching upper body to lower

body (Fig. 5).

(4) Carefully lift and remove upper body, plate and

gaskets from lower body (Fig. 6).

(5) Disassemble and overhaul upper and lower

body sections as outlined in following procedures.

LOWER BODY DISASSEMBLY

(1) Remove check valve and spring, pressure relief

valve and spring and ball check and seat from lower

body. Note location of each valve for assembly refer-

ence (Fig. 1).

Fig. 3 Removing/Installing Detent Spring

Fig. 4 Removing/Installing Manual Valve

Fig. 5 Valve Body Bolt Locations

Fig. 6 Upper Body, Plate And Gaskets

Fig. 1 Lower Body Check Valve And Strainer

Location

21 - 252 AW-4 TRANSMISSION OVERHAULJ

Page 1815 of 2158

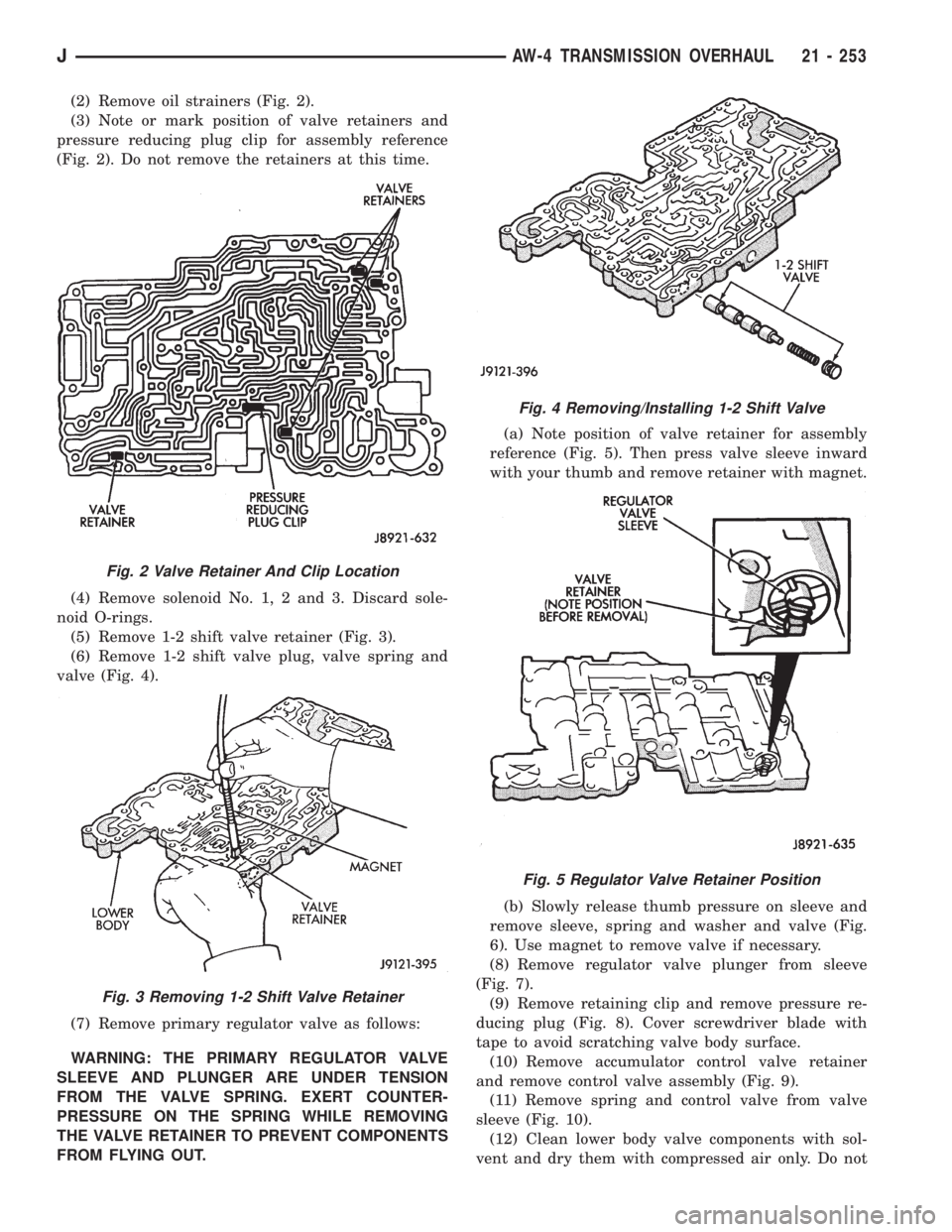

(2) Remove oil strainers (Fig. 2).

(3) Note or mark position of valve retainers and

pressure reducing plug clip for assembly reference

(Fig. 2). Do not remove the retainers at this time.

(4) Remove solenoid No. 1, 2 and 3. Discard sole-

noid O-rings.

(5) Remove 1-2 shift valve retainer (Fig. 3).

(6) Remove 1-2 shift valve plug, valve spring and

valve (Fig. 4).

(7) Remove primary regulator valve as follows:

WARNING: THE PRIMARY REGULATOR VALVE

SLEEVE AND PLUNGER ARE UNDER TENSION

FROM THE VALVE SPRING. EXERT COUNTER-

PRESSURE ON THE SPRING WHILE REMOVING

THE VALVE RETAINER TO PREVENT COMPONENTS

FROM FLYING OUT.(a) Note position of valve retainer for assembly

reference (Fig. 5). Then press valve sleeve inward

with your thumb and remove retainer with magnet.

(b) Slowly release thumb pressure on sleeve and

remove sleeve, spring and washer and valve (Fig.

6). Use magnet to remove valve if necessary.

(8) Remove regulator valve plunger from sleeve

(Fig. 7).

(9) Remove retaining clip and remove pressure re-

ducing plug (Fig. 8). Cover screwdriver blade with

tape to avoid scratching valve body surface.

(10) Remove accumulator control valve retainer

and remove control valve assembly (Fig. 9).

(11) Remove spring and control valve from valve

sleeve (Fig. 10).

(12) Clean lower body valve components with sol-

vent and dry them with compressed air only. Do not

Fig. 2 Valve Retainer And Clip Location

Fig. 3 Removing 1-2 Shift Valve Retainer

Fig. 4 Removing/Installing 1-2 Shift Valve

Fig. 5 Regulator Valve Retainer Position

JAW-4 TRANSMISSION OVERHAUL 21 - 253

Page 1816 of 2158

use shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(13) Inspect condition of lower body components.

Replace lower body if any bores are scored or cor-

roded. Replace valves, plugs or sleeves that are

scored or worn. Replace oil strainers if cut, torn or

damaged in any way.

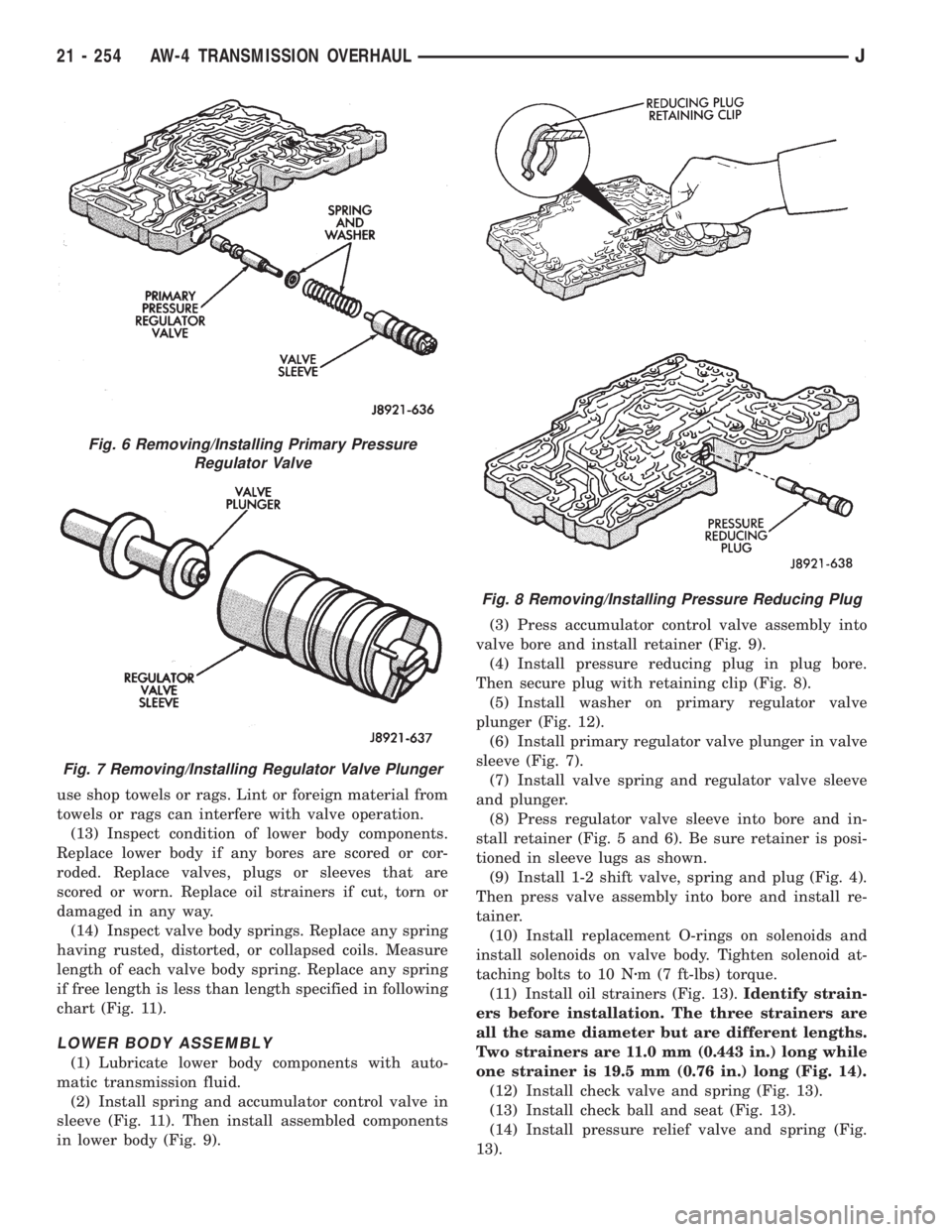

(14) Inspect valve body springs. Replace any spring

having rusted, distorted, or collapsed coils. Measure

length of each valve body spring. Replace any spring

if free length is less than length specified in following

chart (Fig. 11).

LOWER BODY ASSEMBLY

(1) Lubricate lower body components with auto-

matic transmission fluid.

(2) Install spring and accumulator control valve in

sleeve (Fig. 11). Then install assembled components

in lower body (Fig. 9).(3) Press accumulator control valve assembly into

valve bore and install retainer (Fig. 9).

(4) Install pressure reducing plug in plug bore.

Then secure plug with retaining clip (Fig. 8).

(5) Install washer on primary regulator valve

plunger (Fig. 12).

(6) Install primary regulator valve plunger in valve

sleeve (Fig. 7).

(7) Install valve spring and regulator valve sleeve

and plunger.

(8) Press regulator valve sleeve into bore and in-

stall retainer (Fig. 5 and 6). Be sure retainer is posi-

tioned in sleeve lugs as shown.

(9) Install 1-2 shift valve, spring and plug (Fig. 4).

Then press valve assembly into bore and install re-

tainer.

(10) Install replacement O-rings on solenoids and

install solenoids on valve body. Tighten solenoid at-

taching bolts to 10 Nzm (7 ft-lbs) torque.

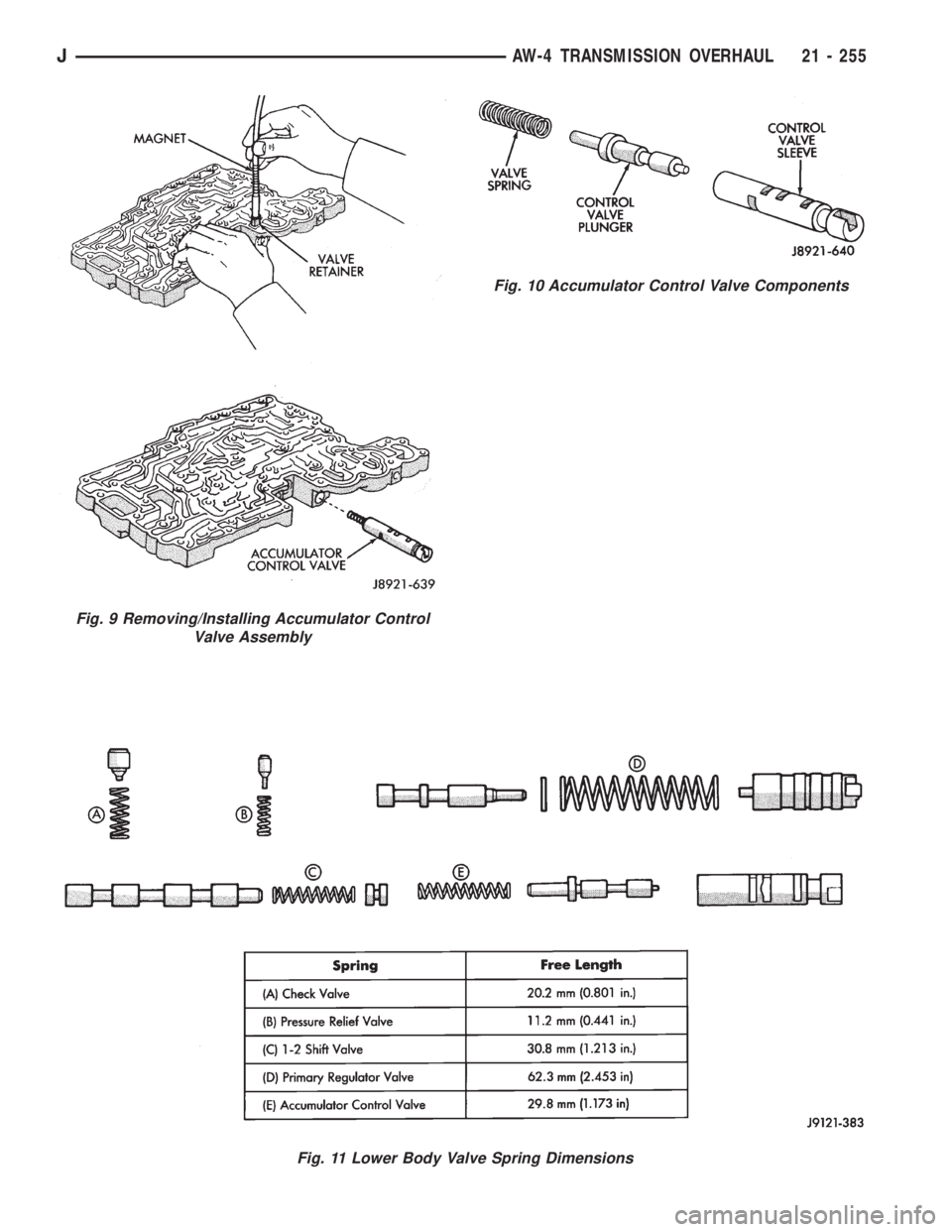

(11) Install oil strainers (Fig. 13).Identify strain-

ers before installation. The three strainers are

all the same diameter but are different lengths.

Two strainers are 11.0 mm (0.443 in.) long while

one strainer is 19.5 mm (0.76 in.) long (Fig. 14).

(12) Install check valve and spring (Fig. 13).

(13) Install check ball and seat (Fig. 13).

(14) Install pressure relief valve and spring (Fig.

13).

Fig. 6 Removing/Installing Primary Pressure

Regulator Valve

Fig. 7 Removing/Installing Regulator Valve Plunger

Fig. 8 Removing/Installing Pressure Reducing Plug

21 - 254 AW-4 TRANSMISSION OVERHAULJ

Page 1817 of 2158

Fig. 10 Accumulator Control Valve Components

Fig. 11 Lower Body Valve Spring Dimensions

Fig. 9 Removing/Installing Accumulator Control

Valve Assembly

JAW-4 TRANSMISSION OVERHAUL 21 - 255

Page 1818 of 2158

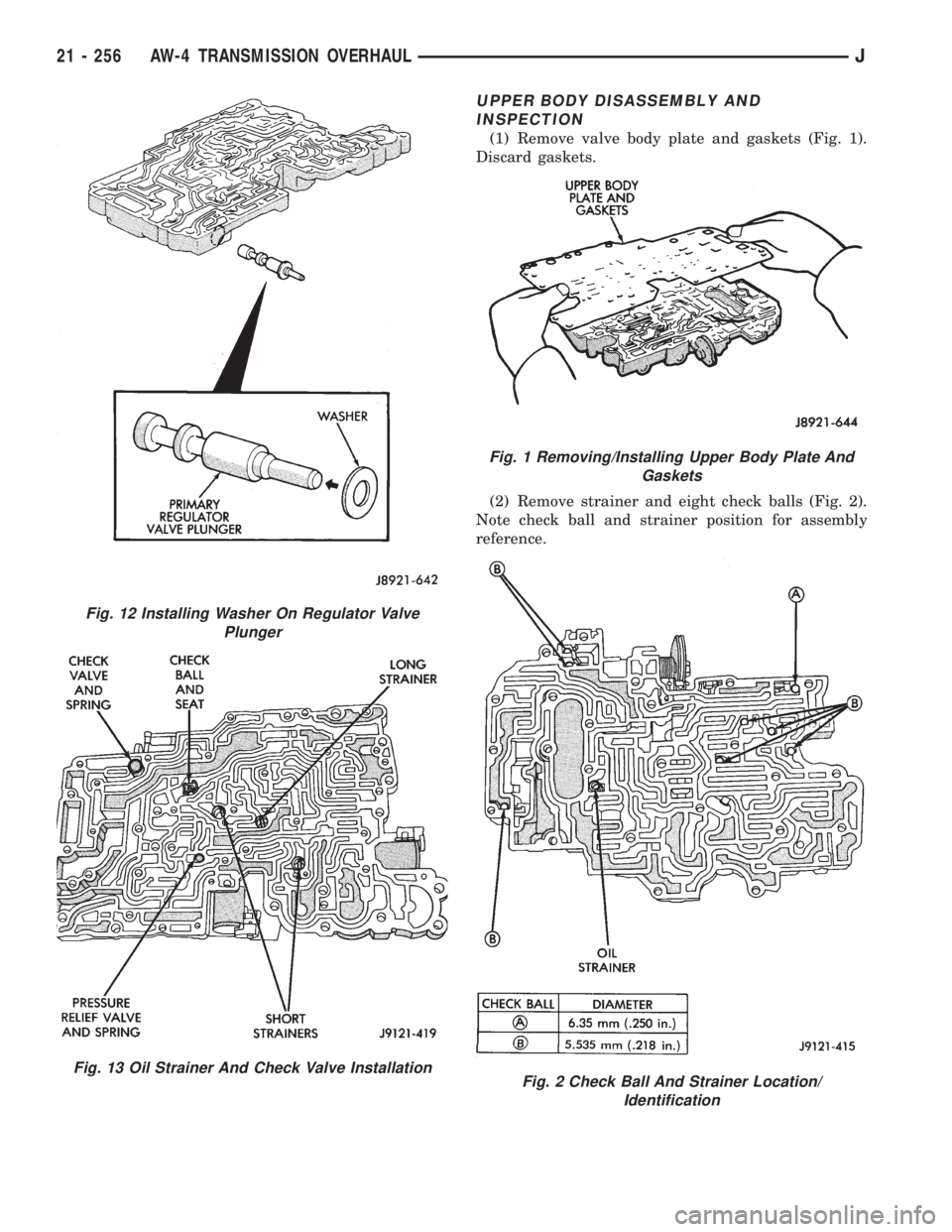

UPPER BODY DISASSEMBLY AND

INSPECTION

(1) Remove valve body plate and gaskets (Fig. 1).

Discard gaskets.

(2) Remove strainer and eight check balls (Fig. 2).

Note check ball and strainer position for assembly

reference.

Fig. 12 Installing Washer On Regulator Valve

Plunger

Fig. 13 Oil Strainer And Check Valve Installation

Fig. 1 Removing/Installing Upper Body Plate And

Gaskets

Fig. 2 Check Ball And Strainer Location/

Identification

21 - 256 AW-4 TRANSMISSION OVERHAULJ

Page 1819 of 2158

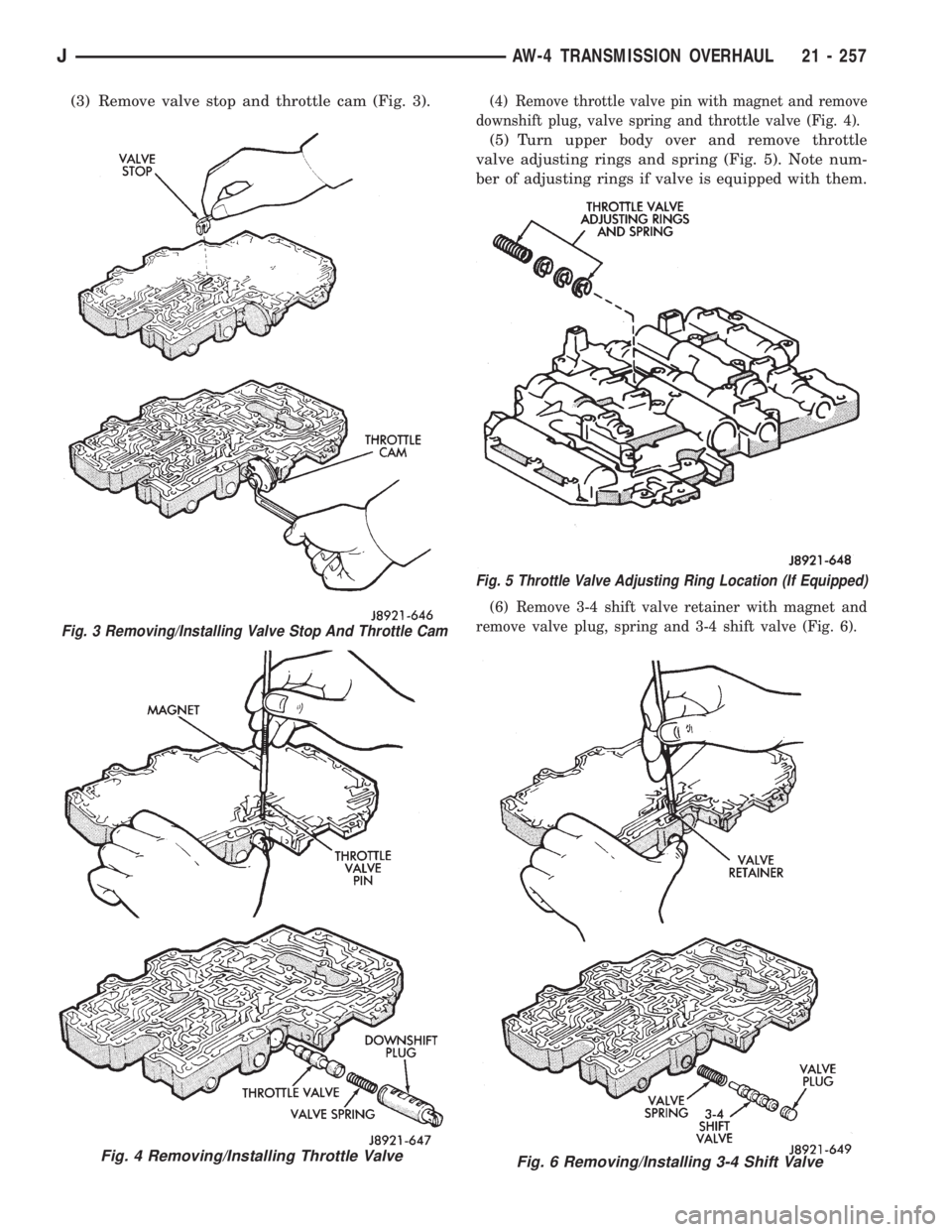

(3) Remove valve stop and throttle cam (Fig. 3).(4) Remove throttle valve pin with magnet and remove

downshift plug, valve spring and throttle valve (Fig. 4).

(5) Turn upper body over and remove throttle

valve adjusting rings and spring (Fig. 5). Note num-

ber of adjusting rings if valve is equipped with them.

(6) Remove 3-4 shift valve retainer with magnet and

remove valve plug, spring and 3-4 shift valve (Fig. 6).

Fig. 3 Removing/Installing Valve Stop And Throttle Cam

Fig. 4 Removing/Installing Throttle ValveFig. 6 Removing/Installing 3-4 Shift Valve

Fig. 5 Throttle Valve Adjusting Ring Location (If Equipped)

JAW-4 TRANSMISSION OVERHAUL 21 - 257

Page 1820 of 2158

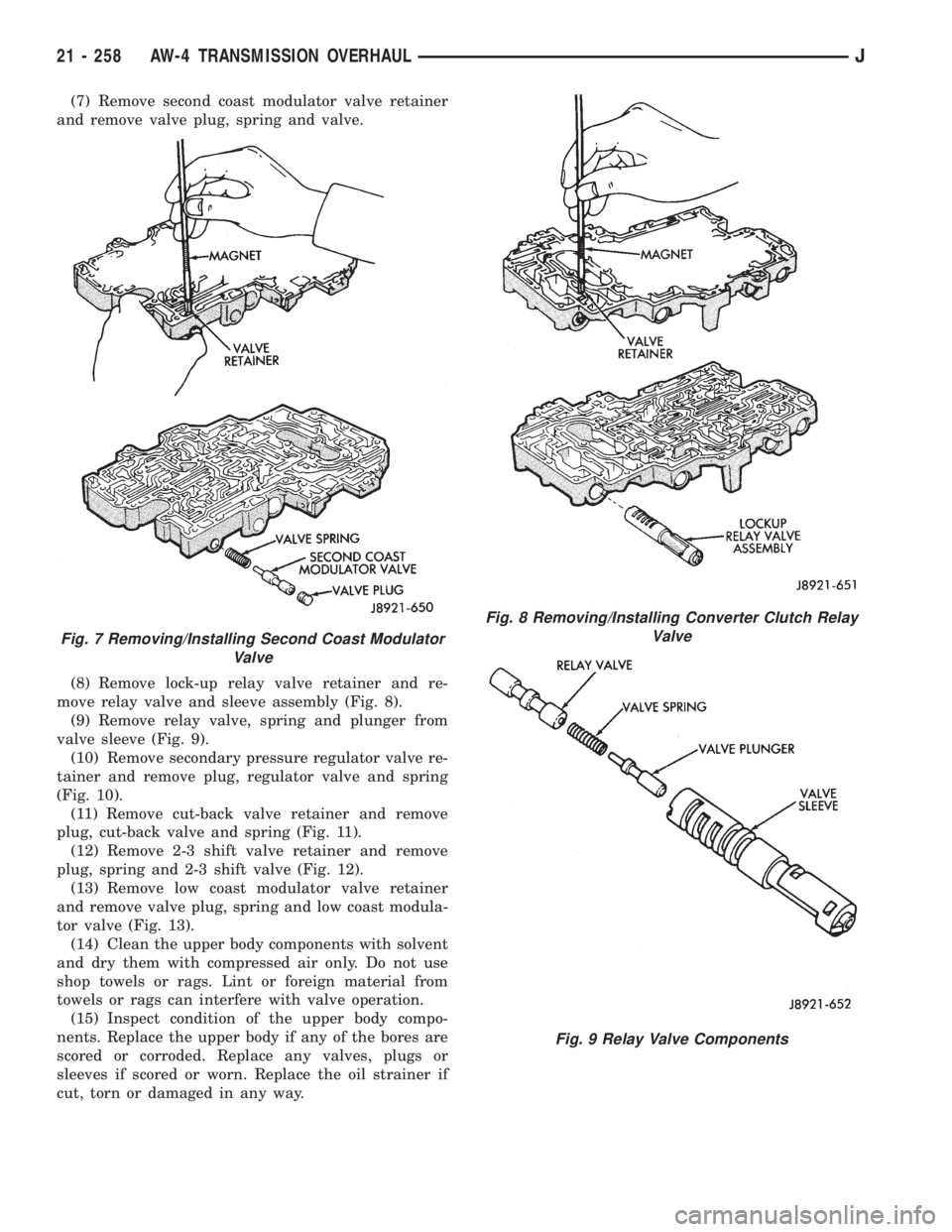

(7) Remove second coast modulator valve retainer

and remove valve plug, spring and valve.

(8) Remove lock-up relay valve retainer and re-

move relay valve and sleeve assembly (Fig. 8).

(9) Remove relay valve, spring and plunger from

valve sleeve (Fig. 9).

(10) Remove secondary pressure regulator valve re-

tainer and remove plug, regulator valve and spring

(Fig. 10).

(11) Remove cut-back valve retainer and remove

plug, cut-back valve and spring (Fig. 11).

(12) Remove 2-3 shift valve retainer and remove

plug, spring and 2-3 shift valve (Fig. 12).

(13) Remove low coast modulator valve retainer

and remove valve plug, spring and low coast modula-

tor valve (Fig. 13).

(14) Clean the upper body components with solvent

and dry them with compressed air only. Do not use

shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(15) Inspect condition of the upper body compo-

nents. Replace the upper body if any of the bores are

scored or corroded. Replace any valves, plugs or

sleeves if scored or worn. Replace the oil strainer if

cut, torn or damaged in any way.

Fig. 7 Removing/Installing Second Coast Modulator

Valve

Fig. 8 Removing/Installing Converter Clutch Relay

Valve

Fig. 9 Relay Valve Components

21 - 258 AW-4 TRANSMISSION OVERHAULJ